The Use of Field Olfactometry in the Odor Assessment of a Selected Mechanical–Biological Municipal Waste Treatment Plant within the Boundaries of the Selected Facility—A Case Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of a Selected Mechanical–Biological Waste Treatment Plant

2.2. Odor Concentration Determination by Field Olfactometry

2.3. Meteorological Data

2.4. Inverse Distance Weighted Method

3. Results and Discussion

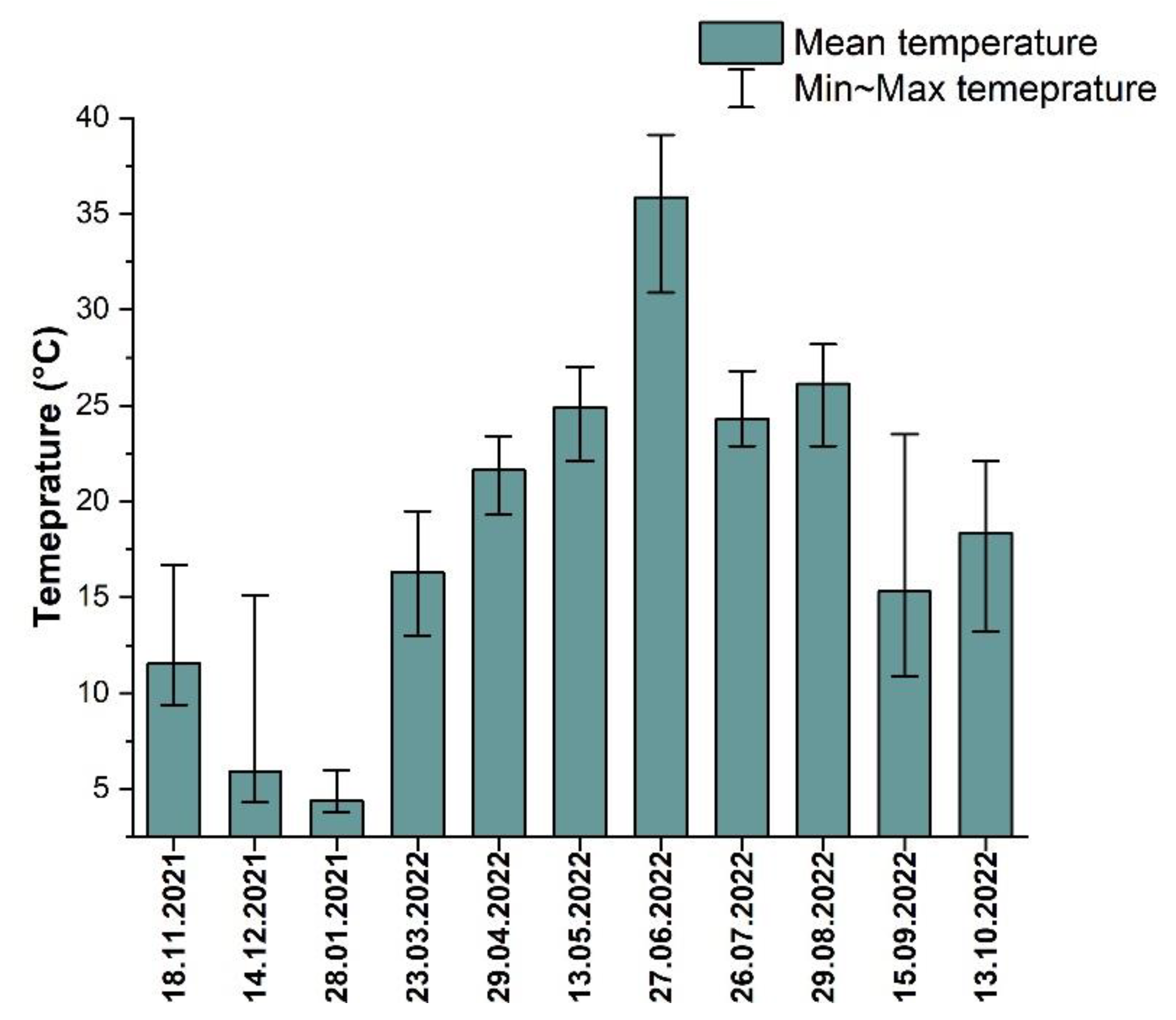

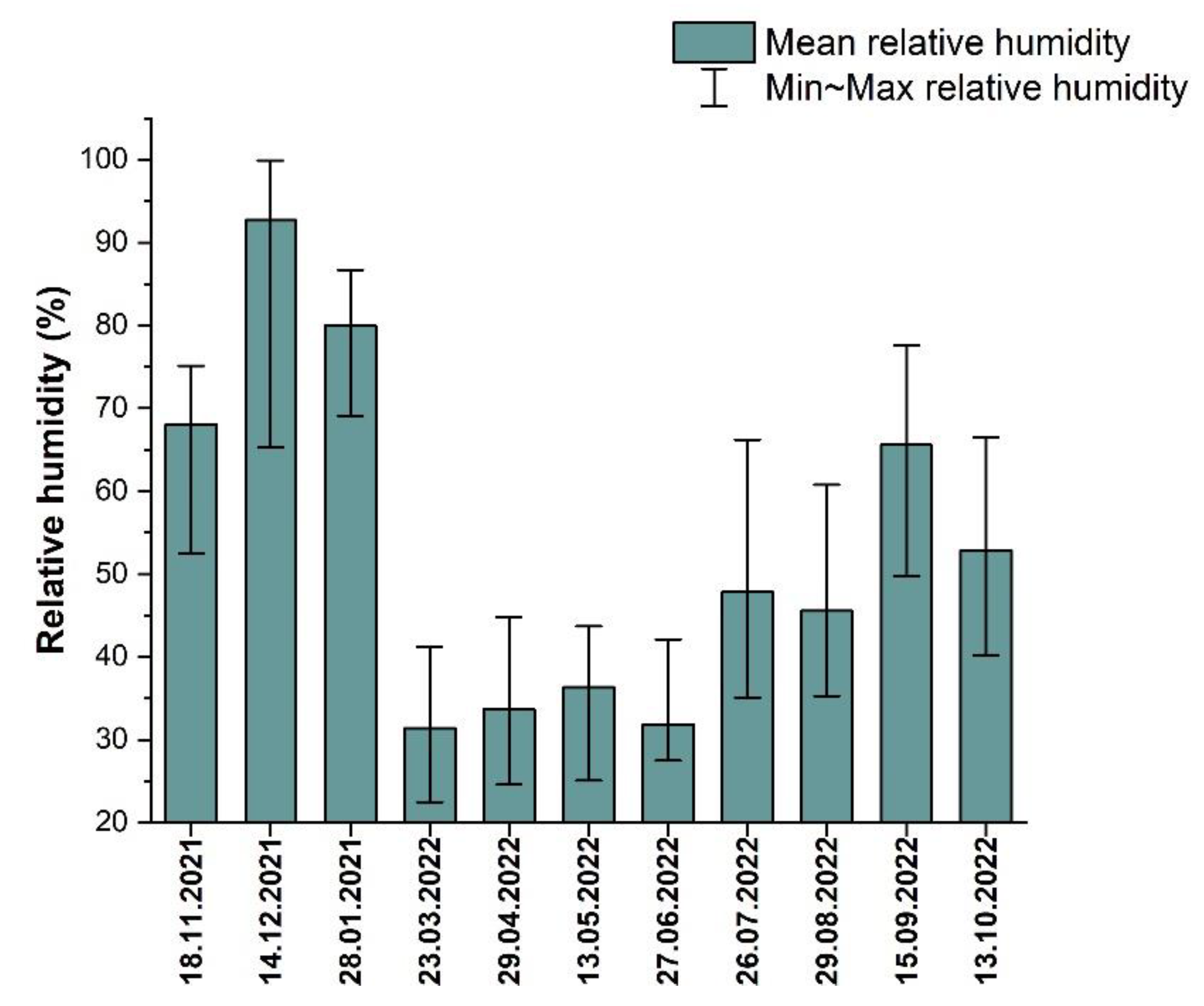

3.1. Meteorological Situation during the Given Measurement Period

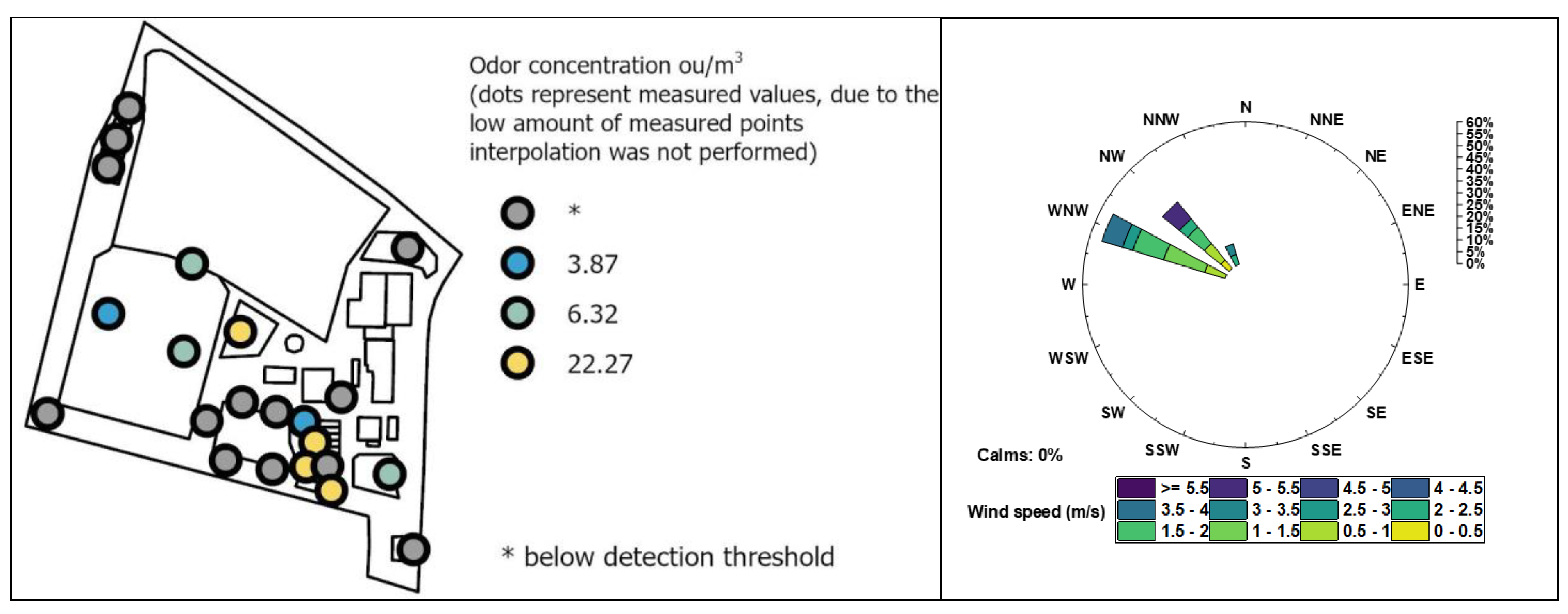

3.2. The Results of Field Olfactometry Measurements

3.3. Statistical Relationship of Collected Data

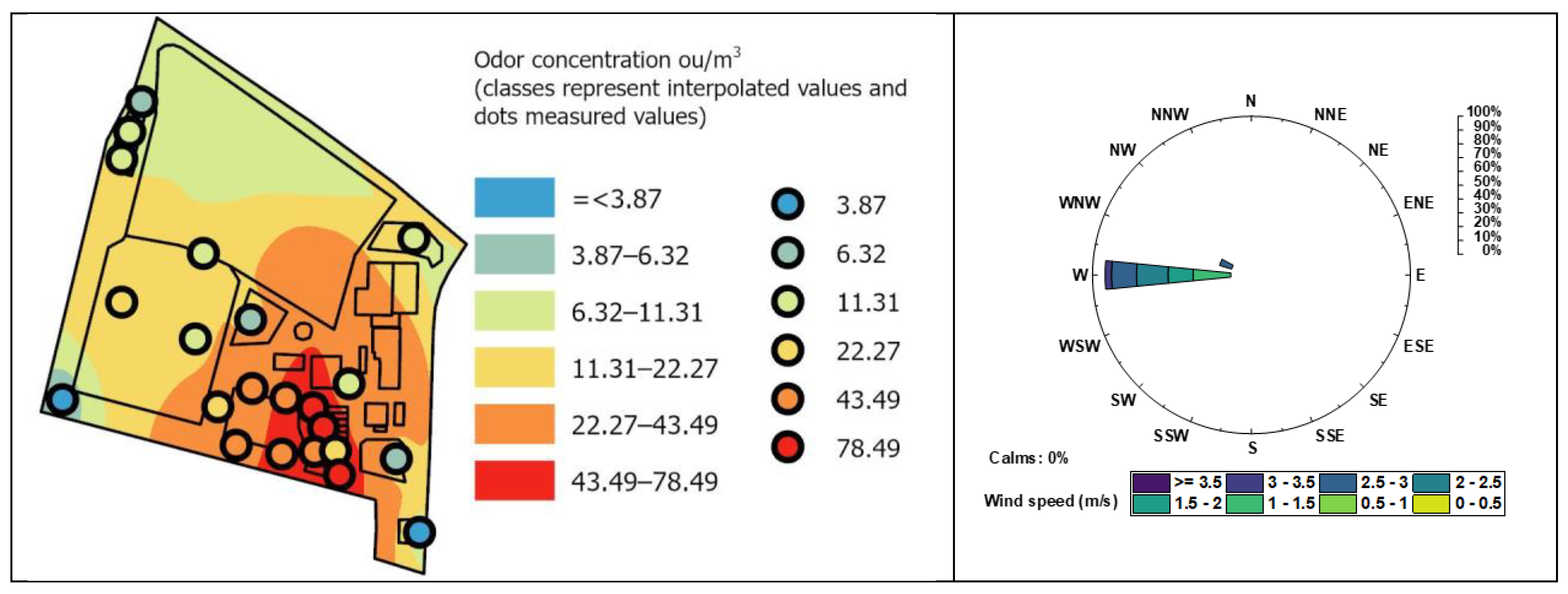

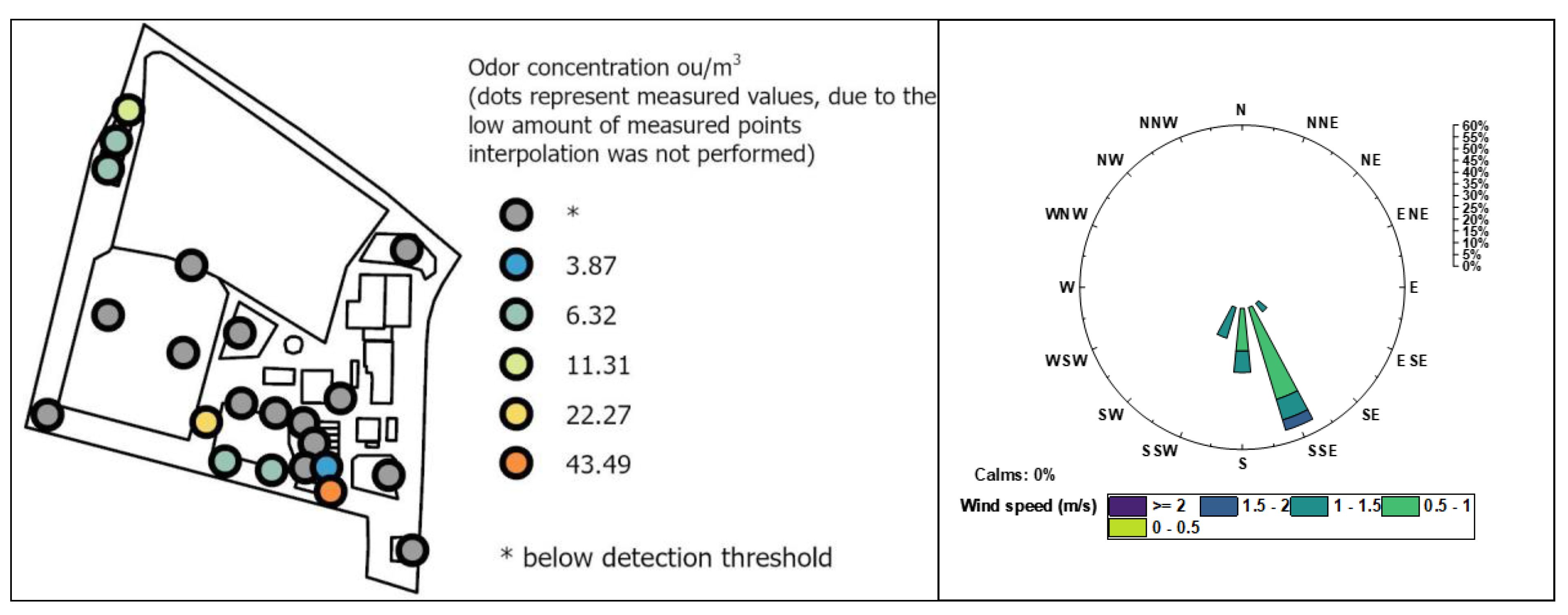

