Who Drives Circularity?—The Role of Construction Company Employees in Achieving High Circular Economy Efficiency

Abstract

:1. Introduction

1.1. Background

1.2. Literature

1.3. Contribution

2. Theory and Hypothesis Development

2.1. Lean Management Theory

- Specify value: For the specification of value, it is at first important to focus on the customer’s view. By doing this, a company should identify the needs of a customer and assess what that customer is willing to pay for a product or a service. This is particularly important for new circular business models, where PSS is being used more often. One prominent example is that of the airport in Amsterdam, to which the Philips company rents out the lighting rather than selling the airport its light bulbs. This circular business model helps the airport with its strategy to produce zero waste by 2030 and to reduce the electricity consumption by 50% by using efficient LED lamps [50]. Similar circular business models have been researched for specific construction components. In the Netherlands, for instance, an EIT Climate KIC project examined a leasing concept for facades at the university TU Delft [51]. The examined values for customers allow for consistent cash flows over time, reduce non-core processes (e.g., maintenance), and improve the flexibility of the facades with regard to design and technology [52].

- Identify the value stream: With this principle, the company must identify all those activities which create value for its customers. Any activities which do not create any additional value should be eliminated. Such activities are considered to be waste and not to contribute to the value that the customer demands. In the circular economy, waste is mainly considered to be resource waste, and thus circular economy practices in the manufacturing industry focus on avoiding waste or substituting it through continuous improvement [39]. Additionally, identifying the remaining waste and considering all relevant value streams are crucial for transitioning to a circular economy [53].

- Make the product flow: By doing so, a company makes sure that it acts and produces products in a process-oriented way and that it does not rely on slow department decisions. Furthermore, by aligning the steps of all processes, waiting times for both machines and employees are reduced, which also minimizes the value losses. This principle is also very relevant for the circular economy, where products and resources can only circulate if all process steps are known and aligned. This view might even include reverse product flow after a product’s useful lifetime.

- Pull of the customer: This principle once again emphasizes the focus on the customer. However, in this case, it is not so much the defining of the value, but rather the delivering of the value at the right time, which means when the customer wants it. Therefore, principles such as just-in-time production and delivery should be applied. While these are not necessarily only relevant for circular economy practices, they should be considered in this field of research. For example, a circular economy practice—such as the take-back mechanisms for used products—requires a high level of process efficiency because the customers decide when and to where they will return the products [54]. In particular, circular economy supply chains rely on product and resource deliveries at the right time to ensure economic efficiency. Ciliberto et al. also argue that such a customer focus correlates positively with circular economy practices, and especially improves economic efficiency [55]. In particular, a customer focus can reduce the volatility of prices, because a company is able to produce exactly what the customer wants, which results in reducing waste.

- Manage toward perfection: The last principle emphasizes continuous improvement and increases the transparency of products and processes, so that waste is shown on the surface. This principle is particularly important in a circular economy where, through continuous improvement, better and more efficient ways need to be found in order to keep the resources in a loop.

