Carbon Footprint Analysis of Ice Cream Production

Abstract

:1. Introduction

- To inform consumers about GHG emissions associated with product manufacturing.

- To develop and apply strategies to manage GHG emissions at various stages of the product life cycle.

- To monitor progress in reducing GHG emissions over time.

2. Methodology and Scope of the Study

2.1. Research Material

2.2. Preparation of Mixtures and Ice Masses under Laboratory Conditions

2.3. Preparation of Ice Cream Mixes and Masses under Artisanal Production Conditions

2.4. Study of the Carbon Footprint of Ice Cream Technology

- Analysis of technologies for the manufacturing of traditional ice cream and ice cream with fat and sugar substitutes in the context of the development of CF methodologies and preparation of unit process diagrams in the production cycle for ice cream production technologies.

- Development of a methodology for estimating the CF of ice cream production for selected technologies within the selected research scope.

- Determination of the method and scope of CF analysis of ice cream production technologies in order to develop the measurement system necessary to determine the CF.

- Study of indirect and direct emissions necessary to the analysis and determination of CF for ice cream technology.

- Determination of the analysis scope, functional unit, and measurement range.

- Analysis of measurement data and evaluation of production technology.

3. Results and Discussion

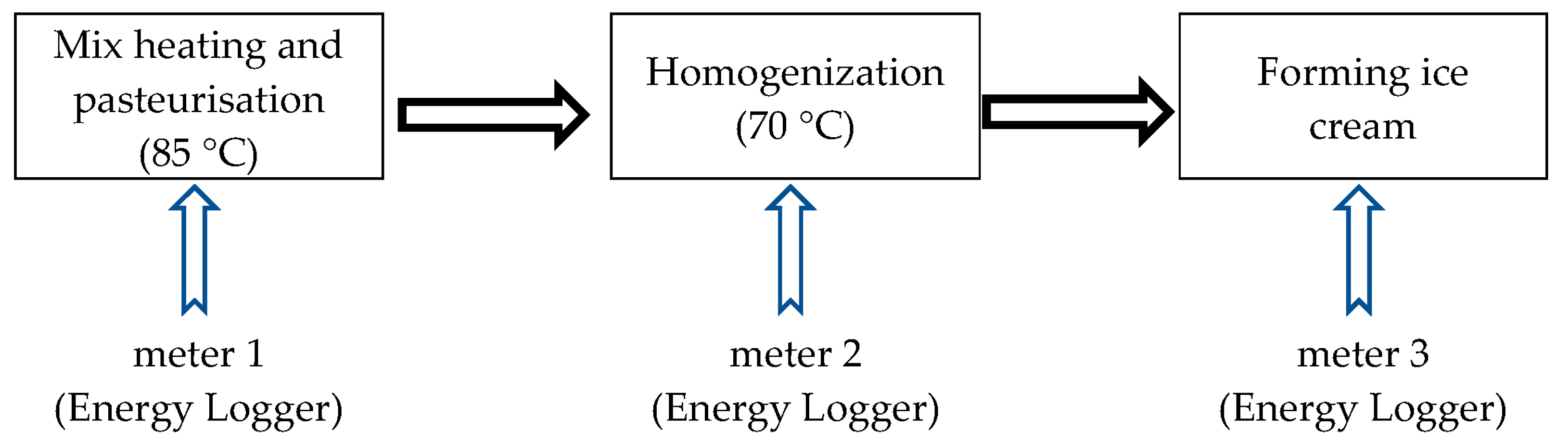

3.1. Determination of the Carbon Footprint of Ice Cream Production Technology under Laboratory Conditions

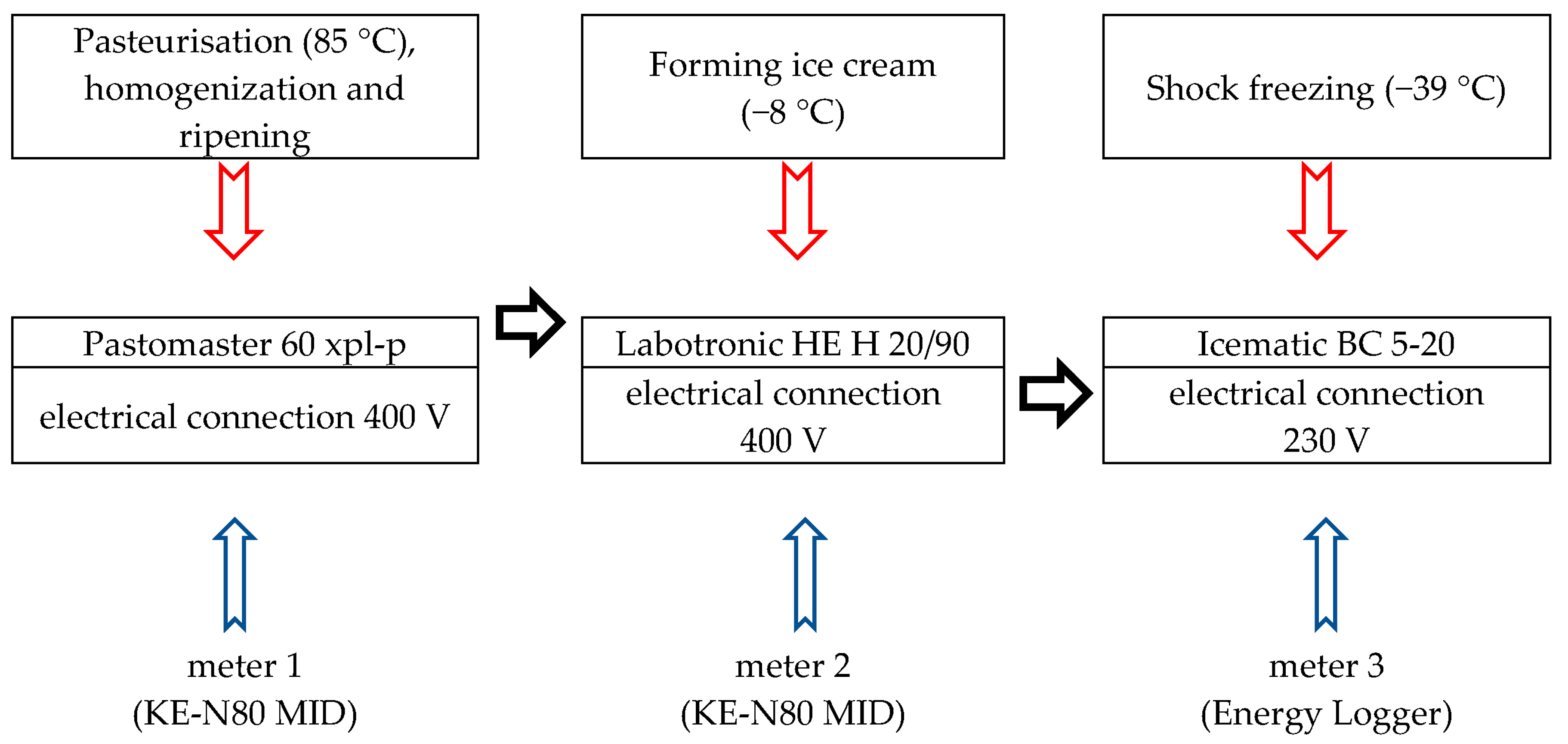

3.2. Determination of the Carbon Footprint of Handicraft Ice Cream Technology

4. Summary and Conclusions

- At the laboratory scale, the determined CF of the production of traditional ice cream was 0.360 kg CO2 per kg of product and for ice cream according to the recipe with fat substitutes (100%) and sugar (100%) 0.385 kg CO2 per kg of product.

