Research on the Impact of Digital Transformation on the Product R&D Performance of Automobile Enterprises from the Perspective of the Innovation Ecosystem

Abstract

:1. Introduction

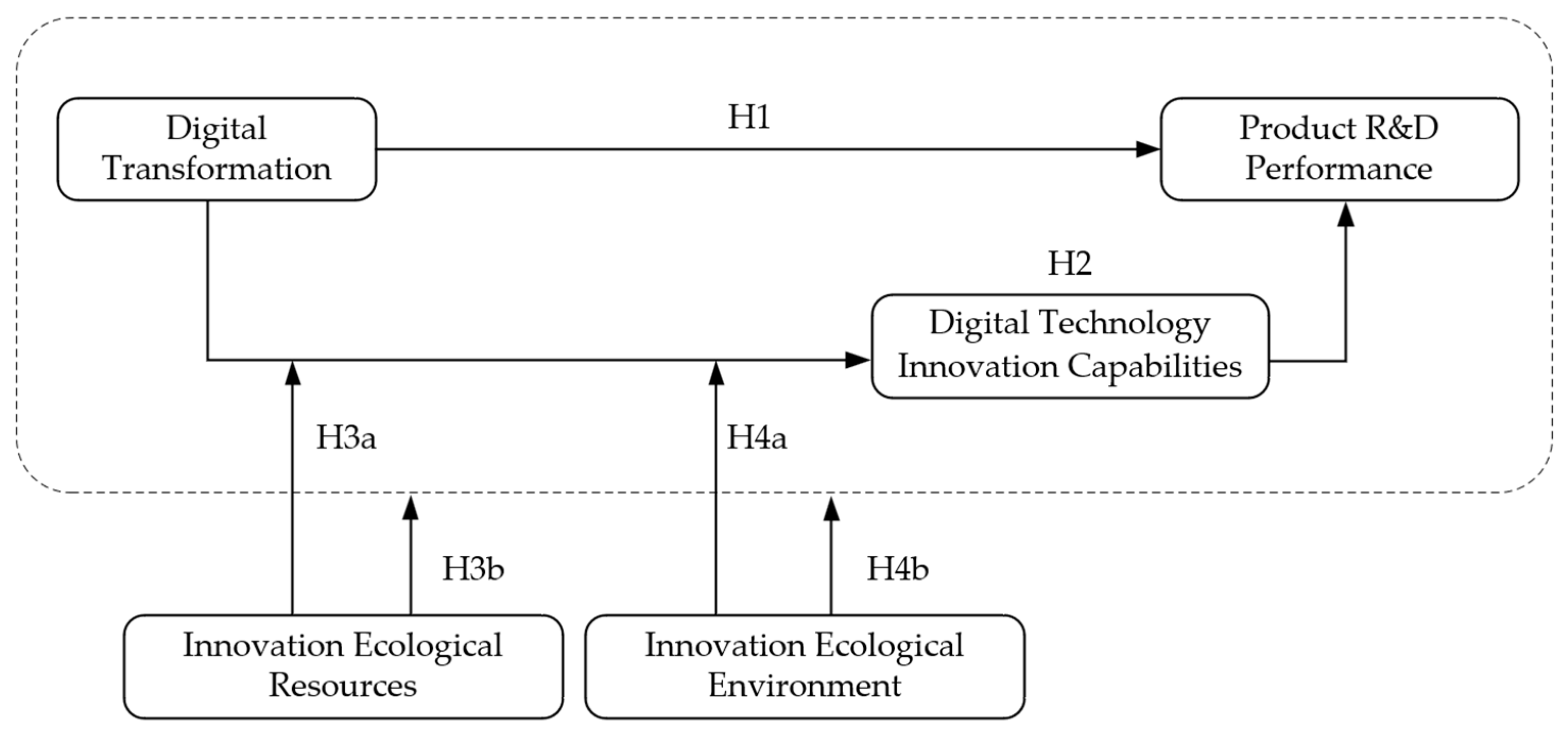

2. Theoretical Basis and Research Hypotheses

2.1. Digital Transformation and Product R&D Performance

2.2. The Mediating Role of Digital Technology Innovation Capabilities

2.3. The Moderating Effect of Innovation Ecological Resources

2.4. The Moderating Effect of Innovation Ecological Environment

3. Research Design

3.1. Data Collection and Sample Statistics

