Complex Analysis of an Auxetic Structure under Compressive Loads

Abstract

1. Introduction

- −

- flexible design—unlimited possibilities from the point of view of shape/geometry (samples with complex geometry, geometry that would be hard or impossible to achieve using conventional technology);

- −

- minimizing waste [2];

- −

- time manufacturing reduction by eliminating operations and planning the production process [53];

- −

- improved efficiency and increased productivity for prototypes and spare parts on a small or medium scale;

- −

- flexibility and agility;

- −

- reduced costs by the removal of traditional process tools and procedures [66].

- −

- reduced surface finish;

- −

- limited range of materials that can be used;

- −

- limited dimensional tolerances (can be caused by raw material’s dimensions);

- −

- reproducibility/repeatability.

2. Theoretical Background

- −

- −

- −

- the rotation of the rigid nodes generates internal forces and moments;

- −

- internal forces that are oriented in a direction perpendicular to the externally applied stress vanish;

- −

- shear deformations of the ligaments are neglected;

- −

- the reaction force is determined by the dimensions of the unit structure and the number along the horizontal axis;

- −

- the deformation range (plateau length) is dependent on the number of units in the vertical direction [85];

- −

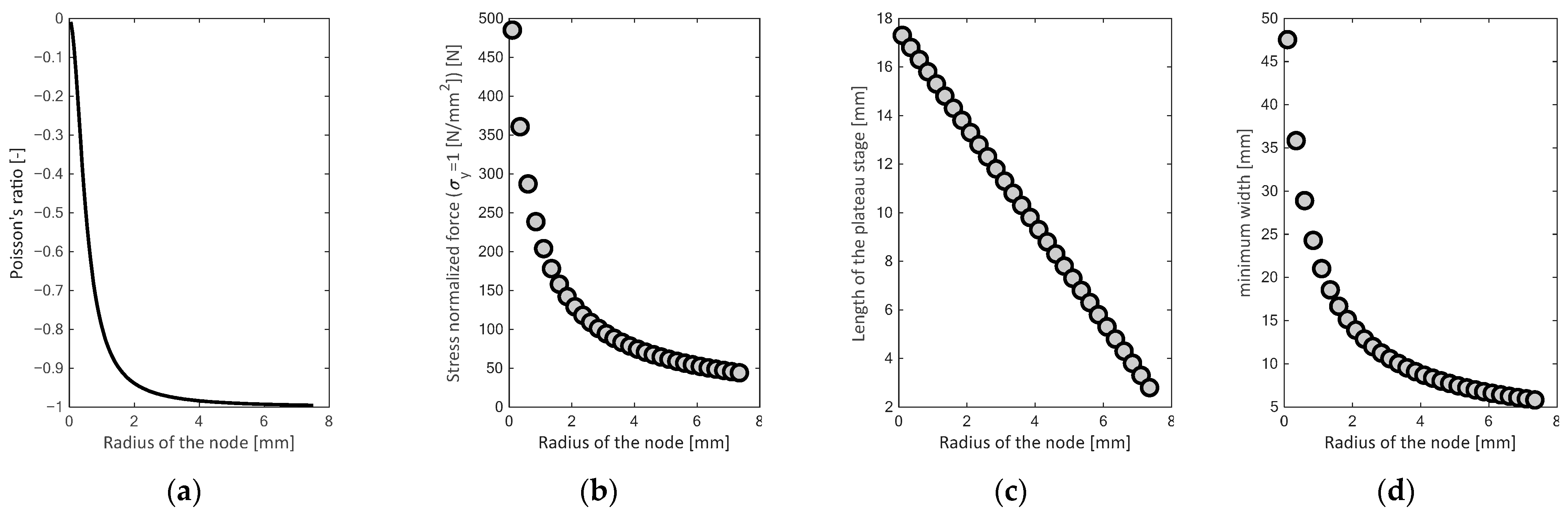

2.1. Poisson’s Ratio

2.2. Plateau Force

2.3. Plateau Length

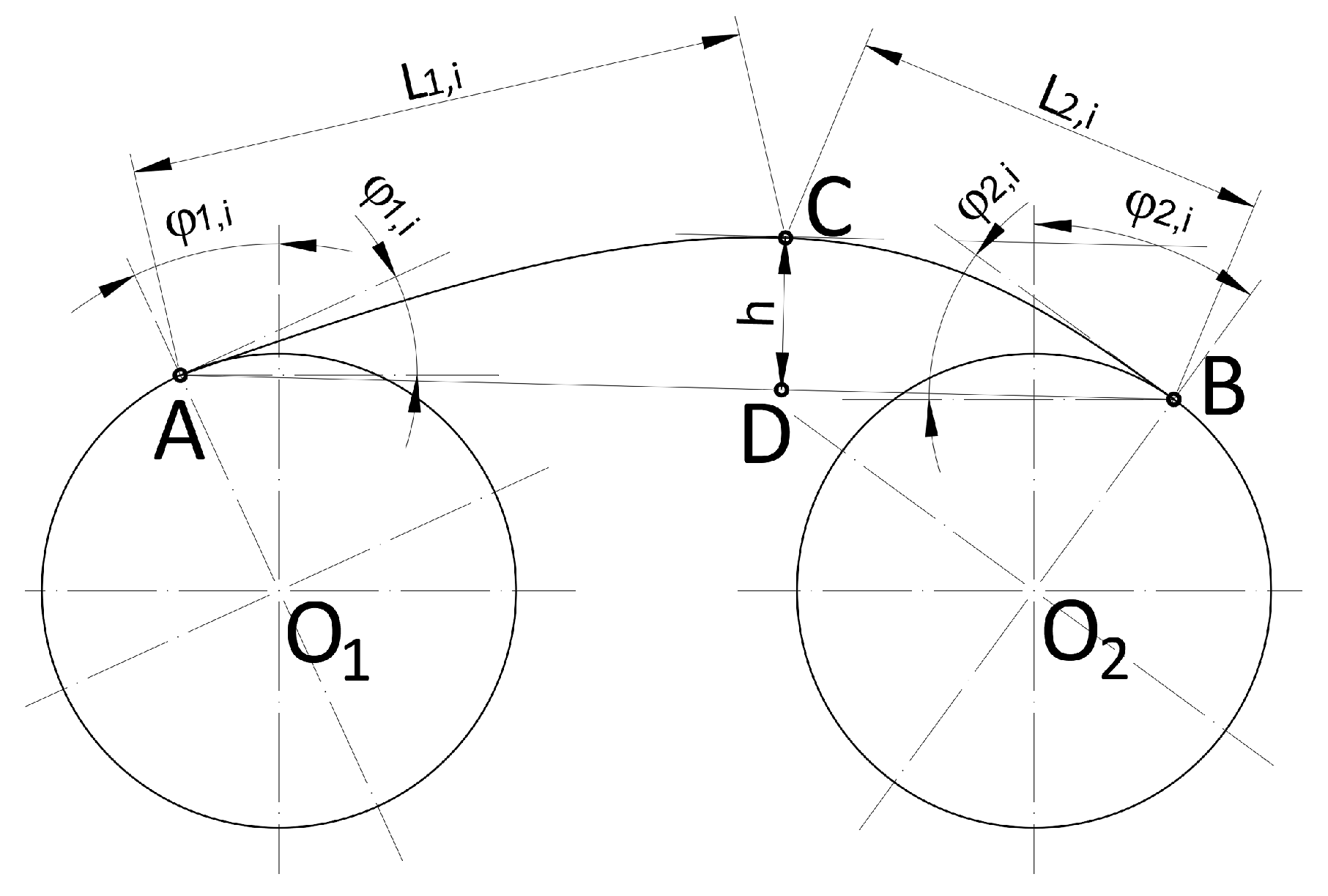

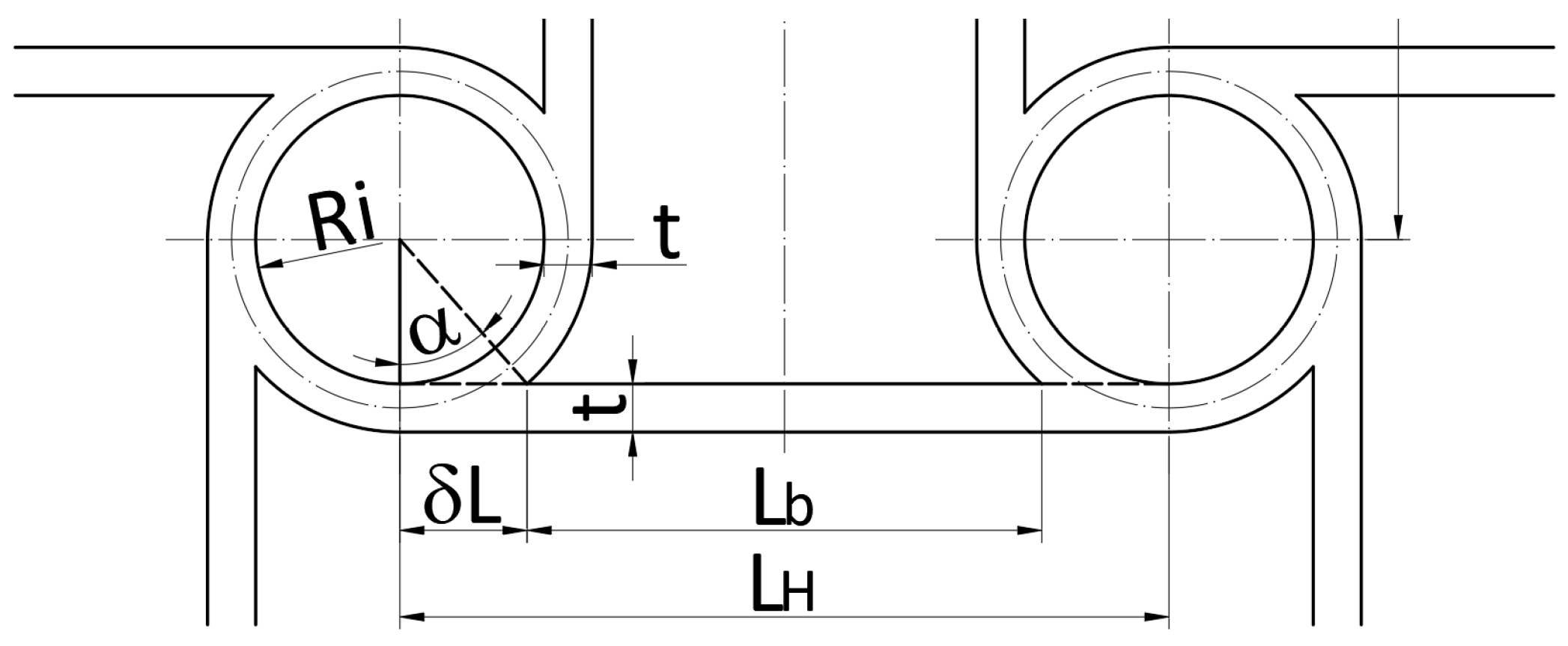

2.4. Geometrical Features of the Structure (Stable Axial Compression Process)

2.5. Model of the Nodal’ Vertical Displacements

2.6. Strain Analysis

3. Material Model

3.1. General Information

- −

- at a temperature equal to 105 °C, the material becomes fluid;

- −

- it is cheap/raw material is available;

- −

- it has excellent characteristics in terms of malleability, being easily transformed into parts of simple or complex shapes;

- −

- it has a low weight, much lower than ordinary metals or even aluminum;

- −

- it is very rigid, resistant to shocks and pressure;

- −

- it can be colored;

- −

- it resists ultraviolet radiation thanks to the added additives, which makes it suitable for the production of plastic objects that are in direct sunlight;

- −

- it has excellent performance, in a wide range of temperatures, without visible degradation;

- −

- it is easy to glue by using common substances;

- −

- it can be printed and painted thanks to its glossy surface;

- −

- it insulates electrically at various temperatures and even in the presence of moisture;

- −

- it sustains a certain amount of deformation before yielding, returning to its original shape when the pressure is stopped.

