Performance Analysis of a Hybrid Renewable-Energy System for Green Buildings to Improve Efficiency and Reduce GHG Emissions with Multiple Scenarios

Abstract

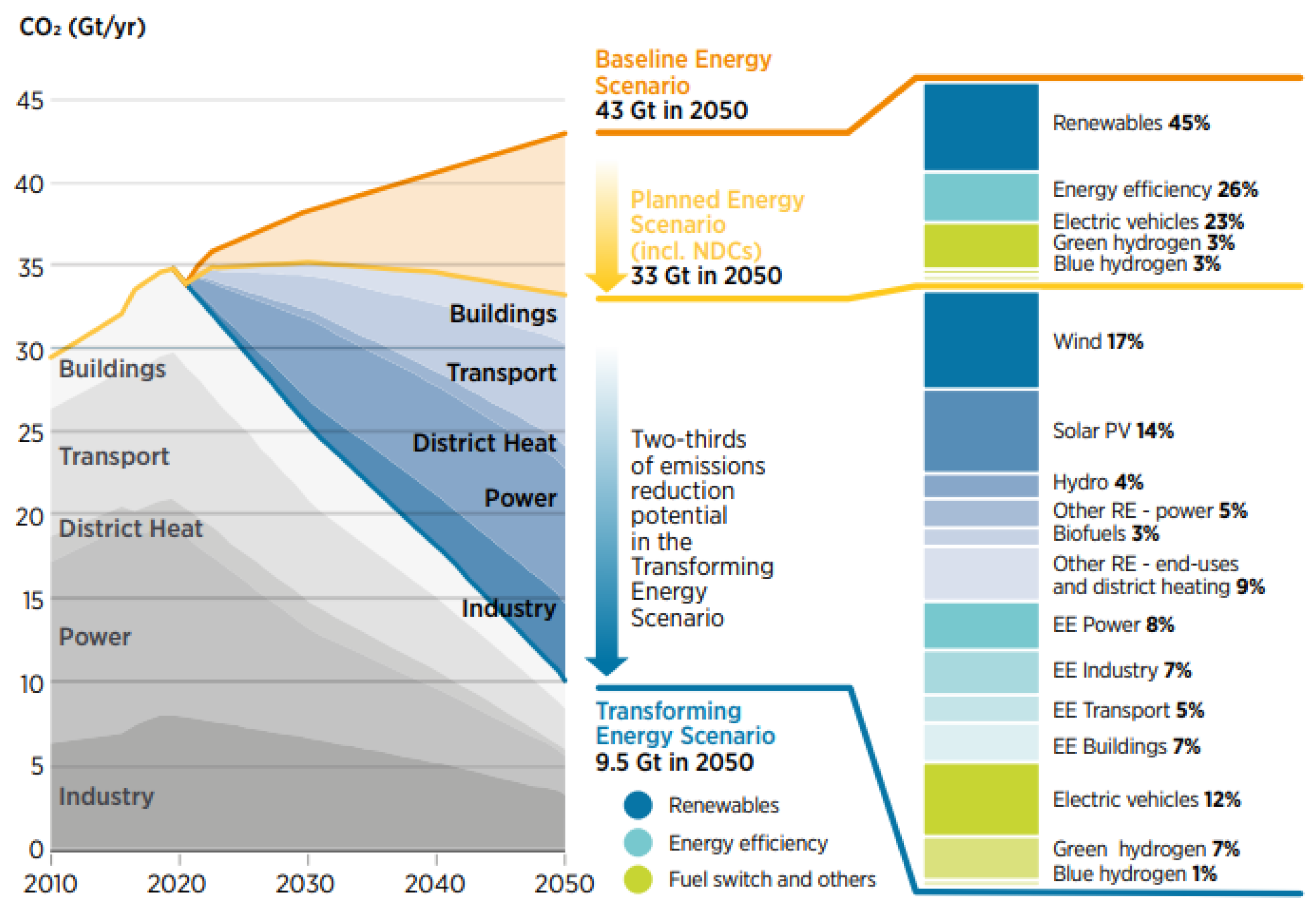

:1. Introduction

- Design a hybrid renewable-energy system (solar, wind energy, and grid network) to supply power to a building that decreases dependence on the electrical grid.

- Analyze the resulting data for power, economic, and environmental output for hybrid systems from HOMER software simulations to investigate overall efficiency and define an optimal configuration.

- Evaluate the environmental impact of GHG reduction by the optimal hybrid renewable-energy configuration.

2. Literature Review

3. Methodology and Experimentation

3.1. Methods and Instruments

- Consists of real and field measurements data collection;

- Using specialist software for this field of study;

- Several comparisons were done on the research results;

- The decision making was done by ordering the best results based on economic and environmental value.

