Development and Application of Adaptive Evaluation System for TBM Tunneling Based on Case-Based Reasoning

Abstract

1. The Introduction

2. Case-Based Reasoning Method for TBM Tunneling Adaptability

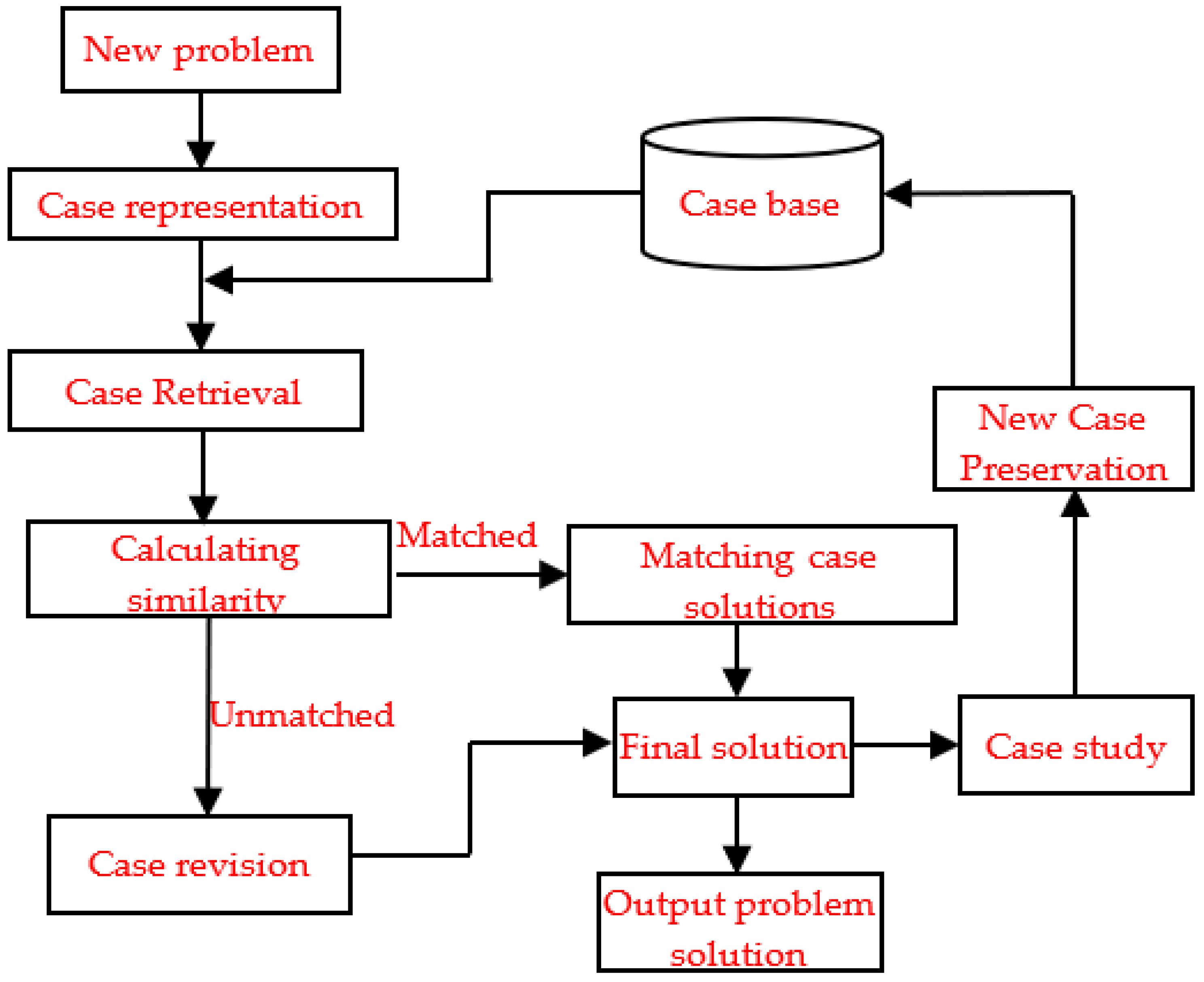

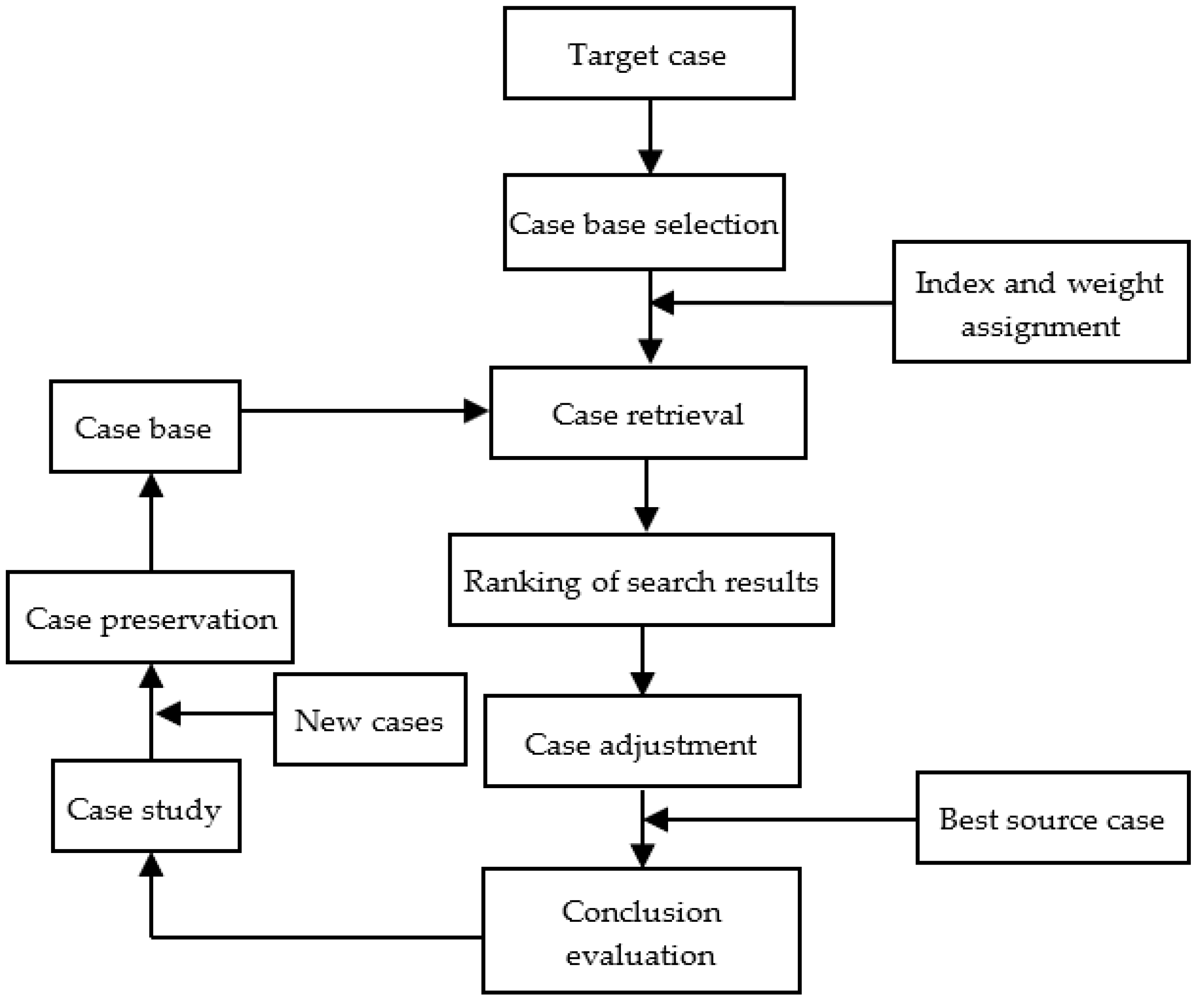

2.1. Working Principle of Case-Based Reasoning

2.2. Similarity Calculation of TBM Tunneling Adaptability

- (1)

- The similarity is non-negative, mean .

- (2)

- The similarity of the case itself should be the largest, which is 1.

- (3)

- When the class satisfies compactness, the monotone function of distance between points is similarity.

- 1.

- Absolute distancewhere vik and vjk are the kth attribute value of case i and case j, respectively.

- 2.

- Euclidean distance

- 3.

- Minkowski distancewhere q > 1. When q = 1 and 2, they are absolute distance and Euclidean distance, respectively.

- 4.

- Chebyshev distanceWhen , the limit of Minkowski distance is Chebyshev distance.

3. TBM Tunneling Retrieval Characteristic Attributes and Weight Acquisition

3.1. Determination of TBM Adaptability Evaluation Indexes

- (1)

- The mean, which measures the importance of each indicator. The larger the mean value, the higher the relative importance of the evaluation index of the TBM’s tunneling adaptability. Only the decision evaluation index whose mean value reaches more than 6 points is retained.

- (2)

- Standard deviation, reflecting the degree of dispersion of a data set. The greater the standard deviation, the greater the differences between the numerical and mean for the TBM adaptability evaluation index.

- (3)

- Coefficient of variation, reflecting the fluctuation degree of the decision index. The smaller the coefficient of variation, the higher the experts in a certain decision evaluation index of coordination degree. When the coefficient of variation of Vj < 0.25, the index’s expert coordination degree meets the requirements.

