Risk Assessment in Practice: A Case Analysis of the Pohang Steel Mill in Korea

Abstract

1. Introduction

2. Materials and Methods

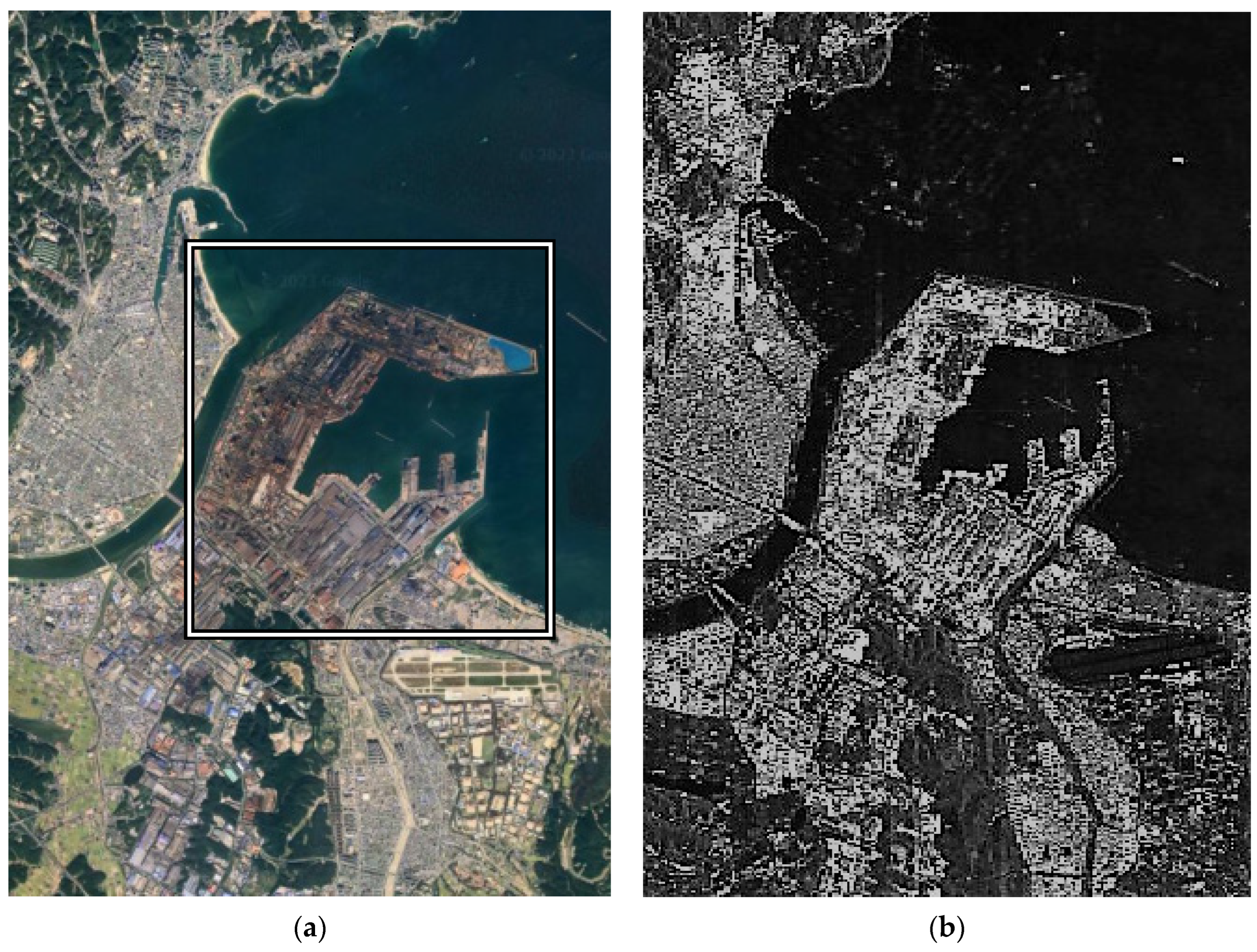

2.1. Case of Study

2.2. Risk Identification

2.3. Risk Analysis

3. Results

3.1. Risk Value

3.2. Risk Priority

3.3. Risk Positioning

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Jang, M.G. POSCO, Selected by WSD as ‘the Most Competitive Steelmaker’ for 13 Consecutive Years. Available online: https://www.ajunews.com/view/20221213160126522 (accessed on 25 January 2023).