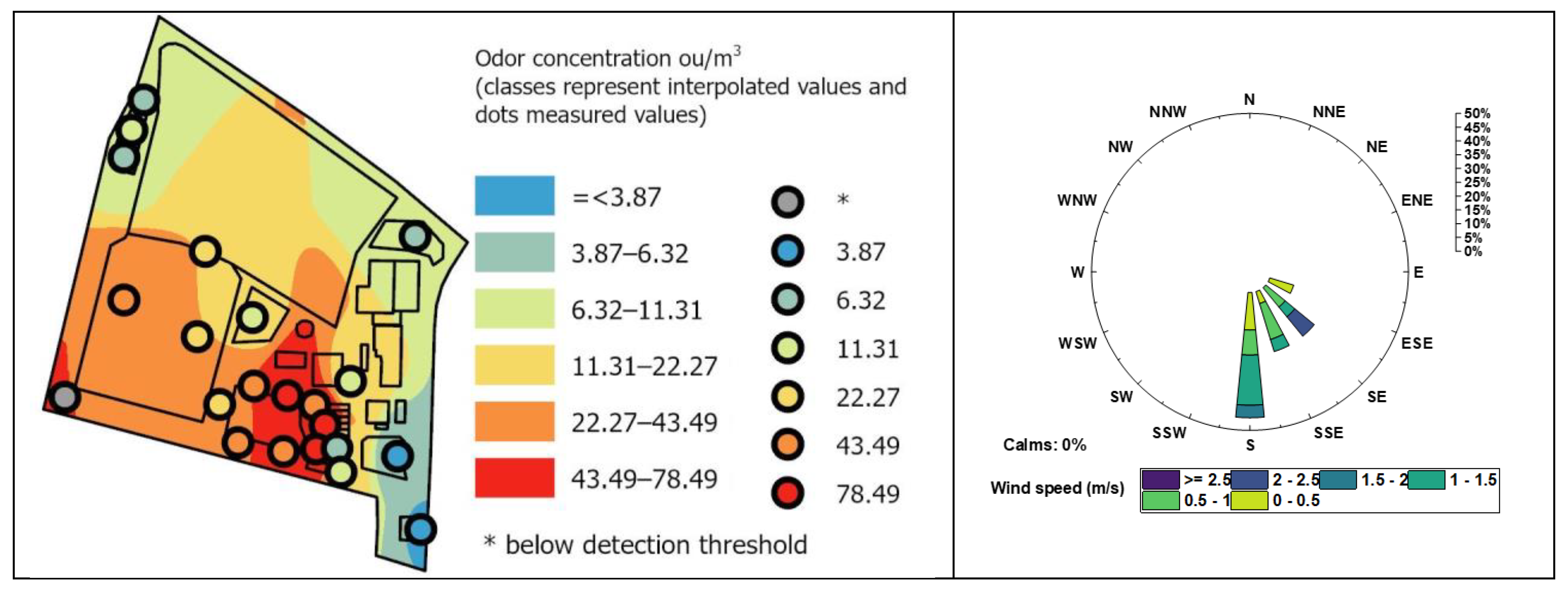

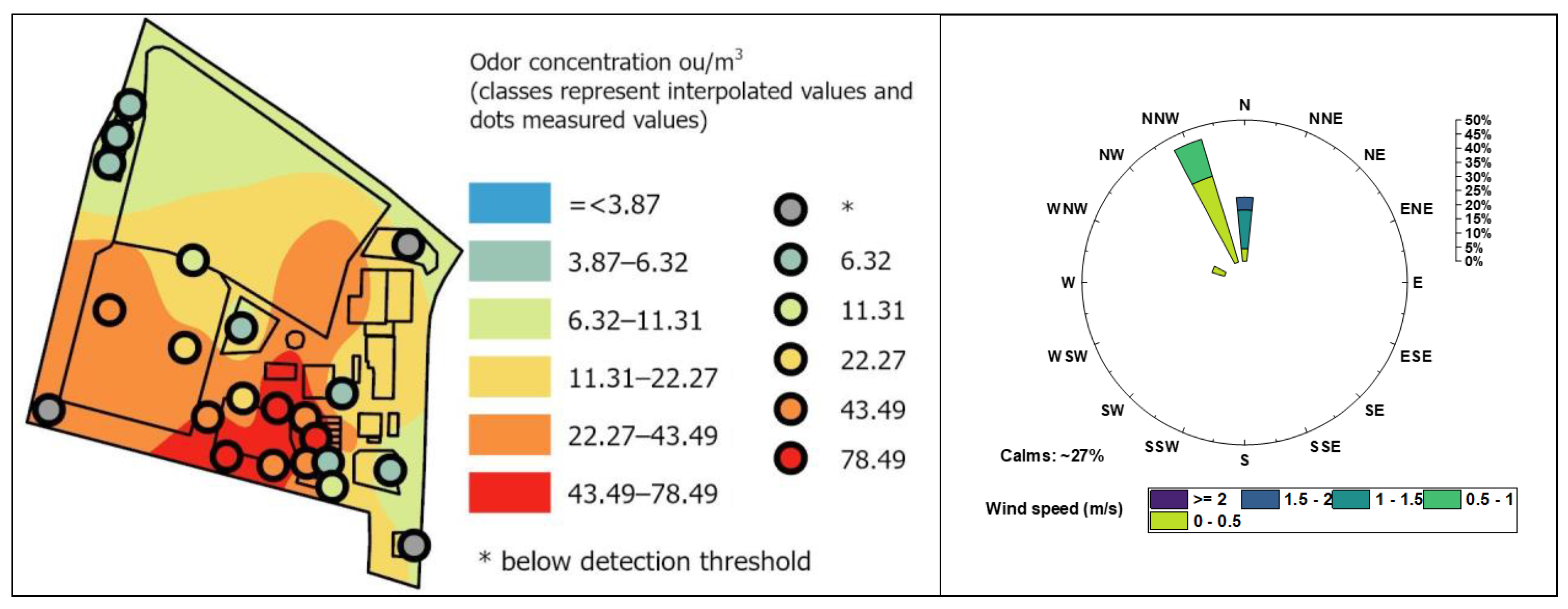

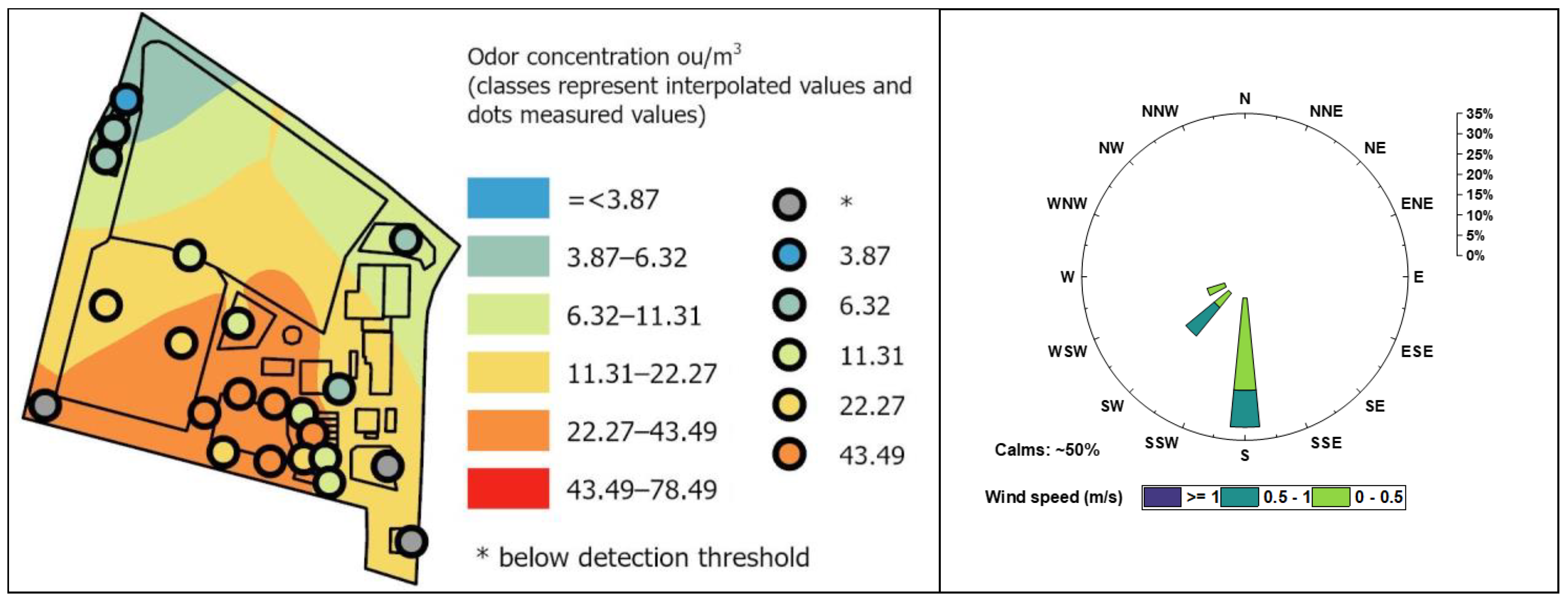

3.4. Spatial Distribution of Odor Concentration and Cross-Validation

- The cross-validation results show that ME (Equation (8)) in every case is higher than zero, which means that the interpolation formula tends to overestimate the predicted values.

