Abstract

Phosphoric acid (H3PO4) is a product that can be used as a stabilizing additive for tropical soils in an exploratory manner by the construction industry. For the drying process of this grain, its husks are used as fuel for ovens, generating rice husk ash (RHA), which is considered an environmental liability if not reused. In this sense, this paper aimed to evaluate the resilient behavior and the simple compressive strength, at different curing ages, of the use of rice husk ash and phosphoric acid in a simple and combined mixture for the stabilization of lateritic soil. The lateritic soil was mixed with different contents of RHA, H3PO4, and water and compacted in intermediate and modified Proctor energies. Fractured soil samples in the mechanical compressive strength tests were analysed by scanning electron microscopy and X-ray diffraction. The results show the potential for stabilization of the lateritic soil in question in terms of resilience and simple compressive strength through the addition of RHA and H3PO4 at different curing ages. The insertion of only H3PO4 produced the most satisfying resilient behavior. By adding RHA, the strength properties were improved, and good mixtures were obtained for use in paving.

1. Introduction

The use of soils in pavement structures designed according to the Brazilian empirical-mechanistic methodology is conditioned to the performance of cyclic tests to assess the resilient modulus (RM), which measures its stiffness and which conditions, together with the thickness of the layers, the states of the stresses, strains, and displacements of the structure. Resilient behavior is dependent on several factors, such as the physical state, the nature and composition of the materials, the degree of saturation, the compaction density and moisture, and the history and state of stresses, among other things [1,2,3,4,5,6,7].

Soils of tropical origin used in paving works can be made unfeasible due to the support capacity of the material in its natural state and when compacted. An alternative used to enable the use of soils with low bearing capacity is stabilization, whether chemical, mechanical and/or granulometric [8,9,10]. Traditional stabilizers such as cement, lime, fly ash and bituminous materials are widely used and studied; however, non-traditional stabilizers need more precise analysis to verify their effectiveness in treating soils [11,12,13].

A wide variety of materials can be used to stabilize the soils used in pavements, aiming to improve the properties of strength, compressibility, permeability, plasticity, and durability [14,15]. Therefore, it is necessary to know the physical, chemical, and mechanical properties of the soil and the additive to be used [16]. Scanning electron microscopy (SEM) and X-ray diffraction (XRD) tests have been useful in evaluating the microstructure of soils with different stabilizing agents, as each type of additive causes different influences and mechanisms in soil stabilization [17,18].

In this alignment, additives that are unconventional but with local availability, as by-products of the industry and previously discarded as waste, have gained notoriety aiming at sustainability [13,15,19,20,21,22,23,24,25,26,27,28,29,30,31].

Rice husk ash (RHA) is waste generated globally, and studies on its use are important for sustainable reasons. Brazil is one of the largest rice producers in the world, with 11.7 million tons produced in 2018, and the southern region is responsible for around 70% of national production [32]. RHA is used as fuel for ovens in the rice-drying process, generating a large amount of ash. In this process, in many cases, there is no control of temperature, burning, or cooling time, and RHA’s pozzolanic properties are compromised, requiring industrial landfills to be deposited, generating, in addition to environmental liabilities, transport and disposal costs.

The use of RHA has shown positive results in the field of paving [33,34,35,36,37,38,39]. RHA is a light, bulky material with high porosity, consisting of more than 90% silica [40]. Its physical/chemical characteristics are directly related to aspects of the burning process, including the temperature, burning time, and cooling method.

H3PO4 is a product used in the pharmaceutical and food industries, among others, and in the field of paving, it has been the object of studies, showing good performance in the stabilization of tropical soils [11,13,41]. Given the fact that stabilization takes place by the chemical action of the additive on the soil minerals, thin soils are the most suitable for this stabilization. The stabilization of soils with phosphoric acid is understood because of the chemical reactions of the acid with the minerals present in the soil based on Fe2O3 and Al2O3. According to [13,42], H3PO4 reacts with those minerals exothermically and may contribute, in a promising way, to the stabilization of soils rich in iron and aluminium oxides.

The treatment of fine clayey soils with phosphoric acid results in the formation of compounds of phosphorus and iron or aluminium, which are hard, insoluble, and crystalline. Free Fe2O3 promotes the formation of these compounds, which makes the bearing capacity of soil thus treated greatly increased. This stabilization process generates strong chemical bonds, and in case of leaching, there will be no environmental damage by the generated compounds [41]. The isolated addition of CCA does not result in gains in strength and resilience in mixtures with lateritic soil; however, the combined addition of H3PO4 makes the use of this waste viable because, besides the environmental bias, it facilitates workability and improves mechanical performance.

The increase in H3PO4 in tropical soil demonstrates the reduction in the intensity of the crystalline peaks, showing that the acid reacts with the crystalline phases of the tropical soil, possibly forming amorphous or crystalline products, which justifies the better mechanical performance of that material [11].

In this sense, this work aimed to evaluate the use of rice husk ash and phosphoric acid, in a simple and combined way, to stabilize lateritic soil and to use it in base and subbase layers of pavements. For this purpose, resilient modulus and simple compressive strength tests were conducted at different curing ages and under varied compaction energies. To understand the behavior of the mixtures under the influence of compaction, scanning electron microscopy tests were conducted, and X-ray diffraction tests were conducted to analyse the mixtures’ compositions.

2. Materials and Methods

2.1. Materials

The lateritic clayey soil came from the city of Cruz Alta, located in the state of Rio Grande do Sul (Brazil). Its collection was conducted on pedological horizon B, under coordinates 28°37′39.40″ S and 53°37′30.50″ W. The soil in question, shown in Figure 1A, originates from Botucatu sandstone or the junction of Botucatu sandstone with basalt. The soil has a reddish colour and medium texture, with approximately 35% clay in its composition. It consists of a typical dystrophic red latosol, with the presence of A, B, and C horizons, with an indistinct transition between them. It presents a slight podzolization, with the migration of aluminium and organic matter, with or without the presence of iron, up to the B horizon.

