The Influence of Green Supply Chain Management Practices on Corporate Sustainability Performance

Abstract

:1. Introduction

2. Literature Review

2.1. Green Supply Chain Management (GSCM) Practices

2.2. Corporate Sustainability Performance (CSP)

2.3. Descriptions of the CSP Triple Bottom Line

2.3.1. Economic Sustainability Performance

2.3.2. Environmental Sustainability Performance

2.3.3. Social Sustainability Performance

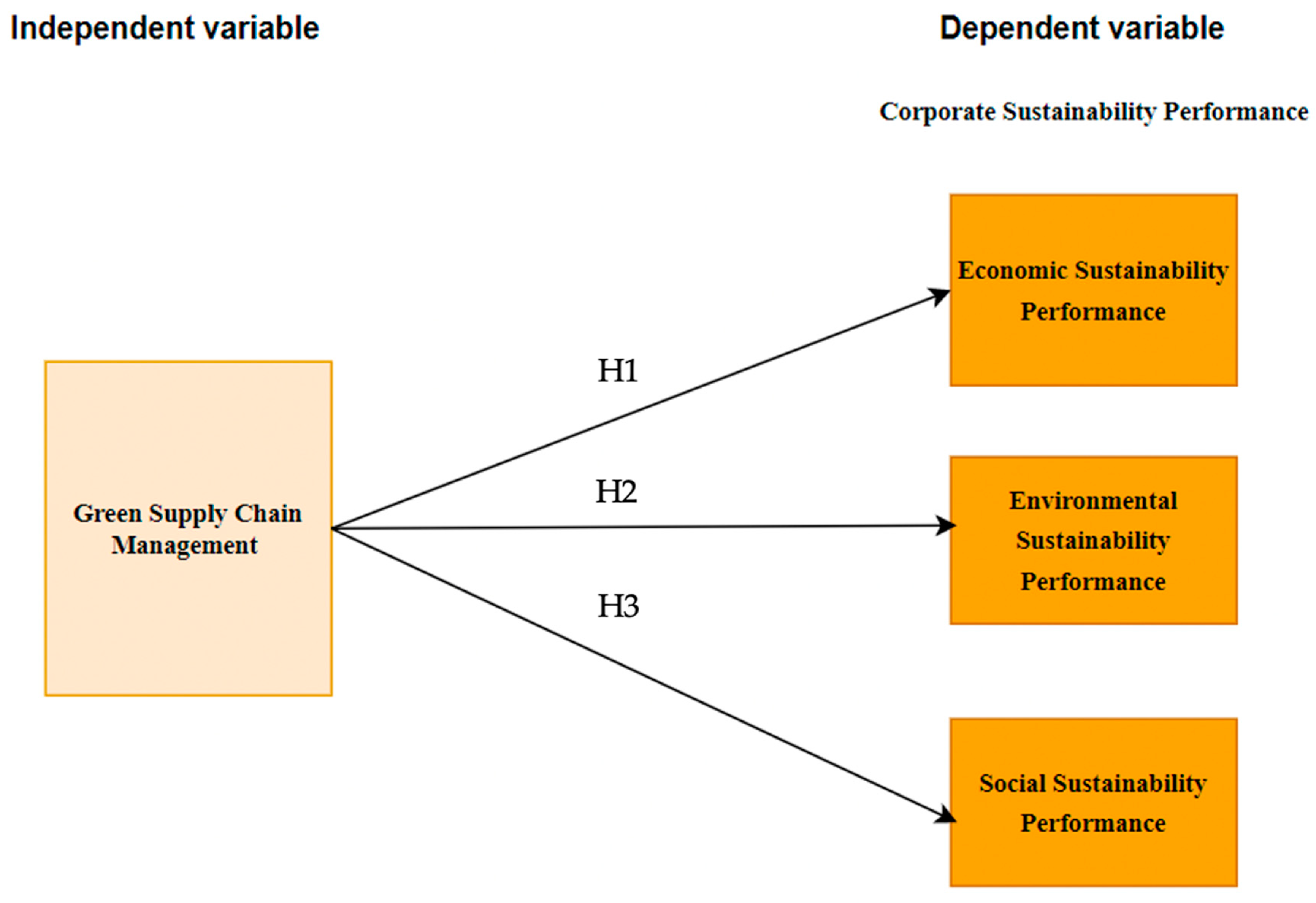

3. Development of the Hypotheses

Green Logistics/Supply Chain Management Impact on Sustainable Performance

4. Methodology

5. Data Analysis and Results

6. Discussion

7. Conclusions, Limitations, and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Environmental Performance | Strongly Disagree | Disagree | Neutral | Agree | Strongly Agree |

|---|---|---|---|---|---|

| The company reduction of solid wastes | |||||

| The company reduced waste and emissions from the operations | |||||

| The company decreased consumption of hazardous/harmful/toxic materials | |||||

| The company decreased of frequency environmental accidents | |||||

| The company’s improvement of an enterprise’s environmental situation | |||||

| Economic Performance | Strongly Disagree | Disagree | Neutral | Agree | Strongly Agree |

| The company decreased the cost of materials purchasing | |||||

| The company decreased the cost of energy consumption | |||||

| The company decreased of fee for waste treatment | |||||

| The company decreased of fee for waste discharge | |||||

| Social Performance | Strongly Disagree | Disagree | Neutral | Agree | Strongly Agree |

| The company improved health and safety for employees or the community. | |||||

| The company protected the claims and rights of aboriginal people or localCommunity. | |||||

| The company showed concern for the visual aspects of the organization‘s facilities and operations | |||||

| The company communicated the organizational environmental impactsand risks to the general public. | |||||

| The company considered the interests of stakeholders in investment decisionsby creating a formal dialogue. | |||||

