The Relationship between Distance and Risk Perception in Multi-Tier Supply Chain: The Psychological Typhoon Eye Effect

Abstract

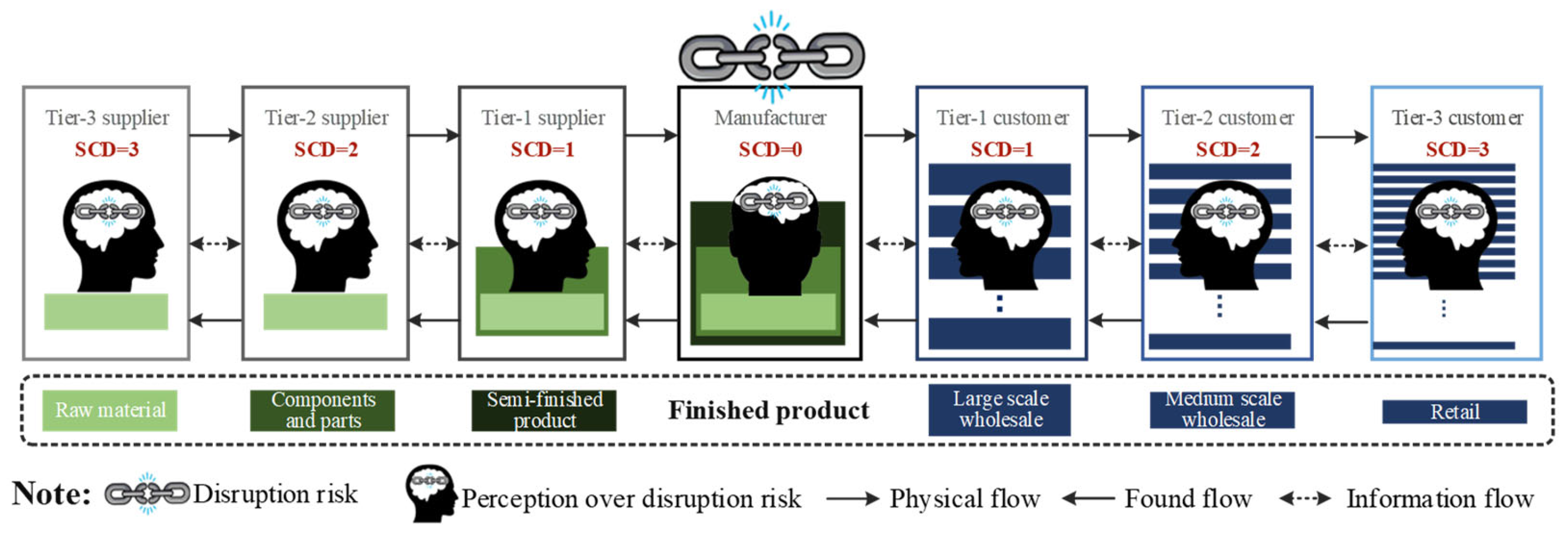

:1. Introduction

2. Theoretical Constructs and Hypotheses

2.1. Effect of Distance upon Risk Perception

2.2. The Mediating Role of Available Risk Information

2.3. The Moderating Role of Job Position Level

2.4. Perceived Risk Influences Individuals’ Response

3. Methodology

3.1. Empirical Study Setting

3.2. Respondents and Data Collection

3.3. Measure Development

3.3.1. Dependent Variable

3.3.2. Independent Variable

3.3.3. Mediate Variable

3.3.4. Moderate Variable

3.3.5. Control Variables

3.4. Construct Validity and Reliability

4. Results

4.1. Descriptive Analyses

4.2. Direct Effect of Distance on Disruption Risk Perception

4.2.1. Supply Chain Distance Affects Disruption Risk Perception

4.2.2. Psychological Distance Affects Disruption Risk Perception

4.3. Indirect Effect of Distance on Disruption Risk Perception Via Perceived Risk Information Quality

4.3.1. The Mediated Effects of Objective (Tier) Distance on Disruption Risk Perception via Perceived Risk Information Quality

4.3.2. The Mediated Effects of Subjective (Psychological) Distance on Disruption Risk Perception via Perceived Risk Information Quality

4.4. The Moderating Effect of Job Position Level

5. Discussion

5.1. Theoretical Contributions

5.2. Managerial Implications

6. Limitations and Future Work

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Zobel, C.W. Exploring supply chain network resilience in the presence of the ripple effect. Int. J. Prod. Econ. 2020, 228, 107693. [Google Scholar] [CrossRef]

- Moosavi, J.; Fathollahi-Fard, A.M.; Dulebenets, M.A. Supply chain disruption during the COVID-19 pandemic: Recognizing potential disruption management strategies. Int. J. Disast. Risk Res. 2022, 75, 102983. [Google Scholar] [CrossRef] [PubMed]

- Kamalahmadi, M.; Shekarian, M.; Mellat Parast, M. The impact of flexibility and redundancy on improving supply chain resilience to disruptions. Int. J. Prod. Res. 2021, 60, 1992–2020. [Google Scholar] [CrossRef]

- Pournader, M.; Kach, A.; Talluri, S. A review of the existing and emerging topics in the supply chain risk management literature. Decis. Sci. 2020, 51, 867–919. [Google Scholar] [CrossRef] [PubMed]