2.2. Natural-Resource-Based View

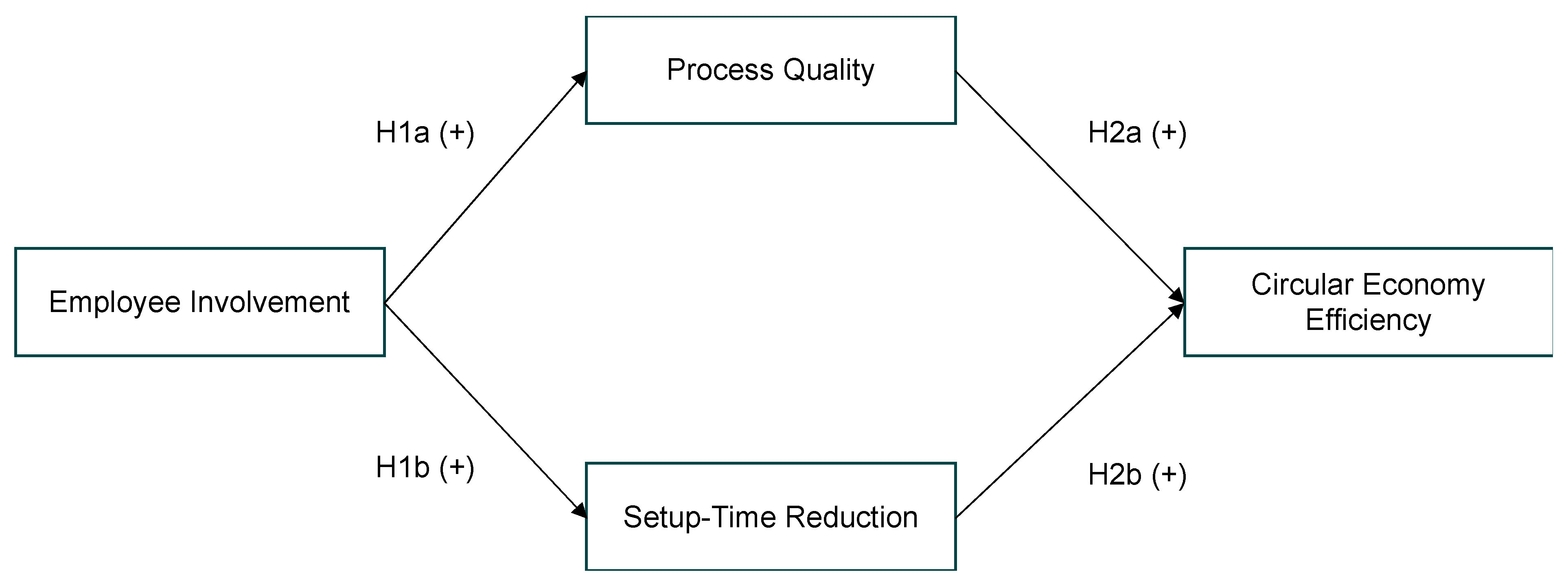

2.3. Hypothesis Development

3. Methodology

3.1. Data Collection

- 233—Manufacture of ceramic building materials;

- 235—Manufacture of cement, lime, and gypsum;

- 236—Manufacture of products from concrete, cement, and plaster;

- 237—Cutting, shaping, and finishing of stone;

- 239—Manufacture of grinding tools, abrasives products, and other products made from non-metallic minerals;

- 381—Collection of waste;

- 382—Waste treatment and repair;

- 383—Recovery;

- 41—Building construction;

- 42—Civil engineering;

- 43—Preparatory construction site work, construction installation, and other finishing trades.

3.2. Construct Measurement

3.3. Employee Involvement

- EI1:

- Shop-floor employees are key to problem-solving teams.

- EI2:

- Shop-floor employees drive suggestion programs.

- EI3:

- Shop-floor employees lead product/process improvement efforts.

- EI4

- Shop-floor employees undergo cross-functional training.

3.4. Setup Time Reduction

- SR1:

- Redesigns equipment to shorten setup time.

- SR2:

- Uses special tools to shorten setup time.

- SR3:

- Trains employees to reduce setup time.

- SR4:

- Redesigns jigs or fixtures to shorten setup time.

3.5. Process Quality

- PQ1:

- Scrap.

- PQ2:

- Rework.

- PQ3:

- On-time delivery.

- PQ4:

- Process time interruptions.

3.6. Circular Economy Efficiency

- CEE1:

- Use of recycled material in the production process.

- CEE2:

- Proactive waste reduction in terms of pollution prevention/waste elimination.

- CEE3:

- Reprocessing of used components in relation to products, where some of the parts or components are recovered or replaced.

- CEE4:

- Use of environmentally oriented design processes to design products eco-efficiently.

- CEE5:

- Quantifiable environmental targets are used in product development.

- CEE6:

- Environmentally friendly alternatives are specifically sought in product development.