Figure 1.

(A) Lateritic clayey soil passing through the 4.75 mm opening sieve; (B) rice husk ash; (C) mixture of soil, RHA, and phosphoric acid (H3PO4); (D) compacted specimen; (E) repeated load triaxial equipment.

The authors [43] performed the physical, chemical, and soil classification, shown in Table 1. They verified the influence of compaction energy on the resilient behavior of the three horizons of the deposit. They showed the good resilient behavior of the compressed horizons in the three Proctor energies, particularly the intermediate and modified energies. There is an increase in stiffness as the compaction energy increases. This can directly impact the distribution of the internal forces of a pavement, which is correlated with the parameters of the compaction curve and the physical indices of the soil condition.

Table 1.

Physical and chemical characterization and classification of the lateritic soil used in this study [43].

By analyzing the granulometric distribution of the soil, it appears that it is composed of 67% fine grains and 33% sandy material. According to the Atterberg limits, the soil presents high plasticity, corroborating the particle size analysis and the predominance of clay particles. Regarding the AASHTO and USCS classifications, the soil in question falls, respectively, in the A-7-6 group, corresponding to plastic clays with the presence of organic matter and high compressibility, and in the MH group, being considered an inorganic elastic silt. However, in the MCT classification [44,45], which was developed for tropical soils, the soil is considered a clay with lateritic behavior (LG’), having low mass loss by immersion, high bearing capacity, low expansion, low permeability, and medium to high plasticity.

Regarding chemical characterization, the presence of silicon dioxide, iron oxide, and aluminium oxide prevailed, with results consistent with the MCT classification and the physical particularities of the deposit. The presence of iron and aluminium hydroxides causes the natural cementation of the material, enhancing its application. The organic matter portion is related to the cation exchange capacity (CEC), characterizing the B horizon as clay with low activity and little or no presence of organic matter.

The rice husk ash used (Figure 1B) was generated in an industry located in the city of Alegrete in the State of Rio Grande do Sul (Brazil). The ash came from the burning of this husk in a rice drying oven without temperature control and with unknown burning and cooling time. The RHA presents a dark color due to the presence of high carbon content and due to the burning being performed at temperatures ranging from 400 to 700 °C. According to the authors [46], burning in this temperature range results in an RHA with a predominance of amorphous structures, responsible for pozzolanic reactions in the presence of calcium hydroxides.

An attempt was made to verify the size of its particles; however, the ash presented with a brittle behavior, and its particles broke as it was sieved. The longer it was sieved, the finer its granulometry. A good portion of the mixture of soil and RHA passed through a sieve of size 0.075 mm, being necessary to perform a sedimentation test. However, when the two materials were stirred, the ash remained in suspension in inside the test cylinder, making it impossible to analyze it.

2.2. Methods

Table 2 summarizes the mixtures conducted, the nomenclatures adopted, the compaction energy used, and the ideal parameters for the compaction of the samples. The definitions of the mixing conditions analyzed in the present research were based on the conclusions of some researchers [41,47] who evaluated the use of RHA and H3PO4 with lateritic soils, concluding that the ideal RHA content varies between 3 and 5%, as well as that the acid is limited to 3% insertion.

Table 2.

Mixing conditions, compaction energy, and nomenclatures used.

The compaction parameters were obtained for each of the ten conditions in a tripartite mould of 100 mm in diameter and 200 mm in height, following the precepts of [48], to obtain the maximum apparent dry mass of the soil (MDD) and optimum moisture (OMC). Ten conditions were analyzed, including two as reference (without chemical stabilizer) and eight mixtures with different energies. Figure 1C illustrates the mixture of lateritic soil with RHA and H3PO4 before material compaction, and Figure 1D shows a compacted specimen about to be tested in the repeated load triaxial equipment (Figure 1E).

The increase in compaction energy results in an increase in the maximum apparent dry mass and a decrease in the optimum reference soil moisture. This behavior is repeated in soil mixtures with RHA and H3PO4 as energy increases. On the other hand, as more RHA is added to the mixtures, the maximum apparent dry mass is increasingly smaller while the moisture content increases. The low density of ash grains justifies this phenomenon of reduced density with the inclusion of RHA, a behavior also evidenced by some research [47,49,50].

2.2.1. Mechanical Tests

The resilient modulus tests were conducted in the repeated load triaxial (RLT) equipment, which is capable of reproducing the cyclic loading conditions that occur in a pavement structure in the labratory. The precepts of the DNIT standard [4] were followed, which has procedures similar to those in AASHTO [51].

For molding the specimens in a mechanical impact compactor, the maximum variations of ±0.5% about the optimum moisture and ±1.0% about the maximum density were respected. Different curing ages of the samples were evaluated with additions of RHA and/or H3PO4 at IE and ME energies, with tests being conducted at the ages of 7, 28, 56, and 91 days. The reference soil was tested with 0 days in the two Proctor compaction energies.

To determine the resilient parameters, two consolidated models, presented in Table 3, were used [43,52,53,54,55,56,57,58], which correlate the applied stresses with experimentally determined constants. Non-linear multiple regressions were performed using the Statistica 10.0 software to verify the model that best represents the behavior of each condition.

Table 3.

Models used to obtain resilient parameters.