- Heckmann, I.; Comes, T.; Nickel, S. A critical review on supply chain risk–Definition, measure and modeling. Omega 2015, 52, 119–132. [Google Scholar] [CrossRef]

- De Martino, B.; Kumaran, D.; Seymour, B.; Dolan, R.J. Frames, biases, and rational decision-making in the human brain. Science 2006, 313, 684–687. [Google Scholar] [CrossRef]

- Tversky, A.; Kahneman, D. Judgment under Uncertainty: Heuristics and Biases: Biases in judgments reveal some heuristics of thinking under uncertainty. Science 1974, 185, 1124–1131. [Google Scholar] [CrossRef]

- Gigerenzer, G.; Gaissmaier, W. Heuristic decision making. Annu. Rev. Psychol. 2011, 62, 451–482. [Google Scholar] [CrossRef]

- Chadist, P. Factors Underlying Companies Response to Supply Chain Disruption: A Grounded Theory Approach. Ph.D. Dissertation, City University London, London, UK, 2012. [Google Scholar]

- Sato, Y.; Tse, Y.K.; Tan, K.H. Managers’ risk perception of supply chain uncertainties. Ind. Manag. Data Syst. 2020, 120, 1617–1634. [Google Scholar] [CrossRef]

- March, J.G.; Shapira, Z. Managerial perspectives on risk and risk taking. Manag. Sci. 1987, 33, 1404–1418. [Google Scholar] [CrossRef]

- Sarafan, M.; Squire, B.; Brandon-Jones, E. The effect of cultural value orientations on responses to supply-side disruption. Int. J. Oper. Prod. Manag. 2020, 40, 1723–1747. [Google Scholar] [CrossRef]

- Scheibe, K.P.; Blackhurst, J. Supply chain disruption propagation: A systemic risk and normal accident theory perspective. Int. J. Prod. Res. 2018, 56, 43–59. [Google Scholar] [CrossRef]

- Burns, W.J.; Peters, E.; Slovic, P. Risk perception and the economic crisis: A longitudinal study of the trajectory of perceived risk. Risk Anal. 2012, 32, 659–677. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, V.W. Organizational risk perception and reduction: A literature review. Br. J. Manag. 1995, 6, 115–133. [Google Scholar] [CrossRef]

- Li, S.; Rao, L.L.; Ren, X.P.; Bai, X.W.; Zheng, R.; Li, J.Z.; Liu, H. Psychological typhoon eye in the 2008 Wenchuan earthquake. PLoS ONE 2009, 4, e4964. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, J.; Chen, A.; Lee, J.E.; An, L. Risk perception of COVID-19: A comparative analysis of China and South Korea. Int. J. Disast. Risk Res. 2021, 61, 102373. [Google Scholar] [CrossRef]

- Li, S.; Rao, L.L.; Bai, X.W.; Zheng, R.; Ren, X.P.; Li, J.Z.; Zhang, K. Progression of the “psychological typhoon eye” and variations since the Wenchuan earthquake. PLoS ONE 2010, 5, e9727. [Google Scholar] [CrossRef]

- Zheng, R.; Rao, L.L.; Zheng, X.L.; Cai, C.; Wei, Z.H.; Xuan, Y.H.; Li, S. The more involved in lead-zinc mining risk the less frightened: A psychological typhoon eye perspective. J. Environ. Psychol. 2015, 44, 126–134. [Google Scholar] [CrossRef]

- Ha, T.M.; Shakur, S.; Do, K.H.P. Linkages among food safety risk perception, trust and information: Evidence from Hanoi consumers. Food Control 2020, 110, 106965. [Google Scholar] [CrossRef]

- Guo, Y.; Li, Y. Online amplification of air pollution risk perception: The moderating role of affect in information. Inform. Commun. Soc. 2018, 21, 80–93. [Google Scholar] [CrossRef]

- Chisty, M.A.; Islam, M.A.; Munia, A.T.; Rahman, M.M.; Rahman, N.N.; Mohima, M. Risk perception and information-seeking behavior during emergency: An exploratory study on COVID-19 pandemic in Bangladesh. Int. J. Disaster Risk Res. 2021, 65, 102580. [Google Scholar] [CrossRef]

- Tazelaar, F.; Snijders, C. Operational risk assessments by supply chain professionals: Process and performance. J. Oper. Manag. 2013, 31, 37–51. [Google Scholar] [CrossRef]

- Hult, G.T.M.; Craighead, C.W.; Ketchen, D.J., Jr. Risk uncertainty and supply chain decisions: A real options perspective. Decis. Sci. 2010, 41, 435–458. [Google Scholar] [CrossRef]

- Tse, Y.K.; Chung, S.H.; Pawar, K.S. Risk perception and decision making in the supply chain: Theory and practice. Ind. Manag. Data Syst. 2018, 118, 1322–1326. [Google Scholar] [CrossRef]

- Singh, N.P.; Hong, P.C. Impact of strategic and operational risk management practices on firm performance: An empirical investigation. Eur. Manag. J. 2020, 38, 723–735. [Google Scholar] [CrossRef]

- Aven, T.; Renn, O. On risk defined as an event where the outcome is uncertain. J. Risk Res. 2009, 12, 1–11. [Google Scholar] [CrossRef]

- Rundmo, T. Associations between affect and risk perception. J. Risk Res. 2002, 5, 119–135. [Google Scholar] [CrossRef]

