Numerical Simulation of an Indirect Contact Mobilized Thermal Energy Storage Container with Different Tube Bundle Layout and Fin Structure

Abstract

:1. Introduction

2. Numerical Method

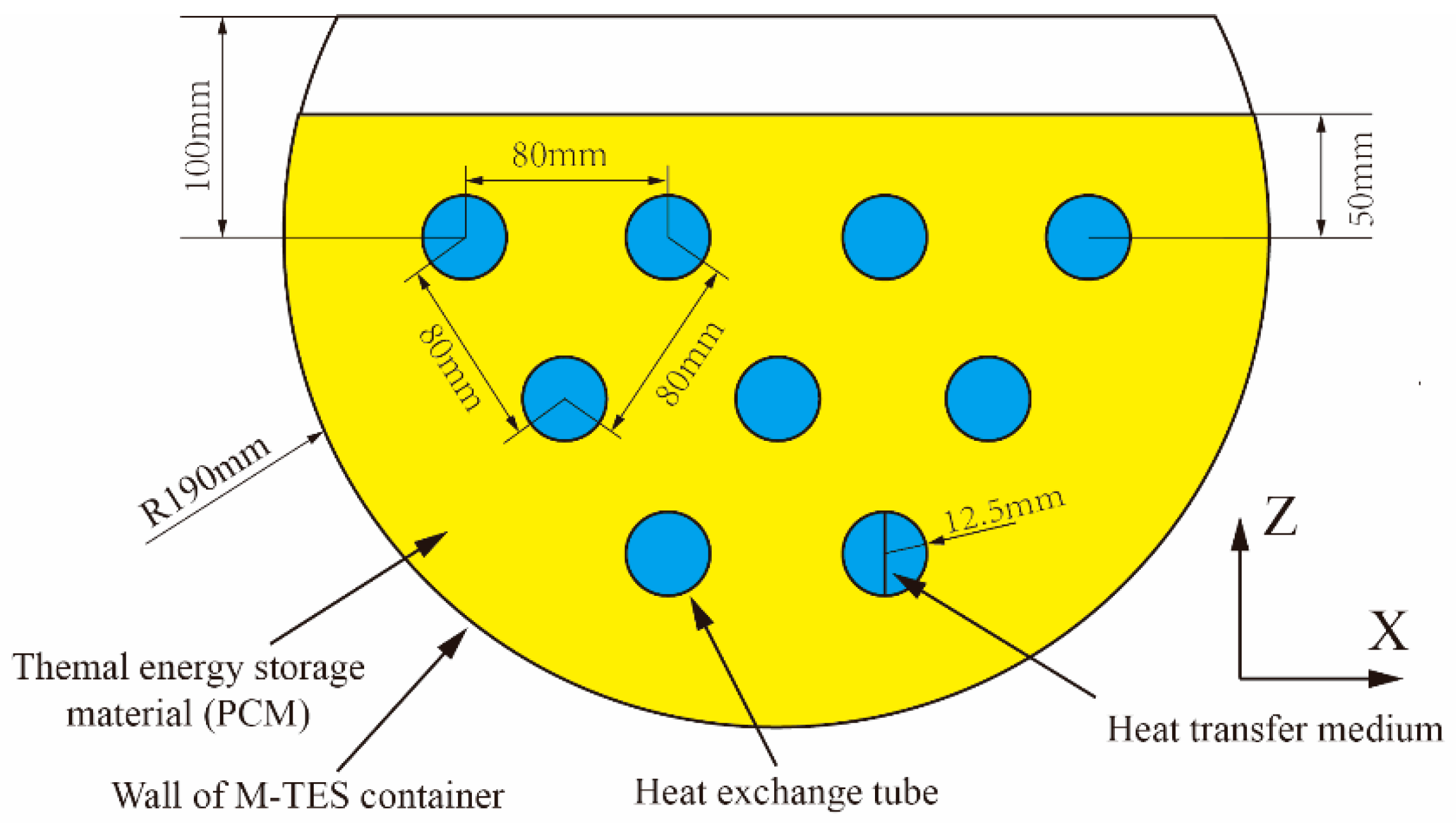

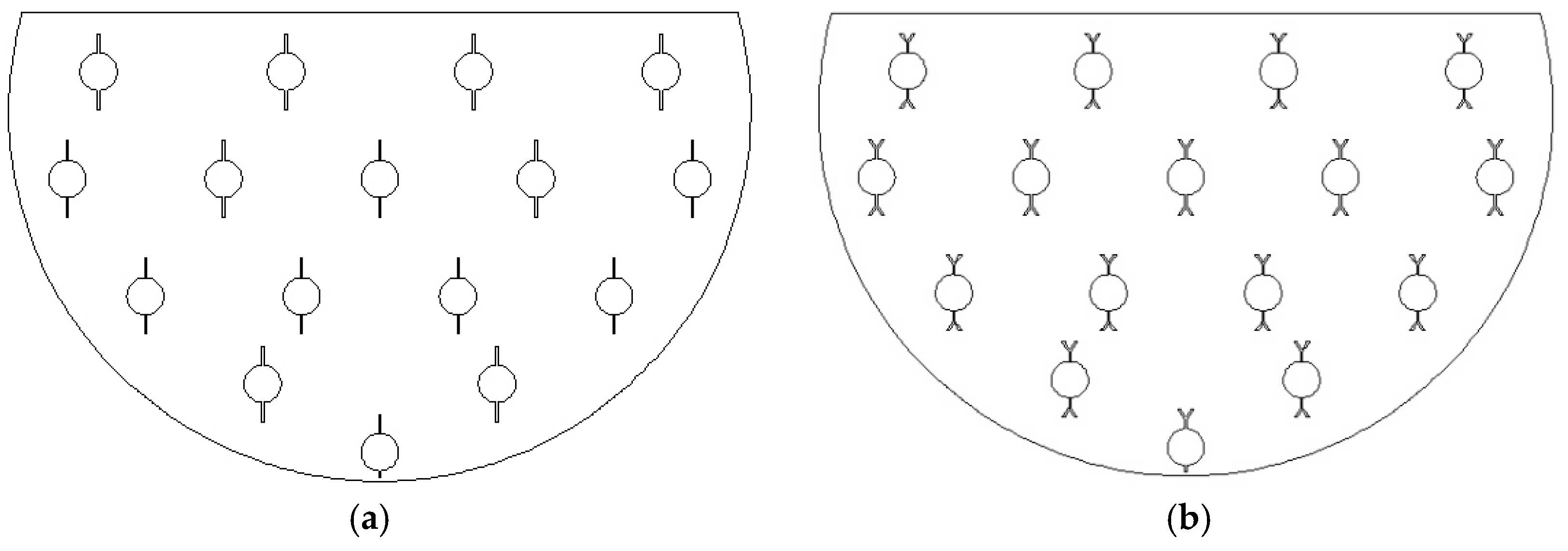

2.1. Geometry Model

2.2. Mathematical Model

2.3. Boundary Condition and Input Data

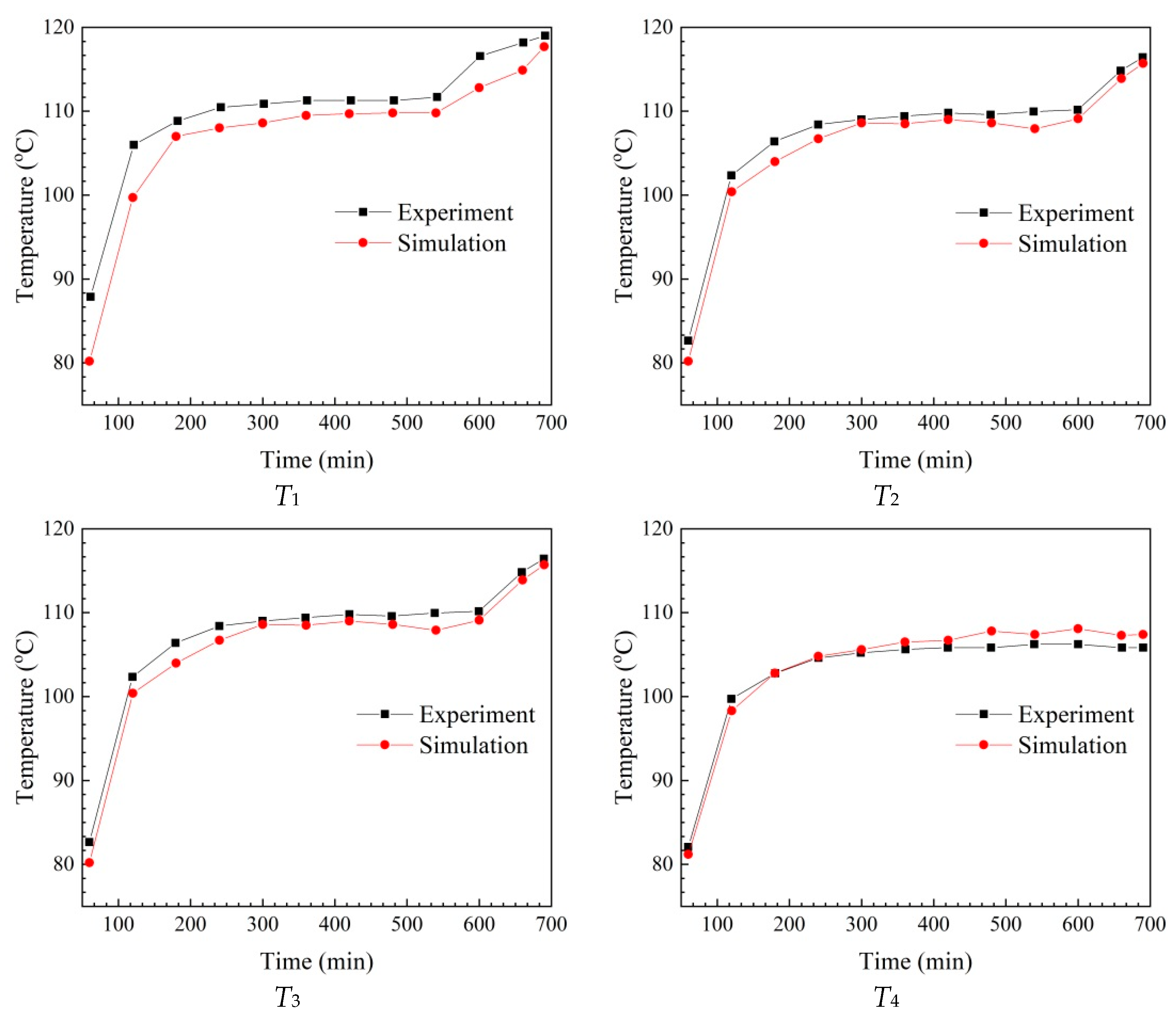

3. Calculation Verification

3.1. Mesh Independence Verification

