The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability

Abstract

:1. Introduction

2. Methodology

3. Results

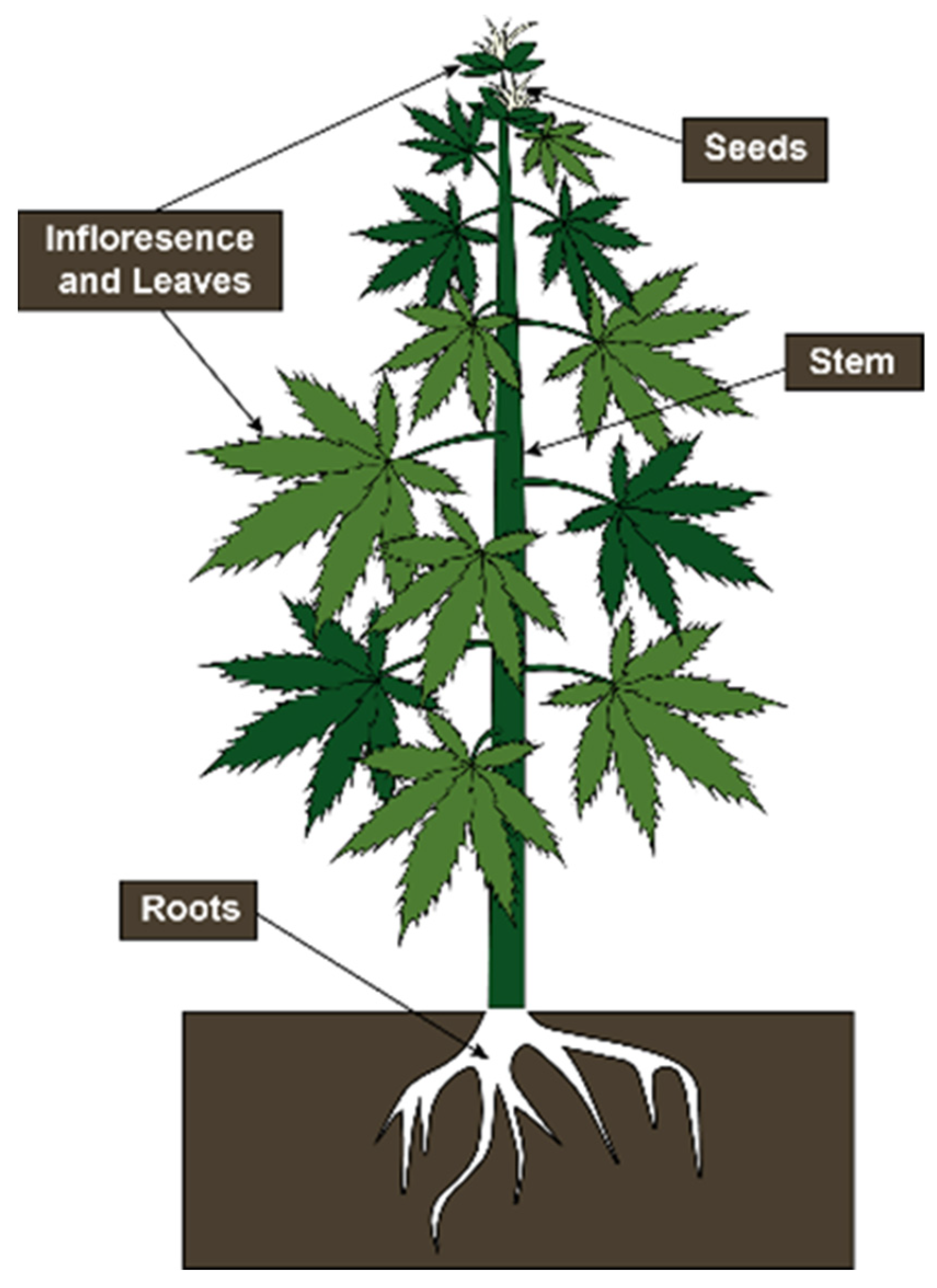

3.1. Industrial Hemp Plant

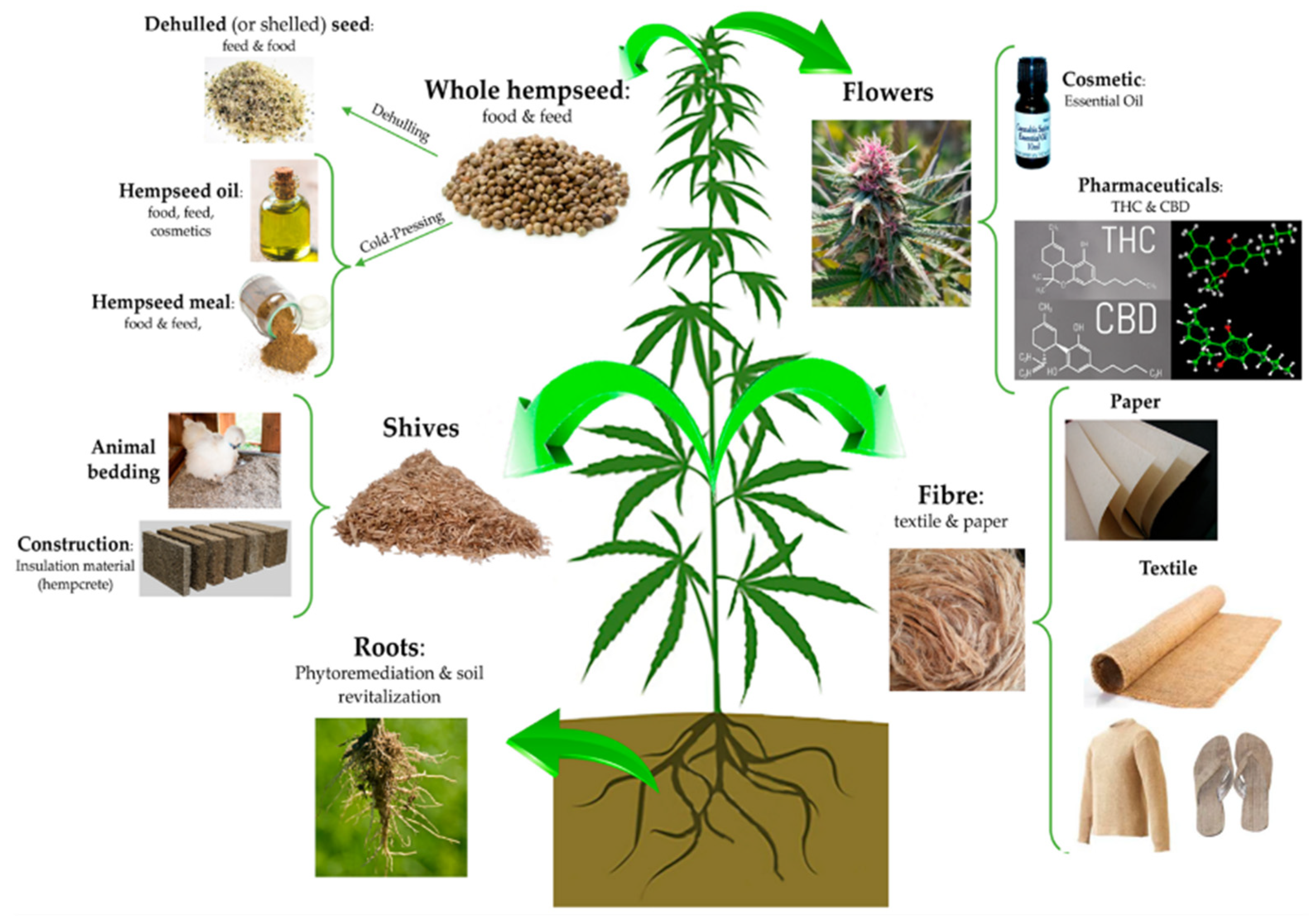

3.2. Parts and Uses for the Industrial Hemp Plant

- a.

- Fiber products: Numerous industrial applications use hemp fiber as a natural source of bast fiber [36]. Known for their strength, durability, and length (fiber bundles can reach 1–5 m), hemp fibers have long been valued for serving many purposes including making rope, paper, and textiles [37,38,39]. The life cycle assessment (LCA) of hemp fibers, from cradle to grave, reveals that hemp fibers perform better than glass fiber by weight [40]. LCA assesses the environmental impact and resource usage of a product, including its raw material acquisition, manufacturing, and disposal phases [41,42,43,44]. The increased global demand for eco-friendly natural products and sustainable systems has increased the market share for textiles, fabrics, and clothing made from hemp fiber [12,45]. Hemp fiber is also used to make biodegradable mulch, horticultural planting materials, pressed fiber products, paper and pulp products, building-construction materials, insulation materials, animal bedding made of hurd, plastic bio composites, and compressed cellulose plastics [12].

- b.