- Slovic, P.; Fischhoff, B.; Lichtenstein, S. Facts and fears: Understanding perceived risk. In Societal Risk Assessment; Springer: Boston, MA, USA, 1980; pp. 181–216. [Google Scholar]

- Polyviou, M.; Rungtusanatham, M.J.; Reczek, R.W.; Knemeyer, A.M. Supplier non-retention post disruption: What role does anger play? J. Oper. Manag. 2018, 61, 1–14. [Google Scholar] [CrossRef]

- Vanpoucke, E.; Ellis, S.C. Building supply-side resilience–a behavioural view. Int. J. Oper. Prod. Manag. 2019, 40, 11–33. [Google Scholar] [CrossRef]

- Spaccatini, F.; Pancani, L.; Richetin, J.; Riva, P.; Sacchi, S. Individual cognitive style affects flood-risk perception and mitigation intentions. Appl. Soc. Psychol. 2021, 51, 208–218. [Google Scholar] [CrossRef]

- Maderthaner, R.; Guttmann, G.; Swaton, E.; Otway, H.J. Effect of distance upon risk perception. J. Appl. Psychol. 1978, 6, 380–382. [Google Scholar] [CrossRef]

- Tilt, B. Perceptions of risk from industrial pollution in China: A comparison of occupational groups. Hum. Org. 2006, 65, 115–127. [Google Scholar] [CrossRef]

- Xie, X.F.; Stone, E.; Zheng, R.; Zhang, R.G. The ‘Typhoon Eye Effect’: Determinants of distress during the SARS epidemic. J. Risk Res. 2011, 14, 1091–1107. [Google Scholar] [CrossRef]

- Lateef, T.; Chen, J.; Tahir, M.; Lateef, T.A.; Chen, B.Z.; Li, J.; Zhang, S.X. Typhoon eye effect versus ripple effect: The role of family size on mental health during the COVID-19 pandemic in Pakistan. Glob. Health 2021, 17. [Google Scholar] [CrossRef] [PubMed]

- Ellis, S.C.; Henry, R.M.; Shockley, J. Buyer perceptions of supply disruption risk: A behavioral view and empirical assessment. J. Oper. Manag. 2010, 28, 34–46. [Google Scholar] [CrossRef]

- Kull, T.J.; Oke, A.; Dooley, K.J. Supplier selection behavior under uncertainty: Contextual and cognitive effects on risk perception and choice. Decis. Sci. 2014, 45, 467–505. [Google Scholar] [CrossRef]

- Wachinger, G.; Renn, O.; Begg, C.; Kuhlicke, C. The risk perception paradox—Implications for governance and communication of natural hazards. Risk Anal. 2013, 33, 1049–1065. [Google Scholar] [CrossRef]

- Wang, M.; Keller, C.; Siegrist, M. The less you know, the more you are afraid of—A survey on risk perceptions of investment products. J. Behav. Financ. 2011, 12, 9–19. [Google Scholar] [CrossRef]

- Letzring, T.D.; Wells, S.M.; Funder, D.C. Information quantity and quality affect the realistic accuracy of personality judgment. J. Personal. Soc. Psychol. 2006, 91, 111–123. [Google Scholar] [CrossRef]

- Yang, S.W.; Xu, M.X.; Kuang, Y.; Ding, Y.; Lin, Y.X.; Wang, F.; Li, S. An Agenda-Setting Account for Psychological Typhoon Eye Effect on Responses to the Outbreak of COVID-19 in Wuhan. Int. J. Environ. Res. Public Health 2023, 20, 4350. [Google Scholar] [CrossRef]

- Yoon, J.; Talluri, S.; Rosales, C. Procurement decisions and information sharing under multi-tier disruption risk in a supply chain. Int. J. Prod. Res. 2020, 58, 1362–1383. [Google Scholar] [CrossRef]

- Hendricks, K.B.; Singhal, V.R. An empirical analysis of the effect of supply chain disruptions on long-run stock price performance and equity risk of the firm. Prod. Oper. Manag. 2005, 14, 35–52. [Google Scholar] [CrossRef]

- Schmidt, W.; Raman, A. When Supply-Chain Disruptions Matter. Working Paper No. 13-006 (July 20, 2012); Harvard Business School: Cambridge, MA, USA, 2012; Available online: www.hbs.edu/research/pdf/13-006.pdf (accessed on 13 November 2012).

- Wang, L.; Foerstl, K.; Zimmermann, F. Supply chain risk management in the automotive industry: Cross-functional and multi-tier perspectives. In Dynamic and Seamless Integration of Production, Logistics and Traffic; Springer: Cham, Switzerland, 2017; pp. 119–144. [Google Scholar]

- Chatterjee, S.; Chaudhuri, R.; Vrontis, D. Role of fake news and misinformation in supply chain disruption: Impact of technology competency as moderator. Ann. Oper. Res. 2022, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Albarracin, D.; Wyer, R.S., Jr. The cognitive impact of past behavior: Influences on beliefs, attitudes, and future behavioral decisions. J. Personal. Soc. Psychol. 2000, 79, 5. [Google Scholar] [CrossRef]

- Evans, J.S.B.; Barston, J.L.; Pollard, P. On the conflict between logic and belief in syllogistic reasoning. Mem. Cogn. 1983, 11, 295–306. [Google Scholar] [CrossRef] [PubMed]