- The RMSE parameter (Equation (9)) is relatively high; the lowest value of RMSE was obtained for the data measured in May 2022 and is equal to 13.24, which means that the predicted values differ on average of 13.24 ou/m3 from the measured values, the highest RMSE was calculated for October 2022; in that case, predicted values differs on average 26.70 ou/m3.

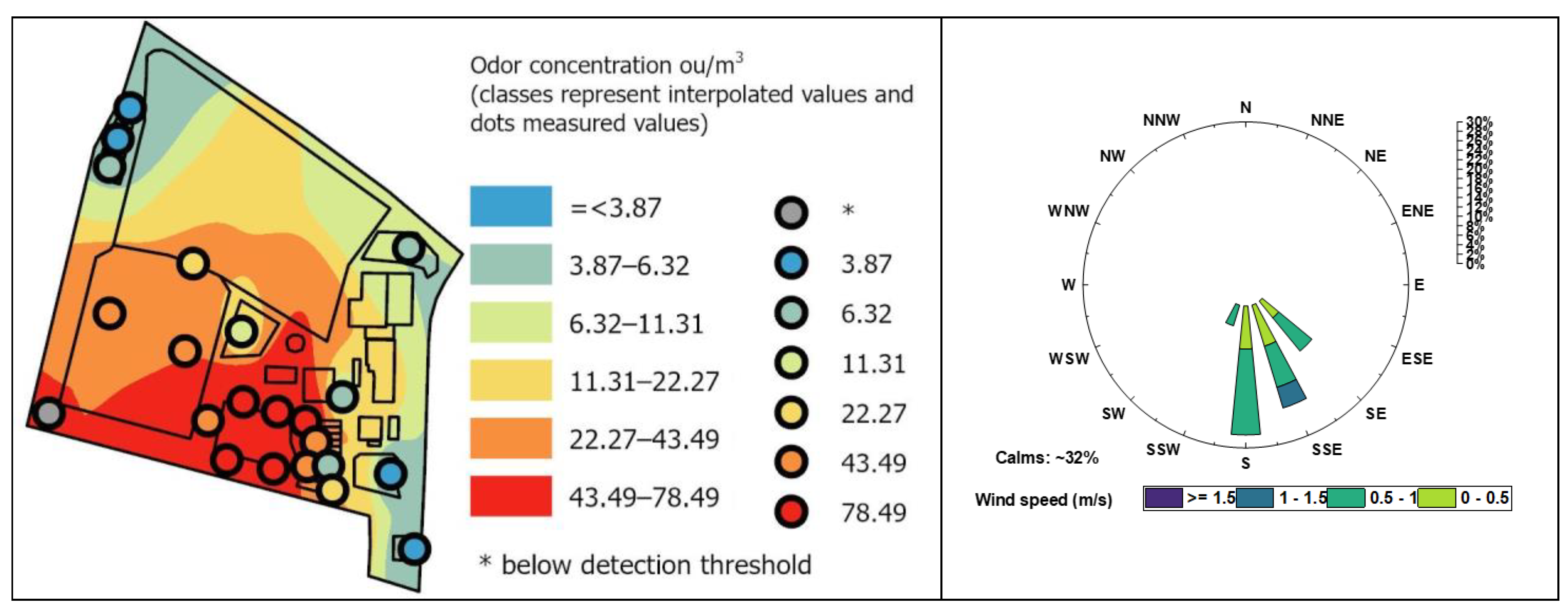

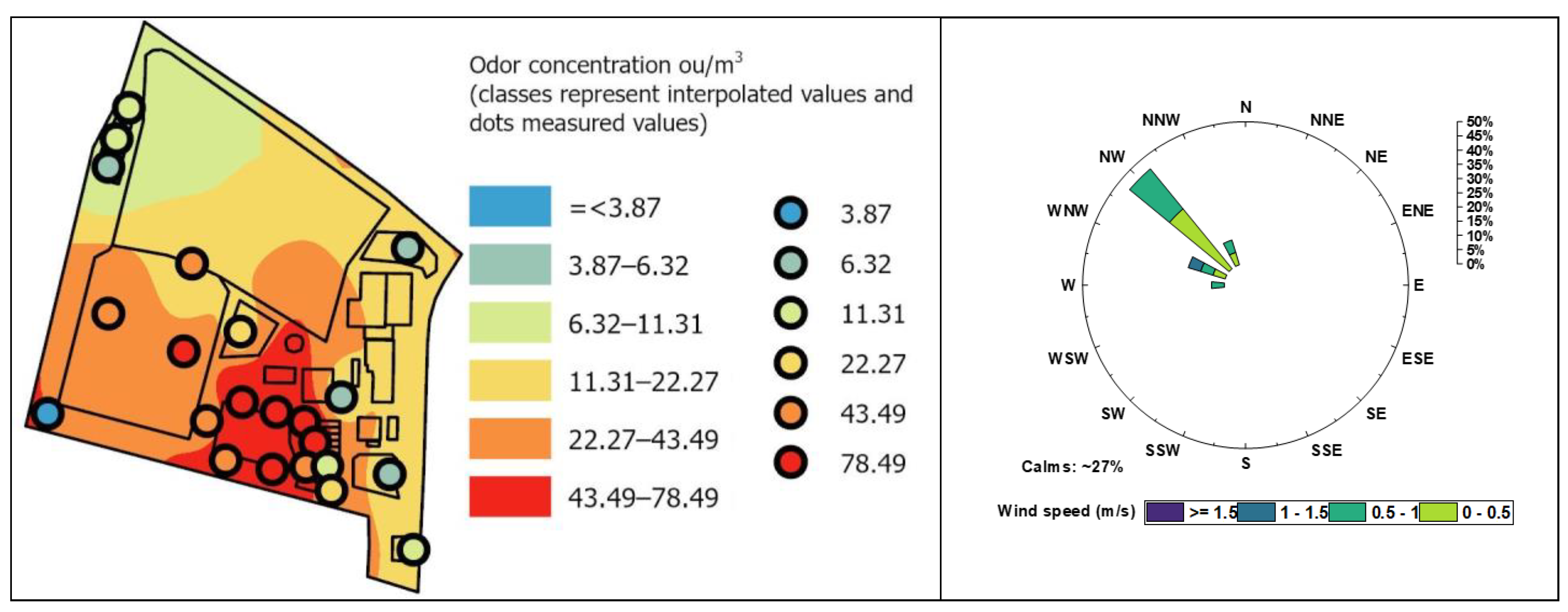

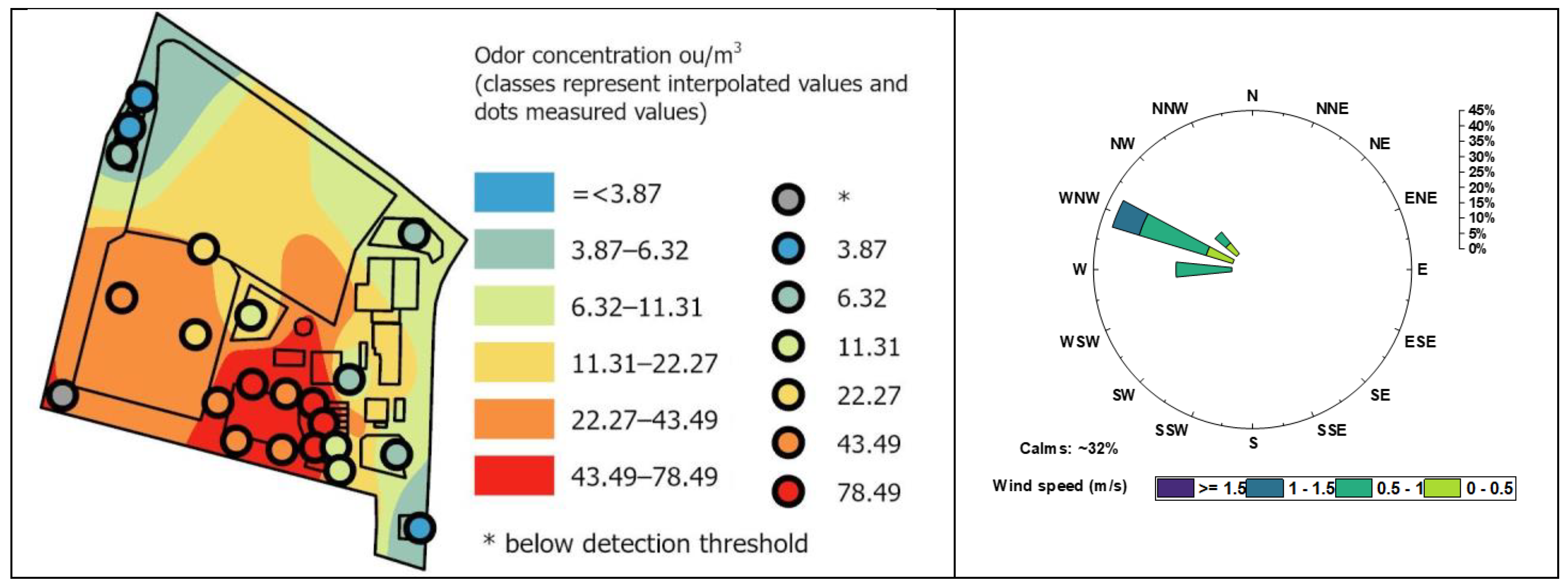

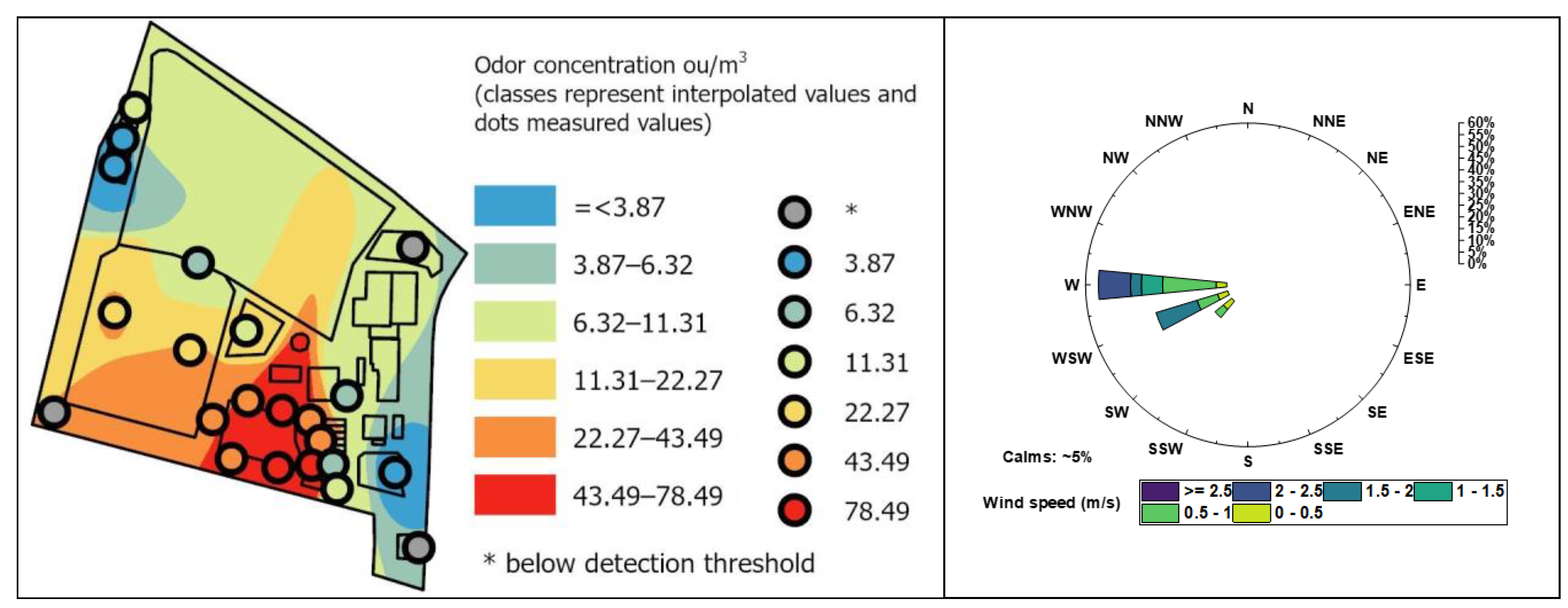

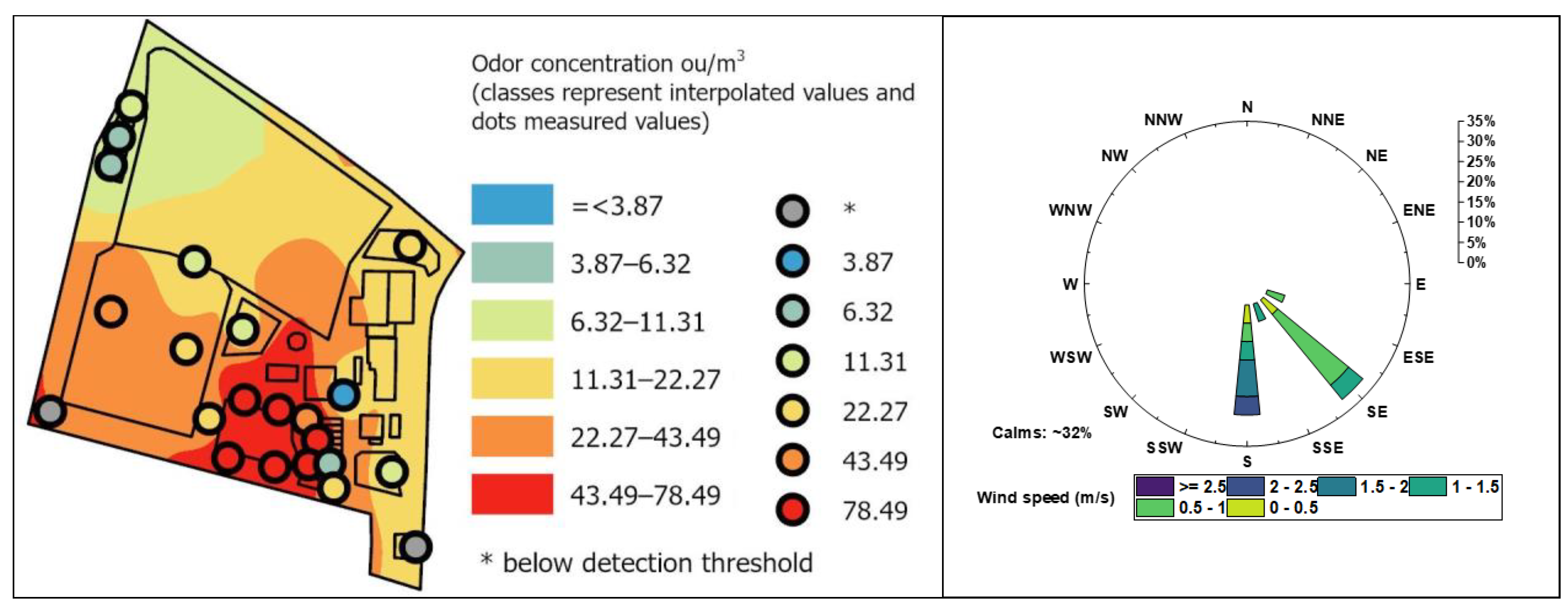

- The analysis of spatial distribution (Figure 5, Figure 6, Figure 7, Figure 8, Figure 9, Figure 10, Figure 11, Figure 12, Figure 13, Figure 14 and Figure 15) confirms the results of cross-validation. In every case, some of the interpolated values differ from measured values and are higher than measured values. The largest difference could be seen when considering lower values. For example, as can be seen in Figure 5, the measured values at the corners of the MBT plant (southeast corner, point 1, administration building and southwest corner, point 32, site boundary) are 3.87 ou/m3, while predicted values obtained by the IDW method are in the range of 3.87 to 6.32 ou/m3. A similar situation can be seen in the middle of the facility (point 13 located in the bulky waste processing and storage area), measured value for that point is 6.32 ou/m3, and the surrounding class is in the range of 6.32 ou/m3 to 11.31 ou/m3 and changes rapidly to the range of 11.31 to 22.27 ou/m3. Such a pattern where lowest measured values do not match with the predicted values is in common for almost every spatial distribution. However, in case of Figure 8 and Figure 14. some of the lower values match exactly with the class—Figure 8, point 1; and Figure 15, points 2, 33, and 34.