- The largest share of the CF of ice cream production with different contents of fat and sugar substitutes was the pasteurization process and amounted to about 77% of total CO2 emissions.

- The CF of the homogenization process, for different durations, was in range 0.005–0.035 kg CO2/kg product.

- The determined CF of the production of traditional ice cream and ice cream with fat and sugar substitutes was 0.253 and 0.248 kg CO2 per kg of product, respectively, under artisanal conditions. In contrast, for the standard handicraft recipe, used at Primulator, the CF was the lowest at 0.234 kg CO2 per kg of product.

- The homogenization and ripening process accounted for the largest share of CF of handicraft ice cream production with different recipes and amounted to about 60% of the total CO2 emissions.

- Analyses showed that nutritional changes in food products reducing sugar and fat content were responsible for a 2-fold increase in the CF of new ice cream produced. The benefits of changing the materials in terms of impact on the chain production was confirmed.

- The presented practical method of CF calculation can be used in other situations in this industry.

- There is a need to continue research in this area for other technologies at the design and implementation stage in order to achieve low-carbon environmentally friendly technologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dąbrowska, A.; Babicz-Zielińska, E. Consumer behavior towards new generation foods. HYGEIA Public Health 2011, 46, 39–46. [Google Scholar]

- Karwacka, M.; Ciurzyńska, A.; Galus, S.; Janowicz, M. Freeze-dried snacks obtained from frozen vegetable by-products and apple pomace–Selected properties, energy consumption and carbon footprint. Innov. Food Sci. Emerg. Technol. 2022, 77, 102949. [Google Scholar] [CrossRef]

- Konieczny, P.; Kijowski, J. Animal origin food preservation and its safety issues. Polish J. Food Nutr. Sci. 2005, 14, 21–29. [Google Scholar]