- Thompson, V.A. Reasoning from false premises: The role of soundness in making logical deductions. Can. J. Exp. Psychol. 1996, 50, 315–319. [Google Scholar] [CrossRef]

- Torrens, D. Individual differences and the belief bias effect: Mental models, logical necessity, and abstract reasoning. Think. Reason 1999, 5, 1–28. [Google Scholar] [CrossRef]

- Thalmann, A.T.; Wiedemann, P.M. Beliefs and emotionality in risk appraisals. J. Risk Res. 2006, 453–466. [Google Scholar] [CrossRef]

- Vaughan, E.; Nordenstam, B. The perception of environmental risks among ethnically diverse groups. J. Cross-Cult. Psychol. 1991, 22, 29–60. [Google Scholar] [CrossRef]

- Siegrist, M.; Keller, C.; Kastenholz, H.; Frey, S.; Wiek, A. Laypeople’s and experts’ perception of nanotechnology hazards. Risk Anal. 2007, 27, 59–69. [Google Scholar] [CrossRef]

- Nikookar, E.; Yanadori, Y. Preparing supply chain for the next disruption beyond COVID-19: Managerial antecedents of supply chain resilience. Int. J. Oper. Prod. Manag. 2022, 42, 59–90. [Google Scholar] [CrossRef]

- Sitkin, S.B.; Pablo, A.L. Reconceptualizing the determinants of risk behavior. Acad. Manag. Rev. 1992, 17, 9–38. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Wagner, S.M. Do perceptions become reality? The moderating role of supply chain resiliency on disruption occurrence. J. Bus. Logist. 2010, 36, 70–90. [Google Scholar] [CrossRef]

- Chae, S.; Lawson, B.; Kull, T.J.; Choi, T. To insource or outsource the sourcing? A behavioral investigation of the multi-tier sourcing decision. Int. J. Oper. Prod. Manag. 2019, 39, 385–405. [Google Scholar] [CrossRef]

- Durach, C.F.; Wiengarten, F.; Choi, T.Y. Supplier-supplier coopetition and supply chain disruption: First-tier supplier resilience in the tetradic context. Int. J. Oper. Prod. Manag. 2020, 40, 1041–1065. [Google Scholar] [CrossRef]

- Carmi, N.; Kimhi, S. Further than the eye can see: Psychological distance and perception of environmental threats. Hum. Ecol. Risk Assess. 2015, 21, 2239–2257. [Google Scholar] [CrossRef]

- Chung, M.; Lim, Y.S. When health organization answers the question: Differential effects of dialogic messages in website and Twitter through social presence and psychological distance. Health Commun. 2020, 37, 685–695. [Google Scholar] [CrossRef]

- Geng, L.; Liu, T.; Zhou, K.; Yang, G. Can power affect environmental risk attitude toward nuclear energy? Energy Policy 2018, 113, 87–93. [Google Scholar] [CrossRef]

- Liberman, N.; Trope, Y. The psychology of transcending the here and now. Science 2008, 322, 1201–1205. [Google Scholar] [CrossRef]

- Birkie, S.E.; Trucco, P. Do not expect others do what you should! Supply chain complexity and mitigation of the ripple effect of disruptions. Int. J. Logist. Manag. 2020, 31, 123–144. [Google Scholar] [CrossRef]

- Ozkul, A.; Barut, M. Measuring supply chain relationships: A social network approach. Int. J. Integr. Supply Manag. 2009, 5, 38–61. [Google Scholar] [CrossRef]

- Chu, H.; Yang, J.Z. Risk or efficacy? How psychological distance influences climate change engagement. Risk Anal. 2020, 40, 758–770. [Google Scholar] [CrossRef]

- Keller, K.L.; Staelin, R. Effects of quality and quantity of information on decision effectiveness. J. Consum. Res. 1987, 14, 200–213. [Google Scholar] [CrossRef]

- Janjua, N.K.; Nawaz, F.; Prior, D.D. A fuzzy supply chain risk assessment approach using real-time disruption event data from Twitter. Enterp. Inf. Syst. 2021, 17, 1959652. [Google Scholar] [CrossRef]

- Hung, K.T.; Tangpong, C. General risk propensity in multifaceted business decisions: Scale development. J. Manag. Iss. 2010, 22, 88–106. [Google Scholar]

- Anderson, J.C.; Gerbing, D.W. Structural equation modeling in practice: A review and recommended two-step approach. Psychol. Bull. 1988, 103, 411–423. [Google Scholar] [CrossRef]

- Myers, M.G.; Stein, M.B.; Aarons, G.A. Cross validation of the Social Anxiety Scale for Adolescents in a high school sample. J. Anxiety Disord. 2002, 16, 221–232. [Google Scholar] [CrossRef] [PubMed]

- Hair, J.F.; Black, W.C.; Babin, B.J. Multivariate Data Analysis: A Global Perspective: International Version, 7th ed.; Pearson Education: London, UK, 2013. [Google Scholar]

- Hu, L.T.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Model. A Multidiscip. J. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Iacobucci, D. Structural equations modeling: Fit indices, sample size, and advanced topics. J. Consum. Psychol. 2010, 20, 90–98. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Hayes, A.F. Methodology in the Social Sciences. Introduction to Mediation, Moderation, and Conditional Process Analysis: A Regression-Based Approach; Guilford Press: New York, NY, USA, 2013. [Google Scholar]

