1. Introduction

The flexibility of the large-capacity floating underwork is incorporated into the dynamic calculation of the floating wind turbine through the use of the radiation diffraction solver directly. The process for constructing a dynamic flexible substructure model and the use of the WAMIT and HAWC2 aeroelastic tools are shown in [

1]. The energy-consuming effect and the inertia-elastic effect of the flexible blade have a competing connection with the overall dynamic response of the wind turbine in the integrated blade-tower model of a large-sized wind turbine [

2]. The coupled dynamic response of a multi-column low CG FOWT system located in shallow water area satisfies the extreme survival requirements of the FOWT system in the shallow water (50 m) in the South China Sea, in addition to the standard operating requirements and the new concept of the system that is available in [

3]. The double frequency effects on the dynamic responses of the flexible tower structure in [

4] could be induced by regular waves. We use the multi-body dynamic analysis approach for fatigue design of the monopile foundation of an offshore wind turbine. Aero-hydro-servo-elastic analysis was used to model the dynamic response of the combined system. Each soil layer that was simulated by

p-y curve is available in [

5]. A new prediction model for calculating unsteady loads, modal characteristics, and structural dynamic responses of blades and towers under various wind conditions is accurate and reliable with high calculation accuracy. The time-variant dynamic responses of blade tip and tower top under NTM and ECD are available in [

6]. When the orientation of the elastic bending-torsion coupling in the blade is twist-to-feather, it has a favorable influence on the dynamic response of the turbine. The impact is finally reflected in decreased aerodynamic stresses on the blade, as can be seen in [

7]. A multi-bodies hydrodynamics and lumped-mass approach-based time-domain hydroelastic model has been proposed. Investigated are the structural loads, VLFS flexible deformation, and wind turbine power output. The results are available in [

8]. The combined concept of CTC demonstrates that, in comparison to CSCs, it performs fairly well in increasing the yearly generation of power. The structure of CTC is shown in [

9]. The flexibility caused by the pile–soil interaction reduces the natural frequency of the tower, thus affecting the response of the tower, and the tower shows a stronger response at its natural frequency [

10]. The fender system in the new installation method for floating offshore wind turbines, which is available in [

11], showed a reduction effect on relative horizontal and vertical displacements, relative alignment, and relative stability by approximately 78%, 64%, and 32%, respectively. The elasticity of the blade and tower has little effect on the dynamic response of floater, and the dynamic equation of floating VAWTs based on multi-body kinematics and dynamics theory considering rigid-flexible aerodynamic coupling is available in [

12]. For large blade strains, the FSI model can more accurately represent turbine performance than CFD, thus compromising aerodynamic performance and structural robustness [

13]. The MBBT-MCM coupled method is used to study the overall dynamic response of FOWT, especially for highly compliant designs [

14]. In the dynamic response analysis of a power transmission system, the bedplate must be viewed as a flexible body with high modes [

15]. The resonance responses of a new experimental FWT model are induced under strongly nonlinear hydrodynamic loads [

16]. In the new HAWT comprehensive nonlinear dynamics model, centrifugal force, angular velocity dependent terms, rotational inertia, and pre-twist have great influence on the dynamic response of blades. For more dynamic response data, see [

17]. Compared with the traditional algorithm, the load shedding strategy of a large flexible wind turbine rotor with controllable flaps driven by the new modeless adaptive control algorithm can effectively reduce RBM and BTD, thus prolonging the fatigue life of the wind turbine [

18].

The research on the dynamic characteristics of a rigid-flexible coupling system of large-scale wind turbines mainly examines nonlinear vibration and aerodynamic response characteristics under multi-load coupling. That is, considering the multi-load coupling effect, the dynamics of a rigid-flexible coupling system of large wind turbines is studied by nonlinear analysis. Through multi-load coupling and pulsating wind excitation, the influence of dynamic parameters such as vibration displacement, linear velocity, and phase difference on the stability of wind turbines is analyzed and the wind turbine is studied [

19]. The key component of nonlinear vibration is important. Through the hydrodynamic analysis of the flange at the section of the tower, the distribution law of the fluid around the tower is revealed with the change of the flange structure. The relationship between the bolt working load and the stress of the flange under different working conditions is deduced, and the main factors affecting the stability of the tower are obtained. The research on dynamic characteristics of a rigid-flexible coupling system of large wind turbines is an applied basic research subject, which will provide certain reference value for condition monitoring and fault diagnosis of large wind turbines. The innovation of the present paper is based on a comprehensive study of the dynamic structure of flexible systems with multiple components, which will improve the stability and stability of the wind turbine and support the growth of industrial chains.