3.2. Weight Acquisition of TBM Tunneling Adaptability Evaluation Index

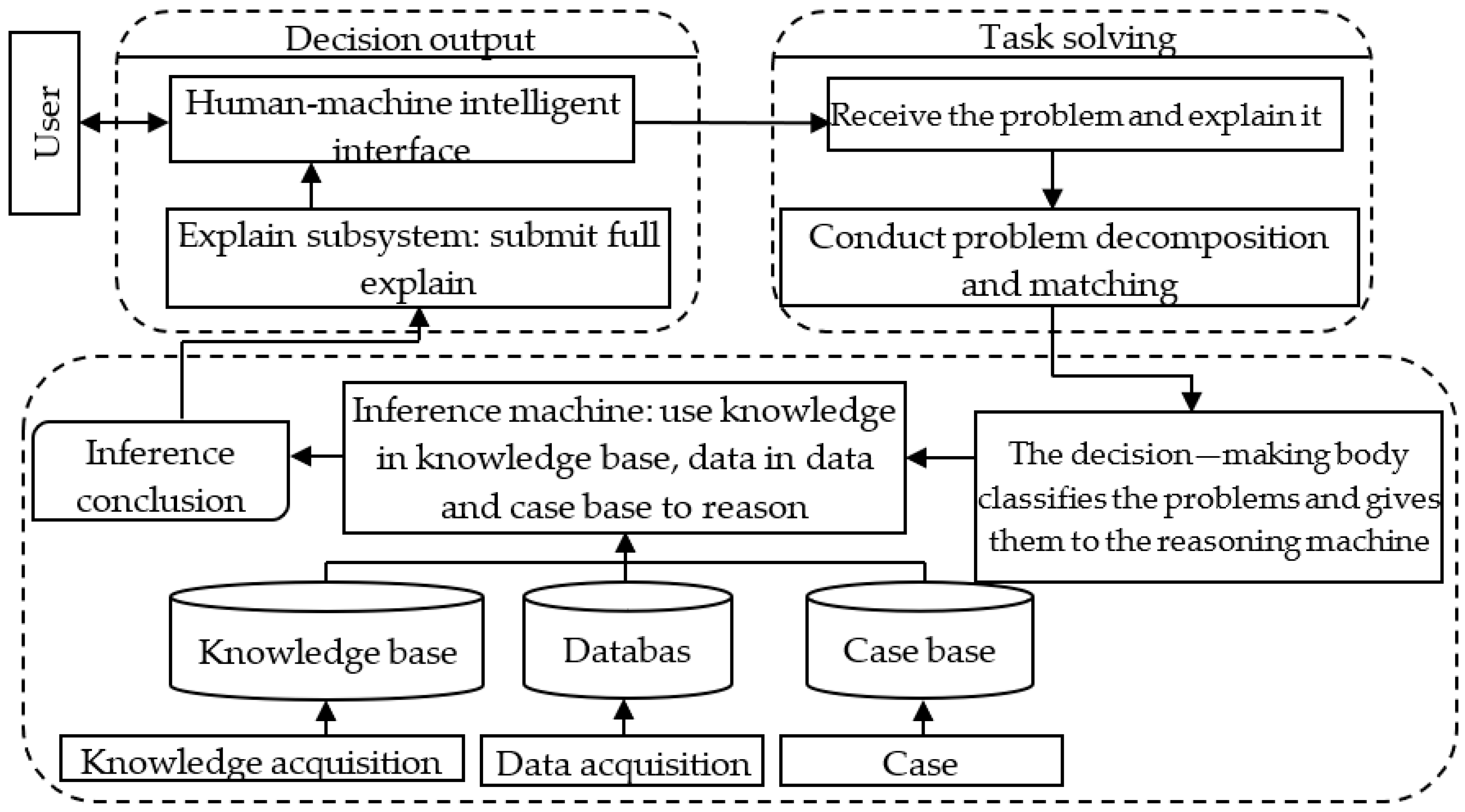

4. Overall Design of CBR-TBMEAEDS

4.1. The Structure and Function Design of the System

4.2. The Evaluation and Decision Process of the System

4.3. TBM Tunneling Adaptability Case Library Design

5. Programming Implementation of CBR-TBMEAEDS

5.1. Programmatic Realization of the System

5.2. Functions of the System

6. Application of Engineering Cases

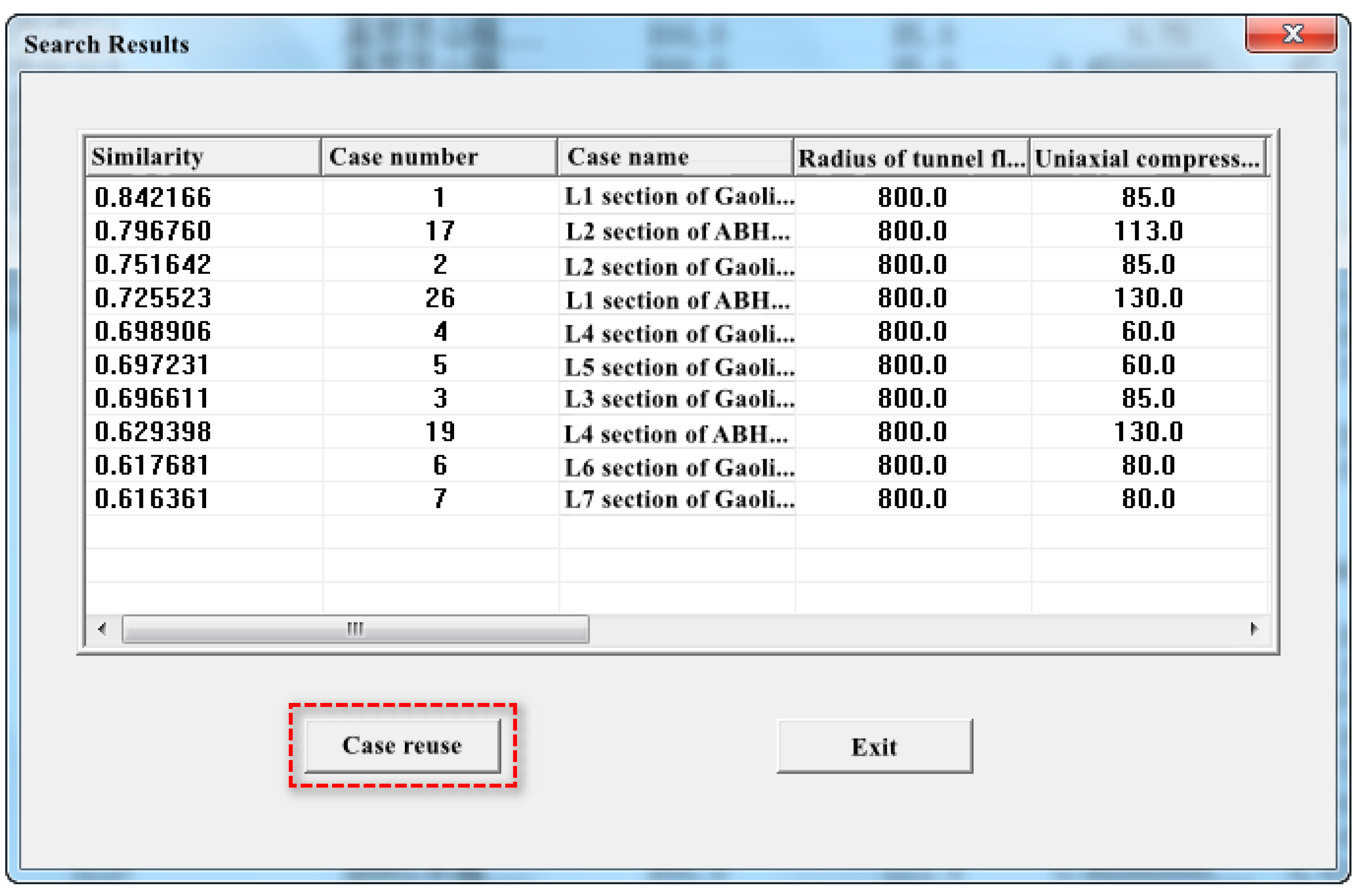

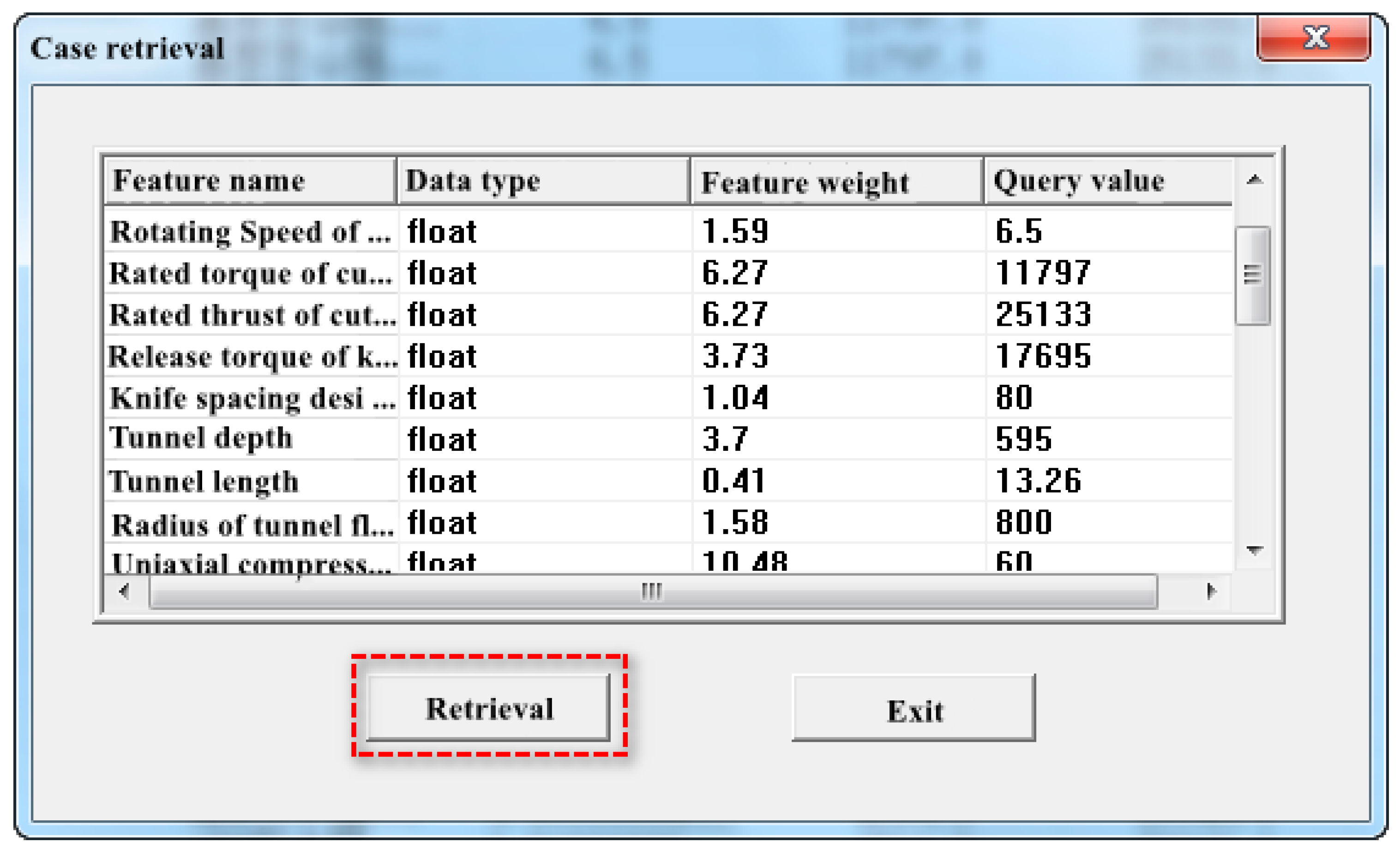

6.1. Case Based Reasoning of TBM Tunneling Adaptability

6.2. Reasoning Result Analysis

7. Conclusions

- (1)

- According to the engineering characteristics of TBM tunneling adaptability evaluation, the nearest neighbor method is used to retrieve the cases, and the calculation formula of TBM tunneling adaptability similarity is obtained. Through the analysis of the main influencing factors of TBM excavation adaptability, the characteristic attributes of retrieval and their weights were determined, and the TBM excavation adaptability evaluation index system was constructed.

- (2)

- Based on the CBR method of case-based reasoning, the structure, function design and evaluation decision making process of CBR-TBMEAEDS are proposed, the TBM tunneling adaptability case base is designed, CBR-TBMEAEDS is developed and the function of the system is determined.

- (3)

- From the application results of adaptive case reasoning in TBM tunneling, it can be seen that the evaluation results of the target case and the source case are positively correlated with the similarity. When the similarity reaches 0.8 or more, the fitness is relatively close, and the deviation is 0.02~1.16%. The