Energy, Thermal, and Economic Benefits of Aerogel Glazing Systems for Educational Buildings in Hot Arid Climates

Abstract

:1. Introduction

- Insulation products that rely solely on the outstanding thermal performance of silica aerogels;

- Monolithic aerogel and translucent or transparent insulating materials based on granular aerogel.

- Promising glazing technology (AGUs) might cut heat loss by up to 58%, translating to a 21% reduction in total energy use (heating, cooling, and lighting);

- For user comfort, AGUs must be able to provide high-quality diffuse light and achieve the best homogenous dispersion of the sun’s glare.

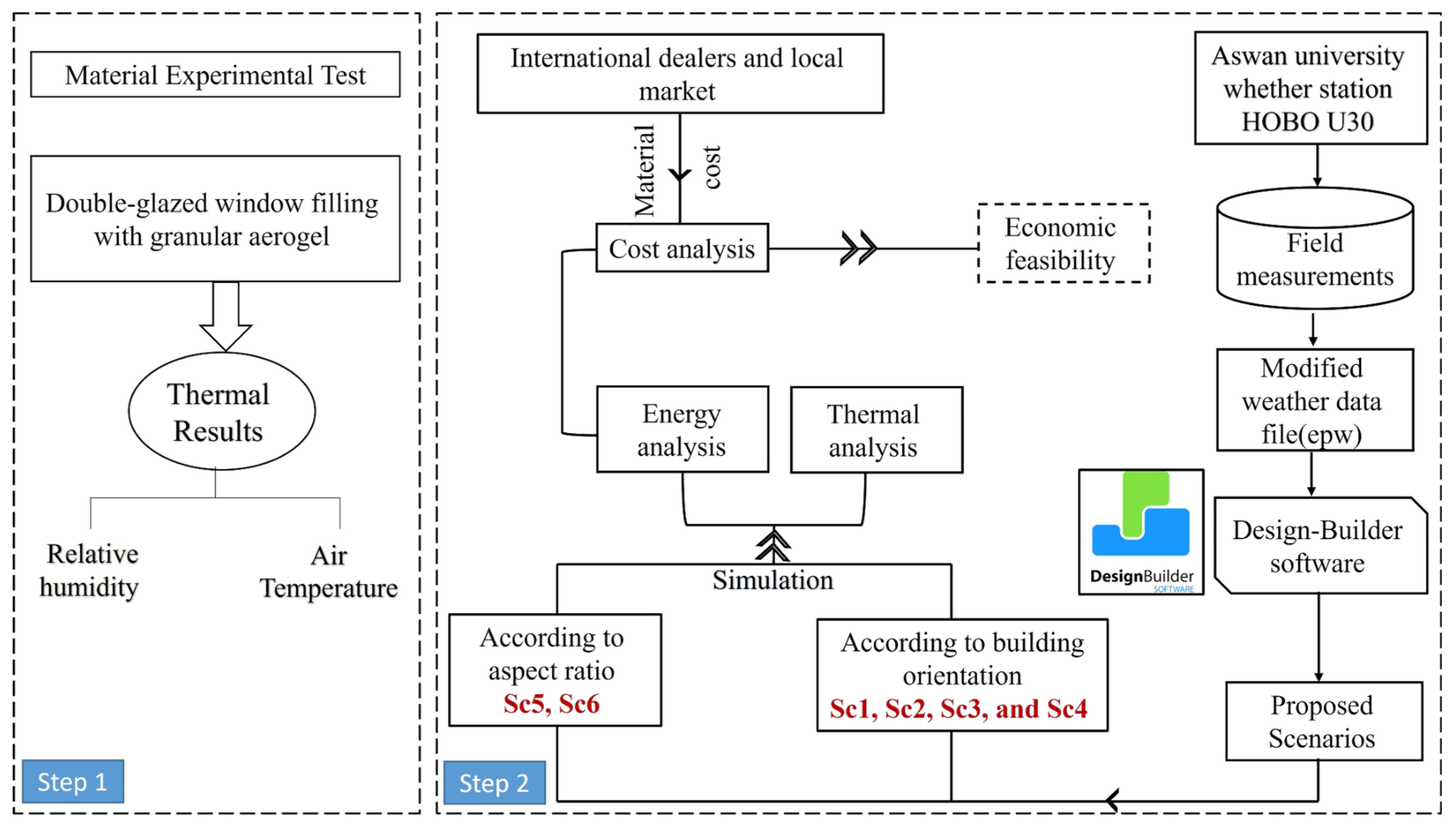

2. Materials and Methods

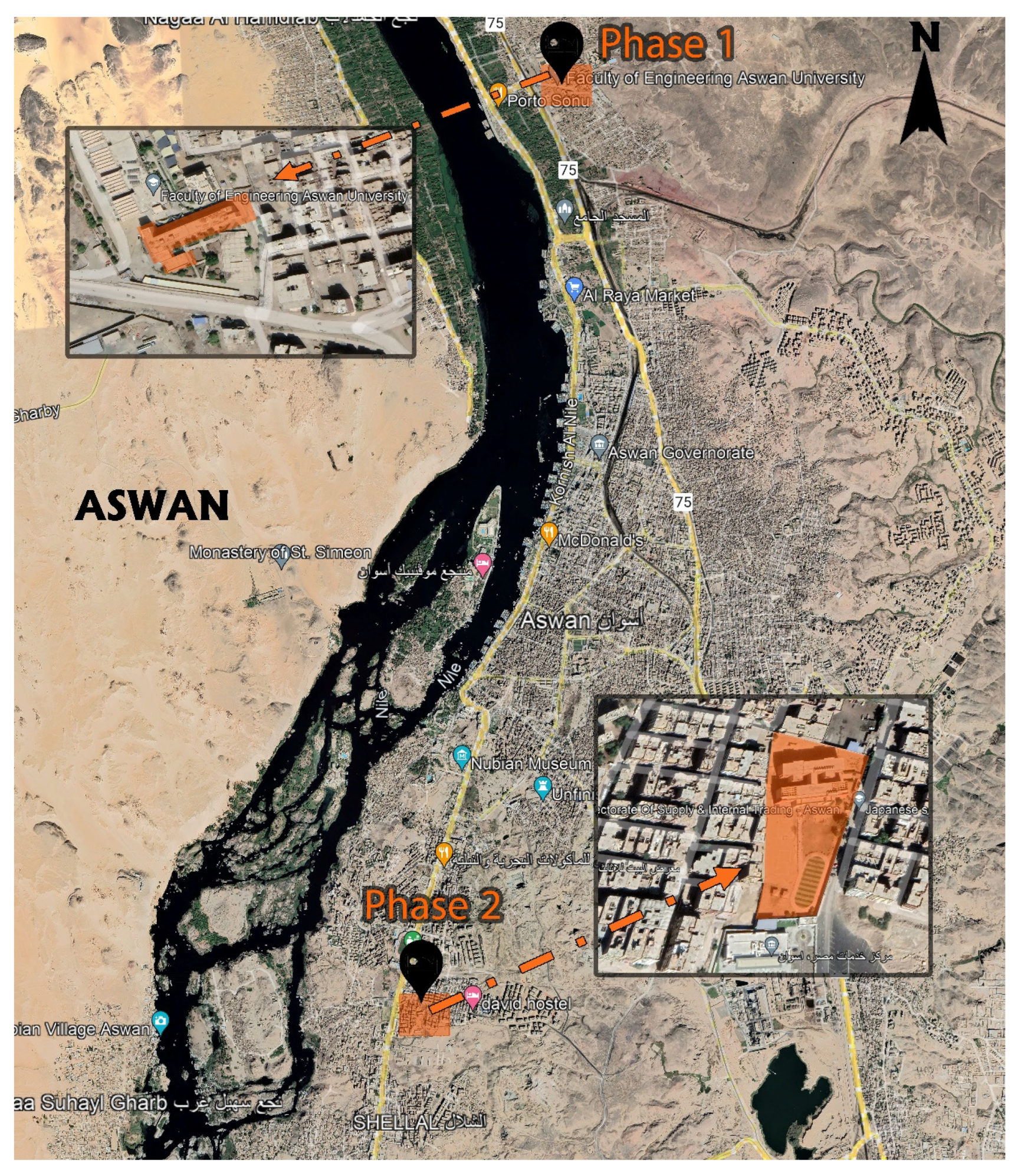

2.1. Case Study Area

2.2. Weather Data File

2.3. Usage Material, LUMIRA TRANSLISENT LA1000

2.4. The Simulation Process Using Design-Builder

2.5. Proposed Study Scenarios

3. Results and Discussion

3.1. Field Investigation Results

3.2. Simulation Results

3.2.1. Thermal Analysis

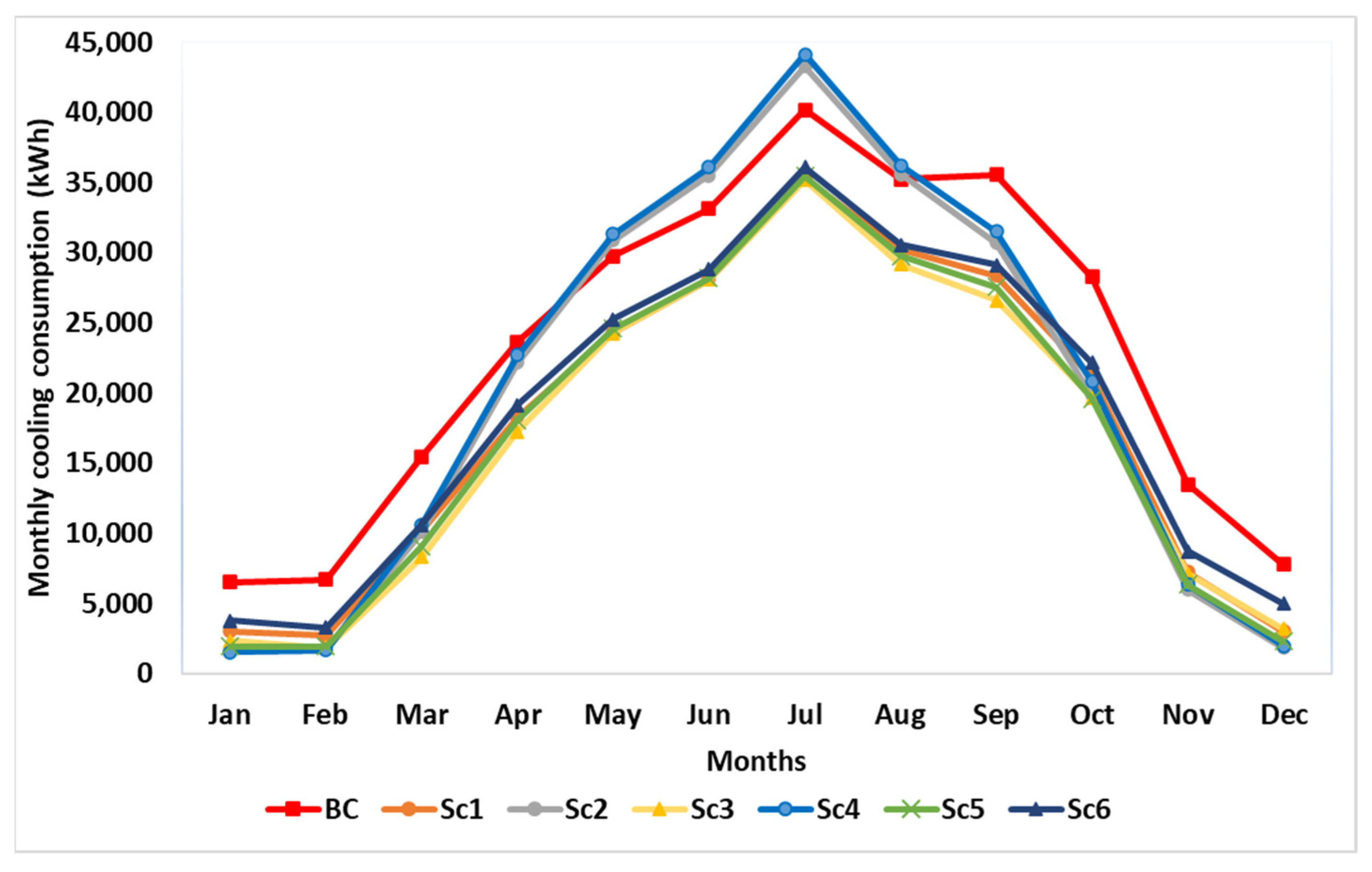