The efficiency of a wind turbine would be reduced in sandstorm weather [

20]. The combination of different types of wave energy converters can be more effective in suppressing the motion response while increasing the total wave energy generation [

21]. The standard deviations of heave and pitch motions of the helical type of floating wind turbine are slightly smaller than those of floating HAWT, while the standard deviations of surge and yaw motions are larger [

22]. A hydraulic transmission applied to a utility-scale spar floating wind turbine eliminates the need for a gearbox and potentially improves the turbine reliability [

23,

24,

25]. The GMPOP-based method, which is an effective way to assess the dynamical alteration of wind turbine, can successfully detect the state anomalies before the occurrence of the outer race fault and inner race fault, and provide anomaly alarms in advance [

26]. The optimized articulated offshore wind turbine is significantly improved in terms of construction cost, structural stability, motion performance, and power generation stability, and fully satisfies the operating requirements under different sea scenarios [

27]. The thrust and torque caused by the rain-induced load increase as the rain intensity increases [

28,

29,

30]. The wave energy converters can obviously contribute to the annual power production of the combined concept when compared with an individual floating wind turbine [

9]. Airfoils’ kinematics significantly affect the load predictions during the dynamic stall phenomenon [

31]. The computational time required for models which are simplified is less than 10% that of the full-order model, without the compromise of accuracy, i.e., less than 5% difference in modal frequency and an excellent agreement in time-domain responses [

32]. The electromechanical–rigid-flexible coupling dynamic model improves the stability and safety of the system, particularly under gust conditions [

33]. Through analyzing the dynamics of FWT platform mooring from structure creep to failure, it was found that the yaw response is the most sensitive to structural damage [

34]. The shared anchoring system applied to offshore floating wind turbines further reduces the cost of wind turbines by reducing the cost of manufacturing and installation [

35]. Platform yaw motion is an important dynamic mode of the systems, particularly for the spar configuration [

36]. DMD has been applied to the wake of the NREL-5MW wind turbine invested by a uniform inflow, to identify the most dynamically relevant coherent structures characterizing this flow [

37]. By taking the non-Gaussian characteristics of wind fields into account, the short-term extreme values are generally larger than those under Gaussian wind fields [

38].

This review work is organized in the following fashion. In

Section 1, the structure of flexible multi-body wind turbine and potential of wind energy development are described, and the objectives of this paper are identified. In

Section 2, the typical structure of wind turbines is introduced. The mechanical structure dynamic response of a flexible multi-body in large wind turbines are then discussed in

Section 3. Transient response of the flexible blade in large wind turbines can be found in

Section 4. In

Section 5, the aeroelastic coupling of a flexible turbine blade is proposed to improve the understanding of the flow behavior of the turbine blade. The final conclusion is presented in

Section 6.

3. The Mechanical Structure Dynamic Response of a Flexible Multi-Body in Large Wind Turbines

The dynamic characteristics of the rigid-flexible coupling system of large wind turbines are studied. The wind turbine is regarded as a rigid-flexible coupling system and the tower and blade are regarded as the main elastic bodies of the wind turbine which form a rigid-flexible coupling system with the engine room. Nonlinear vibration directly affects the coupling between wind turbine components. The vibration of the rigid-flexible coupling system of large wind turbines is a nonlinear coupling vibration. Displacement and stress changes will affect the stability of wind turbines. With the increase of tower height, the dynamic characteristics of flexible components and rigid-flexible coupling structures of wind turbines are more and more important to the stability of the system. The aerodynamic response of the rigid-flexible coupling system has an impact on the stability of large fans. The induction factor directly determines the induction speed, so as to obtain the change of wake flow and provide a reference for the safety and stability of large fans.

In this paper, the three-dimensional finite element method is used to simulate the unsteady CFD of large wind turbine units, and its numerical calculation is carried out. The unsteadiness of the changes in speed, mode of motion, and stress in the circle is explained and analyzed [

44].

Wind power generation technology is mature and low cost and has played a great role in reducing carbon dioxide emissions. Therefore, it has great room for development in the clean energy market. The aerodynamic characteristics of wind energy play an important role in the field of wind energy, which can be seen in

Figure 2 [

45].