Furthermore, to identify the contribution of additives to soil strength, simple compressive strength (UCS) tests were performed according to [61] in molded specimens measuring 50 mm in diameter and 100 mm in height following the optimum compaction conditions presented in Table 2. These were tested at the curing ages of 7 days for the two reference soil conditions and 7 and 91 days for the other mixtures. The choices of these curing ages were strategic, aiming to conduct the tests at the initial and older ages at which the resilient parameters of the proposed mixtures were obtained.

2.2.2. Scanning Electron Microscopy

Scanning electron microscopy was performed to observe the modifications that occurred in different sample conditions. From scanning electron microscopy, it is possible to perform physical visualization of the structural arrangement of the particles, as well as the shape and particle size, while also enabling a perception of the voids present in the material, which tends to vary with the compaction energy and with different compositions. Thus, samples of fractured soils were analysed by scanning electron microscopy, including the reference soil (aged 7 days) and soils containing RHA and H3PO4 (aged 7, 28, and 56 days), at 1000× magnification. The samples were dried in an oven at a temperature of 60 °C for 24 h and then metalized with gold. A JEOL JSM-6360 (Austin, TX, USA) scanning electron microscope was used.

2.2.3. X-ray Diffraction

The mineralogical characterization of the reference soil, RHA, and soil samples containing different levels of RHA, and H3PO4 was performed with the Rigaku diffractometer, model Miniflex® 300, which presents Cu Kα radiation (λ = 1.54051 Å) and energy source of 30 kV, and 10 mA. The Step Mode has a Scan speed of 0.5 s and Scan step of 0.03°, in angles from 5° to 60°. To conduct the XRD analyses, the reference soil and the RHA passing through a 0.149 mm mesh (mesh 100) and 75 µm mesh (mesh 200) sieve were analysed, respectively. Furthermore, the samples for the four mixtures presented in Table 2 were analysed from the crushing and sieving (100 mesh opening) of the specimens compacted in the modified energy at the curing ages of 7, 28, and 56 days. In order to identify the crystalline phases of the studied samples, crystallographic files from the American Mineralogist Crystal Structure Database (AMCSD) were consulted.

3. Results and Discussion

3.1. Resilient Modulus and Simple Compressive Strength

For each condition of addition of phosphoric acid and/or RHA, three specimens were compacted and submitted to the resilient modulus test at the four curing ages, except for dosage S3, which had its samples tested at 7 and 28 days. After repeated load triaxial testing, using non-linear multiple regression, the compound and universal models were evaluated, which have their parameters k1, k2, and k3, shown in Table 4, as well as the average resilient modulus obtained after regression for the joint analysis of the three samples tested for each condition.

Table 4.

Resilient parameters and average resilient modulus for compound and universal models.

The compound and universal models showed good correlations, thus representing the behavior of the conditions and mixtures in question well. When comparing the curing ages within the same mixture condition in both models, it is noted that there is an increase in k1 values in all tested mixtures, regardless of the compaction energy. Therefore, there is a gain in resilience with the addition of the curing age for the same dosage. When comparing the two compaction energies, it is evident that the value of the resilient modulus increases as the compaction energy increases from intermediate to modified.

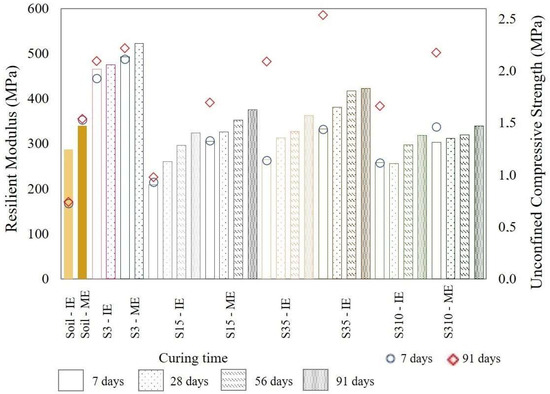

To facilitate the visualization of the mechanical behavior of the evaluated conditions, Figure 2 demonstrates the average resilient modulus for the compound model at different curing ages and the simple compressive strength obtained at 7 and 91 days. The soil compacted in the intermediate energy presented an average RM of 287 MPa and 340 MPa in the modified energy. Regarding the simple compressive strength, the variation of the curing age did not interfere with the behavior, presenting 0.73 MPa and 1.53 MPa for the intermediate and modified energies, respectively, in the two evaluated ages.

Figure 2.

Average RM for the different soil conditions and mixtures analyzed, evaluated by the compound model for four curing ages, and UCS at 7 and 91 days.

The S3 mixture, which involves soil and phosphoric acid, showed the best resilient behavior, reaching 475 MPa and 523 MPa at 28 days in intermediate and modified energies, respectively. There was no considerable gain in compressive strength as the curing ages increased, ranging from 1.91 to 2.10 MPa for intermediate energy in 7 and 91 days, respectively, and 2.11 to 2.22 MPa for modified energy at the same ages.

The addition of RHA in the soil and H3PO4 mixtures resulted in different behavior from the S3 condition. The increase in RHA interfered negatively with the resilient modulus of the S15, S35, and S310 mixtures compared to the reference soil and the S3 mixture. At an early age, the resilient modulus value of these three mixtures was lower than the reference soil in the two compaction energies. Among the mixtures involving RHA, S35 was the one that stood out both in terms of resilient behavior and simple compressive strength when compared to the two energies of the reference soil. S310 had the worst resilience gain among the samples involving RHA as the time interval was varied, while the worst behavior and strength gain was for S15.

Thus, when analyzing all test conditions, it can be concluded that S3 has the best mechanical behavior in the performed tests. Among the samples involving RHA, S35 showed good behaviors. However, the insertion of 10% RHA was not beneficial in the S310 mixture.