3.2. Variable Measurement

3.3. Reliability and Validity Test

3.4. Common Method Deviation Test

4. Analysis Result

4.1. Direct and Mediated Effects Test

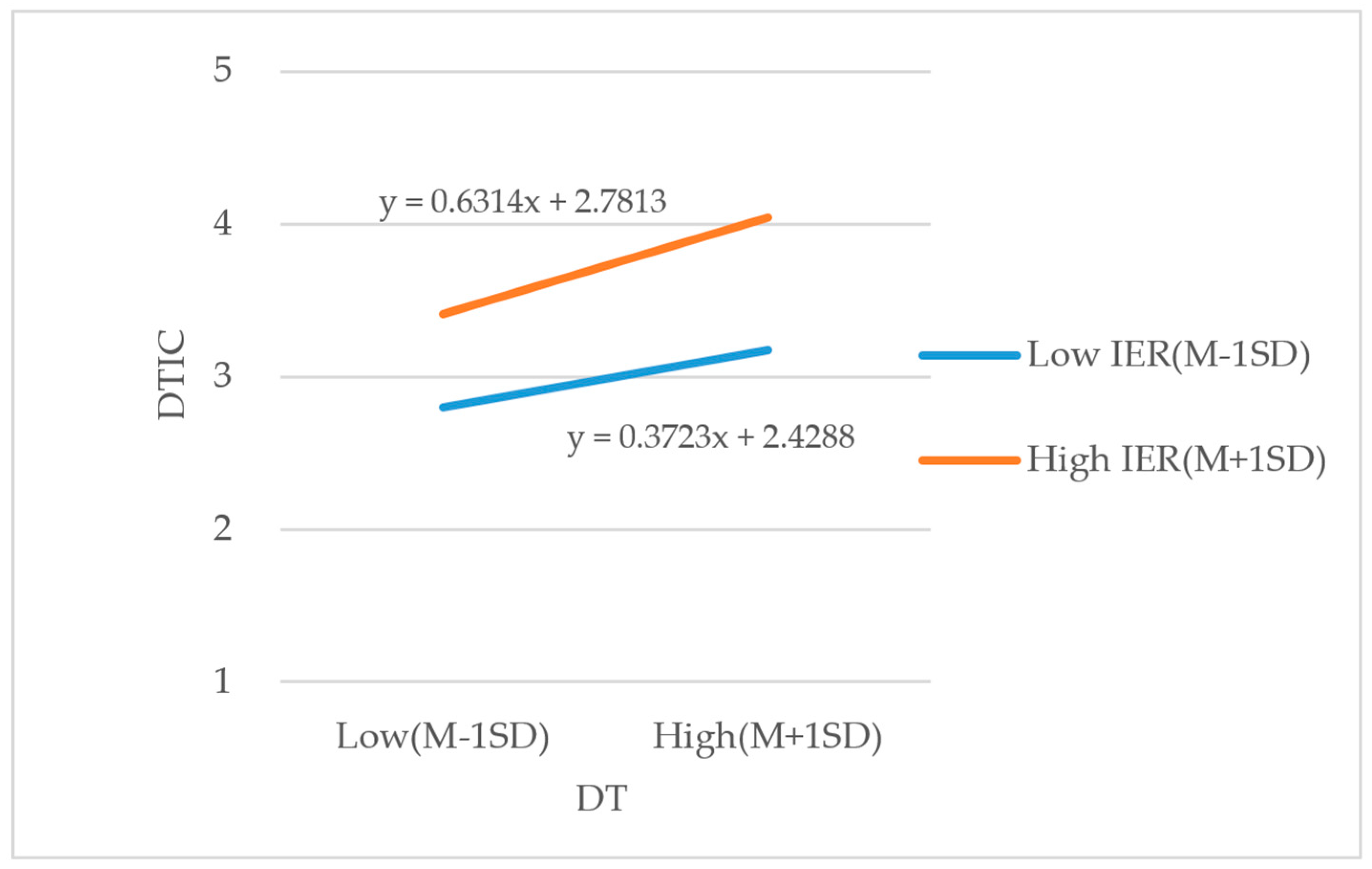

4.2. Moderating Effect Test

4.3. Moderated Mediating Effect Tests

5. Conclusions and Discussion

5.1. Research Conclusions

5.2. Management Enlightenment

5.3. Research Limitations and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, J.; Li, Z.; Kang, Q. Impact of Digital Transformation on National Innovation System and Countermeasures. R&D Manag. 2020, 32, 26–38. [Google Scholar]