3.2. Comparison of Experiment and Simulation

4. Results and Discussion

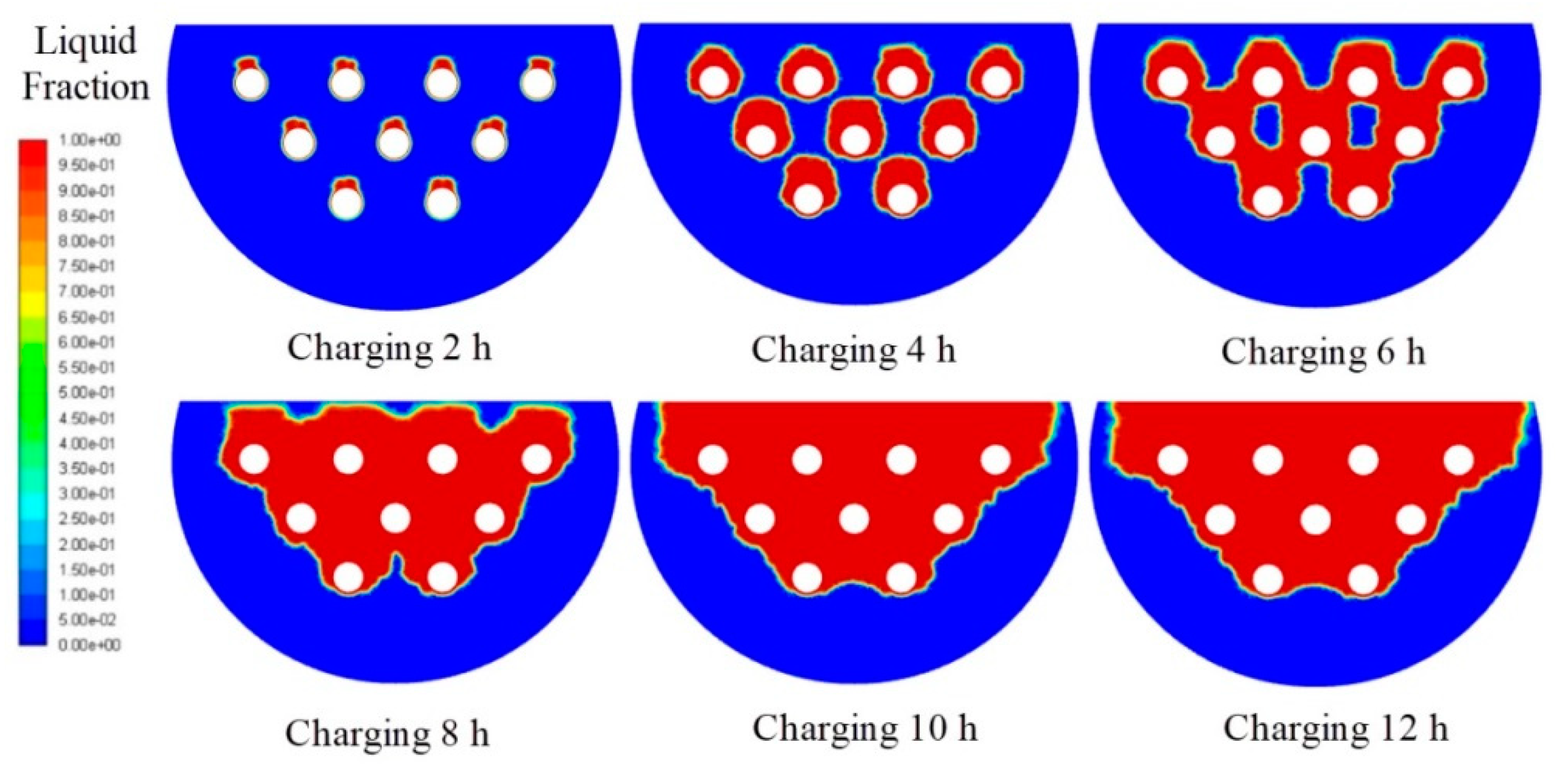

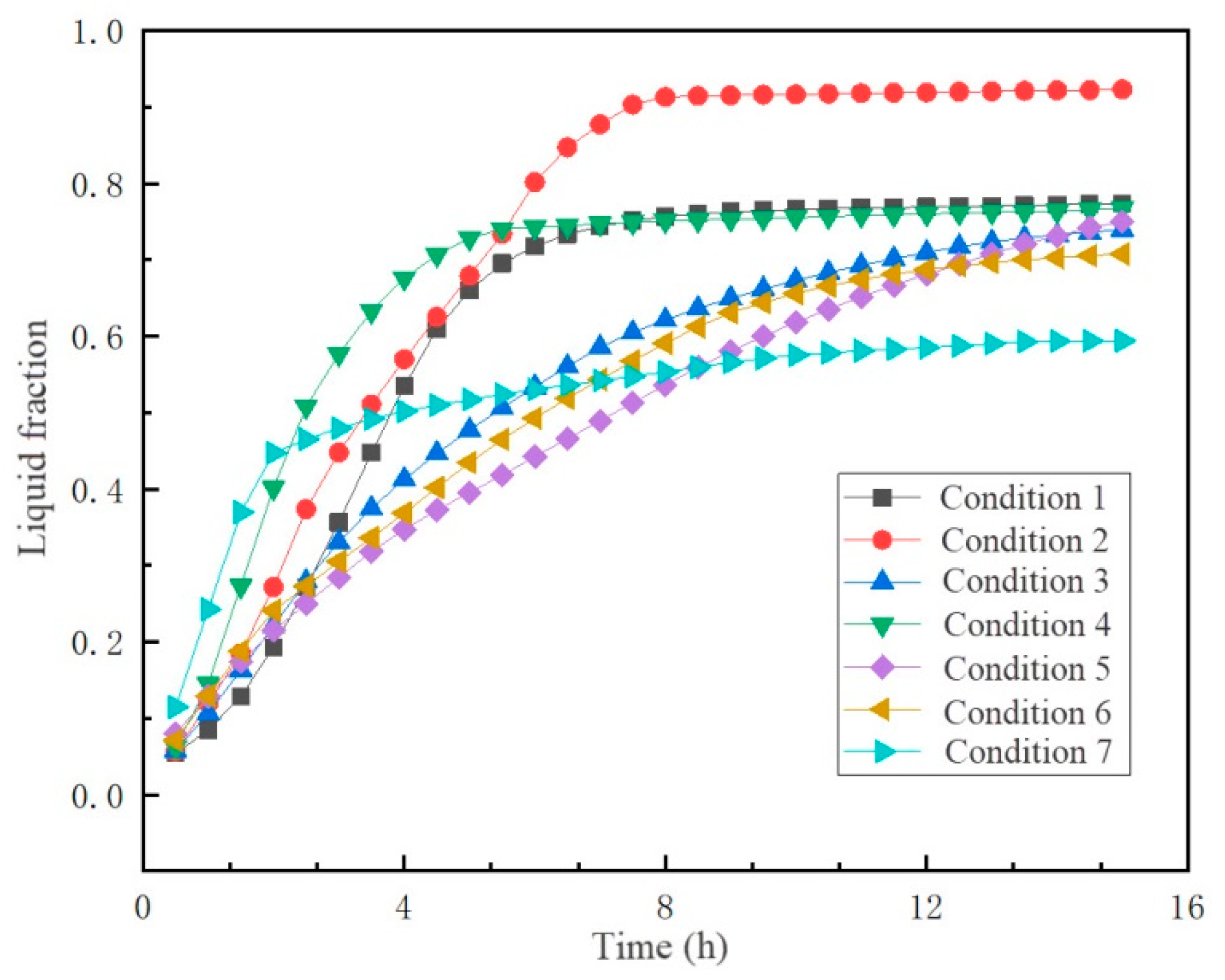

4.1. Effect of the Tube Bundle Layout for the Shell and Tube Type M-TES Container

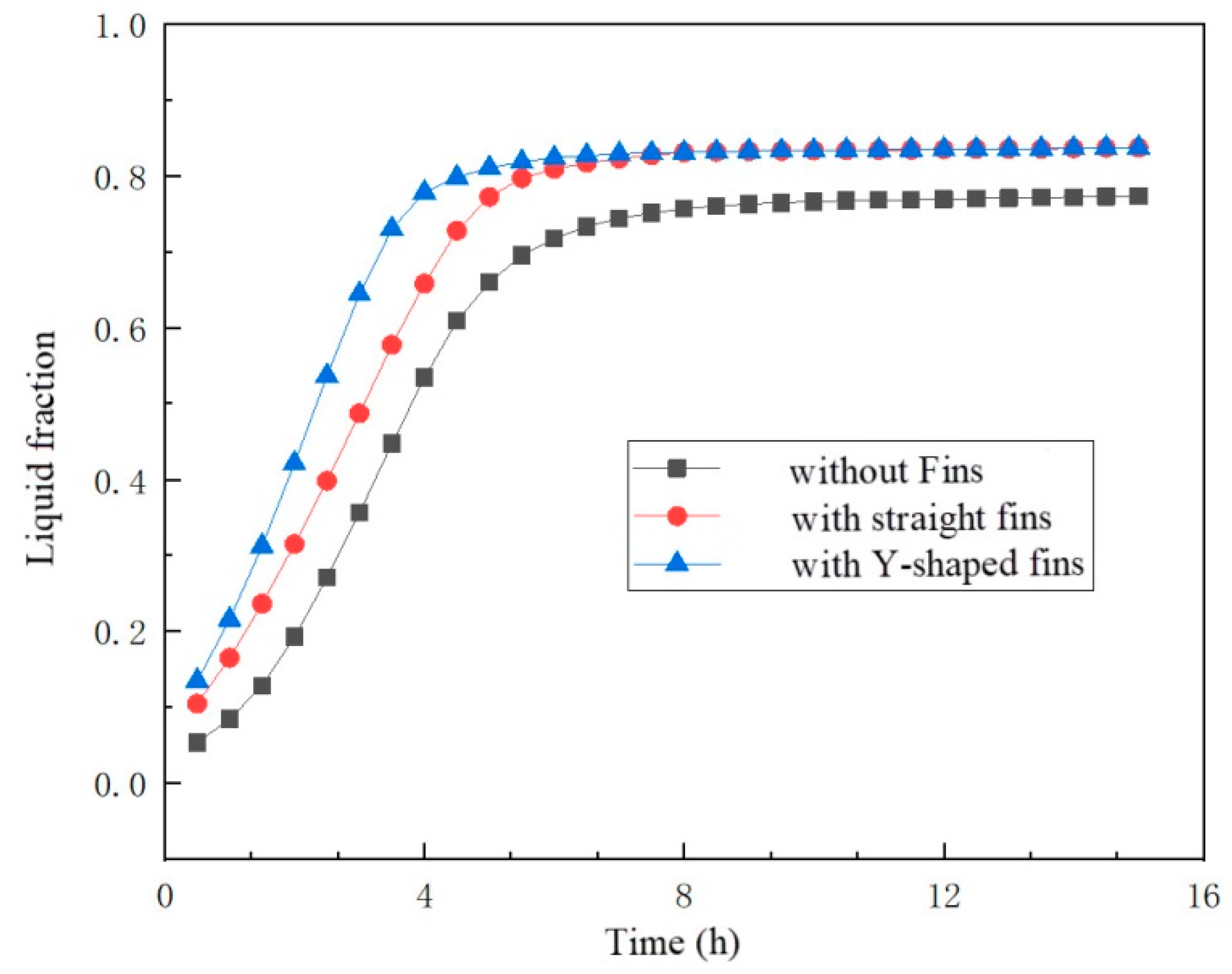

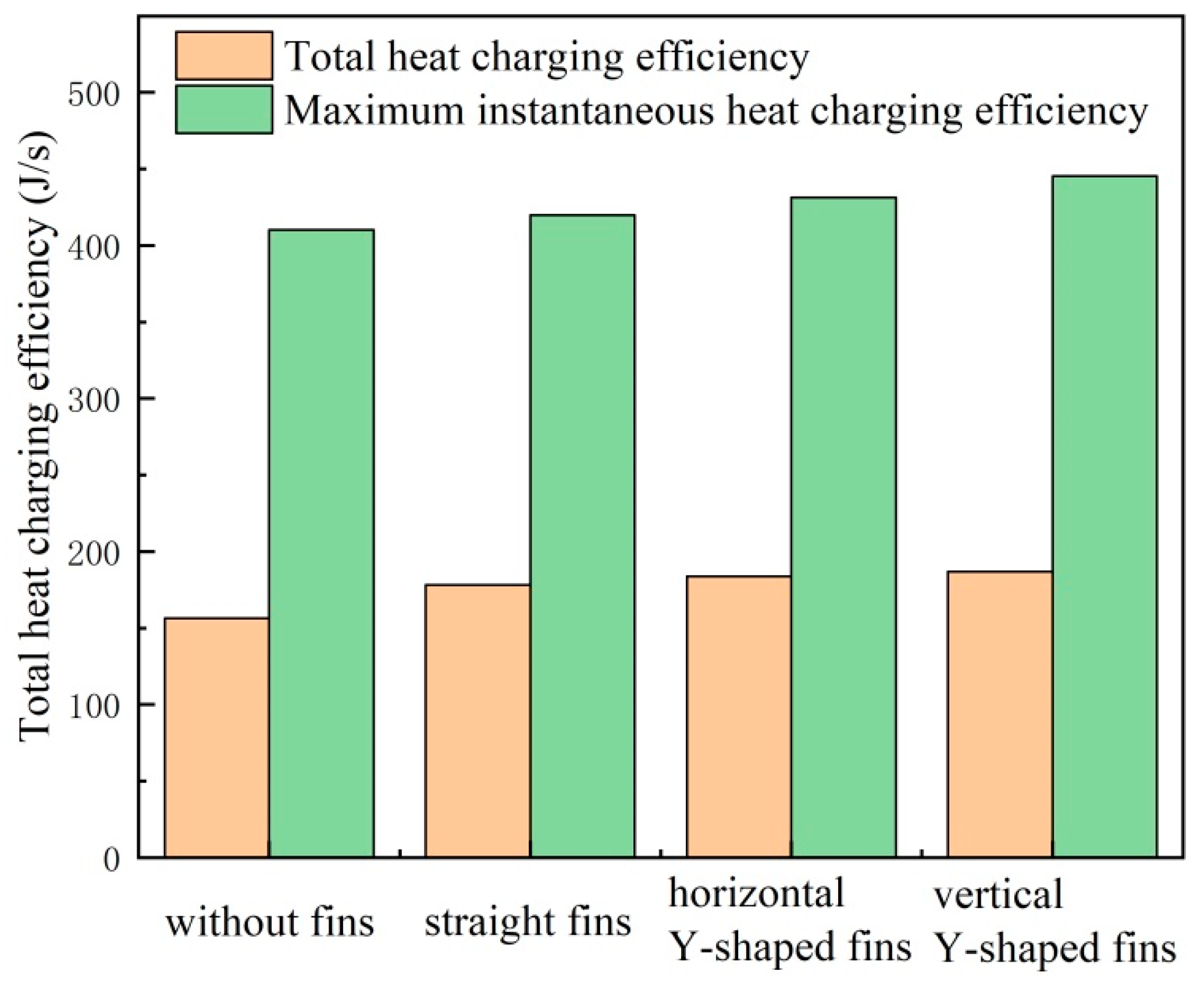

4.2. Effect of Adding Fins for the Shell and Tube Type M-TES Containers

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Niknam, P.H.; Sciacovelli, A. Hybrid PCM-steam thermal