| Green Supply Chain Management Practices | Strongly Disagree | Disagree | Neutral | Agree | Strongly Agree |

| The company Commitment of GSCM from senior managers (IEM1) | |||||

| The company has a support for GSCM from mid-level managers (IEM2) | |||||

| In the company, there are environmental compliance and auditing programs (IEM3) | |||||

| In the company there is cooperation with customers for eco-design (CC1) | |||||

| In the company, there is cooperation with customers for cleaner production (CC2) | |||||

| In the company, there is cooperation with customers for green packaging (CC3) | |||||

| In the company, there is design of products for reduced consumption of material/energy (ED1) | |||||

| In the company, there is the Design of products for reuse, recycling, recovery of material, and parts (ED2) | |||||

| In the company, there is Design of products to avoid or reduce the use of hazardous products and/or theirthe manufacturing process (ED3) |

References

- Geng, R.; Mansouri, S.A.; Aktas, E. The Relationship between Green Supply Chain Management and Performance: A Meta-Analysis of Empirical Evidences in Asian Emerging Economies. Int. J. Prod. Econ. 2017, 183, 245–258. [Google Scholar] [CrossRef] [Green Version]

- Saeed, A.; Jun, Y.; Nubuor, S.; Priyankara, H.; Jayasuriya, M. Institutional Pressures, Green Supply Chain Management Practices on Environmental and Economic Performance: A Two Theory View. Sustainability 2018, 10, 1517. [Google Scholar] [CrossRef] [Green Version]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green Supply Chain Management Practices: Impact on Performance. Supply Chain. Manag. Int. J. 2012, 17, 290–305. [Google Scholar]

- Khan, S.A.R.; Dong, Q.; Zhang, Y.; Khan, S.S. The Impact of Green Supply Chain on Enterprise Performance: In the Perspective of China. J. Adv. Manuf. Syst. 2017, 16, 263–273. [Google Scholar] [CrossRef]

- Sharma, S.; Gandhi, M.A. Exploring Correlations in Components of Green Supply Chain Practices and Green Supply Chain Performance. Compet. Rev. 2016, 26, 332–368. [Google Scholar] [CrossRef]