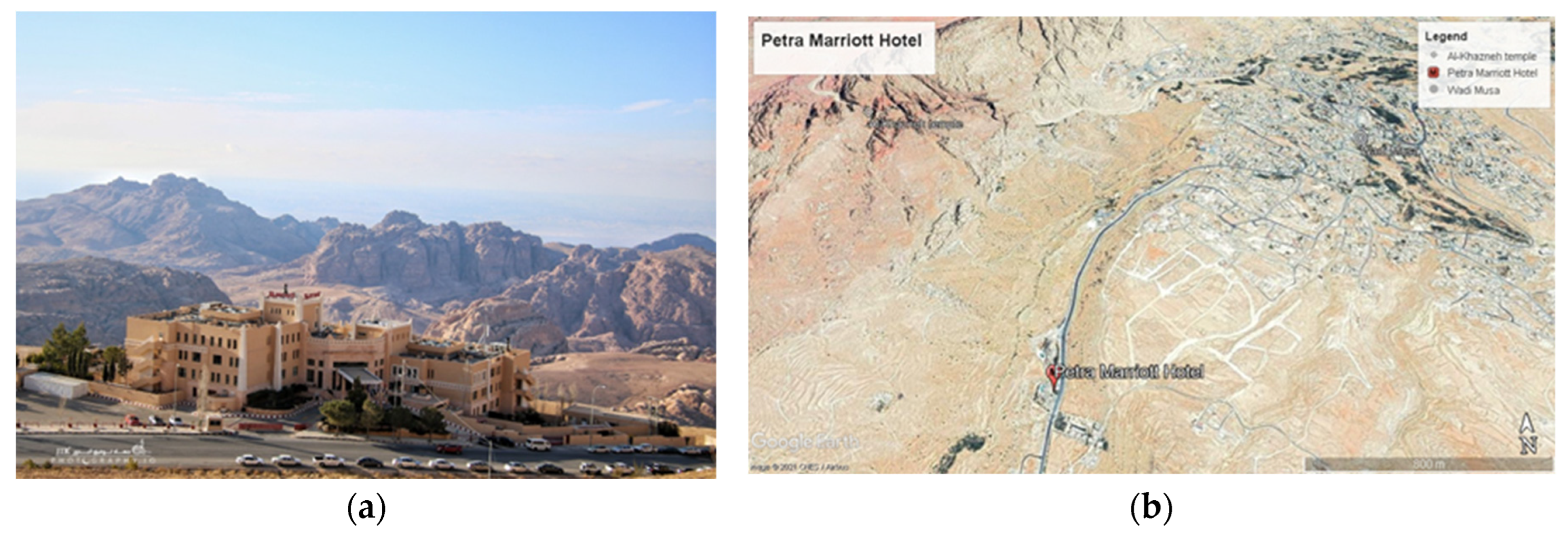

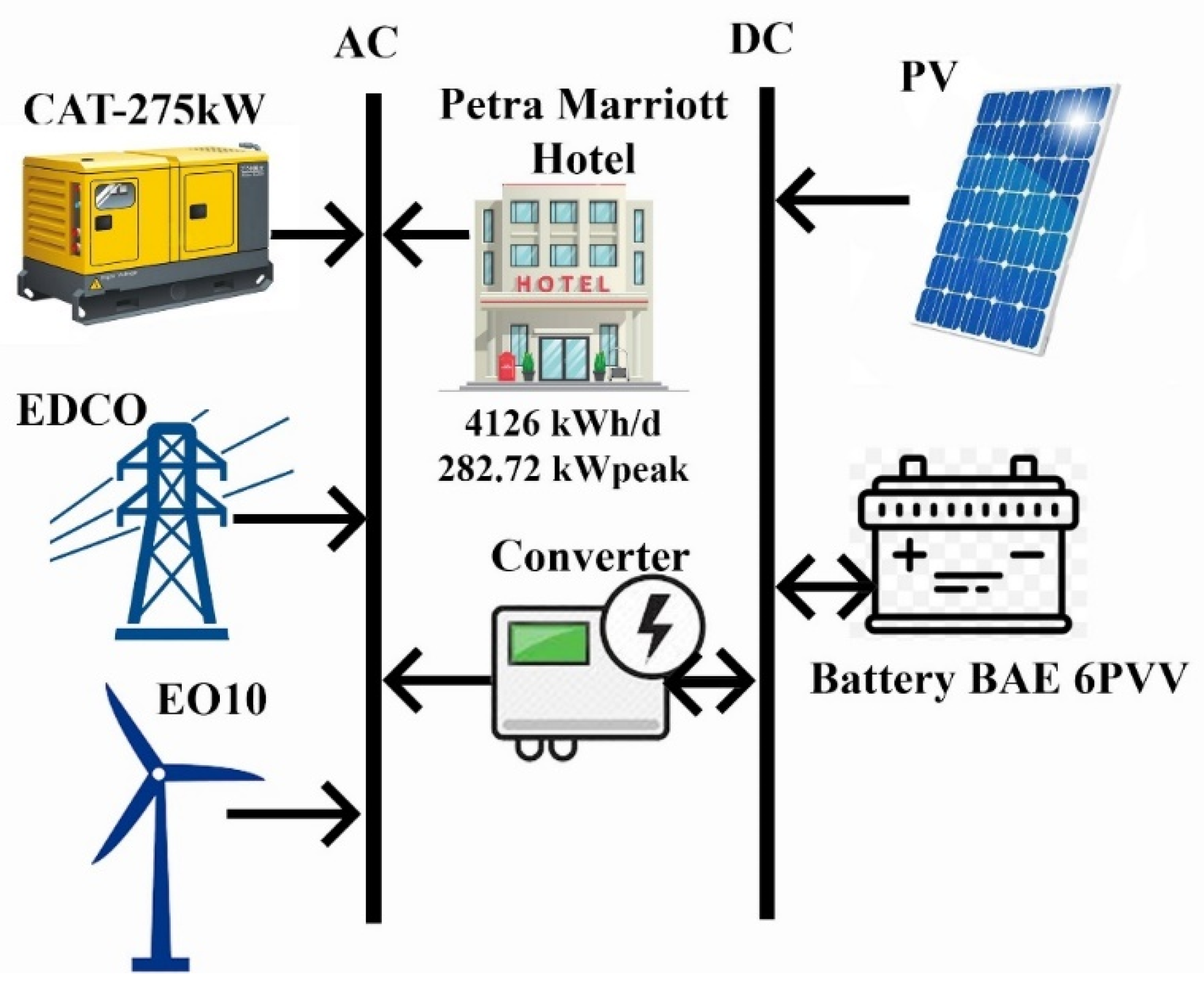

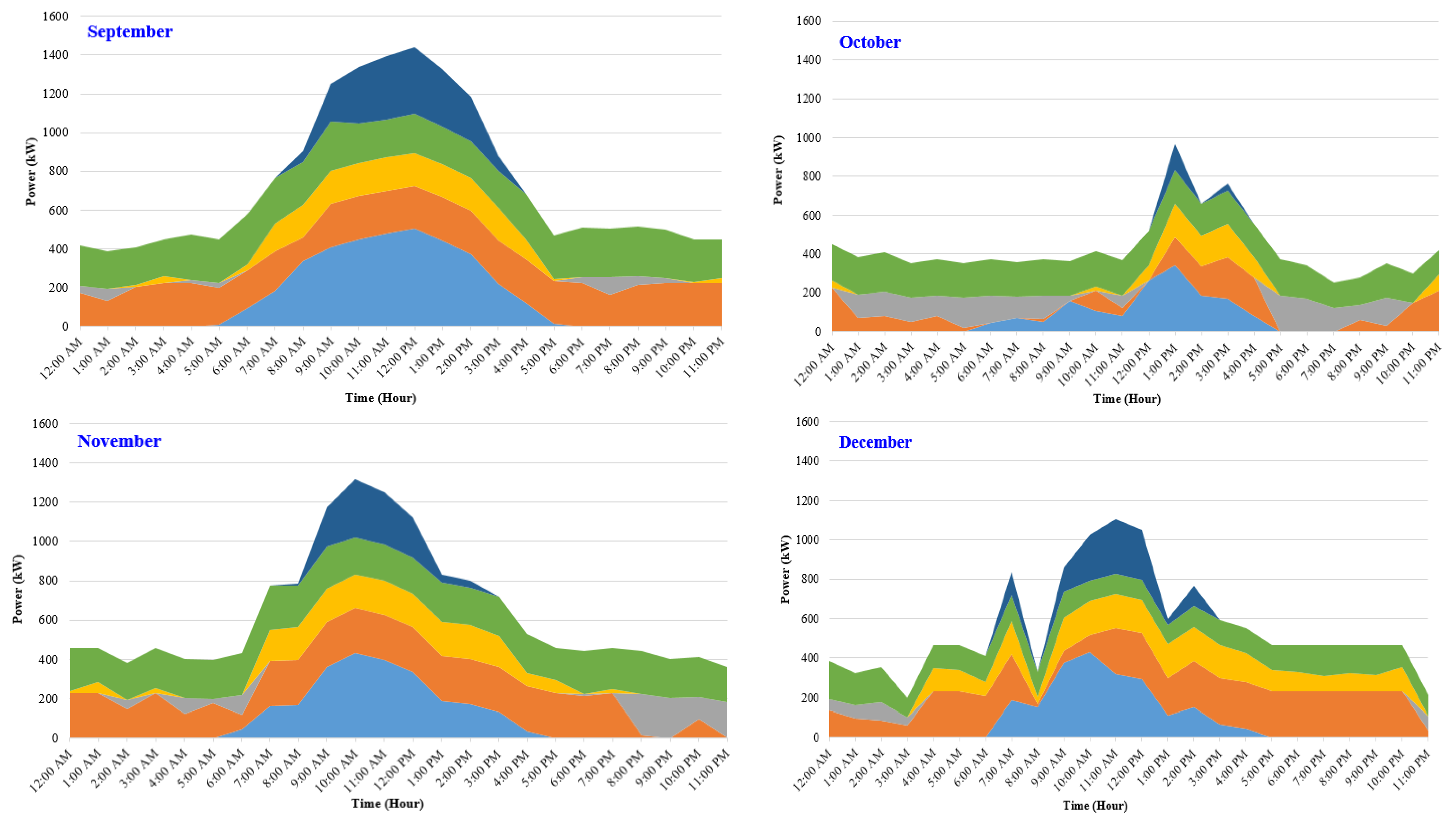

3.2. Petra Marriott Hotel Case Study

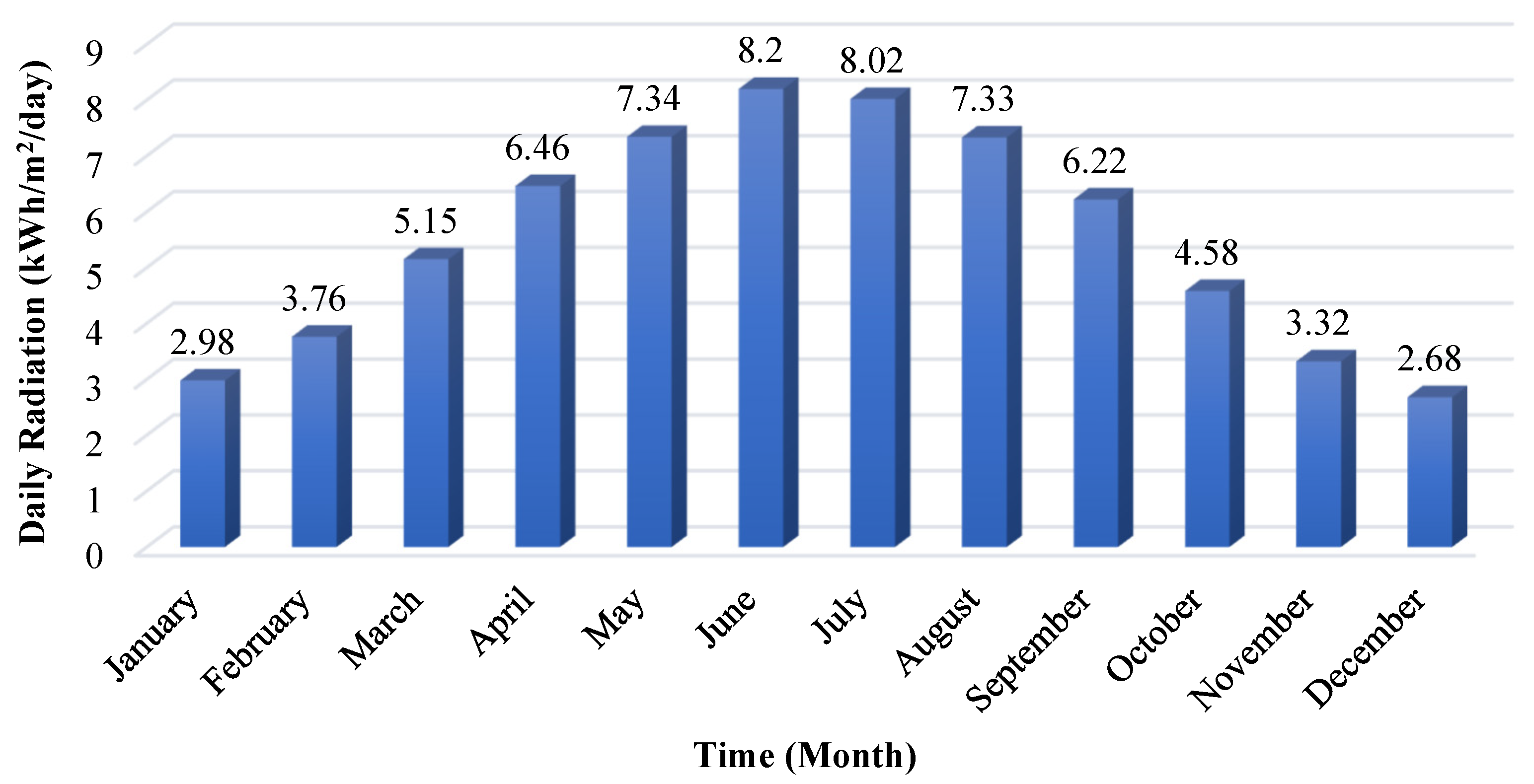

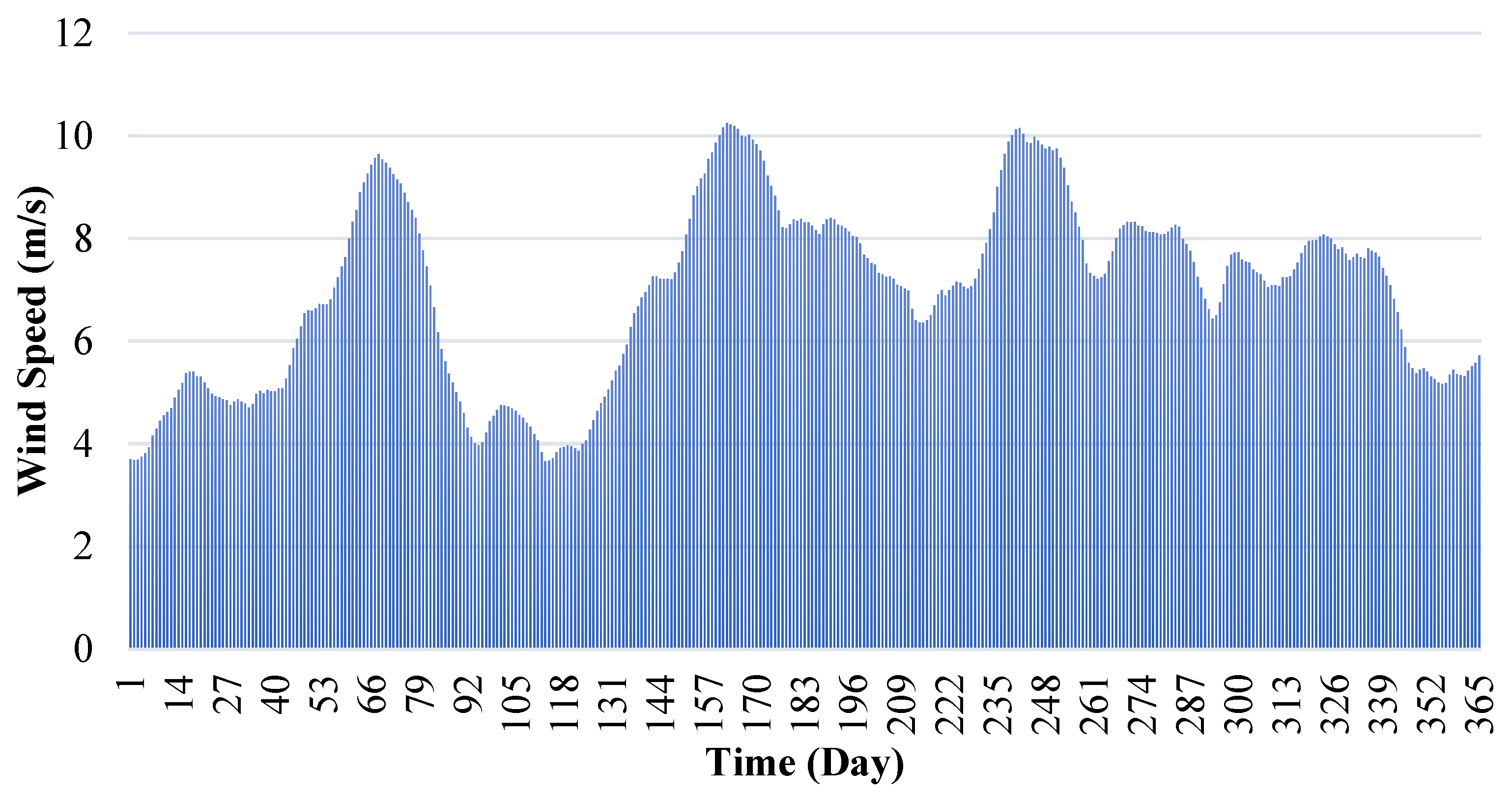

3.2.1. Renewable Resources Assessment for the Case Study

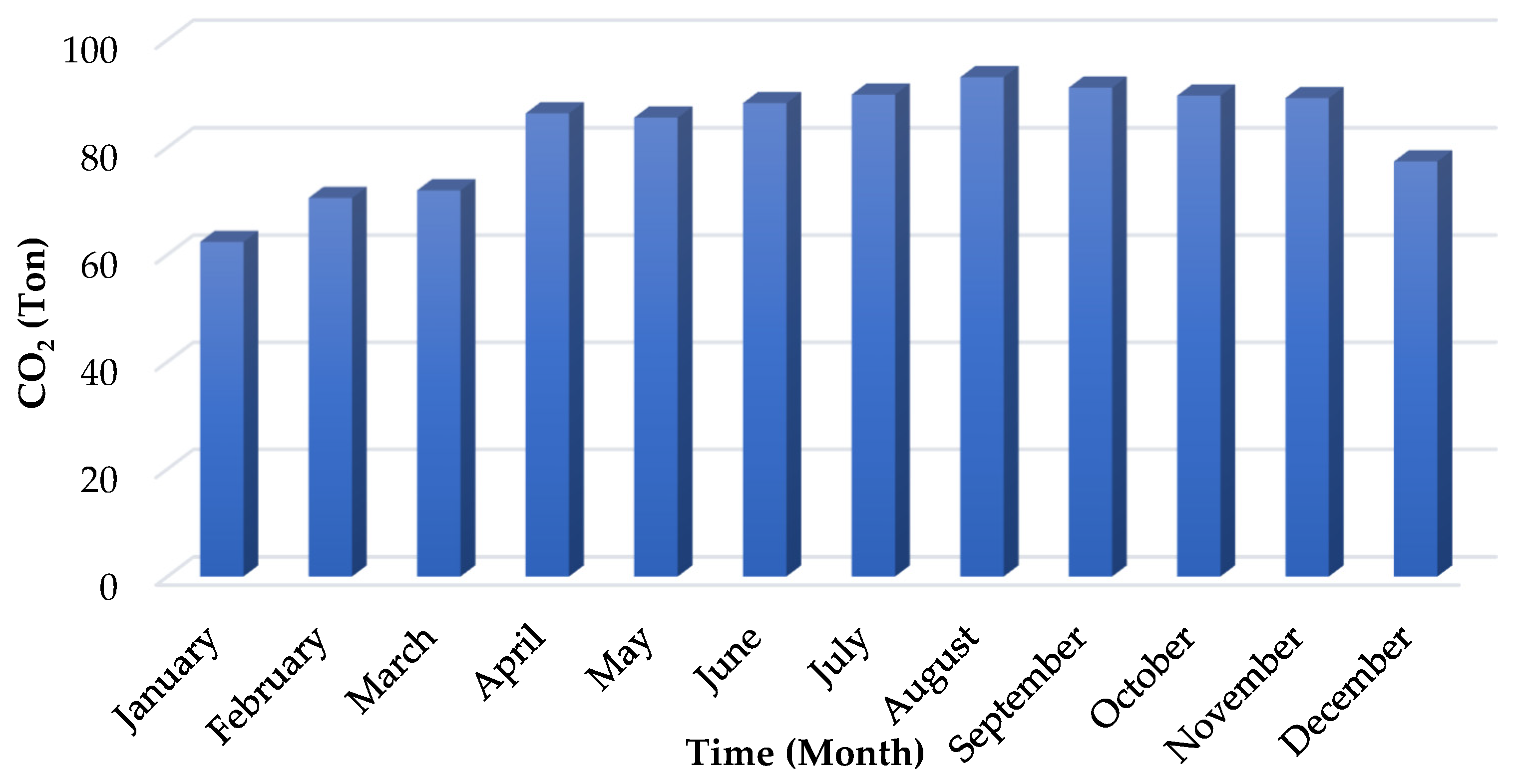

3.2.2. Greenhouse-Gas Emission from Grid Electricity Production

3.3. Design Specifications and Technical Model

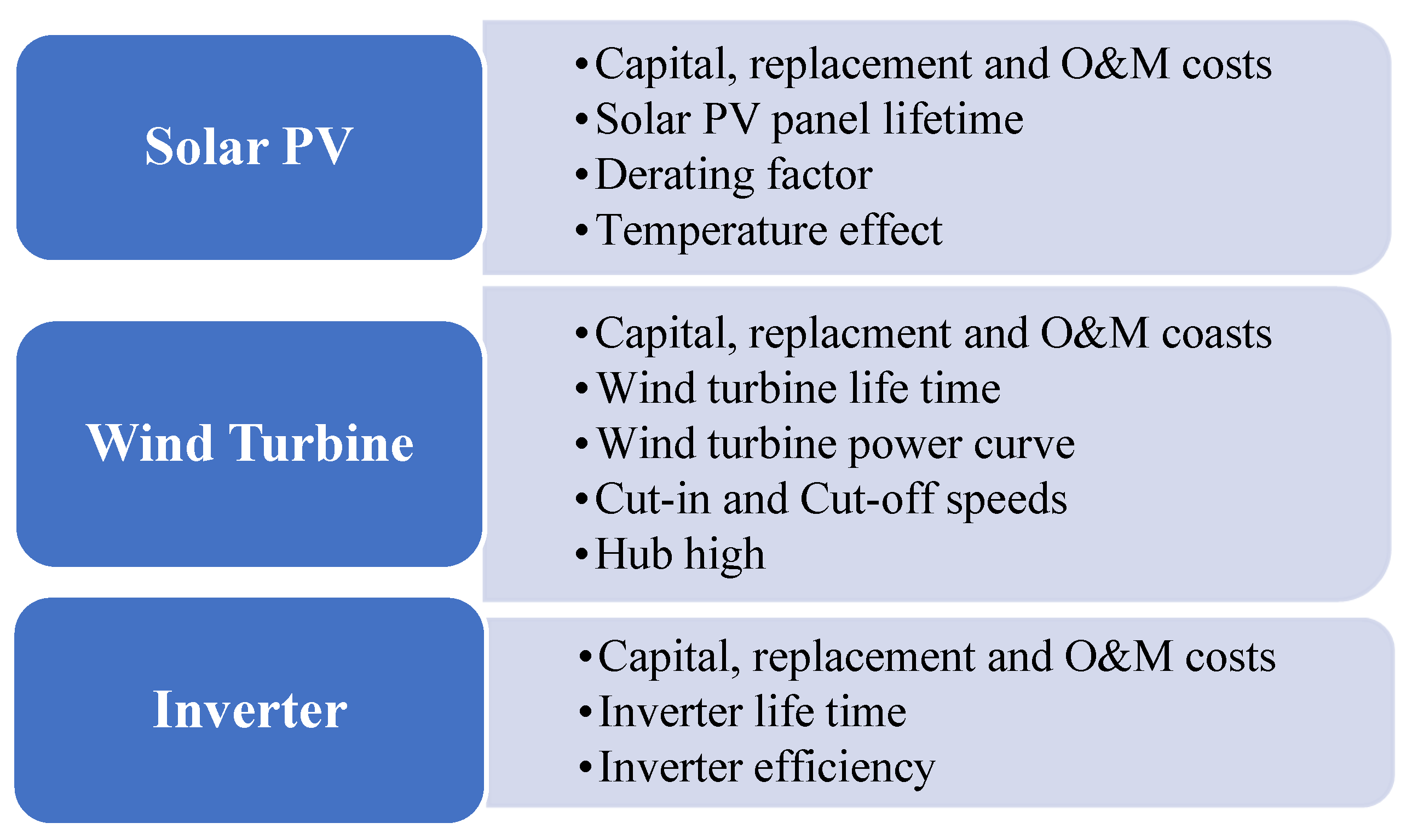

3.3.1. Solar Photovoltaic System

3.3.2. Wind Turbine

3.3.3. Power Inverter

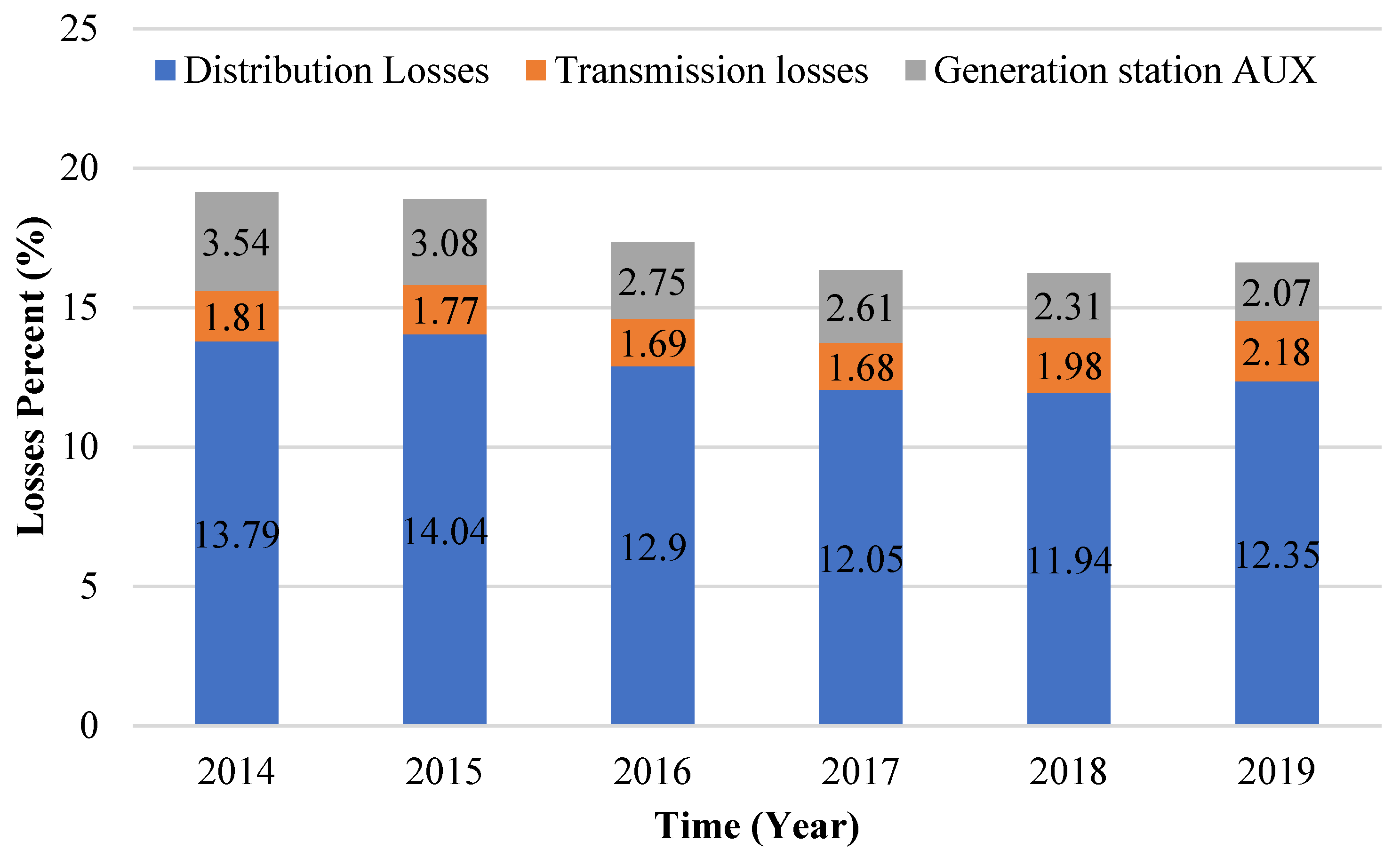

3.3.4. Electrical Network Grid

3.3.5. Diesel Generator

3.3.6. Electrical Energy Efficiency

3.3.7. Battery System

4. Results

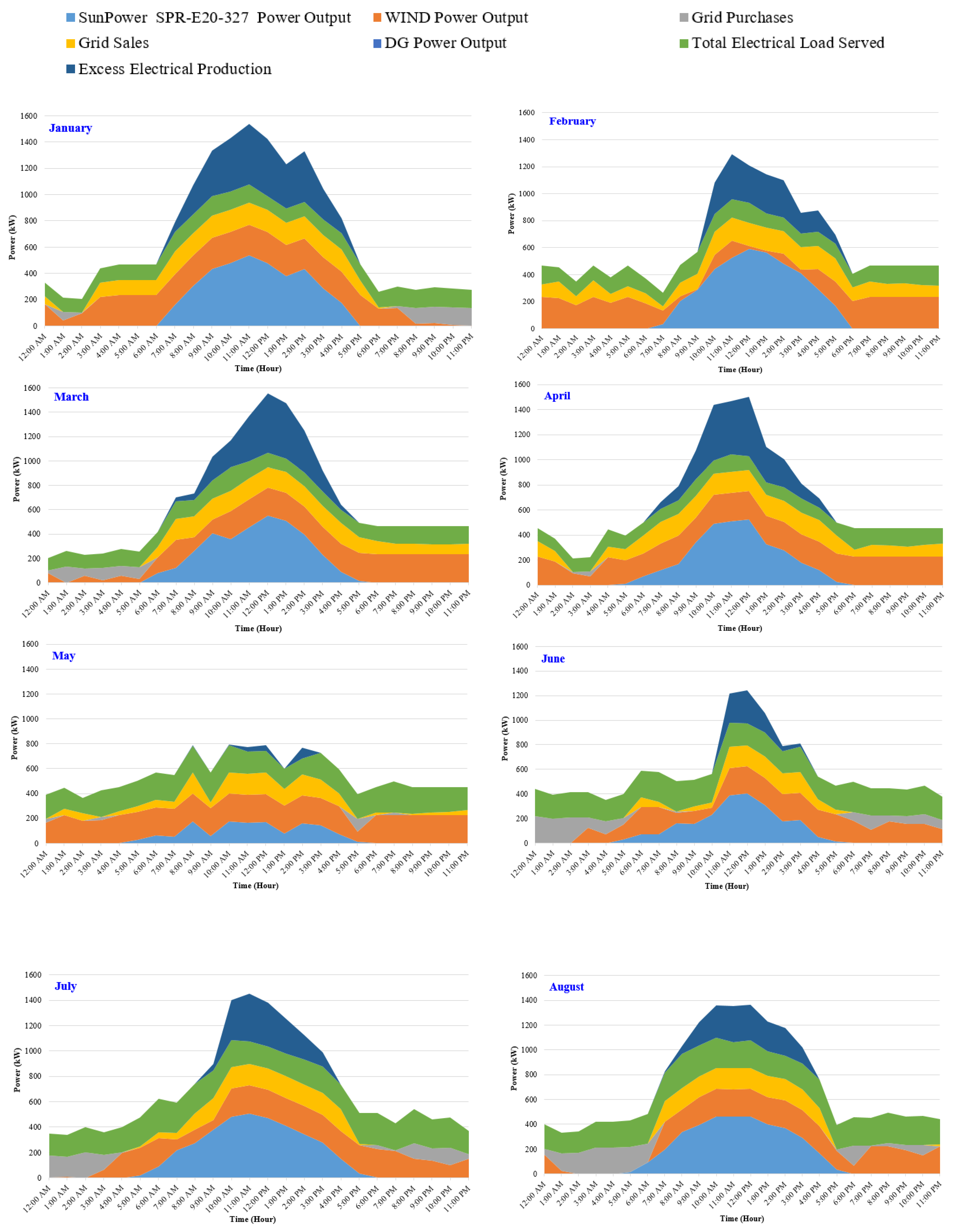

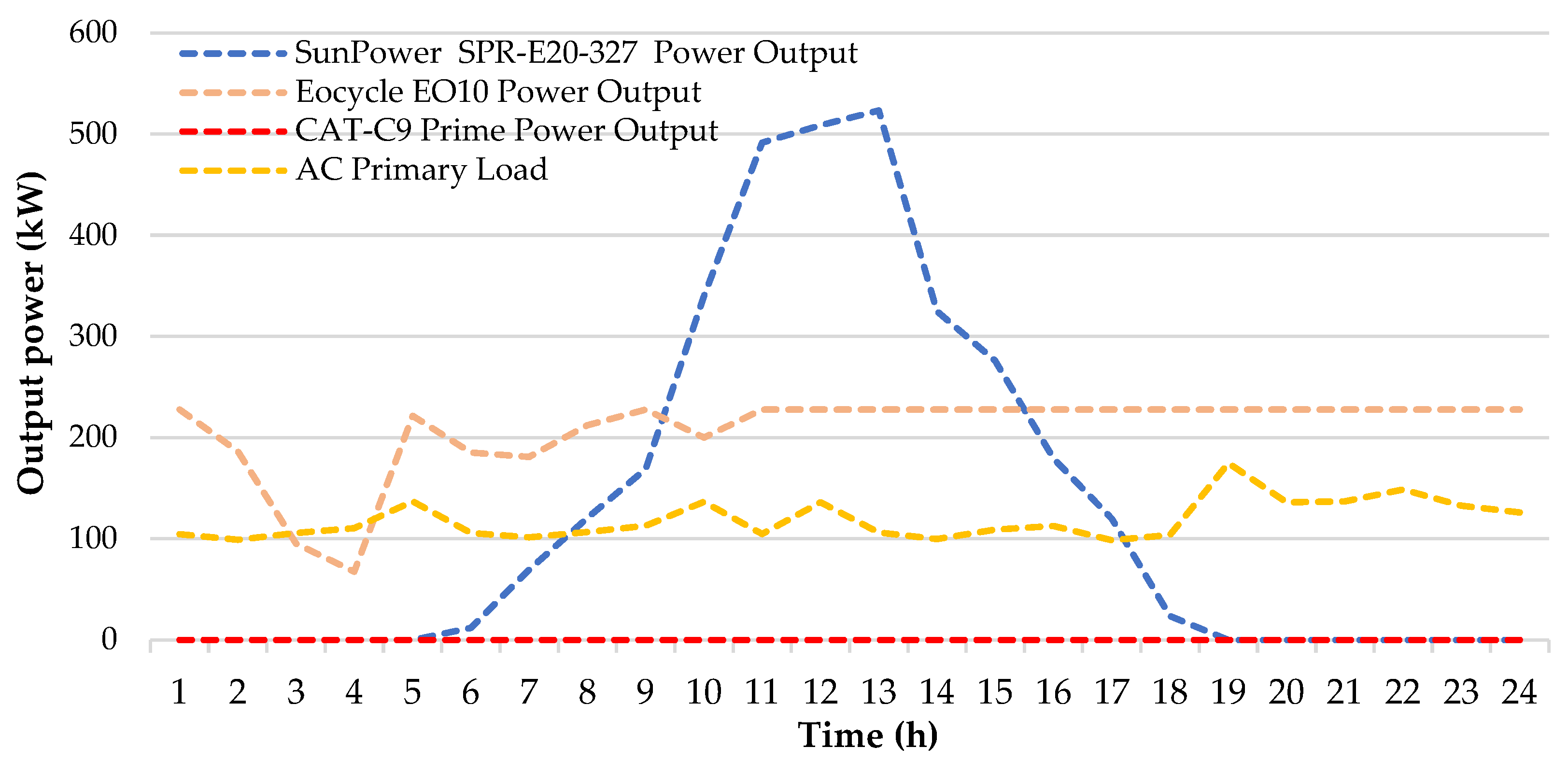

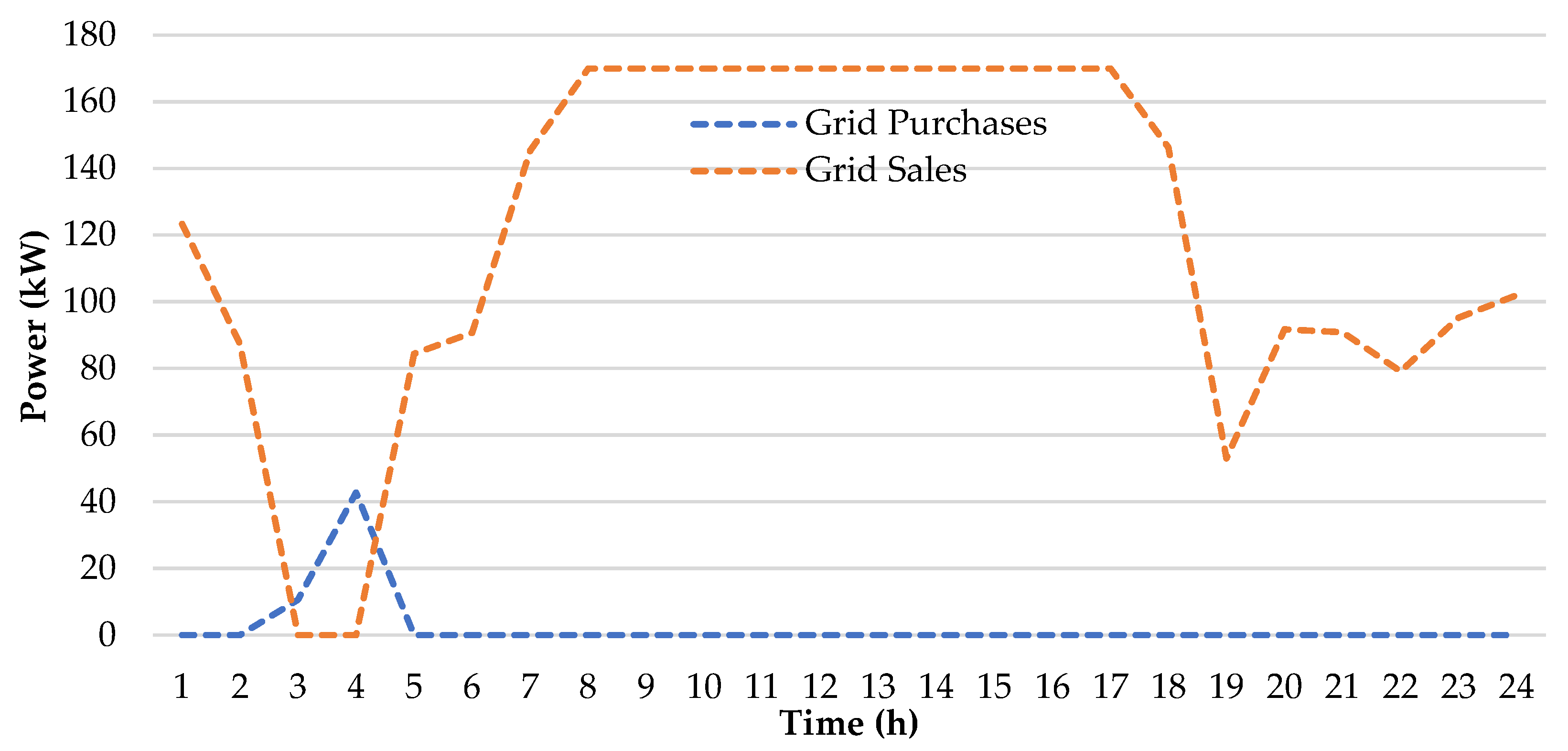

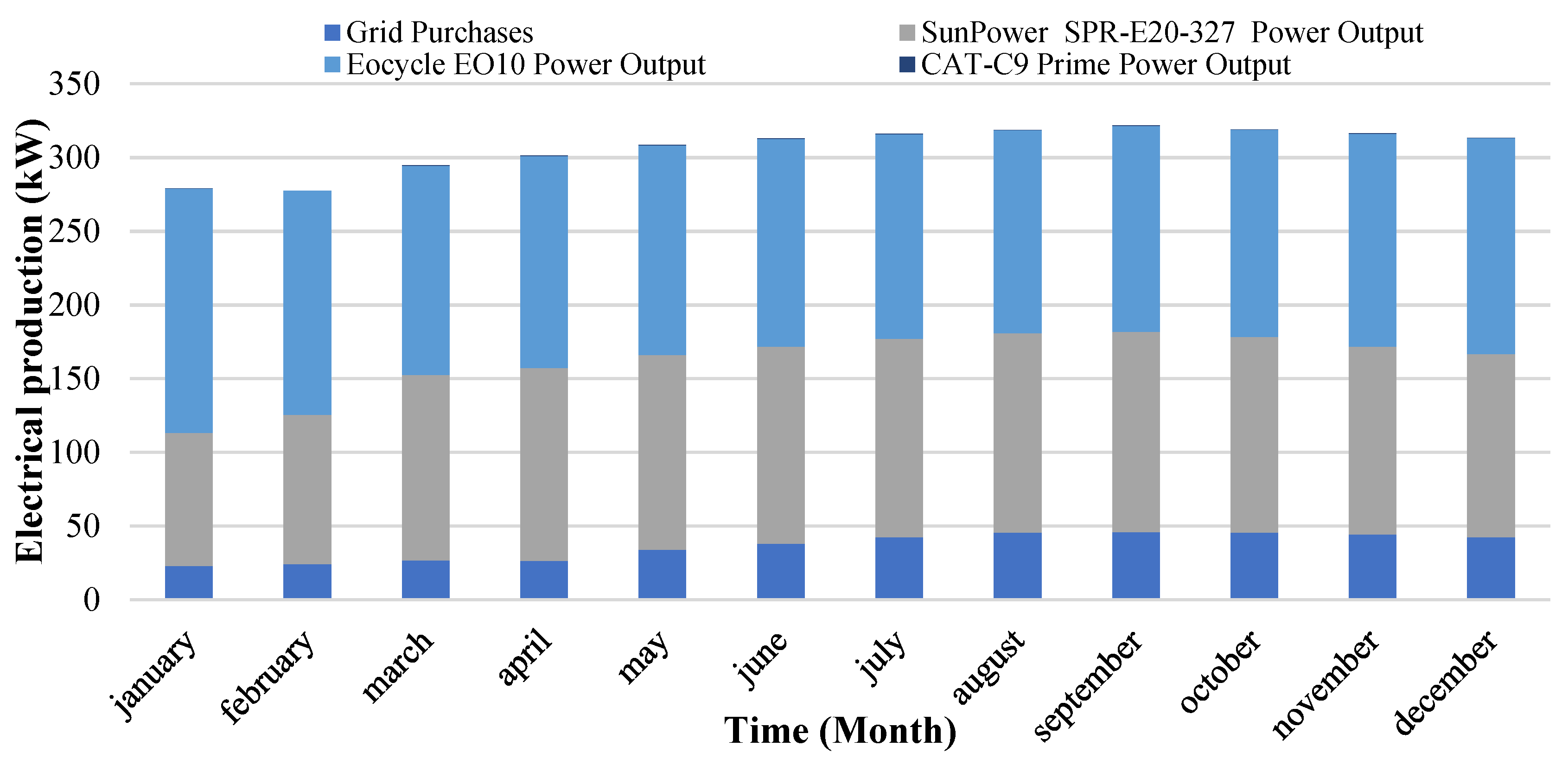

4.1. Operational Performance of the Optimal System

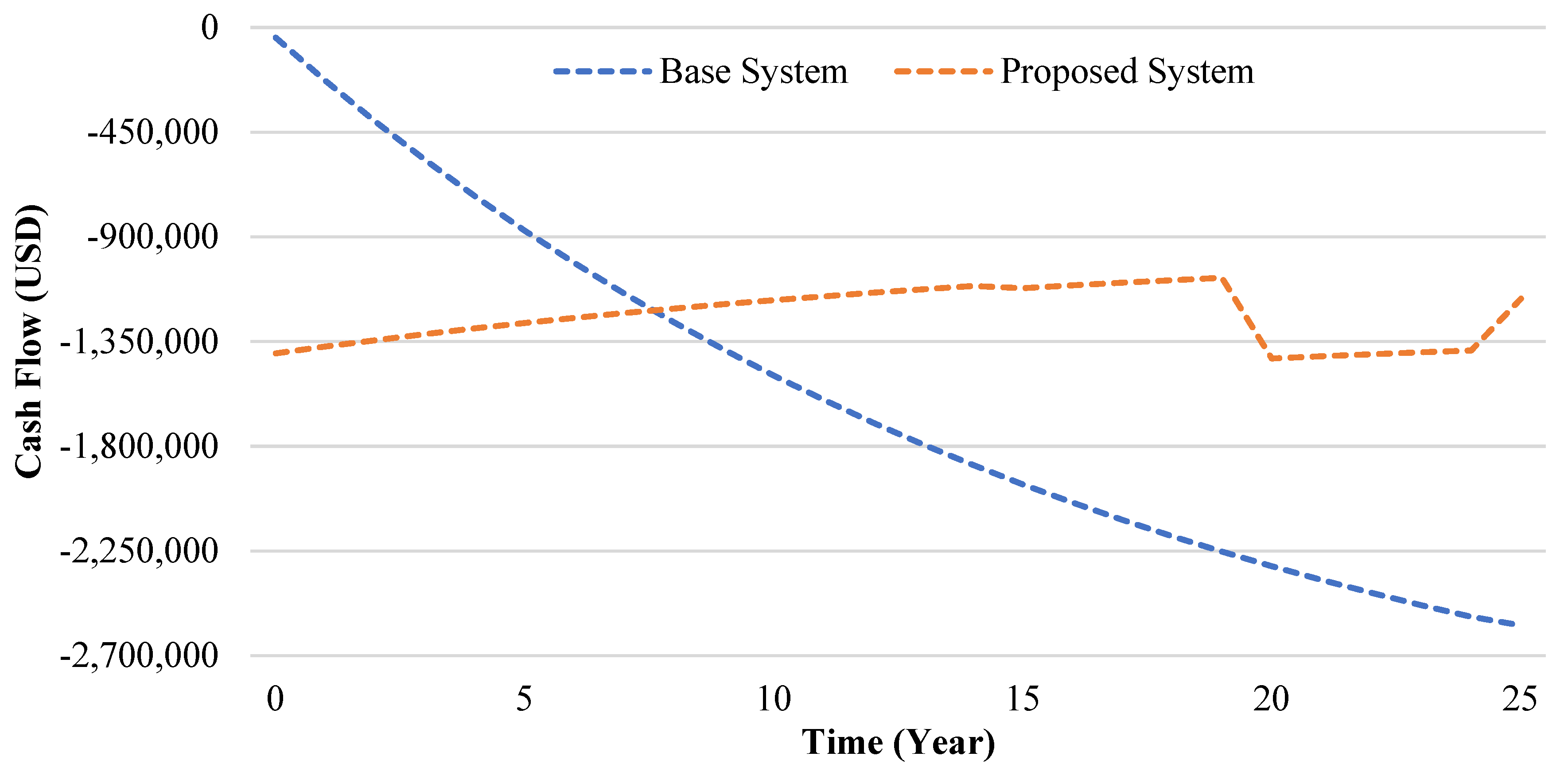

4.2. Economical Performance of the Optimal System

4.3. Environmental Performance of the Optimal System

4.4. Comparison with Other Studies Results

5. Regulation Rule of Energy Storage

- Electrical loss rates of 6% are applied to the user as a result of using the transmission or distribution system or both electrical losses and USD 0.1/kWh;