Figure 2 shows the installed generation capacity of the power sector between 2006 and 2015 with conservative projections to 2040 according to the U. S. EIA, IRENA, and GWEC statistics. Wind and renewable capacities are represented by the primary axis, while the total is represented by the secondary axis. Wind energy contributes greatly to the increasing penetration of renewables into the electricity generation sector and constitutes around 30% of the renewable capacity. Therefore, wind power deserves a deeper survey.

Figure 3 shows the geometry of the wind turbines of Krogstad and Lund. Through the simulation of a dry orchid seed, the geometric shape of the bionic wind turbine blade is obtained. The wing picture of winged seeds is taken from another angle. We used GetDataGD to draw and extract the section formed by the edge and middle of the wing segment from the above picture. Together, these contours form the leading edge, corner, and tail edge of the bionic wind turbine to be built. It is assumed that the shape of blade profile is a curve formed by the profile and radian of each blade. Because the thickness of the wing section is the same only at the root, a fixed wing thickness in this study is proposed to facilitate the establishment of the 3D model. The geometry of the blade was then scaled once into the meant rotor measurement of 0.9 m in diameter [

46].

Figure 4 provides a visual impression of the simulated rotor configuration. The grey geometry in

Figure 4c,d represents the reference configuration C1. Shaft inclination and blade taper are specified in accordance with Reference Report 5 and 2.5, respectively. Since there is no official description of the shape of the nacelle and hub, the general shape is used [

47].

Figure 5 shows the influence of the slenderness ratio on the dynamic performance of the OWT structure with rigid and flexible single piles. It should be noted here that in this paper, the change of the slenderness ratio is only a function of nh, so the bending stiffness of single pile is basically unchanged. It can be seen from the figure that the stiffness correction coefficient of rigid single pile and flexible single pile γ K increases with the increase of the slenderness ratio. The lower limit of this parameter is close to zero, indicating that the structure will develop towards instability [

48].