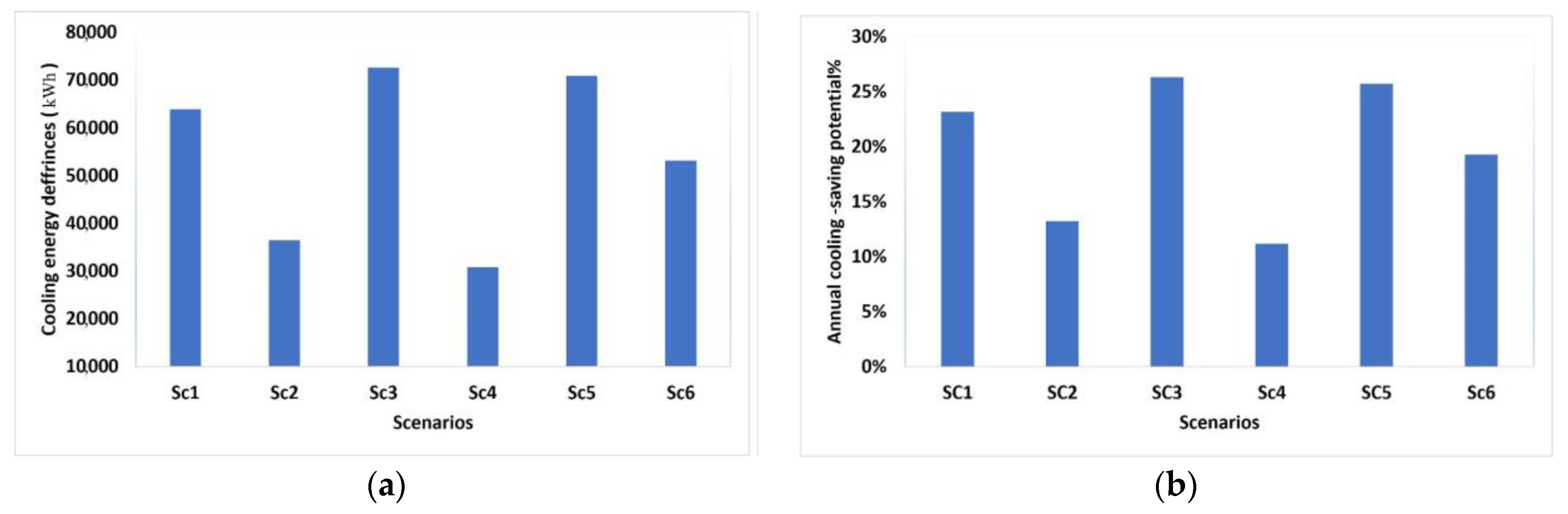

3.2.2. Energy Consumption for Cooling

3.3. The Cost Analysis of the Proposed Aerogel Glazing Scenarios

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbhuiya, S.; Barbhuiya, S. Thermal comfort and energy consumption in a UK educational building. Build. Environ. 2013, 68, 1–11. [Google Scholar] [CrossRef]

- Ministry of Education. Statistics Report 2022; Electronic Education Center: Cairo, Egypt, 2022. Available online: https://emis.gov.eg/annual_book.aspx?id=400 (accessed on 15 July 2022).

- Perez, Y.V.; Capeluto, I.G. Climatic considerations in school building design in the hot–humid climate for reducing energy consumption. Appl. Energy 2009, 86, 340–348. [Google Scholar] [CrossRef]

- Barrett, P.; Davies, F.; Zhang, Y.; Barrett, L. The impact of classroom design on pupils’ learning: Final results of a holistic, multi-level analysis. Build. Environ. 2015, 89, 118–133. [Google Scholar] [CrossRef] [Green Version]

- CIA.gov. Egypt Electricity and Energy-Consumption; CIA: Cairo, Egypt, 2022.