- −

- it is not environmentally friendly;

- −

- it does not resist certain solvents (there are solvents that can dissolve it, and because of this, it cannot be used in certain fields, such as the chemical industry);

- −

- ABS is more expensive than other types of plastic, such as polystyrene and polyethylene;

- −

- burning ABS plastic can produce dangerous gases, which is not desirable;

- −

- the chemical composition of this type of plastic makes it non-biodegradable;

- −

- there is limited use of ABS in the food industry because there are not enough studies to demonstrate the long-term effects of ABS plastic packaging on human health.

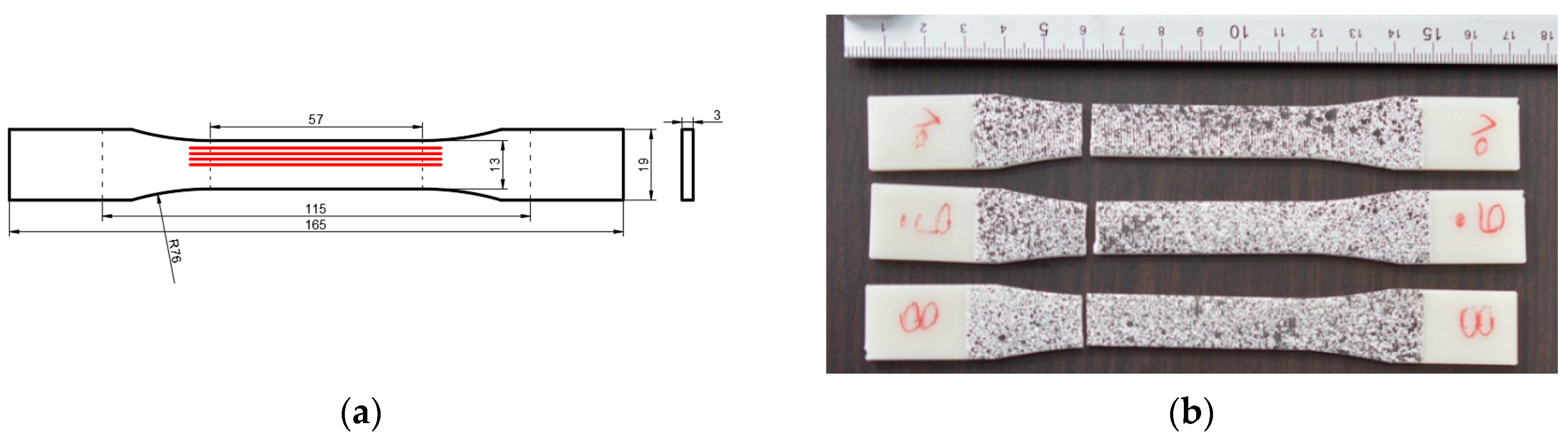

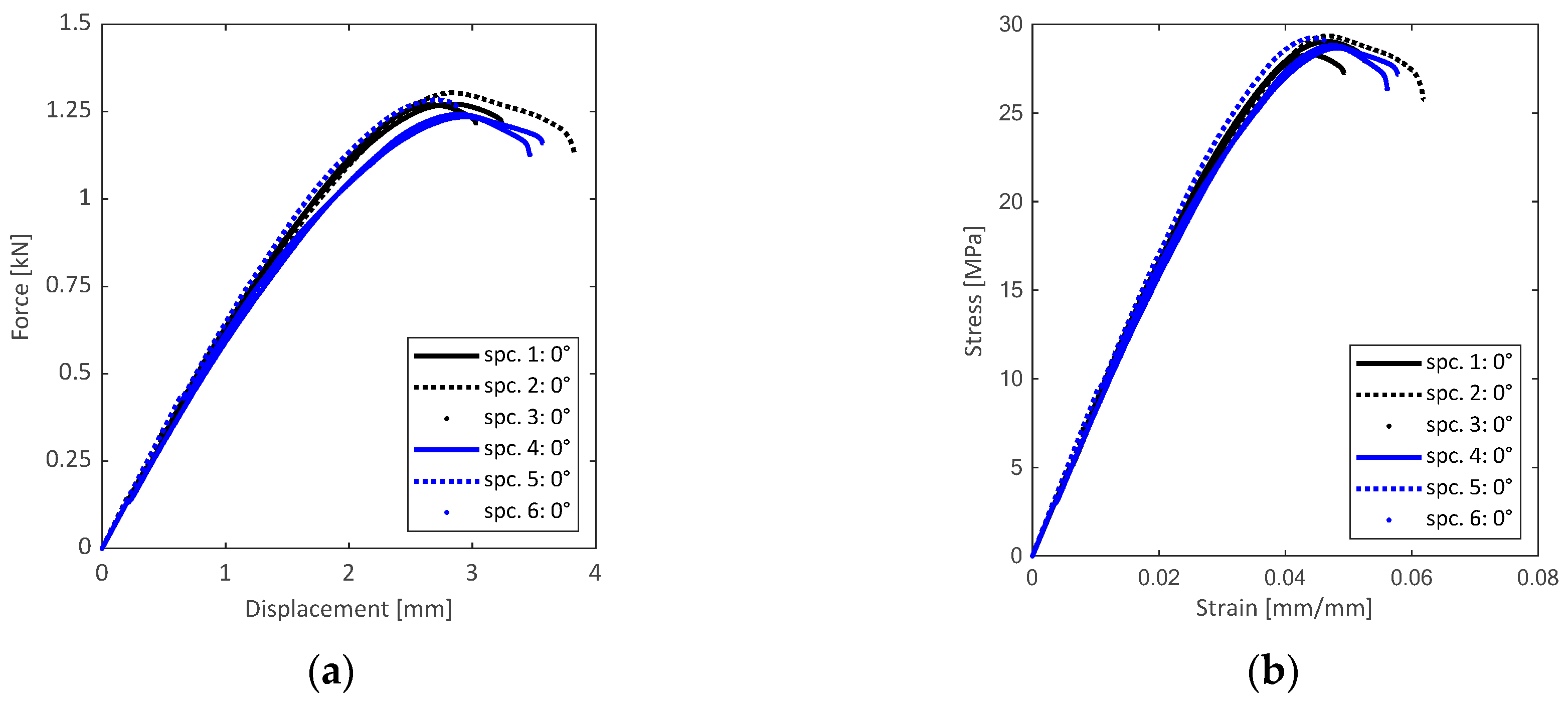

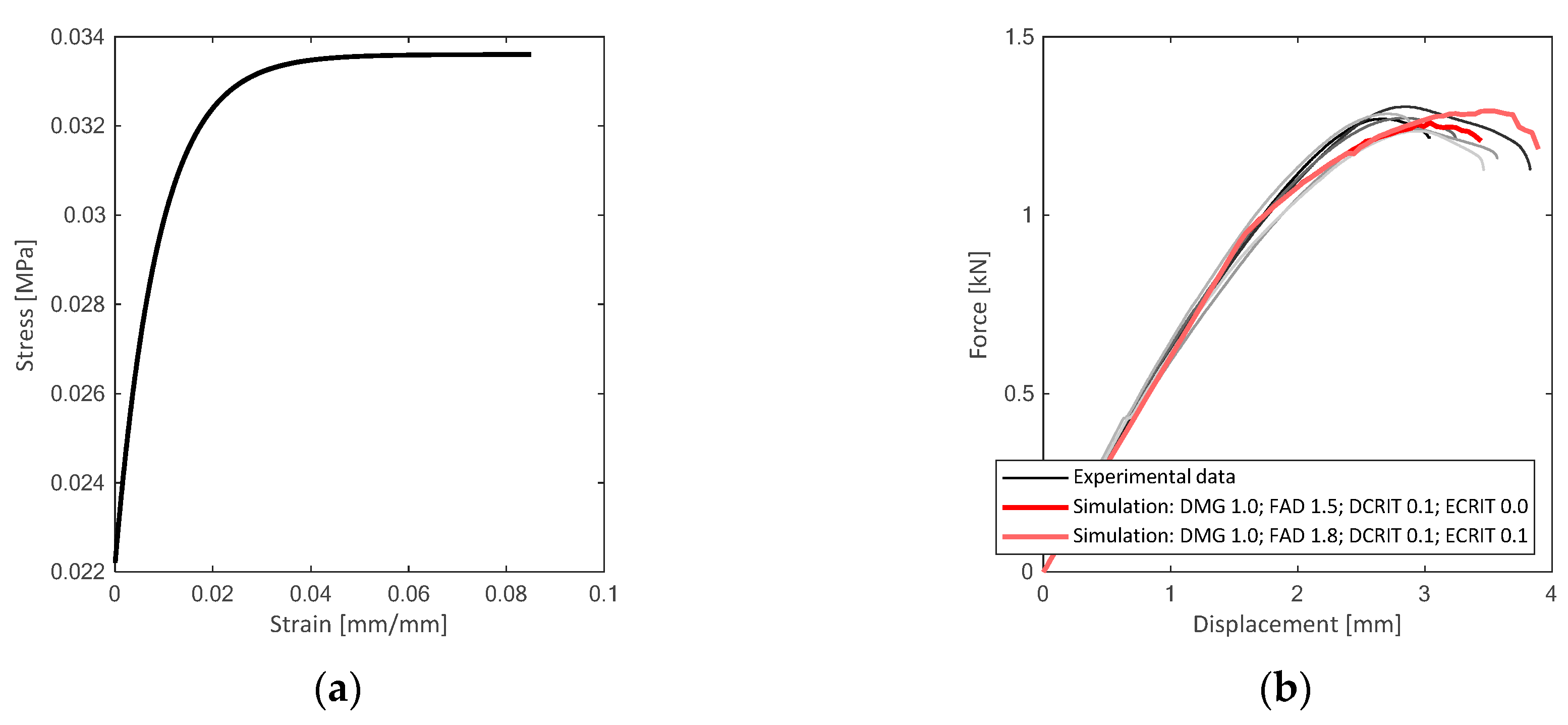

3.2. Standard Material Model

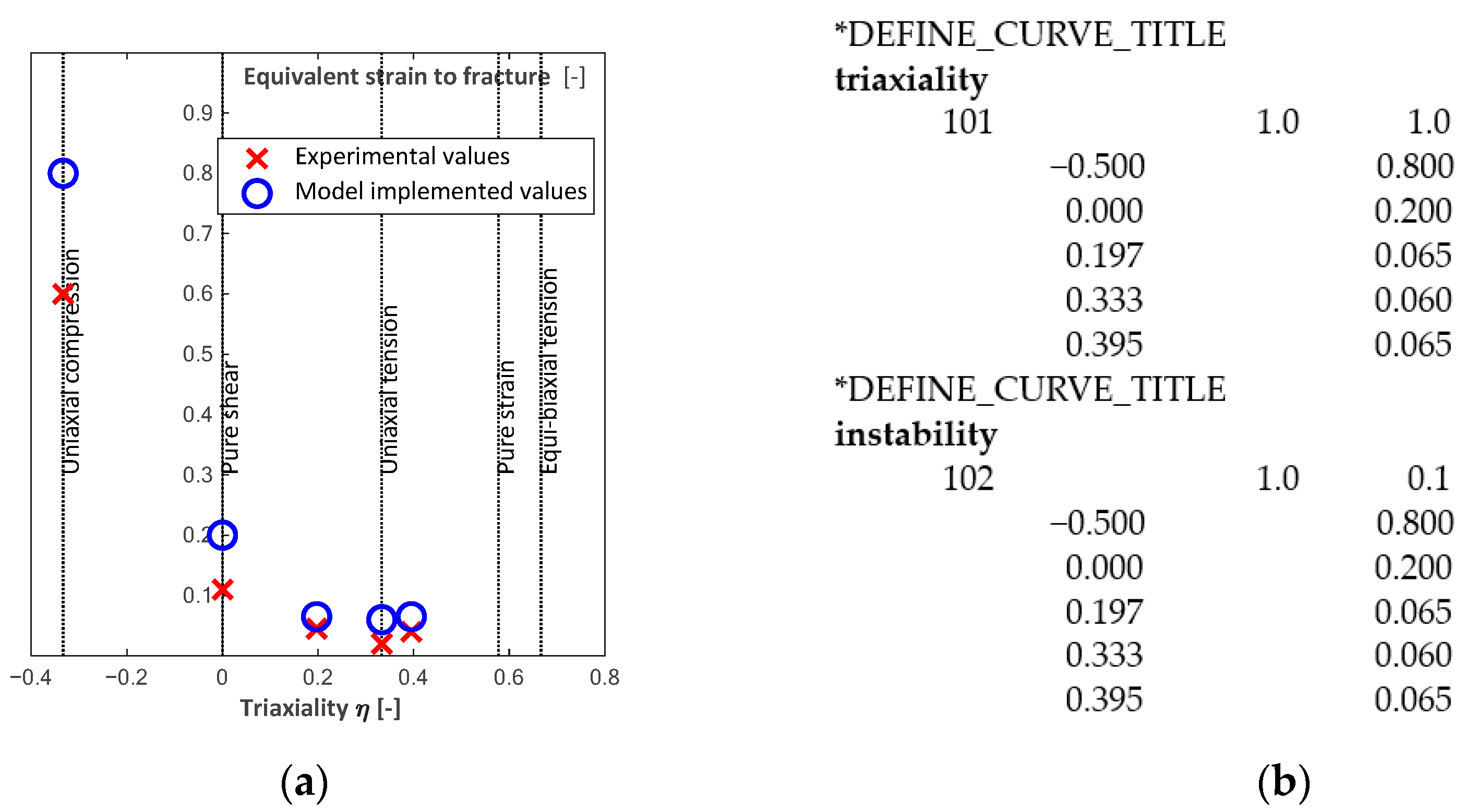

3.3. Material Failure Mechanism

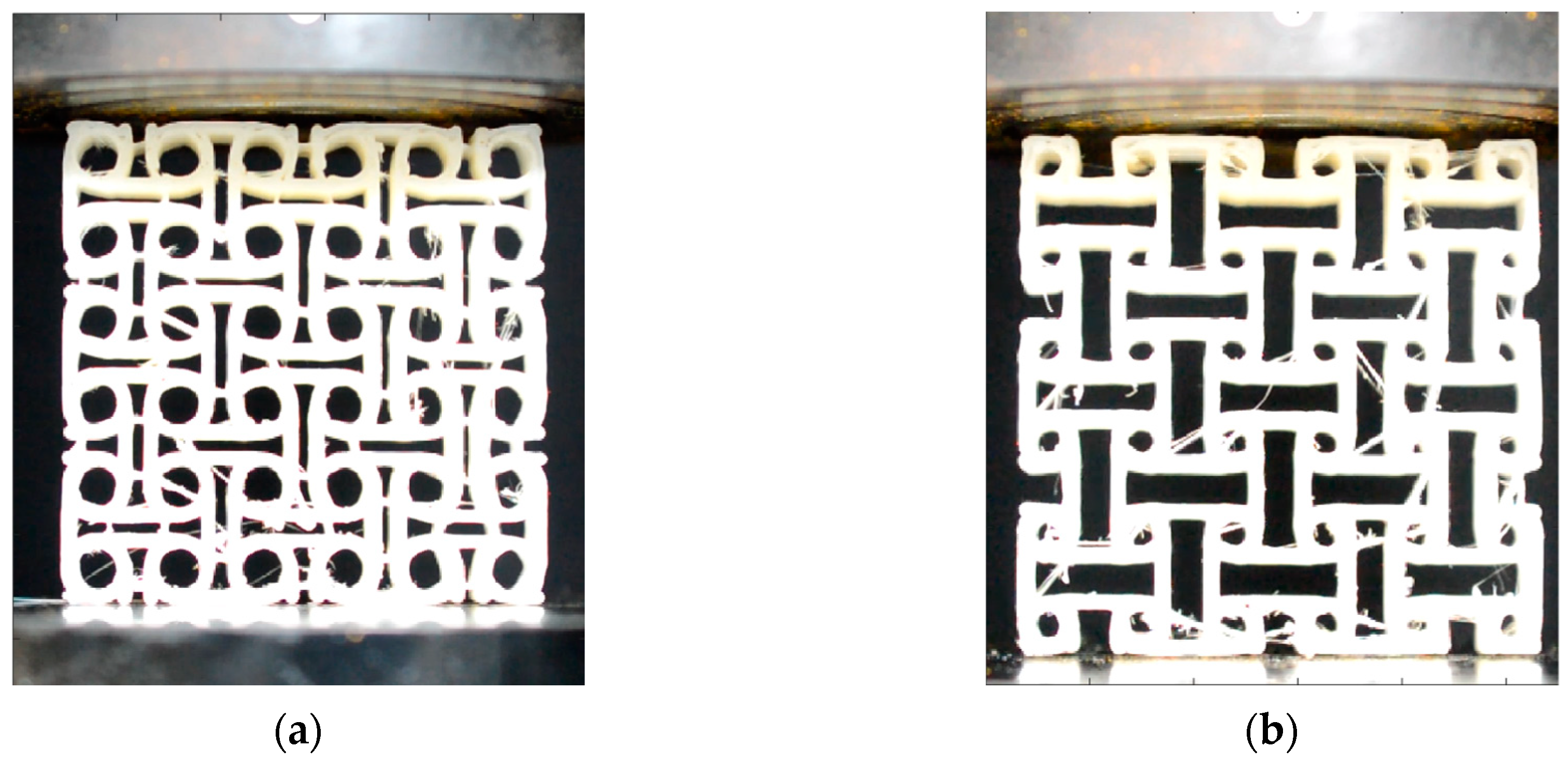

4. Experimental Analysis

4.1. Geometrical Definition of the Experimental Parts