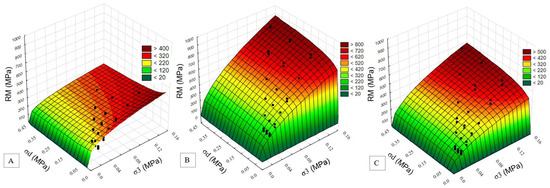

In Figure 3, it is possible to observe the behavior of the samples analyzed with the composite model; in Figure 3A, the behavior of Soil-IE is shown, and in Figure 3B,C, the comportment of S3-IE and S35-IE can be analyzed, respectively. In these figures, it is possible to verify the behavior as the stresses are elevated as well as the average resilient modulus.

Figure 3.

Resilient modulus by composite model: (A) Soil-IE; (B) S3-IE (age 28 days); (C) S35-IE (age 28 days).

The behavior of Soil-IE (Figure 3A) indicates that as the deviating stress increases, there is a decrease in the resilient modulus, whereas as the confining stress increases, there is an increase in the RM. The same behavior regarding stresses can be observed for the S3-IE (Figure 3B) and S35-IE conditions at 28 days (Figure 3C). The RM rises when adding H3PO4 alone and when adding RHA and H3PO4 in combination with fine soil.

It is important to note that the workability when using a mixture with phosphoric addition was difficult compared to the reference soil. However, when introducing RHA into the mixture, it was noticed that RHA reduced the impact of H3PO4 on this factor, and the higher the content of ash on the acid, the better the workability of the mixture. Thus, the use of RHAA, besides contributing to a correct destination aiming at sustainability, tends to improve the mechanical behavior of this lateritic soil.

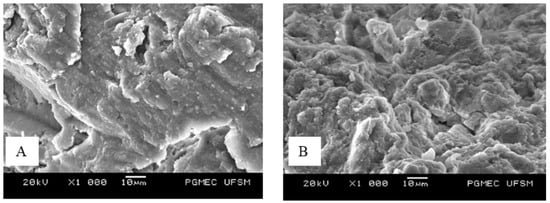

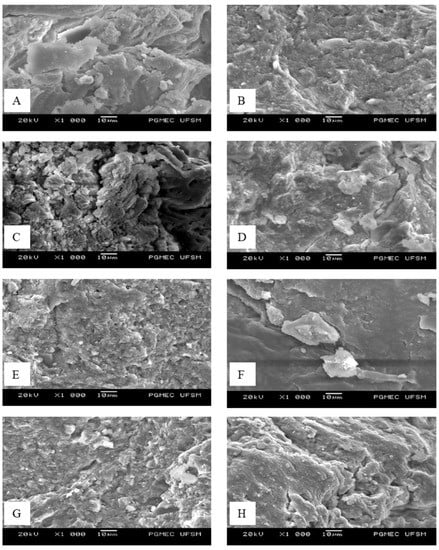

3.2. Electron Microscopy

Figure 4A,B shows micrographs of the fracture surface of samples of compacted reference soils at intermediate and modified energies, respectively, aged 7 days, with a magnitude of 1000×. It is observed that in both samples, the surface presents with a dense aspect, with no noticeable difference in morphology regardless of the compaction energy.

Figure 4.

Micrograph of the fracture surface of the 7-day-old reference soil samples: (A) compacted at intermediate energy; (B) compacted in modified energy.

Although the simple compressive strength is greater for the modified energy sample (1.53 MPa) than for the intermediate energy sample (0.73 MPa), no morphological change is noticed. It is inferred that the reference soil sample compacted at intermediate energy (Figure 4A) presents higher added moisture content, providing this sample with a morphological aspect with greater compactness, similar to samples compacted at modified energy (Figure 4B).

Figure 5 shows several micrographs of the fracture surface of soil samples containing different mixtures with H3PO4 and/or RHA compacted in intermediate and modified energies, aged 28 days. All micrographs presented have a magnitude of 1000× to enable comparison between samples.

Figure 5.

Micrographs of the fracture surface of soil samples aged 28 days: (A) S3-IE, (B) S3-ME, (C) S15-IE, (D) S15-ME, (E) S35-IE, (F) S35-ME, (G) S310-IE, and (H) S310-ME.

It is observed that there was greater compactness of soil samples compacted in modified energy (Figure 5B,D,F,H) when compared to samples compacted in intermediate energy (Figure 5A,C,E,G), with emphasis on the S3 sample compressed in the modified energy. This corroborates with the greater dry apparent specific weight reached by the S3-ME sample (see Table 1), as well as the greater compressive strength at the ages of 7 days and 91 days, as shown in Figure 2. On the other hand, the morphology of the S15-IE soil sample presents the lowest compactness compared to the other morphologies. This lower compactness corroborates the lower compressive strength results of the S15-IE sample at the ages of 7 days and 28 days when compared to the strengths reached by the other samples, except for the reference sample.

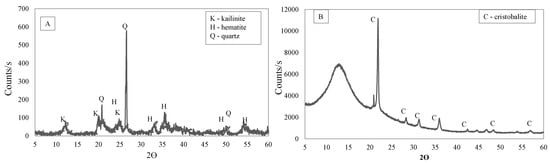

3.3. X-ray Diffractograms

Based on the X-ray diffractogram of the natural soil, shown in Figure 6A, characteristic crystalline peaks of quartz (SiO2), kaolinite (Al2Si2O5(OH)4), and hematite (Fe2O3) were identified. It was possible to identify the presence of quartz (SiO2) in regions close to 2Ɵ = 20.87°, 26.65°, and 50.17° (#AMCSD 0000790), kaolinite (Al2Si2O5(OH)4)) in regions close to 2Ɵ = 12.41°, 20.38°, and 24.97° (#AMCSD 0012237), and hematite (Fe2O3) in regions close to 2Ɵ = 24.16°, 33.21°, 35.62°, 49.49°, and 54.14° (#AMCSD 0002226).

