Abstract

One of the many features of three-dimensional printing (3DP) that contribute to its status as a cutting-edge technology is its positive impact on sustainability. Students in higher education can also use 3DP technologies to understand environmental, social, and economic issues. However, there is a lack of knowledge on how sustainability is integrated through 3DP in higher education, especially in developing countries. Thus, this research explored the teaching of sustainability through 3DP in five public engineering universities in Vietnam using field observations (75 students and five educators), followed by semi-structured interviews with ten students and five educators. The findings revealed that sustainability through 3DP was not taught as a separate unit in the participating institutions as they were not equipped with the necessary tools and software to educate students about sustainability through 3DP, the time spent teaching students about 3DP was limited, and most of the educators were not trained in implementing sustainability through 3DP in higher education. Despite these barriers, students were instructed on how to use 3DP materials economically and were taught which materials were beneficial for the environment. In cases of limited resources and funding, assisting students in assembling low-cost do-it-yourself 3D printers by utilizing open-source materials will maximize their learning outcomes. These findings may help higher education institutions teach sustainability through 3DP and motivate students to explore multidisciplinary knowledge in developing countries. This study also guides both higher education sectors and policymakers on taking the steps necessary for utilizing the benefits of 3DP in engineering education.

1. Introduction

Rossi et al. [1] defined the term “sustainability” as a collective aspiration that relies on several interrelated “pillars”, including economic, environmental, and social obligations [2]. Education is key to achieving the United Nations’ sustainable development goals (SDGs). Formal education is crucial in disseminating knowledge about sustainability and equipping future students with the necessary sustainability abilities, which can directly impact SDG4 (quality education) and SDG7 (affordable and clean energy) [3]. For engineering students, there are several reasons why learning about sustainability is important, including the environmental impact of engineering projects, social responsibility, industry trends, and regulatory requirements [4]. By understanding sustainability, engineering students can design projects that minimize negative impacts, consider the social implications of their work, be competitive in the job market, and comply with legal requirements. If sustainability is not taught in higher education, future engineers may lack the necessary knowledge and skills to contribute toward achieving the SGDs, which could lead to continued unsustainable practices that harm both society and the environment [2]. Scarff Seatter and Ceulemans [5] also stated that the negative consequences of not teaching sustainability in higher education include students’ lack of awareness regarding environmental challenges, engagement in unsustainable practices, missed opportunities for innovation, and reduced employability prospects. Moreover, not teaching sustainability could have long-term impacts on society’s well-being, including resource depletion and pollution control measures. Additionally, it would be difficult for institutions to implement sustainable policies without students understanding their importance or how these policies can be achieved.

By including three-dimensional printing (3DP) technology in the curriculum, students can better understand sustainability concepts in order to create solutions, reduce the costs associated with traditional manufacturing processes, and develop innovative products and services that incorporate ecological considerations [6,7]. 3DP technologies can also be used to encourage students in higher education to consider environmental, social, and economic issues in their work, as 3DP offers hands-on learning experiences and customization opportunities [8], cost-effective prototyping [9], and interdisciplinary collaboration [7]. Additionally, the interdisciplinary nature of 3DP, which involves both technical and design skills, could lend itself to teaching sustainability in a holistic manner that incorporates multiple perspectives and disciplines.

In developing countries, 3DP technology has the potential to promote sustainable development by providing a cost-effective and environmentally friendly alternative to traditional manufacturing methods [10,11]. By teaching sustainability through 3DP in these countries, students can learn how to design and produce environmentally friendly and cost-effective products [12], which can be used to address some of the sustainability challenges these countries face. Using 3DP technology can also help promote local manufacturing and reduce dependence on imported goods [13], positively impacting local economies.

However, the transition to sustainability through 3DP faces many challenges regarding skill requirements and necessary tools [14]. Frey and Osborne [15] claimed that, to do their jobs effectively, workers in these sectors must abandon antiquated methods and quickly learn new ones, as having a multidisciplinary understanding of the field is essential because the final product’s qualities and properties are dependent on a wide range of factors [16]. Although using 3DP to teach students about sustainability is not new in universities in developed nations, which recognize the importance of sustainability, how sustainability is taught through 3DP in developing countries, such as Vietnam, still needs to be explored in the literature.

2. Background

2.1. The Importance of Engineering Students Learning Sustainability through 3DP

3DP technologies have opened up new possibilities in digital fabrication that are impossible when using traditional manufacturing methods [17]. The emergence of these advanced manufacturing technologies creates opportunities for widespread learning of 3DP in higher education sectors, including mechanical engineering, architecture, computing, and medicine. Furthermore, the development of low-cost 3DP [12] and the application of open-source 3DP [18] in classroom settings has many benefits in addition to the many potential sustainability benefits of 3DP technologies, such as creating environmentally friendly products, ensuring a circular economy, and providing social benefits [6]. Moreover, as well as alleviating poverty and raising living standards, the green growth transition that occurs through sustainability also addresses environmental issues such as resource depletion and global warming. Therefore, there is an increasing number of studies on the connection between diverse, sustainable developments and 3DP technologies, including training, education, and technology research as well as quality control of materials ([19,20], Alabi et al. [21]). Indeed, in recent years, there has been an increased research effort and specialization in the intersection between 3DP technologies and sustainability due to greater insights into sustainability. 3DP technologies can help foster a healthy engineering education ecosystem [20], and they also have the potential to impart a general transformational change in most industries generally [22] and to engage students working with these innovative technologies particularly. The introduction of sustainability through 3DP technologies in the classroom is expected to improve students’ educational experiences by incorporating various methodologies into the learning process [23]. For example, a twelve-week introductory design course at Griffith University in Australia encouraged students to question the role of technology in modern society to gain insights into sustainability issues from various perspectives [7]. Furthermore, the cost of 3D printers has dropped by more than tenfold [24], making them more accessible to educational institutions than the slow and expensive printers available for the last 30 years [25].

2.2. Adoption of 3DP in Universities

Reise and Phan [26] stated that the widespread adoption of 3DP in universities has helped to develop students’ sustainable skills, knowledge, and attitudes. Additionally, Vipul Gupta [27] claimed that students who learn about the fundamentals of 3DP at university are in a better position than the competition when entering the workforce, as they can manifest their ideas in the real world. Additionally, adopting 3DP technology allows students to participate in genuine case studies relevant to their everyday life, allowing them to gain a more concrete grasp of sustainability. However, there are several constraints in 3DP education. According to Ford and Minshall [9], Cotteleer et al. [14], and Malik et al. [16], there are many obstacles hindering the implementation of 3DP in higher education, including the academics, the decision-makers in charge of additive manufacturing (AM) technology lacking teaching material and not being sufficiently versed in 3DP curricula, a lack of qualified experts, the technology not being advanced enough, the high costs of 3DP equipment, insufficient 3DP laboratories, the reuse of materials, the effects on the environment, and students lacking multidisciplinary knowledge. Holm et al. [28] emphasized that more tangible steps need to be taken to improve the sustainability of higher education as universities across the world use management systems to comply with regulations requiring quality assurance, thereby safeguarding and improving the quality of the education provided. It is still unknown what models of sustainable development could be implemented or how sustainability can be taught in higher education through the utilization of 3DP, which is important because these are essential topics in the Industry 4.0 era. Moreover, the status of teaching sustainability through 3DP in the context of higher education in developing countries still needs to be determined.

2.3. 3DP, Sustainability, and Higher Education in Developing Countries

University–industry partnerships, technology transfer, continued teaching and training, and cutting-edge research are just a few of the essentials for the long-term sustainability of 3DP in education [20]. However, there is a lack of understanding of how sustainability is introduced through 3DP as well as the challenges and recommendations for introducing 3DP into the higher education sector in developing countries, even though this trend is expanding around the globe. Additionally, how 3DP activities help students collaborate and learn, the activities they complete, and the tools they use in classrooms, and how these activities help them learn sustainability through 3DP, are still unknown.

A few 3DP studies have investigated using 3DP in higher education in developing countries, such as those by Alabi et al. [21] and Inoma et al. [29]. According to these studies, the primary barriers to teaching sustainability through 3DP in universities include a lack of awareness and knowledge about sustainable practices, limited availability or access to eco-friendly materials, high energy consumption during the production process, difficulty in integrating sustainability concepts into existing curricula, the lack of an effective framework for 3DP education, the need for technical expertise, limited access to resources such as funding and infrastructure, a lack of standardization in integrating 3DP technologies into existing curricula that leads to confusion among educators and learners, and a lack of specialized training on designing environmentally friendly products using AM technology. In addition to the rapid growth and emergence of 3DP technologies, there is a skills shortage in the AM industry [14], which requires developing successful training programs and courses to provide students with the skills to meet the industry’s requirements [9].

However, no research has examined the impact of teaching sustainability through 3DP on higher education in developing countries. Thus, this study uses Vietnam as a case study to explore how higher education institutions in developing countries might include sustainability in their curricula using 3DP. According to Vistp [30], Vietnam is one of the most active countries in Southeast Asia, promoting the awareness of Industry 4.0 in academia and industry. Nevertheless, the mechanical engineering industry in Vietnam needs to catch up to the country’s growth goals as this sector is less competitive than its regional and international counterparts [31]. Adopting cutting-edge technologies such as 3DP early on in the manufacturing process will aid Vietnam’s economic development while minimizing the negative effects on the environment. To ensure high-quality human resources for sustainable development, the education sector must take the lead in integrating and bringing 3DP technology into education and the industry.