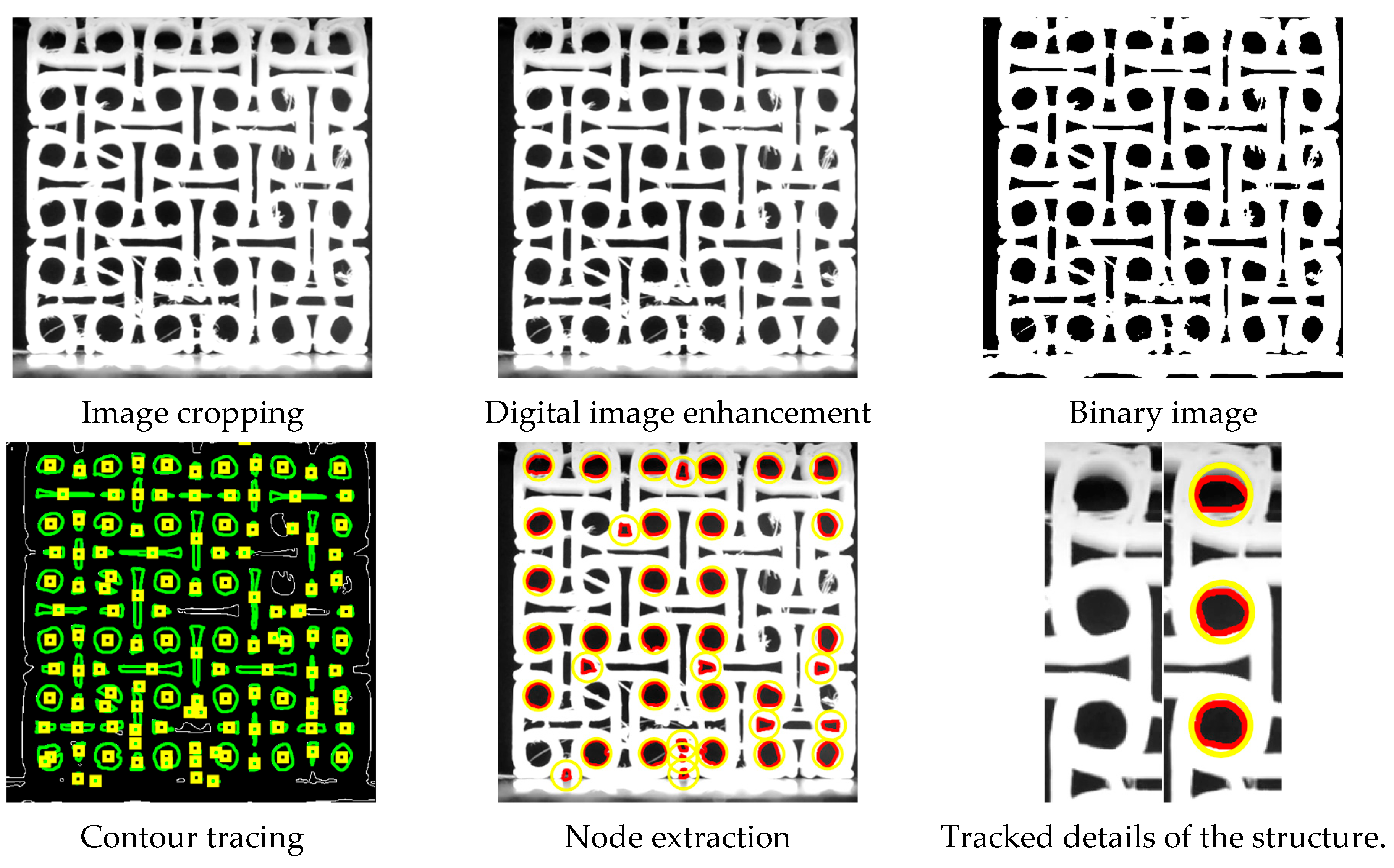

4.2. Compression Test and Data Processing

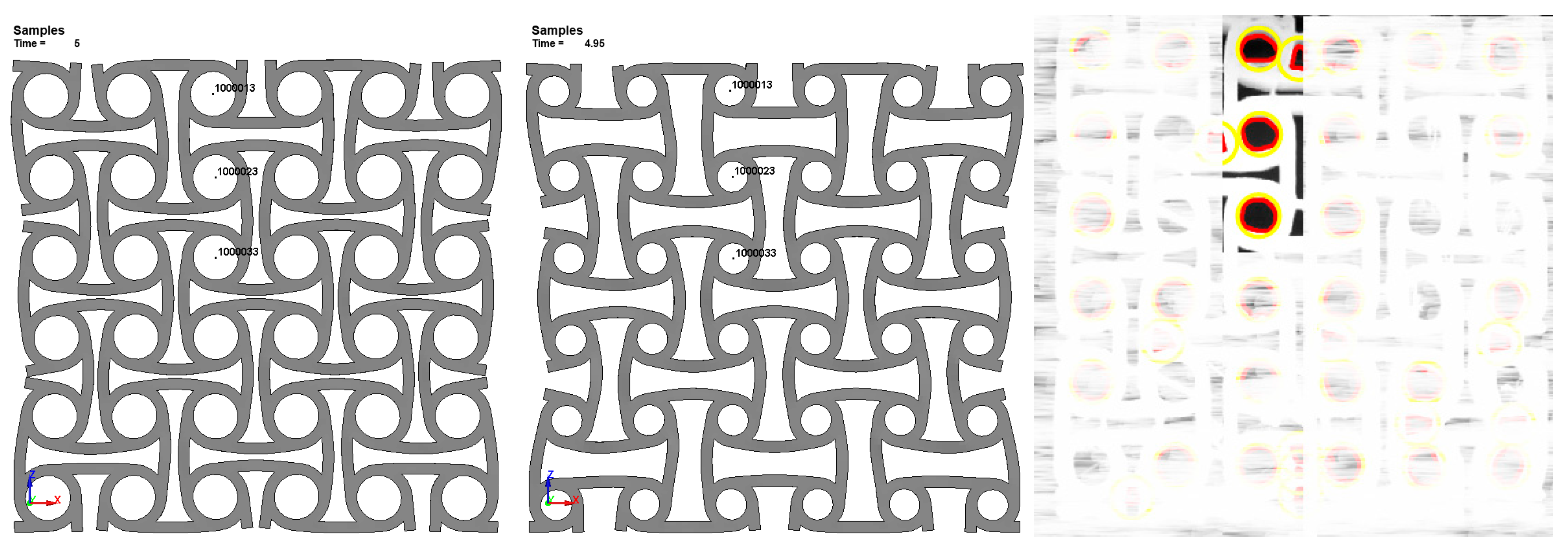

5. Numerical Modeling and Simulation

5.1. Numerical Modeling

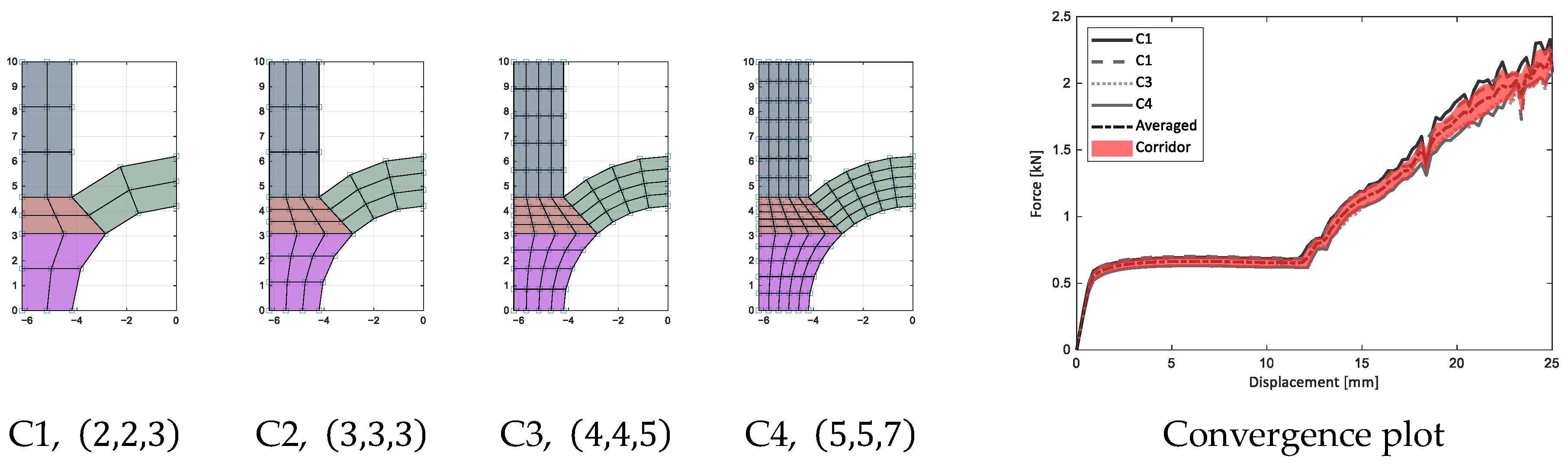

5.2. Convergence Analysis

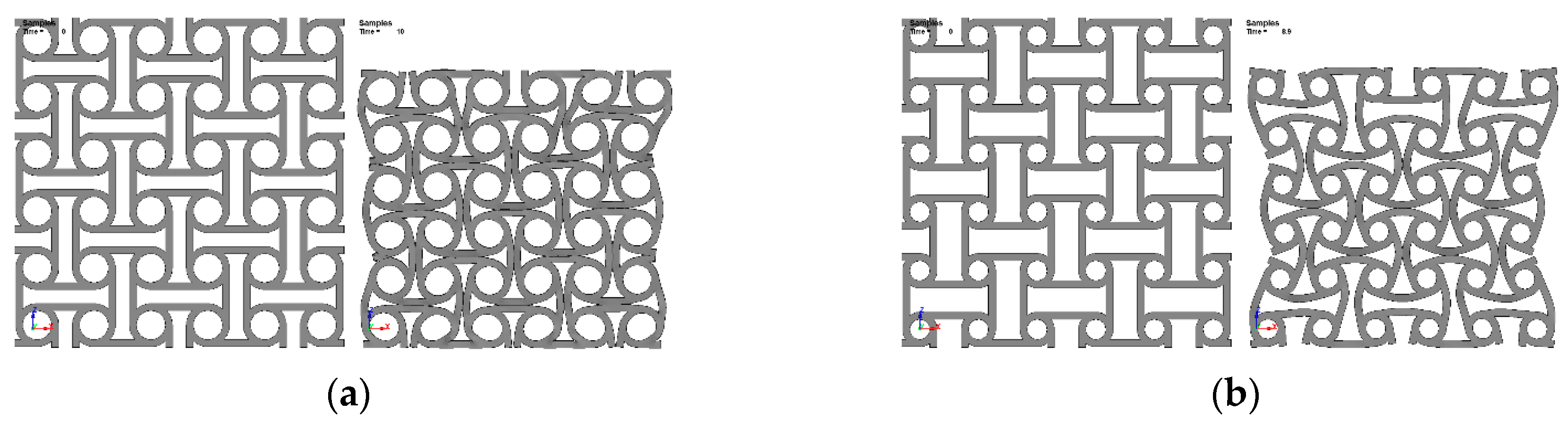

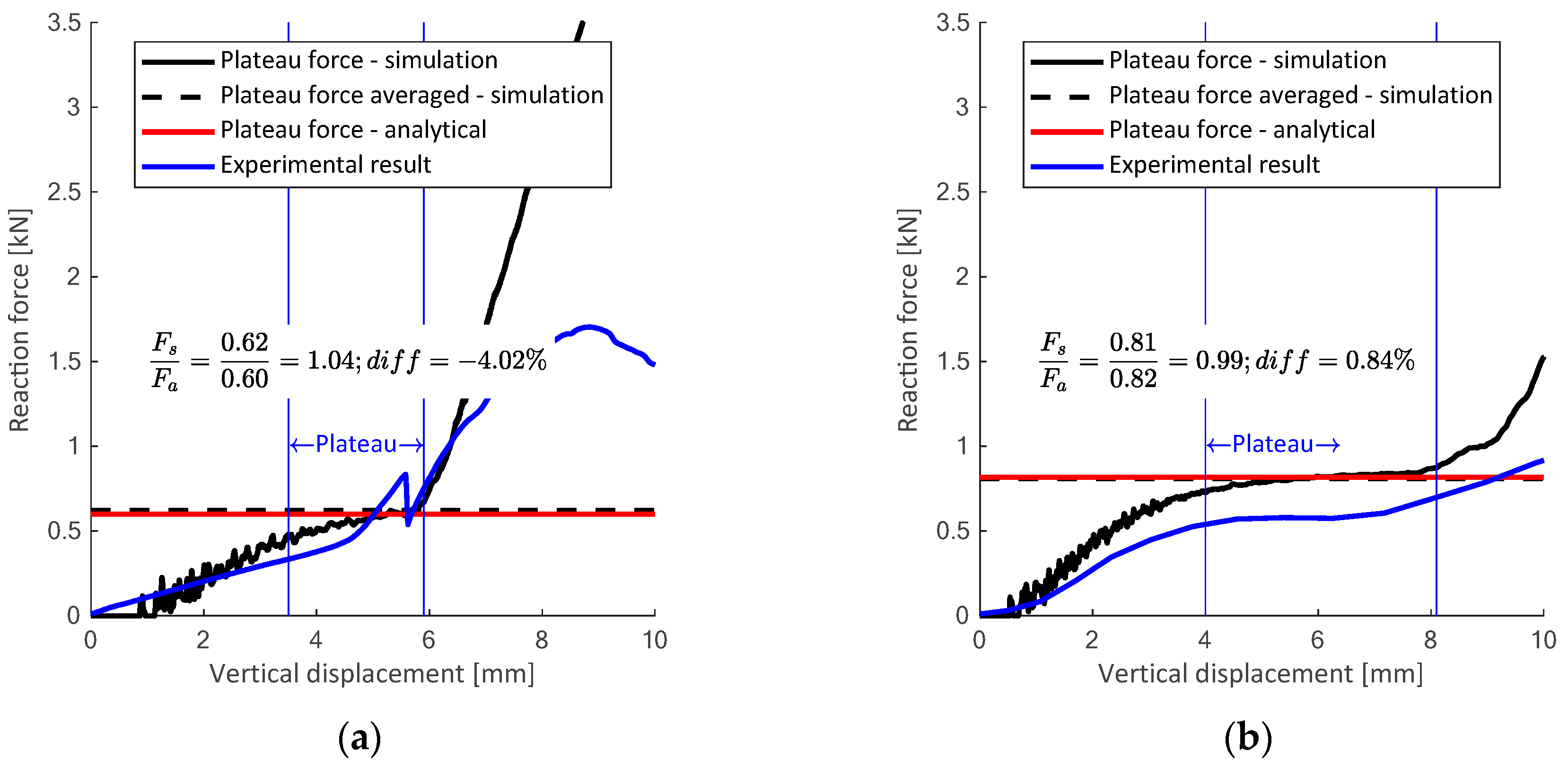

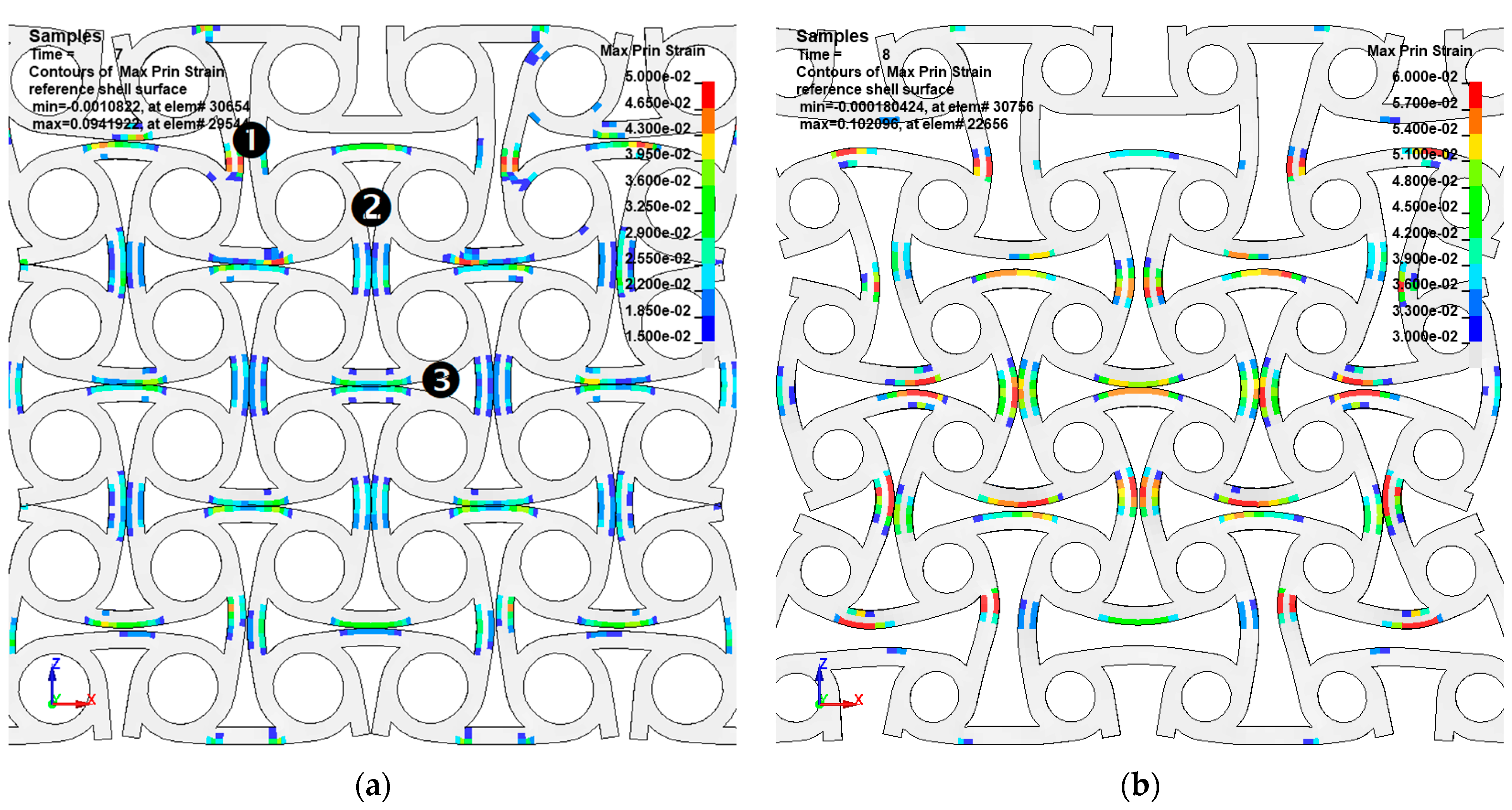

5.3. Analysis of the Results

6. Discussion

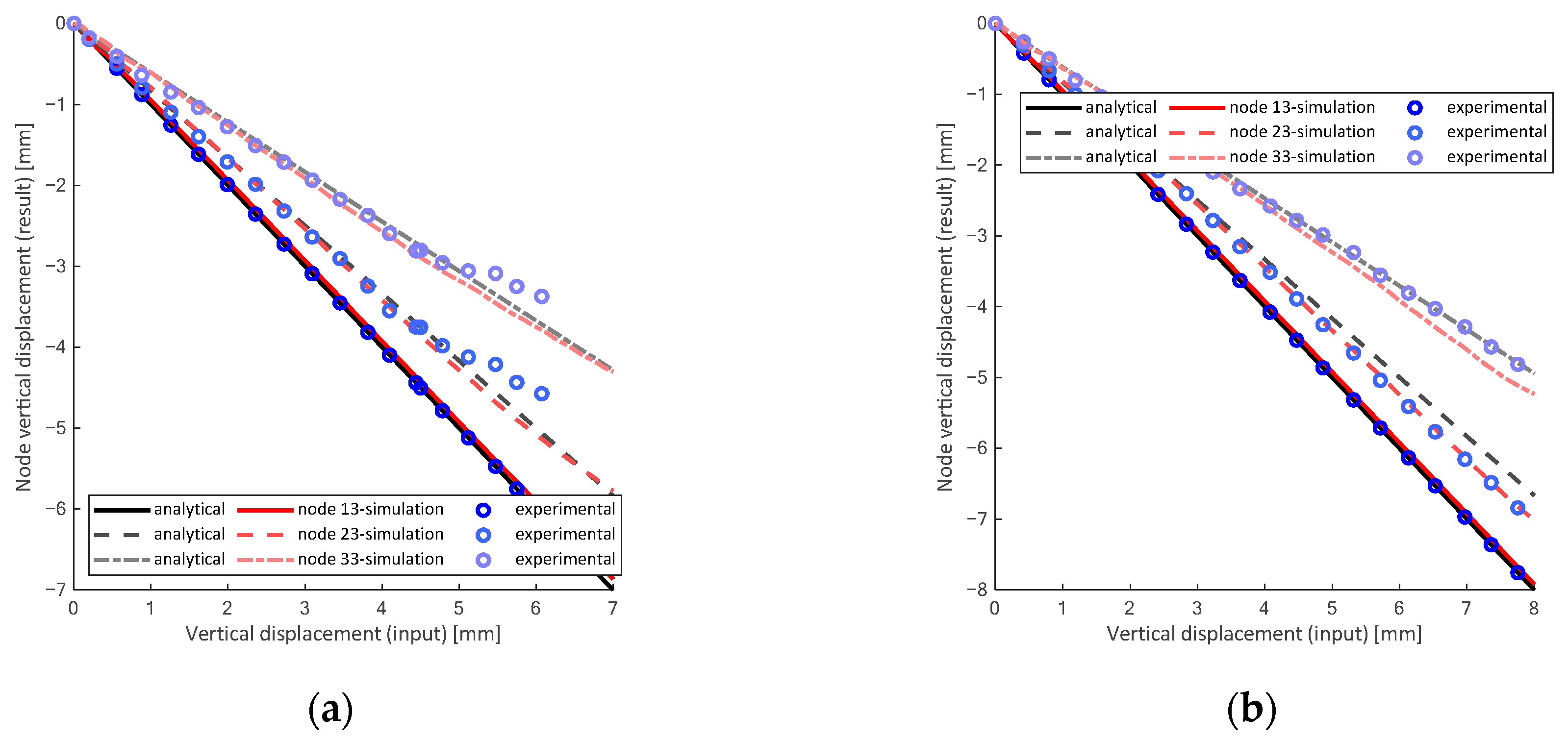

6.1. Analysis of the Vertical Displacements of the Node

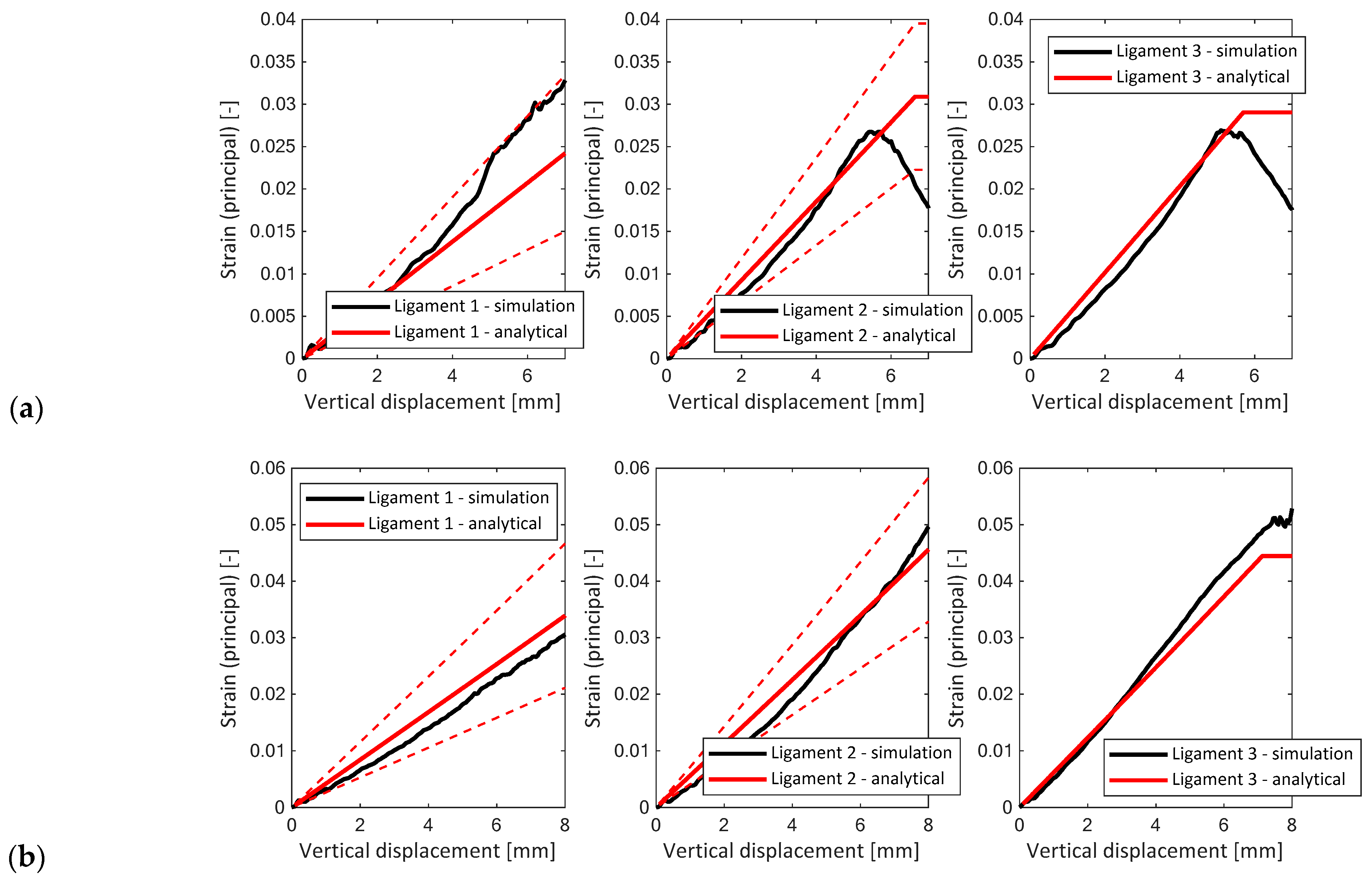

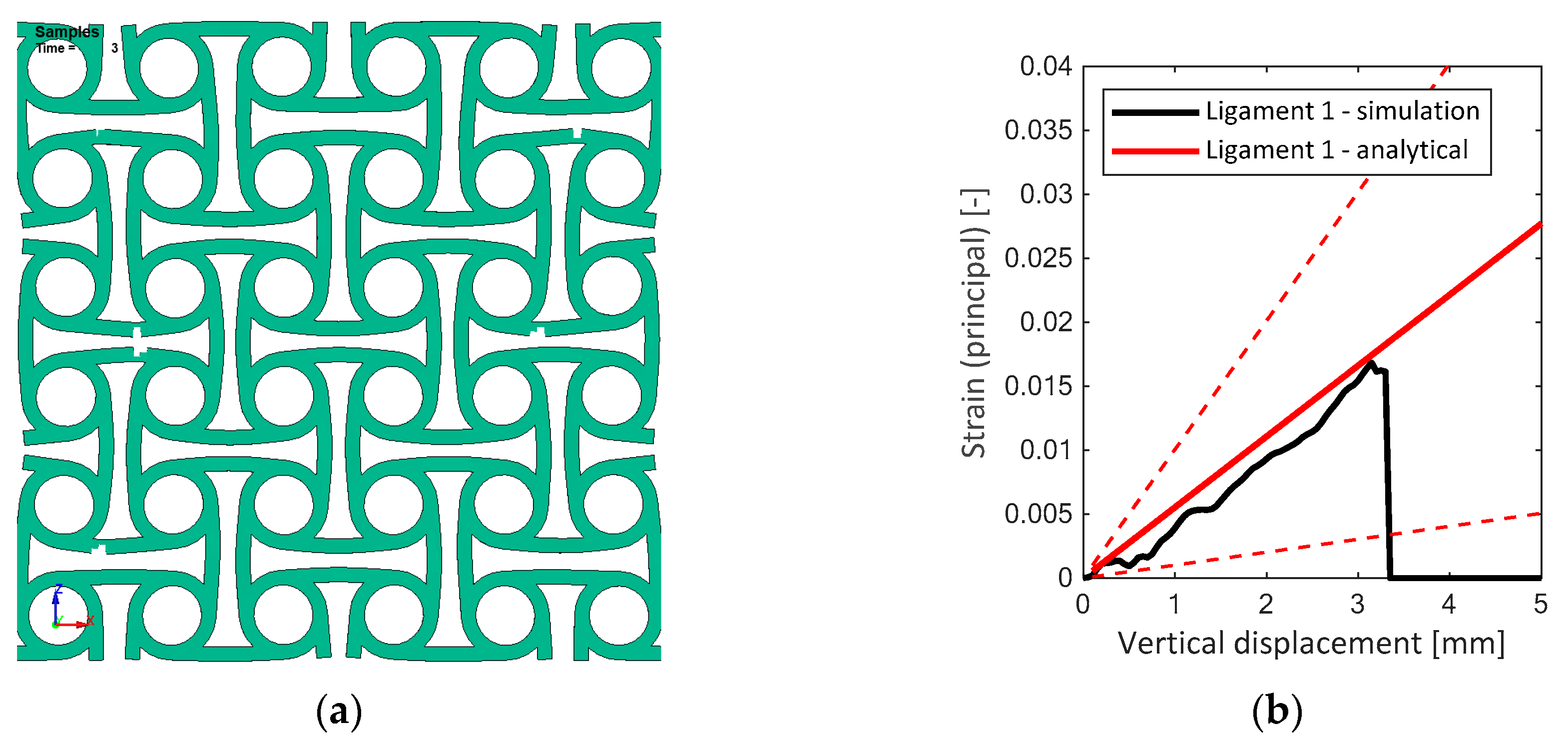

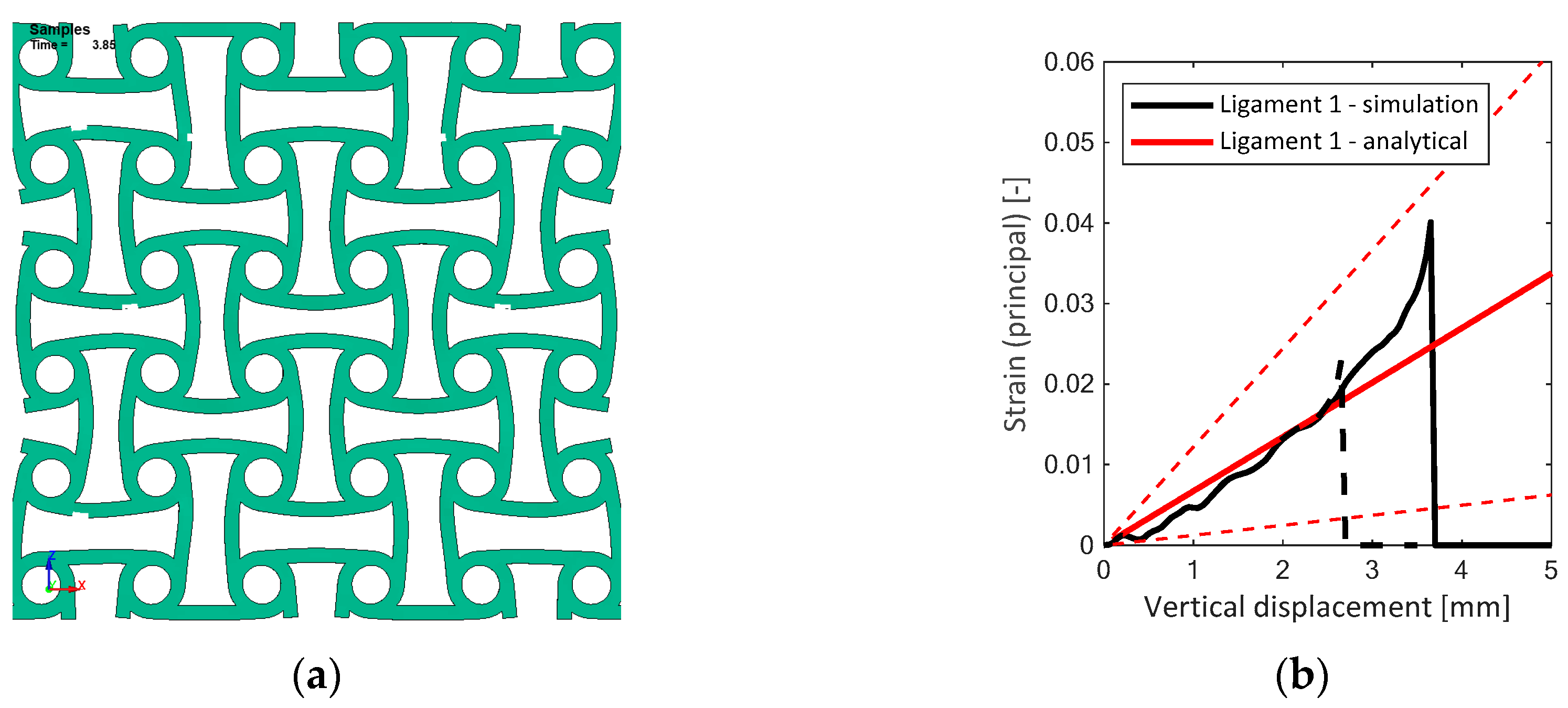

6.2. Strain Analysis

7. Conclusions

- −

- Poisson’s ratio—that is the main parameter of an auxetic structure;

- −

- plateau force—which displays the structural response of the structure under compressive loads;

- −

- plateau length—which outlines the compression performance;

- −

- buckling—which provides a required dimensional verification of the structure subjected to compression;