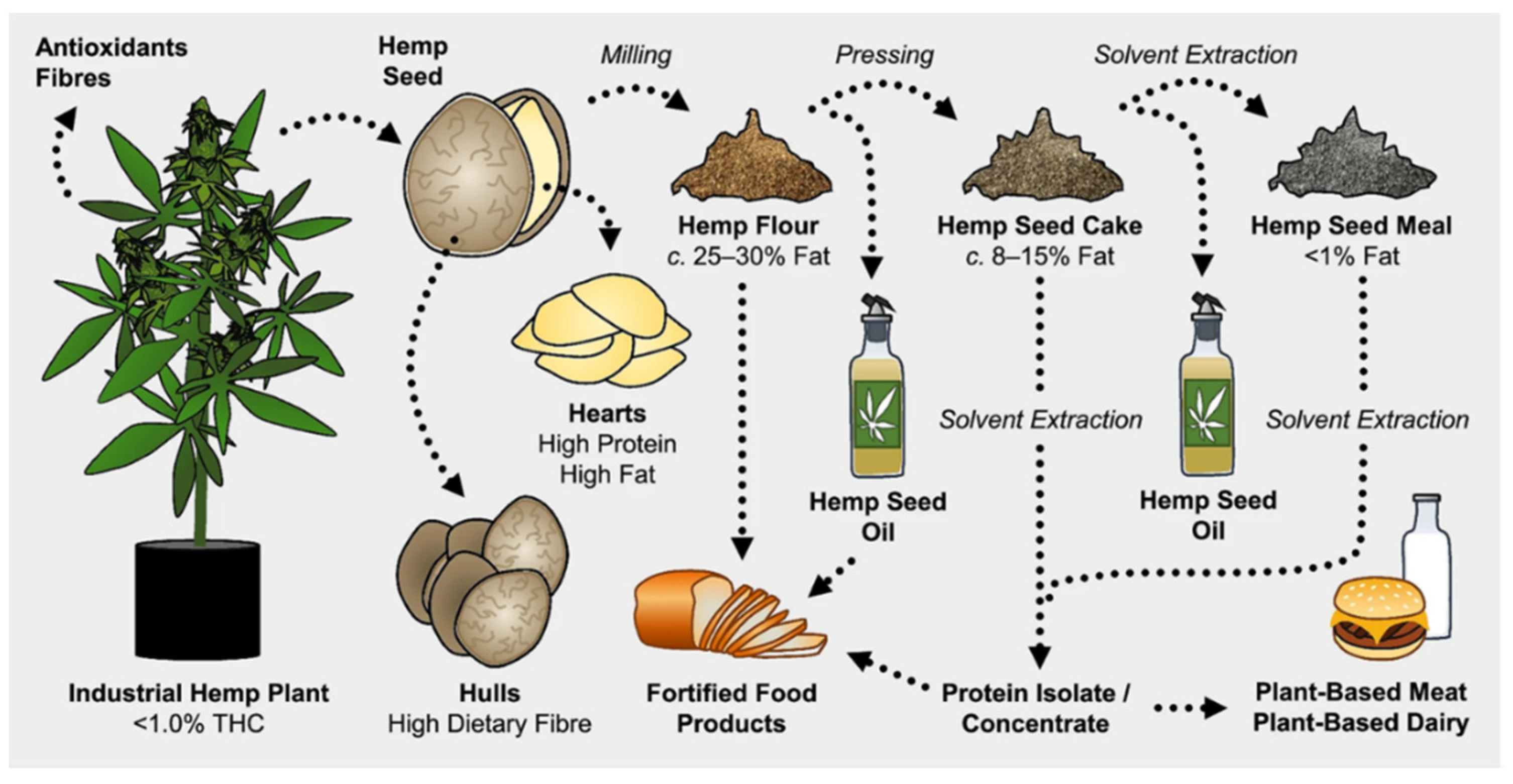

- Seed or grain products: Hemp seed has historically served as a vital food source [46,47]. It consists of 20 to 30% edible oil, 20 to 30% protein, 20 to 25% fiber, 20 to 30% carbohydrates, and many other important nutrients and vitamins recommended for humans [12]. Hemp seed oil and grain products include whole and dehulled hemp seeds, hemp seed oil, hemp seed flour, hemp seed cake (a byproduct of mechanical oil pressing), hemp seed meal, hulls of hemp, and hemp protein isolates and concentrates (Figure 5) [48]. Hemp seeds are used to produce olive oil and salad dressing, and seeds of hemp contain omega 3 fats and proteins. In addition to being used in cosmetics, hemp seed oil can be used as a substitute for industrial oils [12].

- c.

- Products for the medicinal market: CBD oil is a nonintoxicating cannabinoid compound produced using industrial hemp; unlike THC, it is not addictive. Because it is non-addictive and may offer health benefits, many states have recently made CBD oil legal [49]. Although CBD is used in various products, such as sparkling water, lotions, and pharmacological substances, its purported health benefits have not been scientifically verified. These areas offer an exciting opportunity for further research [12]. Medicinal market applications, while important, are not the focus of our review.

- d.

- Products for the recreational market: Because industrial hemp does not include high THC, it is not used for recreational purposes, and this application was not included in our review.

3.3. Sustainability of Industrial Hemp

3.3.1. Hemp Economic Sustainability

- A wide range of products can be made with hemp.

- Hemp products account for a small percentage of food, textiles, personal care products, pharmaceuticals, and nutraceuticals sales in the U.S. and worldwide, but sales are growing quickly.

- Despite the falling production of hemp worldwide, due to its association with marijuana since the 1950s, business and policy changes, infrastructure investment, and improved production methods have led to a rebound in hemp production over the past decade.

3.3.2. Hemp Environmental Sustainability

- The criteria were set based on the author’s familiarity with the topic.

- There is a limitation to the author’s knowledge of a wide range of crops and criteria.

- There may be some criteria that deserve to be heavily weighted, depending on location (e.g., irrigation may be more critical in areas with low water availability).