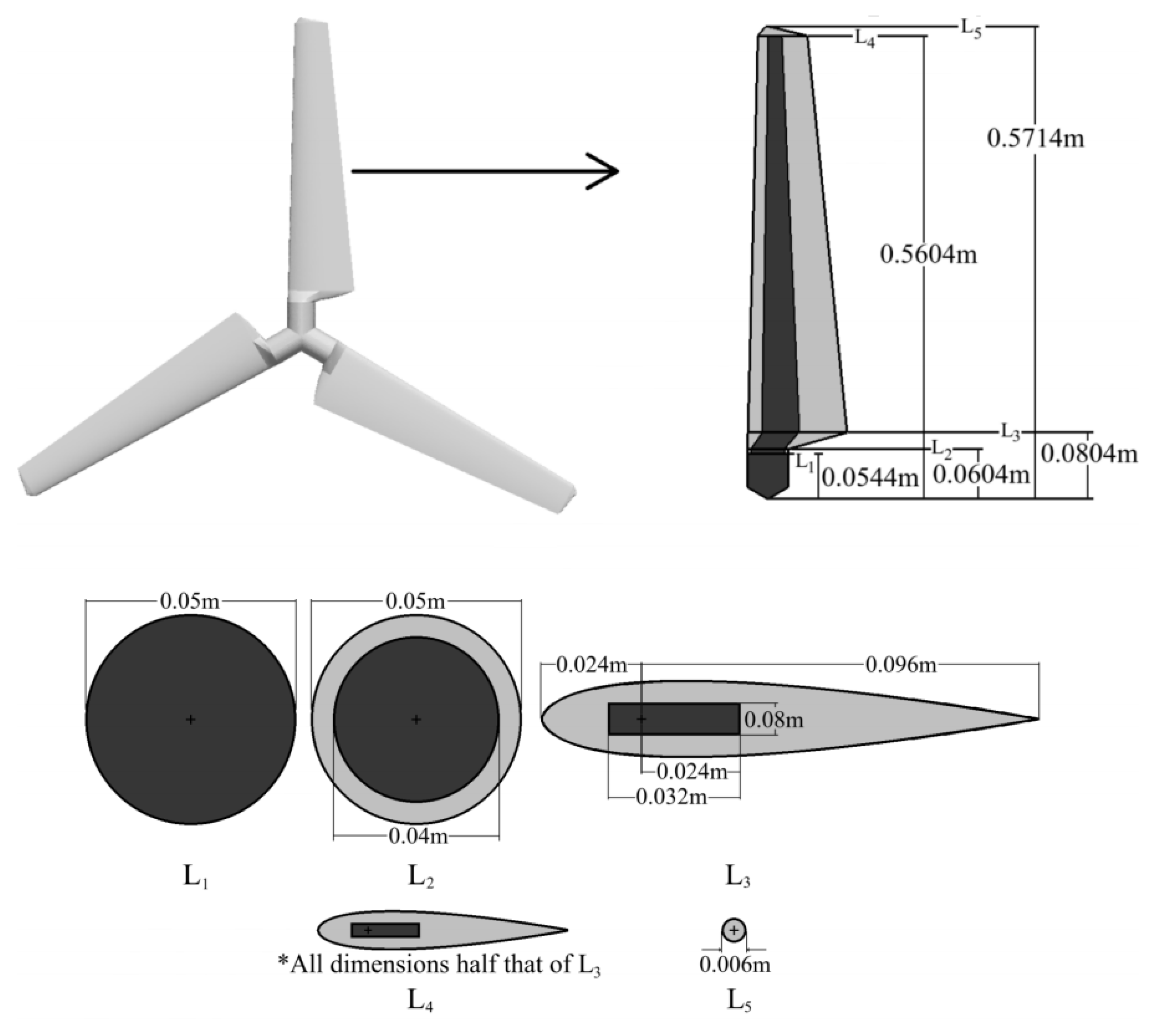

All rotor blades were manufactured with the use of a poured polyurethane molding process, with rigid and flexible blades being identical at some stage in manufacture, as shown in

Figure 6. In this type of test, for simplification, all blades are designed as symmetrical sections, and the airfoil is consistent with the section of NACA 0015. In order to test blades at different pitch angles, the hub was manufactured using a harder version of ABS plastic. The cylindrical hub is 0.05 m in diameter, extends to a span of 0.0604 m, and then, at a span of 0.0804 m, transforms to the appropriate NACA 0015 shape. The chord length at this span is 0.096 m. At a span of 0.5604 m, the blade chord linearly declines to a chord length of 0.048, and at a span of 0.5714 m, it tapers off to a cylinder tip with a diameter of 6 mm. Blades that are stiff were created utilizing a rigid substance that does not flex when in use [

49].

The relative rotation between the rotor and the blade frame could be used to define the twist angle of the blade. Most researchers use approximate aerodynamic models based on XFOIL software results. For a given angle of attack, Reynolds number, and Mach number, XFOIL provides the pressure distribution, C

P(x), lift coefficient, C

L, drag coefficient, C

d, and the lift-to-drag ratio, as shown in

Figure 7 [

50].

The connection between the rotor and the main shaft serves as the primary excitation source in terms of dependability. The effects of radial, thrust, and bending loading DOFs are studied. The forces at the rotor-main shaft connection serve as the input for each of these FRFs.

Figure 8 shows the rotor-main shaft coupling and the corresponding forces. The maximum reaction of DOFs is the displacement of the luggage rack and transmission bushing at the rear PLC-B position [

51].

The rotor is positioned in the middle of the cylinder-shaped computational zone, which has a length of 20 D and a diameter of 10 D and is seen in

Figure 9a. The flow area is divided into rotational area and stationary area, and the information exchange between the two areas is realized through the sliding mesh technique. The entire flow field was meshed with hexahedral cells.

Figure 9b,c shows the rotating area and the grid around the blade, which are generated by the O4H topology. In order to test the independence of the model, this paper proposes two different types of blade models, in which the mesh number of each blade is about 0.7 M and 2.8 M, respectively, and simulates them. The coarse grid and fine grid around the blade are shown in

Figure 9c,d, respectively [

52]. The maximum difference between the results obtained using refined grid and coarse grid is 19.22% and it occurred at wind speed of 5 m/s. This result from the ratio of lift to drag of airfoil is highly sensitive to grid distribution at a low angle of attack. The second maximum percentage difference (less than 3%) occurred at the free stream wind speed of 15 m/s, which is due to the complex flow phenomena, such as separation occurring at blade root, which are also highly sensitive to grid distribution. In the case of intermediate wind speeds, the difference between two sets of grids can be neglected.

In addition to showing cross sections in the Mann’s box with non-dimensional axial velocity U,

Figure 10 provides a generic schematic for the incorporation of the Mann wind turbulence model into CFD Ship-Iowa v4.5 as a wind turbulence boundary condition. A stationary Mann wind turbulence box is created as a preprocessing step [

53]. Given that the velocity field is constructed in a periodic manner, the box’s dimensions are set to span a number of integral length scales, allowing the velocity fields on either side of the box to be treated as uncorrelated. The front face of the Mann box and the CFD domain’s inlet meet at time t = 0, as seen in

Figure 10.