- −

- ligament strain—which investigates the capability of the structure to develop the predicted plateau force during the plateau stage.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Determination of the Bent Lengths of the Ligaments

References

- Santos, J.; Gouveia, R.M.; Silva, F.J.G. Designing a New Sustainable Approach to the Change for Lightweight Materials in Structural Components Used in Truck Industry. J. Clean. Prod. 2017, 164, 115–123. [Google Scholar] [CrossRef]

- Sartal, A.; Bellas, R.; Mej, A.M.; Garc Ia-Collado, A. Sustainable Manufacturing-Review Article The Sustainable Manufacturing Concept, Evolution and Opportunities within Industry 4.0: A Literature Review. Adv. Mech. Eng. 2020, 12, 1687814020925232. [Google Scholar] [CrossRef]

- Shen, L.; Wei, K.; Yuan, K.; Shi, C.; Li, Z.; Wang, Z. A Novel Metamaterial Incorporating Both Auxeticity and Thermal Shrinkage. Int. J. Mech. Sci. 2022, 233, 107650. [Google Scholar] [CrossRef]

- Tao, Z.; Ren, X.; Zhao, A.G.; Sun, L.; Zhang, Y.; Jiang, W.; Han, D.; Zhang, X.Y.; Xie, Y.M. A Novel Auxetic Acoustic Metamaterial Plate with Tunable Bandgap. Int. J. Mech. Sci. 2022, 226, 107414. [Google Scholar] [CrossRef]

- Chadha, K.; Mahesh, V.; Mangalasseri, A.S.; Mahesh, V. On Analysing Vibration Energy Harvester with Auxetic Core and Magneto-Electro-Elastic Facings. Thin-Walled Struct. 2023, 184, 110533. [Google Scholar] [CrossRef]

- Balan, P.M.; Mertens, A.J.; Bahubalendruni, M.V.A.R. Auxetic Mechanical Metamaterials and Their Futuristic Developments: A State-of-Art Review. Mater. Today Commun. 2023, 34, 105285. [Google Scholar] [CrossRef]

- Ammar, M.; Haleem, A.; Javaid, M.; Bahl, S.; Garg, S.B.; Shamoon, A.; Garg, J. Significant Applications of Smart Materials and Internet of Things (IoT) in the Automotive Industry. Mater. Today Proc. 2022, 68, 1542–1549. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Additive Manufacturing Applications in Industry 4.0: A Review. J. Ind. Integr. Manag. 2019, 04, 1930001. [Google Scholar] [CrossRef]

- Suhaib Kamran, S.; Haleem, A.; Bahl, S.; Javaid, M.; Prakash, C.; Budhhi, D. Artificial Intelligence and Advanced Materials in Automotive Industry: Potential Applications and Perspectives. Mater. Today Proc. 2022, 62, 4207–4214. [Google Scholar] [CrossRef]

- Lim, T.-C. Mechanics of Metamaterials with Negative Parameters; Springer Nature: Singapore, 2020; ISBN 978-981-15-6446-8. [Google Scholar]

- Kolken, H.M.A.; Zadpoor, A.A. Auxetic Mechanical Metamaterials. RSC Adv. 2017, 7, 5111–5129. [Google Scholar] [CrossRef]

- Montgomery-Liljeroth, E.; Schievano, S.; Burriesci, G. Elastic Properties of 2D Auxetic Honeycomb Structures—A Review. Appl. Mater. Today 2023, 30, 101722. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Tanaka, S.; Hokamoto, K.; Ren, Z. Compressive Behaviour of Chiral Auxetic Cellular Structures at Different Strain Rates. Int. J. Impact Eng. 2020, 141, 103566. [Google Scholar] [CrossRef]