Several of Vietnam’s top technical universities have been using 3DP technology in their curricula as either required or recommended coursework for the past few years, including the Hanoi University of Science and Technology, Hanoi University of Industry, Industrial University Ho Chi Minh City, and University of Science, Vietnam National University Hanoi. However, students have only gained general knowledge about 3DP, such as fused deposition modeling (FDM) or stereolithography (SLA) technologies [32], as they are expected to be familiar with the fundamentals of 3DP technology as well as the sustainability benefits that result from this technology and other forms of rapid manufacturing technology, including the reduction or elimination of waste from materials, labor, facilities, factories, transportation costs, and emissions. Until now, no research has been conducted to determine the relationships between sustainability, learning, and 3DP and how students collaborate and learn through 3DP in Vietnam’s higher education sector. Therefore, this study comprises a part of our project that is aimed at investigating undiscovered issues in Vietnam’s higher education sector.

2.4. Theoretical Framework: Learning about Sustainability through 3DP

The framework for effective AM education [10] includes five factors that are required for the development of AM education: (1) curriculum development; (2) in-house facilities and equipment; (3) research and development activities; (4) collaboration with industry partners; and (5) postgraduate degree programs. This framework [10] is expected to serve as a baseline that universities across the globe can use to develop their AM education.

Constructivism [33] emphasizes hands-on and experiential learning in which students construct their knowledge by actively engaging with materials. This approach can be applied to the design of products using sustainable principles through utilizing 3DP technology.

According to Social learning theory [34], individuals learn from observing others’ behaviors and outcomes. Therefore, incorporating group projects or collaborative activities that are focused on creating environmentally friendly designs using 3DP could promote social interaction among learners, thereby leading to a better understanding of how these technologies can be used while considering environmental concerns.

Transformative learning theory [35] suggests that people change their perspectives based on new experiences. Therefore, introducing concepts related to sustainability within courses involving 3DP at universities may encourage transformative thinking amongst students, ultimately resulting in their engaging in more eco-friendly practices both inside and outside academic settings.

By applying these theoretical approaches (see Table 1) to lectures, seminars, and workshops, educators can positively impact students’ academic performance and contribute positively toward society and the environment.

Table 1.

The key features of the “framework for effective AM education”, “social learning theory”, and “transformative learning theory”.

Integrating the “framework for effective AM education [10]”, “social learning theory [34]”, and “transformative learning theory [35]” directs the creation and execution of an AM education program. Incorporating instructional design, curriculum development, and assessment, the framework and two theories offer a systematic method for creating an all-encompassing AM education program [10]. The AM education program can benefit from social learning theory, which emphasizes the value of student–student interactions and collaborations [36] in group projects and activities. According to the principles of transformative learning theory, students benefit from having their preconceived notions and worldviews challenged in order to engage in more in-depth learning and development [37]. Students can learn not only about the 3DP technology and its potential uses but also how to think critically [38], solve problems [39], and learn independently [40] by participating in transformative learning experiences as part of the AM education program. Thus, two theories (social and transformative learning) are essential for developing an AM education program in conjunction with the “framework for effective AM education” in higher education.

2.5. The Aim and Research Questions

This study aims to determine the relationships between sustainability, learning, and 3DP as well as how Vietnamese students in higher education settings cooperate and learn sustainability through 3DP. This study will address the gaps in the literature by exploring the use of 3DP as a foundation for introducing sustainability into engineering education in Vietnam. The research questions are as follows:

RQ1: What activities do students and educators engage in and collaborate on through the use of 3DP in the classroom?

RQ2: What are the barriers to teaching sustainability using 3DP, and how might these barriers be overcome?

3. Materials and Methods

Ethical approval was sought from the human research ethics committee of the authors’ institution (Reference number: 20215549-8829). The study is based on a qualitative methodology. To learn about people’s experiences, activities, attitudes, and relationships, qualitative research techniques [41] were employed. In-depth exploration of these topics is possible with qualitative research methods such as field observations, and semi-structured interviews [42], which can yield rich and detailed data useful for gaining a better grasp on the research questions at hand. In addition, qualitative research can shed light on the social and cultural contexts in which phenomena such as the implementation of teaching sustainability through 3DP technology in the classroom occur. The field observations included taking notes, photographing artifacts, and semi-structured interviews involving people on location. The first author conducted the field observation sessions and semi-structured interviews (see Appendix A for the interview questions) to elicit the participants’ perspectives and experiences with incorporating sustainability through 3DP technologies into classroom settings.

3.1. The Participants and Field Observation Sites

Five public universities in North, Central, and South Vietnam were selected for this study. They were selected based on specific criteria, such as their 3DP education being taught in both undergraduate (UG) and postgraduate (PG) programs. According to the Vietnamese Ministry of Education and Training [43], 15 institutions offer AM education in Vietnam. Therefore, our sample included one-third of the Vietnamese higher education sector. The remaining universities and faculties were excluded from this study because they did not offer 3DP education. We observed seven classrooms in five Vietnamese universities, which were chosen based on the universities’ respective 3DP equipment and facility requirements, such as each school having to equip various 3DP technologies and having their own 3DP laboratories. After this, face-to-face interviews were conducted with five tutors and ten students. While we observed seven classroom activities, we chose one student from the active group and one student from the less active group in consultation with teachers in the classroom. In institutions 1 and 2, there were two classrooms in each institution. Because the classroom activities and learning outcomes were similar for those classrooms, we randomly selected two students from the active and less active groups from classrooms 1 and 2 in institution 1, and the same number of students from classrooms 3 and 4 in institution 2, accordingly. For the rest of the institutions, we randomly selected two students in each classroom to interview them. The participants’ demographics and the classroom observations at five universities are shown in Table 2 below.

Table 2.

The participants’ demographic information and the classroom observations in the five universities.

3.2. The Procedure

The first author observed seven classes in five universities over eight weeks, with each observation split into three phases. The first author invited ten educators from the five universities to participate in the field observation study over email at the beginning of the second term (January 2022). Only one educator from each of the five universities agreed to participate. The educators then recruited UG and PG students from their respective mechanical engineering faculties via their institution’s learning management system, as only the students from the engineering faculties were taught 3DP exclusively in the classroom. The following aspects of these classes were then observed: artifacts, devices, lectures, video-based classes, the educational and social contexts, the working environments (i.e., learning design and thinking in 3DP using browser-based software), preparatory activities, how the students used the software, classroom activities and practices, the students’ engagement, post-project activities and reflections, and written reports on artifacts. This was based on the observation lists used in the studies by Fernandes and Simoes [23], Selwyn [44], and Kostakis et al. [45]. In order to observe the classroom activities, we developed an observation checklist (see Appendix B), and the checklist was designed based on the maintenance for sustainability in Industry 4.0 (health and safety guidelines) [46] and 21st century skills [47]. This is because 3DP technology requires a combination of skills such as creativity, critical thinking, real-world problem-solving, collaboration and teamwork, and self-directed learning, which are components of 21st century skills [47].

3.2.1. Phase 1: Before the Field Observation Sessions (February 2022)

Once the five educators agreed to participate in the field observation study, the first author sent the consent forms to them, which were then disseminated to the students to review and sign. The students then returned their signed consent forms to their educators, who, in turn, returned them to the first author via email. The signed consent forms were stored in the author’s OneDrive folder provided by their institution.

3.2.2. Phase 2: During the Field Observation Sessions (March–May 2022)

The first author placed a sign in and outside the classroom that said, “An observation is being conducted”, to alert the students to the field observation. The students were also allowed to sign the consent forms before the class started if they had not done so already. The first author then observed the 3DP activities in the classroom and made notes. The students were not recorded in the field observation study, and their behaviors and what they said were also not observed. Each field observation session lasted from four to five hours, with a total of seven classes across the five public universities being observed over two months.

3.2.3. Phase 3: After the Field Observation Sessions (March–May 2022)

After the observations, the first author took pictures of the 3DP machines, 3DP projects, and artifacts. To avoid disrupting the classes, the first author interviewed the students and educators separately in a quiet area once the classes were dismissed. Each interview lasted from 30 min to one hour. All of the interviews were audio recorded. The first author conducted all the focus group discussions.

3.3. Data Collection and Analysis

The data included field observation notes, artifact images, and audio recordings of the semi-structured interviews, which were obtained with the permission of the respective universities’ engineering faculties. There was one field observation sheet for each of the five universities, totaling five field observation sheets, which served as the primary source material. In addition, there were 42 images of the artifacts, 3DP machines, and 3D design software. Six hours and 30 minutes of audio interview data were transcribed verbatim, which served as the secondary and tertiary source materials, respectively.

These three datasets underwent inductive and thematic analysis, with the five field observations being analyzed first, followed by the artifacts, and then the responses from the semi-structured interviews. The framework for the thematic analysis developed by Braun and Clarke [48] served as the guide for our data analysis. They indicated that the thematic analysis process should include several steps: (1) becoming familiar with the data; (2) producing initial codes; (3) searching for themes; (4) assessing the themes; (5) defining and labeling the themes; and (6) drafting the report. For this study, the field observation data were identified and loaded into NVivo 12, and the two main themes were determined and assessed against the research questions. The subthemes pertinent to the research questions were then identified and analyzed with reference to the field observation notes, artifacts, and interview transcripts. Thus, the first author read the transcripts and field observation notes, reviewed the artifacts multiple times, produced codes, organized them into themes and subthemes, and then examined, defined, and labeled them. The themes that emerged from the dataset were compared and contrasted with the findings from relevant studies. We also highlighted the specific statements made by participants that were considered relevant to determine general patterns and themes.

We used the method of member checking proposed by Varpio et al. [49] and Janesick [50] to minimize bias, correct misinterpretations, and strengthen the reliability of our findings. We summarized the themes and subthemes and then translated them into Vietnamese for member verification, with 75% of the respondents being given access to the data to allow them to provide feedback on the data’s precision. Furthermore, we reviewed the data with the research team members to ensure the data analysis was correct. Constructivism, the social learning theory, and the transformative learning theory were then used to analyze the students’ experimental learning, collaborative activities, group projects, and sustainability perspectives.

4. Results

We identified two main themes: (1) the sustainability activities on which students and educators collaborate using 3DP in the classroom and (2) the status of introducing sustainability using 3DP in the classroom. These themes were informed by the research questions (see Table 3), and the field observations were coded and triangulated using the interview data. The coding table of teaching and learning sustainability through 3DP (semi-structured interviews) in the classroom is shown in Appendix C.