- The biggest concern when it comes to results of interpolations are the months when some of the odor concentration at measuring points were below detection threshold. This can be seen in Figure 8, Figure 9, Figure 10, Figure 11, Figure 12, Figure 13, Figure 14 and Figure 15. For example, in Figure 8, at point 32 (left lower corner of the facility), the cod was below the detection threshold, and the predicted value for that point falls into the highest possible class ranges from 43.49 up to 78.49 ou/m3, which overestimate spatial distribution around that point for almost the whole possible range of odor concentrations.

- Despite the problems mentioned above, it is possible to distinguish areas characterized by higher odor concentrations from areas characterized by lower odor concentrations. For every spatial distribution obtained for given measuring month, it is clearly visible that points scattered around aerobic stabilization area and green storage area are characterized by the highest cod; therefore, it is possible to find areas that could be possibly influenced by odor emissions or could be the odor emitters by itself. It indicates that the spatial interpolation method could possibly be used for identification of areas influenced by odors and the identification of odor sources.

- Comparing the results of odor concentration measurements by the mean of field olfactometry and the spatial distribution of odor concentrations with the wind rose for each measurement month, it is mostly unlikely to find relationship between odor distribution and wind conditions. The presented wind roses were plotted from the wind data obtained for each measuring point; the data was collected during 3–4 h period. The plotted wind roses do not represent the whole meteorological conditions as it could be influenced by local factors. Therefore, the more accurate research should be provided in the future.

4. Summary

- Field olfactometry is a suitable method for odor quantification and odor sources identification. Research shows that the most odor generating sources are these related to directly handling of organic matter contained waste, i.e., aerobic stabilization area, bioreactors for aerobic processes, and green waste storage area. Comparing results with the available literature data shows that there is a significant variability in measured odor concentrations even between similar facilities. The composition of the waste going to different facilities can vary significantly, and the way the waste is treated; therefore, it is difficult to compare the results of odor measurements between such facilities.

- No strong correlation was found between odor concentrations and meteorological parameters, such as temperature and humidity. However, the measurements were carried out in a relatively short time (under 4–5 min per measuring points); therefore, the real relationship between parameters could be missed as no averaging over time for measurements was performed. Therefore, more sophisticated measurement in such a field should be carried out in the future.

- Cross-results validation of inverse distance weighted method algorithm shows relatively high values of RMSE parameters: lowest RMSE calculated for May 2022 was 13.24, and the highest for October 2022 was 26.70. It indicates that interpolated values differ significantly and shows that selected method of odor data interpolation tends to overestimate odor concentration when calculating spatial distribution of odors.

- Despite tendency to overestimating data, the inverse weighted distance method allows for identification of areas of higher/lower odor concentrations. The precision of this is strongly dependent on the basis of how much the data was overestimated. Due to that fact, it is questionable to use the inverse weighted distance method as a reliable tool for the purposes of odor management plans.

- More sophisticated method of spatial data interpolation should be investigated in the future; for example, kriging methods.

Author Contributions

Funding

Conflicts of Interest

References

- PN-EN 13725:2007; Air Quality—Determination of Odour Concentration by Dynamic Olfactometry. Polish Committee for Standardization: Warsaw, Poland, 2007.

- Conti, C.; Guarino, M.; Bacenetti, J. Measurements Techniques and Models to Assess Odor Annoyance: A Review. Environ. Int. 2020, 134, 105261. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, R.; Sivret, E.C.; Parcsi, G.; Lebrero, R.; Wang, X.; Suffet, I.H.; Stuetz, R.M. Monitoring Techniques for Odour Abatement Assessment. Water Res. 2010, 44, 5129–5149. [Google Scholar] [CrossRef]

- Lewkowska, P.; Cieślik, B.; Dymerski, T.; Konieczka, P.; Namieśnik, J. Characteristics of Odors Emitted from Municipal Wastewater Treatment Plant and Methods for Their Identification and Deodorization Techniques. Environ. Res. 2016, 151, 573–586. [Google Scholar] [CrossRef]

- Walgraeve, C.; van Hufffel, K.; Bruneel, J.; van Langenhove, H. Evaluation of the Performance of Field Olfactometers by Selected Ion Flow Tube Mass Spectrometry. Biosyst. Eng. 2015, 137, 84–94. [Google Scholar] [CrossRef]

- Capelli, L.; Sironi, S.; Del Rosso, R.; Guillot, J.M. Measuring Odours in the Environment vs. Dispersion Modelling: A Review. Atmos. Environ. 2013, 79, 731–743. [Google Scholar] [CrossRef]

- Bax, C.; Sironi, S.; Capelli, L. How Can Odors Be Measured? An Overview of Methods and Their Applications. Atmosphere 2020, 11, 92. [Google Scholar] [CrossRef]

- Laor, Y.; Parker, D.; Pagé, T. Measurement, Prediction, and Monitoring of Odors in the Environment: A Critical Review. Rev. Chem. Eng. 2014, 30, 139–166. [Google Scholar] [CrossRef]

- Jońca, J.; Pawnuk, M.; Arsen, A.; Sówka, I. Electronic Noses and Their Applications for Sensory and Analytical Measurements in the Waste Management Plants—A Review. Sensors 2022, 22, 1510. [Google Scholar] [CrossRef]

- Brattoli, M.; de Gennaro, G.; de Pinto, V.; Loiotile, A.D.; Lovascio, S.; Penza, M. Odour Detection Methods: Olfactometry and Chemical Sensors. Sensors 2011, 11, 5290–5322. [Google Scholar] [CrossRef] [PubMed]

- Badach, J.; Kolasińska, P.; Paciorek, M.; Wojnowski, W.; Dymerski, T.; Gębicki, J.; Dymnicka, M.; Namieśnik, J. A Case Study of Odour Nuisance Evaluation in the Context of Integrated Urban Planning. J. Environ. Manag. 2018, 213, 417–424. [Google Scholar] [CrossRef]

- Hawko, C.; Verriele, M.; Hucher, N.; Crunaire, S.; Leger, C.; Locoge, N.; Savary, G. A Review of Environmental Odor Quantification and Qualification Methods: The Question of Objectivity in Sensory Analysis. Sci. Total Environ. 2021, 795, 148862. [Google Scholar] [CrossRef]

- Kulig, A.; Szyłak-Szydłowski, M.; Wiśniewska, M. Application of Chemical Sensors and Olfactometry Method in Ecological Audits of Degraded Areas. Sensors 2021, 21, 6190. [Google Scholar] [CrossRef]

- Wojnarowska, M.; Sołtysik, M.; Turek, P.; Szakiel, J.; Wojnarowska, M.; Sołtysik, M.; Turek, P.; Szakiel, J. Odour Nuisance as a Consequence of Preparation for Circular Economy. Eur. Res. Stud. J. 2020, XXIII, 128–142. [Google Scholar] [CrossRef]

- Brandt, R.C.; Elliott, H.A.; Adviento-Borbe, M.A.A.; Wheeler, E.F.; Kleinman, P.J.A.; Beegle, D.B. Field Olfactometry Assessment of Dairy Manure Land Application Methods. In Proceedings of the American Society of Agricultural and Biological Engineers Annual International Meeting 2008, ASABE 2008, Providence, RI, USA, 29 June–2 July 2008; Volume 11, pp. 6744–6759. [Google Scholar] [CrossRef]

- Dalton, P.; Caraway, E.A.; Gibb, H.; Fulcher, K. A Multi-Year Field Olfactometry Study near a Concentrated Animal Feeding Operation. J. Air Waste Manag. Assoc. 2011, 61, 1398–1408. [Google Scholar] [CrossRef]

- Sówka, I.; Pawnuk, M.; Grzelka, A.; Pielichowska, A. The Use of Ordinary Kriging and Inverse Distance Weighted Interpolation to Assess the Odour Impact of a Poultry Farming Plant. Sci. Rev. Eng. Environ. Sci. 2020, 29, 17–26. [Google Scholar] [CrossRef]

- Sówka, I.; Pawnuk, M.; Miller, U.; Grzelka, A.; Wroniszewska, A.; Bezyk, Y. Assessment of the Odour Impact Range of a Selected Agricultural Processing Plant. Sustainability 2020, 12, 7289. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Olfactometric Testing as a Method for Assessing Odour Nuisance of Biogas Plants Processing Municipal Waste. Arch. Environ. Prot. 2020, 46, 60–68. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants. Appl. Sci. 2021, 11, 3916. [Google Scholar] [CrossRef]

- Barczak, R.; Kulig, A. Odour Monitoring of a Municipal Wastewater Treatment Plant in Poland by Field Olfactometry. Chem. Eng. Trans. 2016, 54, 331–336. [Google Scholar] [CrossRef]

- Barczak, R.J.; Kulig, A. Comparison of Different Measurement Methods of Odour and Odorants Used in the Odour Impact Assessment of Wastewater Treatment Plants in Poland. Water Sci. Technol. 2017, 75, 944–951. [Google Scholar] [CrossRef] [PubMed]

- Kulig, A.; Szyłak-Szydłowski, M. Assessment of the Effects of Wastewater Treatment Plant Modernization by Means of the Field Olfactometry Method. Water 2019, 11, 2367. [Google Scholar] [CrossRef]

- Pawnuk, M.; Szulczyński, B.; den Boer, E.; Sówka, I. Preliminary Analysis of the State of Municipal Waste Management Technology in Poland along with the Identification of Waste Treatment Processes in Terms of Odor Emissions. Arch. Environ. Prot. 2022, 48, 3–20. [Google Scholar] [CrossRef]

- European Commission, Joint Research Centre; Pinasseau, A.; Zerger, B.; Roth, J.; Canova, M.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Treatment: Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control). Publications Office of the European Union, 2018. Available online: https://data.europa.eu/doi/10.2760/407967 (accessed on 15 February 2023).