- Wu, J.; Chen, T.; Gong, Y.; Yang, Y. Digital Transformation of Firms: Theoretical Framework and Research Prospects. Chin. J. Manag. 2021, 18, 1871–1880. [Google Scholar]

- Morakanyane, R.; Grace, A.; O’Reilly, P. Conceptualizing digital transformation in business organizations: A systematic review of literature. In Proceedings of the 30th Bled eConference: Digital Transformation—From Connecting Things to Transforming our Lives (BLED 2017), Bled, Slovenia, 18–21 June 2017. [Google Scholar]

- Vial, G. Understanding digital transformation: A review and a research agenda. J. Strateg. Inf. Syst. 2019, 28, 118–144. [Google Scholar]

- Albert, C.; Rubio, F.; Valero, F. Impact of digital transformation on the automotive industry. Technol. Forecast. Soc. Chang. 2021, 162, 120343. [Google Scholar] [CrossRef] [PubMed]

- Elisa, G.; Francesca, C.; Edoardo, C. Customer agility in the modern automotive sector: How lead management shapes agile digital companies. Technol. Forecast. Soc. Chang. 2022, 175, 121362. [Google Scholar]

- Li, Z.; Lv, T. Digital Transformation: Literature Review and Research Prospects. Study Explor. 2021, 43, 130–138. [Google Scholar]

- Kong, C.; Ding, Z. The Internal Mechanism and Realization Path of Manufacturing Industry Digital Transformation. Reform Econ. Syst. 2021, 39, 98–105. [Google Scholar]

- Zhao, J. Enterprise Digital Transformation: Mechanism, Paradigm and Paths. J. Beijing Univ. Technol. Soc. Sci. Ed. 2022, 22, 94–105. [Google Scholar]

- Stefano, M.; Anh, P.C.T.; Claudio, D. Enlightening the dynamic capabilities of design thinking in fostering digital transformation. Ind. Mark. Manag. 2021, 97, 59–70. [Google Scholar]

- Gupta, S.; Li, C.; Feng, W.X.; Han, S.; Kamble, S. Digital Adaptive Governance, Digital Transformation, and Service Quality in Logistics Enterprises. J. Glob. Inf. Manag. 2022, 30, 1–26. [Google Scholar] [CrossRef]

- Hinings, B.; Gegenhuber, T.; Greenwood, R. Digital innovation and transformation: An institutional perspective. Inf. Organ. 2018, 28, 52–61. [Google Scholar]

- Szabo, R.Z.; Vuksanović Herceg, I.; Hanák, R.; Hortovanyi, L.; Romanová, A.; Mocan, M.; Djuričin, D. Industry 4.0 Implementation in B2B Companies: Cross-Country Empirical Evidence on Digital Transformation in the CEE Region. Sustainability 2020, 12, 9538. [Google Scholar] [CrossRef]

- Huang, D.; Xie, H.; Meng, X.; Zhang, Q. Digital Transformation and Enterprise Value—Empirical Evidence based on Text Analysis Methods. Economist 2021, 33, 41–51. [Google Scholar]

- Nikos, C. Is digital transformation the Deus ex Machina towards sustainability transition of the European SMEs? Ecol. Econ. 2023, 206, 107739. [Google Scholar]

- Li, Q.; Liu, L.; Shao, J. The Effects of Digital Transformation and Supply Chain Integration on Firm Performance: The Moderating Role of Entrepreneurship. Bus. Manag. J. 2021, 43, 5–23. [Google Scholar]

- Zhao, T.; Zhang, Q.; Li, J.; Wang, T. Digital Transformation Promotes Firms’ Outer Circulation: Influence Mechanism and Implementation Path. J. Technol. Econ. 2021, 40, 159–171. [Google Scholar]