3.7. Data Analysis

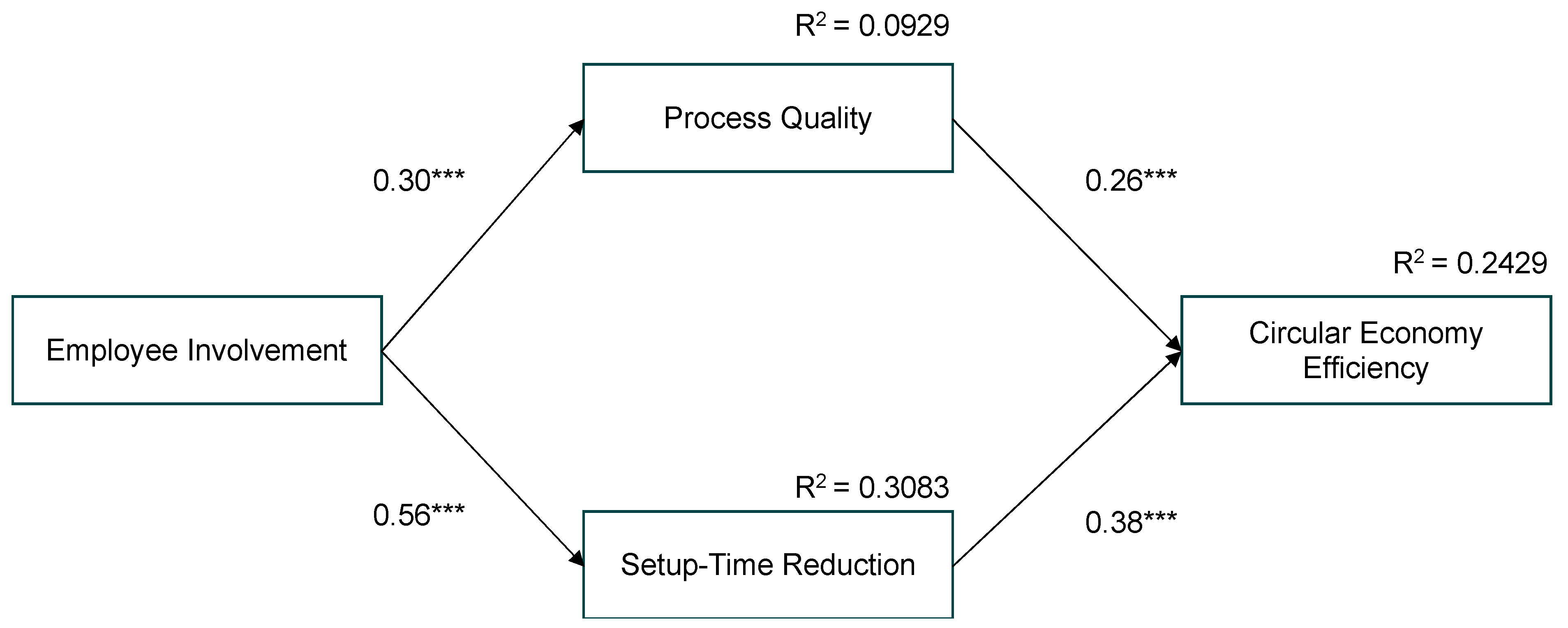

4. Results

5. Conclusions

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BIM | building information modeling |

