Influence of Moisture Content and Dry Density on the Compressibility of Disturbed Loess: A Case Study in Yan’an City, China

Abstract

:1. Introduction

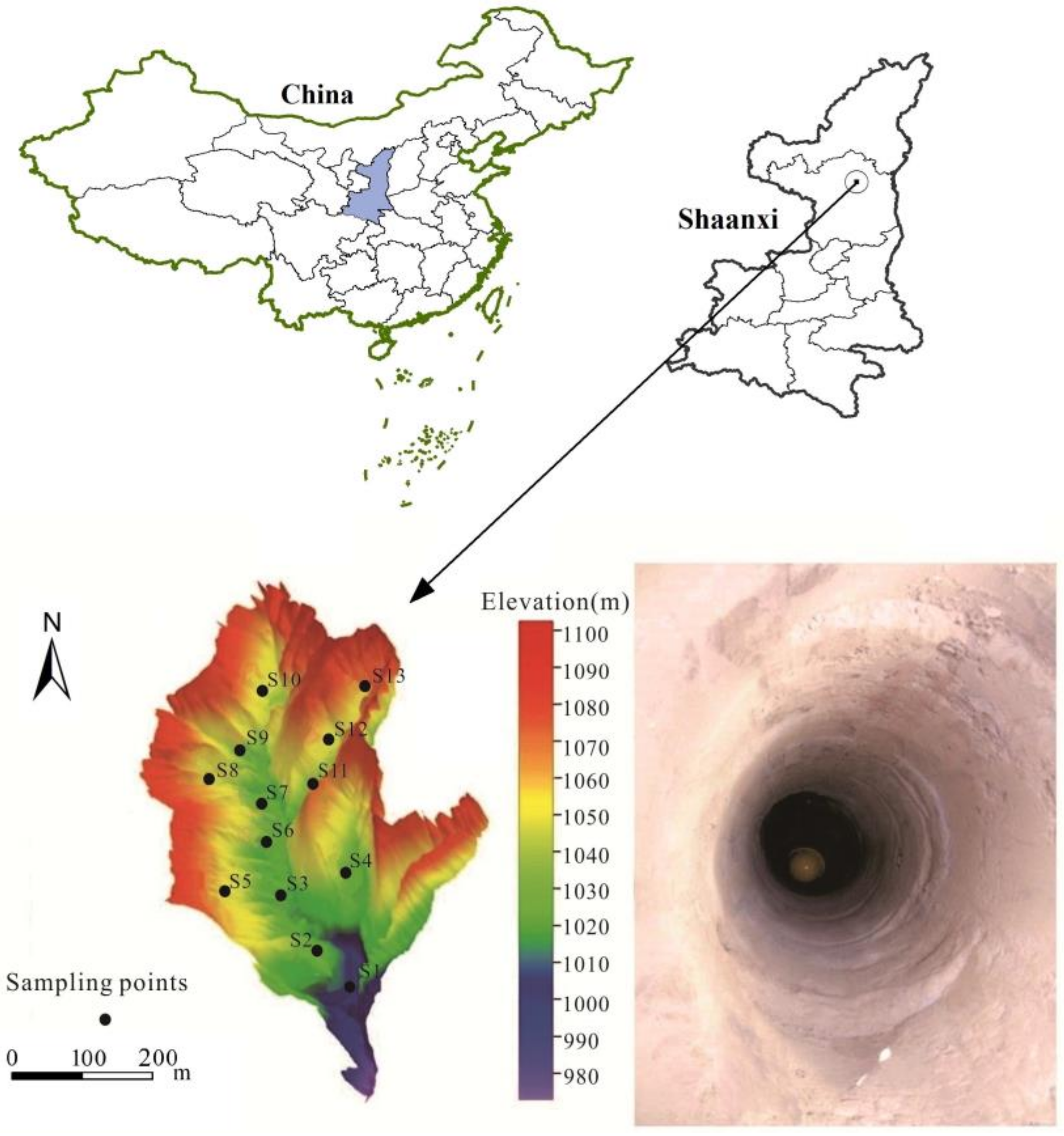

2. Study Area

2.1. Location of the Study Area

2.2. Meteorological and Hydrological Features

2.3. Geology and Hydrogeology Conditions

3. Materials and Methods

3.1. Sampling and Analysis

3.2. Fast Consolidation Test

3.3. Calculation of the Compression Deformation Coefficient

4. Results and Discussion

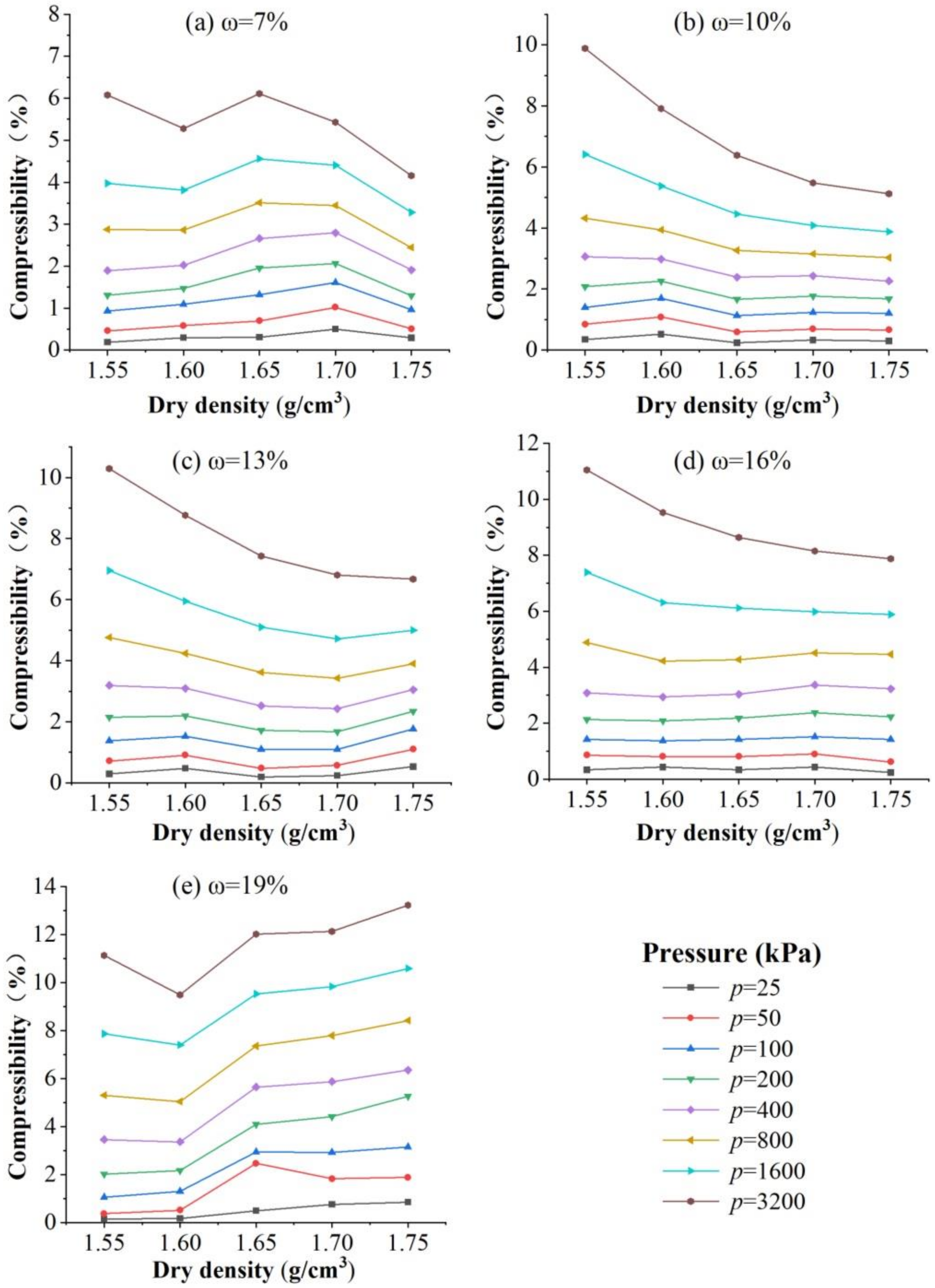

4.1. Compressibility Analysis of Disturbed Loess

4.2. Effect of Moisture Content on Compressibility

4.3. Effect of Dry Density on Compressibility

5. Conclusions

- (1)

- With increasing compression load, the loess specimens are gradually compacted, and the pore ratio decreases. When the water content of the disturbed loess is 7%, the pore ratio coefficient is the largest, and the strength of the soil sample is the highest. When the water content is greater than 10%, the decreasing rate for the pore ratio of disturbed loess increases significantly with the increasing pressure. At a pressure less than 1000 kPa, the e-p curve is hyperbolic, and at a pressure greater than 1200 kPa, the e-p curve relationship is close to linear. In contrast to in situ loess, the compression process in perturbed loess is relatively homogeneous, and there is a compression-yielding phenomenon, which is weaker than the yield stress performance of in situ loess.