- Çankaya, S.; Sezen, B. Effects of Green Supply Chain Management Practices on Sustainability Performance. J. Clean. Prod. 2019, 209, 1565–1578. [Google Scholar]

- Al-Sheyadi, A.; Muyldermans, L.; Kauppi, K. The Complementarity of Green Supply Chain Management Practices and the Impact on Environmental Performance. J. Environ. Manag. 2019, 242, 186–198. [Google Scholar] [CrossRef]

- Zhu, Q.; Qu, Y.; Geng, Y.; Fujita, T. A Comparison of Regulatory Awareness and Green Supply Chain Management Practices among Chinese and Japanese Manufacturers. Bus. Strategy Environ. 2017, 26, 18–30. [Google Scholar] [CrossRef]

- Zaid, A.A.; Jaaron, A.A.M.; Bon, A.T. The impact of green human resource management and green supply chain management practices on sustainable performance: An empirical study. J. Clean. Prod. 2018, 201, 939–951. [Google Scholar] [CrossRef]

- Han, Z.; Huo, B. The Impact of Green Supply Chain Integration on Sustainable Performance. Ind. Manag. Data Syst. 2020; ahead-of-print. [Google Scholar]

- Walker, P.H.; Seuring, P.S.; Sarkis, P.J.; Klassen, P.R. Sustainable Operations Management: Recent Trends and Future Directions. Int. J. Oper. Prod. Manag. 2014, 34. [Google Scholar] [CrossRef]

- Baah, C.; Jin, Z.; Tang, L. Organizational and Regulatory Stakeholder Pressures Friends or Foes to Green Logistics Practices and Financial Performance: Investigating Corporate Reputation as a Missing Link. J. Clean. Prod. 2020, 247, 119125. [Google Scholar] [CrossRef]

- Demir, E.; Huang, Y.; Scholts, S.; Van Woensel, T. A Selected Review on the Negative Externalities of the Freight Transportation: Modeling and Pricing. Transp. Res. Part E Logist. Transp. Rev. 2015, 77, 95–114. [Google Scholar] [CrossRef]

- Herold, D.M.; Lee, K.-H. Carbon management in the logistics and transportation sector: An overview and new research directions. Carbon Manag. 2017, 8, 1–19. [Google Scholar] [CrossRef]

- IPCC Climate. Mitigation of Climate Change Promotion of Climate Change Policies in Turkey LIFE05/TCY/TR164 LAND-USE CHANGE and FORESTRY Transportation Air Quality Management Congestion Management Sustainable Development in the Sector Methane Emissions from Energy and Waste Recycling of Wastes; Pubmed Publishers: Ankara, Turkey, 2014; Available online: https://www.google.com.hk/search?q=Mitigation+of+Climate+Change+Promotion+of+Climate+Change+Policies+in+Turkey+LIFE05%2FTCY%2FTR164+LAND-USE+CHANGE+and+FORESTRY+Transportation+Air+Quality+Management+Congestion+Management+Sustainable+Development+in+the+Sector+Methane+Emissions+from+Energy+and+Waste+Recycling+of+Wastes&ei=BwUYZOfPN-7j2roPk6OtuAw&ved=0ahUKEwin74-W-On9AhXusVYBHZNRC8cQ4dUDCA4&uact=5&oq=Mitigation+of+Climate+Change+Promotion+of+Climate+Change+Policies+in+Turkey+LIFE05%2FTCY%2FTR164+LAND-USE+CHANGE+and+FORESTRY+Transportation+Air+Quality+Management+Congestion+Management+Sustainable+Development+in+the+Sector+Methane+Emissions+from+Energy+and+Waste+Recycling+of+Wastes&gs_lcp=Cgxnd3Mtd2l6LXNlcnAQAzIICAAQogQQsAMyCAgAEKIEELADSgQIQRgBUN8BWN8BYJYKaAFwAHgAgAEAiAEAkgEAmAEAoAECoAEByAECwAEB&sclient=gws-wiz-serp (accessed on 20 January 2023).