energy storage for industrial processes—Link between thermal phenomena and techno-economic performance through dynamic modelling. Appl. Energy 2023, 331, 120358. [Google Scholar] [CrossRef]

- Fujita, Y.; Shikata, I.; Kawai, A.; Kamano, H. Latent heat storage and transportation system “TransHeat Container”. In Proceedings of the IEA/ECES Annex 18, the First workshop and Expert Meeting, Tokyo, Japan, 13–15 November 2006. [Google Scholar]

- Du, K.; Calautit, J.; Eames, P.; Wu, Y. A state-of-the-art review of the application of phase change materials (PCM) in Mobilized-Thermal Energy Storage (M-TES) for recovering low-temperature industrial waste heat (IWH) for distributed heat supply. Renew. Energy 2021, 168, 1040–1057. [Google Scholar] [CrossRef]

- Guo, S.; Liu, Q.; Zhao, J.; Jin, G.; Wu, W.; Yan, J.; Li, H.; Jin, H. Mobilized thermal energy storage: Materials, containers and economic evaluation. Energy Convers. Manag. 2018, 177, 315–329. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM; Heat and Mass Transfer; Springer: Berlin/Heidelberg, Germany, 2008; pp. 11–55. [Google Scholar]

- Horibe, A.; Jang, H.; Haruki, N.; Sano, Y.; Kanbara, H.; Takahashi, K. Melting and solidification heat transfer characteristics of phase change material in a latent heat storage vessel: Effect of perforated partition plate. Int. J. Heat Mass Transf. 2015, 82, 259–266. [Google Scholar] [CrossRef]

- Kaizawa, A.; Kamano, H.; Kawai, A.; Jozuka, T.; Senda, T.; Maruoka, N.; Okinaka, N.; Akiyama, T. Technical feasibility study of waste heat transportation system using phase change material from industry to city. ISIJ Int. 2008, 48, 540–548. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.; Zhao, J.; Wang, W.; Jin, G.; Wang, X.; An, Q.; Gao, W. Experimental study on solving the blocking for the direct contact mobilized thermal energy storage container. Appl. Therm. Eng. 2015, 78, 556–564. [Google Scholar] [CrossRef]