- Jung, K.O.; Lim, E.S. Role of the Korea Steel Industry in the National Economy Analysis. J. Korea Acad.-Ind. Coop. Soc. 2008, 9, 831–839. [Google Scholar]

- Lee, J.J.; Kim, K.S.; Yun, H.S.; Song, M.S. Risk Analysis and Ranking Method for an Expressway Infrastructure Protection Plan. J. Korean Soc. Hazard Mitig. 2018, 18, 29–37. [Google Scholar] [CrossRef]

- Kim, W.H.; Lee, S.Y. Overseas industrial control system security technology R&D trends. J. Korea Inst. Inf. Secur. Cryptol. 2015, 25, 5–11. [Google Scholar]

- Kim, T.H. A Study on the Introduction to Risk Assessment Methods. J. Korean Inst. Fire Sci. Eng. 2000, 1, 2–5. [Google Scholar]

- Marvin, R. Risk Assessment: Theory, Methods, and Applications, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Lee, Y.S.; Moon, G.S. Pohang Works Produces 35% of Domestic Steel... A Direct Hit to the Shipbuilding, Automobile and Construction Industries. Available online: https://m.mk.co.kr/news/business/10449260 (accessed on 25 January 2023).

- Yeo, J.G. ‘Construction Plan Review Process’ Safety Risk Resolution … Pohang Works Strengthens Safety Management. Available online: https://www.asiae.co.kr/article/2022080314374699977 (accessed on 25 January 2023).

- Kim, J.S. Analysis of success factors for POSCO Pohang Steelworks construction project. J. Korean Soc. Proj. Manag. 2011, 1, 11–35. [Google Scholar]

- Jung, H.Y. Equipped with a Total Crude Steel Production Capacity of 20.8 Million Tons within 25 Years of Establishment, Writing a Legend in the Global Steel Industry. Available online: http://monthly.chosun.com/client/news/viw.asp?ctcd=&nNewsNumb=201805100045 (accessed on 26 January 2023).

- Sim, J.J. Towards the Effectiveness of the Regulation of the Health and Safety at Work—In Comparison with the Cases of the UK and Australia. SNU Labor Law Rev. 2015, 39, 1–49. [Google Scholar]

- Merna, T.; Al-Thani, F.F. Corporate Risk Management, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ryu, J.H. Necessity of Disaster Management of Infrastructure Using BCP Standards: Focusing on NFPA 1600 Regulations. J. Korean Soc. Civ. Eng. 2006, 54, 41–49. [Google Scholar]

- Pritchard, C.L. Risk Management, 5th ed.; Auerbach Publications: New York, NY, USA, 2018; pp. 7–24. [Google Scholar] [CrossRef]

- ISO 31000; Risk Management. International Organization for Standardization: London, UK, 2009.

- LEE, Y.J.; Yoon, J.W. Introduction to BCP, 1st ed.; DigitalTimes: Seoul, Republic of Korea, 2004; pp. 57–59. [Google Scholar]

- Yoon, Y.K. A Study on Risk Assessment Possible in Civil Works. J. Korean Soc. Explos. Blasting Eng. 2011, 29, 59–66. [Google Scholar]

- Terje, A. Risk assessment and risk management: Review of recent advances on their foundation. Eur. J. Oper. Res. 2016, 253, 1–13. [Google Scholar]

- Liverant, S.; Scodel, A. Internal and External Control as Determinants of Decision Making under Conditions of Risk. Psychol. Rep. 1960, 7, 59–67. [Google Scholar] [CrossRef]

- Kim, J.H.; Kong, M.K. Policy Studies: Structural Changes and Prospects of the World Steel Industry, 1st ed.; Institute for National Security Strategy: Seoul, Republic of Korea, 2012; pp. 101–131. [Google Scholar]

- Cho, Y.J.; Cho, E.T.; Kim, J.H.; Lee, Y.H.; Rhee, Q.H.; Lee, H.W.; Jang, K.S. Effects of Storm Surge on Vapor Explosion in the Steel Mill Industry. Am. J. Humanit. Soc. Sci. Res. 2021, 4, 96–110. [Google Scholar]

- Choi, J.J.; Jo, Y.J.; Cho, S.H.; Lee, J.H.; Ha, D.M. Steelworks safety management by chemical risk assessment. Proc. Korean Gas Soc. Conf. 2021, 11, 201. [Google Scholar]

- Choi, C.H. Local Article. Available online: https://www.news1.kr/articles/?4580936 (accessed on 2 February 2023).