- Department of Energy, USA. Chapter 5 Increasing Efficiency of Building Systems and Technologies. In Quadrennial Technology Review, An Assessment of Energy Technologies and Research Opportunities; Department of Energy: Washington, DC, USA, 2015; pp. 143–181. [Google Scholar]

- Rucińska, J.; Trząski, A. Measurements and Simulation Study of Daylight Availability and Its Impact on the Heating, Cooling and Lighting Energy Demand in an Educational Building. Energies 2020, 13, 2555. [Google Scholar] [CrossRef]

- Gaitani, N.; Cases, L.; Mastrapostoli, E.; Eliopoulou, E. Paving the way to nearly zero energy schools in Mediterranean region-ZEMedS project. Energy Procedia 2015, 78, 3348–3353. [Google Scholar] [CrossRef] [Green Version]

- Aly, A.M.; Hassn, M.H.; Rady, R.A.y.; Mohammed, T.a. The effect of using nano-materials in external openings on energy consumption in hot desert climate. J. Eng. Sci. 2020, 48, 468–477. [Google Scholar] [CrossRef]

- Mahmoud, A.R. Investigating the Impact of Different Glazing Types on the Energy Performance in Hot Arid Climate. J. Adv. Eng. Trends 2022, 42, 69–84. [Google Scholar] [CrossRef]

- Ragab Abdel Radi, A. The impact of phase change materials on the buildings energy efficiency in the hot desert areas the annexed rooms of the traffic building in new aswan city as a case study. J. Eng. Sci. 2020, 48, 302–316. [Google Scholar]

- Ragab, A.; Abdelrady, A. Impact of green roofs on energy demand for cooling in Egyptian buildings. Sustainability 2020, 12, 5729. [Google Scholar] [CrossRef]

- Aslani, A.; Bakhtiar, A.; Akbarzadeh, M.H. Energy-efficiency technologies in the building envelope: Life cycle and adaptation assessment. J. Build. Eng. 2019, 21, 55–63. [Google Scholar] [CrossRef]

- Ihm, P.; Park, L.; Krarti, M.; Seo, D. Impact of window selection on the energy performance of residential buildings in South Korea. Energy Policy 2012, 44, 1–9. [Google Scholar] [CrossRef]

- Nauclér, T.; Enkvist, P.-A. Pathways to a Low-Carbon Economy: Version 2 of the Global Greenhouse Gas Abatement Cost Curve; McKinsey & Company: New York, NY, USA, 2013; p. 192. [Google Scholar]

- Buratti, C.; Belloni, E.; Merli, F.; Zinzi, M. Aerogel glazing systems for building applications: A review. Energy Build. 2021, 231, 110587. [Google Scholar] [CrossRef]

- Huang, L. Feasibility of Using Silica Aerogel as Insulation for Buildings. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2012. [Google Scholar]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive building energy savings: A review of building envelope components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef] [Green Version]

- Berardi, U. Aerogel-enhanced systems for building energy retrofits: Insights from a case study. Energy Build. 2018, 159, 370–381. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Merli, F.; Mastoori, M.; Sharifi, S.N.; Pignatta, G. Analysis of Nano Silica Aerogel Based Glazing Effect on the Solar Heat Gain and Cooling Load in a School under Different Climatic Conditions. Environ. Sci. Proc. 2021, 12, 15. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef] [Green Version]

- Gao, T.; Ihara, T.; Grynning, S.; Jelle, B.P.; Lien, A.G. Perspective of aerogel glazings in energy efficient buildings. Build. Environ. 2016, 95, 405–413. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Gustavsen, A. Building integration of aerogel glazings. Procedia Eng. 2016, 145, 723–728. [Google Scholar] [CrossRef] [Green Version]

- Gao, T.; Jelle, B.P.; Gustavsen, A.; Jacobsen, S. Aerogel-incorporated concrete: An experimental study. Constr. Build. Mater. 2014, 52, 130–136. [Google Scholar] [CrossRef]

- Hüsing, N.; Schubert, U. Aerogels—Airy Materials: Chemistry, Structure, and Properties. Angew. Chem. Int. Ed. 1998, 37, 22–45. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Mai, N.T.; Reddy, V.R.M.; Jung, J.H.; Truong, N.T.N. Synthesis of silica aerogel particles and its application to thermal insulation paint. Korean J. Chem. Eng. 2020, 37, 1803–1809. [Google Scholar] [CrossRef]

- Dorcheh, A.S.; Abbasi, M.H. Silica aerogel; synthesis, properties and characterization. J. Mater. Process. Technol. 2008, 199, 10–26. [Google Scholar] [CrossRef]

- Koebel, M.; Rigacci, A.; Achard, P. Aerogel-based thermal superinsulation: An overview. J. Sol-Gel Sci. Technol. 2012, 63, 315–339. [Google Scholar] [CrossRef] [Green Version]