- Ai, X.; Jiang, Z.; Zhang, H.; Wang, Y. Low-carbon product conceptual design from the perspectives of technical system and human use. J. Clean. Prod. 2020, 244, 118819. [Google Scholar] [CrossRef]

- Madoumier, M.; Azzaro-Pantel, C.; Gésan-Guiziou, G. Including cleaning and production phases in the eco-design of a milk evaporation process. Food Bioprod. Process. 2020, 123, 427–436. [Google Scholar] [CrossRef]

- Kumar, M.; Choubey, V.K.; Deepak, A.; Gedam, V.V.; Raut, R.D. Life cycle assessment (LCA) of dairy processing industry: A case study of North India. J. Clean. Prod. 2021, 326, 129331. [Google Scholar] [CrossRef]

- Pasqualino, J.; Meneses, M.; Castells, F. The carbon footprint and energy consumption of beverage packaging selection and disposal. J. Food Eng. 2011, 103, 357–365. [Google Scholar] [CrossRef]

- de Vries, H.; Mikolajczak, M.; Salmon, J.M.; Abecassis, J.; Chaunier, L.; Guessasma, S.; Lourdin, D.; Belhabib, S.; Leroy, E.; Trystram, G. Small-scale food process engineering-Challenges and perspectives. Innov. Food Sci. Emerg. Technol. 2018, 46, 122–130. [Google Scholar] [CrossRef]

- Wróbel-Jędrzejewska, M.; Polak, E. Determination of carbon footprint in the processing of frozen vegetables using an online energy measurement system. J. Food Eng. 2022, 322, 110974. [Google Scholar] [CrossRef]

- Konstantas, A.; Stamford, L.; Azapagic, A. Environmental impacts of ice cream. J. Clean. Prod. 2019, 209, 259–272. [Google Scholar] [CrossRef]

- Barendregt, W.; Biørn-Hansen, A.; Andersson, D. Users’ Experiences with the Use of Transaction Data to Estimate Consumption-Based Emissions in a Carbon Calculator. Sustainability 2020, 12, 7777. [Google Scholar] [CrossRef]

- Compton, M.; Willis, S.; Rezaie, B.; Humes, K. Food processing industry energy and water consumption in the Pacific northwest. Innov. Food Sci. Emerg. Technol. 2018, 47, 371–383. [Google Scholar] [CrossRef]

- Konieczny, P.; Dobrucka, R.; Mroczek, E. Using Carbon Footprint to Evaluate Environmental Issues of Food Transportation. LogForum 2013, 9, 3–10. [Google Scholar]

- Zhou, S.; Zhu, Z.; Sun, D.-W.; Xu, Z.; Zhang, Z.; Wang, Q.-J. Effects of different cooling methods on the carbon footprint of cooked rice. J. Food Eng. 2017, 215, 44–50. [Google Scholar] [CrossRef]

- Shenashen, M.A.; Emran, M.Y.; El Sabagh, A.; Selim, M.M.; Elmarakbi, A.; El-Safty, S.A. Progress in sensory devices of pesticides, pathogens, coronavirus, and chemical additives and hazards in food assessment: Food safety concerns. Prog. Mat. Sci. 2022, 124, 100866. [Google Scholar] [CrossRef]

- Ahmed, W.; Haque, A.; Mohibbullah, M.; Khan, S.I.; Islam, M.A.; Mondal, H.T.; Ahmmed, R. A review on active packaging for quality and safety of foods: Current trends, applications, prospects and challenges. Food Pack. Shelf Life 2022, 33, 100913. [Google Scholar] [CrossRef]

- Hartikainen, H.; Roininen, T.; Katajajuuri, J.M.; Pulkkinen, H. Finnish consumer perceptions of carbon footprints and carbon labelling of food products. J. Clean. Prod. 2014, 73, 285. [Google Scholar] [CrossRef]

- Treu, H.; Nordborg, M.; Cederberg, C.; Heuer, T.; Claupein, E.; Hoffmann, H.; Berndes, G. Carbon footprints and land use of conventional and organic diets in Germany. J. Clean. Prod. 2017, 161, 127–142. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; Coninck, H.; Loos, M.; Meyer, L. IPCC, 2005–Carbon Dioxide Capture and Storage; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Pandey, D.; Agrawal, M. Carbon Footprint Estimation in the Agriculture Sector. In Assessment of Carbon Footprint in Different Industrial Sectors, Volume 1; EcoProduction; Springer: Singapore, 2017. [Google Scholar]

- Wiedmann, T.; Minx, J. A definition of ‘carbon footprint’. In Ecological Economics Research Trends; Pertsova, C.C., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2008. [Google Scholar]