Table 3.

The themes and subthemes.

4.1. The Sustainability Activities on which Students and Educators Collaborate Using 3DP in the Classroom

The activities (see Appendix D) provided students with both 3DP theory and practical skills, thereby improving the chances of the students gaining employment in the 3DP industry, especially in making models for casting statues. The various activities directed the students toward the desired outcomes and facilitated the development of a wide range of 21st century skills, such as 3D modeling, creativity, self-directed learning, and more.

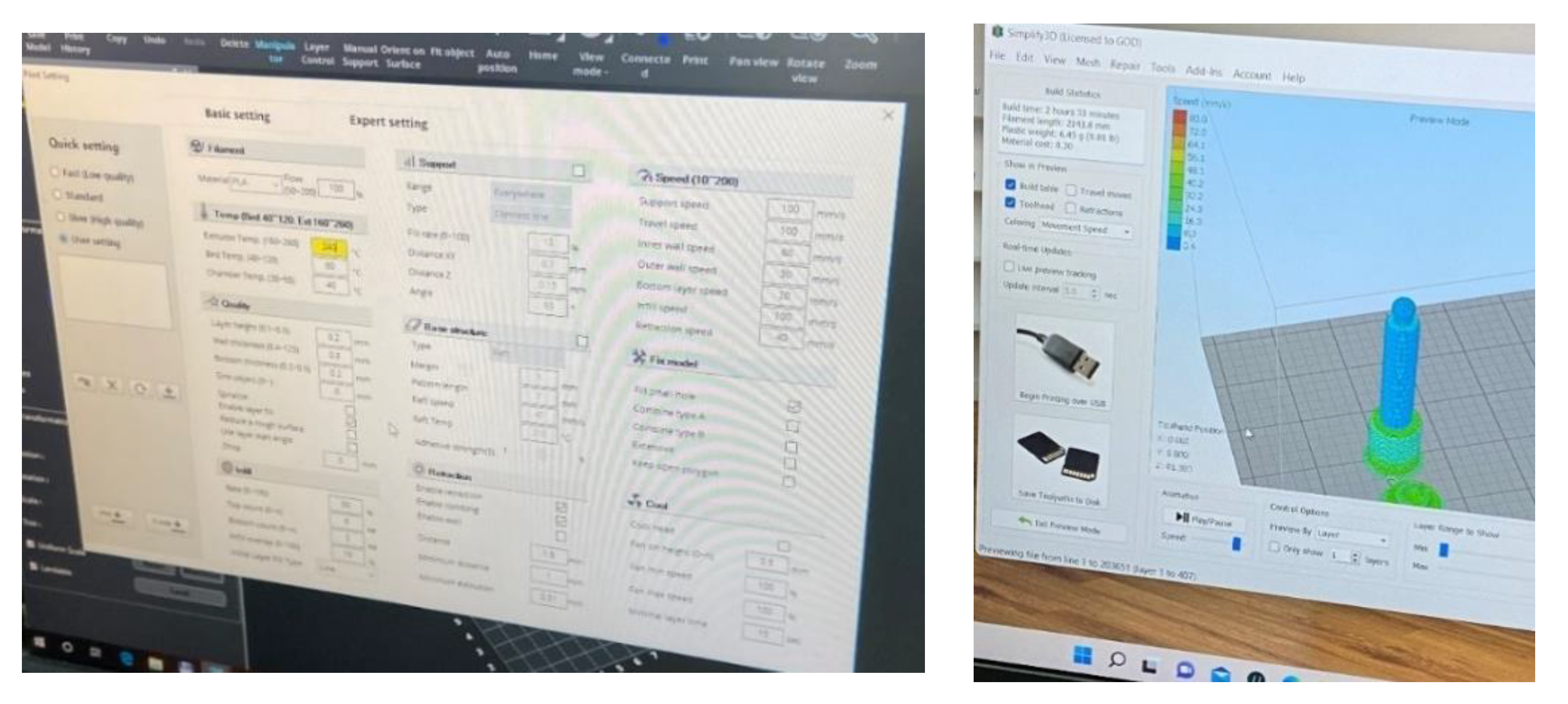

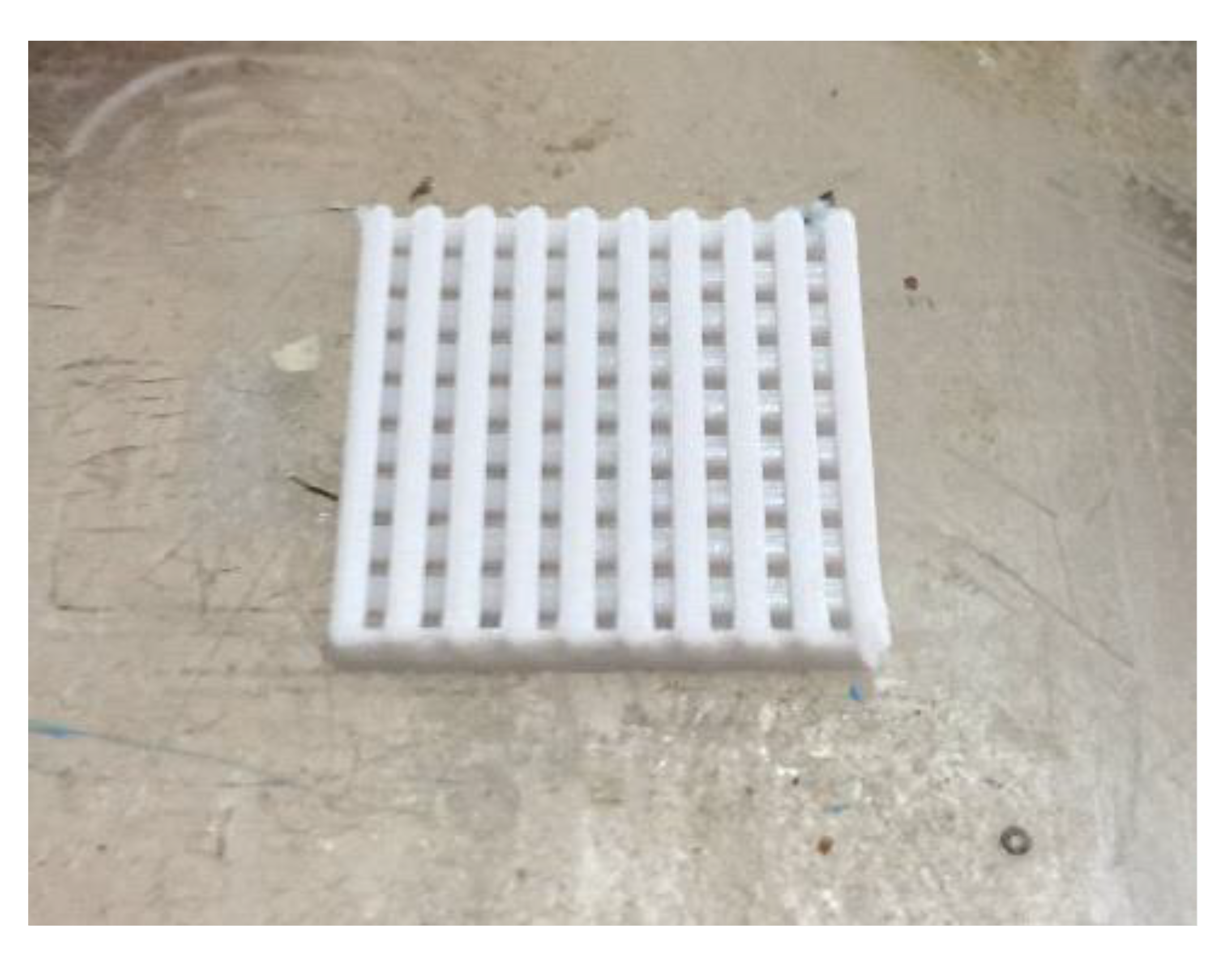

In four universities, the students mostly used FDM printers to design 3D models, download 3D models, set parameters, and discuss projects (Figure 1 and Figure 2) or assemble do-it-yourself (DIY) 3D printers for scientific research or sponsored high school programs over seven sessions.

Figure 1.

The parameters (left) and slice of a 3D model (right) (the images were collected by the first author during the field observation).