- Cotana, F.; Pisello, A.L.; Moretti, E.; Buratti, C. Multipurpose characterization of glazing systems with silica aerogel: In-field experimental analysis of thermal-energy, lighting and acoustic performance. Build. Environ. 2014, 81, 92–102. [Google Scholar] [CrossRef]

- Neugebauer, A.; Chen, K.; Tang, A.; Allgeier, A.; Glicksman, L.R.; Gibson, L.J. Thermal conductivity and characterization of compacted, granular silica aerogel. Energy Build. 2014, 79, 47–57. [Google Scholar] [CrossRef]

- Cannavale, A.; Martellotta, F.; Berardi, U.; Rubino, C.; Liuzzi, S.; De Carlo, V.; Ayr, U. Modeling of an Aerogel-Based “Thermal Break” for Super-Insulated Window Frames. Buildings 2020, 10, 60. [Google Scholar] [CrossRef] [Green Version]

- Abdelrady, A.; Abdelhafez, M.H.H.; Ragab, A. Use of insulation based on nanomaterials to improve energy efficiency of residential buildings in a hot desert climate. Sustainability 2021, 13, 5266. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J.-L. Application of super-insulating translucent silica aerogel glazing system on commercial building envelope of humid subtropical climates—Impact on space cooling load. Energy 2015, 83, 316–325. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J.-L. Energy and visual performance of the silica aerogel glazing system in commercial buildings of Hong Kong. Constr. Build. Mater. 2015, 94, 57–72. [Google Scholar] [CrossRef]

- Abdelhafez, M.H.H.; Aldersoni, A.A.; Gomaa, M.M.; Noaime, E.; Alnaim, M.M.; Alghaseb, M.; Ragab, A. Investigating the Thermal and Energy Performance of Advanced Glazing Systems in the Context of Hail City, KSA. Buildings 2023, 13, 752. [Google Scholar] [CrossRef]

- Berardi, U. Development of Glazing Systems with Silica Aerogel. Energy Procedia 2015, 78, 394–399. [Google Scholar] [CrossRef] [Green Version]

- Dowson, M.; Harrison, D.; Craig, S.; Gill, Z. Improving the thermal performance of single-glazed windows using translucent granular aerogel. Int. J. Sustain. Eng. 2011, 4, 266–280. [Google Scholar] [CrossRef] [Green Version]

- Cha, J.; Kim, S.; Park, K.-W.; Lee, D.R.; Jo, J.-H.; Kim, S. Improvement of window thermal performance using aerogel insulation film for building energy saving. J. Therm. Anal. Calorim. 2013, 116, 219–224. [Google Scholar] [CrossRef]

- Cabotcorporation. Datasheet-LUMIRA-LA2000. 2021. Available online: https://www.cabotcorp.com/-/media/files/product-datasheets/datasheet-lumira-la2000.pdf?la=en&rev=651a02e1271442118e7329218efc74e1 (accessed on 29 March 2023).

- Gutzov, S.; Danchova, N.; Karakashev, S.; Khristov, M.; Ivanova, J.; Ulbikas. Preparation and thermal properties of chemically prepared nanoporous silica aerogels. J. Sol-Gel Sci. Technol. 2014, 70, 511–516. [Google Scholar] [CrossRef]

- Mahmoud, A.R. The Influence of Buildings Proportions and Orientations on Energy Demand for Cooling in Hot Arid Climate. SVU-Int. J. Eng. Sci. Appl. 2022, 3, 8–20. [Google Scholar] [CrossRef]

- Egypt Solar Energy Market. Solar Market Egypt. Available online: http://www.solarmarketegypt.com/ar (accessed on 8 August 2022).

- Littlefair, P. Daylight, sunlight and solar gain in the urban environment. Sol. Energy 2001, 70, 177–185. [Google Scholar] [CrossRef]

- Galatioto, A.; Beccali, M. Aspects and issues of daylighting assessment: A review study. Renew. Sustain. Energy Rev. 2016, 66, 852–860. [Google Scholar] [CrossRef]

- Shaviv, E. The influence of the orientation of the main solar glazing on the total energy consumption of a building EDNA. Sol. Energy 1981, 26, 453–454. [Google Scholar] [CrossRef]

- Theodorson, J. North v. South: The Impact of Orientation in Daylighting School Classrooms. In Proceedings of the SOLAR Conference, San Diego, CA, USA, 2008. Available online: https://www.academia.edu (accessed on 15 October 2022).