- Dong, G.; Mao, X.; Zhou, J.; Zeng, A. Carbon footprint accounting and dynamics and the driving forces of agricultural production in Zhejiang Province, China. Eco. Econom. 2013, 91, 38–47. [Google Scholar] [CrossRef]

- Maravić, N.; Kiss, F.; Šereš, L.; Bogdanović, B.; Bogdanović, B.; Šereš, Z. Economic analysis and LCA of an advanced industrial-scale raw sugar juice purification procedure. Food Bioprod. Process. 2015, 95, 19–26. [Google Scholar] [CrossRef]

- Cimini, A.; Moresi, M. Are the present standard methods effectively useful to mitigate the environmental impact of the 99% EU food and drink enterprises? Trends Food Sci. Technol. 2018, 77, 42–53. [Google Scholar] [CrossRef]

- ISO 14025; Environmental Labels and Declarations-Type III Environmental Declarations-Principles and Procedures. Interna-tional Organization for Standardization: London, UK, 2010.

- Commission Regulation (EU) 2019/2024 of 1 October 2019 laying down ecodesign requirements for refrigerating appliances with a direct sales function pursuant to Directive 2009/125/EC of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2019.315.01.0313.01.ENG (accessed on 22 February 2023).

- Xua, Z.; Suna, D.; Zhanga, Z.; Zhu, Z. Research developments in methods to reduce carbon footprint of cooking operations: A review. Trends Food Sci. Technol. 2015, 44, 49–57. [Google Scholar] [CrossRef]

- Malliaroudaki, M.; Watson, N.J.; Ferrari, R.; Nchari, L.N.; Gomes, R.L. Energy management for a net zero dairy supply chain under climate change. Trends Food Sci. Technol. 2022, 126, 153–167. [Google Scholar] [CrossRef]

- Borsato, E.; Tarolli, P.; Marinello, F. Sustaiable patterns of main agricultural products combining different footprint parameters. J. Clean. Prod. 2018, 179, 357–367. [Google Scholar] [CrossRef]

- Available online: https://www.igifc.pl/ (accessed on 12 August 2022).

- Rees, W.E. Footprint: Our impact on Earth is getting heavier. Nature 2002, 420, 267. [Google Scholar] [CrossRef] [PubMed]

- Sala, S.; Castellani, V. The consumer footprint: Monitoring sustainable development goal 12 with process-based life cycle assessment. J. Clean. Prod. 2019, 240, 118050. [Google Scholar] [CrossRef]

- Yan, M.; Holden, N.M. Life cycle assessment of multi-product dairy processing using Irish butter and milk powders as an example. J. Clean. Prod. 2018, 198, 215–230. [Google Scholar] [CrossRef]

- Laguerre, O.; Hoang, H.M.; Flick, D. Experimental investigation and modelling in the food cold chain: Thermal and quality evolution. Trends Food Sci. Technol. 2013, 29, 87–97. [Google Scholar] [CrossRef]

- Karwacka, M.; Ciurzyńska, A.; Lenart, A.; Janowicz, M. Sustainable Development in the Agri-Food Sector in Terms of the Carbon Footprint: A Review. Sustainability 2020, 12, 6463. [Google Scholar] [CrossRef]

- Al-Mansour, F.; Jejcic, V. A model calculation of the carbon footprint of agricultural products: The case of Slovenia. Energy 2017, 136, 7–15. [Google Scholar] [CrossRef]

- Montzka, S.A.; Dlugokemcky, E.J.; Butler, J.H. Non CO2 greenhouse gases and climate change. Nature 2011, 476, 46–50. [Google Scholar] [CrossRef] [PubMed]

- Regulation (eu) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers, Amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32011R1169 (accessed on 22 February 2023).

- Miraglia, M.; Marvin, H.J.P.; Kleter, G.A.; Battilani, P.; Brera, C.; Coni, E. Climate change and food safety: An emerging issue with special focus on Europe. Food Chem. Toxic. 2009, 47, 1009. [Google Scholar] [CrossRef] [PubMed]

- Bååth, J. How alternative foods become affordable: The co-construction of economic value on a direct-to-customer market. J. Rural Stud. 2022, 94, 63–72. [Google Scholar] [CrossRef]

- Hurtado-Romero, A.; Del Toro-Barbosa, M.; Garcia-Amezquita, L.E.; García-Cayuela, T. Innovative technologies for the production of food ingredients with prebiotic potential: Modifications, applications, and validation methods. Trends in Food Sci. Technol. 2020, 104, 117–131. [Google Scholar] [CrossRef]

- Chung, Y.; Wu, J.; Huang, W. Effects of prebiotics on intestinal physiology, neuropsychological function, and exercise capacity of mice with sleep deprivation. Food Res. Int. 2023, 165, 112568. [Google Scholar] [CrossRef]