Figure 6.

X-ray diffractogram: (A) natural soil, (B) RHA.

An analysis of the RHA X-ray diffractogram, Figure 6B, shows an amorphous halo between 10° and 20°. This diffractogram confirms that there is no control in the rice husk ash burning process. It is also observed that characteristic crystalline peaks are identified as cristobalite phases in regions close to 2Ɵ = 22.07°, 28.57°, 31.53°, 36.50°, 42.89°, 45.02°, 47.16°, 48.83°, and 57.41° (#AMCSD 0018342). The identification of characteristic peaks of this mineral in the RHA indicates that there was not an adequate burning process, which resulted in the absence of a predominantly amorphous material. This behavior is the characteristic of the RHA studied in the present work, which had its burning conducted without controlling temperature, time, and the form of cooling. The authors of [62] studied different temperatures and firing times of rice husks and observed that at 600 °C, the rice husk ash showed an amorphous halo between 15° and 30° (2Ɵ). However, at 700 °C, they observed the formation of crystalline cristobalite phases near 22° (2Ɵ), and at 800 °C they were able to identify new crystalline cristobalite peaks, similar to the peaks identified in Figure 6B.

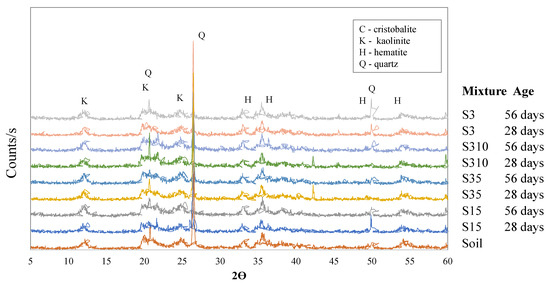

Figure 7 demonstrates the X-ray diffractograms of the four mixtures with two different curing ages compared to the reference soil. It is observed that the characteristic peaks of the quartz (2Ɵ = 20.87°, 26.65°, and 50.17°), kaolinite (2Ɵ = 12.41°, 20.38°, and 24.97°), and hematite (2Ɵ = 24.16°, 33.21°, 35.62°, 49.49°, and 54.14°) phases identified in the natural soil sample remain constant in the samples containing RHA and H3PO4, regardless of age (28 and 56 days). This shows that these phases do not change in the presence of H3PO4.

Figure 7.

X-ray diffractogram for mixtures with different curing ages and reference soil.

In the samples containing RHA, the main peak of the cristobalite phases (2Ɵ = 22.07°) may be superimposed on peaks characteristic of the quartz phase (2Ɵ 20.87°) identified in the natural soil sample. The other characteristic peaks of cristobalite (28.57°, 31.53°, and 36.50°), due to the low intensity in the original RHA (Figure 6B), were not identified in the samples containing the natural soil, H3PO4, and RHA.

A new peak in regions close to 42.22° was identified only in the samples S35 (28 days) and S310 (28 days). It is noted that these samples were obtained by mixing the natural soil with 3% H3PO4 and 5% and 10% RHA, respectively. It is inferred that there was the formation of a crystalline aluminium phosphate (AlPO4) phase from the reaction of H3PO4 with natural soil compounds. Characteristic peaks of berlinite (AlPO4) were identified at 2Ɵ = 26.43°, 20.75°, 49.70°, and 42.22° (#AMCSD 0007986). However, the most intense peaks of the berlinite (AlPO4) phase may be superimposed on peaks characteristic of quartz, kaolinite, and hematite. However, in samples S35 (56 days) and S310 (56 days), the peak was 42.26° (2Ɵ), which indicates that the AlPO4 phase is unstable and, from reactions in the hardened material between the ages of 28 and 56 days, underwent a chemical transformation. This could justify the 27% gain in compressive strength for the S15-ME sample between the ages of 7 and 91 days.

4. Conclusions

Physical, chemical, and mechanical characterizations are essential to choosing stabilized soils and mixtures for use in viable pavement structures. The isolated analysis of soil compaction tests demonstrates that as the compaction energy is modified and increased, the maximum apparent dry mass increases, and the optimum moisture content decreases. By inserting phosphoric acid into the soil in isolation, the MDD increased, and the moisture content was reduced. The insertion of RHA together with H3PO4 in the lateritic soil results in an increase in optimum moisture and a reduction in MDD. The higher the RHA content, the lower the MDD and the higher the optimum moisture content.

Regarding the resilient modulus tests, the additions proved to be positive in the analysis of the resilient behavior of the soil, especially at more advanced curing ages. Even with the decrease in the values noted when rice husk ash was used, all the levels investigated showed an improvement in the results over time, indicating that the RHA, even with the indications that its burning did not occur with temperature control, resulted in a material with pozzolanic activity. As for phosphoric acid, when used alone, the improvement in the resilient modulus is indisputable. However, with the inconvenience noted in the workability of the mixture, the addition of RHA to the mixtures is justified. The gain in compressive strength was more significant under conditions with RHA in their composition. The best strengths occurred in the S3 and S35 mixtures. In general, considering the two mechanical tests, the additions of RHA and H3PO4 were beneficial, mainly in the S3 and S35 mixtures, which showed great potential for use.

With the help of SEM, it was found that there was a greater compactness of fractured soil samples compacted in modified energy when compared to samples compacted in intermediate energy, with an emphasis on sample S3-ME. In the mineralogical analysis, no substantial changes were identified between the diffractograms of the different samples, regardless of the content of H3PO4 and RHA, and the diffractogram of the reference soil. However, it was verified that the characteristic peak of cristobalite reduced the intensity between 28 and 56 days for S15. It is understood that H3PO4 reacts with this crystalline phase over time, which could justify the gain in compressive strength.