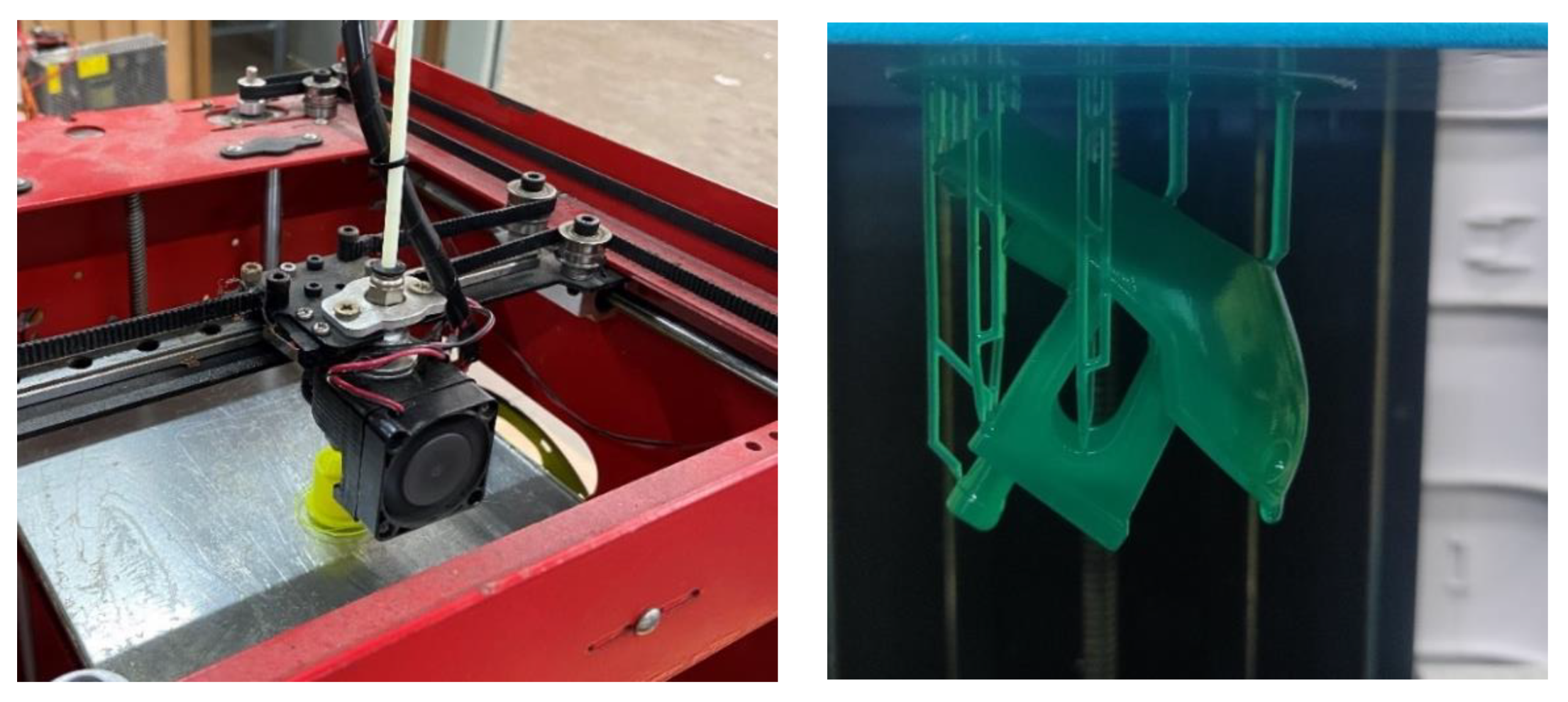

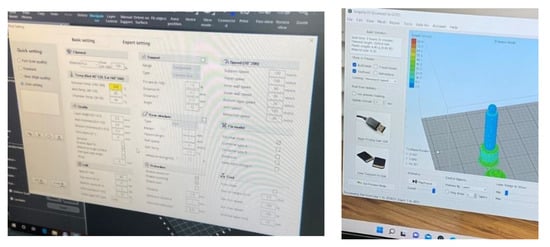

Figure 2.

The 3DP artifacts made using FDM (left) and SLA technology (right) (the images were collected by the first author during the field observation).

4.2. Students’ and Educators’ Perspectives

Learning science, technology, engineering, and mathematics (STEM) and 21st century skills. During the workshop, students learned how to create 3D models, print 3D artifacts (see Table 4), set up and use 3D printers, modify the settings of 3D models, and engage in group and individual reflections on their coursework, thereby positioning them at the forefront of technological progress. Thus, the 3DP workshop activities from this study can be used to support STEM education initiatives, advance scientific research, and make 3DP technology accessible to students.

Table 4.

The two types of artifacts produced in two of the universities (the images were collected by the first author during the field observation).

Both the educators and students believed that the students could develop expertise in various activities, including operating machinery, producing models, and conducting research. Therefore, these activities allowed the university to ensure that highly qualified experts enter the 3DP industry as the students developed their competencies in design, programming, teamwork, problem-solving, and self-directed learning. Educator 2 indicated that it is important to, “Bring 3DP technology into STEM training, mainly to stimulate students in the process of product development and operation of technical skills for self-study as well as to develop design skills, product manufacturing skills, and product design development. [It is important that] students understand that process so that they can prepare for their career; after graduation, they will work in the field of product design and manufacturing, mainly in the mechanic[al] field”.

Furthermore, most of the educators and students claimed that the students developed their capacity for design through collaborative group work at the workshops. As a result, they were able to create complex structures using 3DP technology, which also fostered their creativity and critical thinking capabilities as well as their ability to apply their talents to practical problems. The students also acquired various skills through hands-on experience and independent study in the laboratory, including design, self-directed learning, programming, and controlling 3DP systems. Student 6 claimed that “It has the benefit of giving students a lot of learning experience. The device itself can also help students learn the processes in production, [such as] equipment usage and troubleshooting. Problems can be a perfect tool to exchange problem-solving skills and feel more passionate”.

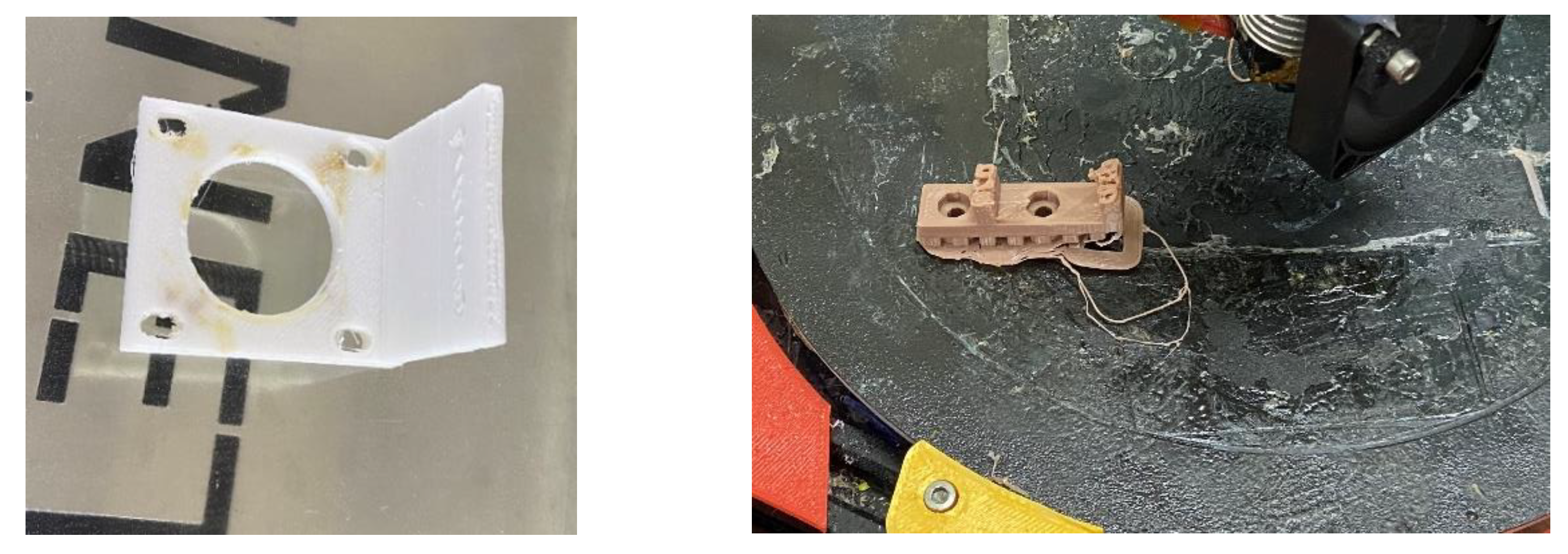

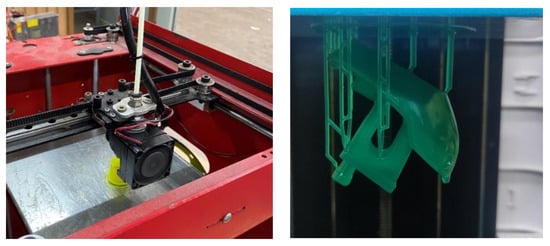

However, some participants claimed that there were some issues affecting the students’ 21st century skills (see Figure 3), the majority of which were related to the incorrect operation of FDM and SLA printers as well as broken artifacts. Most students had not used 3DP systems in a long time as they had learned about 3DP via online learning or self-directed learning using the internet during the COVID-19 pandemic, which led to insufficient practical knowledge. This resulted in their incorrectly operating the printers or forgetting some steps when adjusting the artifacts’ settings. However, the educators helped these students. For example, before any artifacts were printed, the educators insisted that the students complete a series of predetermined tasks, such as analyzing the issues, fabricating solutions, and conducting quality assurance checks. Additionally, the students had to redo some of the steps if they faced the same issues.

Figure 3.

Broken artifacts (left: layer separation and warping in a broken artifact; right: a broken artifact not sticking to the bed) (the images were collected by the first author during the field observation).