- Yin, Q.; Tian, Y. The Mechanism of Digital Transformation Affecting Innovation Efficiency of High-Tech Industry. Forum Sci. Technol. China 2021, 37, 103–112. [Google Scholar]

- Karim, F.A.; Zo, H.; Ananth, C. Digital Transformation and Environmental Sustainability: A Review and Research Agenda. Sustainability 2021, 13, 1530. [Google Scholar]

- Sabine, K.; Moritz, H. Digital transformation going local: Implementation, impacts and constraints from a German perspective. Public Money Manag. 2023, 43, 147–155. [Google Scholar]

- Chen, J.; Yang, W.; Yu, F. Ecological Collaborative Innovation Strategy in Digital Transformation -A Strategy Workshop Based on Huawei Enterprise Business Group (EBG) China. Tsinghua Bus. Rev. 2019, 10, 195–214. [Google Scholar]

- Chen, W.; Wang, J. Platform-dependent Upgrade: Digital Transformation Strategy of Complementors in Platform-based Ecosystem. Manag. World 2021, 37, 195–214. [Google Scholar]

- Yi, J.B.; Li, X.; Yang, X.P.; Jiao, J.P. Agricultural Digital Transformation from the Perspective of Innovation Ecosystem Theory: Driving Factors, Strategic Framework and Realization Path. Issues Agric. Econ. 2021, 42, 101–116. [Google Scholar]

- Pappas, I.O.; Mikalef, P.; Giannakos, M.N.; Krogstie, J.; Lekakos, G. Big data and business analytics ecosystems: Paving the way towards digital transformation and sustainable societies. Inf. Syst. E-Bus. Manag. 2018, 16, 479–491. [Google Scholar] [CrossRef] [Green Version]

- Samara, E.; Georgiadis, P.; Bakouros, I. The impact of innovation policies on the performance of national innovation systems: A system dynamics analysis. Technovation 2012, 32, 624–638. [Google Scholar] [CrossRef]

- Liu, X.; Sun, H.; Ma, X. Management of Science and Technology from Innovation-Ecosystem Approach. Sci. Sci. Manag. S.& T 2015, 36, 18–27. [Google Scholar]

- Xie, X.; Wang, H.; Tang, H. Relationship Between Innovation Ecological Strategy and Innovation Efficiency from the Perspective of Innovative Ecological Network. J. Syst. Manag. 2020, 29, 1065–1077. [Google Scholar]

- Zhang, X.; Yang, Q. Digital Technology Capability, Business Model Innovation and Enterprise Performance. Sci. Technol. Manag. Res. 2021, 41, 144–151. [Google Scholar]

- Zhang, J.; Long, J. How Does Digital Technology Applications Drive Enterprise Breakthrough Innovation. J. Shanxi Univ. Financ. Econ. 2022, 44, 69–83. [Google Scholar]

- Meng, Q.; Yu, J.; Chen, F.; Lu, C. Impact Mechanism of Digital Technology Innovation on New Generation of Information Technology Industry Upgrading. R&D Manag. 2021, 33, 90–100. [Google Scholar]

- Gefen, D.; Carmel, E. Is the World Really Flat? A Look at Offshoring at an Online Programming Marketplace. MIS Q. 2008, 32, 367–384. [Google Scholar] [CrossRef] [Green Version]

- Luo, J.; Jiang, Q. The Influence of Digital Technology on Product and Service Innovation: A Review and Prospects. Sci. Technol. Prog. Policy 2020, 37, 152–160. [Google Scholar]

- Wang, J.; Luo, L. Knowledge sharing behaviors, innovation and development performance of complex products. Sci. Res. Manag. 2015, 36, 37–45. [Google Scholar]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Mowery, D.C.; Oxley, J.E.; Silverman, B.S. Technological overlap and interfirm cooperation: Implications for the resource-based view of the firm. Res. Policy 1998, 27, 507–523. [Google Scholar] [CrossRef]

- Weerawardena, J.; Mort, G.S.; Liesch, P.W.; Knight, G. Conceptualizing accelerated internationalization in the born global firm: A dynamic capabilities perspective. J. World Bus. 2007, 42, 294–306. [Google Scholar] [CrossRef]