Therefore, the additions of H3PO4 and RHA were positive in analysing the resilient behavior and the simple compressive strength of lateritic clayey soil. The increase in compaction energy and the insertion of these materials can be a beneficial resource in the search for better behavior of pavement subbases and bases.

Author Contributions

A.M.d.S.e.S.: conceptualization, methodology, validation, investigation, data curation. P.T.P.: conceptualization, methodology, validation, formal analysis, investigation, data curation, writing—original draft, writing—review & editing. M.B.: conceptualization, writing—review & editing, supervision. A.S.d.V.: writing—review & editing. J.B.: writing–review & editing. L.P.S.: writing—review & editing, funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

Angelo Magno dos Santos e Silva reports financial support provided by Conselho Nacional de Desenvolvimento Científico e Tecnológico. Paula Taiane Pascoal reports financial support provided by Agência Nacional de Petróleo and Conselho Nacional de Desenvolvimento Científico e Tecnológico (0050.0100766.16.9). Magnos Baroni reports financial support provided by Agência Nacional de Petróleo (0050.0100766.16.9). Luciano Pivoto Specht reports financial support provided by Agência Nacional de Petróleo (0050.0100766.16.9) and Conselho Nacional de Desenvolvimento Científico e Tecnológico (300967/2018-7).

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful to the Agência Nacional de Petróleo (ANP/PETROBRAS), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), and Universidade Federal de Santa Maria for their support, the reviewers for their valuable contributions, and Universidade Federal do Pampa for providing research materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hicks, R.G.; Monismith, C. Factors influencing the resilient properties of granular materials. Transp. Res. Board 1971, 345, 5–31. [Google Scholar]

- Li, D.; Selig, E. Resilient modulus for fine-grained subgrade soils. J. Geotech. Eng. 1994, 120, 939–957. [Google Scholar] [CrossRef]

- De Carvalho, J.C.; Rezende, L.R.; Cardoso, F.B.F.; Lucena, L.C.F.L.; Guimarães, R.C.; Valencia, Y.G. Tropical soils for highway construction: Peculiarities and considerations. Transp. Geotech. 2015, 5, 3–19. [Google Scholar] [CrossRef]

- Medina, J.; Motta, L.M.G. Mecânica dos Pavimentos, 3rd ed.; Interciência: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- Tamakar, P.; Nazarian, S. Impact of Gradation and Moisture Content on Stiffness Parameters of Base Materials; University of Texas at El Paso: El Paso, TX, USA, 2016. [Google Scholar]

- Zhang, S.; Tang, C.; Hu, P.; Zhang, X.; Zhang, Z. Reversible and irreversible strain behavior of frozen aeolian soil under dynamic loading. Environ. Earth Sci. 2016, 75, 245. [Google Scholar] [CrossRef]

- Kodikara, J.; Islam, T.; Sounthararajah, A. Review of soil compaction: History and recent developments. Transp. Geotech. 2018, 17, 24–34. [Google Scholar] [CrossRef]

- Ingles, O.G.; Metcalf, J.B. Soil Stabilization: Principles and Practice; Butterworths: Melbourne, Australia, 1972. [Google Scholar]

- Yoder, E.J.; Witczak, M.W. Principles of Pavement Design; John Wiley & Sons Inc.: New York, NY, USA, 1975. [Google Scholar]

- Bilgen, G. Utilization of powdered glass in lime-stabilized clayey clayey soil with sea water. Environ. Earth Sci. 2020, 79, 437. [Google Scholar] [CrossRef]

- Eisazadeh, A.; Nur, H.; Kassim, K.A. Characterization of phosphoric acid- and lime-stabilized tropical lateritic clay. Environ. Earth Sci. 2010, 63, 1057–1066. [Google Scholar] [CrossRef]

- Kassim, K.A.; Hamir, R.; Kok, K.C. Modification and stabilization of Malaysian cohesive soils with lime. Geotech. Eng. 2005, 36, 123–132. [Google Scholar]

- Eisazadeh, A.; Nur, H.; Kassim, K.A. Cation Exchange capacity of phosphoric acid and lime stabilized montmorillonitic and kaolinitic soils. Geotech. Geol. Eng. 2002, 30, 1435–1440. [Google Scholar] [CrossRef]

- Behnood, A. Soil and clay stabilization with calcium- and non-calcium-based additives: A state-of-the-art review of challenges, approaches and techniques. Transp. Geotech. 2018, 18, 14–32. [Google Scholar] [CrossRef]

- Jaffar, S.T.A.; Abid, M.M.; Zhan, S.Z.; Jafri, T.; Rehman, Z.U.; Tariq, M.A.U.R.; Ng, A.W.M. Evaluation of Conventional and Sustainable Modifiers to Improve the Stiffness Behavior of Weak Sub-Grade Soil. Sustainability 2022, 14, 2493. [Google Scholar] [CrossRef]

- Hatami, A.M.; Sabour, M.R.; Joshaghani, A. Research trends on ash stabilization in the pavement during 2002–2021. Environ. Sci. Pollut. Res. 2023, 30, 1611–1621. [Google Scholar] [CrossRef]

- Latifi, N.; Eisazadeh, A.; Marto, A. Strength behavior and microstructural characteristics of tropical laterite soil treated with sodium silicate-based liquid stabilizer. Environ. Earth Sci. 2014, 72, 91–98. [Google Scholar] [CrossRef]