- The generating capacity of the system of renewable-energy sources to be connected to the system licensed for transmission or licensed for distribution and retail supply shall be determined, so that the annual amount of energy generated from this system does not exceed the actual consumption for the last 12 months from the date of submitting the application for the beneficiary subscription, in addition to the amount of energy calculated to cover the losses. Electricity results from the transmission of electrical energy through the transmission system and distribution system. Regarding new subscriptions that have had no actual consumption for the last 12 months, the applicant estimates the generating capacity in the application;

- The user is not compensated for the annual surplus quantities if the amount of excess energy exceeds 10% of the energy consumed by the subscriber benefiting from the transit transportation process.

6. Conclusions

- -

- Using a hybrid renewable-energy system was more effective than using a single type of renewable-energy system, as it was more sustainable and cost effective;

- -

- Policymakers should ease the rules and limitations on using renewable-energy and their share of the grid;

- -

- Proposed a local fabricated system for parts production due to the energy cost still being high as the cost of imported RE systems is high;

- -

- Using solar water heaters can improve the overall system’s cost effectivity by reducing energy to heat water by electricity heaters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fraunhofer Institute for Solar Energy Systems, ISE with Support of PSE Projects GmbH. Fraunhofer ISE: Photovoltaics Report. I: PHOTOVOLTAICS REPORT (nov. 2016). 2019. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Photovoltaics-Report.pdf (accessed on 15 March 2021).

- Lee, J.; Zhao, F.; Dutton, A.; Backwell, B.; Fiestas, R.; Qiao, L.; Balachandran, N. Global Wind Report 2019; Global Wind Energy Council (GWEC): Brussels, Belgium, 2020; Available online: https://gwec.net/wp-content/uploads/2020/08/Annual-Wind-Report_2019_digital_final_2r.pdf (accessed on 21 March 2021).

- Hasan, A.O.; Osman, A.I.; Ala’a, H.; Al-Rawashdeh, H.; Abu-jrai, A.; Ahmad, R.; Gomaa, M.R.; Deka, T.J.; Rooney, D.W. An experimental study of engine characteristics and tailpipe emissions from modern DI diesel engine fuelled with methanol/diesel blends. Fuel Process. Technol. 2021, 220, 106901. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Al-Dmour, N.; AL-Rawashdeh, H.A.; Shalby, M. Theoretical model of a fluidized bed solar reactor design with the aid of MCRT method and synthesis gas production. Renew. Energy 2020, 148, 91–102. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Mustafa, R.J.; Al-Dmour, N. Solar Thermochemical Conversion of Carbonaceous Materials into Syngas by Co-Gasification. J. Clean. Prod. 2020, 248, 119185. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Mustafa, R.J.; Al-Dhaifallah, M.; Rezk, H. A Low-Grade Heat Organic Rankine Cycle Driven by Hybrid Solar Collectors and a Waste Heat Recovery System. Energy Rep. 2020, 6, 3425–3445. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Hammad, W.; Al-Dhaifallah, M.; Rezk, H. Performance enhancement of grid-tied PV system through new design cooling techniques under dry desert condition: An experimental study and comparative analysis. Sol. Energy 2020, 211, 1110–1127. [Google Scholar] [CrossRef]

- Muneer, T.; Asif, M.; Munawwar, S. Sustainable production of solar electricity with particular reference to the Indian economy. Renew. Sustain. Energy Rev. 2005, 9, 444–473. [Google Scholar] [CrossRef]

- Ministry of Energy and Mineral Resources (MEMR). Annual Reports, Amman, Jordan, Page 30. 2018. Available online: https://www.memr.gov.jo/echobusv3.0/SystemAssets/56dcb683-2146-4dfd-8a15-b0ce6904f501.pdf (accessed on 17 October 2019).

