Assessment of the Compression Properties of Different Giant Bamboo Species for Sustainable Construction

Abstract

1. Introduction

2. Materials and Methods

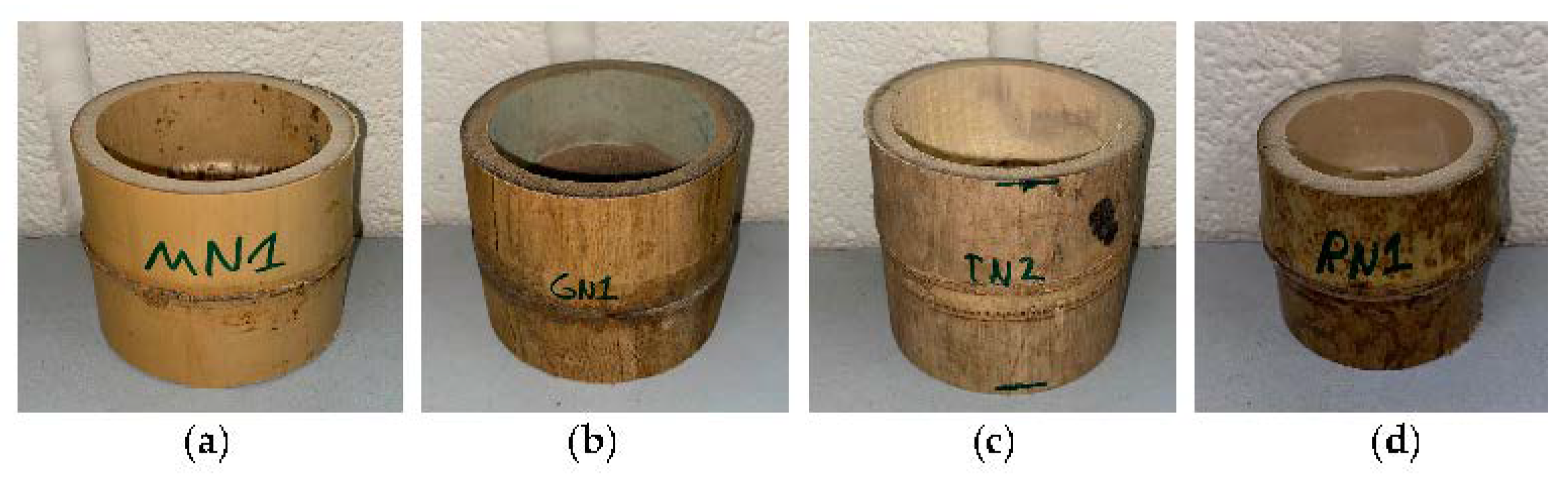

2.1. Materials

2.2. Methods

3. Results

3.1. Failure Modes