- Agyabeng-Mensah, Y.; Afum, E.; Ahenkorah, E. Exploring Financial Performance and Green Logistics Management Practices: Examining the Mediating Influences of Market, Environmental and Social Performances. J. Clean. Prod. 2020, 258, 120613. [Google Scholar] [CrossRef]

- Evangelista, P. Environmental Sustainability Practices in the Transport and Logistics Service Industry: An Exploratory Case Study Investigation. Res. Transp. Bus. Manag. 2014, 12, 63–72. [Google Scholar] [CrossRef]

- Mitra, S.; Datta, P.P. Adoption of Green Supply Chain Management Practices and Their Impact on Performance: An Exploratory Study of Indian Manufacturing Firms. Int. J. Prod. Res. 2013, 52, 2085–2107. [Google Scholar] [CrossRef]

- Scur, G.; Barbosa, M.E. Green Supply Chain Management Practices: Multiple Case Studies in the Brazilian Home Appliance Industry. J. Clean. Prod. 2017, 141, 1293–1302. [Google Scholar] [CrossRef]

- Mathivathanan, D.; Kannan, D.; Haq, A.N. Sustainable Supply Chain Management Practices in Indian Automotive Industry: A Multi-Stakeholder View. Resour. Conserv. Recycl. 2018, 128, 284–305. [Google Scholar] [CrossRef]

- Namagembe, S.; Ryan, S.; Sridharan, R. Green Supply Chain Practice Adoption and Firm Performance: Manufacturing SMEs in Uganda. Manag. Environ. Qual. Int. J. 2019, 30, 5–35. [Google Scholar] [CrossRef]

- Kouaib, A. Corporate Sustainability Disclosure and Investment Efficiency: The Saudi Arabian Context. Sustainability 2022, 14, 13984. [Google Scholar] [CrossRef]

- Kouaib, A.; Amara, I. Corporate Social Responsibility Disclosure and Investment Decisions: Evidence from Saudi Indexed Companies. J. Risk Financ. Manag. 2022, 15, 495. [Google Scholar] [CrossRef]

- Singh, H.P.; Singh, A.; Alam, F.; Agrawal, V. Impact of Sustainable Development Goals on Economic Growth in Saudi Arabia: Role of Education and Training. Sustainability 2022, 14, 14119. [Google Scholar] [CrossRef]

- Choudhary, K.; Sangwan, K.S. Adoption of Green Practices throughout the Supply Chain: An Empirical Investigation. Benchmarking Int. J. 2019, 26, 1650–1675. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, Y.; Zhang, N.; Huang, T. An Optimization Model for Green Supply Chain Management by Using a Big Data Analytic Approach. J. Clean. Prod. 2017, 142, 1085–1097. [Google Scholar] [CrossRef]

- Habib, M.A.; Bao, Y.; Ilmudeen, A. The Impact of Green Entrepreneurial Orientation, Market Orientation and Green Supply Chain Management Practices on Sustainable Firm Performance. Cogent Bus. Manag. 2020, 7, 1743616. [Google Scholar] [CrossRef]

- Masudin, I.; Wastono, T.; Zulfikarijah, F. The Effect of Managerial Intention and Initiative on Green Supply Chain Management Adoption in Indonesian Manufacturing Performance. Cogent Bus. Manag. 2018, 5, 1485212. [Google Scholar] [CrossRef]

- Tippayawong, K.; Niyomyat, N.; Sopadang, A.; Ramingwong, S. Factors Affecting Green Supply Chain Operational Performance of the Thai Auto Parts Industry. Sustainability 2016, 8, 1161. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Sarkis, J.; Lai, K. Examining the Effects of Green Supply Chain Management Practices and Their Mediations on Performance Improvements. Int. J. Prod. Res. 2012, 50, 1377–1394. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green Supply-Chain Management: A State-of-The-Art Literature Review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Ali, A.; Haseeb, M. Radio Frequency Identification (RFID) Technology as a Strategic Tool towards Higher Performance of Supply Chain Operations in Textile and Apparel Industry of Malaysia. Uncertain Supply Chain. Manag. 2019, 7, 215–226. [Google Scholar] [CrossRef]