adaptability levels are the same; when the similarity is less than 0.7, the deviation value is higher, the fitness difference is large, and the adaptability levels are basically inconsistent. That is to say, the higher the similarity between the two, the smaller the deviation value and the closer the evaluation result. In contrast, a greater the deviation value shows the effectiveness of CBR-TBMEAEDS case reasoning.

- (4)

- The application of case-based reasoning in TBM tunneling adaptability evaluation is still in the exploratory stage, and there are still many problems to be solved. This concept has not been verified by a large number of cases, so a more perfect case base should be built to make the evaluation results increasingly accurate. At the same time, case adjustment and learning methods need to be further explored to improve the model’s initial self-learning ability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharafat, A.; Latif, K.; Seo, J. Risk Analysis of TBM Tunneling Projects Based on Generic Bow-Tie Risk Analysis Approach in Difficult Ground Conditions. Tunn. Undergr. Space Technol. 2021, 111, 103860. [Google Scholar] [CrossRef]

- Hao, W.U.; Zhao, G.Y. Failure Behavior of Horseshoe-Shaped Tunnel in Hard Rock Under High Stress: Phenomenon and Mechanisms. Trans. Nonferrous Met. Soc. China 2022, 32, 639–656. [Google Scholar]

- Bai, B.; Zhou, R.; Cai, G.; Hu, W.; Yang, G. Coupled Thermo-Hydro-Mechanical Mechanism in View of the Soil Particle Rearrangement of Granular Thermodynamics. Comput. Geotech. 2021, 137, 104272. [Google Scholar] [CrossRef]

- Simser, B.P. Rockburst Management in Canadian Hard Rock Mines. J. Rock Mech. Geotech. Eng. 2019, 11, 1036–1043. [Google Scholar] [CrossRef]