- Choi, Y.; Kim, K.; Kim, S.; Kim, D. Identification of Odor Emission Sources in Urban Areas Using Machine Learning-Based Classification Models. Atmos. Environ. X 2022, 13, 100156. [Google Scholar] [CrossRef]

- Li, J.; Heap, A.D. Spatial Interpolation Methods Applied in the Environmental Sciences: A Review. Environ. Model. Softw. 2014, 53, 173–189. [Google Scholar] [CrossRef]

- Kumar, A.; Dhakhwa, S.; Dikshit, A.K. Comparative Evaluation of Fitness of Interpolation Techniques of ArcGIS Using Leave-One-Out Scheme for Air Quality Mapping. J. Geov. Spat. Anal. 2022, 6, 9. [Google Scholar] [CrossRef]

- Xie, X.; Semanjski, I.; Gautama, S.; Tsiligianni, E.; Deligiannis, N.; Rajan, R.T.; Pasveer, F.; Philips, W. A Review of Urban Air Pollution Monitoring and Exposure Assessment Methods. ISPRS Int. J. Geo-Inf. 2017, 6, 389. [Google Scholar] [CrossRef]

- Lu, G.Y.; Wong, D.W. An Adaptive Inverse-Distance Weighting Spatial Interpolation Technique. Comput. Geosci. 2008, 34, 1044–1055. [Google Scholar] [CrossRef]

- Babak, O.; Deutsch, C.V. Statistical Approach to Inverse Distance Interpolation. Stoch. Environ. Res. Risk Assess. 2009, 23, 543–553. [Google Scholar] [CrossRef]

- Shukla, K.; Kumar, P.; Mann, G.S.; Khare, M. Mapping Spatial Distribution of Particulate Matter Using Kriging and Inverse Distance Weighting at Supersites of Megacity Delhi. Sustain. Cities Soc. 2020, 54, 101997. [Google Scholar] [CrossRef]

- NasalRanger Field Olfactometer Manufacturer Website. Available online: https://www.fivesenses.com/equipment/nasalranger/nasalranger/ (accessed on 22 January 2023).

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Odour Emissions of Municipal Waste Biogas Plants-Impact of Technological Factors, Air Temperature and Humidity. Appl. Sci. 2020, 10, 1093. [Google Scholar] [CrossRef]

- Barczak, R.; Kulig, A.; Szyłak-Szydłowski, M. Olfactometric Methods Application for Odour Nuisance Assessment of Wastewater Treatment Facilities in Poland. Chem. Eng. Trans. 2012, 30, 187–192. [Google Scholar] [CrossRef]

- Reference Tool for IDW Method by ESRI for ArcGIS Software. Available online: https://pro.arcgis.com/en/pro-app/latest/tool-reference/spatial-analyst/how-idw-works.htm (accessed on 22 January 2023).

- Cross-Validation Guide for ArcGIS Software by ESRI. Available online: https://pro.arcgis.com/en/pro-app/latest/help/analysis/geostatistical-analyst/performing-cross-validation-and-validation.htm (accessed on 22 January 2022).

- Wiśniewska, M. Methods of Assessing Odour Emissions from Biogas Plants Processing Municipal Waste. J. Ecol. Eng. 2020, 21, 140–147. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Szyłak-Szydłowski, M. The Air and Sewage Pollutants from Biological Waste Treatment. Processes 2021, 9, 250. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Comparative Analysis of Preliminary Identification and Characteristic of Odour Sources in Biogas Plants Processing Municipal Waste in Poland. SN Appl. Sci. 2019, 1, 550. [Google Scholar] [CrossRef]

- den Boer, E.; Jedrczak, A.; Kowalski, Z.; Kulczycka, J.; Szpadt, R. A Review of Municipal Solid Waste Composition and Quantities in Poland. Waste Manag. 2010, 30, 369–377. [Google Scholar] [CrossRef] [PubMed]

- King, A.P.; Eckersley, R.J. Inferential Statistics IV: Choosing a Hypothesis Test. In Statistics for Biomedical Engineers and Scientists; Elsevier: Amsterdam, The Netherlands, 2019; pp. 147–171. [Google Scholar]

- King, A.P.; Eckersley, R.J. Descriptive Statistics II: Bivariate and Multivariate Statistics. In Statistics for Biomedical Engineers and Scientists; Elsevier: Amsterdam, The Netherlands, 2019; pp. 23–56. [Google Scholar]

- Rovetta, A. Raiders of the Lost Correlation: A Guide on Using Pearson and Spearman Coefficients to Detect Hidden Correlations in Medical Sciences. Cureus 2020, 12, e11794. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The Importance of the Microclimatic Conditions inside and Outside of Plant Buildings in Odorants Emission at Municipal Waste Biogas Installations. Energies 2020, 13, 6463. [Google Scholar] [CrossRef]

- Rohde, R.A.; Muller, R.A. Air Pollution in China: Mapping of Concentrations and Sources. PLoS ONE 2015, 10, e0135749. [Google Scholar] [CrossRef] [PubMed]

- Núñez-Alonso, D.; Pérez-Arribas, L.V.; Manzoor, S.; Cáceres, J.O. Statistical Tools for Air Pollution Assessment: Multivariate and Spatial Analysis Studies in the Madrid Region. J. Anal. Methods Chem. 2019, 2019, 9753927. [Google Scholar] [CrossRef]

- Vuolo, M.R.; Acutis, M.; Tyagi, B.; Boccasile, G.; Perego, A.; Pelissetti, S. Odour Emissions and Dispersion from Digestate Spreading. Atmosphere 2023, 14, 619. [Google Scholar] [CrossRef]

- Khan, J.; Ketzel, M.; Kakosimos, K.; Sørensen, M.; Jensen, S.S. Road Traffic Air and Noise Pollution Exposure Assessment—A Review of Tools and Techniques. Sci. Total Environ. 2018, 634, 661–676. [Google Scholar] [CrossRef] [PubMed]

| Point Number | 18 November 2021 | 14 December 2021 | 28 January 2022 | 23 March 2022 | 29 April 2022 | 13 May 2022 | 27 June 2022 | 26 July 2022 | 28 August 2022 | 15 September 2022 | 13 October 2022 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3.87 | * | * | 3.87 | * | * | 3.87 | 11.31 | 3.87 | * | * |

| 2 | 6.32 | * | 6.32 | 3.87 | 6.32 | * | 3.87 | 6.32 | 6.32 | 3.87 | 11.31 |

| 4 | 11.31 | * | * | 6.32 | * | 6.32 | 6.32 | 6.32 | 6.32 | * | 22.27 |

| 10 | 11.31 | * | 6.32 | 22.27 | 11.31 | 11.31 | 22.27 | 43.49 | 22.27 | 6.32 | 11.31 |

| 11 | 22.27 | * | 3.87 | 43.49 | 43.49 | 22.27 | 43.49 | 43.49 | 43.49 | 22.27 | 43.49 |

| 12 | 11.31 | * | 6.32 | 22.27 | 22.27 | 22.27 | 43.49 | 78.49 | 22.27 | 22.27 | 22.27 |

| 13 | 6.32 | * | 22.27 | 11.31 | 6.32 | 11.31 | 11.31 | 22.27 | 11.31 | 11.31 | 11.31 |

| 14 | 43.49 | * | * | 43.49 | 22.27 | 43.49 | 78.49 | 78.49 | 78.49 | 43.49 | 78.49 |

| 15 | 43.49 | * | * | 78.49 | 78.49 | 43.49 | 78.49 | 78.49 | 43.49 | 78.49 | 78.49 |