3.3.3. Hemp Social Sustainability

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Letcher, T.M. Global warming—A complex situation. In Climate Change; Elsevier: Amsterdam, The Netherlands, 2021; pp. 3–17. [Google Scholar]

- Al-Delaimy, W.; Ramanathan, V.; Sánchez Sorondo, M. Health of People, Health of Planet and Our Responsibility: Climate Change, Air Pollution and Health; Springer Nature: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Singh, R.L.; Singh, P.K. Global environmental problems. In Principles and Applications of Environmental Biotechnology for a Sustainable Future; Springer: Berlin/Heidelberg, Germany, 2017; pp. 13–41. [Google Scholar] [CrossRef]

- McMichael, A.J.; Lindgren, E. Climate change: Present and future risks to health, and necessary responses. J. Intern. Med. 2011, 270, 401–413. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, D.C.; Kumar, R.; Dhanasekaran, M. Cannabis/Hemp for Sustainable Agriculture and Materials; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Pal, L.; Lucia, L.A. Renaissance of industrial hemp: A miracle crop for a multitude of products. BioResources 2019, 14, 2460–2464. [Google Scholar]

- Thedinger, S. Prohibition in the United States: International and US regulation and control of industrial hemp. Colo. J. Int’l Envtl. L. Pol’y 2005, 17, 419. [Google Scholar]

- Musto, D.F. The marihuana tax act of 1937. Arch. Gen. Psychiatry 1972, 26, 101–108. [Google Scholar] [CrossRef]

- Johnson, R. Defining hemp: A fact sheet. Congr. Res. Serv. 2019, 44742. [Google Scholar]

- NCSL. State Industrial Hemp Statutes. 2020. Available online: https://www.ncsl.org/agriculture-and-rural-development/state-industrial-hemp-statutes (accessed on 8 June 2022).

- Fortenbery, T.R.; Bennett, M. Is Industrial Hemp Worth Further Study in the US? A Survey of the Literature. 2001. Available online: https://doi.org/10.22004/ag.econ.12680 (accessed on 8 June 2022).

- Jeliazkov, V.D.; Noller, J.S.; Angima, S.; Rondon, S.I.; Roseberg, R.J.; Summers, S.; Jones, G.B.; Sikora, V. What is Industrial Hemp? Oregon State University Extension Service: Corvallis, OR, USA, 2019. [Google Scholar]

- Miller, N.G. The genera of the Cannabaceae in the southeastern United States. J. Arnold Arbor. 1970, 51, 185–203. [Google Scholar] [CrossRef]

- Agate, S.; Tyagi, P.; Naithani, V.; Lucia, L.; Pal, L. Innovating generation of nanocellulose from industrial hemp by dual asymmetric centrifugation. ACS Sustain. Chem. Eng. 2020, 8, 1850–1858. [Google Scholar] [CrossRef]

- Atakan, Z. Cannabis, a complex plant: Different compounds and different effects on individuals. Ther. Adv. Psychopharmacol. 2012, 2, 241–254. [Google Scholar] [CrossRef] [Green Version]

- Simiyu, D.C.; Jang, J.H.; Lee, O.R. Understanding Cannabis sativa L.: Current Status of Propagation, Use, Legalization, and Haploid-Inducer-Mediated Genetic Engineering. Plants 2022, 11, 1236. [Google Scholar] [CrossRef]

- Iseger, T.A.; Bossong, M.G. A systematic review of the antipsychotic properties of cannabidiol in humans. Schizophr. Res. 2015, 162, 153–161. [Google Scholar] [CrossRef]

- Bridgeman, M.B.; Abazia, D.T. Medicinal cannabis: History, pharmacology, and implications for the acute care setting. Pharm. Ther. 2017, 42, 180. [Google Scholar]

- Rupasinghe, H.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial hemp (Cannabis sativa subsp. sativa) as an emerging source for value-added functional food ingredients and nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- USDA. Industrial Hemp in the United States: Status and Market Potential; USDA: Washingtion, DC, USA, 2000; p. 182773. Available online: https://www.ers.usda.gov/webdocs/publications/41740/15867_ages001e_1_.pdf?v=42087 (accessed on 8 June 2022).

- Sgrò, S.; Lavezzi, B.; Caprari, C.; Polito, M.; D’Elia, M.; Lago, G.; Furlan, G.; Girotti, S.; Ferri, E.N. Delta9-THC determination by the EU official method: Evaluation of measurement uncertainty and compliance assessment of hemp samples. Anal. Bioanal. Chem. 2021, 413, 3399–3410. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Xiong, H.; Chen, J. Regional Comparison and Strategy Recommendations of Industrial Hemp in China Based on a SWOT Analysis. Sustainability 2021, 13, 6419. [Google Scholar] [CrossRef]

- Arnall, B.; Bushong, J.; Lofton, J. Agronomic Considerations for Industrial Hemp Production; Oklahoma Cooperative Extension Service: Stillwater, OK, USA, 2019. [Google Scholar]