- (2)

- The compression coefficient of disturbed loess showed an initial increasing and then decreasing trend with increasing mass water content. At low dry density, the compression coefficient of the specimen increases more rapidly with the water content up to 10%. When the water content is larger than 10%, the growth rate of the compression coefficient of the perturbed loess becomes slower. The dry density reaches its maximum at a mass water content of approximately 16%. That is, the best compaction is achieved when the moisture content of the filled loess material is adjusted to approximately 16% in a practical engineering project.

- (3)

- The compressive deformation coefficient generally decreases with increasing dry density and increases with increasing water content under different loading conditions. However, in the case where both the dry density and the water content are small, the compression coefficient increases with the dry density for a range of dry densities due to the easy formation of cohesive structures in soil. In the case of a larger dry density and water content, the compressibility rapidly becomes larger as the dry density and water content increase since it is closer to saturated soft loess.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, Y.; Xue, D.; Ma, B.; Yang, K.; Mi, W. Urbanization Process and Its Ecological Environment Response Pattern on the Loess Plateau China. Econ. Geogr. 2020, 40, 174–184. [Google Scholar]

- Chen, Y.; Huo, W.X.; Qian, H.; Li, B.C. Research on Holocene Loess Erosion Associated to Climate Evolution in China. Pol. J. Environ. Stud. 2020, 29, 409–417. [Google Scholar] [CrossRef]

- Ding, Z.; Liu, T. Progresses of Loess research in China (part1) Loess stratigraphy. Quat. Sci. 1989, 1, 24–35. [Google Scholar]

- Li, P.; Qian, H.; Wu, J. Accelerate research on land creation. Nature 2014, 510, 29–31. [Google Scholar] [CrossRef] [Green Version]

- Derbyshire, E. Geological hazards in loess terrain, with particular reference to the loess regions of China. Earth Sci. Rev. 2001, 54, 231–260. [Google Scholar] [CrossRef]

- Leng, Y.; Peng, J.; Wang, S.; Lu, F. Development of water sensitivity index of loess from its mechanical properties. Eng. Geol. 2020, 280, 105918. [Google Scholar] [CrossRef]

- Yang, C.; Wu, J.; Li, P.; Wang, Y.; Yang, N. Evaluation of soil-water characteristic curves for different textural soils using fractal analysis. Water 2023, 15, 772. [Google Scholar] [CrossRef]