With the shortage of traditional energy and the increasing use of renewable energy, wind energy is one of the fastest growing and most widely used renewable energy sources. Wind power is the main form of wind energy utilization. Large-scale wind turbines are the trend of wind power generation of the future. The tower, wind turbine, and engine room, which are the key components of wind turbines are composed. A rigid-flexible coupling structure and the dynamic characteristics of its rigid-flexible coupling system are the key problems in the operation of wind turbines, which provides a reference value for condition monitoring and control of a large wind turbine. It has broad application prospects in operation, optimization, and control.

Importantly, the development and industrial concentration of large wind turbines may be an important trend of wind power technology. In 2017, China’s wind power equipment was mainly manufactured by more than 10 large wind turbine manufacturers. Mergers and acquisitions of wind power equipment manufacturing enterprises can increase gradually. China’s wind power manufacturing companies have completed the industrial layout. In the main markets, they have established factory production bases. A large company is equivalent to integrating multiple companies. The horizontal axis wind turbine technology is still mainstream. Because of its high conversion efficiency, shorter wind axis, and more economic advantages in large wind turbines, the horizontal axis wind turbine is still the mainstream model for the development of large wind turbines and accounts for more than 100% of the market share. Variable pitch power regulation technology has been widely used in wind power development. It combines the application of variable pitch technology and power electronics technology. Most wind turbine manufacturers have adopted variable speed constant frequency technology and developed variable pitch, variable speed wind turbines, which further improve the conversion efficiency of wind energy. The rapid development of direct-driven wind power technology can effectively reduce the faults caused by the gearbox, and thus effectively improve the service life and reliability of the system operation and reduce the maintenance costs of a wind farm, which have gradually won the favor of the market. Various full-power converters for wind turbines have been applied. With the increase of high-speed gearboxes for direct-driven permanent magnet wind turbines and high-speed permanent magnet wind turbines, full-power converter technology has been widely developed and applied.

The potential development prospects of wind power generation technology in China are as follows. China is rich in wind energy resources. The reserves of developed and utilized wind energy are about 1 billion kilowatts, the reserves of onshore wind energy are about 253 million kilowatts (the height for 10 m), and the reserves of developed and utilized marine wind energy are about 750 million kilowatts, with a total of 1 billion kilowatts. Large-scale offshore wind power is still the direction of technological development in recent years. In the future, the cost of wind power will show a downward trend, which is mainly affected by wind energy resource conditions, wind farm construction conditions, wind power generation technology and cost, wind farm operation and management technology, and other factors.

4. Transient Response of the Flexible Blade in Large Wind Turbines

This method uses the vortex ring singularity grid with constant cycle GietT to solve the potential flow on the lifting surface, as shown in

Figure 11. This method is based on the time stepping technique. At the initial stage, there was only one blade constrained vortex. At each stage, the blades move in the fluid, and a row of vortex ring elements fall off from the trailing edge and convection, forming a free vortex plate (i.e., wake). The intensity of this eddy current is known and equal to the cycle obtained in the previous time step (at the trailing edge). This is equivalent to the Kutta condition of unsteady flow. When the vortex is separated, its strength remains unchanged (Kelvin’s law) and does not carry aerodynamic load, so it moves with local speed [

34].

The wind velocities in the rotor plane are depicted in

Figure 12. The resultant wind velocity on the profile is denoted by

Ve (x

3, t).

V1, 0 and

V2, 0 denote the mean axial wind and rotational velocity components co-directional to the moving x

1- and x

2-axes, respectively, and ɑ and ɑ’ are the related axial and tangential induction factors, respectively [

55].

V1(x

3, t) and

V2(x

3, t) are the instantaneous wind velocities in local x

1-direction and x

2-direction, respectively, seen by an observer fixed to the moving (x

1; x

2; x

3)-coordinate system.