| CEE | circular economy efficiency |

| CFI | comparative fit index |

| EI | employee involvement |

| EU | European Union |

| e.g. | exempli gratia—“for example” |

| FA | factor analysis |

| GHG | greenhouse gas emissions |

| i.e. | id est—“that is” |

| LCA | life cycle assessment |

| PSS | product service system |

| RMSEA | root mean square of approximation |

| SEM | structural equation model |

| SR | setup time reduction |

| SRMR | standardized root mean square residual |

| TLI | Tucker–Lewis index |

| TQM | total quality management |

Appendix A

| Variable | Factor Loadings |

|---|---|

| Circular Economy Efficiency | Cronbach’s Alpha: 0.8836 |

| CEE1 | 0.5294 |

| CEE2 | 0.5452 |

| CEE3 | 0.5091 |

| CEE4 | 0.7519 |

| CEE5 | 0.8419 |

| CEE6 | 0.8978 |

| Process Quality | Cronbach’s Alpha: 0.7591 |

| PQ1 | 0.5408 |

| PQ2 | 0.7045 |

| PQ3 | 0.5872 |

| PQ4 | 0.7045 |

| Setup Time Reduction | Cronbach’s Alpha: 0.8949 |

| ST1 | 0.7126 |

| ST2 | 0.8052 |

| ST3 | 0.9178 |

| ST4 | 0.8410 |

| Employee Involvement | Cronbach’s Alpha: 0.8687 |

| EI1 | 0.8291 |

| EI2 | 0.7964 |

| EI3 | 0.7958 |

| EI4 | 0.5954 |

| CEE | PQ | ST | EI | |

|---|---|---|---|---|

| CEE | 1 | |||

| PQ | 0.3363 *** | 1 | ||

| ST | 0.4543 *** | 0.2842 *** | 1 | |

| EI | 0.2637 ** | 0.3142 *** | 0.5544 *** | 1 |

References

- European Commission. Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Eurostat. Generation of Waste by Waste Category, Hazardousness and NACE Rev. 2 Activity [WWW Document]; Eurostat: Luxembourg, 2018. [Google Scholar]

- European Union. Level(s): Taking Action on the TOTAL Impact of the Construction Sector En. 2019. Available online: https://op.europa.eu/en/web/general-publications/doi (accessed on 14 July 2022).

- Hertwich, E.; Lifset, R.; Pauliuk, S.; Heeren, N.; Ali, S.; Tu, Q.; Ardente, F.; Berrill, P.; Fishman, T.; Kanaoka, K.; et al. Resource Efficiency and Climate Change: Material Efficiency Strategies for a Low-Carbon Future; International Resource Panel (IRP): Paris, France, 2019. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Chen, H.-M.; Sharmina, M.; Mendoza, J.M.F. Links between circular economy and climate change mitigation in the built environment. J. Clean. Prod. 2020, 260, 121115. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Keijer, T.; Bakker, V.; Slootweg, J.C. Circular chemistry to enable a circular economy. Nat. Chem. 2019, 11, 190–195. [Google Scholar] [CrossRef]

- Webster, K. The Circular Economy: A Wealth of Flows; The Ellen Macarthur Foundation: The Isle of Wight, UK, 2015. [Google Scholar]

- Evans, S.; Gregory, M.; Ryan, C.; Bergendahl, M.N.; Tan, A. Towards a Sustainable Industrial System: With Recommendations for Education, Research, Industry and Policy; University of Cambridge, Institute for Manufacturing: Cambridge, UK, 2009. [Google Scholar]

- European Commission. Circular Economy-Principles for Buildings Design; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Heisel, F.; Schlesier, K.; Hebel, D.E. Prototypology for a circular building industry: The potential of re-used and recycled building materials. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012023. [Google Scholar] [CrossRef]

- Dräger, P.; Letmathe, P.; Reinhart, L.; Robineck, F. Measuring circularity: Evaluation of the circularity of construction products using the ÖKOBAUDAT database. Environ. Sci. Eur. 2022, 34, 13. [Google Scholar] [CrossRef]

- Eisele, J.; Harzdorf, A.; Hüttig, L.; Otto, J.; Stroetmann, R.; Trautmann, B.; Weller, C. Multifunktionale Büro Und Geschäftshäuser; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Katerusha, D. Attitude towards sustainability, study contents and the use of recycled concrete in building construction-case study Germany and Switzerland. J. Clean. Prod. 2021, 289, 125688. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Swift, J.; Ness, D.; Kim, K.; Gelder, J.; Jenkins, A.; Xing, K. Towards adaptable and reusable building elements: Harnessing the versatility of the construction database through RFID and BIM. In Proceedings of the UIA 2017 Seoul World Architects Congress, Seoul, Republic of Korea, 3–10 September 2017; pp. 1–7. [Google Scholar]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Ünal, E.; Urbinati, A.; Chiaroni, D.; Manzini, R. Value Creation in Circular Business Models: The case of a US small medium enterprise in the building sector. Resour. Conserv. Recycl. 2019, 146, 291–307. [Google Scholar] [CrossRef]