- Benson, C.H.; Daniel, D.E. Influence of Clods on the Hydraulic Conductivity of Compacted Clay. J. Geotech. Eng. 1990, 116, 1231–1248. [Google Scholar] [CrossRef]

- An, J.; Zhang, Y.; Yu, N. Quantifying the effect of soil physical properties on the compressive characteristics of two arable soils using uniaxial compression tests. Soil Tillage Res. 2015, 145, 216–223. [Google Scholar] [CrossRef]

- Otálvaro, I.F.; Neto, M.P.C.; Caicedo, B. Compressibility and microstructure of compacted laterites. Transp. Geotech. 2015, 5, 20–34. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, J.; Yang, X. A novel rigid wheel for agricultural machinery applicable to paddy field with muddy soil. J. Terramech. 2020, 87, 21–27. [Google Scholar] [CrossRef]

- Barr, A.D.; Clarke, S.D.; Tyas, A.; Warren, J.A. Effect of Moisture Content on High Strain Rate Compressibility and Particle Breakage in Loose Sand. Exp. Mech. 2018, 58, 1331–1334. [Google Scholar] [CrossRef] [Green Version]

- Granovsky, A.; McCoy, E. Air flow measurements to describe field variation in porosity and permeability of soil macropores. Soil Sci. Soc. Am. J. 1997, 61, 1569–1576. [Google Scholar] [CrossRef]

- Lade, P.V.; Boer, R.D. The concept of effective stress for soil, concrete and rock. Géotechnique 1997, 47, 61–78. [Google Scholar] [CrossRef]

- Akagi, H. A Physico-Chemical Approach to the Consolidation Mechanism of Soft Clays. Soils Found. 1994, 34, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Akagi, D.X. Mechanical Effects of Solid Water on the Particle Skeleton of Soil: Mechanism Analysis. Geofluids 2021, 2021, 9969023. [Google Scholar] [CrossRef]

- Garlanger, J.E. The consolidation of soils exhibiting creep under constant effective stress. Géotechnique 1972, 22, 71–78. [Google Scholar] [CrossRef]

- Xu, P.P.; Zhang, Q.Y.; Qian, H.; Li, M.N.; Yang, F.X. An investigation into the relationship between saturated permeability and microstructure of remolded loess: A case study from Chinese Loess Plateau. Geoderma 2021, 382, 114774. [Google Scholar] [CrossRef]

- Yu, M.Z.; Peng, X.F.; Fang, Z.H. Water morphologies and distribution in wet soil and sands. In Proceedings of the 1st ASME Micro/Nanoscale Heat Transfer International Conference, Tainan, Taiwan, 6–9 June 2008; pp. 881–887. [Google Scholar]

- Liu, Z.; Liu, F.; Ma, F.; Wang, M.; Bai, X.; Zheng, Y.; Yin, H.; Zhang, G. Collapsibility, composition, and microstructure of loess in China. Can. Geotech. J. 2016, 53, 673–686. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Shao, S.; She, F. A new method for evaluating loess collapsibility and its application. Eng. Geol. 2020, 264, 105376. [Google Scholar] [CrossRef]

- Lei, L.; Gu, Q. Study on Changes Rule of Silty Loess Consolidation Parameter. Subgrade Eng. 2010, 4, 175–177. [Google Scholar]

- Delage, P. A microstructure approach to the sensitivity and compressibility of some Eastern Canada sensitive clays. Geotechnique 2010, 60, 353–368. [Google Scholar] [CrossRef]

- Jiang, M.J.; Li, T.; Hu, H.J.; Thornton, C. DEM analyses of one-dimensional compression and collapse behaviour of unsaturated structural loess. Comput. Geotech. 2014, 60, 47–60. [Google Scholar] [CrossRef]