- Li, L.P.; Xiong, Y.F.; Wang, J.; Gao, X.C.; Wang, K.; Sun, H.C.; Fang, Z.D. Comprehensive Influence Analysis of Multiple Parameters on the Safety Thickness against Water Inrush in Shield Tunnel. Int. J. Geomech. 2020, 20, 04020226. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, J.; Pan, Y.; Kong, X.; Hong, K. A Case Study of TBM Performance Prediction Using a Chinese Rock Mass Classification System–Hydropower Classification (HC) Method. Tunn. Undergr. Space Technol. 2017, 65, 140–154. [Google Scholar] [CrossRef]

- Lin, P.; Xiong, Y.; Xu, Z.; Wang, W.; Shao, R. Risk Assessment of TBM Jamming Based on Bayesian Networks. Bull. Eng. Geol. Environ. 2022, 81, 47. [Google Scholar] [CrossRef]

- Gong, Q.; Lu, J.; Xu, H.; Chen, Z.; Zhou, X.; Han, B. A Modified Rock Mass Classification System for TBM Tunnels and Tunneling Based on the HC Method of China. Int. J. Rock Mech. Min. Sci. 2021, 137, 104551. [Google Scholar] [CrossRef]

- Liu, B.; Wang, R.; Zhao, G.; Guo, X.; Wang, Y.; Li, J.; Wang, S. Prediction of Rock Mass Parameters in the TBM Tunnel Based on BP Neural Network Integrated Simulated Annealing Algorithm. Tunn. Undergr. Space Technol. 2020, 95, 103103. [Google Scholar] [CrossRef]

- Neil, D.M.; Haramy, K.Y.; Hanson, D.H.; Descour, J.M. Tomography to Evaluate Site Conditions during Tunneling. Geo-Engineering for Underground Facilities; American Society of Civil Engineers (ASCE): Reston, VA, USA, 1999; pp. 271–281. [Google Scholar]

- Mikaeil, R.; Naghadehi, M.Z.; Sereshki, F. Multifactorial Fuzzy Approach to the Penetrability Classification of TBM in Hard Rock Conditions. Tunn. Undergr. Space Technol. 2009, 24, 500–505. [Google Scholar] [CrossRef]

- Benardos, A.G.; Kaliampakos, D.C. A Methodology for Assessing Geotechnical Hazards for TBM Tunnelling—Illustrated by the Athens Metro, Greece. Int. J. Rock Mech. Min. Sci. 2004, 41, 987–999. [Google Scholar] [CrossRef]

- Sapigni, M.; Berti, M.; Bethaz, E.; Busillo, A.; Cardone, G. TBM Performance Estimation Using Rock Mass Classifications. Int. J. Rock Mech. Min. Sci. 2002, 39, 771–788. [Google Scholar] [CrossRef]

- Gong, Q.; Yin, L.; Ma, H.; Zhao, J. TBM Tunnelling Under Adverse Geological Conditions: An Overview. Tunn. Undergr. Space Technol. 2016, 57, 4–17. [Google Scholar] [CrossRef]

- Song, S.; Tian, R.; Li, L.; Hu, J.; Shen, C.; Peng, S. Adaptability Study of EPB Shield Machine in Clay Stratum in Xuzhou. Geotech. Geol. Eng. 2019, 37, 2335–2341. [Google Scholar] [CrossRef]

- Lin, C.; Bu, Z.; Pan, D.; Wang, X.; Lin, P.; Zhang, Y. A Performance-Oriented Adaptability Assessment Method for TBM Tunneling. Arab. J. Geosci. 2022, 15, 622. [Google Scholar] [CrossRef]

- Guo, D.; Li, J.; Li, X.; Li, Z.; Li, P.; Chen, Z. Advance Prediction of Collapse for TBM Tunneling Using Deep Learning Method. Eng. Geol. 2022, 299, 106556. [Google Scholar] [CrossRef]

- Tan, Z.; Li, Z.; Zhou, Z.; Lai, H.; Jiao, Y.; Li, F.; Wang, L. Research on an Evaluation Method for the Adaptability of TBM Tunnelling. Appl. Sci. 2022, 12, 4590. [Google Scholar] [CrossRef]

- Hyun, K.C.; Min, S.; Choi, H.; Park, J.; Lee, I.M. Risk Analysis Using Fault-Tree Analysis (FTA) and Analytic Hierarchy Process (AHP) Applicable to Shield TBM Tunnels. Tunn. Undergr. Space Technol. 2015, 49, 121–129. [Google Scholar] [CrossRef]

- Salimi, A.; Rostami, J.; Moormann, C.; Delisio, A. Application of Non-Linear Regression Analysis and Artificial Intelligence Algorithms for Performance Prediction of Hard Rock TBMs. Tunn. Undergr. Space Technol. 2016, 58, 236–246. [Google Scholar] [CrossRef]

- Shaheen, A.A.; Fayek, A.R.; AbouRizk, S.M. Methodology for Integrating Fuzzy Expert Systems and Discrete Event Simulation in Construction Engineering. Can. J. Civ. Eng. 2009, 36, 1478–1490. [Google Scholar] [CrossRef]

- Li, X.; Zhao, S.; Shen, Y.; Li, G.; Zhu, H. Integrated Parameter Optimization Approach: Just-In-Time (JIT) Operational Control Strategy for TBM Tunnelling. Tunn. Undergr. Space Technol. 2023, 135, 105040. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, L.; Fu, X. Time Series Prediction of Tunnel Boring Machine (TBM) Performance During Excavation Using Causal Explainable Artificial Intelligence (CX-AI). Autom. Constr. 2023, 147, 104730. [Google Scholar] [CrossRef]

- Yang, H.; Liu, X.; Song, K. A Novel Gradient Boosting Regression Tree Technique Optimized by Improved Sparrow Search Algorithm for Predicting TBM Penetration Rate. Arab. J. Geosci. 2022, 15, 461. [Google Scholar] [CrossRef]

- Müller, G. Workflow Modeling Assistance by Case-Based Reasoning; Springer Vieweg: Wiesbaden, Germany, 2018. [Google Scholar]