- Estades, J.; Ramani, S.V. Technological competence and the influence of networks: A comparative analysis of new biotechnology firms in france and britain. Technol. Anal. Strateg. Manag. 1998, 10, 483–495. [Google Scholar] [CrossRef]

- Li, Z.; He, P.; Peng, Z. Key Resources Acquisition, New Product Creativity, Strategic Positional Advantages and New Service Product Development Performance. Sci. Sci. Manag. S.& T. 2017, 38, 129–140. [Google Scholar]

- Bouncken, R.B.; Ratzmann, M.; Kraus, S. Anti-aging: How innovation is shaped by firm age and mutual knowledge creation in an alliance. J. Bus. Res. 2021, 137, 422–429. [Google Scholar] [CrossRef]

- Van de Ven, A. Central Problems in the Management of Innovation. Manag. Sci. 1986, 32, 590–607. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, K.; Li, Y. Research on Innovation Environment Assessment: Review of Concepts, Indicators and Methods. Sci. Sci. Manag. S.& T 2019, 40, 89–99. [Google Scholar]

- Yang, H.; Li, L.; Liu, J. Impact of Home Market Scale on Technological Innovation and Its Regional Differences. Forum Sci. Technol. China 2015, 31, 27–32. [Google Scholar]

- Wei, X.; Wang, H.; Xu, H. Innovation Input, Innovation Environment and Performance of High-tech Industry. Forum Sci. Technol. China 2019, 35, 30–37. [Google Scholar]

- Bentler, P.M.; Chou, C.P. Practical Issues in Structural Modeling. Sociol. Methods Res. 1987, 16, 78–117. [Google Scholar] [CrossRef]

- Chi, M.; Ye, D.; Wang, J.; Zhai, S.S. How Can Chinese Small-and Medium-sized Manufacturing Enterprises Improve the New Product Development (NPD) Performance? From the Perspective of Digital Empowerment. Nankai Bus. Rev. 2020, 23, 63–75. [Google Scholar]

- Hu, Q. Mechanism and Performance of Enterprise Digital Transformation. Zhejiang Acad. J. 2020, 58, 146–154. [Google Scholar]

- Xiong, J.; Sun, D. A Study of the Relationship among Enterprise Social Capital, Technical Knowledge Acquisition and Product Innovation Performance. Manag. Rev. 2017, 29, 23–39. [Google Scholar]

- Zhang, H.; Li, W.; Gao, C.; Wang, X. Group Cohesiveness’s Mediated Role on the Relationship Between Group Justice Climate and R&D Performance. R&D Manag. 2014, 26, 42–55. [Google Scholar]

- Cooper, R.G.; Kleinschmidt, E.J. What makes a new product a winner: * Success factors at the project level*. R&D Manag. 1987, 17, 175–189. [Google Scholar]

- Wen, Z.; Huang, B.; Tang, D. Preliminary Work for Modeling Questionnaire Data. J. Psychol. Sci. 2018, 41, 204–210. [Google Scholar]

- Henry, L.V.; Jerker, M. Digital Transformation of the Automotive Industry: An Integrating Framework to Analyse Technological Novelty and Breadth. Ind. Innov. 2023, 30, 67–102. [Google Scholar]

| Variable | Index | Sample Size | Frequency |

|---|---|---|---|

| Enterprise Size (ten thousand people) | <5 | 76 | 31.67% |

| 5–10 | 86 | 35.83% | |

| 10–15 | 51 | 21.25% | |

| >15 | 27 | 11.25% | |

| Years of Establishment | <15 | 64 | 26.67% |

| 15–30 | 99 | 41.25% | |

| 30–50 | 64 | 26.67% | |

| >50 | 13 | 5.42% | |

| Percentage of R&D Staff | <3% | 41 | 17.09% |

| 3–10% | 124 | 51.67% | |

| 10–15% | 55 | 22.91% | |

| >15% | 20 | 8.33% | |

| R&D Investment Ratio | <5% | 36 | 15% |

| 5–10% | 101 | 42.08% | |

| 10–15% | 81 | 33.75% | |

| >15% | 22 | 9.17% |

| Variable Dimension | Item Description |

|---|---|

| Digital Transformation | DT1: Enterprises invest more in digital software and hardware. |