- Chu, S.; Yang, H.; Lee, M.; Park, S. The Impact of Institutional Pressures on Green Supply Chain Management and Firm Performance: Top Management Roles and Social Capital. Sustainability 2017, 9, 764. [Google Scholar] [CrossRef] [Green Version]

- Wilkerson, T. Environmental life cycle. ACS ChemWorx 2005, 45, 4570–4578. [Google Scholar]

- Zhu, Q.; Sarkis, J.; Lai, K. Confirmation of a Measurement Model for Green Supply Chain Management Practices Implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Al-Ghwayeen, W.S.; Abdallah, A.B. Green Supply Chain Management and Export Performance. J. Manuf. Technol. Manag. 2018, 29, 1233–1252. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable Supply Chain Management (SSCM) in Malaysia: A Survey. Int. J. Prod. Econ. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Siferd, S.P. Environmental Purchasing: A Framework for Theory Development. Eur. J. Purch. Supply Manag. 2001, 7, 61–73. [Google Scholar] [CrossRef]

- Vijayvargy, L.; Thakkar, J.; Agarwal, G. Green Supply Chain Management Practices and Performance. J. Manuf. Technol. Manag. 2017, 28, 299–323. [Google Scholar] [CrossRef]

- Bouzon, M.; Govindan, K.; Rodriguez, C.M.T. Evaluating Barriers for Reverse Logistics Implementation under a Multiple Stakeholders’ Perspective Analysis Using Grey Decision Making Approach. Resour. Conserv. Recycl. 2018, 128, 315–335. [Google Scholar] [CrossRef]

- Marshall, D.; McCarthy, L.; Heavey, C.; McGrath, P. Environmental and Social Supply Chain Management Sustainability Practices: Construct Development and Measurement. Prod. Plan. Control 2014, 26, 673–690. [Google Scholar] [CrossRef]

- Shad, M.K.; Lai, F.-W.; Fatt, C.L.; Klemeš, J.J.; Bokhari, A. Integrating Sustainability Reporting into Enterprise Risk Management and Its Relationship with Business Performance: A Conceptual Framework. J. Clean. Prod. 2019, 208, 415–425. [Google Scholar] [CrossRef]

- KOÇ, S.; Durmaz, V. Future Oriented Corporate Leadership Model. J. Glob. Strateg. Manag. 2015, 1, 52. [Google Scholar] [CrossRef]

- Wu, Y.; Su, G.; Tang, S.; Liu, W.; Ma, Z.; Zheng, X.; Liu, H.; Yu, H. The combination of in silico and in vivo approaches for the investigation of disrupting effects of tris (2-chloroethyl) phosphate (TCEP) toward core receptors of zebrafish. Chemosphere 2017, 168, 122–130. [Google Scholar] [CrossRef]

- Jan, A.; Marimuthu, M.; Mat Isa, M.P. bin M. The Nexus of Sustainability Practices and Financial Performance: From the Perspective of Islamic Banking. J. Clean. Prod. 2019, 228, 703–717. [Google Scholar] [CrossRef]

- Compact, U.G. Transforming Care Is Everyone’s Business. Nurs. Stand. 2015, 29, 3. [Google Scholar]

- Hassini, E.; Surti, C.; Searcy, C. A Literature Review and a Case Study of Sustainable Supply Chains with a Focus on Metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Desjardins, R.L.; Sivakumar, M.V.K. Foreword. Agric. For. Meteorol. 2007, 142, 88–89. [Google Scholar] [CrossRef]

- Mdolo, A.; Banda, R.; Phiri, A.; Sambala, E.Z.; Wiyeh, A.B.; Wiysonge, C.S. Burden of Seasonal Influenza in Sub-Saharan Africa: A Systematic Review Protocol. BMJ Open 2018, 8, e022949. [Google Scholar]