- Perisic, G.A.; Ovalle, C.; Barrios, A. Compressibility and creep of a diatomaceous soil. Eng. Geol. 2019, 258, 105145. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, S.; Yu, Y.; Zhang, Y.; Li, Z.; Hou, X.; Ma, L.; Zou, Y.; Guo, S.; Peng, J. A comparative study on the physical properties of natural sedimentary loess and manual filling compacted loess. Environ. Earth Sci. 2021, 80, 721. [Google Scholar] [CrossRef]

- Juang, C.H.; Dijkstra, T.; Wasowski, J.; Meng, X.M. Loess geohazards research in China: Advances and challenges for mega engineering projects. Eng. Geol. 2019, 251, 1–10. [Google Scholar] [CrossRef]

- Xu, Y. Experiment study on the compression resilience of loess. IOP Conf. Ser. Earth Environ. Sci. 2020, 558, 032019. [Google Scholar] [CrossRef]

- Dang, B.; Zhao, H.; Li, W.H.; Chen, Y.S.; Zeng, X.J.; Yan, Z.Q.; Jia, Y.Q. Identification of sequence boundaries of different orders in the Upper Triassic Yanchang Formation in northern Shaanxi, Ordos basin. Geol. China 2007, 34, 414–421. (In Chinese) [Google Scholar]

- Zhao, J.; Wang, D.; Fan, B.; Lu, H.; Zhang, X.; Qu, W.; Wen, L.; Li, D. Geochemical characteristics of the loess deposit at Yan’an and its implication to changes of East Asia summer monsoon during the past 130 ka. Geochimica 2004, 33, 495–500. (In Chinese) [Google Scholar]

- An, Z.; Kukla, G.; Porter, S.; Xiao, J. Magnetic susceptibility evidence of monsoon variation on the Loess Plateau of central China during the last 130,000 years. Quat. Res. 1991, 36, 29–36. [Google Scholar] [CrossRef]

- Ding, Z.L.; Sun, J.M.; Liu, T.S.; Zhu, R.X.; Yang, S.L.; Guo, B. Wind-blown origin of the Pliocene red clay formation in the central Loess Plateau. China. Earth Planet Sci. Lett. 1998, 161, 135–143. [Google Scholar] [CrossRef]

- Dong, Y.; Santosh, M. Tectonic architecture and multiple orogeny of the Qinling Orogenic Belt, Central China. Gondwana Res. 2016, 29, 1–40. [Google Scholar] [CrossRef]

- Bao, Z.; Wang, Q.; Bai, G.; Zhao, Z.; Song, Y.; Liu, X. Geochronology and geochemistry of the Fangcheng Neoproterozoic alkali-syenites in East Qinling orogen and its geodynamic implications. Chin. Sci. Bull. 2008, 53, 2050–2061. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.B.; Ma, Y.D.; Cao, J.J.; Wei, J.P.; Shao, T.J. Effect of Quaternary climatic change on modern hydrological systems in the southern Chinese Loess Plateau. Environ. Earth Sci. 2015, 73, 1161–1167. [Google Scholar] [CrossRef]

- Wissa, A.E.; Christian, J.T.; Davis, E.H.; Heiberg, S. Consolidation at constant rate of strain. J. Soil Mech. Found. Div. 1971, 97, 1393–1413. [Google Scholar] [CrossRef]

- Raheena, M.; Robinson, R.G. Determination of Coefficient of Secondary Compression in Accelerated Incremental Loading Consolidation Test. In Geotechnical Characterization and Modelling, Proceedings of IGC 2018 Lecture Notes in Civil Engineering; Springer: Singapore, 2020; Volume 85, pp. 1113–1125. [Google Scholar] [CrossRef]

- GE/T 50266-2013; Ministry of Housing and Urban-Rural Development of the P. R. China. Standard for Test Methods of Engineering Rock Mass. China Standards Press: Beijing, China, 2013. (In Chinese)

- Leng, Y.Q.; Peng, J.B.; Wang, Q.Y.; Meng, Z.J.; Huang, W.L. A fluidized landslide occurred in the Loess Plateau: A study on loess landslide in South Jingyang tableland. Eng. Geol. 2018, 236, 129–136. [Google Scholar] [CrossRef]