- Anandan, S.S.; Sundarababu, J. A comprehensive review on mobilized thermal energy storage. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–24. [Google Scholar] [CrossRef]

- Peiró, G.; Gasia, J.; Miró, L.; Cabeza, L.F. Experimental evaluation at pilot plant scale of multiple PCMs (cascaded) vs. single PCM configuration for thermal energy storage. Renew. Energy 2015, 83, 729–736. [Google Scholar] [CrossRef] [Green Version]

- Höhlein, S.; König-Haagen, A.; Brüggemann, D. Thermophysical characterization of MgCl2· 6H2O, xylitol and erythritol as phase change materials (PCM) for latent heat thermal energy storage (LHTES). Materials 2017, 10, 444. [Google Scholar] [CrossRef] [Green Version]

- Diarce, G.; Gandarias, I.; Campos-Celador, A.; García-Romero, A.; Griesser, U. Eutectic mixtures of sugar alcohols for thermal energy storage in the 50–90 C temperature range. Sol. Energy Mater. Sol. Cells 2015, 134, 215–226. [Google Scholar] [CrossRef]

- Yang, X.; Lu, Z.; Bai, Q.; Zhang, Q.; Jin, L.; Yan, J. Thermal performance of a shell-and-tube latent heat thermal energy storage unit: Role of annular fins. Appl. Energy 2017, 202, 558–570. [Google Scholar] [CrossRef]

- Nagano, K.; Ogawa, K.; Mochida, T.; Hayashi, K.; Ogoshi, H. Thermal characteristics of magnesium nitrate hexahydrate and magnesium chloride hexahydrate mixture as a phase change material for effective utilization of urban waste heat. Appl. Therm. Eng. 2004, 24, 221–232. [Google Scholar] [CrossRef]

- Nomura, T.; Okinaka, N.; Akiyama, T. Waste heat transportation system, using phase change material (PCM) from steelworks to chemical plant. Resour. Conserv. Recycl. 2010, 54, 1000–1006. [Google Scholar] [CrossRef]

- Kumar, Y.A.; Kim, H.-J. Effect of time on a hierarchical corn skeleton-like composite of coo@ zno as capacitive electrode material for high specific performance supercapacitors. Energies 2018, 11, 3285. [Google Scholar] [CrossRef] [Green Version]

- Moniruzzaman, M.; Anil Kumar, Y.; Pallavolu, M.R.; Arbi, H.M.; Alzahmi, S.; Obaidat, I.M. Two-dimensional core-shell structure of cobalt-doped@ MnO2 nanosheets grown on nickel foam as a binder-free battery-type electrode for supercapacitor application. Nanomaterials 2022, 12, 3187. [Google Scholar] [CrossRef] [PubMed]

- Kaizawa, A.; Kamano, H.; Kawai, A.; Jozuka, T.; Senda, T.; Maruoka, N.; Akiyama, T. Thermal and flow behaviors in heat transportation container using phase change material. Energy Convers. Manag. 2008, 49, 698–706. [Google Scholar] [CrossRef]

- Wang, W.; Guo, S.; Li, H.; Yan, J.; Zhao, J.; Li, X.; Ding, J. Experimental study on the direct/indirect contact energy storage container in mobilized thermal energy system (M-TES). Appl. Energy 2014, 119, 181–189. [Google Scholar] [CrossRef]

- Wang, W.; Li, H.; Guo, S.; He, S.; Ding, J.; Yan, J.; Yang, J. Numerical simulation study on discharging process of the direct-contact phase change energy storage system. Appl. Energy 2015, 150, 61–68. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.; Yan, J.; Dahlquist, E. Economic assessment of the mobilized thermal energy storage (M-TES) system for distributed heat supply. Appl. Energy 2013, 104, 178–186. [Google Scholar] [CrossRef]

- Agyenim, F.; Eames, P.; Smyth, M. Heat transfer enhancement in medium temperature thermal energy storage system using a multitube heat transfer array. Renew. Energy 2010, 35, 198–207. [Google Scholar] [CrossRef]

- Al-Mudhafar, A.H.; Nowakowski, A.F.; Nicolleau, F.C. Performance enhancement of PCM latent heat thermal energy storage system utilizing a modified webbed tube heat exchanger. Energy Rep. 2020, 6, 76–85. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, K.; Ling, X. Experimental study on thermal performance of a mobilized thermal energy storage system: A case study of hydrated salt latent heat storage. Energy Build. 2020, 210, 109744. [Google Scholar] [CrossRef]

- Guo, S.; Zhao, J.; Wang, W.; Yan, J.; Jin, G.; Zhang, Z.; Gu, J.; Niu, Y. Numerical study of the improvement of an indirect contact mobilized thermal energy storage container. Appl. Energy 2016, 161, 476–486. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Chen, Y. Improving the energy discharging performance of a latent heat storage (LHS) unit using fractal-tree-shaped fins. Appl. Energy 2020, 259, 114102. [Google Scholar] [CrossRef]