- Nguyen, M.; Phan, A.; Matsui, Y. Contribution of Quality Management Practices to Sustainability Performance of Vietnamese Firms. Sustainability 2018, 10, 375. [Google Scholar] [CrossRef] [Green Version]

- Seth, D.; Shrivastava, R.L.; Shrivastava, S. An Empirical Investigation of Critical Success Factors and Performance Measures for Green Manufacturing in Cement Industry. J. Manuf. Technol. Manag. 2016, 27, 1076–1101. [Google Scholar] [CrossRef]

- Elkington, J. Partnerships from Cannibals with Forks: The Triple Bottom Line of 21st-Century Business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Artiach, T.; Lee, D.; Nelson, D.; Walker, J. The Determinants of Corporate Sustainability Performance. Account. Financ. 2010, 50, 31–51. [Google Scholar] [CrossRef]

- Liern, V.; Pérez-Gladish, B. Ranking Corporate Sustainability: A Flexible Multidimensional Approach Based on Linguistic Variables. Int. Trans. Oper. Res. 2017, 25, 1081–1100. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.K. Biofertilizers for Sustainable Agriculture; Updesh Purohit for Agrobios: Jodhpur, India, 2003; pp. 41–46. [Google Scholar]

- Brockett, A.; Zabihollah, R. Corporate Sustainability; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Orlitzky, M.; Swanson, D.L. Corporate Social and Financial Performance: An Integrative Review. In Toward Integrative Corporate Citizenship; Palgrave Macmillan: London, UK, 2008; pp. 83–120. [Google Scholar]

- Aktin, T.; Gergin, Z. Mathematical Modelling of Sustainable Procurement Strategies: Three Case Studies. J. Clean. Prod. 2016, 113, 767–780. [Google Scholar] [CrossRef]

- Hallegatte, S.; Heal, G.; Fay, M.; Treguer, D. From Growth to Green Growth—A Framework; NBER: Cambridge, MA, USA, 2023. [Google Scholar]

- Pero, M.; Moretto, A.; Bottani, E.; Bigliardi, B. Environmental Collaboration for Sustainability in the Construction Industry: An Exploratory Study in Italy. Sustainability 2017, 9, 125. [Google Scholar] [CrossRef] [Green Version]

- Abdul Aziz, N.; Ong, T.; Foong, S.; Senik, R.; Attan, H. Green Initiatives Adoption and Environmental Performance of Public Listed Companies in Malaysia. Sustainability 2018, 10, 2003. [Google Scholar] [CrossRef] [Green Version]

- Tsoi, J. Stakeholders’ Perceptions and Future Scenarios to Improve Corporate Social Responsibility in Hong Kong and Mainland China. J. Bus. Ethics 2009, 91, 391–404. [Google Scholar] [CrossRef]

- Saedi, A.M.; Majid, A.A.; Isa, Z. Evaluation of Safety Climate Differences among Employees’ Demographic Variables: A Cross-Sectional Study in Two Different-Sized Manufacturing Industries in Malaysia. Int. J. Occup. Saf. Ergon. 2019, 27, 714–727. [Google Scholar] [CrossRef]

- Yang, M.X.; Li, J.; Yu, I.Y.; Zeng, K.J.; Sun, J. Environmentally Sustainable or Economically Sustainable? The Effect of Chinese Manufacturing Firms’ Corporate Sustainable Strategy on Their Green Performances. Bus. Strategy Environ. 2019, 28, 989–997. [Google Scholar] [CrossRef]

- Chiou, T.-Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The Influence of Greening the Suppliers and Green Innovation on Environmental Performance and Competitive Advantage in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Schoenherr, T. The Role of Environmental Management in Sustainable Business Development: A Multi-Country Investigation. Int. J. Prod. Econ. 2012, 140, 116–128. [Google Scholar] [CrossRef]