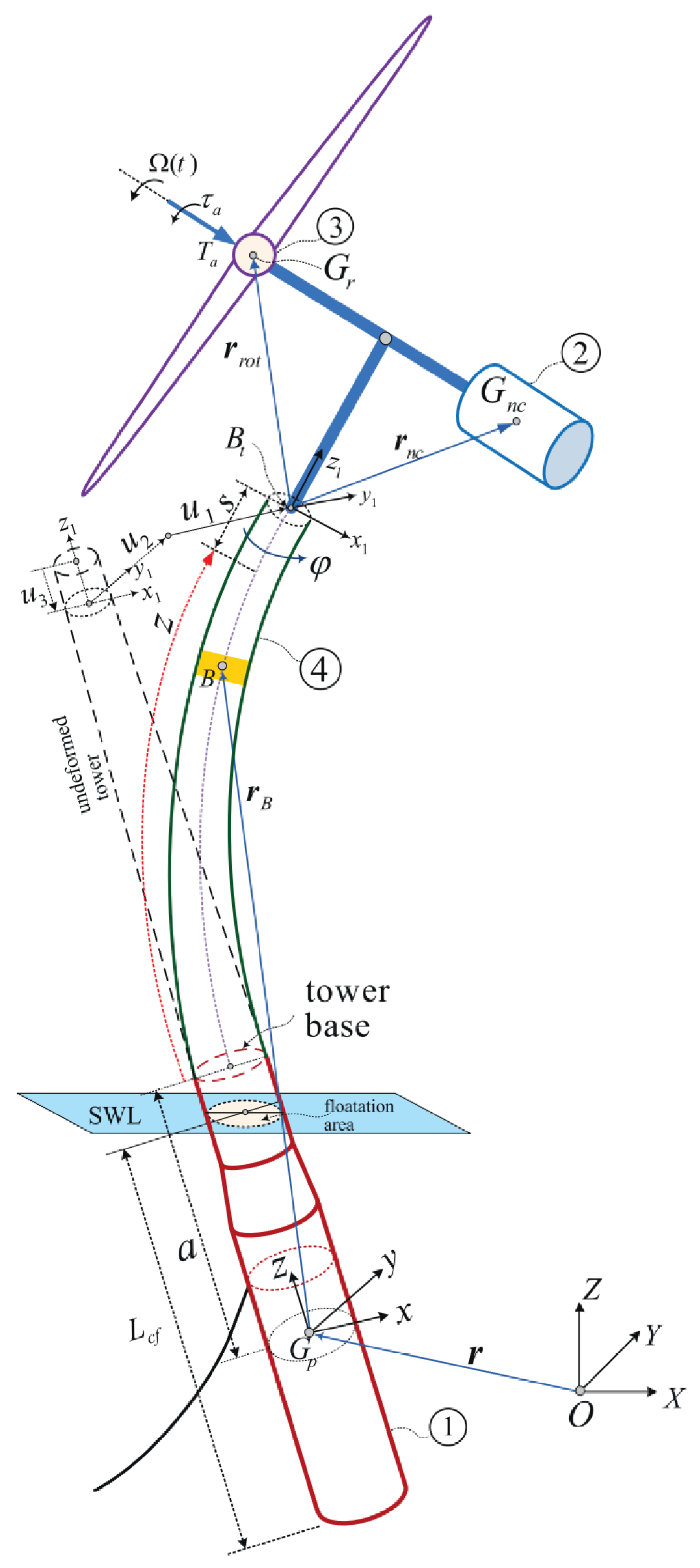

This method regards the whole system as two rigid bodies: the tower body is an integral structural component, which can carry the whole RNA, including a floating ship body; RNA is a complete component that can be offset from the tower on the machine. The implementation of this method requires the use of multiple coordinate systems to derive the EOM of the entire system. In the dynamic equation, the external excitation is continuously calculated and projected into the corresponding coordinate system.

Figure 13 shows the (X, Y, Z) and (XM, YM, ZM) systems, which are the fixed global coordinate systems of the earth. The origins are located at the CM and static water level of the whole system. If the system is in zero displacement equilibrium state, see [

56].

According to

Figure 14, the rotor-nacelle system is made up of elastic blades, a rigid hub, a rigid engine room, a generator, etc. A permanent joint connects the bottom of the engine room to the ground. In this way, the rigid cabin will remain stationary during the simulation process. The generator is simplified to a rotary joint of 17.2 rpm. The three-bladed rotary joint, which runs parallel to the engine room’s center line, joins the compartments together. The shaft can be rotated by the blades. Each blade’s root does not flex during rotation, yet the elastic blade may move about freely. The combined effects of inertial force, elastic force, and aerodynamic force operate on the blade as it rotates, and gravity, Coriolis force, and centrifugal force are the three basic types of inertial force. As illustrated in

Figure 15, the multi-point approach is used to apply the aerodynamic force to the blade structure of each blade section after the aerodynamic force has been computed using the free vortex wake method. The multi-body approach developed in this study is used to determine the structure’s dynamic response [

57].