- Parsazadeh, M.; Duan, X. Numerical study on the effects of fins and nanoparticles in a shell and tube phase change thermal energy storage unit. Appl. Energy 2018, 216, 142–156. [Google Scholar] [CrossRef]

- Brent, A.; Voller, V.R.; Reid, K. Enthalpy-porosity technique for modeling convection-diffusion phase change: Application to the melting of a pure metal. Numer. Heat Transf. Part A Appl. 1988, 13, 297–318. [Google Scholar]

- Kakiuchi, H. A study of erythritol as phase change material. In Proceedings of the IEA Annex 10-PCMs and Chemical Reactions for Thermal Energy Storage 2nd Workshop, Sofia, Bulgaria, 11–13 April 1998. [Google Scholar]

- Lorenzini, G.; Moretti, S. Numerical heat transfer optimization in modular systems of Y-shaped fins. J. Heat Transf. 2008, 130, 081801. [Google Scholar] [CrossRef]

- Lorenzini, G.; Moretti, S. Numerical analysis on heat removal from Y-shaped fins: Efficiency and volume occupied for a new approach to performance optimisation. Int. J. Therm. Sci. 2007, 46, 573–579. [Google Scholar] [CrossRef]

| Property | Erythritol [29] | Xylitol [11,12] | MCHH [14] | Sodium Hydroxide [15] |

|---|---|---|---|---|

| Latent heat (kJ/kg) | 340 | 280 | 167 | 164 |

| Melting point (°C) | 119 | 93 | 115 | 58 |

| Density (kg/m3) | 1480 (at 20 °C) | 1515 | 1569 (20 °C); 1450 (120 °C) | |

| 1300 (at 140 °C) | 1422 (128 °C) | |||

| Specific heat (kJ/(kg·K)) | 1.38 (at 20 °C) | 1.33 (solid) | 2.1 (25 °C); 2.25 (100 °C) | 2.79 (solid) |

| 2.61 (120 °C) | ||||

| 2.77 (at 140 °C) | 2.36 (liquid) | |||

| Viscosity (kg·m−1·s−1) | 0.02895 (at 20 °C) | |||

| 0.01602 (at 140 °C) | ||||

| Thermal conductivity (W·m−1·K−1) | 0.732 (at 20 °C) | 0.52 (solid) | 0.704 (110 °C) | 0.7 (solid) |

| 0.125 (at 140 °C) | 0.36 (liquid) | 0.570 (120 °C) | ||

| Price ($/t) | 1458–1596 | 4352–5802 | 1360 | 128 |

| Name | Layout |

|---|---|

| Condition 1 | Uniform distribution |

| Condition 2 | Peripheral distribution |

| Condition 3 | The upper part is sparse and the lower part is dense |

| Condition 4 | The upper part is dense and the lower part is sparse |

| Condition 5 | Sparse on both sides and dense in the middle. |

| Condition 6 | Dense on both sides and sparse in the middle. |

| Condition 7 | Center 4 × 4 distribution |

| Fin Type | Number of Fins | Fin Height | Fin Thickness |

|---|---|---|---|

| Straight fins | 2 × 16 | 10 | 1 |

| Y-shaped fins | 2 × 16 | 10 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, Z.; Zhou, W.; Qiu, K.; Wang, C.; Qin, Z.; Zhang, B.; Yao, Q. Numerical Simulation of an Indirect Contact Mobilized Thermal Energy Storage Container with Different Tube Bundle Layout and Fin Structure. Sustainability 2023, 15, 5511. https://doi.org/10.3390/su15065511

Kang Z, Zhou W, Qiu K, Wang C, Qin Z, Zhang B, Yao Q. Numerical Simulation of an Indirect Contact Mobilized Thermal Energy Storage Container with Different Tube Bundle Layout and Fin Structure. Sustainability. 2023; 15(6):5511. https://doi.org/10.3390/su15065511

Chicago/Turabian StyleKang, Zhangyang, Wu Zhou, Kaijie Qiu, Chaojie Wang, Zhaolong Qin, Bingyang Zhang, and Qiongqiong Yao. 2023. "Numerical Simulation of an Indirect Contact Mobilized Thermal Energy Storage Container with Different Tube Bundle Layout and Fin Structure" Sustainability 15, no. 6: 5511. https://doi.org/10.3390/su15065511

APA StyleKang, Z., Zhou, W., Qiu, K., Wang, C., Qin, Z., Zhang, B., & Yao, Q. (2023). Numerical Simulation of an Indirect Contact Mobilized Thermal Energy Storage Container with Different Tube Bundle Layout and Fin Structure. Sustainability, 15(6), 5511. https://doi.org/10.3390/su15065511