| 17 | 11.31 | * | * | 11.31 | 6.32 | 6.32 | 6.32 | 6.32 | 6.32 | 6.32 | 3.87 |

| 18 | 78.49 | * | 3.87 | 43.49 | 43.49 | 11.31 | 78.49 | 78.49 | 78.49 | 43.49 | 43.49 |

| 25 | 78.49 | * | 22.27 | 78.49 | 78.49 | 43.49 | 43.49 | 78.49 | 78.49 | 43.49 | 78.49 |

| 26 | 43.49 | * | 22.27 | 78.49 | 43.49 | 22.27 | 43.49 | 43.49 | 78.49 | 78.49 | 78.49 |

| 27 | 22.27 | 3.87 | * | 6.32 | 6.32 | 11.31 | 6.32 | 11.31 | 11.31 | 6.32 | 6.32 |

| 28 | 43.49 | 6.32 | * | 43.49 | 43.49 | 43.49 | 78.49 | 78.49 | 43.49 | 78.49 | 78.49 |

| 29 | 43.49 | 6.32 | * | 43.49 | 78.49 | 22.27 | 78.49 | 43.49 | 43.49 | 43.49 | 78.49 |

| 30 | 22.27 | 22.27 | * | 22.27 | 43.49 | 43.49 | 43.49 | 43.49 | 43.49 | 43.49 | 22.27 |

| 31 | 78.49 | 43.49 | 22.27 | 11.31 | 11.31 | 11.31 | 22.27 | 22.27 | 11.31 | 11.31 | 22.27 |

| 32 | 3.87 | * | * | * | * | * | * | 3.87 | * | * | * |

| 33 | 11.31 | 6.32 | * | 6.32 | 6.32 | 6.32 | 6.32 | 6.32 | 6.32 | 3.87 | 6.32 |

| 34 | 11.31 | 6.32 | * | 11.31 | 6.32 | 6.32 | 3.87 | 11.31 | 3.87 | 3.87 | 6.32 |

| 35 | 6.32 | 11.31 | * | 6.32 | 6.32 | 3.87 | 3.87 | 11.31 | 3.87 | 11.31 | 11.31 |

| Point Number | 18 November 2021 | 14 December 2021 | 28 January 2022 | 23 March 2022 | 29 April 2022 | 13 May 2022 | 27 June 2022 | 26 July 2022 | 28 August 2022 | 15 September 2022 | 13 October 2022 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 22.27 | ** | 11.31 | 11.31 | 11.31 | 11.31 | 11.31 | 11.31 | 11.31 | 11.31 | 78.49 |

| 5 | 6.32 | ** | ** | 11.31 | 6.32 | 3.87 | 3.87 | 6.32 | 6.32 | 3.87 | 43.49 |

| 6 | 3.87 | *** | *** | 3.87 | *** | *** | *** | *** | 3.87 | *** | 6.32 |

| 7 | 3.87 | *** | *** | 3.87 | *** | *** | *** | *** | 3.87 | *** | 3.87 |

| 8 | 6.32 | *** | *** | 11.31 | *** | *** | *** | *** | 6.32 | *** | 6.32 |

| 9 | 22.27 | ** | 22.27 | 22.27 | 43.49 | 43.49 | 43.49 | 78.49 | 43.49 | 43.49 | 43.49 |

| 16 | 43.49 | ** | 43.49 | 43.49 | 78.49 | 78.49 | 78.49 | 43.49 | 43.49 | 43.49 | 78.49 |

| 19 | 43.49 | * | * | 78.49 | * | * | * | * | * | * | 78.49 |

| 20 | 78.49 | * | * | 78.49 | * | * | * | * | 78.49 | * | 78.49 |

| 21 | * | * | * | * | * | * | * | * | * | * | 78.49 |

| 22 | 78.49 | * | * | * | 78.49 | * | * | * | 78.49 | 78.49 | 78.49 |

| 23 | * | * | * | * | 78.49 | * | * | * | * | 78.49 | 78.49 |

| 24 | * | * | * | * | * | * | * | * | * | * | 78.49 |

| Odor Concentration | Temperature | Humidity | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Date | Statistic | p-Value | Decision at Level (5%) | Statistic | p-Value | Decision at Level (5%) | Statistic | p-Value | Decision at Level (5%) |

| 18 November 2021 | 0.81065 | <0.05 | reject normality | 0.81952 | <0.05 | reject normality | 0.88308 | <0.05 | reject normality |

| 14 December 2021 | 0.69823 | <0.05 | reject normality | 0.59594 | <0.05 | reject normality | 0.71975 | <0.05 | reject normality |

| 28 January 2022 | 0.83126 | <0.05 | reject normality | 0.78834 | <0.05 | reject normality | 0.92713 | >0.05 | cannot reject normality |

| 23 March 2022 | 0.79742 | <0.05 | reject normality | 0.94903 | >0.05 | cannot reject normality | 0.94190 | >0.05 | cannot reject normality |

| 29 April 2022 | 0.79742 | <0.05 | reject normality | 0.88698 | <0.05 | reject normality | 0.96850 | >0.05 | cannot reject normality |

| 13 May 2022 | 0.81886 | <0.05 | reject normality | 0.94852 | >0.05 | cannot reject normality | 0.96741 | >0.05 | cannot reject normality |

| 27 June 2022 | 0.80947 | <0.05 | reject normality | 0.87822 | <0.05 | reject normality | 0.85298 | <0.05 | reject normality |

| 26 July 2022 | 0.81105 | <0.05 | reject normality | 0.95002 | >0.05 | cannot reject normality | 0.94166 | >0.05 | cannot reject normality |

| 28 August 2022 | 0.79580 | <0.05 | reject normality | 0.94524 | >0.05 | cannot reject normality | 0.94997 | >0.05 | cannot reject normality |

| 15 September 2022 | 0.82769 | <0.05 | reject normality | 0.87924 | <0.05 | reject normality | 0.96101 | >0.05 | cannot reject normality |

| 13 October 2022 | 0.77401 | <0.05 | reject normality | 0.94977 | >0.05 | cannot reject normality | 0.98543 | >0.05 | cannot reject normality |

| 18 November 2021 | 14 December 2021 | 28 January 2022 | 23 March 2022 | 29 April 2022 | 13 May 2022 | 27 June 2022 | 26 July 2022 | 28 August 2022 | 15 September 2022 | 13 October 2022 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Spearman’s Correlation rs | |||||||||||

| cod–temperature | −0.10666 | −0.09628 | −0.15873 | 0.20211 | 0.06973 | 0.71479 | −0.01299 | 0.31703 | 0.23345 | 0.21114 | 0.08681 |

| cod–humidity | 0.20527 | 0.31262 | 0.28485 | 0.14397 | −0.10124 | 0.2041 | 0.15626 | 0.63653 | 0.47584 | 0.14597 | 0.29144 |

| 18 November 2021 | 14 December 2021 | 28 January 2022 | 23 March 2022 | 29 April 2022 | 13 May 2022 | 27 June 2022 | 26 July 2022 | 28 August 2022 | 15 September 2022 | 13 October 2022 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Count | 22 | - | - | 21 | 19 | 19 | 21 | 22 | 21 | 19 | 20 |

| Mean Error | 4.99 | - | - | 3.61 | 2.70 | 1.06 | 1.69 | 4.71 | 5.01 | 2.16 | 1.92 |

| Root Mean Square Error | 21.88 | - | - | 21.02 | 24.03 | 13.24 | 20.70 | 23.06 | 22.09 | 17.49 | 26.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawnuk, M.; Sówka, I.; Naddeo, V. The Use of Field Olfactometry in the Odor Assessment of a Selected Mechanical–Biological Municipal Waste Treatment Plant within the Boundaries of the Selected Facility—A Case Study. Sustainability 2023, 15, 7163. https://doi.org/10.3390/su15097163

Pawnuk M, Sówka I, Naddeo V. The Use of Field Olfactometry in the Odor Assessment of a Selected Mechanical–Biological Municipal Waste Treatment Plant within the Boundaries of the Selected Facility—A Case Study. Sustainability. 2023; 15(9):7163. https://doi.org/10.3390/su15097163

Chicago/Turabian StylePawnuk, Marcin, Izabela Sówka, and Vincenzo Naddeo. 2023. "The Use of Field Olfactometry in the Odor Assessment of a Selected Mechanical–Biological Municipal Waste Treatment Plant within the Boundaries of the Selected Facility—A Case Study" Sustainability 15, no. 9: 7163. https://doi.org/10.3390/su15097163

APA StylePawnuk, M., Sówka, I., & Naddeo, V. (2023). The Use of Field Olfactometry in the Odor Assessment of a Selected Mechanical–Biological Municipal Waste Treatment Plant within the Boundaries of the Selected Facility—A Case Study. Sustainability, 15(9), 7163. https://doi.org/10.3390/su15097163