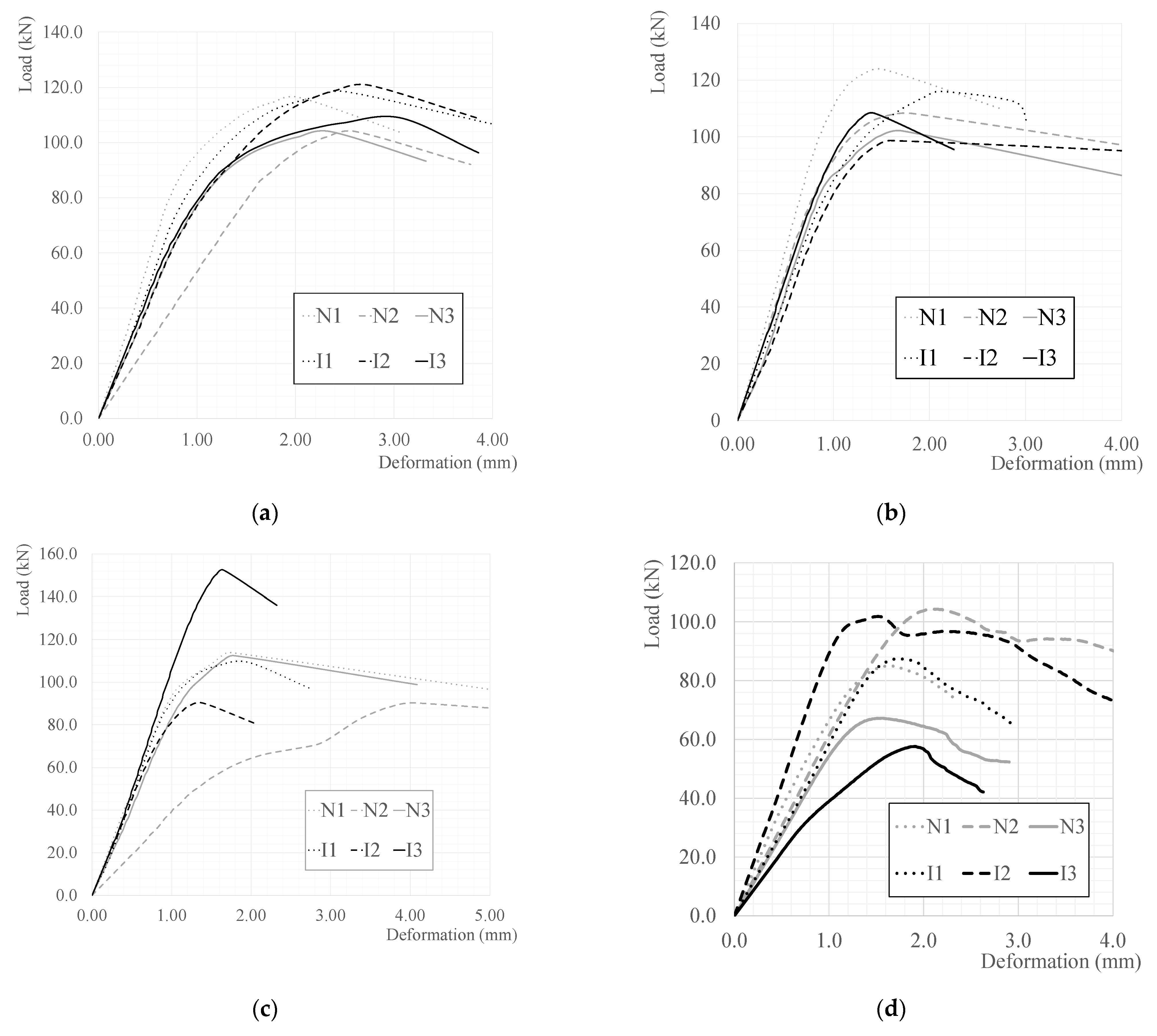

3.2. Displacement Response

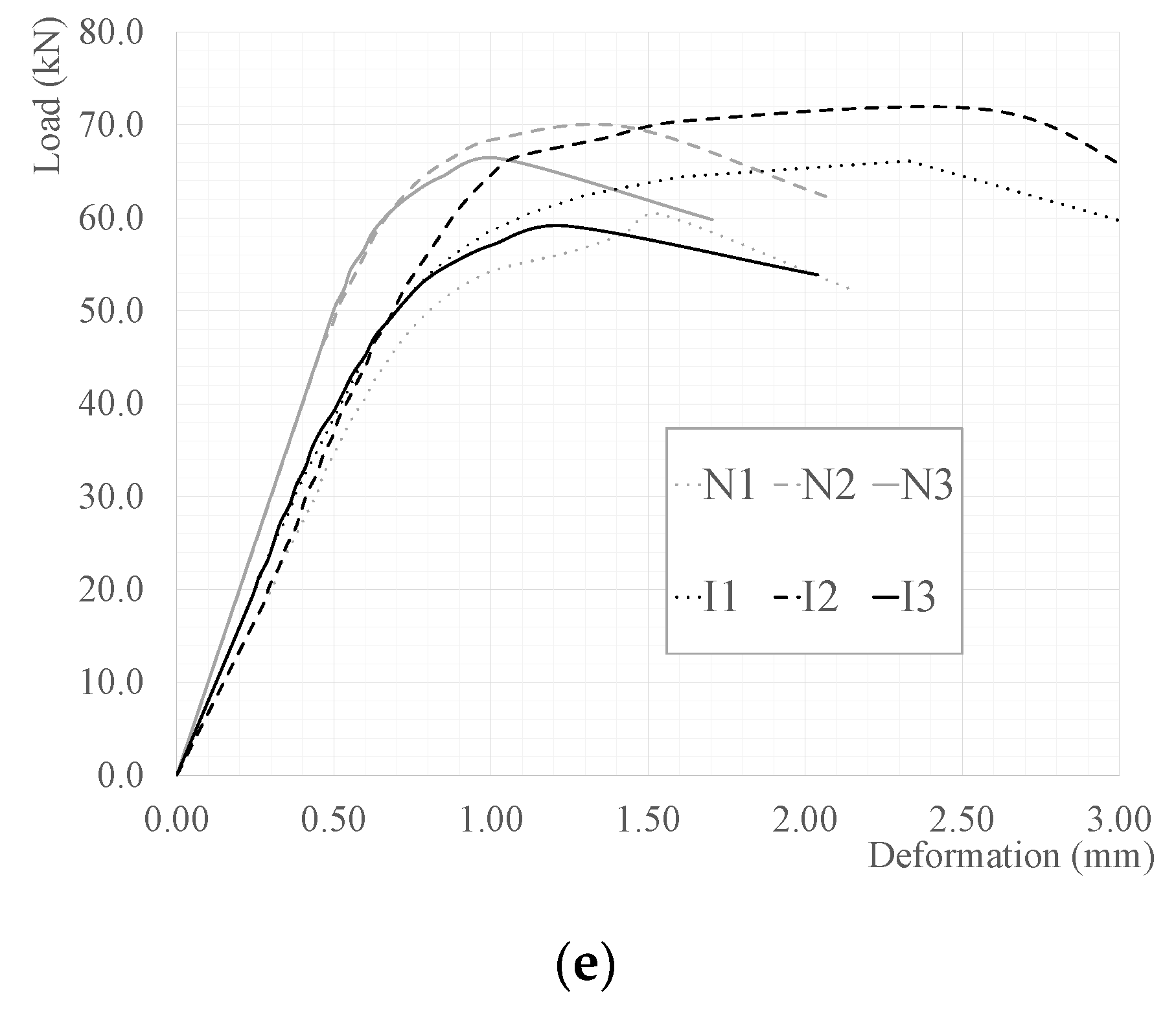

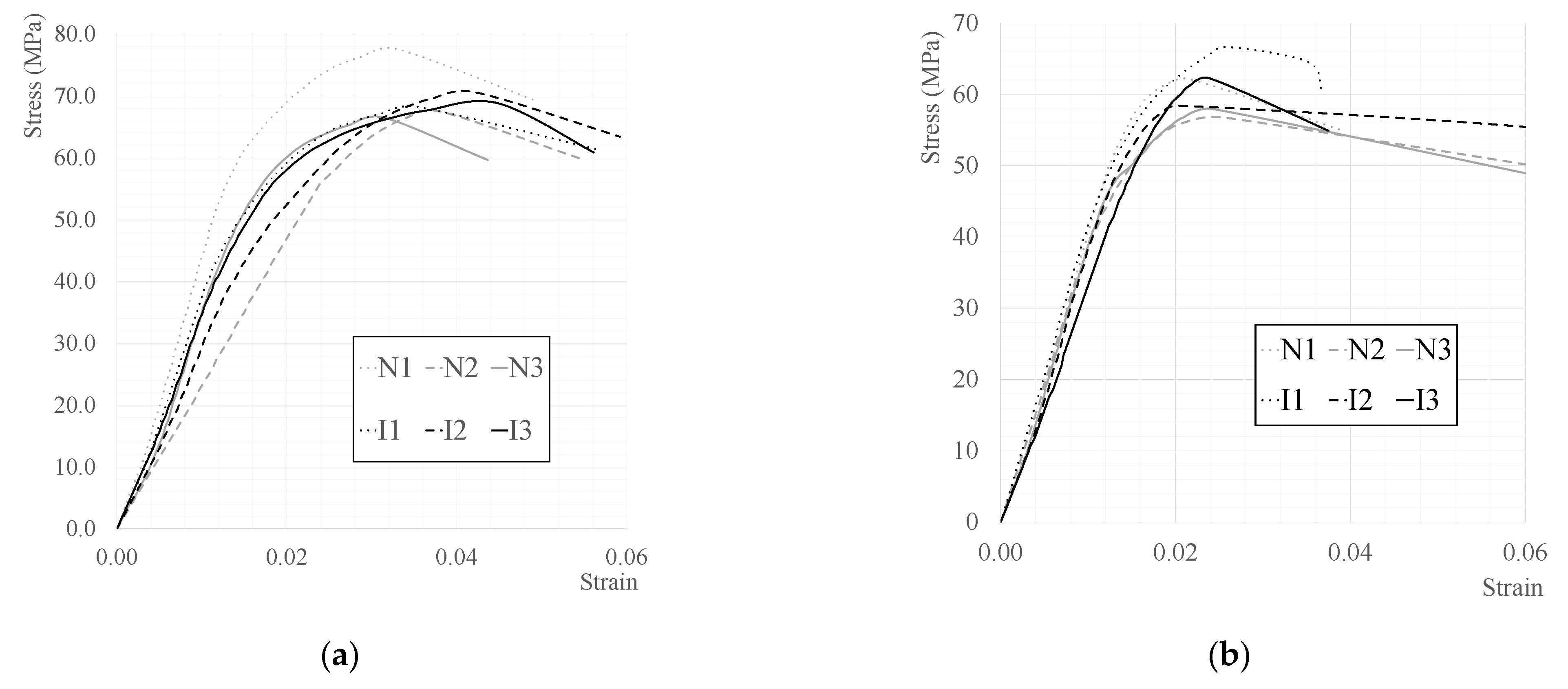

3.3. Strain Response

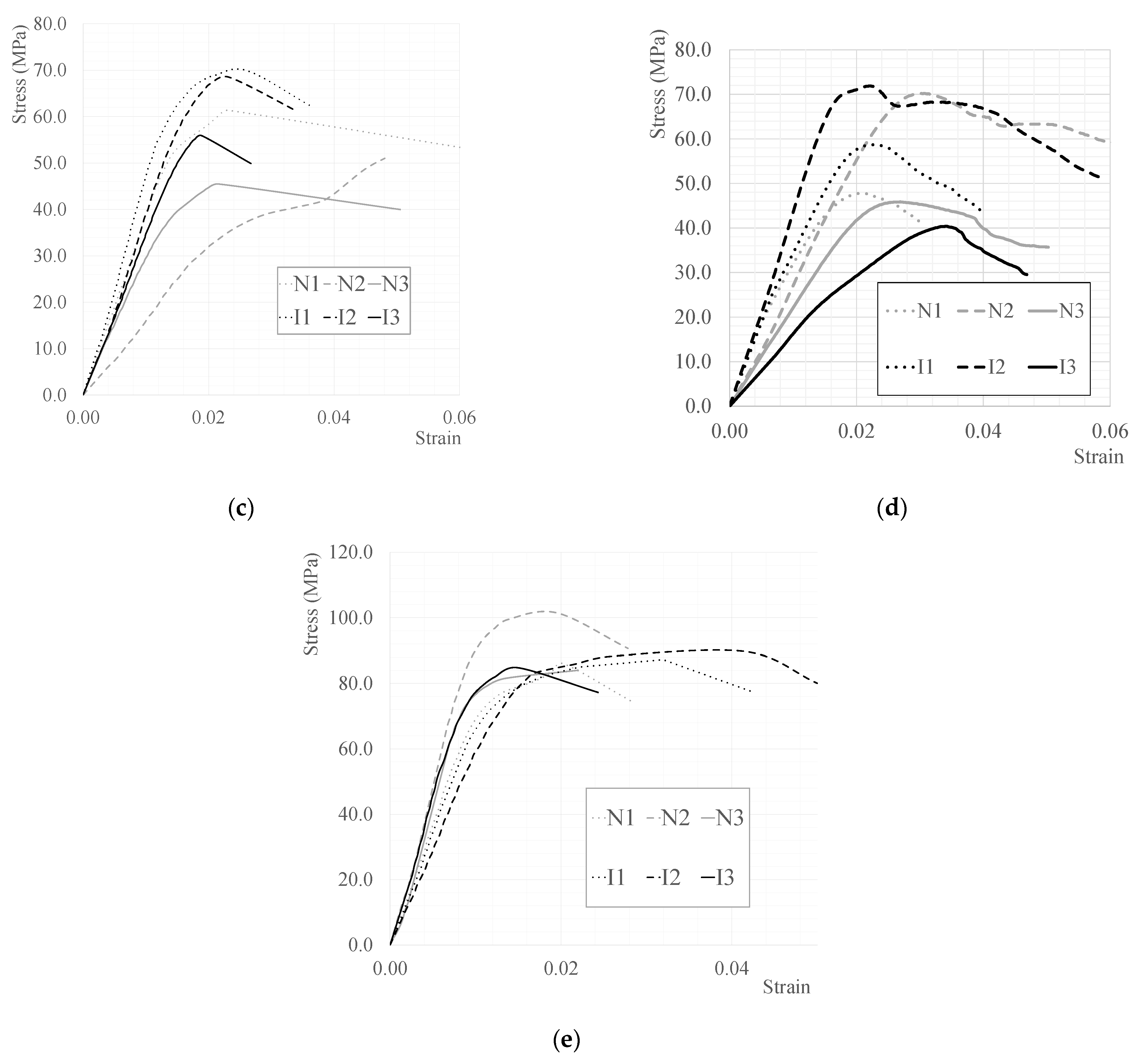

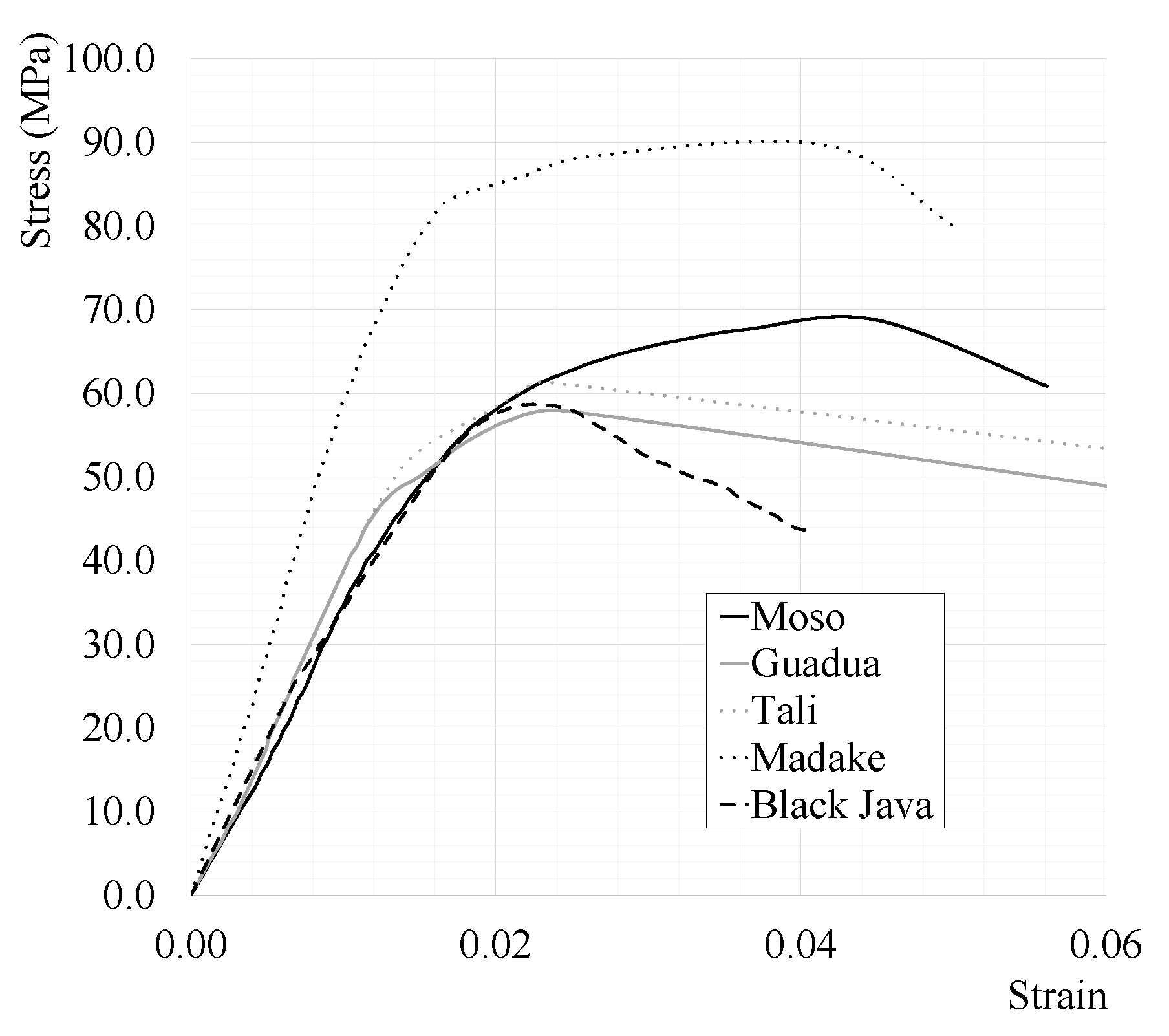

4. Discussion

4.1. Displacement Response

4.2. Strain Response

4.3. Modulus of Elasticity in Compression

4.4. Reliability as a Construction Material

5. Conclusions

- The greatest load sustained by a test specimen in this study was 152.4 kN in specimen TI3 from the Tali test series.

- The maximum average load in a test series belongs to Moso, Tali and Guadua test series with 112.1 kN, 111.4 kN and 109.5 kN, respectively.

- The maximum sustained compressive stresses belonged to Madake specimens with a smaller diameter compared to the rest of the tested species reaching an average compressive strength of 88.9 MPa.

- Among the specimens with larger diameters, the greatest average ultimate strengths achieved were as follows for Moso, Guadua and Tali with 69.9 MPa, 60.7 MPa and 59.1 MPa compressive strengths, respectively.