- Shirzad, M.; Zolfagharian, A.; Bodaghi, M.; Nam, S.Y. Auxetic Metamaterials for Bone-Implanted Medical Devices: Recent Advances and New Perspectives. Eur. J. Mech. A Solids 2023, 98, 104905. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; He, N.; Wang, C.H. Crashworthiness Behavior of Koch Fractal Structures. Mater. Des. 2018, 144, 229–244. [Google Scholar] [CrossRef]

- Li, Z.; Wang, K.F.; Wang, B.L. Indentation Resistance of Brittle Auxetic Structures: Combining Discrete Representation and Continuum Model. Eng. Fract. Mech. 2021, 252, 107824. [Google Scholar] [CrossRef]

- Novak, N.; Starčevič, L.; Vesenjak, M.; Ren, Z. Blast Response Study of the Sandwich Composite Panels with 3D Chiral Auxetic Core. Compos. Struct. 2019, 210, 167–178. [Google Scholar] [CrossRef]

- Novak, N.; Krstulović-Opara, L.; Ren, Z.; Vesenjak, M. Compression and Shear Behaviour of Graded Chiral Auxetic Structures. Mech. Mater. 2020, 148, 103524. [Google Scholar] [CrossRef]

- Alderson, A.; Alderson, K.L.; Chirima, G.; Ravirala, N.; Zied, K.M. The In-Plane Linear Elastic Constants and out-of-Plane Bending of 3-Coordinated Ligament and Cylinder-Ligament Honeycombs. Compos. Sci. Technol. 2010, 70, 1034–1041. [Google Scholar] [CrossRef]

- Zhong, R.; Fu, M.; Yin, Q.; Xu, O.; Hu, L. Special Characteristics of Tetrachiral Honeycombs under Large Deformation. Int. J. Solids Struct. 2019, 169, 166–176. [Google Scholar] [CrossRef]

- Li, P.; Wang, Z.; Song, R.; Qian, W.; Wen, P.; Yang, Z.; He, D. Customizable Fabrication for Auxetic Graphene Assembled Macrofilms with High Conductivity and Flexibility. Carbon N. Y. 2020, 162, 545–551. [Google Scholar] [CrossRef]

- D’Mello, R.J.; Waas, A.M. Synergistic Energy Absorption in the Axial Crush Response of Filled Circular Cell Honeycombs. Compos. Struct. 2012, 94, 1669–1676. [Google Scholar] [CrossRef]

- Ren, X.; Das, R.; Tran, P.; Ngo, T.D.; Xie, Y.M. Auxetic Metamaterials and Structures: A Review. Smart Mater. Struct. 2018, 27, 023001. [Google Scholar] [CrossRef]

- Kelkar, P.U.; Kim, H.S.; Cho, K.H.; Kwak, J.Y.; Kang, C.Y.; Song, H.C. Cellular Auxetic Structures for Mechanical Metamaterials: A Review. Sensors 2020, 20, 3132. [Google Scholar] [CrossRef] [PubMed]

- Evans, K.E.; Alderson, A. Auxetic Materials: Functional Materials and Structures from Lateral Thinking! Adv. Mater. 2000, 12, 617–628. [Google Scholar] [CrossRef]

- Meena, K.; Singamneni, S. A New Auxetic Structure with Significantly Reduced Stress Concentration Effects. Mater. Des. 2019, 173, 107779. [Google Scholar] [CrossRef]

- Günaydın, K.; Rea, C.; Kazancı, Z. Energy Absorption Enhancement of Additively Manufactured Hexagonal and Re-Entrant (Auxetic) Lattice Structures by Using Multi-Material Reinforcements. Addit. Manuf. 2022, 59, 10307. [Google Scholar] [CrossRef]

- Ali, M.N.; Busfield, J.J.C.; Rehman, I.U. Auxetic Oesophageal Stents: Structure and Mechanical Properties. J. Mater. Sci. Mater. Med. 2014, 25, 527–553. [Google Scholar] [CrossRef]

- Liu, J.; Yao, X.; Wang, Z.; Ye, J.; Luan, C.; He, Y.; Lin, H.; Fu, J. A Flexible Porous Chiral Auxetic Tracheal Stent with Ciliated Epithelium. Acta Biomater. 2021, 124, 153–165. [Google Scholar] [CrossRef]

- Bacigalupo, A.; Gambarotta, L. Chiral Two-Dimensional Periodic Blocky Materials with Elastic Interfaces: Auxetic and Acoustic Properties. Extrem. Mech. Lett. 2020, 39, 100769. [Google Scholar] [CrossRef]

- Oh, J.H.; Kim, J.S.; Nguyen, V.H.; Oh, I.K. Auxetic Graphene Oxide-Porous Foam for Acoustic Wave and Shock Energy Dissipation. Compos. B Eng. 2020, 186, 107817. [Google Scholar] [CrossRef]

- Huang, T.T.; Ren, X.; Zeng, Y.; Zhang, Y.; Luo, C.; Zhang, X.Y.; Xie, Y.M. Based on Auxetic Foam: A Novel Type of Seismic Metamaterial for Lamb Waves. Eng. Struct. 2021, 246, 112976. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, X.; Han, D.; Cheng, X.; Jiang, W.; Zhang, X.G.; Zhang, X.Y.; Xie, Y.M. Static and Dynamic Properties of a Perforated Metallic Auxetic Metamaterial with Tunable Stiffness and Energy Absorption. Int. J. Impact Eng. 2022, 164, 104193. [Google Scholar] [CrossRef]

- Taherkhani, B.; Chegini, M.M.; Rahmani, P. Highly Sensitive, Piezoresistive, Silicon/Graphite Powder-Based, Auxetic Sensor with Linear Sensing Performance. Sens. Actuators A Phys. 2022, 345, 113776. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lim, S.M.; Yi, S.M.; Lee, J.H.; Kang, S.G.; Choi, G.M.; Han, H.N.; Sun, J.Y.; Choi, I.S.; Joo, Y.C. Auxetic Elastomers: Mechanically Programmable Meta-Elastomers with an Unusual Poisson’s Ratio Overcome the Gauge Limit of a Capacitive Type Strain Sensor. Extrem. Mech. Lett. 2019, 31, 100516. [Google Scholar] [CrossRef]

- Mohsenizadeh, S.; Ahmad, Z. Auxeticity Effect on Crushing Characteristics of Auxetic Foam-Filled Square Tubes under Axial Loading. Thin-Walled Struct. 2019, 145, 10637. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, Y.; Han, C.Z.; Han, D.; Zhang, X.Y.; Zhang, X.G.; Xie, Y.M. Mechanical Properties of Foam-Filled Auxetic Circular Tubes: Experimental and Numerical Study. Thin-Walled Struct. 2022, 170, 108584. [Google Scholar] [CrossRef]

- Lee, W.; Jeong, Y.; Yoo, J.; Huh, H.; Park, S.J.; Park, S.H.; Yoon, J. Effect of Auxetic Structures on Crash Behavior of Cylindrical Tube. Compos. Struct. 2019, 208, 836–846. [Google Scholar] [CrossRef]

- Luo, C.; Ren, X.; Han, D.; Zhang, X.G.; Zhong, R.; Zhang, X.Y.; Xie, Y.M. A Novel Concrete-Filled Auxetic Tube Composite Structure: Design and Compressive Characteristic Study. Eng. Struct. 2022, 268, 11475. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, Y.; Yan, J.; Wang, B.; Bai, F.; Shi, Z.; Huang, F. Anti-Blast Performance of 3D-Printed Sandwich Panels with Auxetic Hexagonal and Regular Hexagonal Honeycomb Cores. Eng. Struct. 2022, 272, 114996. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent Applications of Carbon-Based Composites in Defence Industry: A Review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Sanami, M.; Ravirala, N.; Alderson, K.; Alderson, A. Auxetic Materials for Sports Applications. In Proceedings of the Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; Volume 72, pp. 453–458. [Google Scholar]

- Neelakantan, S.; Tan, J.C.; Markaki, A.E. Out-of-Plane Auxeticity in Sintered Fibre Network Mats. Scr. Mater. 2015, 106, 30–33. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L. Impact Resistance of Additively Manufactured 3D Double-U Auxetic Structures. Thin-Walled Struct. 2021, 169, 108373. [Google Scholar] [CrossRef]

- Gao, D.; Wang, S.; Zhang, M.; Zhang, C. Experimental and Numerical Investigation on In-Plane Impact Behaviour of Chiral Auxetic Structure. Compos. Struct. 2021, 267, 113922. [Google Scholar] [CrossRef]

- Linforth, S.; Ngo, T.; Tran, P.; Ruan, D.; Odish, R. Investigation of the Auxetic Oval Structure for Energy Absorption through Quasi-Static and Dynamic Experiments. Int. J. Impact Eng. 2021, 147, 103741. [Google Scholar] [CrossRef]

- Methods, C.; Mech, A.; Gao, J.; Xue, H.; Gao, L.; Luo, Z.; Methods, C.; Mech, A.; Gao, J.; Xue, H.; et al. Topology Optimization for Auxetic Metamaterials Based on Isogeometric Analysis. Comput. Methods Appl. Mech. Eng. 2019, 352, 211–236. [Google Scholar] [CrossRef]

- Mousanezhad, D.; Haghpanah, B.; Ghosh, R.; Hamouda, A.M.; Nayeb-Hashemi, H.; Vaziri, A. Elastic Properties of Chiral, Anti-Chiral, and Hierarchical Honeycombs: A Simple Energy-Based Approach. Theor. Appl. Mech. Lett. 2016, 6, 81–96. [Google Scholar] [CrossRef]

- Rafsanjani, A.; Pasini, D. Bistable Auxetic Mechanical Metamaterials Inspired by Ancient Geometric Motifs. Extrem. Mech. Lett. 2016, 9, 291–296. [Google Scholar] [CrossRef]

- Savolainen, J.; Collan, M. How Additive Manufacturing Technology Changes Business Models?—Review of Literature. Addit. Manuf. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Chang, K.-H. Rapid Prototyping. e-Design 2015, 2015, 743–786. [Google Scholar] [CrossRef]

- Gong, G.; Ye, J.; Chi, Y.; Zhao, Z.; Wang, Z.; Xia, G.; Du, X.; Tian, H.; Yu, H.; Chen, C. Research Status of Laser Additive Manufacturing for Metal: A Review. J. Mater. Res. Technol. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- Liu, W.; Liu, X.; Liu, Y.; Wang, J.; Evans, S.; Yang, M. Unpacking Additive Manufacturing Challenges and Opportunities in Moving towards Sustainability: An Exploratory Study. Sustainability 2023, 15, 382. [Google Scholar] [CrossRef]

- Rodríguez-Gonzálvez, P.; Zolfagharian, A.; Bodaghi, M.; Hamzehei, R.; Parr, L.; Fard, M.; Rolfe, B.F. 3D-Printed Programmable Mechanical Metamaterials for Vibration Isolation and Buckling Control. Sustainability 2022, 14, 6831. [Google Scholar] [CrossRef]

- Zou, Z.; Xu, F.; Pan, Y.; Niu, X.; Fang, T.; Zeng, C. Parametric Analysis and Multi-Objective Optimization of Pentamode Metamaterial. Sustainability 2023, 15, 3421. [Google Scholar] [CrossRef]

- Bayart, M.; Charlon, S.; Soulestin, J. Fused Filament Fabrication of Scaffolds for Tissue Engineering; How Realistic Is Shape-Memory? A Review. Polymer 2021, 217, 123440. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and Future Trends in Topology Optimization for Additive Manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder. Materials 2017, 10, 672. [Google Scholar] [CrossRef]

- Bourell, D.; Pierre, J.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. CIRP Annals—Manufacturing Technology Materials for Additive Manufacturing. CIRP Ann. Manuf. Technol. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Additive Manufacturing Applications in Medical Cases: A Literature Based Review. Alex. J. Med. 2018, 54, 411–422. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy Design via Additive Manufacturing: Advantages, Challenges, Applications and Perspectives. Mater. Today 2022, 52, 207–224. [Google Scholar] [CrossRef]

- Kumar, S. Selective Laser Sintering/Melting. Compr. Mater. Process. 2014, 10, 93–134. [Google Scholar] [CrossRef]

- Doñate-Buendía, C.; Gu, D.; Schmidt, M.; Barcikowski, S.; Korsunsky, A.M.; Gökce, B. On the Selection and Design of Powder Materials for Laser Additive Manufacturing. Mater. Des. 2021, 204, 109653. [Google Scholar] [CrossRef]

- Industria 4.0—Evoluția Către a 4-a Revoluție Industrială—GreenSoft. Available online: https://www.greensoft.ro/industria-4-0/ (accessed on 8 October 2022).