- Liu, M.D.; Carter, J.P.; Desai, C.S.; Xu, K.J. Analysis of the compression of structured soils using the disturbed state concept. Int. J. Numer. Anal. Methods Geomech. 2000, 24, 723–735. [Google Scholar] [CrossRef]

- Munoz-Castelblanco, J.; Delage, P.; Pereira, J.M.; Cui, Y.J. Some aspects of the compression and collapse behaviour of an unsaturated natural loess. Geotech. Lett. 2011, 1, 17–22. [Google Scholar] [CrossRef] [Green Version]

- Jiang, M.J.; Hu, H.J.; Liu, F. Summary of collapsible behaviour of artificially structured loess in oedometer and triaxial wetting tests. Can. Geotech. J. 2012, 49, 1147–1157. [Google Scholar] [CrossRef]

- Chen, K.S.; Sha, A.M. Experimental study on the compression characteristics of disturbed loess. J. China Foreign Highw. 2010, 3, 285–289. (In Chinese) [Google Scholar] [CrossRef]

- Liu, H.T.; Zhang, A.J.; Duan, T.; Lian, J.B.; Dong, X.H. The influence of alternate dry-wet on the strength and permeability of remolded loess. Hydro. Sci. Eng. 2010, 4, 38–42. [Google Scholar]

- Burton, G.J.; Pineda, J.A.; Sheng, D.C.; Airey, D. Microstructural changes of an undisturbed, reconstituted and compacted high plasticity clay subjected to wetting and drying. Eng. Geol. 2015, 193, 363–373. [Google Scholar] [CrossRef]

- Han, Z.; Zhao, G.T.; Lin, J.G.; Fan, K.W.; Zou, W.L. Influences of temperature and moisture histories on the hydrostructural characteristics of a clay during desiccation. Eng. Geol. 2022, 297, 106533. [Google Scholar] [CrossRef]

- Gerard, P.; Mahdad, M.; McCormack, A.R.; Francois, B. A unified failure criterion for unstabilized rammed earth materials upon varying relative humidity conditions. Constr. Build. Mater. 2015, 95, 437–447. [Google Scholar] [CrossRef]

- Cheng, Q.; Tang, C.S.; Zeng, H.; Zhu, C.; An, N.; Shi, B. Effects of microstructure on desiccation cracking of a compacted soil. Eng. Geol. 2020, 265, 105418. [Google Scholar] [CrossRef]

- Xu, L.; Coop, M.R. Influence of structure on the behavior of a saturated clayey loess. Can. Geotech. J. 2016, 53, 1026–1037. [Google Scholar] [CrossRef]

- Mu, Q.; Dang, Y.; Dong, Q.; Liao, H.; Dong, H. Water-retention characteristics and collapsibity behaviors: Comparison between intact and compacted loesses. Chin. J. Geotech. Eng. 2019, 41, 1496–1504. [Google Scholar]

- Zhao, Z.; Zhu, Y.; Ye, S. Study on settlement deformation of high fill foundation in large thickness loess area. Arab. J. Geosci. 2021, 14, 1173. [Google Scholar] [CrossRef]

- Li, P.; Shao, S.; Vanapalli, S.K. Characterizing and modeling the pore-size distribution evolution of a compacted loess during consolidation and shearing. J. Soils Sediments 2020, 20, 2855–2867. [Google Scholar] [CrossRef]

- Li, Y.; Mo, P.; Wang, Y.; Zhang, T.; Zhang, H. Strength anisotropy of Malan loess and the implications for the formation of loess walls and columns. Catena 2020, 194, 104809. [Google Scholar] [CrossRef]

- Lo, W.C.; Lee, J.W. Effect of water content and soil texture on consolidation in unsaturated soils. Adv. Water Resour. 2015, 82, 51–69. [Google Scholar] [CrossRef]