- Hart, S. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef]

- Rothenberg, S.; Pil, F.K.; Maxwell, J. Lean, Green, and the Quest for Superior Environmental Performance. Prod. Oper. Manag. 2009, 10, 228–243. [Google Scholar] [CrossRef]

- King, A.A.; Lenox, M.J. Lean and green? An empirical examination of the relationship between lean production and environmental performance. Prod. Oper. Manag. 2009, 10, 244–256. [Google Scholar] [CrossRef]

- Letmathe, P. Flexbile Standardisierung: Ein Dezentrales Produktionsmanagement Für Kleine Und Mittlere Unternehmen; Deutscher Universitäts-Verlag GmbH: Wiesbaden, Germany, 2002. [Google Scholar]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Bakker, C.; Wang, F.; Huisman, J.; den Hollander, M. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving ‘leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef]

- Dräger, P.; Letmathe, P. Value losses and environmental impacts in the construction industry—Tradeoffs or correlates? J. Clean. Prod. 2022, 336, 130435. [Google Scholar] [CrossRef]

- Chui, M.; Mischke, J. Global Infrastructure Initiative the Impact and Opportunities of Automation in Construction. McKinsey 2019. Available online: https://www.mckinsey.com/~/media/McKinsey/Industries/Capital%20Projects%20and%20Infrastructure/Our%20Insights/The%20impact%20and%20opportunities%20of%20automation%20in%20construction/The-impact-and-opportunities-of-automation-in-construction.pdf (accessed on 25 July 2022).

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Love, P.E.D.; Heng, L.I.; Irani, Z.; Faniran, O. Total quality management and the learning organization: A dialogue for change in construction. Constr. Manag. Econ. 2000, 18, 321–331. [Google Scholar] [CrossRef]

- Egan, S.J. Rethinking Construction: Report of the Construction Task Force, Construction Task Force. Dep. Environ. 1998. Available online: http://constructingexcellence.org.uk/wp-content/uploads/2014/10/rethinking_construction_report.pdf (accessed on 19 May 2021).

- Denham, N.; Ackers, P.; Travers, C. Doing yourself out of a job? Empl. Relat. Int. J. 1997, 19, 147–159. [Google Scholar] [CrossRef]

- Marin-Garcia, J.A.; Bonavia, T. Relationship between employee involvement and lean manufacturing and its effect on performance in a rigid continuous process industry. Int. J. Prod. Res. 2015, 53, 3260–3275. [Google Scholar] [CrossRef]

- Alazzaz, F.; Whyte, A. Linking employee empowerment with productivity in off-site construction. Eng. Constr. Arch. Manag. 2015, 22, 21–37. [Google Scholar] [CrossRef]

- Price, A.D.F.; Bryman, A.; Dainty, A.R.J. Empowerment as a Strategy for Improving Construction Performance. Leadersh. Manag. Eng. 2004, 4, 27–37. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, H.; Kang, X.; Lu, W. Critical success factors for on-site sorting of construction waste: A china study. Resour. Conserv. Recycl. 2010, 54, 931–936. [Google Scholar] [CrossRef]

- Kurdve, M.; Bellgran, M. Green lean operationalisation of the circular economy concept on production shop floor level. J. Clean. Prod. 2021, 278, 123223. [Google Scholar] [CrossRef]

- Kurdve, M.; Wiktorsson, M. Green performance map: Visualizing environmental KPI’s. In Proceedings of the International EurOMA Conference, Dublin, Ireland, 7–12 June 2013. [Google Scholar]

- Diekmann, J.E.; Krewedi, M.; Joshua, B.; Stewart, T.; Won, S. Application of Lean Manufacturing Principles to Construction; University of Colorado: Denver, CO, USA, 2005. [Google Scholar]

- Jørgensen, B.; Emmitt, S. Lost in transition: The transfer of lean manufacturing to construction. Eng. Constr. Arch. Manag. 2008, 15, 383–398. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University: Stanford, CA, USA, 1992; Volume 72. [Google Scholar]