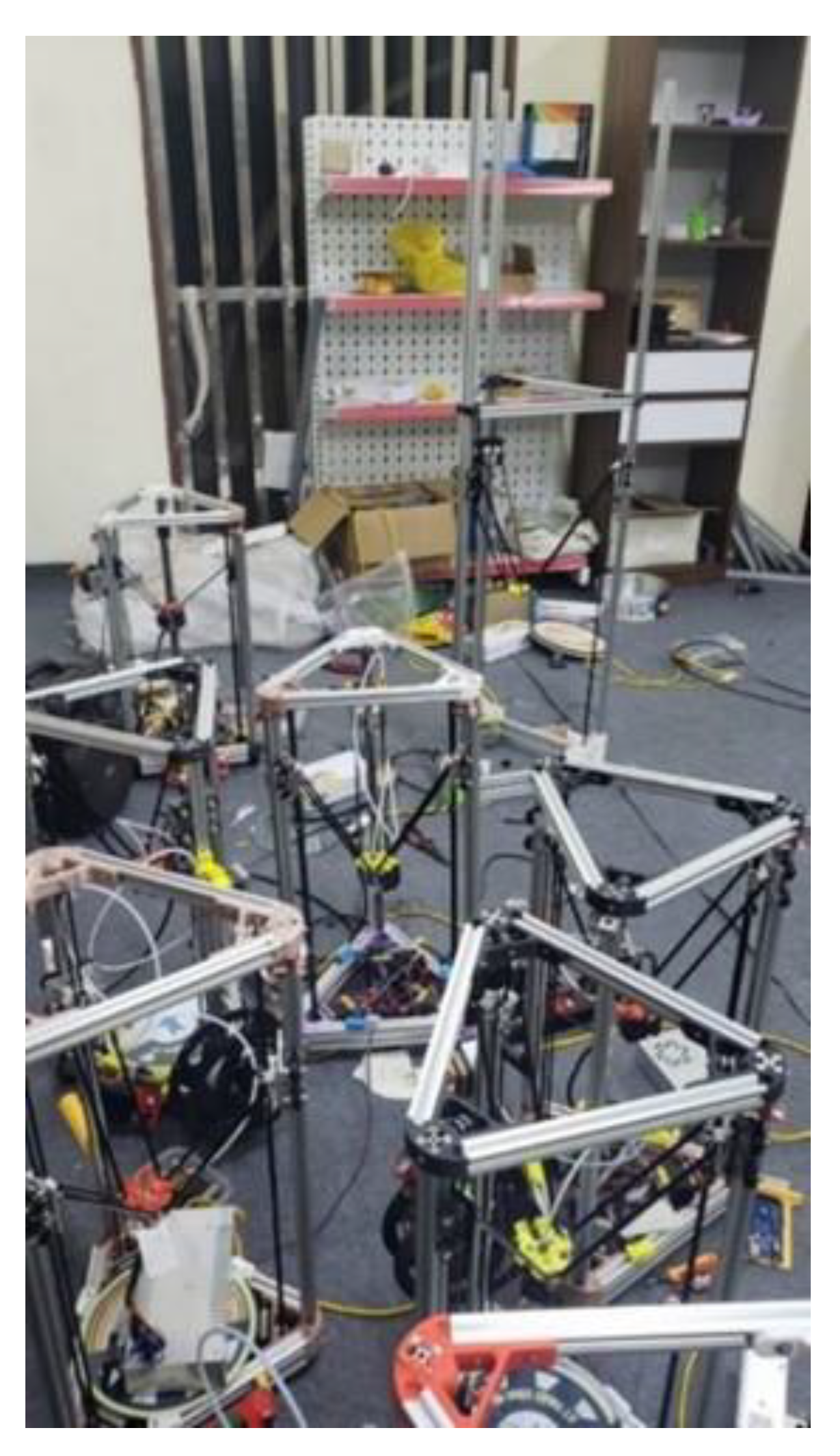

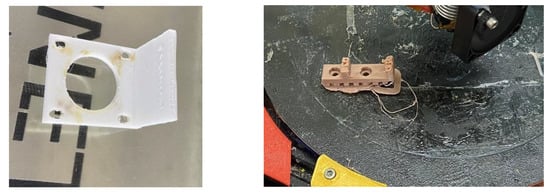

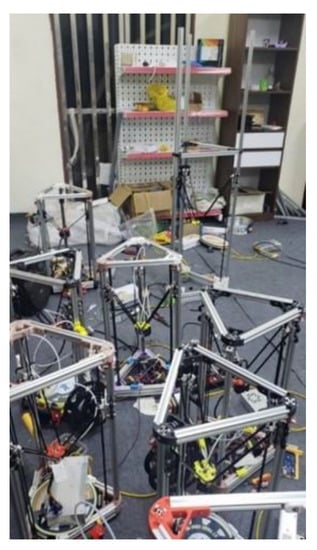

Assembling DIY printers for scientific research. This subtheme was observed in five of the sessions in which the students were guided in assembling DIY FDM printers (see Figure 4) in four of the universities: Institution 1, Institution 3, Institution 4, and Institution 5. The assembling activities affected the degree to which the students could utilize and improve upon their 21st century and STEM skills. Furthermore, the students gained many STEM skills when assembling the DIY printers as they had to build mechanical and mechatronics components from raw materials.

Figure 4.

The assembly of DIY 3D printers for high school programs (the images were collected by the first author during the field observation).

The educators expressed that, when they lacked 3DP facilities and equipment, they had two purposes when guiding students who were assembling DIY 3D printers: (1) to meet the learning outcomes with limited resources as the students would have had sufficient equipment to practice if they made the DIY 3D printers and (2) to encourage students to participate in scientific research, thereby aiding them in becoming experts in the 3DP industry. Educator 1 stated that in “Each course, I instruct six to eight student[s]. Each year makes one FDM machine, [and] the… group[s contain] about eight to ten students. [They work on] DIY mechanical design[s] for eight months, and control components are selected and assembled. [A] FDM print size [of] 400 × 400 × 400 [with an] automatic printing table push mechanism with large products should operate normally for two years. However, we must replace the print head [and] thermal sensor every three months. The accuracy is 1/100, [which] meets the requirements given”. The majority of the students also had access to free, open-source materials, allowing them to build their own low-cost DIY FDM printers. Student 3 reported that, “I have to learn C to edit the open-source code, so I can code 3D printers at my discretion and [in line with] the 3D design software”.

Nevertheless, the students faced many challenges when building the DIY FDM printers, such as needing multidisciplinary knowledge. The students were in the mechanical engineering faculty, but needed to have knowledge from other disciplines when assembling the DIY 3D printers for scientific research. Student 3 also stated, “I have some difficulties in the research process of 3DP materials and the mechanistic properties of each material. I also have difficulties designing and manufacturing 3D printers and [with] the control software of each type of 3D printer”.

Assembling DIY printers for sponsored high school programs. Even though this was only observed in one session in Institution 5 (see Figure 5), the students and their educators produced more than 30 DIY 3D printers for the 3DP program for high schools, which was founded in 2018. After assembling the DIY 3D printers, the students presented their printers at the university’s scientific research contests and industry contests. This fostered the students’ passion for future research and working in the 3DP industry. Thus, these 3D FDM printer programs provided an unmatched and rewarding learning experience and provided the students with a sense of excitement when they assembled the 3D printers independently. When the students designed the models, it was an authentic experience because they had to review the print size and whether the design was thicker or thinner, amongst other criteria, and they had to troubleshoot any complications that occurred with the printers. Therefore, they learnt through a combination of practical experience and independent study in the laboratory how to achieve the best possible outcomes.

Figure 5.

The assembly of the DIY 3D printers for the high school program (the images were collected by the first author during the field observation).

Because universities are expected to assist in the development of STEM learning methods and to cultivate a culture of scientific inquiry in order to equip students with a sound basis for their future jobs, the collaboration between students from Institution 5 and high schools allowed the students to acquire a broad range of abilities, including operating equipment, printing models, and conducting research.

The students stated that they were allowed to learn advanced skills in 3DP and gain knowledge from their peers in multiple disciplines while assembling the DIY printers. Student 3 claimed that “Since we do development research, there are many things that do not belong to our major, but we… have to do it, so we have gained much experience through our studies. For example, we had to source qualified goods to assemble the 3D printer, and we learned how to program the 3D printer so that it can operate after being assembled according to the available parameters”.

However, both groups complained about some constraints, including the 3DP program which included three groups (i.e., Institution 5, the students in the mechanical engineering faculty, and high schools) being held in a remote location, the facilities and funding being restricted, and the students facing challenges when assembling the 3D printers as they had to synthesize their own information about DIY 3D printers with the support of students from other departments due to their lack of knowledge.

4.3. The Status of Introducing Sustainability through 3DP in the Classroom

Sustainability through 3DP is not officially taught as a distinct unit. The majority of the educators and students reported that a limited amount of time was spent on teaching 3DP in the classroom and that sustainability through 3DP was integrated into other learning modules, such as electrical discharge machining, rapid prototyping technology, robotics, and reserve engineering, meaning that it had not yet become an official subject. Furthermore, the method of teaching was mainly theoretical. The 3DP technology training in the programs only consisted of a chapter on rapid prototyping technology, with a portion of the module covering special processing methods. Thus, sustainability still needs to be formally covered in the laboratory. Moreover, in some universities, 3DP technology currently still needs to be considered as a specialized field. We observed this subtheme in four of the universities’ field observation sessions. Educator 1 reported that “In fact, 3DP at our university belongs to the subject of special processing methods or rapid prototyping technology, which replaces the graduation thesis. Therefore, the[re is not a lot of teaching] of 3DP technology in the current training program at my university’s mechanical engineering faculty, so sustainability in 3DP is introduced but not taught to students now”.

Lack of experts who understand sustainability as well as a lack of tools and software that can be used to evaluate the sustainability of 3DP. The majority of the educators were not trained in sustainability, and there are also currently not enough experts who have an in-depth understanding of sustainability through 3DP in Vietnam. Moreover, the tools (e.g., measuring and other relevant equipment) and software available in the classroom for teaching sustainability through 3DP are insufficient. Educator 5 said, “Not many people are taught about sustainable development and technology as there are not many experts trained in this field, and there is a lack of tools and software that can be used to evaluate the sustainability of 3DP”.

Efficient use of printing materials that are suitable for product development. The students were instructed on how to use 3DP materials economically and which materials were beneficial for the environment, and they also learned about the ways in which to select the materials for their projects as many options were made available to them. This included teaching them how to select materials that were safe for the environment and why they should prioritize using materials that ensure financial savings and sustainability. Both the educators and students shared the same view regarding the efficient use of materials:

Interviewer: How would you expect students to learn sustainability from 3DP?

Educator 2: I understand sustainable development is clean energy [and] how to recycle and use endless energy, and in 3DP, sustainable development [includes] the process of developing PLA materials [that are] made from self-biodegradable cereal flour when… 3D printed. It can be recycled or, when [it is] released into the environment, it is non-hazardous and decompose[s] in a short time.

Student 6: I think that by giving a suitable structure to minimize the materials, I can [3D] print the object… which saves materials and ensures sustainability.