- Aiken, L.S.; West, S.G. Multiple Regression: Testing and Interpreting Interactions; Sage: Thousand Oaks, CA, USA, 1991. [Google Scholar]

- Li, S.; Li, J.L.; Yang, S.W.; Wu, X.J.; Chen, J.F.; Ding, Y.; Zheng, R. The psychological typhoon eye effect in responses to terrorism. J. Pac. Rim Psychol. 2020, 14, e21. [Google Scholar] [CrossRef]

- Cantor, D.E.; Blackhurst, J.V.; Cortes, J.D. The clock is ticking: The role of uncertainty, regulatory focus, and level of risk on supply chain disruption decision making behavior. Transp. Res. Part E Logist. 2014, 72, 159–172. [Google Scholar] [CrossRef]

- Mena, C.; Humphries, A.; Choi, T.Y. Toward a theory of multi-tier supply chain management. J. Supply Chain Manag. 2013, 49, 58–77. [Google Scholar] [CrossRef]

- Wang-Mlynek, L.; Foerstl, K. Barriers to multi-tier supply chain risk management. Int. J. Logist. Manag. 2020, 31, 465–487. [Google Scholar] [CrossRef]

- Ivanov, D.; Sokolov, B.; Dolgui, A. The Ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’ in disruption management. Int. J. Prod. Res. 2014, 52, 2154–2172. [Google Scholar] [CrossRef]

- Marchese, K.; Paramasivam, S. The Ripple Effect How manufacturing and retail executives view the growing challenge of supply chain risk. Deloitte DEV LLC. 2013. [Google Scholar]

- Park, Y.W.; Blackhurst, J.; Paul, C.; Scheibe, K.P. An analysis of the ripple effect for disruptions occurring in circular flows of a supply chain network. Int. J. Prod. 2022, 60, 4693–4711. [Google Scholar] [CrossRef]

- Sjöberg, L. Worry and risk perception. Risk Anal. 1998, 18, 85–93. [Google Scholar] [CrossRef]

- Plapp, T.; Werner, U. Understanding risk perception from natural hazards: Examples from Germany. In RISK21-Coping with Risks Due to Natural Hazards in the 21st Century; CRC Press: Boca Raton, FL, USA, 2006; pp. 111–118. [Google Scholar]

- Sarkar, S.; Kumar, S. A behavioral experiment on inventory management with supply chain disruption. Int. J. Prod. Econ. 2015, 169, 169–178. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, C.; Wang, K.; Ba, S.L. Understanding online purchase decision making: The effects of unconscious thought, information quality, and information quantity. Decis. Support Syst. 2012, 53, 772–781. [Google Scholar] [CrossRef]

- Dane, E.; Pratt, M.G. Exploring intuition and its role in managerial decision making. Acad. Manag. Rev. 2007, 32, 33–54. [Google Scholar] [CrossRef]

- Messina, D.; Barros, A.C.; Soares, A.L.; Matopoulos, A. An information management approach for supply chain disruption recovery. Int. J. Logist. Manag. 2020, 31, 489–519. [Google Scholar] [CrossRef]

- Kumar, S.; Himes, K.J.; Kritzer, C.P. Risk assessment and operational approaches to managing risk in global supply chains. J. M. Technol. Manag. 2014, 25, 873–890. [Google Scholar] [CrossRef]

- Mousavi, S.; Gigerenzer, G. Risk, uncertainty, and heuristics. J. Bus. Res. 2014, 67, 1671–1678. [Google Scholar] [CrossRef]

- Bode, C.; Wagner, S.M.; Petersen, K.J.; Ellram, L.M. Understanding responses to supply chain disruptions: Insights from information processing and resource dependence perspectives. Acad. Manag. J. 2011, 54, 833–856. [Google Scholar] [CrossRef]

- Ellinger, A.E.; Chen, H.; Tian, Y.; Armstrong, C. Learning orientation, integration, and supply chain risk management in Chinese manufacturing firms. Int. J. Logist-Res. App. 2015, 18, 476–493. [Google Scholar] [CrossRef]

- Chopra, S.; Sodhi, M.; Lücker, F. Achieving supply chain efficiency and resilience by using multi-level commons. Decis. Sci. 2021, 52, 817–832. [Google Scholar] [CrossRef]

- Basole, R.C.; Bellamy, M.A. Supply network structure, visibility, and risk diffusion: A computational approach. Decis. Sci. 2014, 45, 753–789. [Google Scholar] [CrossRef]

- Cao, S.F.; Bryceson, K.; Hine, D. Improving supply chain risk visibility and communication with a multi-view risk ontology. Supply Chain Forum 2020, 21, 1–15. [Google Scholar] [CrossRef]

- Li, Y.; Zobel, C.W.; Russell, R.S. Value of supply disruption information and information accuracy. J. Purch. Supply Manag. 2017, 23, 191–201. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, H.; Huang, H. Media exposure to COVID-19 information, risk perception, social and geographical proximity, and self-rated anxiety in China. BMC Public Health 2020, 20, 1649. [Google Scholar] [CrossRef] [PubMed]

- Lu, P.; Kong, D.; Shelley, M. Risk perception, preventive behavior, and medical care avoidance among American older adults during the COVID-19 pandemic. J. Aging Health 2021, 33, 577–584. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Lee, N.; Dockter, C.E. Effects of message presentation type on gm food risk perception, similarity judgment, and attitude. Health Commun. 2021, 36, 1666–1676. [Google Scholar] [CrossRef]