- The presence of the nodes did not seem to have a significant effect on the compressive strength of bamboo specimens. In fact, for Moso and Madake test series, nodal specimens have greater compressive strengths compared to those of the internodal specimens, whereas for Guadua, Tali and Black Java test series, the internodal specimens provided greater compressive strengths compared to those of the nodal specimens in the same test series.

- Guadua test series was able to provide outstanding consistency in the provided compressive behaviour and strength among all the tested specimens. This was evidenced by rather low CoV for compressive strength and modulus of elasticity that are respectively equal to 5.53% and 7.92%, and considerably similar load-deformation and stress–strain curves of Guadua specimens. Moso and Madake specimens were able to provide reliable compressive strengths with the CoVs of 5.25% and 6.65%, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Intergovernmental Panel on Climate Change: Climate Change 2014: Synthesis Report. In Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change Report; Pachauri, R.K., Meyer, L., Eds.; World Meteorological Organization: Geneva, Switzerland, 2015. [Google Scholar]

- Jiang, J.; Du, J.; Li, H.; Mei, C.; Gong, X. Hydrophobicity improvement on wood for a better application of this bio-based material. Coatings 2022, 12, 1465. [Google Scholar] [CrossRef]

- Paris Agreement to the United Nations Framework Convention on Climate Change. In Treaties and Other International Acts Series (TIAS) No. 16-1104; U.S. Department of State: Washington, DC, USA, 2015.

- Matthews, H.; Caldeira, K. Stabilizing climate requires near-zero emissions. Geophys. Res. Lett. 2008, 35, 323. [Google Scholar] [CrossRef]

- Arioğlu Akan, M.Ö.; Dhavale, D.G.; Sarkis, J. Greenhouse gas emissions in the construction industry: An analysis and evaluation of a concrete supply chain. J. Clean. Prod. 2017, 167, 1195–1207. [Google Scholar] [CrossRef]

- Giesekam, J.; Tingley, D.; Cotton, I. Aligning carbon targets for construction with (inter)national climate change mitigation commitments. Energy Build. 2018, 165, 106–117. [Google Scholar] [CrossRef]

- Klee, H. Briefing: The cement sustainability initiative. Proc. Inst. Civ. Eng.—Eng. Sustain. 2004, 157, 9–11. [Google Scholar] [CrossRef]

- Rodrigues, F.; Joekes, I. Cement industry: Sustainability, challenges and perspectives. Environ. Chem. Lett. 2010, 9, 151–166. [Google Scholar] [CrossRef]

- World Steel Association. Steel’s Contribution to a Low-Carbon Future and Climate Resilient Societies; World Steel Association: Brussels, Belgium, 2020; Report. 6. [Google Scholar]

- Khatib, J.M. Sustainability of Construction Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2016; 742p. [Google Scholar]

- Nunes, N. Nonwood bio-based materials. Perform. Bio-Based Build. Mater. 2017, 3, 97–186. [Google Scholar]

- Harries, K.A.; Sharma, B.; Richard, M. Structural Use of Full Culm Bamboo: The Path to Standardization. Int. J. Archit. Eng. Constr. 2012, 1, 66–75. [Google Scholar] [CrossRef]

- Bhagat, D.; Maheshwari, A.; Bhalla, S. Composite bamboo beam elements for structural applications. In Proceedings of the UK-India Education and Research Initiative (UKIERI) Congress on Innovations in Concrete Construction, Jalandhar, India, 5 August 2013. [Google Scholar]

- Kaminski, S.; Lawrence, A.; Trujillo, D. Structural use of bamboo. Part 1: Introduction to bamboo. Struct. Eng. 2016, 98, 40–43. [Google Scholar]

- Trujillo, D.; López, L.F. Bamboo material characterisation. In Nonconventional and Vernacular Construction Materials, 2nd ed.; Harries, K.A., Sharma, B., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 365–392. [Google Scholar]

- Van der Lugt, P.; Abrahams, R.; Van den Dobbelsteen, A. Bamboo as a building material alternative for Western Europe? A study of the environmental performance, costs and bottlenecks of the use of bamboo (products) in Western Europe. J. Bamboo Ratt. 2003, 2, 205–223. [Google Scholar] [CrossRef]

- Yiping, L.; Yanxia, L.; Buckingham, K.; Henley, K.; Guomo, Z. Bamboo and climate change mitigation. In International Network for Bamboo and Rattan; Technical Report No. 32, 2010; INBAR: Beijing, China, 2010; p. 32. [Google Scholar]