- Hong, S.M.; Park, P.; Sun, S.B. Deduction of Main Hazard Cause to the Progress of Iron Work for Accident Analysis. J. Korea Saf. Manag. Sci. 2009, 11, 33–40. [Google Scholar] [CrossRef] [PubMed]

- Han, W.S. POSCO Invests KRW 1.105 Trillion in Disaster Prevention over Three Years. Available online: https://www.donga.com/news/Economy/article/all/20180524/90238915/1 (accessed on 25 January 2023).

- Kim, Y.R. Gyeongsangbuk-do Chemical Safety Management Forum Article. Available online: https://search.naver.com/p/crd/rd?m=1&px=563&py=187&sx=563&sy=187&p=h9WbLwprvh8sssw2Ot0ssssss%2B0-208783&q=%ED%8F%AC%ED%95%AD%EC%A0%9C%EC%B2%A0%EC%86%8C+%EC%A0%80%EC%9E%A5+%EC%9C%A0%EB%8F%85%EB%AC%BC%EC%A7%88&ie=utf8&rev=1&ssc=tab.nx.all&f=nexearch&w=nexearch&s=2pkF8bdjVSzMIglbxjGKOAkC&time=1675314745168&abt=%5B%7B%22eid%22%3A%22ONEBEST-PRIOR%22%2C%22vid%22%3A%224%22%7D%2C%7B%22eid%22%3A%22SBR1%22%2C%22vid%22%3A%22736%22%7D%5D&a=web_gen*D.link&r=1&i=a00000fa_6096708f75e0b7365c6e0331&u=https%3A%2F%2Fwww.gb.go.kr%2FMain%2Fcommon%2Fboard%2Fdownload.do%3FB_STEP%3D25705999%26B_ORDER%3D4&cr=1 (accessed on 2 February 2023).

- Kim, Y.H. Education/Labor Article. Available online: http://m.pn.or.kr/news/articleView.html?idxno=17569 (accessed on 2 February 2023).

- Park, D.M. Pohang Construction Union Strike Ends. Available online: https://www.mk.co.kr/news/all/4137547 (accessed on 26 January 2023).

- Kim, C.S. Pohang Steelworks, Simulated Training to Counter Cyber Terrorism... Smart Security Enhancement. Available online: https://tk.newdaily.co.kr/site/data/html/2019/06/27/2019062700200.html (accessed on 25 January 2023).

- Yun, H.S.; Jo, J.M.; Choi, H.J.; Hwang, J.S. Disaster Risk Assessment Theory: Disaster Risk Assessment Using Spatial Information, 1st ed.; Moonwoondang: Seoul, Republic of Korea, 2014; pp. 450–451. [Google Scholar]

- Ahn, S.G.; Jo, D.H.; Heo, J.H.; Moon, S.J.; Yoo, H.S. A study on plant project risk assessment and management system. Plant J. 2010, 6, 56–63. [Google Scholar]

- Olechowski, A.; Oehmen, J.; Seering, W. Ben-Daya, M. The professionalization of risk management: What role can the ISO 31000 risk management principles play? Int. J. Proj. Manag. 2016, 34, 1568–1578. [Google Scholar] [CrossRef]

- Kim, J.D.; Park, I.B.; Baek, T.S.; Hwang, S.H. International standards and overseas trends in Information Security Incident Management. Korea Rev. KIISC 2010, 20, 28–33. [Google Scholar]

| Cause of Fire and Explosion | Proportion (%) |

|---|---|

| Gas leak | 13 |

| Facility (machine) abnormality | 6 |

| Welding melting spark | 61 |

| Spontaneous combustion | 3 |

| Residual gas | 3 |

| Glowing splash | 6 |

| Electricity | 3 |

| Other | 3 |

| Level | Point | Described | |

|---|---|---|---|

| Probability | Very low | 1.0 | Possible, but may be caused by exceptional circumstances over a period exceeding 1000 years. |