The guide-roller system at their interfaces is used to link the two rigid bodies that make up the MWWC system (a monopole type FWT and a heave type WEC), as illustrated in

Figure 16. The AQWA code, which is adaptable for modeling multi-body systems and can accommodate the introduction of both mechanical and hydrodynamic couplings between two bodies, was used to simulate the hydrodynamic properties and the coupling interaction effects of two rigid bodies involved in the MWWC system. In

Figure 17 [

58], hydrodynamic panel models are displayed.

With regard to the role of swell, there is no ocean condition in multiple directions, which may lead to the difference between the average direction and the peak direction. Therefore, the average wave direction is a good estimate of the wave direction, and the uncertainty is within 30° (93% confidence interval). In order to construct the wind rise and wave rise as shown in

Figure 18, the directions are divided into 12 directions, 30° each, and the distance between the main wind direction and the wave is 10° [

59].

It can be seen from

Figure 19 that the studied section is separated by a 1 m thick segmented uniform layer. When the depth exceeds 80 m, it is assumed that the shear rate is constant with the depth (half space domain). Soil density

ρs = 1800 kg/m

3, Poisson’s ratio

νs = 0:35, and the hysteretic damping factor

ξs = 5% remains unchanged. The suggested approach consists of a three-step process that creates a simplified model to analyze the variations in fundamental frequency and damping brought on by the rigidity of the foundation [

60]. The soil profiles assumed for the sites in the analyses are presented in terms of the shear wave velocity cs in

Figure 19. The value of the cs, 30 (Eurocode, 2004), for each profile is also displayed above each plot as it is widely used to characterize the soil. The selected profiles correspond to C (180 < cs, 30 < 360 m/s) or D soils (cs, 30 < 180 m/s), which are the ones that OWT systems are usually founded on.

The temporal history of the rotor speed and pitch angle during the initial seismic loading excitation is shown in

Figure 20. The test findings demonstrate that during typical operation, the rotor speed and pitch angle fluctuate continually. According to the characteristics of boundary element method and airfoil, it is ascertained that under normal working conditions, the average value of trust on the tower top will be larger than that in the parking state due to the shift in rotor speed and pitch angle. This is why the average value of structural response in the first case is greater than that in the second case. Modeling findings suggest that, when subjected to both earthquake and aerodynamic forces, the dynamic response of large wind turbines is reduced compared to when they are in a stationary state under normal conditions [

61].

5. Aeroelastic Coupling Analysis of the Flexible Blade of Large Wind Turbines

In NREL 5 MW HAWT blades, four super-elements are used to construct the blade topology, as shown in

Figure 21. Because the last rigid body of the supercell is rigidly connected with the first rigid body of the next adjacent supercell, they can be combined into a rigid body (the merged bodies are shown in

Figure 21 as B4, B7, and B10). In this way, the blade is divided into 13 rigid bodies with a total of 21 DOFs [

62].

The speed of LSS is consistent with the reference. This is because the coupling equation estimates the required torque, so that the support in the gearbox can achieve the reference speed, so that sufficient load transfer can be carried out on the gearbox connected to the generator. It must be underlined that the carrier speed depicted in

Figure 22b corresponds to the solution of the state given to the carrier once the EOMs are resolved at each instant (that is, the dynamic response of the carrier). The mechanical controller used in this test is carried out according to the reference value and compensates forthe step change of power accordingly. In the transient process, damping plays a key role in the whole system. Although the steady-state values of the rotor speed are compared, there are differences in the changing rules of the rotor speed under the stable state. This is because the control parameters of the simulation and the actual system are different. In addition, the torque reached its peak at about 110 s. In this case, the vibration is due to the change of speed step, as shown in

Figure 22b. However, from the consistency of test results and simulation results, the damping in the model is reasonable [

63].

As an illustration,

Figure 23 depicts the dynamic reaction of an NREL-5MW RWT’s rotor under changing circumstances brought on by tower interference. The NREL-5MW RWT served as the foundation for constructing scenarios of quick pitch-control actuation for the current study. It is a well-known benchmark for a cutting-edge turbine. Measurable qualities in the presence of the tower revealed fluctuations that impact the loads operating on the rotor and its performance, such as variations in thrust and torque as well as power deficits. When the NREL-5MW RWT is operating at its nominal operational settings of 12:1 rpm, the instantaneous power P is shown in

Figure 23a for a period of 5 s, which is comparable to the period of rotation. The three pulsations in the instantaneous power generated each time a blade crosses in front of the tower are seen in the 5 s span. Along with a reduction in average power relative to a rotor running without tower interference, pulsation also has an adverse impact on instantaneous power, as shown by the horizontal lines in

Figure 23 [

64]. As an example of the fluctuating aerodynamic conditions on the blade sections,

Figure 23b shows the angle of attack on the section located at 90% span from the root of the blade.