- Song, X.; Zhou, G.; Jiang, H.; Yu, S.; Fu, J.; Li, W.; Wang, W.; Ma, Z.; Peng, C. Carbon sequestration by Chinese bamboo forests and their ecological benefits: Assessment of potential, problems, and future challenges. Environ. Rev. 2011, 19, 418–428. [Google Scholar] [CrossRef]

- Chung, K.; Yu, W. Mechanical properties of structural bamboo for bamboo scaffoldings. Eng. Struct. 2002, 24, 429–442. [Google Scholar] [CrossRef]

- Huang, Z.; Sun, Y.; Musso, F. Assessment of bamboo application in building envelope by comparison with reference timber. Constr. Build. Mater. 2017, 156, 844–860. [Google Scholar] [CrossRef]

- Mitch, D.; Harries, K.; Sharma, B. Characterization of splitting behavior of bamboo culms. J. Mater. Civ. Eng. 2010, 22, 1195–1199. [Google Scholar] [CrossRef]

- Oka, G.M.; Triwiyono, A.; Awaludin, A.; Siswosukarto, S. Effects of node, internode and height position on the mechanical properties of Gigantochloa Atroviolacea bamboo. Procedia Eng. 2014, 95, 31–37. [Google Scholar] [CrossRef]

- ISO 22157-2:2004; Bamboo—Determination of Physical and Mechanical Properties—Part 2: Laboratory Manual. International Standards Organization: Geneva, Switzerland, 2004.

- Dixon, P.G.; Gibson, L.J. The structure and mechanics of Moso bamboo material. J. R. Soc. Interface 2014, 11, 20140321. [Google Scholar] [CrossRef] [PubMed]

- IS 6874:1973; Methods of Tests for Round Bamboos. Bureau of Indian Standards: Old Delhi, India, 1973.

- ISO 22157-1:2004; Bamboo—Determination of Physical and Mechanical Properties—Part 1: Requirements. International Standards Organization: Geneva, Switzerland, 2004.

- ISO 22156:2004; Bamboo—Structural Design. International Standards Organization: Geneva, Switzerland, 2004.

- ISO 22157:2019; Bamboo structures—Determination of Physical and Mechanical Properties of Bamboo Culms—Test Methods. International Standards Organization: Geneva, Switzerland, 2019.

- ISO 22156:2021; Bamboo—Structural Design. International Standards Organization: Geneva, Switzerland, 2021.

- Gauss, C.; Savastano, H., Jr.; Harries, K. Use of ISO 22157 mechanical test methods and the characterisation of Brazilian, P. edulis bamboo. Constr. Build. Mater. 2019, 228, 116728. [Google Scholar] [CrossRef]

- Kenneth, O.I.; Uzodimma, U.O. Evaluation of the Compressive Strength of Bamboo Culms under Node and Internode Conditions. Saudi J. Civ. Eng. 2021, 5, 251–258. [Google Scholar]

| Species | Douter 1 (mm) | t (mm) | A (mm2) | L (mm) | me (g) | ρ (kg/m3) | q (g/mm) |

|---|---|---|---|---|---|---|---|

| Moso | 80.8 | 6.9 | 1605 | 70.0 | 81 | 746 | 1.19 |

| Guadua | 82.1 | 7.4 | 1728 | 72.7 | 86 | 655 | 1.13 |

| Tali | 81.0 | 8.6 | 1939 | 75.5 | 87 | 669 | 1.27 |

| Black Java | 73.8 | 7.2 | 1511 | 66.6 | 64 | 630 | 0.94 |

| Madake | 45.8 | 5.9 | 738 | 44.5 | 27 | 803 | 0.59 |

| Species | Specimen | Douter (mm) | A (mm2) | ΔLc,0 (mm) | εc,0 | Fult (kN) | fc,0 (MPa) | Εc,0 (GPa) |