- Molina-Azorín, J.F.; Claver-Cortés, E.; Pereira-Moliner, J.; Tarí, J.J. Environmental Practices and Firm Performance: An Empirical Analysis in the Spanish Hotel Industry. J. Clean. Prod. 2009, 17, 516–524. [Google Scholar] [CrossRef]

- Hart, S.L. A Natural-Resource-Based View of the Firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef] [Green Version]

- Sharma, S.; Aragón-Correa, J.A.; Rueda-Manzanares, A. The Contingent Influence of Organizational Capabilities on Proactive Environmental Strategy in the Service Sector: An Analysis of North American and European Ski Resorts. Can. J. Adm. Sci./Rev. Can. Des Sci. De L’administration 2007, 24, 268–283. [Google Scholar] [CrossRef]

- Ochieng, B.E. Effect of Green Purchasing Practices on Performance of Large Chemical Manufacturing Firms in Nairobi County Kenya. J. Innov. Bus. Manag. 2019, 11, 89–103. [Google Scholar]

- Halbusi, H.A.; Tehseen, S. Supply Chain Management and Practices of Firm Performance: A Review Paper. J. Hum. Dev. Educ. Spec. Res. (JHDESR) 2018, 4, 11–20. [Google Scholar]

- Sellitto, M.A.; Hermann, F.F. Influence of Green Practices on Organizational Competitiveness: A Study of the Electrical and Electronics Industry. Eng. Manag. J. 2019, 31, 98–112. [Google Scholar] [CrossRef]

- Thong, K.-C.; Wong, W.-P. Pathways for Sustainable Supply Chain Performance—Evidence from a Developing Country, Malaysia. Sustainability 2018, 10, 2781. [Google Scholar] [CrossRef] [Green Version]

- Santos, H.; Lannelongue, G.; Gonzalez-Benito, J. Integrating Green Practices into Operational Performance: Evidence from Brazilian Manufacturers. Sustainability 2019, 11, 2956. [Google Scholar] [CrossRef] [Green Version]

- Gay, L.R.; Diehl, P.L. Research Methods for Business and Management; Mc. Millan Publishing Company: New York, NY, USA, 1992. [Google Scholar]

- Krejcie, R.V.; Morgan, D.W. Determining Sample Size for Research Activities. Educ. Psychol. Meas. 1970, 30, 607–610. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Sarstedt, M.; Matthews, L.M.; Ringle, C.M. Identifying and Treating Unobserved Heterogeneity with FIMIX-PLS: Part I—Method. Eur. Bus. Rev. 2016, 28, 63–76. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Abdul-Rashid, S.H.; Sakundarini, N.; Raja Ghazilla, R.A.; Thurasamy, R. The Impact of Sustainable Manufacturing Practices on Sustainability Performance. Int. J. Oper. Prod. Manag. 2017, 37, 182–204. [Google Scholar] [CrossRef]

- Foo, B. The State of Food and Agriculture 2018: Migration, Agriculture and Rural Development; Food and Agriculture Organization of the United Nations: Rome, Italy, 2018. [Google Scholar]

- Maghsoudi, A.; Zailani, S.; Ramayah, T.; Pazirandeh, A. Coordination of Efforts in Disaster Relief Supply Chains: The Moderating Role of Resource Scarcity and Redundancy. Int. J. Logist. Res. Appl. 2018, 21, 407–430. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K.; Xu, L.; Diabat, A. Using AHP to Evaluate Barriers in Adopting Sustainable Consumption and Production Initiatives in a Supply Chain. Int. J. Prod. Econ. 2016, 181, 342–349. [Google Scholar] [CrossRef]