Teaching students about sustainability through 3DP and investing in 3DP equipment and facilities. Most educators believe that universities can invest more in equipment to overcome various challenges, such as a lack of 3DP facilities and equipment. However, due to their limited resources, educational institutions are encouraged to manufacture and research suitable equipment for teaching and learning about 3DP, such as cheap DIY 3D printers, as this is the most important factor that leads to long-term sustainability in the future. In addition, it is necessary to educate students on the fundamentals of sustainability in 3DP, including why the sustainability of 3DP will be so important in the future. This subtheme was recorded in one field observation session in each of the five universities. Educator 4 stated that “I will teach students what the nature of sustainability in 3DP technology is, [and] from there… I will guide students through some useful software, such as software [that can be used] to choose materials [along] with the suitable printing mode and printing materials, and the university will have to invest in more machinery and equipment for this 3DP technology”.

Policies that support sustainable development through 3DP. More than half of the educators suggested that it is essential to have policies that support the promotion of 3DP training, particularly environmentally friendly 3DP technology. The Vietnamese Ministry of Science and Technology and Ministry of Education and Training are aware of the significant role that 3DP printing will play in the Industry 4.0 era and that its applications will be pervasive across various industries. Therefore, they need to develop policies that support investment in equipment. Educator 5 said, “We must have policies and guidelines, especially [from the] government. For example, [there are no policies for] the 3DP industry. On that basis, the government has to provide [money] and resources to develop the 3DP industry”.

Motivating students to join the 3DP industry. Some of the educators and students stated that 3DP technology is not yet widespread in Vietnam and only a small number of businesses make consistent use of this technology. Furthermore, the 3DP industry is still a recent development in Vietnam, and many people are unaware of this advanced technology in the Industry 4.0 era. However, when the students used 3DP in the workshops, they came to understand how to create products using 3DP, thereby providing them with knowledge on the career for which they were training, what 3DP is for, how 3DP develops, what they needed to do to in order to meet the requirements of future jobs, and demonstrating the knowledge and skills they needed for their future careers. We observed this subtheme in two of the universities’ field observation sessions. Student 5 said that “3D printers [are] a new technology and help us [gain] experience [that can be used for] working in a company later or [that we can use to] develop… a new industry in Vietnam [ourselves]”.

5. Discussion

This study aims to explore the relationships between sustainability, learning, and 3DP and how Vietnamese students in higher education cooperate and learn sustainability through 3DP. Our findings reveal several barriers to and recommendations for teaching sustainability using 3DP in the classroom, which are discussed below.

5.1. 3DP and Project-Based Learning of Sustainability

In this field observation study, we explored how students were exposed to 3DP through project-based learning. The findings indicate that students mostly preferred to work in groups rather than as individuals. They were encouraged to improve their abilities in this area by completing major assignments in groups, with five skills being identified: (1) teamwork; (2) creativity; (3) critical thinking; (4) self-directed learning; and (5) novel problem-solving. These skills demonstrated by the students are considered major 21st century skills [47]. Furthermore, Williams and Seepersad [51] believe that project-based learning entails providing students with real-world tasks that require applying what they have learned and using their knowledge of the subject matter. Thus, students can also benefit from cognitive apprenticeship, a teaching method that allows students to gain metacognitive abilities and processes through their work with a project mentor.

In the five universities, the students engaged with their peers and tutors through project-based exercises and building DIY 3D printers for scientific research and high school programs. 3DP allowed the students to learn not only STEM and 21st century skills but also provided them with knowledge from multiple disciplines. These are some of the concrete skills that the Vietnamese mechanical engineering students learned that are associated with 3DP technology in classroom settings:

- Conducting research across a wide range of fields in both English and Vietnamese

- Utilizing the information gained from a wide range of disciplines

- Investigating the inner workings of open-source 3D printers

- Developing and designing the control systems of 3D printers

- Experimentally investigating 3D printers’ fundamental parameters

- Assembling the mechanical components of 3D printers in collaboration with others

- Utilizing different 3DP materials

The findings on the collaboration between educators and students were similar to previous studies by Fonda et al. [12], Kostakis et al. [45], Trust and Maloy [47], and Schelly et al. [52] in that 3DP technologies have the potential to enhance education by giving students a sense of agency as a result of their active participation, thereby fostering cross-curricular engagement. This also better ensures their success in today’s information-intensive workforce. Furthermore, 3DP may significantly affect higher education institutions as students will be allowed to exercise their creativity and work within multiple disciplines while completing projects or assembling DIY printers.

We observed that different sorts of artifacts had been developed in the classroom settings (see Table 4). However, there was no specific sustainable goal in mind while developing artifacts. Therefore, it is recommended that when students develop these sorts of artifacts in the classroom through 3DP, they have a special goal to achieve and learn better through this process.

Constructivism and the social learning theory were reflected through the activities in which the students engaged in the classroom. Our study, which relied on field observations and semi-structured interviews, found that AM education and sustainability activities are being promoted by sustainability activities and research activities (assembling DIY printers for scientific and high school programs) at five Vietnam public engineering universities, which is consistent with the social learning theory. According to social learning theory [34], students and educators gain knowledge from one another by working together (to create models, discuss projects, and assemble DIY 3D printers). Our research showed, however, that many students had to switch to online classes during the COVID-19 pandemic, and those students had not used 3D printers in quite some time. Thus, when they returned to the 3DP lab, they found operating the 3DP printers challenging. According to social learning theory, students require some form of e-learning (simulation).

5.2. Developing Multidisciplinary Skills through DIY 3DP Programs

The participants also reported substantial achievements in assembling DIY printers for scientific research and sponsored high school programs. These findings were consistent with other studies by Fonda et al. [12], Gallup and Pearce [18], and Inoma et al. [29], who claimed that open-source 3DP software and hardware allow students in developing countries such as Vietnam to access low-cost 3DP technology. Therefore, the DIY 3DP approach could allow students to unlock their potential by solving challenges that closely resemble real-life scenarios.

The findings on assembling DIY 3D printers for sponsored high school programs were unique, as no other study had similar findings. Students were required to work within multiple disciplines, including design, software, coding, and fundamental engineering, when assembling the 3D printers, which is echoed in the studies by Cotteleer et al. [14] and Loy et al. [53], who indicated that the successful deployment of AM requires teams to work across several disciplines, including engineering, design, materials science, and manufacturing. Interviewees from the business sector expressed a need for a labor force that could more fluidly move between different fields of study. However, the students encountered difficulties when assembling the DIY 3D printers as they did not have expertise in multiple disciplines. This represents a challenge in implementing 3DP in higher education. Despeisse and Minshall [54] suggested that multidisciplinary knowledge could be enhanced if students have access to a more complete and coherent AM knowledge base, thereby ensuring engineers that contribute to a more robust workforce.

The results of the seven field observation sessions in the five universities were consistent with previous studies [55,56,57]. Thirty-eight and forty-two artifacts were designed, printed, and explicitly designated for mechanical purposes in two universities, respectively; the remaining artifacts were biometric models. However, to print the 3DP artifacts successfully, the students had to select the appropriate tools and materials carefully, and they had to customize the 3D models. There were also a few failed artifacts during the field observations, and the students encountered obstacles when prototyping the artifacts as they were concerned with poor-quality artifacts or the reliability of the 3D printers. It took time for the students to address these issues. Therefore, when teaching 3DP in the classroom, educators should detail troubleshooting measures and the unanticipated outcomes so as to improve students’ learning experiences with 3DP technology significantly.

Some essential equipment, such as 3D scanning, was not available in the workshops. Bull et al. [58] claimed that integration, which was considered herein, and continued professional education are necessary for supporting students and teachers when they are learning how to use 3DP technology.

When assembling the low-cost DIY 3D printers, the students were required to develop their multidisciplinary skills. The field observations demonstrated that the students’ learning styles were homogeneous as there were no significant differences between the students across the five universities, aside from a slight distinction in Institution 5, which aligned with an established learning model. Therefore, it is a valid approach.

Transformative learning theory [35] suggests that learning involves a process of critical reflection and self-awareness, which transforms how students think about and approach different problems. The study confirms the field observation by showing that DIY 3DP programs that encourage the development of multidisciplinary skills can lead to fruitful outcomes, such as low-cost DIY 3D printers. This supports the idea that AM education can facilitate a shift in students’ thinking and approach to various problems, an essential component of the transformative learning theory. The research also shows that university students can benefit from a more in-depth understanding of sustainability issues and a more substantial commitment to sustainable behavior due to participating in sustainability education.

5.3. Sustainability Was Introduced through 3DP

The majority of the participants from all five universities agreed that their institutions were not equipped with the necessary tools and software to teach about sustainability through 3DP, that the 3DP teaching time for students was limited, and that most of the educators were not trained for discussing sustainability in higher education. These were the primary reasons why sustainability was not officially taught in the classroom, even though some of the educators introduced the students to the background of sustainability through 3DP. This finding aligned with studies by Loy [7], Huang and Leu [20], and Alabi et al. [21], which stated that many obstacles still needed to be overcome, including the lack of qualification and certification methodologies for AM processes and the difficulties encountered in getting students to grasp the complexities of life-cycle assessment in terms of sustainability, which could lead to relatively poor partial accuracy due to the stair-stepping effect. This lack of educators was also found to be an obstacle by Lee and Lee [59], who stated that there is a shortage of skilled STEM teachers worldwide and a lack of teachers who are prepared to teach technology in some nations. Moreover, some countries also have teachers who are unprepared to embrace integrated STEM models.