The reference wind turbine’s single pile foundation (bending moment, Mx), tower top (displacement, dy), and dynamic (time-history) response are shown in

Figure 24 under the effect of various hazardous environments in three operating scenarios. It should be pointed out that after 300 s, seismic excitation, namely the seismic activity of Northridge and Tabas, requires more energy after 300 s. The same conclusion is also obtained by seismic excitation of OWTs supported by tripod and jacket. Especially in the 5 MW power system, due to the impact of the earthquake, the demand coefficients of Mx and dy increased by 496% on average, while the demand coefficients of dy increased by 425% on average. Such seismic damage management emphasizes the need to incorporate seismic forces into the structural design and evaluation of wind turbines [

65,

66].

Figure 25 shows that in order to help the reader understand the basic assumptions discussed in the next part, the model will be introduced briefly, and then we will use the nonlinear model to test the linear perturbation dynamics. The platform, engine room, and rotor are rigid bodies, and the only elastic body is the tower. This model does not contain a single rotor blade but simulates the rotor as a rigid disk. This model has been greatly simplified and provides a clearer view of the main system dynamics [

67].

As mentioned in the introduction, the OWT supported on the jacket is a fixed base structure, while the role of SSI is ignored. Under this assumption, the legs of the substructure are connected with the mud line. In this part, the overall maximum average response of the OWT structure under the rated wind speed has been studied. This is compared with the response obtained by including soil components, as shown in

Figure 26. Different from the model based on the fixed model, the introduction of soil will make the system more flexible to some extent, which will improve the response, and its size depends on the soil stiffness [

68]. As observed from

Figure 26, the stiffer, dense sand has a lateral response marginally greater than that of the fixed OWT. However, offshore wind farms may not always be sited on such uniform, ideal soil profiles and this necessitates the analysis of OWTs using realistic soil data, which may be layered.

The upwind flow field is far field potential and disturbance potential φ

T. The sum of T shows the flow curve of Y = r

T and −10r

T in

Figure 27 (tower radius 0.2 m). On this basis, the unsteady aerodynamic characteristics of the floating wind turbine under platform surge motion are predicted. The aerodynamic characteristics of a floating wind turbine, the stability of releasing eddy current, and aerodynamic stability are analyzed in detail [

69]. After the flow has passed through the tower it reattaches, as it is an inviscid ideal potential flow. According to a previous study, the theoretical analysis of the potential flow around a circular cylinder is almost the same as an experimental test in the upwind region and differs from the actual flow thereafter.

6. Conclusions

The dynamic parameters of the flexible multi-body system are analyzed to enhance the stability of the wind turbine and prevent structural fracture caused by abnormal dynamic parameters, so as to drive parts for manufacturing wind turbines, optimize the design, research, and development, and drive the growth of manufacturing industry. Wind turbine detection and maintenance can maintain the normal power generation efficiency of wind turbines, so that it gradually becomes a kind of industry. The manufacture of batteries is closely linked with wind power generation, and energy storage has become a research direction. Wind turbine construction in the seaside or grassland, where the scenery is better, can help to develop tourism. The growth of the wind energy industry to promote economic development is effective and feasible.

The sustained growth of technology and the gradual accumulation of wind power operating experience, wind turbine prices, wind farm investment, and operation maintenance costs will bring down the cost of wind power generation. With the market regulation and the integration process having been accelerated, Chinese wind farms and the industry concentrations have gradually improved. Thos promotes acceleration of the integration of the wind power parts industry and the experience of a high-speed development stage of the dynamic response of flexible multi-body large wind turbines that is going through the industry structure optimization adjustment period. Meanwhile, wind turbine blade optimization, pile foundation structure design of wind turbines, and flexible multi-body dynamics need to be studied in the future.

The interaction and coupling between elastic deformation and rotational motion of flexible blades of large wind turbines during their rotation around the axis of the wind turbine is particularly important for the design of their aeroelastic stability and control system. It is the core feature of multi-body system dynamics to study the interaction or coupling between object deformation and rigid body motion and the dynamic effect caused by this coupling. Studying the stability of flexible multi-body system of wind turbines can provide reference value for the normal and stable operation of wind turbines.