- Francis, A.; Thomas, A. Exploring the relationship between lean construction and environmental sustainability: A review of existing literature to decipher broader dimensions. J. Clean. Prod. 2020, 252, 119913. [Google Scholar] [CrossRef]

- Holt, G.D.; Love, P.E.d.; Jawahar Nesan, L. Employee empowerment in construction: An implementation model for process improvement. Team Perform. Manag. Int. J. 2000, 6, 47–51. [Google Scholar] [CrossRef]

- Porter, M.E.; van der Linde, C. Toward a New Conception of the Environment-Competitiveness Relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Bon, R.; Hutchinson, K. Sustainable construction: Some economic challenges. Build. Res. Inf. 2000, 28, 310–314. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Womack, J.; Jones, D.; Roos, D. The Machine That Changed the World: The Story of Lean Production, Toyota’s Secret Weapon in the Global Car Wars That Is Now Revolutionizing World Industry; Free Press: New York, NY, USA, 1990. [Google Scholar]

- Circular Economy Institute (CEI). Renting lighting: Schiphol Airport [WWW Document]. 2015. Available online: https://www.circulareconomyclub.com/solutions/renting-lighting-schiphol-airport/#post_profile (accessed on 14 July 2022).

- ClimateKIC; Azcarate-Aguerre, J.F. Project: Façade Leasing. 2015. Available online: https://www.climate-kic.org/projects/facade-leasing/ (accessed on 7 December 2022).

- Azcarate-Aguerre, J.F.; Klein, T.; Vrijhoef, R. Façade Leasing: Drivers and Barriers to the Delivery of Integrated Façades-as-a-Service Creating the Network of Knowledge Labs for Sustainable and Resilient Environments-KLABS View Project Juritecture View Project. 2018. Available online: https://www.researchgate.net/publication/329034829 (accessed on 7 December 2022).

- Perey, R.; Benn, S.; Agarwal, R.; Edwards, M. The place of waste: Changing business value for the circular economy. Bus. Strat. Environ. 2018, 27, 631–642. [Google Scholar] [CrossRef]

- Hazen, B.T.; Mollenkopf, D.A.; Wang, Y. Remanufacturing for the Circular Economy: An Examination of Consumer Switching Behavior. Bus. Strat. Environ. 2017, 26, 451–464. [Google Scholar] [CrossRef]

- Ciliberto, C.; Szopik-Depczyńska, K.; Tarczyńska-Łuniewska, M.; Ruggieri, A.; Ioppolo, G. Enabling the Circular Economy transition: A sustainable lean manufacturing recipe for Industry 4.0. Bus. Strat. Environ. 2021, 30, 3255–3272. [Google Scholar] [CrossRef]

- Yang, M.G.; Hong, P.; Modi, S.B. Impact of lean manufacturing and environmental management on business performance: An empirical study of manufacturing firms. Int. J. Prod. Econ. 2011, 129, 251–261. [Google Scholar] [CrossRef]

- Durmiševic, E. Reversible building design. In Designing for the Circular Economy; Charter, M., Ed.; Routledge: New York, NY, USA, 2018; pp. 344–359. [Google Scholar] [CrossRef]

- Dixit, S.; Mandal, S.N.; Sawhney, A.; Singh, S. Relationship between skill development and productivity in construction sector: A literature review. Int. J. Civ. Eng. Technol. 2017, 8, 649–665. [Google Scholar]

- Lapré, M.A.; Mukherjee, A.S.; Van Wassenhove, L.N. Behind the Learning Curve: Linking Learning Activities to Waste Reduction. Manag. Sci. 2000, 46, 597–611. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Moringa, n.d. Moringa [WWW Document]. 2022. Available online: www.moringa.eco (accessed on 7 December 2022).

- ZukunftBau. Material Recovery Right; Forschungsförderung; ZukunftBau: Aachen, Germany, 2022; Available online: https://www.zukunftbau.de/projekte/forschungsfoerderung/1008187-2247#projektbeteiligte (accessed on 7 December 2022).