- Bach, K.; Marling, C. Case-Based Reasoning Research and Development; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Schank, R.C. Dynamic Memory: A Theory of Reminding and Learning in Computers and People; Cambridge University Press: Cambridge, UK, 1982. [Google Scholar]

- Kolodner, J.L. Improving Human Decision Making Through Cased-based Reasoning Techniques. AI Mag. 1991, 12, 52–59. [Google Scholar]

- Tawfik, A.A.; Fowlin, J.; Kelley, K.; Anderson, M.; Vann, S.W. Supporting Case-Based Reasoning in Pharmacy Through Case Sequencing. J. Form. Des. Learn. A Publ. Assoc. Educ. Commun. Technol. 2019, 3, 111–122. [Google Scholar] [CrossRef]

- Zhai, Z.; Martínez Ortega, J.F.; Beltran, V.; Lucas Martínez, N. An Associated Representation Method for Defining Agricultural Cases in a Case-Based Reasoning System for Fast Case Retrieval. Sensors 2019, 19, 5118. [Google Scholar] [CrossRef]

- Liang, P.; Qin, C.Z.; Zhu, A.X.; Hou, Z.W.; Fan, N.Q.; Wang, Y.J. A Case-Based Method of Selecting Covariates for Digital Soil Mapping. J. Integr. Agric. 2020, 19, 2127–2136. [Google Scholar] [CrossRef]

- Leake, D.B. A Companion to Cognitive Science; Wiley: Hoboken, NJ, USA, 2017; pp. 465–476. [Google Scholar]

- Richter, M.M.; Aamodt, A. Case-Based Reasoning Foundations. Knowl. Eng. Rev. 2005, 20, 203–207. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, Y.; Pan, Y. A New Locally Adaptive k-Nearest Neighbor Algorithm Based on Discrimination Class. Knowl. Based Syst. 2020, 204, 106185. [Google Scholar] [CrossRef]

- Borter, N.; Völke, A.E.; Troche, S.J. The Development of Inductive Reasoning Under Consideration of the Effect due to Test Speededness. Psychol. Test Assess. Model. 2020, 62, 344–358. [Google Scholar]

- Yadav, P. Case Retrieval Algorithm Using Similarity Measure and Fractional Brain Storm Optimization for Health Informaticians. Int. Arab J. Inf. Technol. 2019, 16, 281–287. [Google Scholar] [CrossRef]

- Khetwal, A.; Rostami, J.; Nelson, P.P. Investigating the Impact of TBM Downtimes on Utilization Factor Based on Sensitivity Analysis. Tunn. Undergr. Space Technol. 2020, 106, 103586. [Google Scholar] [CrossRef]

- Khademi, J. A Methodology for Selection of TBM According to Geotechnical Conditions. Ph.D. Thesis, Amirkabir University of Technology, Tehran, Iran, 2006. [Google Scholar]

- Farrokh, E.; Mortazavi, A.; Shamsi, G. Evaluation of Ground Convergence and Squeezing Potential in the TBM Driven Ghomroud Tunnel Project. Tunn. Undergr. Space Technol. 2006, 21, 504–510. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill International: New York, NY, USA, 1980. [Google Scholar]

| Criterion Level Index | Mean | Standard Deviation | Variable Coefficient |

|---|---|---|---|

| TBM design | 7.73 | 0.541 | 0.070 |

| Tunnel design | 6.65 | 0.495 | 0.074 |

| Geologic setting | 8.41 | 0.427 | 0.051 |

| Bad geological problem | 9.17 | 0.516 | 0.056 |

| Organization management in construction | 6.39 | 0.551 | 0.086 |

| Criterion Level Index | Index Layer Index | Mean | Standard Deviation | Variable Coefficient |

|---|---|---|---|---|

| TBM design | Type selection design of cutterhead body | 4.24 | 0.514 | 0.121 |

| Support structure design of cutterhead | 4.36 | 0.714 | 0.164 | |

| Opening rate design | 5.04 | 0.525 | 0.104 | |

| Knife spacing design | 6.71 | 0.693 | 0.103 | |

| Rotating speed of cutter | 6.97 | 0.605 | 0.087 | |

| Rated torque of cutter plate | 8.73 | 0.498 | 0.057 | |

| Rated thrust of cutter plate | 8.71 | 0.733 | 0.084 | |

| Release torque of knife disc | 8.28 | 0.687 | 0.083 | |

| Backup system | 5.51 | 0.602 | 0.109 | |

| Tunnel design | Tunnel depth | 8.25 | 0.782 | 0.095 |

| Tunnel length | 6.33 | 0.679 | 0.107 | |

| Radius of tunnel flat curve | 6.95 | 0.638 | 0.092 | |

| Tunnel gradient | 3.37 | 0.576 | 0.171 | |

| Tunnel section size | 3.61 | 0.563 | 0.156 | |

| Geological conditions | Uniaxial compressive strength of rock | 9.32 | 0.281 | 0.030 |

| Integrity coefficient of rock mass | 9.39 | 0.264 | 0.028 | |

| Volume joint number of rock mass | 4.14 | 0.545 | 0.132 | |

| Rock quality index (RQD) | 4.21 | 0.541 | 0.129 | |

| Quartz content | 7.59 | 0.540 | 0.071 | |

| Abrasion index of rock | 7.62 | 0.498 | 0.065 | |

| Ground stress level | 7.11 | 0.588 | 0.083 | |

| Permeable rate | 6.53 | 0.739 | 0.113 | |

| Bad geological problem | Water inrush | 9.47 | 0.424 | 0.045 |

| Rockburst | 8.65 | 0.540 | 0.062 | |

| Fault fracture zone | 9.04 | 0.289 | 0.032 | |

| Large deformation of surrounding rock under compression | 9.06 | 0.282 | 0.031 | |

| Karst | 7.29 | 0.671 | 0.092 | |

| Compound stratum | 7.74 | 0.636 | 0.082 | |

| High ground temperature | 6.87 | 0.735 | 0.107 | |

| Noxious gas | 6.65 | 0.620 | 0.093 | |

| Organization management in construction | Technical level of construction | 7.53 | 0.562 | 0.075 |