- Yu, F.W. Particle breakage in granular soils: A review. Part. Sci. Technol. 2021, 39, 91–100. [Google Scholar] [CrossRef]

- Han, J.; Yin, Z.Y.; Dano, C.; Hicher, P.Y. Effect of strain rate on the adhesive bond shearing resistance of stiff clay. Transp. Geotech. 2021, 27, 100479. [Google Scholar] [CrossRef]

- Dijkstra, T.A.; Smalley, I.J.; Rogers, C.D.F. Particle packing in loess deposits and the problem of structure collapse and hydroconsolidation. Eng. Geol. 1995, 40, 49–64. [Google Scholar] [CrossRef]

- Al-Sharrad, M.A.; Gallipoli, D.; Wheeler, S.J. Experimental investigation of evolving anisotropy in unsaturated soils. Geotechnique 2017, 67, 1033–1049. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Qian, H. Water in loess. In Encyclopedia of Sustainability Science and Technology; Meyers, R.A., Ed.; Springer: New York, NY, USA, 2018; pp. 1–17. [Google Scholar] [CrossRef]

| Physical Index | Dry Density (g/cm3) | Moisture Content (%) | Specific Gravity (g/cm3) | Void Ratio | Degree of Saturation (%) | |

|---|---|---|---|---|---|---|

| Qp3 | Sample size | 1150 | 1150 | 1150 | 1150 | 1150 |

| Max | 1.510 | 16.6 | 2.71 | 1.153 | 50 | |

| Min | 1.265 | 10.2 | 2.7 | 0.786 | 27.2 | |

| Mean | 1.392 | 12.748 | 2.703 | 0.941 | 36.715 | |

| SD | 0.038 | 1.248 | 0.004 | 0.054 | 3.963 | |

| Coefficient of variation | 0.027 | 0.097 | 0.001 | 0.057 | 0.107 | |

| Qp2 | Sample size | 2446 | 2446 | 2446 | 2446 | 2446 |

| Max | 1.816 | 26.8 | 2.71 | 0.908 | 100 | |

| Min | 1.418 | 12.7 | 2.7 | 0.491 | 47 | |

| Mean | 1.616 | 18.466 | 2.705 | 0.679 | 74.011 | |

| SD | 0.067 | 2.586 | 0.004 | 0.067 | 13.15 | |

| Coefficient of variation | 0.041 | 0.14 | 0.001 | 0.099 | 0.177 | |

| Disturbed loess | Sample size | 135 | 95 | 95 | 135 | 95 |

| Max | 1.883 | 24.902 | 2.71 | 0.548 | 89.389 | |

| Min | 1.293 | 5.271 | 2.7 | 0.308 | 13.529 | |

| Mean | 1.562 | 12.896 | 2.705 | 0.439 | 46.72 | |

| SD | 0.125 | 4.147 | 0.004 | 0.049 | 18.377 | |

| Coefficient of variation | 0.043 | 0.129 | 0.001 | 0.075 | 0.143 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Yang, N.; Li, P.; Yang, C. Influence of Moisture Content and Dry Density on the Compressibility of Disturbed Loess: A Case Study in Yan’an City, China. Sustainability 2023, 15, 6212. https://doi.org/10.3390/su15076212

Wu J, Yang N, Li P, Yang C. Influence of Moisture Content and Dry Density on the Compressibility of Disturbed Loess: A Case Study in Yan’an City, China. Sustainability. 2023; 15(7):6212. https://doi.org/10.3390/su15076212

Chicago/Turabian StyleWu, Jianhua, Ningning Yang, Peiyue Li, and Chunliu Yang. 2023. "Influence of Moisture Content and Dry Density on the Compressibility of Disturbed Loess: A Case Study in Yan’an City, China" Sustainability 15, no. 7: 6212. https://doi.org/10.3390/su15076212