- Dhingra, R.; Kress, R.; Upreti, G. Does lean mean green? J. Clean. Prod. 2014, 85, 1–7. [Google Scholar] [CrossRef]

- Yang, C.-L.; Lin, S.-P.; Chan, Y.-H.; Sheu, C. Mediated effect of environmental management on manufacturing competitiveness: An empirical study. Int. J. Prod. Econ. 2010, 123, 210–220. [Google Scholar] [CrossRef]

- Nam, C.H.; Tatum, C.B. Major characteristics of constructed products and resulting limitations of construction technology. Constr. Manag. Econ. 1988, 6, 133–147. [Google Scholar] [CrossRef]

- Han, S.; Lee, S.; Fard, M.G.; Pena-Mora, F. Modeling and representation of non-value adding activities due to errors and changes in design and construction projects. In Proceedings of the 2007 Winter Simulation Conference, Washington, DC, USA, 9–12 December 2007; pp. 2082–2089. [Google Scholar] [CrossRef]

- Wu, P.; Low, S.P.; Jin, X. Identification of non-value adding (NVA) activities in precast concrete installation sites to achieve low-carbon installation. Resour. Conserv. Recycl. 2013, 81, 60–70. [Google Scholar] [CrossRef]

- Melenbrink, N.; Werfel, J.; Menges, A. On-site autonomous construction robots: Towards unsupervised building. Autom. Constr. 2020, 119, 103312. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Developing strategies for managing construction and demolition wastes in Malaysia based on the concept of circular economy. J. Mater. Cycles Waste Manag. 2017, 19, 1144–1154. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Nußholz, J.L.K.; Nygaard Rasmussen, F.N.; Milios, L. Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour. Conserv. Recycl. 2019, 141, 308–316. [Google Scholar] [CrossRef]

- Akanbi, L.; Oyedele, L.; Delgado, J.M.D.; Bilal, M.; Akinade, O.; Ajayi, A.; Mohammed-Yakub, N. Reusability analytics tool for end-of-life assessment of building materials in a circular economy. World J. Sci. Technol. Sustain. Dev. 2019, 16, 40–55. [Google Scholar] [CrossRef]

- Xue, K.; Hossain, U.; Liu, M.; Ma, M.; Zhang, Y.; Hu, M.; Chen, X.; Cao, G. BIM Integrated LCA for Promoting Circular Economy towards Sustainable Construction: An Analytical Review. Sustainability 2021, 13, 1310. [Google Scholar] [CrossRef]

- Eurostat. NACE Rev. 2–Statistical Classification of Economic Activities in the European Community, Office for Official Publications of the European Communities; Eurostat: Luxembourg, 2008. [Google Scholar]

- Babakus, E.; Mangold, W.G. Adapting the SERVQUAL scale to hospital services: An empirical investigation. Health Serv. Res. 1992, 26, 767–786. [Google Scholar]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Marodin, G.; Frank, A.G.; Tortorella, G.L.; Netland, T. Lean product development and lean manufacturing: Testing moderation effects. Int. J. Prod. Econ. 2018, 203, 301–310. [Google Scholar] [CrossRef]

- Fullerton, R.R.; Wempe, W.F. Lean manufacturing, non-financial performance measures, and financial performance. Int. J. Oper. Prod. Manag. 2009, 29, 214–240. [Google Scholar] [CrossRef]

- Montabon, F.; Sroufe, R.; Narasimhan, R. An examination of corporate reporting, environmental management practices and firm performance. J. Oper. Manag. 2007, 25, 998–1014. [Google Scholar] [CrossRef]

- Lee, L.; Petter, S.; Fayard, D.; Robinson, S. On the use of partial least squares path modeling in accounting research. Int. J. Account. Inf. Syst. 2011, 12, 305–328. [Google Scholar] [CrossRef]

- Bollen, K.A. Structural Equations with Latent Variables; Wiley: New York, NY, USA, 1989. [Google Scholar]