| Construction management level | 6.45 | 0.683 | 0.106 | |

| TBM transportation and assembly | 3.35 | 0.521 | 0.155 | |

| TBM maintenance and disassembly | 3.73 | 0.586 | 0.157 |

| Target Layer | Adaptability of TBM Tunneling (D) | ||||

|---|---|---|---|---|---|

| Rule layer | TBM design P1 | Tunnel design P2 | Geological conditions P3 | Bad geological problem P4 | Organization management in construction P5 |

| Index layer | Rotating speed of cutter U1 Rated torque of cutter plate U2 Rated thrust of cutter plate U3 Release torque of knife disc U4 Knife spacing design U5 | Tunnel depth U6 Tunnel length U7 Radius of tunnel flat curve U8 | Uniaxial compressive strength of rock U9 Integrity coefficient of rock mass U10 Quartz content U11 Abrasion index of rock U12 Ground stress level U13 Permeable rate U14 | Water inrush U15 Rockburst U16 Fault fracture zone U17 Large deformation of surrounding rock under compression U18 Karst U19 Compound stratum U20 High ground temperature U21 Noxious gas U22 | Technical level of construction U23 Construction management level U24 |

| aij | Basis |

|---|---|

| 1 | Ui is just as important as Uj |

| 3 | Ui is slightly more important than Uj |

| 5 | Ui is significantly more important than Uj |

| 7 | Ui is more important than Uj |

| 9 | Ui is more important than Uj |

| 2, 4, 6, 8 | The median values of the above two judgments |

| D | P1 | P2 | P3 | P4 | P5 |

|---|---|---|---|---|---|

| P1 | 1 | 5 | 1/2 | 1/3 | 7 |

| P2 | 1/5 | 1 | 1/6 | 1/7 | 3 |

| P3 | 2 | 6 | 1 | 1/2 | 8 |

| P4 | 3 | 7 | 2 | 1 | 9 |

| P5 | 1/7 | 1/3 | 1/8 | 1/9 | 1 |

| Single-layer weight | 0.1890 | 0.0568 | 0.2881 | 0.4353 | 0.0307 |

| λmax = 5.1837, CI = 0.0459, RI = 1.1185, CR = 0.0411 < 0.1 | |||||

| P1 | U1 | U2 | U3 | U4 | U5 |

|---|---|---|---|---|---|

| U1 | 1 | 1/4 | 1/4 | 1/3 | 2 |

| U2 | 4 | 1 | 1 | 2 | 5 |

| U3 | 4 | 1 | 1 | 2 | 5 |

| U4 | 3 | 1/2 | 1/2 | 1 | 4 |

| U5 | 1/2 | 1/5 | 1/5 | 1/4 | 1 |

| Single-layer weight | 0.0840 | 0.3317 | 0.3317 | 0.1976 | 0.0550 |

| λmax = 5.0553, CI = 0.0138, RI = 1.1185, CR = 0.0124 < 0.1 | |||||

| P2 | U6 | U7 | U8 |

|---|---|---|---|

| U6 | 1 | 7 | 3 |

| U7 | 1/7 | 1 | 1/5 |

| U8 | 1/3 | 5 | 1 |

| Single-layer weight | 0.6491 | 0.0719 | 0.2790 |

| λmax = 3.0649, CI = 0.0324, RI = 0.5149, CR = 0.0630 < 0.1 | |||

| P3 | U9 | U10 | U11 | U12 | U13 | U14 |

|---|---|---|---|---|---|---|

| U9 | 1 | 1 | 5 | 5 | 6 | 8 |

| U10 | 1 | 1 | 5 | 5 | 6 | 8 |

| U11 | 1/5 | 1/5 | 1 | 1 | 2 | 4 |

| U12 | 1/5 | 1/5 | 1 | 1 | 2 | 4 |

| U13 | 1/6 | 1/6 | 1/2 | 1/2 | 1 | 3 |

| U14 | 1/8 | 1/8 | 1/4 | 1/4 | 1/3 | 1 |

| Single-layer weight | 0.3638 | 0.3638 | 0.0923 | 0.0923 | 0.0585 | 0.0293 |

| λmax = 6.1697, CI = 0.0339, RI = 1.2494, CR = 0.0272 < 0.1 | ||||||

| P4 | U15 | U16 | U17 | U18 | U19 | U20 | U21 | U22 |

|---|---|---|---|---|---|---|---|---|

| U15 | 1 | 3 | 2 | 2 | 6 | 5 | 7 | 8 |

| U16 | 1/3 | 1 | 1/2 | 1/2 | 4 | 3 | 5 | 6 |

| U17 | 1/2 | 2 | 1 | 1 | 5 | 4 | 6 | 7 |

| U18 | 1/2 | 2 | 1 | 1 | 5 | 4 | 6 | 7 |

| U19 | 1/6 | 1/4 | 1/5 | 1/5 | 1 | 1/2 | 2 | 3 |

| U20 | 1/5 | 1/3 | 1/4 | 1/4 | 2 | 1 | 3 | 4 |

| U21 | 1/7 | 1/5 | 1/6 | 1/6 | 1/2 | 1/3 | 1 | 2 |

| U22 | 1/8 | 1/6 | 1/7 | 1/7 | 1/3 | 1/4 | 1/2 | 1 |

| Single-layer weight | 0.3002 | 0.1330 | 0.2018 | 0.2018 | 0.0448 | 0.0652 | 0.0311 | 0.0221 |

| λmax = 8.2636, CI = 0.0377, RI = 1.4200, CR = 0.0265 < 0.1 | ||||||||

| P5 | U23 | U24 |

|---|---|---|

| U23 | 1 | 4 |

| U24 | 1/4 | 1 |

| Single-layer weight | 0.8 | 0.2 |

| λmax = 2.0, CI = 0, RI = 0, CR = 0 < 0.1 | ||

| The Criterion Level (Local Weights) | The Index Level (Local Weights) | Global Weights |