- Tversky, A.; Kahneman, D. The framing of decisions and the psychology of choice. Science 1981, 211, 453–458. [Google Scholar] [CrossRef]

- Gupta, M.; Gupta, S. Influence of national cultures on operations management and supply chain management practices-a research agenda. Prod. Oper. Manag. 2019, 28, 2681–2698. [Google Scholar] [CrossRef]

- DuHadway, S.; Carnovale, S.; Kannan, V.R. Organizational communication and individual behavior: Implications for supply chain risk management. J. Supply Chain Manag. 2018, 54, 3–19. [Google Scholar] [CrossRef]

| Frequency | Percentage (%) | ||

|---|---|---|---|

| Supply chain position | ZTE corporation | 295 | 28.0 |

| Tier-1 suppliers | 193 | 18.3 | |

| Tier-2 suppliers | 166 | 15.7 | |

| Tier-1 wholesalers | 207 | 19.6 | |

| Tier-2 wholesalers/retailers | 194 | 18.4 | |

| Number of employees | ≤10 | 38 | 3.6 |

| 11–50 | 166 | 15.7 | |

| 51–100 | 250 | 23.7 | |

| 101–500 | 335 | 31.8 | |

| 501–1000 | 129 | 12.2 | |

| ≥1001 | 137 | 13.0 | |

| Annual sales revenue (CNY) | <1 million | 137 | 13.0 |

| 1–4.99 million | 246 | 23.3 | |

| 5–9.99 million | 233 | 22.1 | |

| 10–49.99 million | 188 | 17.8 | |

| ≥50 million | 251 | 23.8 |

| Frequency | Percentage (%) | ||

|---|---|---|---|

| Gender | Male | 554 | 52.5 |

| Female | 501 | 47.5 | |

| Age | ≤30 | 404 | 38.3 |

| 31–40 | 423 | 40.1 | |

| 41–50 | 160 | 15.2 | |

| 51–60 | 64 | 6.1 | |

| >60 | 4 | 0.4 | |

| Education level | Secondary education certificate | 5 | 0.5 |

| Senior school diploma | 49 | 4.6 | |

| Three-year college diploma | 178 | 16.9 | |

| Bachelor’s degree | 691 | 65.5 | |

| Graduate degree | 132 | 12.5 | |

| Work experience | <3 years | 155 | 14.7 |

| 3–5 years | 222 | 21.0 | |

| 6–10 years | 295 | 28.0 | |

| 11–20 years | 219 | 20.8 | |

| >20 years | 164 | 15.5 | |

| Job Function | Planning and purchasing | 313 | 29.7 |

| Operations and production | 233 | 22.1 | |

| Warehousing and logistics | 179 | 17.0 | |

| Research and development | 25 | 2.4 | |

| Sales and marketing | 305 | 28.9 | |

| Job position level | Executive-level manager | 148 | 14.0 |

| Middle-level manager | 247 | 23.4 | |

| Low-level manager | 326 | 30.9 | |

| Ordinary employee | 334 | 31.7 |

| Measurement Items | Factor 1 (PRIQ) | Factor 2 (MR) | Factor 3 (PD) | Factor 4 (DRP) | Factor 5 (RPr) |

|---|---|---|---|---|---|

| PRIQ 1 | 0.854 | −0.029 | −0.072 | −0.252 | 0.095 |

| PRIQ 2 | 0.858 | 0.089 | −0.034 | −0.202 | 0.047 |

| PRIQ 3 | 0.898 | 0.013 | −0.019 | −0.118 | 0.073 |

| PRIQ 4 | 0.719 | −0.256 | −0.014 | −0.095 | 0.164 |

| MR 1 | −0.056 | 0.867 | 0.106 | 0.276 | 0.007 |

| MR 2 | −0.048 | 0.897 | 0.124 | 0.142 | 0.006 |

| MR 3 | −0.044 | 0.884 | 0.103 | 0.179 | 0.040 |

| PD 1 | −0.039 | 0.134 | 0.897 | 0.075 | 0.003 |

| PD 2 | −0.019 | 0.082 | 0.890 | 0.101 | 0.002 |

| PD 3 | −0.058 | 0.118 | 0.864 | 0.101 | −0.012 |

| PD 4 | 0.035 | 0.542 | 0.171 | 0.559 | 0.059 |

| DRP 1 | −0.260 | 0.158 | 0.048 | 0.731 | −0.198 |

| DRP 2 | −0.268 | 0.239 | 0.131 | 0.774 | −0.090 |

| DRP 3 | −0.251 | 0.229 | 0.108 | 0.785 | −0.103 |

| RPr 1 | 0.044 | 0.079 | 0.004 | −0.212 | 0.709 |

| RPr 2 | 0.084 | 0.038 | −0.019 | −0.060 | 0.787 |

| RPr 3 | 0.068 | 0.129 | 0.024 | −0.106 | 0.752 |

| RPr4 | 0.142 | −0.281 | −0.019 | 0.115 | 0.637 |

| Proportion variance (%) | 29.246 | 16.525 | 10.832 | 10.122 | 5.993 |

| Cumulative (%) of variance explained | 29.246 | 45.771 | 56.603 | 66.725 | 72.718 |