- Hair, J.F. Multivariate Data Analysis; Kennesaw State University: Kennesaw, GA, USA, 2009. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Matthews, L.M.; Matthews, R.L.; Sarstedt, M. PLS-SEM or CB-SEM: Updated guidelines on which method to use. Int. J. Multivar. Data Anal. 2017, 1, 107. [Google Scholar] [CrossRef]

- Hu, L.T.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Model. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Jang, S.; Lee, G. Process, productivity, and economic analyses of BIM–based multi-trade prefabrication—A case study. Autom. Constr. 2018, 89, 86–98. [Google Scholar] [CrossRef]

| # | References | Circular Economy | Process Orientation | Employee Orientation | Construction Industry |

|---|---|---|---|---|---|

| [16] | Geissdoerfer et al. (2018) | X | - | - | X |

| [17] | Swift et al. (2017) | X | - | - | X |

| [18] | Leising et al. (2018) | X | - | - | X |

| [19] | Ünal et al. (2019) | X | X | ||

| [21] | Rothenberg et al. (2009) | X | X | - | - |

| [22] | King and Lenox (2009) | X | X | - | - |

| [24] | Pomponi and Moncaster (2017) | X | - | - | X |

| [23] | Letmathe (2002) | - | X | X | - |

| [25] | Geissdoerfer et al. (2017) | X | - | - | - |

| [26] | Bakker et al. (2014) | X | - | - | - |

| [27] | Bocken et al., (2016) | X | - | - | - |

| [28] | Geng and Doberstein (2008) | - | X | - | X |

| [29] | Dräger and Letmathe (2022) | X | X | - | X |

| [31] | Benachio et al. (2020) | X | - | - | X |

| [32] | Love et al. (2000) | - | X | X | X |

| [33] | Egan (1998) | - | - | X | X |

| [34] | Denham et al. (1997) | - | - | X | X |

| [35] | Marin-Garcia and Bonavia (2015) | - | X | X | - |

| [36] | Alazzaz and Whyte (2015) | - | X | X | X |

| [37] | Price et al. (2004) | - | - | X | X |

| [38] | Wang et al. (2010) | X | - | X | X |

| [39] | Kurdve and Bellgran (2021) | X | X | X | - |

| [40] | Kurdve and Wiktorsson (2013) | X | X | ||

| [41] | Diekmann et al. (2005) | - | X | X | X |

| [42] | Jørgensen and Emmitt (2008) | - | X | - | X |

| [43] | Koskela (1992) | - | X | - | X |

| [44] | Francis and Thomas (2020) | X | X | - | X |

| [45] | Holt et al. (2000) | - | X | X | X |

| [46] | Porter and Linde (1995) | - | X | - | - |

| [47] | Bon and Hutchinson (2000) | X | - | - | X |

| [48] | Cherrafi et al. (2016) | X | X | X | - |

| Model 1 | Model 2 | Model 3 | |

|---|---|---|---|

| PQ → CEE | 0.2595437 *** | 0.355743 *** | 0.2624001 ** |

| SR → CEE | 0.3773866 | 0.3648605 *** | 0.3859567 *** |

| EI → CEE | −0.0165585 | ||

| EI → PQ | 0.3048599 *** | 0.5350242 *** | 0.3048599 *** |

| EI → SR | 0.5552202 *** | 0.6408256 *** | 0.5552202 *** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dräger, P.; Letmathe, P. Who Drives Circularity?—The Role of Construction Company Employees in Achieving High Circular Economy Efficiency. Sustainability 2023, 15, 7110. https://doi.org/10.3390/su15097110

Dräger P, Letmathe P. Who Drives Circularity?—The Role of Construction Company Employees in Achieving High Circular Economy Efficiency. Sustainability. 2023; 15(9):7110. https://doi.org/10.3390/su15097110

Chicago/Turabian StyleDräger, Philipp, and Peter Letmathe. 2023. "Who Drives Circularity?—The Role of Construction Company Employees in Achieving High Circular Economy Efficiency" Sustainability 15, no. 9: 7110. https://doi.org/10.3390/su15097110