| Item | Specification |

|---|---|

| Type | Standard two rooms |

| Location | Faculty of engineering-Aswan-Egypt |

| Floor area (m2) | 9 |

| Floor height (m) | 3 |

| Window dimensions (m) | 1.00 × 1.00 |

| Door dimensions (m) | 0.90 × 2.20 |

| Wall layers (m) | Outer Cement plaster = 0.02 Inner Brickwork = 0.12 |

| Ceiling (m) | Metal roofing sheet = 0.01 Foam sheet = 0.05 Cement plaster = 0.03 |

| Building Orientation | Aspect Ratio | Glazing Type | U-Value | Light Transmission | Solar Heat Transmission (SHGC) | |

|---|---|---|---|---|---|---|

| BC | North | 1.2 | Sgl Clr 3 mm | 5.894 | 0.898 | 0.861 |

| SC1 | North | 1.2 | Dbl Clr 6 mm/6 mm Aerogel | 2.320 | 0.671 | 0.616 |

| SC2 | East | |||||

| SC3 | South | |||||

| SC4 | West | |||||

| SC5 | North | 2.4 | ||||

| SC6 | North | 0.6 |

| Material | Thickness [mm] | U-Value [W/(m2K)] | R-Value [(m2-K)/W] | |

|---|---|---|---|---|

| External wall |

| 20 250 20 | 1.911 | 0.523 |

| Internal wall |

| 20 120 20 | 2.386 | 0.419 |

| Ceiling | Reinforced concrete slab | 200 | 2.847 | 0.351 |

| Item | Specification |

|---|---|

| Latitude | 23.97 |

| Longitude | 32.78 |

| Elevation above sea level (m) | 194 |

| Maximum monthly outdoor dry-bulb temperature (°C) | 34.82 |

| Minimum monthly outdoor dry-bulb temperature (°C) | 15.89 |

| Type | Multi-story educational building |

| Floor area (m2) | 1760 |

| Floor height (m) | 3.20 |

| Occupancy (m2/person) | 0.41 |

| Open-plan office occupancy schedule | 8:00–15:00 |

| Windows | Double-glazed (DG) with aerogel granules filling |

| Lighting (lux) | 300 |

| HVAC | split air conditioner |

| Cooling setpoint (°C) | 25 |

| Heating setpoint (°C) | 20 |

| Aerogel granule thermal conductivity coefficient (mW/mK) | 18 |

| Aerogel specific heat coefficient (j/kg-k) | 1320 [42] |

| Wall Cost (EGP) | Window Cost (EGP) | Total Cost (EGP) | Additional Investment (EGP) | Energy Cost (EGP/year) | Annual Saving (EGP/year) | SPP (year) | |

|---|---|---|---|---|---|---|---|

| BC | 491,625 | 300,000 | 791,625 | - | 441,205.49 | - | - |

| Sc3 | 491,625 | 780,000 | 1,271,625 | 480,000 | 325,048.34 | 116,157.16 | 4.13 |

| Sc5 | 473,625 | 780,000 | 1,253,625 | 462,000 | 327,757.12 | 113,448.37 | 4.07 |

| Sc6 | 527,625 | 780,000 | 1,307,625 | 516,000 | 356,132.71 | 85,072.78 | 6.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, A.F.; Gomaa, M.M.; Amir, A.A.; Ragab, A. Energy, Thermal, and Economic Benefits of Aerogel Glazing Systems for Educational Buildings in Hot Arid Climates. Sustainability 2023, 15, 6332. https://doi.org/10.3390/su15086332

Mohamed AF, Gomaa MM, Amir AA, Ragab A. Energy, Thermal, and Economic Benefits of Aerogel Glazing Systems for Educational Buildings in Hot Arid Climates. Sustainability. 2023; 15(8):6332. https://doi.org/10.3390/su15086332

Chicago/Turabian StyleMohamed, Abdelaziz Farouk, Mohammed M. Gomaa, Amira Ahmed Amir, and Ayman Ragab. 2023. "Energy, Thermal, and Economic Benefits of Aerogel Glazing Systems for Educational Buildings in Hot Arid Climates" Sustainability 15, no. 8: 6332. https://doi.org/10.3390/su15086332