| DT2: Enterprise digital technology integration and application ability is strong. | |

| DT3: Enterprises to promote digital design, manufacturing, and management. | |

| DT4: Enterprises adopt digital technology to transform and upgrade products, production processes and pre-sale and after-sales services. | |

| DT5: Enterprises develop digital products and services. | |

| DT6: Enterprises are willing to promote and publicize digital skills and management knowledge. | |

| DT7: Enterprise internal consensus that the use of digital technology and digital management is conducive to enterprise development. | |

| Product R&D Performance | PDP1: The sales volume of new products of enterprises is higher than that of the same type of products of competitors. |

| PDP2: The success rate of enterprise new product research and development is higher. | |

| PDP3: The R&D expenditure of new products can be controlled within the project budget. | |

| PDP4: The new products developed by the enterprise can reach the initial design index. | |

| PDP5: The sales of the new products developed by the enterprise can reach the expected target. | |

| PDP6: Industry research and development of new product profits can reach the expected target. | |

| Digital Technology Innovation Capability | DTIC1: Enterprise digital equipment investment accounts for a high proportion of the total internal expenditure of R&D funds. |

| DTIC2: The cost of enterprise digital technology transformation accounts for a higher proportion of new investment in fixed assets. | |

| DTIC3: Companies produce more patents after applying digital technology than before. | |

| Innovation Ecological Resources | IER1: The region where the enterprise is located has a higher market demand for digital technology. |

| IER2: Enterprises can easily obtain the knowledge resources needed for digital transformation. | |

| IER3: Enterprises can easily obtain the activity funds required for digital transformation. | |

| Innovation Ecological Environment | IEE1: The region where the enterprise is located has a higher market demand for digital technology. |

| IEE2: The company is located in a region with favorable policies for the application of digital technology. | |

| IEE3: The enterprise is located in a region with better digital technology infrastructure. |

| Questionnaire Items | Factor Loading | KMO | Cronbach’s α | AVE | C.R. |

|---|---|---|---|---|---|

| DT1–DT7 | 0.683–0.894 | 0.880 | 0.911 | 0.598 | 0.912 |

| PRDP1–PRDP6 | 0.705–0.862 | 0.849 | 0.886 | 0.570 | 0.888 |

| DTIC1–DTIC3 | 0.851–0.914 | 0.752 | 0.921 | 0.806 | 0.926 |

| IER1–IER3 | 0.830–0.937 | 0.725 | 0.908 | 0.774 | 0.911 |

| IEE1–IEE3 | 0.784–0.955 | 0.716 | 0.903 | 0.766 | 0.907 |

| χ2/df | RMSEA | IFI | TLI | CFI |

|---|---|---|---|---|

| 2.799 | 0.087 | 0.916 | 0.902 | 0.915 |

| Mean | Standard Deviation | DT | PDP | DTIC | IER | IE | |

|---|---|---|---|---|---|---|---|

| DT | 4.399 | 0.709 | 0.773 | ||||

| PRDP | 4.013 | 0.723 | 0.637 *** | 0.750 | |||

| DTIC | 3.397 | 0.731 | 0.637 *** | 0.668 *** | 0.898 | ||

| IER | 3.163 | 0.717 | 0.642 *** | 0.696 *** | 0.783 *** | 0.880 | |

| IEE | 3.456 | 0.588 | 0.593 *** | 0.620 *** | 0.715 *** | 0.684 *** | 0.875 |

| Regression Equation (n = 240) | Fitting Index | Significance of the Coefficient | |||