|---|---|---|---|---|---|---|---|---|

| Moso (M) | MN1 | 76.6 | 1499.9 | 2.0 | 0.0330 | 116.4 | 77.6 | 4.77 |

| MN2 | 78.6 | 1539.9 | 2.6 | 0.0379 | 104.0 | 67.5 | 2.35 | |

| MN3 | 80.1 | 1563.1 | 2.4 | 0.0314 | 104.0 | 66.5 | 4.13 | |

| MI1 | 83.3 | 1735.0 | 2.5 | 0.0353 | 118.4 | 68.3 | 4.07 | |

| MI2 | 84.5 | 1709.5 | 2.7 | 0.0421 | 120.7 | 70.6 | 3.01 | |

| MI3 | 81.8 | 1582.2 | 3.1 | 0.0448 | 109.0 | 68.8 | 3.61 | |

| Guadua (G) | GN1 | 83.9 | 1991.5 | 1.5 | 0.0217 | 123.8 | 62.1 | 4.57 |

| GN2 | 81.6 | 1905.8 | 1.8 | 0.0255 | 108.2 | 56.8 | 4.01 | |

| GN3 | 81.8 | 1731.8 | 1.7 | 0.0243 | 102.1 | 58.0 | 4.20 | |

| GI1 | 83.2 | 1739.9 | 2.1 | 0.0258 | 116.0 | 66.7 | 4.26 | |

| GI2 | 79.9 | 1688.5 | 1.6 | 0.0202 | 98.7 | 58.5 | 4.14 | |

| GI3 | 82.3 | 1309.6 | 1.4 | 0.0239 | 108.3 | 62.3 | 3.49 | |

| Tali (T) | TN1 | 81.8 | 1856.9 | 1.7 | 0.0232 | 113.9 | 61.4 | 3.91 |

| TN2 | 79.9 | 1694.8 | 4.1 | 0.0543 | 90.3 | 53.3 | 1.63 | |

| TN3 | 81.6 | 2472.4 | 1.8 | 0.0216 | 112.4 | 45.5 | 2.88 | |

| TI1 | 80.2 | 1563.8 | 2.0 | 0.0261 | 109.3 | 69.9 | 5.02 | |

| TI2 | 81.0 | 1317.7 | 1.4 | 0.0233 | 90.3 | 68.5 | 4.24 | |

| TI3 | 81.2 | 2727.3 | 1.7 | 0.0189 | 152.4 | 55.9 | 3.55 | |

| Black Java (B) | BN1 | 76.5 | 1780.8 | 1.6 | 0.0207 | 85.1 | 47.8 | 2.65 |

| BN2 | 68.4 | 1486.5 | 2.1 | 0.0249 | 104.4 | 65.7 | 2.87 | |

| BN3 | 76.6 | 1466.3 | 1.6 | 0.0223 | 67.2 | 44.2 | 2.20 | |

| BI1 | 76.5 | 1489.8 | 1.7 | 0.0253 | 87.5 | 57.7 | 2.67 | |

| BI2 | 68.4 | 1417.1 | 1.5 | 0.0220 | 101.8 | 71.9 | 4.46 | |

| BI3 | 76.6 | 1426.5 | 1.9 | 0.0342 | 57.6 | 40.4 | 1.57 | |

| Madake (P) | PN1 | 45.5 | 702.0 | 1.5 | 0.0203 | 60.4 | 86.1 | 7.60 |

| PN2 | 45.3 | 687.7 | 1.4 | 0.0195 | 69.8 | 101.5 | 10.71 | |

| PN3 | 43.8 | 790.4 | 1.0 | 0.0220 | 66.4 | 84.0 | 10.12 | |

| PI1 | 46.8 | 758.1 | 2.3 | 0.0319 | 66.2 | 87.3 | 6.97 | |

| PI2 | 45.6 | 798.4 | 2.6 | 0.0415 | 71.6 | 89.7 | 5.95 | |

| PI3 | 47.9 | 697.6 | 1.2 | 0.0150 | 59.2 | 84.8 | 9.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drury, B.; Padfield, C.; Russo, M.; Swygart, L.; Spalton, O.; Froggatt, S.; Mofidi, A. Assessment of the Compression Properties of Different Giant Bamboo Species for Sustainable Construction. Sustainability 2023, 15, 6472. https://doi.org/10.3390/su15086472

Drury B, Padfield C, Russo M, Swygart L, Spalton O, Froggatt S, Mofidi A. Assessment of the Compression Properties of Different Giant Bamboo Species for Sustainable Construction. Sustainability. 2023; 15(8):6472. https://doi.org/10.3390/su15086472

Chicago/Turabian StyleDrury, Ben, Cameron Padfield, Mirko Russo, Lowri Swygart, Oliver Spalton, Sam Froggatt, and Amir Mofidi. 2023. "Assessment of the Compression Properties of Different Giant Bamboo Species for Sustainable Construction" Sustainability 15, no. 8: 6472. https://doi.org/10.3390/su15086472

APA StyleDrury, B., Padfield, C., Russo, M., Swygart, L., Spalton, O., Froggatt, S., & Mofidi, A. (2023). Assessment of the Compression Properties of Different Giant Bamboo Species for Sustainable Construction. Sustainability, 15(8), 6472. https://doi.org/10.3390/su15086472