| Low | 2.0 | May be caused by conditions for 100–1000 years | |

| Medium | 3.0 | May be caused by conditions projected in 50–100 years | |

| High | 4.0 | May be caused by conditions projected over 10–50 years | |

| Very High | 5.0 | May occur more frequently than once in 10 years | |

| Impact | Minor | 1.0 | Damage is present, but negligible |

| Light | 2.0 | Level of concern due to deteriorating competitiveness | |

| Medium | 3.0 | Continuous operation is temporarily difficult | |

| Major | 4.0 | Circumstances where continuous inability to operate persists | |

| Catastrophic | 5.0 | The level at which large-scale unemployment and bankruptcy of related companies occur due to the inability to operate |

| Risk | Probability Average | Impact Average | Risk Value | |

|---|---|---|---|---|

| External | International economic crisis | 1.0 | 1.0 | 1.0 |

| Growth of competitor | 2.2 | 2.33 | 5.1 | |

| Natural disaster | 1.07 | 1.27 | 1.4 | |

| Complaints from nearby residents | 3.53 | 3.87 | 13.7 | |

| Internal | Fire and explosion | 4.33 | 4.27 | 18.5 |

| Safety accident | 4.33 | 4.33 | 18.7 | |

| Leakage of toxic substances | 1.0 | 1.0 | 1.0 | |

| Subcontractor strike | 1.0 | 1.0 | 1.0 | |

| Release of confidential information | 4.27 | 4.13 | 17.6 |

| Priority | Risk | Risk Value |

|---|---|---|

| 1 | Safety accident | 18.7 |

| 2 | Fire and explosion | 18.5 |

| 3 | Release of confidential information | 17.6 |

| 4 | Complaints from nearby residents | 13.7 |

| 5 | Growth of a competitor | 5.1 |

| 6 | Natural disaster | 1.4 |

| 7 | International economic crisis | 1.0 |

| 7 | Leakage of toxic substances | 1.0 |

| 7 | Subcontractor strike | 1.0 |

| Risk | Type of Treatment | Content |

|---|---|---|

| Safety accident | Structural | Expansion of ILS (Isolation-Locking System) to all facilities |

| Conducting the ‘Good Drive’ exercise (driving at 40 km/h or less, turning on the headlights even during the day) | ||

| Non-Structural | Compliance with the Fail Safety principle | |

| Compliance with the Fool Proof principle | ||

| Reinforcing safety education, implementing safety patrol | ||

| Suspension of entry for violators of safety rules | ||

| Fire and explosion | Structural | Strictly prohibited fire work (spark work such as welding and cutting) |

| Periodic inspection and replacement of old gas piping and facilities | ||

| Establishment of non-smoking zones throughout the steel mill | ||

| Prohibition of possession of ignition sources such as lighters (when entering) and punishment for violators | ||

| Non-Structural | Compulsory completion of firefighting training (direct management, outsourcing companies, even daily workers) | |

| 24-h fire prevention patrol | ||

| Fire prevention campaign | ||

| Release of confidential information | Structural | Restriction on external mail sending (if necessary, sending after payment) |

| Security checkpoint equipment improvements | ||

| Installation of mobile phone automatic control function app when entering and exiting the steelworks | ||

| Non-Structural | Reinforcing security education and conducting campaigns | |

| Conduct nighttime security checks | ||

| Complaints from nearby residents | Structural | Coal silo installation to prevent coal from scattering |

| Perform dust filtering by installing a dust collector | ||

| Non-Structural | Creation of environment for resident welfare | |

| Creation of revitalization of nearby commercial districts | ||

| Preferential recruitment of local residents to the company |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, M.; Yun, H. Risk Assessment in Practice: A Case Analysis of the Pohang Steel Mill in Korea. Sustainability 2023, 15, 6047. https://doi.org/10.3390/su15076047

Cho M, Yun H. Risk Assessment in Practice: A Case Analysis of the Pohang Steel Mill in Korea. Sustainability. 2023; 15(7):6047. https://doi.org/10.3390/su15076047

Chicago/Turabian StyleCho, MinKyung, and HongSik Yun. 2023. "Risk Assessment in Practice: A Case Analysis of the Pohang Steel Mill in Korea" Sustainability 15, no. 7: 6047. https://doi.org/10.3390/su15076047

APA StyleCho, M., & Yun, H. (2023). Risk Assessment in Practice: A Case Analysis of the Pohang Steel Mill in Korea. Sustainability, 15(7), 6047. https://doi.org/10.3390/su15076047