|---|---|---|---|---|---|

| Outcome Variable | Predictor Variable | R2 | F | β | t |

| PRDP | 0.353 | 25.553 *** | |||

| Size | 0.047 | 0.867 | |||

| Years | 0.031 | 0.542 | |||

| R&D Staff | −0.021 | −0.330 | |||

| R&D Investment | −0.029 | −0.484 | |||

| DT | 0.591 | 11.224 *** | |||

| DTIC | 0.392 | 30.182 *** | |||

| Size | 0.073 | 1.400 | |||

| Years | 0.042 | 0.756 | |||

| R&D Staff | −0.075 | −1.223 | |||

| R&D Investment | −0.041 | −0.700 | |||

| DT | 0.615 | 12.052 *** | |||

| PDP | 0.453 | 32.176 *** | |||

| Size | 0.017 | 0.342 | |||

| Years | 0.014 | 0.265 | |||

| R&D Staff | 0.010 | 0.163 | |||

| R&D Investment | −0.013 | −0.226 | |||

| DT | 0.341 | 5.529 *** | |||

| DTIC | 0.406 | 6.526 *** | |||

| Effect Size | Boot Standard Error | Boot LLCI | Boot ULCI | Effect Ratio | |

|---|---|---|---|---|---|

| Mediation Effect | 0.254 | 0.043 | 0.175 | 0.344 | 42.21% |

| Direct Effect | 0.348 | 0.062 | 0.219 | 0.461 | 57.80% |

| Total Effect | 0.602 | 0.054 | 0.497 | 0.708 |

| Regression Equation (n = 240) | Fitting Index | Significance of the Coefficient | |||

|---|---|---|---|---|---|

| Outcome Variable | Predictor Variable | R2 | F | β | t |

| DTIC | 0.591 | 47.897 *** | |||

| Size | 0.027 | 0.625 | |||

| Years | 0.029 | 0.644 | |||

| R&D Staff | 0.004 | 0.087 | |||

| R&D Investment | −0.012 | −0.250 | |||

| DT | 0.369 | 5.427 *** | |||

| IER | 0.545 | 10.010 *** | |||

| DT×IER | 0.131 | 2.288 * | |||

| DTIC | 0.553 | 40.955 *** | |||

| Size | 0.042 | 0.937 | |||

| Years | 0.062 | 1.292 | |||

| R&D Staff | −0.032 | −0.594 | |||

| R&D Investment | −0.019 | −0.381 | |||

| DT | 0.417 | 7.080 *** | |||

| IEE | 0.484 | 9.060 *** | |||

| DT×IEE | 0.120 | 2.239 * | |||

| Mediating Variable | Indirect Effects | ||||

|---|---|---|---|---|---|

| DTIC | IER | Effect Size | Boot Standard Error | Boot LLCI | Boot ULCI |

| M − 1SD | 0.113 | 0.028 | 0.060 | 0.168 | |

| Mean | 0.153 | 0.033 | 0.090 | 0.221 | |

| M + 1SD | 0.192 | 0.044 | 0.109 | 0.283 | |

| IEE | Effect Size | Boot Standard Error | Boot LLCI | Boot ULCI | |

| M − 1SD | 0.138 | 0.030 | 0.085 | 0.203 | |

| Mean | 0.173 | 0.035 | 0.110 | 0.247 | |

| M + 1SD | 0.207 | 0.044 | 0.128 | 0.299 | |

| Adjustment of Intermediary Index | ||||

|---|---|---|---|---|

| Adjustment variables | Judgment index | Boot Standard Error | Boot LLCI | Boot ULCI |

| IER | 0.060 | 0.025 | 0.013 | 0.112 |

| IEE | 0.065 | 0.027 | 0.015 | 0.122 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Men, F.; Dong, F.; Liu, Y.; Yang, H. Research on the Impact of Digital Transformation on the Product R&D Performance of Automobile Enterprises from the Perspective of the Innovation Ecosystem. Sustainability 2023, 15, 6265. https://doi.org/10.3390/su15076265

Men F, Dong F, Liu Y, Yang H. Research on the Impact of Digital Transformation on the Product R&D Performance of Automobile Enterprises from the Perspective of the Innovation Ecosystem. Sustainability. 2023; 15(7):6265. https://doi.org/10.3390/su15076265

Chicago/Turabian StyleMen, Feng, Fangqi Dong, Yiying Liu, and Hongxiong Yang. 2023. "Research on the Impact of Digital Transformation on the Product R&D Performance of Automobile Enterprises from the Perspective of the Innovation Ecosystem" Sustainability 15, no. 7: 6265. https://doi.org/10.3390/su15076265

APA StyleMen, F., Dong, F., Liu, Y., & Yang, H. (2023). Research on the Impact of Digital Transformation on the Product R&D Performance of Automobile Enterprises from the Perspective of the Innovation Ecosystem. Sustainability, 15(7), 6265. https://doi.org/10.3390/su15076265