The educators proposed that the lack of distinct units on sustainability through 3DP was a barrier and recommended that institutions should invest in educational materials for long-term use, that low-cost DIY 3D printers should be built to help students learn about 3DP technology effectively, and that students should be taught about the fundamentals of sustainability through 3DP. Furthermore, there should be a substantial framework from policymakers in both the Vietnamese Ministry of Science and Technology and the Ministry of Education and Training that is aimed toward developing the AM industry and encouraging engineering students to learn 3DP and join AM workforces in the future, and the government can help fund the development of sustainable 3DP technologies, which will provide a foundation upon which future researchers and educators can build. Universities and research institutions can apply to support their efforts to develop sustainable materials, processes, and applications. In this case, Vietnam can benefit if there is funding for development from the government. In order for students to fully grasp the differences in the systems used to create products, they must make a direct and practical connection between learning 3DP technology and the industry as it exists today and as it is envisioned in the future because this is an opportunity to teach sustainability through 3DP in Vietnam’s higher education. However, teaching sustainability through 3DP has not been implemented in Vietnam due to significant barriers, including technical limitations, a lack of resources, and the need for pedagogical innovation. The need to provide educational materials and a framework is echoed in similar studies [21,60]. However, building low-cost DIY 3D printers is a novel proposal that is not included in recent studies. Students were also taught about the fundamental aspects of sustainability, such as the economical use of materials for 3DP and selecting environmentally friendly materials, as the students were given a wide range of options of materials for their projects. This is in line with the findings from research on 3DP in higher education, including studies by Cotteleer et al. [14], Alabi et al. [21], Litsey et al. [61], Huang et al. [62], and Bourell et al. [63]. Thus, it would be more effective to train students in how to use 3DP materials efficiently as this could be implemented in Vietnam’s higher education institutions, most of which lack resources for education and use ineffective and outdated teaching practices [64].

Furthermore, it is essential to increase the time dedicated to teaching sustainability through 3DP in the classroom. The best way to ensure all students are exposed to topics such as sustainability and 3DP is to incorporate them into the current curriculum. Adding topics such as sustainability and 3DP to existing courses or creating new courses may be necessary. In addition, educators should enhance their 3DP and sustainability skills, as Novak [8] claimed that due to the widespread availability and popularity of 3DP in universities, educators will need to acquire and implement novel teaching strategies, pedagogical frameworks, and curricular materials. Training educators in sustainable practices and 3DP as part of their professional development can help fill the education workforce’s knowledge gaps in these areas. Workshops, seminars, and even online courses could help with this goal. Working with professionals in the field or other educational institutions that have experience with 3DP and sustainability can be a great way to pool resources and gain new insights. Partnerships in the industry, academic exchanges, and other forms of collaborative research are all examples.

These barriers to teaching sustainability through 3DP are addressed in the framework of effective AM education by Alabi et al. [10]. However, this framework was not designed specifically for ensuring sustainability in developing countries. Thus, this study details the significant barriers that are encountered in integrating sustainability through 3DP in higher education, and novel recommendations are provided.

5.4. Implications

The results of this study can be applied to sustainability initiatives at higher learning institutions in developing nations. Thus, this study could have far-reaching consequences for policymakers, educators, students, and even future researchers. The first implication entails the development of a national educational policy by both the Vietnamese Ministry of Science and Technology and the Ministry of Education and Training in order to develop the AM industry as well as to encourage engineering students to learn 3DP and join the AM workforce. Policymakers should also prioritize educational and application-focused research into 3DP technology as well as initiatives aimed toward increasing public understanding of 3DP technology through public awareness campaigns, training programs, and infrastructure investment initiatives. The second implication concerns the higher education sector in that universities should make long-term investments in educational resources and build low-cost DIY 3D printers to help students understand 3DP technology. These 3D printers can also be used to teach students about the basics of sustainability through 3DP technology and to develop students’ proficiency in various fields.

5.5. Limitations

Only mechanical engineering students were observed in this study. Thus, we could not compare students from different disciplines, including product design and industrial arts. Additionally, only male participants were interviewed because there were no female mechanical engineering students in the five universities in this study, which may have skewed the results. Lastly, a relatively small sample size of ten students and five teachers was used for the semi-structured interviews, which may have resulted in essential details about some of the participants’ educational experiences being missed.

6. Conclusions

This study explored how 3DP has been utilized to incorporate sustainability into higher education in developing countries, specifically Vietnam. The study involved field observations and semi-structured interviews with students and educators from five public universities. Two themes emerged from the findings: (1) the sustainability activities on which students and educators collaborated using 3DP in the classroom and (2) the status of introducing sustainability using 3DP in the classroom.

The first theme discussed the results of conducting 3DP workshops in five universities to support STEM education initiatives and scientific research. The workshops helped students learn various skills, such as creating 3D models, printing artifacts, modifying 3D printers, and problem-solving. However, issues such as incorrect printer operation and broken artifacts affected their 21st century skills due to insufficient practical knowledge. Students also assembled DIY 3D printers for scientific research and high school programs, which allowed them to gain STEM skills, but they faced challenges such as a lack of multidisciplinary knowledge and limited resources. The study revealed a lack of experts who understand sustainability and tools/software to evaluate 3DP’s sustainability. Thus, teachers should guide students in building low-cost DIY 3D printers to maximize learning outcomes with limited resources and funding.

The second theme focused on how sustainability can be integrated into 3DP education in Vietnamese universities. Sustainability was not taught as a separate subject, but integrated into other modules. The teaching methods were mainly theoretical, and students were taught to use 3DP materials efficiently and select environmentally safe materials. The educators suggested that universities should invest in 3DP equipment and facilities and that policy support is needed to promote environmentally friendly 3DP technology. Additionally, students should be motivated to join the 3DP industry and 3DP resources, such as materials, should be used in the classroom to teach students how to use the technology for sustainability purposes.

The skills students gained through participating in STEM-related educational activities related to integrating sustainability through 3DP in higher education. While some educators acknowledged the potential impacts of teaching sustainability through 3DP, technical constraints, resource shortages, and the need for pedagogical innovation prevented these impacts from being recognized. By applying the knowledge gained from this study, students and universities can achieve sustainability while developing 21st century skills such as creativity, critical thinking, problem-solving, collaboration, and self-directed learning.

Author Contributions

Conceptualization, A.A.M., T.T.T., and C.R.; methodology, A.A.M.; formal analysis, T.T.T.; investigation, T.T.T.; resources, A.A.M. and C.R.; data curation, A.A.M.; writing—original draft preparation, T.T.T.; writing—review and editing, A.A.M. and C.R.; supervision, A.A.M. and C.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was conducted in accordance with the Declaration of Helsinki and approved by Swinburne University of Technology Human Research Ethics Committee (Ethics ID# 20215549-8829 and Date of approval: 17/11/2021).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study as per the approved ethical protocol.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

We acknowledge the cooperation of participating institutions, teachers, and students.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

The interview study aimed to investigate the implementation of 3D printing integration in the higher education sector.

Table A1.

Open-Ended Questions.

Table A1.

Open-Ended Questions.

| No. | Section A—Open-Ended Questions—Barriers of 3DP Technology and Sustainability (This Section Aims to Investigate the Barriers of 3DP Technology in the Higher Education Sector)—For Students |

|---|---|

| 1. | Do you learn about sustainability in 3DP technology at your university? If yes, how do you learn sustainability through 3DP? What are the best and worst parts? Can you identify any constraints of incorporating sustainability into 3DP subjects? |

| 2. | What are the benefits and challenges of learning 3DP in the classroom? What are the most important about cooperating with AM industry? |

| 3. | What types of support have you received from your university? |

| 4. | What are the challenges of studying sustainability through 3DP in the classroom? |

| 5. | What are your experiences studying 3DP in the classroom? What do you want to learn from 3DP? |

| No. | Section B1—Open-Ended Questions—Barriers of 3DP Technology and Sustainability (This Section Aims to Investigate the Barriers of 3DP Technology in the Higher Education Sector)—For Faculty and Staff |

| 6. | Do you teach sustainability in 3DP technology at your university? If yes, how do you teach sustainability through 3DP? what are the best and worst parts? Can you identify any constraints of incorporating sustainability into 3DP subjects? Finally, what do you want to expect students learning sustainability from 3DP? |

| 7. | What are the benefits and challenges of learning 3DP in the classroom? What are the most important about cooperating with AM industry? |

| 8. | What types of support have you received from your university? |

| 9. | What are the barriers to teaching 3DP as one tool for prototyping in the overall context of design and manufacturing education? What should the government and policymakers need to support sustainable development using 3DP technologies in higher education? What measures are required? |

| 10. | How integrating 3DP in the higher educational settings will help Vietnam achieve sustainable development? |

| Section B2—Open-Ended Questions—3DP Creativity, Innovation, Research and Development, and Technology Transfer (This Section Aims to Investigate the 3DP Curriculum in the Higher Education Sector)—For Faculty and Staff | |

| 11. | What do you think about 3DP technology becomes a platform for technology transfer and innovation between your university and AM industry? In particular, What’s your understanding of technology transfer and innovation in 3DP? |

| 12. | What are the roles of 3DP technologies in helping students to achieve the creativity, innovation and cultural disparities inherent to sustainability? |

| 13. | What should the government and your university need to provide support or resources for research and development using 3D printing technologies in higher education? What measures are needed? |

| No. | Section C—Close-Ended Questions—3DP Capacities and Barriers (This Section Aims to Investigate the 3DP Curriculum and Sustainability in the Higher Education Sector)—For Faculty and Staff and Students |

| 14. | What are your recommendations for the 3D printing integration in the classroom? How effective is the 3DP course in your classroom? What limitations do you think 3DP has in the classroom? |

| 15. | In terms of sustainability, how can you provide better education using 3D printing technology? |

| 16. | In your own words, please briefly describe what the term “sustainability” in 3D Printing means to you? |

Appendix B

Table A2.

The Checklist for Field Observation.

Table A2.