- Gomaa, M.R.; Rezk, H. Passive Cooling System for Enhancement the Energy Conversion Efficiency of Thermo-Electric Generator. Energy Rep. 2020, 6, 87–692. [Google Scholar] [CrossRef]

- National Electric Power Company, NEPCO Annual Report, 2019. Available online: http://www.nepco.com.jo/store/docs/web/2019_en.pdf (accessed on 4 February 2021).

- Van der Geest, K.; Warner, K. Loss and damage in the IPCC Fifth Assessment Report (Working Group II): A text-mining analysis. Clim. Policy 2020, 20, 729–742. [Google Scholar] [CrossRef]

- Lucchi, E. Renewable Energies and Architectural Heritage: Advanced Solutions and Future Perspectives. Buildings 2023, 13, 631. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Rezk, H.; Mustafa, R.J.; Al-Dhaifallah, M. Evaluating the Environmental Impacts and Energy Performance of a Wind Farm System Utilizing the Life-Cycle Assessment Method: A Practical Case Study. Energies 2019, 12, 3263. [Google Scholar] [CrossRef]

- National Electric Power Company (NEPCO). Annual Reports, Amman, Jordan. Available online: http://www.nepco.com.jo/store/docs/web/2018_en.pdf (accessed on 21 October 2019).

- Global Renewables Outlook: Energy Transformation 2050; IRENA: Abu Dhabi, United Arab Emirates, 2020.

- Suresh, V.; Muralidhar, M.; Kiranmayi, R. Modelling and optimization of an off-grid hybrid renewable energy system for electrification in a rural area. Energy Rep. 2020, 6, 594–604. [Google Scholar] [CrossRef]

- Bagheri, M.; Shirzadi, N.; Bazdar, E.; Kennedy, C.A. Optimal planning of hybrid renewable energy infrastructure for urban sustainability: Green Vancouver. Renew. Sustain. Energy Rev. 2018, 95, 254–264. [Google Scholar] [CrossRef]

- Olatomiwa, L.; Blanchard, R.; Mekhilef, S.; Akinyele, D. Hybrid renewable energy supply for rural healthcare facilities: An approach to quality healthcare delivery. Sustain. Energy Technol. Assess. 2018, 30, 121–138. [Google Scholar] [CrossRef]

- Ali, S.; Jang, C.M. Optimum Design of Hybrid Renewable Energy System for Sustainable Energy Supply to a Remote Island. Sustainability 2020, 12, 1280. [Google Scholar] [CrossRef]

- Odou, O.D.T.; Bhandari, R.; Adamou, R. Hybrid off-grid renewable power system for sustainable rural electrification in Benin. Renew. Energy 2020, 145, 1266–1279. [Google Scholar] [CrossRef]

- Kasaeian, A.; Rahdan, P.; Rad, M.A.V.; Yan, W.M. Optimal design and technical analysis of a grid-connected hybrid photovoltaic/diesel/biogas under different economic conditions: A case study. Energy Convers. Manag. 2019, 198, 111810. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Ala’a, K.; Al-Dhaifallah, M.; Rezk, H.; Ahmed, M. Optimal design and economic analysis of a hybrid renewable energy system for powering and desalinating seawater. Energy Rep. 2023, 9, 2473–2493. [Google Scholar] [CrossRef]

- Karunathilake, H.; Hewage, K.; Brinkerhoff, J.; Sadiq, R. Optimal renewable energy supply choices for net-zero ready buildings: A life cycle thinking approach under uncertainty. Energy Build. 2019, 201, 70–89. [Google Scholar] [CrossRef]

- Islam, M.S. A techno-economic feasibility analysis of hybrid renewable energy supply options for a grid-connected large office building in southeastern part of France. Sustain. Cities Soc. 2018, 38, 492–508. [Google Scholar] [CrossRef]

- Mayer, M.J.; Szilágyi, A.; Gróf, G. Environmental and economic multi-objective optimization of a household level hybrid renewable energy system by genetic algorithm. Appl. Energy 2020, 269, 115058. [Google Scholar] [CrossRef]

- Wang, W.; Peng, Y.; Li, X.; Qi, Q.; Feng, P.; Zhang, Y. A two-stage framework for the optimal design of a hybrid renewable energy system for port application. Ocean Eng. 2019, 191, 106555. [Google Scholar] [CrossRef]

- Fulzele, J.B.; Daigavane, M.B. Design and optimization of hybrid PV-wind renewable energy system. Mater. Today Proc. 2018, 5, 810–818. [Google Scholar] [CrossRef]

- Jeong, Y.; Lee, M.; Kim, J. Scenario-Based Design and Assessment of renewable energy supply systems for green building applications. Energy Procedia 2017, 136, 27–33. [Google Scholar] [CrossRef]

- Chen, P.J.; Wang, F.C. Design optimization for the hybrid power system of a green building. Int. J. Hydrogen Energy 2018, 43, 2381–2393. [Google Scholar] [CrossRef]

- Jung, J.; Villaran, M. Optimal planning and design of hybrid renewable energy systems for microgrids. Renew. Sustain. Energy Rev. 2017, 75, 180–191. [Google Scholar] [CrossRef]

- Mavroyeoryos, K.; Engonopoulos, I.; Tyralis, H.; Dimitriadis, P.; Koutsoyiannis, D. Simulation of electricity demand in a remote island for optimal planning of a hybrid renewable energy system. Energy Procedia 2017, 125, 435–442. [Google Scholar] [CrossRef]

- Pérez-Navarro, A.; Alfonso, D.; Ariza, H.E.; Cárcel, J.; Correcher, A.; Escrivá-Escrivá, G.; Hurtado, E.; Ibáñez, F.; Peñalvo, E.; Roig, R.; et al. Experimental verification of hybrid renewable systems as feasible energy sources. Renew. Energy 2016, 86, 384–391. [Google Scholar] [CrossRef]

- Nurunnabi, M.; Roy, N.K. Grid connected hybrid power system design using HOMER. In Proceedings of the 2015 International Conference on Advances in Electrical Engineering (ICAEE), Dhaka, Bangladesh, 17–19 December 2015; IEEE: Manhattan, NY, USA, 2015; pp. 18–21. [Google Scholar]

- Peerapong, P.; Limmeechokchai, B. Investment incentive of grid connected solar photovoltaic power plant under proposed feed-in tariffs framework in Thailand. Energy Procedia 2014, 52, 179–189. [Google Scholar] [CrossRef]

- Phurailatpam, C.; Rajpurohit, B.S.; Wang, L. Planning and optimization of autonomous DC microgrids for rural and urban applications in India. Renew. Sustain. Energy Rev. 2018, 82, 194–204. [Google Scholar] [CrossRef]

- Dhundhara, S.; Verma, Y.P.; Williams, A. Techno-economic analysis of the lithium-ion and lead-acid battery in microgrid systems. Energy Convers. Manag. 2018, 177, 122–142. [Google Scholar] [CrossRef]

- Usman, M.; Khan, M.T.; Rana, A.S.; Ali, S. Techno-economic analysis of hybrid solar-diesel-grid connected power generation system. J. Electr. Syst. Inf. Technol. 2018, 5, 653–662. [Google Scholar] [CrossRef]

- Shafiullah, G.M. Hybrid renewable energy integration (HREI) system for subtropical climate in Central Queensland, Australia. Renew. Energy 2016, 96, 1034–1053. [Google Scholar] [CrossRef]

- El Khashab, H.; Al Ghamedi, M. Comparison between hybrid renewable energy systems in Saudi Arabia. J. Electr. Syst. Inf. Technol. 2015, 2, 111–119. [Google Scholar] [CrossRef]

- Adaramola, M.S.; Agelin-Chaab, M.; Paul, S.S. Analysis of hybrid energy systems for application in southern Ghana. Energy Convers. Manag. 2014, 88, 284–295. [Google Scholar] [CrossRef]

- Ranaboldo, M.; Lega, B.D.; Ferrenbach, D.V.; Ferrer-Martí, L.; Moreno, R.P.; García-Villoria, A. Renewable energy projects to electrify rural communities in Cape Verde. Appl. Energy 2014, 118, 280–291. [Google Scholar] [CrossRef]

- Google Earth pro 7.3 2020, Petra Marriott Hotel, Jordan, 30°18′16.44″ N, 35°27′49.77″ E, Elevation 1303M. 2D Map. Available online: http://www.google.com/earth/index.html (accessed on 5 February 2021).

- NASA POWER|Prediction of Worldwide Energy Resources. 2021. Available online: https://power.larc.nasa.gov/ (accessed on 12 July 2021).

- Global Wind Atlas. 2021. Available online: https://globalwindatlas.info/ (accessed on 28 July 2021).

- Hiendro, A.; Kurnianto, R.; Rajagukguk, M.; Simanjuntak, Y.M. Techno-economic analysis of photovoltaic/wind hybrid system for onshore/remote area in Indonesia. Energy 2013, 59, 652–657. [Google Scholar] [CrossRef]

- Department of Statistics. 2021. Available online: http://dosweb.dos.gov.jo/ (accessed on 15 May 2021).

- Phalippou, L. An Inconvenient Fact: Private Equity Returns and the Billionaire Factory. J. Invest. 2020, 30, 11–39. [Google Scholar] [CrossRef]

- Canadiansolar, 2021. Available online: https://www.canadiansolar.com/ (accessed on 13 February 2021).

- LONGi Solar. 2021. Available online: https://en.longi-solar.com (accessed on 13 February 2021).

- SunPower-United States. Home Solar Panels, Commercial & Utility-Scale Solar Solutions|SunPower. 2021. Available online: https://us.sunpower.com/ (accessed on 12 March 2020).

- Chowdhury, S.; Chowdhury, S.P.; Crossley, P. Microgrids and Active Distribution Networks; The Institution of Engineering and Technology: London, UK, 2009. [Google Scholar]

- Profitable Wind Energy Sources|Eocycle. 2021. Available online: https://eocycle.com/ (accessed on 17 April 2021).

- Shiroudi, A.; Taklimi, S.R.H.; Mousavifar, S.A.; Taghipour, P. Stand-alone PV-hydrogen energy system in Taleghan-Iran using HOMER software: Optimization and techno-economic analysis. Environ. Dev. Sustain. 2013, 15, 1389–1402. [Google Scholar] [CrossRef]

- Power Converters and Inverters. 2021. Available online: https://new.abb.com/power-converters-inverters (accessed on 11 June 2021).