- Marsh, G. Next step for automotive materials. Mater. Today 2003, 4, 36–43. [Google Scholar] [CrossRef]

- Ouajai, S.; Shanks, R. Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym. Degrad. Stab. 2005, 89, 327–335. [Google Scholar] [CrossRef]

- John, F.; Williams, D.; Trey, R.; Jared, N.; Patrick, F.; Jeff, K.; Williams, D.; Williams, R.; Brian, C.; Dong, Z. Industrial Hemp as a Modern Commodity Crop; American Society of Agronomy: Madison, WI, USA, 2019. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties characterization of chemically modified hemp hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef]

- Li, X.; Wu, N.; Morrell, J.J.; Du, G.; Tang, Z.; Wu, Z.; Zou, C. Influence of hemp plant eccentric growth on physical properties and chemical compounds of hemp hurd. BioResources 2018, 13, 290–298. [Google Scholar] [CrossRef] [Green Version]

- Johnson, R. Hemp as an Agricultural Commodity; Library of Congress Washington DC Congressional Research Service: Washington, DC, USA, 2014. [Google Scholar]

- Johnson, R. Production, Marketing, and Regulation of Hemp Products; IF11860; Congressional Research Service: Washington, DC, USA, 2021. Available online: https://crsreports.congress.gov/product/pdf/IF/IF11860 (accessed on 8 June 2022).

- Deitch, R. Hemp: American History Revisited: The Plant with a Divided History; Algora Publishing: New York, NY, USA, 2003. [Google Scholar]

- Kraenzel, D.G. Industrial Hemp as an Alternative Crop in North Dakota: A White Paper Study of the Markets, Profitability, Processing, Agronomics and History; North Dakota State University: Fargo, ND, USA, 1998. [Google Scholar] [CrossRef]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The seed of industrial hemp (Cannabis sativa L.): Nutritional quality and potential functionality for human health and nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef]

- FAOSTAT FAO. Available online: https://www.fao.org/faostat/en/#home (accessed on 14 August 2022).

- Zimniewska, M. Hemp fibre properties and processing target textile: A review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Small, E.; Pocock, T.; Cavers, P. The biology of Canadian weeds. 119. Cannabis sativa L. Can. J. Plant Sci. 2003, 83, 217–237. [Google Scholar] [CrossRef] [Green Version]

- Sen, T.; Reddy, H.J. Various industrial applications of hemp, kinaf, flax and ramie natural fibres. Int. J. Innov. Manag. Technol. 2011, 2, 192. [Google Scholar]

- Fan, M. Characterization and Performance of Elementary Hemp Fibres: Factors Influencing Tensile Strength. Bioresources 2010, 5, 2307–2322. [Google Scholar] [CrossRef]

- Anderson, J.; Jansz, A.; Steele, K.; Thistlethwaite, P.; Bishop, G.; Black, A. Green Guide to Composites: An Environmental Profiling System for Composite Materials and Products; BRE Press: Berkshire, UK, 2004. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Hauschild, M.Z.; Boulay, A.-M.; Fantke, P.; Laurent, A.; Núñez, M.; Vieira, M. Life cycle impact assessment. In Life Cycle Assessment: Theory and Practice; Springer: Cham, Switzerland, 2018; pp. 167–270. [Google Scholar] [CrossRef] [Green Version]

- Curran, M. Encyclopedia of ecology. Encycl. Ecol. 2008, 2168–2174. [Google Scholar] [CrossRef]

- Duda, M.; Shaw, J.S. Life cycle assessment. Society 1997, 35, 38–43. [Google Scholar] [CrossRef]

- GrandViewResearch. Eco Fiber Market Size, Share & Trends Analysis Report By Product (Organic, Manmade/Regenerated, Recycled) By Application (Textiles/Apparel, Industrial, Medical), By Region, And Segment Forecasts, 2023–2030. 2020. Available online: https://www.grandviewresearch.com/industry-analysis/eco-fiber-market (accessed on 8 June 2022).

- Callaway, J.C. Hempseed as a nutritional resource: An overview. Euphytica 2004, 140, 65–72. [Google Scholar] [CrossRef]

- Crescente, G.; Piccolella, S.; Esposito, A.; Scognamiglio, M.; Fiorentino, A.; Pacifico, S. Chemical composition and nutraceutical properties of hempseed: An ancient food with actual functional value. Phytochem. Rev. 2018, 17, 733–749. [Google Scholar] [CrossRef]

- Burton, R.A.; Andres, M.; Cole, M.; Cowley, J.M.; Augustin, M.A. Industrial hemp seed: From the field to value-added food ingredients. J. Cannabis Res. 2022, 4, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Mead, A. The legal status of cannabis (marijuana) and cannabidiol (CBD) under US law. Epilepsy Behav. 2017, 70, 288–291. [Google Scholar] [CrossRef] [Green Version]

- Barbier, E.B. The concept of sustainable economic development. Environ. Conserv. 1987, 14, 101–110. [Google Scholar] [CrossRef]