The Checklist for Field Observation.

| 1. Safety | Are the students following safety guidelines in the laboratory? (Yes/No) |

| 2. Equipment | Is the 3D printing (3DP) equipment functioning correctly? (Yes/No) |

| 3. Material usage | Are students making appropriate and effective use of resources? (Yes/No) |

| 4. Workflow | Is the workflow of the 3DP process smooth and efficient? (Yes/No) |

| 5. Knowledge | Do the students have a clear understanding of 3DP concepts (theory/practice)? (Yes/No) |

| 6. Creativity | Are students utilizing 3DP to create unique and innovative designs? (Yes/No) |

| 7. Critical thinking | Do students make decisions and solve problems using critical thinking skills in the 3DP process? (Yes/No) |

| 8. Collaboration | Are students able to successfully complete their 3DP projects in groups or pairs? (Yes/No) |

| 9. Communication | Do students share their understanding of 3DP with their classmates and teachers? (Yes/No) |

| 10. Self-directed learning | Are students taking ownership of their learning and using available resources to improve their 3DP skills? (Yes/No) |

| 11. Multidisciplinary knowledge | Are students able to apply knowledge from different fields of study to 3DP projects? (Yes/No) |

| 12. Problem-solving | Do students have the ability to identify and rectify issues that may arise during the 3DP process? (Yes/No) |

| 13. Finished products | Do the final products (artifacts) satisfy all of the specified conditions and criteria? (Yes/No) |

| 14. Feedback | Are the students receiving feedback from the instructor and utilizing it to improve their 3DP skills? (Yes/No) |

Appendix C

Table A3.

Teaching and Learning Sustainability through 3DP in the Classroom.

Table A3.

Teaching and Learning Sustainability through 3DP in the Classroom.

| Teaching and Learning Sustainability through 3DP in the Classroom | (n ) and Ratio (%) of Participants Reporting Each Barrier/Recommendation | ||

|---|---|---|---|

| Educators | Students | ||

| Definition of sustainability through 3DP | Future technology trend and shortens the development cycle | n = 5; 100% | n = 6; 60% |

| Reduce waste, economic efficiency, and environmentally friendly | n = 5; 100% | n = 5; 50% | |

| Development orientations for students | n = 3; 60% | n = 0 | |

| Experience of teaching and learning sustainability through 3DP | Efficient use of material | n = 5; 100% | n = 5; 50% |

| Open-source 3D printers | n = 5; 100% | n = 7; 70% | |

| Suitable for product development | n = 5; 100% | n = 6; 60% | |

| Assemble DIY FDM printers | n = 5; 100% | n = 8; 80% | |

| Benefits of teaching and learning sustainability through 3DP | The process to contribute to sustainable development | n = 5; 100% | n = 0 |

| Barriers to teaching and learning sustainability through 3DP | Sustainability is not taught through 3DP | n = 5; 100% | n = 6; 60% |

| Lack of experts understanding sustainability and tools and software to evaluate the sustainability of 3DP | n = 5; 100% | n = 0 | |

| Sustainability has not gained much attention in universities | n = 4; 80% | n = 0 | |

| High cost of equipment | n = 5; 100% | n = 6; 60% | |

| 3DP teaching time is limited | n = 4; 80% | n = 6; 60% | |

| Recommendations to teach and learn sustainability through 3DP | Policy support for sustainable development | n = 5; 100% | n = 0 |

| Teach students the nature of sustainability in 3DP and invest in equipment and facilities | n = 5; 100% | n = 0 | |

| Encourage teachers to offer 3DP training abroad or through online courses | n = 4; 80% | n = 0 | |

| Encourage students and teachers to participate in scientific research | n = 5; 100% | n = 0 | |

| Increase the time in teaching sustainability through 3DP | n = 5; 100% | n = 0 | |

Appendix D

Table A4.

The Observed Activities in the Five Universities.

Table A4.

The Observed Activities in the Five Universities.

| Observed Classroom | Theoretical Component | Participants | Assignments | Classroom Activities | Learning Outcomes |

|---|---|---|---|---|---|

| Class 1 | Learning about the fundamentals of fast prototyping, rapid tooling, and reverse engineering | Twelve UG students from the faculty of mechanical engineering, split into three groups of three to five students, and one educator |

|

|

|

| Class 2 | N/A | Eleven UG students from the faculty of mechanical engineering, split into three groups of three to five students, and no educator | N/A |

| |

| Class 3 | N/A | Nine UG students from the faculty of mechanical engineering, acting as individuals, and one educator | N/A |

|

|

| Class 4 | N/A | Twelve UG students from the faculty of mechanical engineering, acting as individuals, and one educator | |||

| Class 5 | N/A | Four UG students in Year 5 from the faculty of mechanical engineering, acting as individuals, and no educator |

|

|

|

| Class 6 | An overview of and knowledge on rapid prototyping technology as well as liquid, solid, and powder-based materials in rapid prototyping systems | Eight UG students in Years 2 and 4 from the faculty of mechanical engineering and one educator | N/A |

|

|

| Class 7 | Applying the knowledge gained to product manufacturing and STEM education | Nineteen UG students in Year 4 from the faculty of mechanical engineering and one educator | N/A |

|

|

Note. * = Selective laser sintering.

References

- Rossi, E.; Di Nicolantonio, M.; Barcarolo, P.; Lagatta, J. Sustainable 3D Printing: Design Opportunities and Research Perspectives. In Advances in Additive Manufacturing, Modeling Systems and 3D Prototyping; Springer: Berlin/Heidelberg, Germany, 2019; Volume 975, pp. 3–15. [Google Scholar] [CrossRef]

- Žalėnienė, I.; Pereira, P. Higher Education for Sustainability: A Global Perspective. Geogr. Sustain. 2021, 2, 99–106. [Google Scholar] [CrossRef]

- United Nations. The 17 Goals; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Seatter, C.S.; Ceulemans, K. Teaching Sustainability in Higher Education: Pedagogical Styles that Make a Difference. Can. J. High. Educ. 2017, 47, 47–70. [Google Scholar] [CrossRef]

- Gebler, M.; Schoot Uiterkamp, A.J.M.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Loy, J. 3D Printing Interdisciplinary Learning for Complex Problems. In Interdisciplinary and International Perspectives on 3D Printing in Education; IGI Global: Hershey, PA, USA, 2019; pp. 94–109. [Google Scholar] [CrossRef]

- Novak, J.I. Re-Educating the Educators: Collaborative 3D Printing Education. In Interdisciplinary and International Perspectives on 3D Printing in Education; IGI Global: Hershey, PA, USA, 2019; pp. 28–49. [Google Scholar]

- Ford, S.; Minshall, T. Invited review article: Where and how 3D printing is used in teaching and education. Addit. Manuf. 2019, 25, 131–150. [Google Scholar] [CrossRef]

- Alabi, M.O.; de Beer, D.J.; Wichers, H.; Kloppers, C.P. Framework for effective additive manufacturing education: A case study of South African universities. Rapid Prototyp. J. 2019, 26, 801–826. [Google Scholar] [CrossRef]

- Pearce, J.M.; Blair, C.M.; Laciak, K.J.; Andrews, R.; Nosrat, A.; Zelenika-Zovko, I. 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development. J. Sustain. Dev. 2010, 3, 17–29. [Google Scholar] [CrossRef]

- Fonda, C.; Canessa, E.; Zennaro, M. Low-Cost 3D Printing for Science, Education and Sustainable Development. Available online: http://sdu.ictp.it/3D/book.html (accessed on 5 May 2021).

- Caldona, E.B.; Dizon, J.R.C.; Espera, A.H.; Advincula, R.C. On the Economic, Environmental, and Sustainability Aspects of 3D Printing toward a Cyclic Economy. ACS Symp. Ser. 2022, 1412, 507–525. [Google Scholar]

- Cotteleer, M.; Hughes, A.; Scala, G.; Holdowsky, J. 3D Opportunity for Higher Education Preparing the Next Generation of Additive Manufacturing Professionals. Available online: https://www2.deloitte.com/us/en/insights/focus/3d-opportunity/additive-manufacturing-higher-education-degree.html (accessed on 2 February 2021).

- Frey, C.B.; Osborne, M.A. The future of employment: How susceptible are jobs to computerisation? Technol. Forecast. Soc. Change 2017, 114, 254–280. [Google Scholar] [CrossRef]

- Malik, A.; Haq, M.I.U.; Raina, A.; Gupta, K. 3D printing towards implementing Industry 4.0: Sustainability aspects, barriers and challenges. Ind. Robot. Int. J. Robot. Res. Appl. 2022, 49, 491–511. [Google Scholar] [CrossRef]

- Mehta, P.U.; Berdanier, C.G. A Systematic Review of Additive Manufacturing Education: Toward Engineering Education Research in AM. In Proceedings of the ASEE Annual Conference and Exposition, Conference Proceedings, Tampa, FL, USA, 15 June–19 October 2019. [Google Scholar] [CrossRef]

- Gallup, N.; Pearce, J.M. The Economics of Classroom 3-D Printing of Open-Source Digital Designs of Learning Aids. Designs 2020, 4, 50. [Google Scholar] [CrossRef]

- Machado, C.G.; Despeisse, M.; Winroth, M.; da Silva, E.H.D.R. Additive manufacturing from the sustainability perspective: Proposal for a self-assessment tool. Procedia CIRP 2019, 81, 482–487. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C. Frontiers of Additive Manufacturing Research and Education. Available online: http://nsfam.mae.ufl.edu/2013NSFAMWorkshopReport.pdf (accessed on 13 March 2021).

- Alabi, M.O.; De Beer, D.; Wichers, H. Applications of additive manufacturing at selected South African universities: Promoting additive manufacturing education. Rapid Prototyp. J. 2019, 25, 752–764. [Google Scholar] [CrossRef]

- Campbell, T.; Williams, C.; Ivanova, O.; Garrett, B. Could 3D Printing Change the World? Technologies, Potential, and Implications of Additive Manufacturing; Atlantic Council: Washington, DC, USA, 2011; pp. 3–7. [Google Scholar]

- Fernandes, S.C.F.; Simoes, R. Collaborative use of different learning styles through 3D printing. In Proceedings of the CISPEE 2016-2nd International Conference of the Portuguese Society for Engineering Education, Proceedings, Vila Real, Portugal, 19–21 October 2016. [Google Scholar]