- Sinha, S.; Chandel, S.S. Review of software tools for hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2014, 32, 192–205. [Google Scholar] [CrossRef]

- Legislation and Regulation. Legislation and regulation—Energy & Minerals Regulatory Commission. (n.d.). Available online: https://emrc.gov.jo/Pages/viewpage?pageID=256&CategoryID=8 (accessed on 14 March 2022).

| Ref. | Configuration | Component | Location | Software | Result Summary |

|---|---|---|---|---|---|

| Suresh et al. [17] | Off-grid Hybrid | Biogas–PV–WT–Fuel Cell as Battery | India | Genetic Algorithm (GA) and HOMER | COE was at 0.163 USD/kWh illustrating the use of multisystems. |

| Bagheri et al. [18] | Off-grid Hybrid | Biomass–PV | Canada | HOMER | NPCs were 59, 116, and USD 290 M and illustrate three different places |

| Olatomiwa et al. [19] | Off-grid Hybrid | PV–WT–DG–Battery | Nigeria | HOMER | NPC USD 102,949 and the COE 0.311 USD/kWh illustrate high cost. |

| Ali and Jang [20] | Off-grid Hybrid | PV–WT–Pumped Hydro Storage–Battery | South Korea | HOMER | COE at 0.159 USD/kWh and NPC USD 11.3 M, illustrate an economic comparison between the PHS and a battery and indicate that PHS can be a cheaper choice |

| Odou et al. [21] | Off-grid Hybrid | PV–DG–Battery | Benin Republic | HOMER | Shows that an off-grid hybrid system was a suitable technology to sustainably electrify the village of Fouay with a COE of 0.207 USD/kWh. |

| Kasaeian et al. [22] | Off-grid Hybrid | PV–DG–Biomass | Iran | HOMER | The NPC USD 23,148.84 illustrates the benefits of using an HRE system with Biomass over a PV/DG system. |

| Kasaeian et al. [22] | On-grid hybrid system | PV–Biomass–DG | Iran | HOMER | Resulted in a comparative cost for the gid purchase with COE 0.13 USD/kWh and NPC USD 0.97 M |

| Karunathilake et al. [24] | Off-grid Hybrid | PV–Heat Pumps | Canada | ENERGY-PLUS | Paid back within (22–23) years. And the per capita annual energy cost saving with the proposed system was USD 7. RE energy systems feasible environmental and energy security. |

| Islam, Md Shahinur [25] | On-grid Hybrid | PV–Grid | France | HOMER | The result shows that the PV/Grid system was the most cost-effective system configuration and minimizes above 90% emission compared to the existing emission in the study site, with COE of 0.087 USD/kWh. |

| Chen and Wang [30] | Off-grid Hybrid | PV–WT–DG | China | (MATLAB) (SimPowerSystem) | Improve the system reliability from Loss of Power Supply Probability (LPSP) 5.08% to 0%. |

| Jung and Villaran, [31] | Microgrid Hybrid Systems | PV–DG–Battery | US | DER-CAM | Illustrate the efficiency improvement to a proposed hybrid system |

| Mavroyeoryos et al. [32] | Electrical Energy Demand | PV–WT | Greek | Exploratory data analysis | Illustrate a considerable correlation between energy consumption and temperature |

| Pérez-Navarro et al. [33] | On-grid Hybrid System | PV–WT–Biomass–Battery | Spain | LABDER laboratory | Illustrated the best feasibility by standard demand curve of the residential segment |

| Nurunnabi et al. [34] | On-grid off-grid Hybrid System | PV–WT–Grid | Bangladesh | HOMER | Illustrate cost-effective value with NPC USD 0.535 M and COE 0.099 USD/kW |

| Peerapong and Limmeechokchai [35] | On grid | PV–Grid | Thailand | RETscreen | For the residential rooftop and the integrated ground-mounted and rooftop with 0.48 USD/kW and 0.31 USD/kW |

| Phurailatpam et al. [36] | On-grid hybrid system | PV–WT–Biodiesel Generator | India | HOMER | Illustrate acceptable COE 0.269 USD/kWh and NPC of 0.613 MUSD |

| Dhundhara et al. [37] | On-grid hybrid system | PV–WT–Battery–Grid | India | HOMER | With COE of 0.225 USD/kWh and NPC of 1.12 MUSD and illustrate the high cost of using a storage system |

| Usman et al. [38] | On-grid hybrid system | PV–DG–Grid | India | HOMER Pro | NPC of USD 3.12 M and CEO of USD 0.120 illustrate solar energy penetration of 18% of the total load |

| Shafiullah, G.M. [39] | On-grid Hybrid | PV–WT–Battery–Grid | Australia | HOMER | Using the wind-solar hybrid system was more economical than using a PV grid-connected with a payback of 7.8 years for the hybrid system for a PV–Battery–Grid-connected system, NPC, COE, and RF are 16,347 USD/year, 0.240 USD/kWh and 0.77, respectively. |

| El Khashab and Al Ghamedi [40] | Off-grid Hybrid | PV, wind turbine, and fuel cell | Saudi Arabia | HOMER | The researchers imply that the energy cost for the three investigated systems was still high due to the high cost of imported RE systems without locally fabricated system parts with each system found to be 0.36 0.49 and 7.3 USD/kWh, respectively. |

| Adaramola et al. [41] | Off-grid Hybrid | solar panels, wind turbines, and diesel generators | Ghana | HOMER | The results show that the electricity costs for this hybrid system were 0.281 USD/kW h. and the result will be a guide to the government policy and investment in Ghana. |

| Ranaboldo et al. [42] | Off-grid Hybrid | wind and solar photovoltaic system | Cape Verde | HOMER | The results show that when using the hybrid renewable system of energy in demand points with microgrids it can save more than 30% of the initial investment comparing with individual generation configurations. |

| Parameter | GHG Emission Factors (CO2/MWh) | Conversion Factors |

|---|---|---|

| Electricity | 0.670 | - |

| LPG | 0.227 | 13.1 MWh/ton |

| Diesel | 0.267 | 10 kWh/l |

| Fuel | 2016 | 2017 | 2018 | 2019 | Percent |

|---|---|---|---|---|---|

| Heavy Fuel | 344.6 | 454.2 | 120.0 | 15.1 | 87.4% |

| Natural Gas | 3377.1 | 3340.9 | 3402.2 | 3337.9 | 1.9% |

| Diesel | 13.6 | 9.4 | 4.2 | 1.8 | 57.1% |

| Total | 3735.3 | 3804.4 | 3526.4 | 3354.8 | 4.9% |

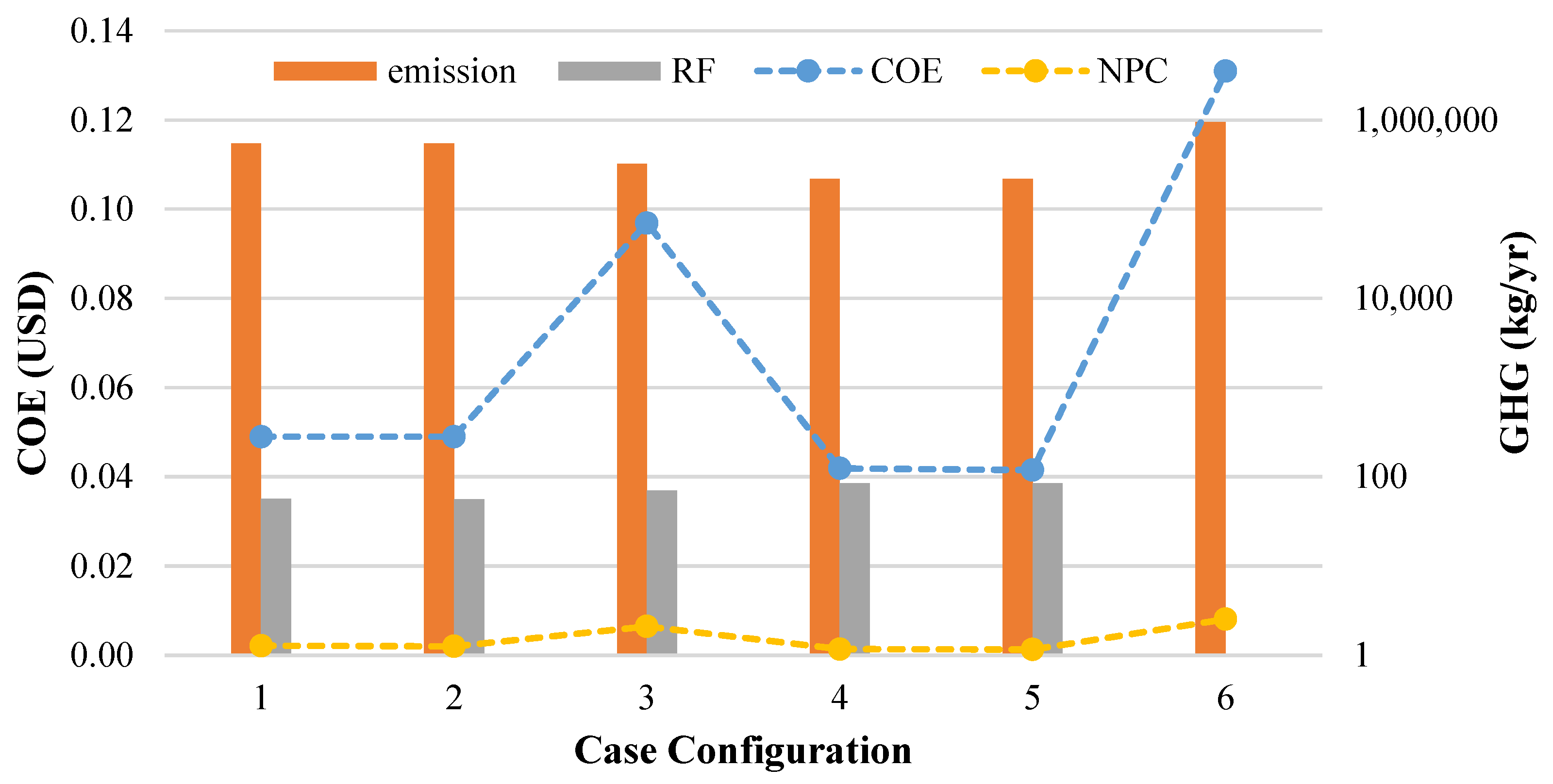

| Rank | Configuration | System Component | Optimum Size | NPC (MUSD) | COE (USD//kWh) | RF (%) | Capital Cost (USD) | Replacement Cost (USD) | O&M (USD) | Salvage (USD) | Grid Consumption (USD) | GHG (kg/Year) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Fifth | PV WT Converter DG | 573 KW 20 Qty. 317 KW 275 KW | 1.16 | 0.0415 | 84.1 | 1.40 M | 379,916 | −403,238 | −216,047 | 344,156 | 218,497 |

| 2 | Fourth | PV WT Converter Battery DG | 562 KW 20 Qty. 303 KW 2 strings 275 KW | 1.17 | 0.0419 | 84.1 | 1.40 M | 385,637 | −396,753 | −215,872 | 343,639 | 218,170 |

| 3 | First | PV Converter DG | 1050 KW 413 KW 275 KW | 1.275 | 0.049 | 56.5 | 420,790 | 29,792 | 804,476 | −9066 | 861,570 | 546,481 |

| 4 | Second | PV Converter Battery DG | 982 KW 403 KW 6 strings 275 KW | 1.257 | 0.049 | 56 | 431,526 | 43,322 | 828,517 | −16,501 | 865,027 | 549,777 |

| 5 | Third | WT DG Converter Battery | 18 Qty. 160 KW 490 KW 89 strings | 2.097 | 0.0969 | 69.6 | 1.19 M | 493,292 | 615,529 | −201,586 | 507,666 | 321,993 |

| 6 | Base case | DG Grid | 275 KW | 2.54 | 0.131 | 0 | 0 | 0 | 2.53 M | −3451 | 1,502,474 | 952,763 |

| Component | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Unit |

|---|---|---|---|---|---|---|

| Annualized Utility Bill Saving | 145,696 | 143,017 | 151,427 | 236,760 | 237,389 | USD/year |