- Duran, D.C.; Gogan, L.M.; Artene, A.; Duran, V. The components of sustainable development-a possible approach. Procedia Econ. Financ. 2015, 26, 806–811. [Google Scholar] [CrossRef] [Green Version]

- Giddings, B.; Hopwood, B.; O’brien, G. Environment, economy and society: Fitting them together into sustainable development. Sustain. Dev. 2002, 10, 187–196. [Google Scholar] [CrossRef]

- Goodland, R. Sustainability: Human, social, economic and environmental. Encycl. Glob. Environ. Change 2002, 5, 481–491. [Google Scholar]

- Small, E.; Marcus, D. Hemp: A new crop with new uses for North America. Trends New Crops New Uses 2002, 24, 284–326. [Google Scholar]

- Mark, T.; Shepherd, J.; Olson, D.; Snell, W.; Proper, S.; Thornsbury, S. Economic viability of industrial hemp in the United States: A review of state pilot programs. AgEcon Search Res. Agricul. Appl. Econ. 2020. [Google Scholar] [CrossRef]

- Mark, T.B.; Will, S. Economic issues and perspectives for industrial hemp. In Industrial Hemp as a Modern Commodity Crop; American Society of Agronomy: Madison, WI, USA, 2019; pp. 107–118. [Google Scholar] [CrossRef]

- USDA. Remediation and Disposal Guidelines for Hemp Growing Facilities, U.S. Domestic Hemp Production Program; 2021. Available online: https://www.ams.usda.gov/sites/default/files/media/HempRemediationandDisposalGuidelines.pdf (accessed on 8 June 2022).

- Australia, A. Industrial Hemp. 2017. Available online: https://www.agrifutures.com.au/farm-diversity/industrial-hemp/ (accessed on 18 November 2022).

- Panchenko, V.; Izmailov, A.; Kharchenko, V.; Lobachevskiy, Y. Photovoltaic solar modules of different types and designs for energy supply. In Research Anthology on Clean Energy Management and Solutions; IGI Global: Hershey, PA, USA, 2021; pp. 731–752. [Google Scholar]

- ExpertMarketResearch. Global Industrial Hemp Market: By Source: Conventional, Organic; By Product Type: Hemp Seed, Hemp Fibre, Hemp Seed Oil, CBD hemp Oil; By Application: Food and Beverages, Personal Care, Pharmaceuticals; Regional Analysis; Historical Market and Forecast. Available online: https://www.expertmarketresearch.com/reports/industrial-hemp-market (accessed on 8 June 2022).

- MarketsandMarkets. Industrial Hemp Market by Type (Hemp Seed, Hemp Seed Oil, Hemp Fiber, and CBD Hemp Oil), Application (Food, Beverages, Personal Care Products, Textiles, and Pharmaceuticals), Source (Organic and Conventional), and Region—Global Forecast to 2025. 2019. Available online: https://www.marketsandmarkets.com/Market-Reports/industrial-hemp-market-84188417.html (accessed on 8 June 2022).

- MarketDataForecast. Global Industrial Hemp Market Size, Share, Trends, COVID-19 Impact & Growth Analysis Report—Segmented By Type, Application and Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa)—Industry Forecast (2022 to 2027). 2022. Available online: https://www.marketdataforecast.com/market-reports/industrial-hemp-market (accessed on 8 June 2022).

- Imarc. Industrial Hemp Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022–2027; SR112023A4473. 2022. Available online: https://www.imarcgroup.com/industrial-hemp-market (accessed on 8 June 2022).

- Schmidt, E. Hemp & CBD market value: January 2020 price trends for crude, flower biomass isolate. ACS Lab. 2020. [Google Scholar]

- Allen, C.; Whitney, B. The Field of Dreams. An Economic Survey of the United States Hemp Cultivation Industry; Whitney Economics: Portland, Oregon, 2019. [Google Scholar]

- Euromonitor International. Alcoholic & Soft Drinks and Packaged Food—Market Size Data. 2020. Available online: https://www.euromonitor.com/industries (accessed on 10 October 2022).

- Technavio. Global Textile Market 2019–2023. 2019. Available online: https://www.technavio.com/report/textile-manufacturing-market-analysis (accessed on 10 October 2022).

- Euromonitor International. Beauty and Personal Care—Market Size Data. 2020. Available online: https://www.euromonitor.com/beauty-and-personal-care (accessed on 10 October 2022).

- Wagner, C. What is Industrial Hemp? Open Hemp University: Oakland, CA, USA, 2015. [Google Scholar] [CrossRef]

- Victoria State Government. 2020 Industrial Hemp Update-Industrial Hemp Taskforce; State of Victoria, Department of Jobs, Precincts and Regions: Melbourne, Australia, 2020. [Google Scholar]

- Cherney, J.H.; Small, E. Industrial hemp in North America: Production, politics and potential. Agronomy 2016, 6, 58. [Google Scholar] [CrossRef] [Green Version]

- McGrath, C. Hemp Annual Report; Report No. CH2020-0018; USDAFAS: Washington, DC, USA, 2019. [Google Scholar]

- Horner, J.; Milhollin, R.; Roach, A.; Morrison, C.; Schneider, R. Comparative Analysis of the Industrial Hemp Industry: Guide to the Evolution of the US Industrial Hemp Industry in the Global Economy; University of Missouri Extension Service: Columbia, MI, USA, 2019. [Google Scholar]

- Hemp. European Commission. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 3 April 2022).