- Mirzendehdel, A.M.; Suresh, K. Support Structure Constrained Topology Optimization for Additive Manufacturing. CAD Comput. Aided Des. 2016, 81, 1–13. [Google Scholar] [CrossRef]

- Venturi, F.; Taylor, R. Additive Manufacturing in the Context of Repeatability and Reliability. J. Mater. Eng. Perform. 2023. [Google Scholar] [CrossRef]

- Nouri, A.; Rohani Shirvan, A.; Li, Y.; Wen, C. Surface Modification of Additively Manufactured Metallic Biomaterials with Active Antipathogenic Properties. Smart Mater. Manuf. 2023, 1, 100001. [Google Scholar] [CrossRef]

- Chikkanna, N.; Krishnapillai, S.; Ramachandran, V. In-Plane and out-of-Plane Quasi-Static Compression Performance Enhancement of 3D Printed Re-Entrant Diamond Auxetic Metamaterial with Geometrical Tuning and Fiber Reinforcement. Def. Technol. 2022. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H. Experimental and Numerical Investigation on Crush Resistance of Polygonal Columns and Angle Elements. Thin-Walled Struct. 2012, 57, 25–36. [Google Scholar] [CrossRef]

- Atatreh, S.; Alyammahi, M.S.; Vasilyan, H.; Alkindi, T.; Susantyoko, R.A. Evaluation of the Infill Design on the Tensile Properties of Metal Parts Produced by Fused Filament Fabrication. Results Eng. 2023, 17, 10095. [Google Scholar] [CrossRef]

- Yadav, A.; Rohru, P.; Babbar, A.; Kumar, R.; Ranjan, N.; Chohan, J.S.; Kumar, R.; Gupta, M. Fused Filament Fabrication: A State-of-the-Art Review of the Technology, Materials, Properties and Defects. Int. J. Interact. Des. Manuf. 2022. [Google Scholar] [CrossRef]

- Li, K.; Zhang, Y.; Hou, Y.; Su, L.; Zeng, G.; Xu, X. Mechanical Properties of Re-Entrant Anti-Chiral Auxetic Metamaterial under the in-Plane Compression. Thin-Walled Struct. 2023, 184, 110465. [Google Scholar] [CrossRef]

- Lu, H.; Wang, X.; Chen, T. In-Plane Dynamics Crushing of a Combined Auxetic Honeycomb with Negative Poisson’s Ratio and Enhanced Energy Absorption. Thin-Walled Struct. 2021, 160, 107366. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Yu, C.; Yang, S. In-Plane Crushing Response of Tetra-Chiral Honeycombs. Int. J. Impact Eng. 2019, 130, 247–265. [Google Scholar] [CrossRef]

- Gao, Q.; Ding, Z.; Liao, W.-H. Effective Elastic Properties of Irregular Auxetic Structures. Compos. Struct. 2022, 287, 115269. [Google Scholar] [CrossRef]

- Gao, Q.; Tan, C.A.; Hulbert, G.; Wang, L. Geometrically Nonlinear Mechanical Properties of Auxetic Double-V Microstructures with Negative Poisson’s Ratio. Eur. J. Mech. A Solids 2020, 80, 103933. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, X.; Xie, Y.M.; Wang, Z.; Zhou, S. Re-Entrant Auxetic Lattices with Enhanced Stiffness: A Numerical Study. Int. J. Mech. Sci. 2020, 178, 105619. [Google Scholar] [CrossRef]

- Jiang, Y.; Rudra, B.; Shim, J.; Li, Y. Limiting Strain for Auxeticity under Large Compressive Deformation: Chiral vs. Re-Entrant Cellular Solids. Int. J. Solids Struct. 2019, 162, 87–95. [Google Scholar] [CrossRef]

- Prall, D.; Lakes, R.S. Properties of a Chiral Honeycomb with a Poisson’s Ratio of −1. Int. J. Mech. Sci. 1997, 39, 305–314. [Google Scholar] [CrossRef]

- Wu, W.; Tao, Y.; Xia, Y.; Chen, J.; Lei, H.; Sun, L.; Fang, D. Mechanical Properties of Hierarchical Anti-Tetrachiral Metastructures. Extrem. Mech. Lett. 2017, 16, 18–32. [Google Scholar] [CrossRef]

- Tabacu, S.; Negrea, R.F.; Negrea, D. Experimental, Numerical and Analytical Investigation of 2D Tetra-Anti-Chiral Structure under Compressive Loads. Thin-Walled Struct. 2020, 155, 106929. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, Z.; Lu, Z.; Li, X. Mechanical Responses of 3D Cross-Chiral Auxetic Materials under Uniaxial Compression. Mater. Des. 2020, 186, 108226. [Google Scholar] [CrossRef]

- Khakalo, S.; Balobanov, V.; Niiranen, J. Modelling Size-Dependent Bending, Buckling and Vibrations of 2D Triangular Lattices by Strain Gradient Elasticity Models: Applications to Sandwich Beams and Auxetics. Int. J. Eng. Sci. 2018, 127, 33–52. [Google Scholar] [CrossRef]

- Tabacu, S.; Predoiu, P.; Negrea, R. A Theoretical Model for the Estimate of Plateau Force for the Crushing Process of 3D Auxetic Anti-Tetra Chiral Structures. Int. J. Mech. Sci. 2021, 199, 106405. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, X.; Zhang, X.Y.; Huang, T.T.; Sun, L.; Xie, Y.M. A Novel Buckling-Restrained Brace with Auxetic Perforated Core: Experimental and Numerical Studies. Eng. Struct. 2021, 249, 113223. [Google Scholar] [CrossRef]

- Tabacu, S.; Stanescu, D.N. Axial Compression and Buckling Analysis of Columnar Structures with Tetra-Anti-Chiral Configuration. J. Appl. Mech. 2022, 89, 081007. [Google Scholar] [CrossRef]

- Atilla Yolcu, D.; Okutan Baba, B. Measurement of Poisson’s Ratio of the Auxetic Structure. Measurement 2022, 204, 112040. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, A.S.; Sun, J.; Quan, Z.; Gu, B.; Sun, B.; Cotton, C.; Heider, D.; Chou, T.W. Characterization of Residual Stress and Deformation in Additively Manufactured ABS Polymer and Composite Specimens. Compos. Sci. Technol. 2017, 150, 102–110. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical Strength of Welding Zones Produced by Polymer Extrusion Additive Manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef] [PubMed]

- ABS Plastic Filament Engineering Information. Engineers Edge. Available online: https://www.engineersedge.com/3D_Printing/abs_plastic_filament_engineering_information_14211.htm (accessed on 10 January 2023).

- Gu, G.; Xia, Y.; Zhou, Q. On the Fracture Possibility of Thin-Walled Tubes under Axial Crushing. Thin-Walled Struct. 2012, 55, 85–95. [Google Scholar] [CrossRef]

- Kõrgesaar, M. The Effect of Low Stress Triaxialities and Deformation Paths on Ductile Fracture Simulations of Large Shell Structures. Mar. Struct. 2019, 63, 45–64. [Google Scholar] [CrossRef]

- Dai, M.; Ying, L.; Wang, S.; Ma, H.; Hu, P.; Wang, Y. Modeling the Crashworthiness Analysis of Functional Graded Strength Thin-Walled Structure with Phenomenological GISSMO Model. Thin-Walled Struct. 2022, 180, 109766. [Google Scholar] [CrossRef]

- Tabacu, S.; Ducu, C. Numerical Investigations of 3D Printed Structures under Compressive Loads Using Damage and Fracture Criterion: Experiments, Parameter Identification, and Validation. Extrem. Mech. Lett. 2020, 39, 100775. [Google Scholar] [CrossRef]

- Hallquist, J. LS-DYNA® Theory Manual; Livermore Software Technology Corporation: Livermore, CA, USA, 2006; ISBN 9254492507. [Google Scholar]

- Blumenfeld, R.; Edwards, S.F. Theory of Strains in Auxetic Materials. J. Supercond. Nov. Magn. 2012, 25, 565–571. [Google Scholar] [CrossRef]

| Parameter | Value | Units |

|---|---|---|

| 1.00–1.22 | ||

| 1.12–2.87 | ||

| Elongation at break | 3–75 | |

| Melting Temperature | 88–128 | |

| Glass Transition Temperature | 100 | |

| 18.5–51 | ||

| 33–110 |

| Parameter | Value | MakerBot Slicer’s Settings |

|---|---|---|

| Extruder temperature | 230 °C | |

| Bead temperature | 110 °C | |

| Layer thickness | 0.3 mm | maxSparseFillThickness |

| Raft | on | raftSurfaceLayers |

| Infill | 100% | infillDensity |

| Infill pattern | linear | sparseInfillPattern |

| Speed of the head | 50 mm/min | feed rate |

| Air gap | default | spurOverlap |

| Pattern alignment | 0° | solidFillOrientationInterval: 0° |

| Parameter | Configuration A | Configuration B |

|---|---|---|

| Poisson’s ratio (theoretical) | ||

| 3 | 3 | |

| 3 | 3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabacu, S.; Badea, A.; Sandu, A. Complex Analysis of an Auxetic Structure under Compressive Loads. Sustainability 2023, 15, 6805. https://doi.org/10.3390/su15086805

Tabacu S, Badea A, Sandu A. Complex Analysis of an Auxetic Structure under Compressive Loads. Sustainability. 2023; 15(8):6805. https://doi.org/10.3390/su15086805

Chicago/Turabian StyleTabacu, Stefan, Ana Badea, and Alina Sandu. 2023. "Complex Analysis of an Auxetic Structure under Compressive Loads" Sustainability 15, no. 8: 6805. https://doi.org/10.3390/su15086805

APA StyleTabacu, S., Badea, A., & Sandu, A. (2023). Complex Analysis of an Auxetic Structure under Compressive Loads. Sustainability, 15(8), 6805. https://doi.org/10.3390/su15086805