- Otles, S.; Gokgunnec, L. Safety Considerations in Developing Functional Foods and Nutraceuticals. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Strieder, M.; Arruda, H.; Pastore, G.; Silva, E. Inulin-type dietary fiber stability after combined thermal, mechanical, and chemical stresses related to ultrasound processing of prebiotic apple beverage. Food Hydrocoll. 2023, 139, 10848. [Google Scholar] [CrossRef]

- Franck, A. Technological functionality of inulin and oligofructose. Br. J. Nutrit. 2002, 87, S287–S291. [Google Scholar] [CrossRef]

- Selvi, M.K.; Sowmya, B.; Kannan, T.; Latha, M.; Jena, I.; Kumar, V.A.; Vijayaraj, P. Chapter 2-Advances in personalized food and nutrition. In Research and Technological Advances in Food Science; Prakash, B., Ed.; Academic Press: Cambridge, MA, USA, 2022; pp. 31–60. [Google Scholar] [CrossRef]

- Szajner, P. The ice cream market in Poland. Przem. Spożywczy 2009, 63, 44–46. (In Polish) [Google Scholar]

- Granato, D.; Carocho, M.; Barros, L.; Zabetakis, I.; Andrei Mocan, A.; Alexandros Tsoupras, A.; Gomes Cruz, A.; Pimentel, T. Implementation of Sustainable Development Goals in the dairy sector: Perspectives on the use of agro-industrial side-streams to design functional foods. Trends Food Sci. Technol. 2022, 124, 128–139. [Google Scholar] [CrossRef]

- Sundarakani, B.; De Souza, R.; Goh, M.; Wagner, S.M.; Manikandan, S. Modeling carbon footprints across the supply chain. Int. J. Prod. Econom. 2010, 128, 43. [Google Scholar] [CrossRef]

- Kobylko, E. Technological and technical conditions of food ice cream production. Acta Sci. Polonorum. Tech. Agrar. 2013, 12, 27–37. [Google Scholar]

- Abdeldaiema, A.M.; Ali, A.H.; Mousa, A.H.; Elkot, W.F.; Simal-Gandara, J. Ice cream supplemented with roasted and grilled corn powders: Physical properties, rheology, antioxidant activity, color, sensory evaluation, and production cost. Int. J. Gast. Food Sci. 2023, 32, 100692. [Google Scholar] [CrossRef]

- Bekiroglu, H.; Goktas, H.; Karaibrahim, D.; Bozkurt, F.; Sagdic, O. Determination of rheological, melting and sensorial properties and volatile compounds of vegan ice cream produced with fresh and dried walnut milk. Int. J. Gast. Food Sci. 2022, 28, 100521. [Google Scholar] [CrossRef]

- Genovese, A.; Balivo, A.; Salvati, A.; Sacchi, R. Functional ice cream health benefits and sensory implications. Food Res. Int. 2022, 161, 111858. [Google Scholar] [CrossRef] [PubMed]

- Atalar, I.; Kurt, A.; Gul, O.; Yazici, F. Improved physicochemical, rheological and bioactive properties of ice cream: Enrichment with high pressure homogenized hazelnut milk. Int. J. Gast. Food Sci. 2021, 24, 100358. [Google Scholar] [CrossRef]

- Narala, V.R.; Jugbarde, M.A.; Orlovs, I.; Masin, M. Inulin as a prebiotic for the growth of vegan yoghurt culture in pea protein-based vegan yoghurt-ice cream, while improving the textural properties. Appl. Food Res. 2022, 2, 100136. [Google Scholar] [CrossRef]

- Narala, V.R.; Orlovs, I.; Jugbarde, M.A.; Masin, M. Inulin as a fat replacer in pea protein vegan ice cream and its influence on textural properties and sensory attributes. Appl. Food Res. 2022, 2, 100066. [Google Scholar] [CrossRef]

- Pontonio, E.; Montemurro, M.; Dingeo, C.; Rotolo, M.; Centrone, D.; Carofiglio, V.E.; Rizzello, C.G. Design and characterization of a plant-based ice cream obtained from a cereal/legume yogurt-like. LWT 2022, 161, 113327. [Google Scholar] [CrossRef]

- Scipioni, A.; Manzardo, A.; Mazzi, A.; Mastrobuono, M. Monitoring the carbon footprint of products: A methodological proposal. J. Clean. Prod. 2012, 36, 94–101. [Google Scholar] [CrossRef]

- Vasilaki, V.; Katsou, E.; Ponsá, S.; Colón, J. Water and carbon footprint of selected dairy products: A case study in Catalonia. J. Clean. Prod. 2016, 139, 504–516. [Google Scholar] [CrossRef]

- ISO/TS 14067; Greenhouse Gases–Carbon Footprint of Products–Requirements and Guidelines for Quantification and Communication. International Organization for Standardization: London, UK, 2013.