| Construct | Item | Cronbach’s α | AVE | CR | Loading | t-Value | SE |

|---|---|---|---|---|---|---|---|

| Psychological Distance (PD) | 0.88 | 0.71 | 0.88 | ||||

| PD1 | 0.88 | - | - | ||||

| PD2 | 0.84 | 31.35 | 0.03 | ||||

| PD3 | 0.80 | 29.74 | 0.03 | ||||

| Perceived Risk Information Quality (PRIQ) | 0.88 | 0.66 | 0.88 | ||||

| PRIQ1 | 0.86 | - | - | ||||

| PRIQ2 | 0.85 | 34.55 | 0.03 | ||||

| PRIQ3 | 0.87 | 35.93 | 0.03 | ||||

| PRIQ4 | 0.64 | 22.88 | 0.03 | ||||

| Risk Propensity (RPr) | 0.70 | 0.40 | 0.72 | ||||

| RPr1 | 0.61 | - | - | ||||

| RPr2 | 0.74 | 15.12 | 0.06 | ||||

| RPr3 | 0.69 | 15.05 | 0.06 | ||||

| RPr4 | 0.43 | 10.97 | 0.06 | ||||

| Disruption Risk Perception (DPR) | 0.83 | 0.63 | 0.83 | ||||

| DRP1 | 0.70 | - | - | ||||

| DRP2 | 0.84 | 23.47 | 0.05 | ||||

| DRP3 | 0.83 | 23.36 | 0.05 | ||||

| Managerial Response (MR) | 0.92 | 0.81 | 0.93 | ||||

| MR1 | 0.89 | - | - | ||||

| MR2 | 0.90 | 41.05 | 0.03 | ||||

| MR3 | 0.91 | 41.76 | 0.03 |

| M | SD | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Gender | 0.47 | 0.50 | |||||||||||

| 2 Age | 1.90 | 0.90 | 0.12 *** | ||||||||||

| 3 Educational background | 3.85 | 0.71 | 0.07 * | −0.10 ** | |||||||||

| 4 Work experience | 3.01 | 1.28 | 0.17 *** | 0.82 *** | −0.15 *** | ||||||||

| 5 Job position level | 2.20 | 1.04 | −0.04 | 0.00 | 0.03 | 0.09 ** | |||||||

| 6 Number of employees | 3.72 | 1.33 | −0.02 | −0.04 | 0.25 *** | −0.05 | 0.01 | ||||||

| 7 Annual sales revenue | 3.16 | 1.36 | 0.03 | −0.10 ** | 0.23 *** | −0.07 * | 0.02 | 0.67 ** | |||||

| 8 Risk propensity | 5.02 | 1.37 | 0.05 | −0.02 | 0.04 | −0.03 | 0.04 | −0.02 | -0.05 | ||||

| 9 Psychological distance | 5.94 | 1.92 | −0.01 | −0.19 *** | 0.08 ** | −0.19 *** | 0.04 | 0.05 | 0.09 ** | −0.02 | |||

| 10 Perceived risk information quality | 4.88 | 1.68 | 0.01 | 0.09 ** | 0.04 | 0.11 *** | −0.02 | −0.02 | −0.07 * | 0.24 *** | −0.11*** | ||

| 11 Disruption risk perception | 6.39 | 1.98 | 0.03 | −0.18 *** | 0.11 *** | −0.18 *** | −0.04 | 0.11 *** | 0.18 *** | −0.27 *** | 0.24 *** | −0.48 *** | |

| 12 Managerial response | 5.45 | 1.93 | −0.00 | −0.18 *** | 0.08 ** | −0.17 *** | 0.04 | 0.08 * | 0.14 *** | −0.02 | 0.26 *** | −0.14 *** | 0.44 *** |