|---|---|---|

| P1 (0.1890) | U1 (0.0840) | 0.0159 |

| U2 (0.3317) | 0.0627 | |

| U3 (0.3317) | 0.0627 | |

| U4 (0.1976) | 0.0373 | |

| U5 (0.0550) | 0.0104 | |

| P2 (0.0568) | U6 (0.6491) | 0.037 |

| U7 (0.0719) | 0.0041 | |

| U8 (0.2790) | 0.0158 | |

| P3 (0.2881) | U9 (0.3638) | 0.1048 |

| U10 (0.3638) | 0.1048 | |

| U11 (0.0923) | 0.0266 | |

| U12 (0.0923) | 0.0266 | |

| U13 (0.0585) | 0.0169 | |

| U14 (0.0293) | 0.0084 | |

| P4 (0.4353) | U15 (0.3002) | 0.1307 |

| U16 (0.1330) | 0.058 | |

| U17 (0.2018) | 0.0878 | |

| U18 (0.2018) | 0.0878 | |

| U19 (0.0448) | 0.0195 | |

| U20 (0.0652) | 0.0284 | |

| U21 (0.0311) | 0.0135 | |

| U22 (0.0221) | 0.0096 | |

| P5 (0.0307) | U23 (0.8) | 0.0246 |

| U24 (0.2) | 0.0061 |

| Case Number | Case Name | Evaluation Index | Adaptability | Evaluation Level | Weights | ||

|---|---|---|---|---|---|---|---|

| TBM tunneling evaluation index | TBM tunneling evaluation index weight | ||||||

| U1 | Rotating speed of cutter | W1 | Rotating speed of cutter | ||||

| U2 | Rated torque of cutter plate | W2 | Rated torque of cutter plate | ||||

| ⋯⋯ | ⋯⋯ | ⋯⋯ | ⋯⋯ | ||||

| U23 | Technical level of construction | W23 | Technical level of construction | ||||

| U24 | Construction management level | W24 | Construction management level | ||||

| Case Name | L5 Section of the Gaoligongshan Tunnel (Case Number 5) | L12 Section of the Gaoligongshan Tunnel (Case Number 12) | L5 Section of the ABH Diversion Tunnel (III Standard) (Case Number 30) | L14 Section of the ABH Diversion Tunnel (III Standard) (Case Number 39) | |

|---|---|---|---|---|---|

| Evaluation Index | |||||

| U1 | 6.5 | 6.5 | 9.8 | 9.8 | |

| U2 | 11,797 | 11,797 | 4510 | 4510 | |

| U3 | 25,133 | 25,133 | 20,040 | 20,040 | |

| U4 | 17,695 | 17,695 | 10,045 | 10,045 | |

| U5 | 80 | 80 | 83 | 83 | |

| U6 | 595 | 687 | 1191 | 1312 | |

| U7 | 13.26 | 13.26 | 14 | 14 | |

| U8 | 800 | 800 | 800 | 800 | |

| U9 | 60 | 6.5 | 149 | 3.4 | |

| U10 | 0.55 | 0.25 | 0.55 | 0.35 | |

| U11 | 40.25 | 40.25 | 17.9 | 17.9 | |

| U12 | 3.34 | 3.34 | 2.2 | 2.2 | |

| U13 | 0.212 | 3846 | 0.273 | 11.765 | |

| U14 | 7.37 | 18.59 | 0.05 | 6.06 | |

| U15 | 68.57 | 19.3 | 3.01 | 10.62 | |

| U16 | 4.71 | 7 | 3.663 | 7 | |

| U17 | 0 | 50 | 0 | 7 | |

| U18 | 4.71 | 0.26 | 3.663 | 0.085 | |

| U19 | 0.67 | 0.67 | 0.92 | 0.92 | |

| U20 | 0 | 100 | 0 | 100 | |

| U21 | 28 | 28 | 32 | 33 | |

| U22 | 0 | 0 | 0 | 0 | |

| U23 | 8.5 | 8.5 | 8 | 8 | |

| U24 | 8.5 | 8.5 | 8 | 8 | |

| Case Number | Target Case | Source Case | Similarity | Target Case Adaptability | Source Case Adaptability | Deviation | ||

|---|---|---|---|---|---|---|---|---|

| Adaptability | Adaptability Level | Adaptability | Adaptability Level | |||||

| 5 | L5 section of the Gaoligongshan tunnel | L4 section of the Gaoligongshan tunnel | 0.9042 | 0.8237 | Adaptable (height) | 0.8235 | Adaptable (height) | 0.02% |

| 12 | L12 section of the Gaoligongshan tunnel | L15 section of the Gaoligongshan tunnel | 0.9835 | 0.5624 | Slightly adaptable | 0.5559 | Slightly adaptable | 1.16% |

| 30 | L5 section of the ABH diversion tunnel (III standard) | L4 section of the ABH diversion tunnel (III standard) | 0.6633 | 0.7007 | Adaptable (moderate) | 0.9087 | Completely adaptable | 29.68% |

| 39 | L14 section of the ABH diversion tunnel (III standard) | L11 section of the ABH diversion tunnel (III standard) | 0.8363 | 0.5818 | Slightly adaptable | 0.5836 | Slightly adaptable | 0.31% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, J.; Wang, J.; Chen, S.; Luo, C.; Zhou, Y. Development and Application of Adaptive Evaluation System for TBM Tunneling Based on Case-Based Reasoning. Sustainability 2023, 15, 5768. https://doi.org/10.3390/su15075768

Zhan J, Wang J, Chen S, Luo C, Zhou Y. Development and Application of Adaptive Evaluation System for TBM Tunneling Based on Case-Based Reasoning. Sustainability. 2023; 15(7):5768. https://doi.org/10.3390/su15075768

Chicago/Turabian StyleZhan, Jinwu, Jiacheng Wang, Song Chen, Caisong Luo, and Yalai Zhou. 2023. "Development and Application of Adaptive Evaluation System for TBM Tunneling Based on Case-Based Reasoning" Sustainability 15, no. 7: 5768. https://doi.org/10.3390/su15075768

APA StyleZhan, J., Wang, J., Chen, S., Luo, C., & Zhou, Y. (2023). Development and Application of Adaptive Evaluation System for TBM Tunneling Based on Case-Based Reasoning. Sustainability, 15(7), 5768. https://doi.org/10.3390/su15075768