| Internal Rate of Return (IRR) | 32.7 | 33.7 | 11.6 | 15.8 | 15.8 | % |

| Payback Period | 3.05 | 2.95 | 7.60 | 5.99 | 5.98 | Year |

| Fuel Consumption | 745 | 742 | 434 | 374 | 375 | (L/year) |

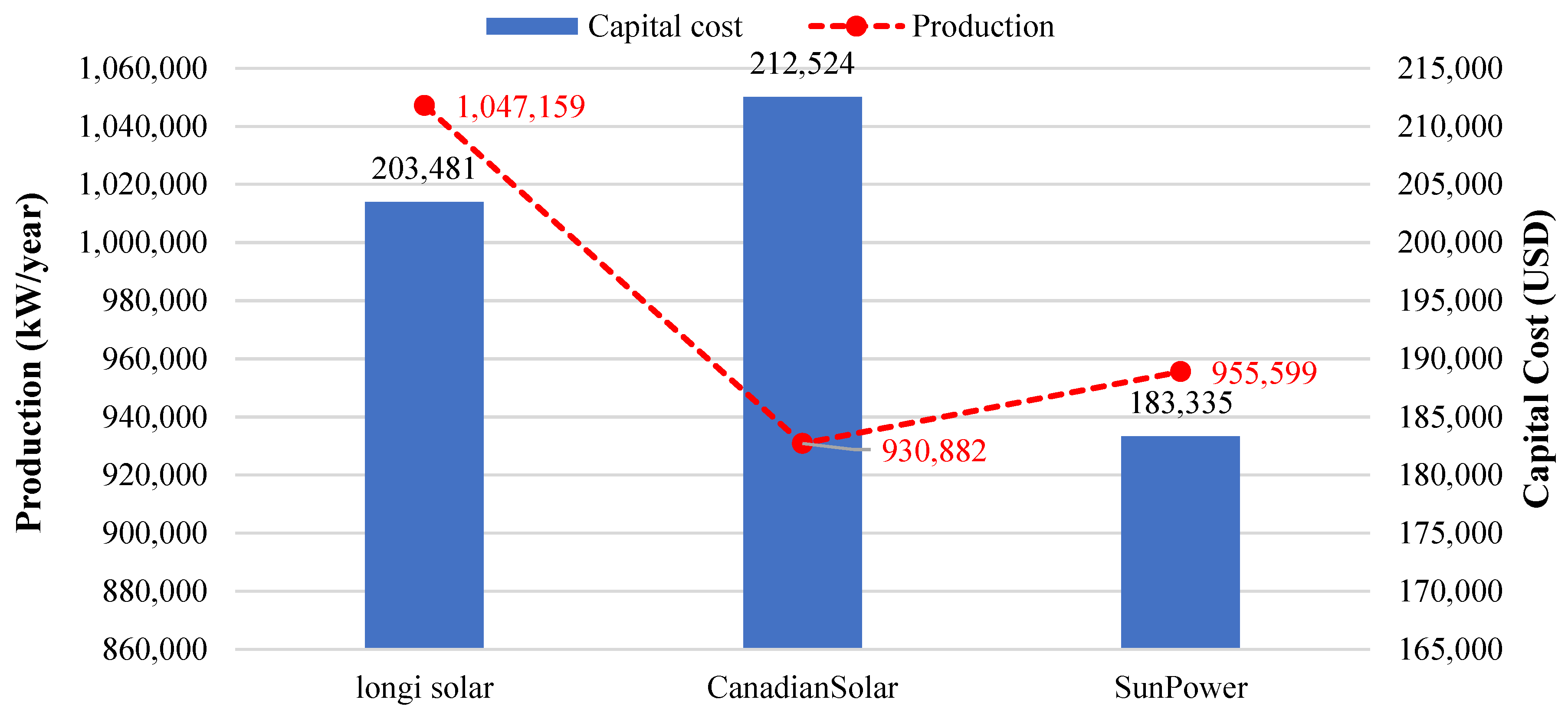

| Parameter | SunPower | CanadianSolar | LongiSolar | Unit |

|---|---|---|---|---|

| Rated power | 0.327 | 0.475 | 0.44 | kW |

| Size | 573 | 518 | 535 | kW |

| Capital cost | 183,335 | 212,524 | 203,481 | USD |

| O&M | 88,877 | 80,412 | 83,068 | USD/year |

| Efficiency | 20.4 | 21 | 21.1 | % |

| Production | 1,047,159 | 930,882 | 955,599 | kWh/year |

| Rank | Configuration | NPC Reduction (%) | COE Reduction (%) | O&M Reduction (%) | Grid Consumption Reduction (%) | GHG Reduction (%) |

|---|---|---|---|---|---|---|

| 1 | Fifth | 54 | 68 | 116 | 76.92 | 77.1 |

| 2 | Fourth | 53 | 68 | 115 | 77.12 | 77.22 |

| 3 | First | 50 | 62 | 68 | 42.62 | 41.45 |

| 4 | Second | 50 | 62 | 67 | 42.41 | 42.32 |

| 5 | Third | 18 | 26 | 75 | 66.23 | 65.93 |

| Parameter | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Unit |

|---|---|---|---|---|---|---|

| Using storage | No | Yes | No | Yes | No | Yes–No |

| Battery size | 0 | 6 | 0 | 2 | 0 | String |

| COE | 0.0488 | 0.0508 | 0.0969 | 0.0419 | 0.0415 | USD/kWh |

| NPC | 1,252,733 | 1,293,578 | 2,097,264 | 1,173,615 | 1,165,217 | USD |

| Battery annual throughput | 0 | 2807 | 0 | 1289 | 0 | kWh/year |

| Hybrid system production | 1,921,655 | 1,797,014 | 1,172,200 | 2,329,636 | 2,348,993 | kWh/year |

| Battery percentage throughput | 0 | 0.15 | 0 | 0.05 | 0 | % |

| Component | Production (kWh/Year) | Percent |

|---|---|---|

| SunPower SPR-E20-327 | 1,047,159 | 38.9 |

| CAT-C9 Prime | 1019 | 0.0378 |

| Eocycle EO10 | 1,300,815 | 48.3 |

| Grid Purchases | 344,156 | 12.8 |

| Total | 2,693,150 | 100 |

| Quantity | During Outage | Unit |

|---|---|---|

| Diesel Generator DG run time | 8.73 | Hours/day |

| Diesel Generator DG O&M cost | 0.0873 | USD/day |

| Diesel Generator DG fuel consumption | 409 | L/day |

| Diesel Generator DG fuel cost | 286 | USD/day |

| Capacity-shortage hours | 0 | Hour |

| Component | Production (kWh/Year) | Percent | Load | kWh/Year | Percent |

|---|---|---|---|---|---|

| SunPower SPR-E20-327 | 1,047,159 | 38.9 | Electrical load | 2,173,742 | 100% |

| CAT-C9 Prime | 1019 | 0.0378 | Electrical excess | 491,576 | 18.3 |

| Eocycle EO10 | 1,300,815 | 48.3 | Unmeted load | 0 | 0 |

| Grid Purchases | 344,156 | 12.8 | Capacity shortage | 0 | 0 |

| Total | 2,693,150 | 100 |

| Name | Capital | Operating | Replacement | Salvage | Resource | Total |

|---|---|---|---|---|---|---|

| CAT-C9 Prime | USD 44,000 | USD 1.03 | USD 0.00 | −USD 10,517 | USD 3,389 | USD 36,873 |

| EDCO | USD 0.00 | −USD 543,826 | USD 0.00 | USD 0.00 | USD 0.00 | −USD 543,826 |

| Eocycle EO10 | USD 1.12 M | USD 51,710 | USD 357,064 | −USD 201,229 | USD 0.00 | USD 1.33 M |

| SunPower SPR-E20-327 | USD 183,335 | USD 88,877 | USD 0.00 | USD 0.00 | USD 0.00 | USD 272,212 |

| System Converter | USD 53,861 | USD 0.00 | USD 22,852 | −USD 4,301 | USD 0.00 | USD 72,412 |

| System | USD 1.40 M | −USD 403,238 | USD 379,916 | −USD 216,047 | USD 3,389 | USD 1.17 M |

| Quantity | Value | Unit |

|---|---|---|

| Carbon Dioxide | 218,497 | kg/year |

| Carbon Monoxide | 0.604 | kg/year |

| Unburned Hydrocarbons | 0.0173 | kg/year |

| Particulate Matter | 0.0570 | kg/year |

| Sulfur Dioxide | 945 | kg/year |

| Nitrogen Oxides | 471 | kg/year |

| Region | HRES Structure | NPC (MUSD) | COE (USD/kWh) | Simulation | Grid Type | Reference |

|---|---|---|---|---|---|---|

| Iran | PV–DG–BIO DG–Converter–Grid | 0.970 | 0.130 | HOMER Pro | On grid | Kasaeian et al. [22] |

| Bangladesh | PV–WT–Converter–Grid | 0.535 | 0.099 | HOMER Pro | On grid | Nurunnabi et al. [34] |

| Thailand | PV–Converter–Grid | N/A | 0.280 | RETscreen | On grid | Peerapong and Limmeechokchai, [35] |

| India | PV–WT–Converter–Grid | 0.613 | 0.269 | HOMER Pro | On grid | Phurailatpam et al. [36] |

| India | PV–WT–Converter–Battery–Grid | 1.12 | 0.225 | HOMER Pro | On grid | Dhundhara et al. [37] |

| India | PV–Converter–Grid | 3.12 | 0.120 | HOMER Pro | On grid | Usman et al. [38] |

| Jordan | PV–WT–Converter–DG–Grid | 1.16 | 0.0415 | HOMER Grid | On grid | Current study 2021 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Rawashdeh, H.; Al-Khashman, O.A.; Al Bdour, J.T.; Gomaa, M.R.; Rezk, H.; Marashli, A.; Arrfou, L.M.; Louzazni, M. Performance Analysis of a Hybrid Renewable-Energy System for Green Buildings to Improve Efficiency and Reduce GHG Emissions with Multiple Scenarios. Sustainability 2023, 15, 7529. https://doi.org/10.3390/su15097529

Al-Rawashdeh H, Al-Khashman OA, Al Bdour JT, Gomaa MR, Rezk H, Marashli A, Arrfou LM, Louzazni M. Performance Analysis of a Hybrid Renewable-Energy System for Green Buildings to Improve Efficiency and Reduce GHG Emissions with Multiple Scenarios. Sustainability. 2023; 15(9):7529. https://doi.org/10.3390/su15097529

Chicago/Turabian StyleAl-Rawashdeh, Hani, Omar Ali Al-Khashman, Jehad T. Al Bdour, Mohamed R. Gomaa, Hegazy Rezk, Abdullah Marashli, Laith M. Arrfou, and Mohamed Louzazni. 2023. "Performance Analysis of a Hybrid Renewable-Energy System for Green Buildings to Improve Efficiency and Reduce GHG Emissions with Multiple Scenarios" Sustainability 15, no. 9: 7529. https://doi.org/10.3390/su15097529

APA StyleAl-Rawashdeh, H., Al-Khashman, O. A., Al Bdour, J. T., Gomaa, M. R., Rezk, H., Marashli, A., Arrfou, L. M., & Louzazni, M. (2023). Performance Analysis of a Hybrid Renewable-Energy System for Green Buildings to Improve Efficiency and Reduce GHG Emissions with Multiple Scenarios. Sustainability, 15(9), 7529. https://doi.org/10.3390/su15097529