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: London, UK, 2009.

- ISO 14044; Environmental Management, Life Cycle Assessment-Requirements and GUIDELINES. International Organization for Standardization: London, UK, 2009.

- PAS 2050; Guide to PAS 2050 How to assess the carbon footprint of goods and services. British Standards: London, UK, 2008.

- FAO. Livestock’s Long Shadow–Environmental Issues and Options; Food and Agriculture Organization of the United Nations: Rome, Italy, 2006. [Google Scholar]

- FAO. Fats and Fatty Acids in Human Nutrition, Report of an Expert Consultation; FAO: Rome, Italy, 2010. [Google Scholar]

- PGE. Information for Customers on the Structure of Fuels Used to Generate Electricity Sold by PGE Obrót, S.A. in 2020 in Accordance with §37 of the Regulation of the Minister of Economy on Detailed Conditions for the Operation of the Power System Dated 4 May 2007; PGE: Emeryville, CA, USA, 2020. [Google Scholar]

- Cimini, A.; Moresi, M. Design and Development of a Novel Dietetic and Sustainable Ice Cream Cookie Sandwich. Chem. Eng. Trans. 2019, 75, 415–420. [Google Scholar]

- Garcia-Suarez, T.; Sim, S.; Mauser, A.; Marshall, P. Greenhouse Gas Assessment of Ben & Jerry’s ice-cream: Communicating their ‘Climate Hoofprint’. In Proceedings of the 6th International Conference on LCA in the Agri-Food Sector, Zurich, Switzerland, 12–14 November 2008; Volume 12–14, pp. 314–351. [Google Scholar]

- Dowlati, M.; Aghbashlo, M.; Soufiyan, M.M. Exergetic performance analysis of an ice-cream manufacturing plant: A comprehensive survey. Energy 2017, 123, 445–459. [Google Scholar] [CrossRef]

- Soufiyan, M.M.; Aghbashlo, M.; Mobli, H. Exergetic performance assessment of a long-life milk processing plant: A comprehensive survey. J. Clean. Prod. 2017, 140, 590–607. [Google Scholar] [CrossRef]

- Jokandan, M.J.; Aghbashlo, M.; Mohtasebi, S.S. Comprehensive exergy analysis of an industrial-scale yogurt production plant. Energy 2015, 93, 1832–1851. [Google Scholar] [CrossRef]

- Soufiyan, M.M.; Aghbashlo, M. Application of exergy analysis to the dairy industry: A case study of yogurt drink production plant. Food Bioprod. Process. 2017, 101, 118–131. [Google Scholar] [CrossRef]

- Available online: https://theconversation.com/which-milk-is-best-for-the-environment-we-compared-dairy-nut-soy-hemp-and-grain-milks-147660 (accessed on 28 July 2022).

- Available online: https://www.healabel.com/cream-side-effects/ (accessed on 28 July 2022).

- Available online: https://apps.carboncloud.com/climatehub/product-reports/id/5243965108 (accessed on 28 July 2022).

- Available online: http://www.garethhuwdavies.com/environment/environment_blog/butter-margarine-spread-breakfasts-carbon-footprint/ (accessed on 28 July 2022).

- García, C.A.; García-Treviño, E.S.; Aguilar-Rivera, N.; Armendáriz, C. Carbon footprint of sugar production in Mexico. J. Clean. Prod. 2016, 112, 263–264. [Google Scholar] [CrossRef]

- Available online: https://apps.carboncloud.com/climatehub/product-reports/id/75046256759 (accessed on 28 July 2022).

- Tsiropoulos, I.; Cok, B.; Patel, M. Energy and greenhouse gas assessment of European glucose production from corn–A multiple allocation approach for a key ingredient of the bio-based economy. J. Clean. Prod. 2013, 43, 182–190. [Google Scholar] [CrossRef]

- Sarkar, R.; Bhowmik, A.; Kundu, A.; Dutta, A.; Nain, L.; Chawla, G.; Saha, S. Inulin from Pachyrhizus erosus root and its production intensification using evolutionary algorithm approach and response surface methodology. Carbohydr. Polym. 2021, 251, 117042. [Google Scholar] [CrossRef]

- Available online: https://zdrowie.radiozet.pl/W-zdrowym-ciele/Zdrowe-zywienie/Produkty/Stewia-jak-jej-uzywac-czy-jest-bezpieczna-rowniez-w-cukrzycy (accessed on 28 July 2022).