- Omnes, M.-A. Industrial Hemp in France; USDA Foreign Agricultural Service: Washington, DC, USA, 2021. [Google Scholar]

- Carus, M.; Sarmento, L. The European Hemp Industry: Cultivation, processing and applications for fibres, shivs, seeds and flowers. Eur. Ind. Hemp Assoc. 2016, 5, 1–9. [Google Scholar]

- USDA. National Hemp Report; USDA National Agricultural Statistics Service: Washington, DC, USA, 2022. [Google Scholar]

- Dhondt, F.; Muthu, S.S.; Dhondt, F.; Muthu, S.S. The Environmental and Social Impacts of Hemp. In Hemp and Sustainability; Springer: Singapore, 2021; pp. 15–35. [Google Scholar] [CrossRef]

- Bouloc, P.; Allegret, S.; Arnaud, L. Hemp: Industrial Production and Uses; CABI: Wallingford, UK, 2013. [Google Scholar]

- Ranalli, P.; Venturi, G. Hemp as a raw material for industrial applications. Euphytica 2004, 140, 1–6. [Google Scholar] [CrossRef]

- Valić, F.; Žuškin, E. Effects of different vegetable dust exposures. Occup. Environ. Med. 1972, 29, 293–297. [Google Scholar] [CrossRef] [Green Version]

- Roulac, J.W. Hemp Horizons: The Comeback of the World’s Most Promising Plant; Chelsea Green Publishing Company: Chelsea, VT, USA, 1997. [Google Scholar]

- Schultes, R.E. Random Thoughts and Queries on the Botany of Cannabis; J. & A. Churchill: London, UK, 1970. [Google Scholar]

- Montford, S.; Small, E. A comparison of the biodiversity friendliness of crops with special reference to hemp (Cannabis sativa L.). J. Int. Hemp Assoc 1999, 6, 53–63. [Google Scholar]

- Dempsey, N.; Bramley, G.; Power, S.; Brown, C. The social dimension of sustainable development: Defining urban social sustainability. Sustain. Dev. 2011, 19, 289–300. [Google Scholar] [CrossRef]

- Donham, K.J.; Thelin, A. Agricultural Medicine: Rural Occupational and Environmental Health, Safety, and Prevention; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Bouhuys, A.; Barbero, A.; Lindell, S.-E.; Roach, S.; Schilling, R. Byssinosis in hemp workers. Arch. Environ. Health Int. J. 1967, 14, 533–543. [Google Scholar] [CrossRef]

- Zuskin, E.; Kanceljak, B.; Pokrajac, D.; Schachter, E.; Witek, T. Respiratory symptoms and lung function in hemp workers. Occup. Environ. Med. 1990, 47, 627–632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McPartland, J.M. Byssinosis in hemp mill workers. J. Ind. Hemp 2003, 8, 33–44. [Google Scholar] [CrossRef]

- Valić, F.; Žuškin, E.; Walford, J.; Keršić, W.; Pauković, R. Byssinosis, chronic bronchitis, and ventilatory capacities in workers exposed to soft hemp dust. Occup. Environ. Med. 1968, 25, 176–186. [Google Scholar] [CrossRef] [Green Version]

- Fishwick, D.; Pickering, C. Byssinosis--a form of occupational asthma? Thorax 1992, 47, 401. [Google Scholar] [CrossRef] [Green Version]

- Blair, A.; Ritz, B.; Wesseling, C.; Freeman, L.B. Pesticides and Human Health; BMJ Publishing Group Ltd.: London, UK, 2015; Volume 72, pp. 81–82. [Google Scholar] [CrossRef]

- Sankhla, M.S.; Kumari, M.; Sharma, K.; Kushwah, R.S.; Kumar, R. Water contamination through pesticide & their toxic effect on human health. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 967–970. [Google Scholar] [CrossRef]

- Alavanja, M.C.; Bonner, M.R. Occupational pesticide exposures and cancer risk: A review. J. Toxicol. Environ. Health Part B 2012, 15, 238–263. [Google Scholar] [CrossRef] [PubMed]

- Davidson, M.; Reed, S.; Oosthuizen, J.; O’Donnell, G.; Gaur, P.; Cross, M.; Dennis, G. Occupational health and safety in cannabis production: An Australian perspective. Int. J. Occup. Environ. Health 2018, 24, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Martyny, J.W.; Serrano, K.A.; Schaeffer, J.W.; Van Dyke, M.V. Potential exposures associated with indoor marijuana growing operations. J. Occup. Environ. Hyg. 2013, 10, 622–639. [Google Scholar] [CrossRef]