- Brunnermeier, M.K.; Pedersen, L.H. Market Liquidity and Funding Liquidity. Rev. Financ. Stud. 2009, 22, 2201–2238. [Google Scholar] [CrossRef] [Green Version]

| Cronbach’s Alpha | rho_A | Composite Reliability | Average Variance Extracted (AVE) | |

|---|---|---|---|---|

| Economic Performance | 0.792 | 0.856 | 0.858 | 0.564 |

| Environment Performance | 0.817 | 0.823 | 0.878 | 0.644 |

| GSCM | 0.910 | 0.919 | 0.927 | 0.590 |

| Social Performance | 0.821 | 0.832 | 0.874 | 0.583 |

| Economic Performance | Environment Performance | GSCM | Social Performance | |

|---|---|---|---|---|

| CC1 | 0.719 | 0.588 | 0.801 | 0.641 |

| CC2 | 0.738 | 0.651 | 0.849 | 0.680 |

| CC3 | 0.701 | 0.540 | 0.780 | 0.792 |

| ED1 | 0.708 | 0.490 | 0.854 | 0.686 |

| ED2 | 0.744 | 0.508 | 0.875 | 0.712 |

| ED3 | 0.720 | 0.560 | 0.821 | 0.664 |

| Econ1 | 0.719 | 0.440 | 0.595 | 0.615 |

| Econ2 | 0.853 | 0.566 | 0.764 | 0.673 |

| Econ3 | 0.362 | 0.183 | 0.217 | 0.241 |

| Econ4 | 0.826 | 0.559 | 0.725 | 0.639 |

| Econ5 | 0.872 | 0.526 | 0.783 | 0.696 |

| Envi1 | 0.508 | 0.814 | 0.574 | 0.544 |

| Envi2 | 0.507 | 0.827 | 0.548 | 0.561 |

| Envi3 | 0.433 | 0.775 | 0.431 | 0.474 |

| Envi4 | 0.573 | 0.793 | 0.597 | 0.640 |

| IEM1 | 0.526 | 0.409 | 0.637 | 0.529 |

| IEM2 | 0.515 | 0.452 | 0.596 | 0.512 |

| IEM3 | 0.593 | 0.457 | 0.640 | 0.519 |

| Soca1 | 0.678 | 0.482 | 0.701 | 0.744 |

| Soca2 | 0.690 | 0.560 | 0.760 | 0.828 |

| Soca3 | 0.558 | 0.557 | 0.565 | 0.757 |

| Soca4 | 0.503 | 0.500 | 0.533 | 0.697 |

| Soca5 | 0.569 | 0.576 | 0.592 | 0.785 |

| Economic Performance | Environment Performance | GSCM | Social Performance | |

|---|---|---|---|---|

| Economic Performance | 0.751 | |||

| Environment Performance | 0.636 | 0.802 | ||

| GSCM | 0.870 | 0.678 | 0.768 | |

| Social Performance | 0.795 | 0.698 | 0.838 | 0.763 |

| Original Sample (O) | Sample Mean (M) | Standard Deviation (STDEV) | T Statistics (|O/STDEV|) | p-Values | |

|---|---|---|---|---|---|

| GSCM -> Economic | 0.870 | 0.875 | 0.027 | 32.675 | 0.000 |

| GSCM -> Environment | 0.678 | 0.681 | 0.056 | 12.159 | 0.000 |

| GSCM -> Social | 0.838 | 0.837 | 0.031 | 27.047 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hejazi, M.T.; Al Batati, B.; Bahurmuz, A. The Influence of Green Supply Chain Management Practices on Corporate Sustainability Performance. Sustainability 2023, 15, 5459. https://doi.org/10.3390/su15065459

Hejazi MT, Al Batati B, Bahurmuz A. The Influence of Green Supply Chain Management Practices on Corporate Sustainability Performance. Sustainability. 2023; 15(6):5459. https://doi.org/10.3390/su15065459

Chicago/Turabian StyleHejazi, Mohammed Taj, Bader Al Batati, and Ahmed Bahurmuz. 2023. "The Influence of Green Supply Chain Management Practices on Corporate Sustainability Performance" Sustainability 15, no. 6: 5459. https://doi.org/10.3390/su15065459

APA StyleHejazi, M. T., Al Batati, B., & Bahurmuz, A. (2023). The Influence of Green Supply Chain Management Practices on Corporate Sustainability Performance. Sustainability, 15(6), 5459. https://doi.org/10.3390/su15065459