| Variable | Model 1 | Model 2 | ||||

|---|---|---|---|---|---|---|

| B | SE | β | B | SE | β | |

| Step 1 | ||||||

| (Constant) | 7.257 *** | 0.534 | 5.643 *** | 0.576 | ||

| Gender | 0.009 | 0.145 | 0.002 | −0.008 | 0.141 | −0.002 |

| Age | −0.084 | 0.142 | −0.038 | −0.036 | 0.138 | −0.016 |

| Educational background | 0.243 * | 0.107 | 0.086 | 0.240 * | 0.104 | 0.085 |

| Work experience | −0.239 * | 0.100 | −0.155 | −0.200 * | 0.097 | −0.129 |

| Risk propensity | −0.392 *** | 0.051 | −0.278 | −0.377 *** | 0.049 | −0.268 |

| Number of employees | 0.061 | 0.075 | 0.040 | 0.063 | 0.073 | 0.041 |

| Annual sales revenue | 0.232 *** | 0.072 | 0.160 | 0.213 *** | 0.070 | 0.147 |

| Step 2 | ||||||

| Psychological distance | 0.233 *** | 0.036 | 0.228 | |||

| F value | 18.879 | 22.659 | ||||

| R2 | 0.170 | 0.219 | ||||

| Adj. R2 | 0.161 | 0.210 | ||||

| ∆Adj R 2 | 0.170 | 0.050 | ||||

| Variable | Model 1 | Model 2 | ||||

|---|---|---|---|---|---|---|

| B | SE | β | B | SE | β | |

| Step 1 | ||||||

| (Constant) | 8.233 *** | 0.542 | 7.139 *** | 0.579 | ||

| Gender | 0.438 ** | 0.148 | 0.108 | 0.440 ** | 0.146 | 0.108 |

| Age | −0.223 | 0.139 | −0.099 | −0.179 | 0.137 | −0.080 |

| Educational background | 0.127 | 0.105 | 0.045 | 0.099 | 0.103 | 0.035 |

| Work experience | −0.199 * | 0.101 | −0.124 | −0.172 * | 0.099 | −0.107 |

| Risk propensity | −0.383 *** | 0.054 | −0.256 | −0.382 *** | 0.053 | −0.255 |

| Number of employees | −0.080 | 0.071 | −0.054 | −0.069 | 0.070 | −0.046 |

| Annual sales revenue | 0.184 ** | 0.069 | 0.126 | 0.168 ** | 0.068 | 0.115 |

| Step 2 | ||||||

| Psychological distance | 0.182 *** | 0.038 | 0.174 | |||

| F value | 14.579 | 16.123 | ||||

| R2 | 0.129 | 0.158 | ||||

| Adj. R2 | 0.120 | 0.148 | ||||

| ∆Adj R 2 | 0.129 | 0.029 | ||||

| Path of Mediating Effect | Point Estimate | SE | 95% CI | |

|---|---|---|---|---|

| Low | High | |||

| Group of Tier 1: | ||||

| Relative total effect (Tier 1 → disruption risk perception) | 0.476 | 0.146 | 0.190 | 0.762 |

| Relative direct effect (Tier 1 → disruption risk perception) | −0.167 | 0.136 | −0.434 | 0.099 |

| Relative mediating effect (Tier 1 → Perceived risk information quality → disruption risk perception) | 0.643 a | 0.085 | 0.482 | 0.813 |

| Group of Tier 2: | ||||

| Relative total effect (Tier 2 → disruption risk perception) | 0.908 | 0.150 | 0.614 | 1.201 |

| Relative direct effect (Tier 2 → disruption risk perception) | 0.057 | 0.143 | −0.224 | 0.338 |

| Relative mediating effect (Tier 2 → Perceived risk information quality → disruption risk perception) | 0.850 a | 0.093 | 0.677 | 1.033 |

| Dependent Variable: DRP | Dependent Variable: MR | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | ||||||

| Estimate | SE | Estimate | SE | Estimate | SE | Estimate | SE | Estimate | SE | |

| Layer 1: Control Variables | ||||||||||

| (Constant) | −0.543 | 0.373 | −0.887 ** | 0.447 | −0.847 ** | 0.336 | −0.097 | 0.381 | 0.131 | 0.348 |

| Gender | 0.265 * | 0.116 | 0.197 † | 0.105 | 0.197 † | 0.104 | 0.060 | 0.119 | −0.051 | 0.109 |

| Age | −0.183 | 0.112 | −0.235 * | 0.101 | −0.243 * | 0.101 | −0.286 ** | 0.114 | −0.209 * | 0.104 |

| Education | 0.184 * | 0.085 | 0.262 *** | 0.076 | 0.259 *** | 0.076 | 0.100 | 0.086 | 0.022 | 0.079 |

| Experience | −0.168 * | 0.080 | −0.055 | 0.072 | −0.049 | 0.072 | −0.069 | 0.081 | 0.002 | 0.074 |

| Rpr | −0.393 *** | 0.042 | −0.240 *** | 0.039 | −0.234 *** | 0.039 | −0.033 | 0.043 | 0.132 *** | 0.040 |

| Number of employees | −0.030 | 0.058 | −0.009 | 0.052 | −0.015 | 0.052 | −0.034 | 0.059 | −0.021 | 0.054 |

| Annual sales revenue | 0.213 *** | 0.056 | 0.161 ** | 0.051 | 0.160 ** | 0.051 | 0.179 ** | 0.058 | 0.089 | 0.053 |

| Layer 2: Main effect | ||||||||||

| PRIQ | −0.506 *** | 0.032 | −0.558 *** | 0.038 | ||||||

| JPL | −0.211 * | 0.107 | −0.207 * | 0.106 | ||||||

| DRP | 0.421 *** | 0.029 | ||||||||

| Layer 3: Interaction effect | ||||||||||

| JPL × PRIQ | 0.158 * | 0.065 | ||||||||

| R2 | 0.140 | 0.311 | 0.315 | 0.051 | 0.212 | |||||

| Adjusted R2 | 0.134 | 0.305 | 0.308 | 0.044 | 0.206 | |||||

| R2 change | 0.140 | 0.171 | 0.004 | 0.051 | 0.161 | |||||

| F-statistic | 24.376 | 52.356 | 47.926 | 8.006 | 35.230 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, M.-X.; Li, S.; Rao, L.-L.; Zheng, L. The Relationship between Distance and Risk Perception in Multi-Tier Supply Chain: The Psychological Typhoon Eye Effect. Sustainability 2023, 15, 7507. https://doi.org/10.3390/su15097507

Xu M-X, Li S, Rao L-L, Zheng L. The Relationship between Distance and Risk Perception in Multi-Tier Supply Chain: The Psychological Typhoon Eye Effect. Sustainability. 2023; 15(9):7507. https://doi.org/10.3390/su15097507

Chicago/Turabian StyleXu, Ming-Xing, Shu Li, Li-Lin Rao, and Lei Zheng. 2023. "The Relationship between Distance and Risk Perception in Multi-Tier Supply Chain: The Psychological Typhoon Eye Effect" Sustainability 15, no. 9: 7507. https://doi.org/10.3390/su15097507