- KG, S.; Das, S. Hazards Associated with Dying in Finishing Process of a Textile Industry. Int. Res. J. Eng. Technol. 2019, 6. [Google Scholar]

- Malik, N.; Maan, A.A.; Pasha, T.S.; Akhtar, S.; Ali, T. Role of hazard control measures in occupational health and safety in the textile industry of Pakistan. Pak. J. Agri. Sci. 2010, 47, 72–76. [Google Scholar]

- Freeman, G.L. Allergic skin test reactivity to marijuana in the Southwest. West. J. Med. 1983, 138, 829. [Google Scholar] [PubMed]

- Kumar, R.; Gupta, N. A case of bronchial asthma and allergic rhinitis exacerbated during Cannabis pollination and subsequently controlled by subcutaneous immunotherapy. Indian J. Allergy Asthma Immunol. 2013, 27, 143. [Google Scholar] [CrossRef]

- Stokes, J.R.; Hartel, R.; Ford, L.B.; Casale, T.B. Cannabis (hemp) positive skin tests and respiratory symptoms. Ann. Allergy Asthma Immunol. 2000, 85, 238–240. [Google Scholar] [CrossRef]

- Williams, C.; Thompstone, J.; Wilkinson, M. Work-related contact urticaria to Cannabis sativa. Contact Dermat. 2008, 58, 62–63. [Google Scholar] [CrossRef]

- Fishwick, D.; Allan, L.; Wright, A.; Barber, C.; Curran, A. Respiratory symptoms, lung function and cell surface markers in a group of hemp fiber processors. Am. J. Ind. Med. 2001, 39, 419–425. [Google Scholar] [CrossRef]

- Wang, S.; Gusovius, H.-J.; Lühr, C.; Musio, S.; Uhrlaub, B.; Amaducci, S.; Müssig, J. Assessment system to characterise and compare different hemp varieties based on a developed lab-scaled decortication system. Ind. Crops Prod. 2018, 117, 159–168. [Google Scholar] [CrossRef]

- Turunen, L.; Van der Werf, H. Life cycle analysis of hemp textile yarn, comparison of three hemp fiber processing scenarios and a flax scenario. J. Ind. Hemp 2006, 12, 43–66. [Google Scholar] [CrossRef]

- Grace Annapoorani, S. Social sustainability in textile industry. In Sustainability in the Textile Industry; Springer: Singapore, 2017; pp. 57–78. [Google Scholar] [CrossRef]

- Sakthi Nagaraj, T.; Jeyapaul, R.; Vimal, K.; Mathiyazhagan, K. Integration of human factors and ergonomics into lean implementation: Ergonomic-value stream map approach in the textile industry. Prod. Plan. Control. 2019, 30, 1265–1282. [Google Scholar] [CrossRef]

- Polat, O.; Kalayci, C.B. Ergonomic risk assessment of workers in garment industry. In Proceedings of the Eight International Conference on Textile Science & Economy VIII, Zranjanin, Sarbia, 16–19 May 2016; pp. 16–21. [Google Scholar]

- Hamm, B. Challenges to secure human rights through voluntary standards in the textile and clothing industry. In Business and Human Rights; Edward Elgar Publishing: Northampton, MA, USA, 2012; pp. 220–242. [Google Scholar]

- Organization, I.L. Promoting fair globalization in textiles and clothing in a post-MFA environment: Report for Discussion at the Tripartite Meeting on Promoting Fair Globaliztion in Textiles and Clothing in a Post-MFA Environment; International Labour Office: Geneva, Switzerland, 2005. [Google Scholar]

- Committee, I.C.A. Literature Review and Research Evaluation Relating to Social Impacts of Global Cotton Production for ICAC Expert Panel on Social, Environmental and Economic Performance of Cotton (SEEP); Prepared by Ergon; International Cotton Advisory Committee: Washington, DC, USA, 2008. [Google Scholar]

- Wills, J.; Hale, A. Threads of labour in the global garment industry. In Threads of Labour: Garment Industry Supply Chains from the Workers’ Perspective; Wiley-Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2005; pp. 1–15. [Google Scholar] [CrossRef]

- Peña, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Pires, A.C.; Weidema, B.; Mieras, E.; Wang, F.; Fava, J.; Canals, L.M.i. Using life cycle assessment to achieve a circular economy. Int. J. Life Cycle Assess. 2021, 26, 215–220. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; De Vries, W.; De Wit, C.A. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347, 1259855. [Google Scholar] [CrossRef] [Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaur, G.; Kander, R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability 2023, 15, 6457. https://doi.org/10.3390/su15086457

Kaur G, Kander R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability. 2023; 15(8):6457. https://doi.org/10.3390/su15086457

Chicago/Turabian StyleKaur, Gurinder, and Ronald Kander. 2023. "The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability" Sustainability 15, no. 8: 6457. https://doi.org/10.3390/su15086457