- Rein, P.W. The carbon footprint of sugar. Proc. Int. Soc. Sugar Cane Technol. 2010, 27, 1–15. [Google Scholar] [CrossRef]

- Han, J.; Zuo, M.; Zhu, W.; Zuo, J.; Lü, E.; Yang, X. A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends. Trends Food Sci. Technol. 2021, 109, 536–551. [Google Scholar] [CrossRef]

- Heddeghem, W.; Vereecken, W.; Colle, D.; Pickavet, M.; Demeester, P. Distributed computing Carbon Footprint of Fruit for carbon footprint reduction by exploiting low-footprint energy availability. Future Gener. Comp. Syst. 2012, 28, 405–414. [Google Scholar]

- Chaudhary, A.; Tremorin, D. Nutritional and Environmental Sustainability of Lentil Reformulated Beef Burger. Sustainability 2020, 12, 6712. [Google Scholar] [CrossRef]

| Ingredients | Recipe | ||||||

|---|---|---|---|---|---|---|---|

| 0 | A | B | C | D | E | F | |

| sugar | + | + | + | − | + | + | − |

| skimmed milk powder | + | + | + | + | + | + | + |

| Butter | + | − | + | + | + | − | − |

| stabilizing and emulsifying preparation | + | + | + | + | + | + | + |

| Inulin | − | + | + | + | + | + | + |

| Oligofructose | − | − | − | + | + | + | + |

| Stevia | − | − | − | + | + | + | + |

| Water | + | + | + | + | + | + | + |

| Ingredients | Recipe | ||

|---|---|---|---|

| I | II | III | |

| milk | + | − | − |

| Cream | + | − | − |

| Dextrose | + | − | − |

| Sugar | + | + | + |

| glucose syrup | + | − | − |

| skimmed milk powder | + | + | + |

| stabilizing and emulsifying preparation | + | + | + |

| Butter | − | + | + |

| Inulin | − | − | + |

| Oligofructose | − | − | + |

| Stevia | − | − | + |

| Water | − | + | + |

| Sample | Sugar [%] | Fat [%] | Mix Heating and Pasteurisation (85 °C) | Homogenization (70 °C) | Forming Ice Cream |

|---|---|---|---|---|---|

| 2.5 kg | 1.5 kg | ||||

| 0 | 100% sugar | 100% fat | 0.890 ± 0.001 kWh | 0.062 ± 0.001 kWh | 0.135 ± 0.001 kWh |

| 1 h 10 min | 15 min | 1 h 20 min | |||

| A | 100% sugar | 100% fat replacer | 0.967 ± 0.001 kWh | 0.061 ± 0.001 kWh | 0.133 ± 0.001 kWh |

| 1 h 15 min | 15 min | 1 h 19 min | |||

| B | 100% sugar | 50% fat 50% fat replacement | 0.866 ± 0.001 kWh | 0.059 ± 0.001 kWh | 0.139 ± 0.001 kWh |

| 1 h 8 min | 15 min | 1 h 31 min | |||

| C | 100% sugar substitute | 50% fat 50% fat replacement | 0.841 ± 0.001 kWh | 0.059 ± 0.001 kWh | 0.131 ± 0.001 kWh |

| 1 h 4 min | 15 min | 1 h 19 min | |||

| D | 50% sugar substitute 50% sugar | 50% fat 50% fat replacement | 0.896 ± 0.001 kWh | 0.061 ± 0.001 kWh | 0.135 ± 0.001 kWh |

| 1 h 10 min | 15 min | 1 h 20 min | |||

| E | 50% sugar 50% sugar substitute | 100% fat replacer | 0.895 ± 0.001 kWh | 0.060 ± 0.001 kWh | 0.135 ± 0.001 kWh |

| 1 h 10 min | 15 min | 1 h 20 min | |||

| F | 100% sugar substitute | 100% fat replacer | 0.982 ± 0.001 kWh | 0.058 ± 0.001 kWh | 0.131 ± 0.001 kWh |

| 1 h 17 min | 15 min | 1 h 19 min | |||

| Recipe | CF Preheat and Pasteurisation | CF Homogenization | CF Ice Cream Forming | CF Technology |

|---|---|---|---|---|

| 0 | 0.272 | 0.019 | 0.069 | 0.360 |

| A | 0.296 | 0.019 | 0.068 | 0.382 |

| B | 0.265 | 0.018 | 0.071 | 0.354 |

| C | 0.257 | 0.018 | 0.067 | 0.342 |

| D | 0.274 | 0.019 | 0.069 | 0.362 |

| E | 0.274 | 0.018 | 0.069 | 0.361 |

| F | 0.300 | 0.018 | 0.067 | 0.385 |

| Temp. Water in the Bath | Mix Heating and Pasteurisation (85 °C) | CF Heating and Pasteurization | Homogenization (70 °C) | CF Homogenization | Forming Ice Cream | CF Forming Ice Cream | CF [kgCO2/kg of Product] | |