- Ogila, W.A.M. Effectiveness of fresh cement kiln dust as a soil stabilizer and stabilization mechanism of high swelling clays. Environ. Earth Sci. 2020, 80, 283. [Google Scholar] [CrossRef]

- Winterkorn, H.F. Soil stabilization with phosphorus compounds and additives. Highw. Res. Board Bull. 1962, 318, 1–13. [Google Scholar]

- Rodrigues, M.S.; Beraldo, A.L. Caracterização física e mecânica de argamassas à base de cimento Portland e cinza de casca de arroz industrial. Rev. Eng. Agrícola 2010, 302, 193–204. [Google Scholar] [CrossRef]

- Latifi, N.; Marto, A.; Eisazadeh, A. Strength and Physico-chemical Characteristics of Fly Ash–Bottom Ash Mixture. Arab. J. Sci. Eng. 2015, 40, 2447–2455. [Google Scholar] [CrossRef]

- Abu-Farsakh, M.; Dhakal, S.; Chen, Q. Laboratory characterization of cementitious treated/stabilized very weak subgrade soil under cyclic loading. Soils Found. 2015, 55, 504–516. [Google Scholar] [CrossRef]

- Elkady, T.; Al-Mahbashi, A.; Al-Shamrani, M. Resilient Modulus of Lime-Treated Expansive Subgrade. In Proceedings of the XV Pan-American Conference on Soil Mechanics and Geotechnical Engineering, Argentinean Geotechnical Engineering Society, Buenos Aires, Argentina, 15–18 November 2015; pp. 1631–1638. [Google Scholar]

- Pires, G.M.; Specht, L.P.; Pinheiro, R.J.B.; Pereira, D.S.; Renz, E.D. Comportamento mecânico de material fresado após processo de estabilização granulométrica e química por meio da incorporação de cimento e cinza de casca de arroz moída. Rev. Matéria 2016, 21, 365–384. [Google Scholar] [CrossRef][Green Version]

- Ikeagwuani, C.C.; Nwonu, D.C. Resilient Modulus of Lime-Bamboo Ash Stabilized Subgrade Soil with Different Compactive Energy. Geotech. Geol. Eng. 2019, 37, 3557–3565. [Google Scholar] [CrossRef]

- Nasiri, H.; Khayat, N.; Mirzababaei, M. Simple yet quick stabilization of clay using a waste by-product. Transp. Geotech. 2020, 28, 100531. [Google Scholar] [CrossRef]

- Rahman, I.U.; Raheel, M.; Ali Khawaja, M.W.; Khan, R.; Li, J.; Khan, A.; Khan, M.T. Characterization of engineering properties of weak subgrade soils with different pozzolanic & cementitious additives. Case Stud. Constr. Build. Mater. 2021, 15, e00676. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N. Coupling effect of pond ash and polypropylene fiber on strength and durability of expansive soil subgrades: An integrated experimental and machine learning approach. J. Rock Mech. Geotech. Eng. 2021, 13, 1101–1112. [Google Scholar] [CrossRef]

- Consoli, N.C.; Festugato, L.; Miguel, G.D.; Moreira, E.B.; Scheuermann Filho, H.C. Fatigue Life of Green Stabilized Fiber-Reinforced Sulfate-Rich Dispersive Soil. J. Mater. Civ. Eng. 2021, 33, 9. [Google Scholar] [CrossRef]

- Saldanha, R.B.; Rochas, C.G.; Caicedo, A.M.L.; Consoli, N.C. Technical and environmental performance of eggshell lime for soil stabilization. Constr. Build. Mater. 2021, 298, 123648. [Google Scholar] [CrossRef]

- Qamar, W.; Khan, A.H.; Rehman, Z.; Masoud, Z. Sustainable Application of Wool-Banana Bio-Composite Waste Material in Geotechnical Engineering for Enhancement of Elastoplastic Strain and Resilience of Subgrade Expansive Clays. Sustainability 2022, 14, 13215. [Google Scholar] [CrossRef]

- Companhia Nacional de Abastecimento—CONAB. Acompanhamento da safra brasileira. Décimo Levant. 2018, 10, 145. [Google Scholar]

- Rathan, R.R.; Banupriya, S.; Dharani, R. Stabilizations of soil using rice husk ash. Int. J. Comput. Eng. Res. 2016, 6, 43–50. [Google Scholar] [CrossRef]

- Anupam, A.K.; Kumar, P.; Ransinchung, R.N. Effect of Fly Ash and Rice Husk Ash on Permanent Deformation Behavior of Subgrade Soil under Cyclic Triaxial Loading. Transp. Res. Procedia 2016, 17, 596–606. [Google Scholar] [CrossRef]

- Ojuri, O.O.; Adavi, A.A.; Oluwatuyi, O.E. Geotechnical and environmental evaluation of lime–cement stabilized soil–mine tailing mixtures for highway construction. Transp. Geotech. 2017, 10, 1–12. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Behak, L.; Núñez, W.P. Mechanistic behavior under traffic load of a clayey silt modified with lime. Road Mater. Pavement Des. 2018, 19, 1072–1088. [Google Scholar] [CrossRef]

- Jittin, V.; Bahurudeen, A.; Ajinkya, S.D. Utilisation of rice husk ash for cleaner production of different construction products. J. Clean. Prod. 2020, 263, 121578. [Google Scholar] [CrossRef]

- Muñoz, Y.O.; Izzo, R.L.S.; Almeida, J.L.; Baldovino, J.A.; Rose, J.L. The role of rice husk ash, cement and polypropylene fibers on the mechanical behavior of a soil from Guabirotuba formation. Transp. Geotech. 2021, 31, 100673. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Muntohar, A.S. Effect of the cement—rice husk ash on the plasticity and compaction of soil. Eletronic J. Geotech. Eng. 2003, 8, 1–8. [Google Scholar]