|---|---|---|---|---|---|---|---|---|

| 2.5 kg | 1.5 kg | |||||||

| 22.5 °C | 0.925 ± 0.001 kWh | 0.283 | 0.016 ± 0.001 kWh | 0.005 | 0.131 ± 0.001 kWh | 0.067 | 0.355 | |

| 1 h 10 min | 5 min | 1 h 20 min | ||||||

| 20.1 °C | 0.958 ± 0.001 kWh | 0.293 | 0.057 ± 0.001 kWh | 0.017 | 0.131 ± 0.001 kWh | 0.067 | 0.377 | |

| 1 h 15 min | 15 min | 1 h 20 min | ||||||

| 21.5 °C | 0.960 ± 0.001 kWh | 0.294 | 0.114 ± 0.001 kWh | 0.035 | 0.131 ± 0.001 kWh | 0.067 | 0.395 | |

| 1 h 16 min | 25 min | 1 h 20 min | ||||||

| Recipe | Pasteurizer [kg] | Muter [kg] | Shocker [kg] |

|---|---|---|---|

| I | 60.00 | 58.30 | 58.30 |

| II | 60.00 | 57.30 | 57.30 |

| III | 60.00 | 56.98 | 56.98 |

| Recipe | Pasteurizer | Muter | Shocker | |||||

|---|---|---|---|---|---|---|---|---|

| Homogenization, Pasteurisation | Cooling | Maturation | Emptying | Washing | Process | Washing | Cooling | |

| I | 5.000 ± 0.001 | 2.550 ± 0.001 | 2.000 ± 0.001 | 0.040 ± 0.001 | 0.990 ± 0.001 | 4.990 ± 0.001 | 1.060 ± 0.001 | 1.422 ± 0.001 |

| II | 4.730 ± 0.001 | 2.700 ± 0.001 | 1.910 ± 0.001 | 1.550 ± 0.001 | 0.970 ± 0.001 | 4.760 ± 0.001 | 1.230 ± 0.001 | 1.745 ± 0.001 |

| III | 4.520 ± 0.001 | 2.740 ± 0.001 | 1.620 ± 0.001 | 1.360 ± 0.001 | 0.780 ± 0.001 | 5.790 ± 0.001 | 0.320 ± 0.001 | 1.953 ± 0.001 |

| Recipe | Pasteurizer | Muter | Shocker | |||||

|---|---|---|---|---|---|---|---|---|

| Homogenization, Pasteurisation | Cooling | Maturation | Emptying | Washing | Process | Washing | Cooling | |

| I Σ | 0.064 | 0.033 | 0.026 | 0.0005 | 0.013 | 0.065 | 0.014 | 0.019 |

| 0.136 | 0.079 | 0.019 | ||||||

| 0.234 | ||||||||

| II Σ | 0.060 | 0.034 | 0.024 | 0.020 | 0.012 | 0.064 | 0.016 | 0.023 |

| 0.150 | 0.080 | 0.023 | ||||||

| 0.253 | ||||||||

| III Σ | 0.058 | 0.035 | 0.021 | 0.017 | 0.010 | 0.077 | 0.004 | 0.026 |

| 0.141 | 0.081 | 0.026 | ||||||

| 0.248 | ||||||||

| Component | CF [kg CO2/kg Component] | Source Data |

|---|---|---|

| milk | 1.14–2.5 | [73] |

| cream | 2.4 | [74] |

| skimmed milk powder | 9.9 | [75] |

| butter | 9.4 | [76] |

| sugar | 0.45–0.63 | [77] |

| glucose syrup powder | 1 | [78] |

| dextrose | 0.62 | [79] |

| inulina | 40 | [80] |

| oligofructose | * | - |

| stevia sweetener | 0.24–0.31 | [81,82] |

| RECIPE | I | II | III |

|---|---|---|---|

| CF components | 2.386 | 2.203 | 4.388 |

| CF production | 0.234 | 0.253 | 0.248 |

| CF total | 2.620 | 2.457 | 4.636 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wróbel-Jędrzejewska, M.; Polak, E. Carbon Footprint Analysis of Ice Cream Production. Sustainability 2023, 15, 6887. https://doi.org/10.3390/su15086887

Wróbel-Jędrzejewska M, Polak E. Carbon Footprint Analysis of Ice Cream Production. Sustainability. 2023; 15(8):6887. https://doi.org/10.3390/su15086887

Chicago/Turabian StyleWróbel-Jędrzejewska, Magdalena, and Elżbieta Polak. 2023. "Carbon Footprint Analysis of Ice Cream Production" Sustainability 15, no. 8: 6887. https://doi.org/10.3390/su15086887

APA StyleWróbel-Jędrzejewska, M., & Polak, E. (2023). Carbon Footprint Analysis of Ice Cream Production. Sustainability, 15(8), 6887. https://doi.org/10.3390/su15086887