- Medina, J.; Guida, H.N. Stabilization of lateritic soils with phosphoric acid. Geotech. Geol. Eng. 1995, 13, 199–216. [Google Scholar] [CrossRef]

- Soliz, V.V.P. Estudo de Três Solos Estabilizados com Emulsão Asfáltica; Universidade Federal do Rio de Janeiro: Rio de Janeiro, Brazil, 2007. [Google Scholar]

- Pascoal, P.T.; Sagrilo, A.V.; Baroni, M.; Specht, L.P.; Pereira, D.S. Evaluation of the influence of compaction energy on the resilient behavior of lateritic soil in the field and laboratory. Soils Rocks 2021, 44, 071321. [Google Scholar] [CrossRef]

- Nogami, J.S.; Villibor, D.F. Pavimentação de Baixo Custo Com SOLOS Lateríticos; Editora Villibor: São Paulo, Brazil, 1995. [Google Scholar]

- DNER-CLA 259; Classificação de Solos Tropicais para Finalidades Rodoviárias Utilizando Corpos-de-Prova Compactados em Equipamento Miniatura. Departamento Nacional de Estradas de Rodagem: Rio de Janeiro, Brazil, 1996.

- Della, V.P.; Kühn, I.; Hotza, D. Reciclagem de resíduos agro-industriais: Cinza de casca de arroz como fonte alternativa de sílica. Cerâmica Ind. 2005, 10, 22–25. [Google Scholar]

- Budny, J. Verificação do Potencial de Estabilização de um Solo Laterítico com o Uso de Ácido Fosfórico, Ácido Cítrico e Cinza de Casca de Arroz; Universidade Federal do Rio de Janeiro: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- DNIT 134; ME Pavimentação—Solos—Determinação do Módulo de Resiliência—Método de Ensaio. Departamento Nacional de Infraestrutura de Transportes: Rio de Janeiro, Brazil, 2018.

- Freitas, J.E. Uso de Cinza da Casca de Arroz na Estabilização de Solos Para Uso em Pavimento Rodoviário; Universidade de Brasília: Brasília, Brazil, 2018. [Google Scholar]

- Behak, L.; Núñez, W.P. Caracterización de un material compuesto por suelo arenoso, cenizas de cáscara de arroz y cal potencialmente útil para su uso en pavimentación. Rev. Ing. Construcción 2008, 23, 34–41. [Google Scholar] [CrossRef]

- AASHTO T307-99; Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State Highway and Transportation Officials: Washington, WA, USA, 2017.

- Lima, C.D.A.; Motta, L.M.G.; Aragão, F.T.S.; Guimarães, A.C.R. Mechanical characterization of fine-grained lateritic soils for mechanistic-empirical flexible pavement design. J. Test. Eval. 2020, 48, 1–17. [Google Scholar] [CrossRef]

- Lima, C.D.A.; Motta, L.M.G.; Aragão, F.T.S. A permanent deformation predictive model for fine tropical soils considering the effects of the compaction moisture content on material selection. Transp. Geotech. 2021, 28, 100534. [Google Scholar] [CrossRef]

- Zago, J.P.; Pinheiro, R.J.B.; Baroni, M.; Specht, L.P.; Delongui, L.; Sagrilo, A.V. Study of the permanent deformation of three soils employed in highway subgrades in the municipality of Santa Maria—RS, Brazil. Int. J. Pavement Res. Technol. 2020, 14, 729–739. [Google Scholar] [CrossRef]

- Rabab’ah, S.; Al Hattamleh, O.; Aldeeky, H.; Alfoul, B.A. Effect of glass fiber on the properties of expansive soil and its utilization as subgrade reinforcement in pavement applications. Case Stud. Constr. Build. Mater. 2021, 14, e00485. [Google Scholar] [CrossRef]

- Yaghoubi, E.; Yagouhbi, M.; Guerrieri, M.; Sudarsanan, N. Improving expansive clay subgrades using recycled glass: Resilient modulus characteristics and pavement performance. Constr. Build. Mater. 2021, 302, 124384. [Google Scholar] [CrossRef]

- Hassan, H.J.A.; Rasul, J.; Samin, M. Effects of Plastic Waste Materials on Geotechnical Properties of Clayey Soil. Transp. Infrastruct. Geotechnol. 2021, 8, 390–413. [Google Scholar] [CrossRef]

- Jibon, M.; Mishra, D.; Kassem, E. Laboratory characterization of fine-grained soils for pavement ME design implementation in Idaho. Transp. Geotech. 2021, 25, 100395. [Google Scholar] [CrossRef]

- Pezo, R.F.; Claros, G.; Hudson, W.R.; Stokoe, K.H. Development of Reliable Resiliente Modulus Test for Subgrade and Non-Granular Subbase Materials for Use in Routine Pavement Design; Research Report 1177-4F; Department of Transportation, University of Texas at Austin: Austin, TX, USA, 1992. [Google Scholar]

- NCHRP 1-37A; National Cooperative Highway Research Program—Guide for mechanistic-empirical design of new and rehabilitated pavement structures—Final Report. Transportation Research Board: Washington, WA, USA, 2004.

- ABNT NBR 12025; Solo-Cimento—Ensaio de Compressão Simples de Corpos de Prova Cilíndricos—Método de Ensaio. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2012.

- Shen, J.; Liu, X.; Zhu, S.; Zhang, H.; Tan, J. Effects of calcinations parameters on the silica phase of original and leached rice husk ash. Mater. Lett. 2011, 65, 1179–1183. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).