Waste Not, Want Not: Sustainable Use of Anti-Stripping-Treated Waste Ceramic in Superpave Asphalt Mixtures

Abstract

:1. Introduction

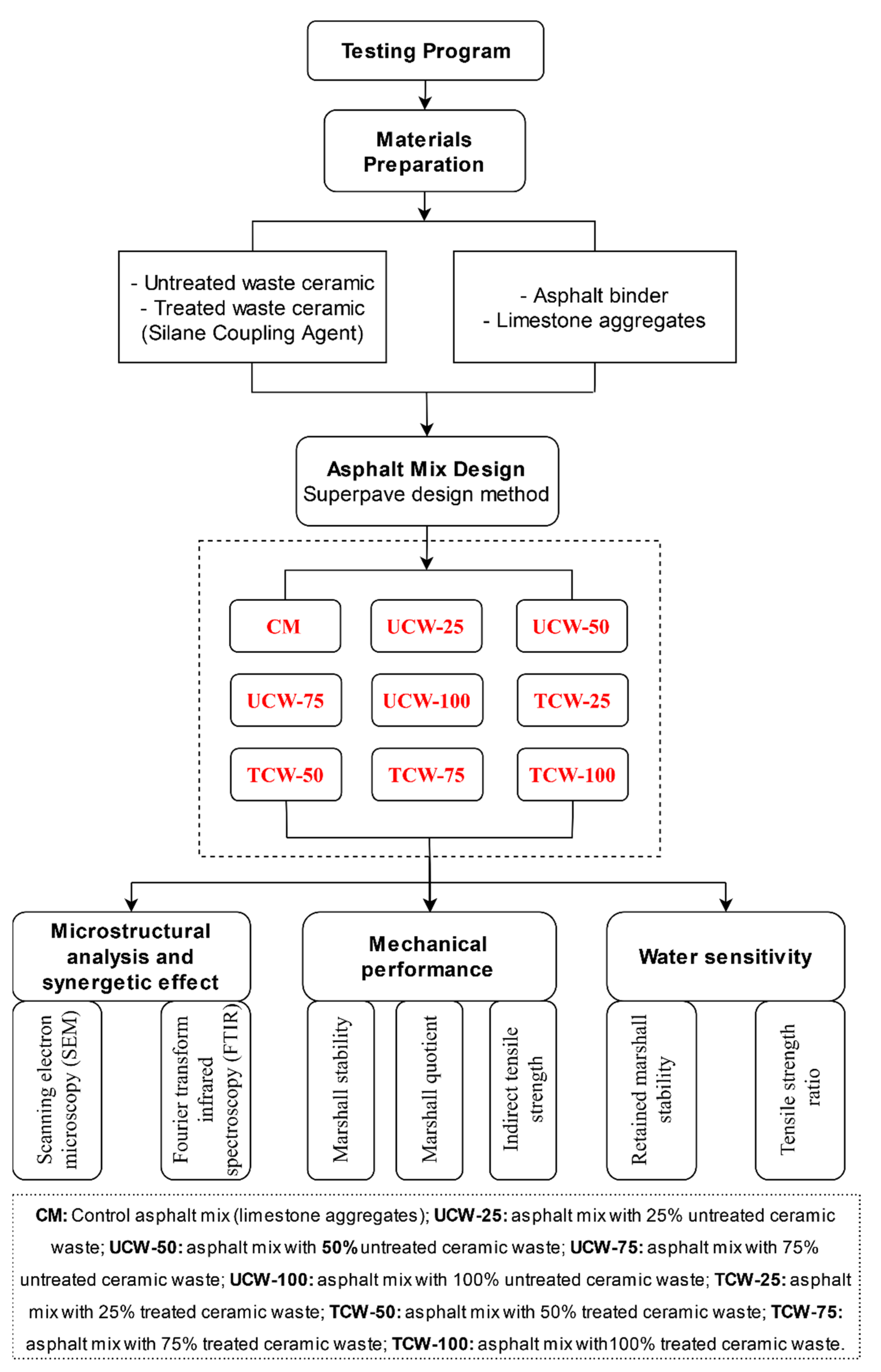

2. Material Characterization and Testing

2.1. Raw Materials

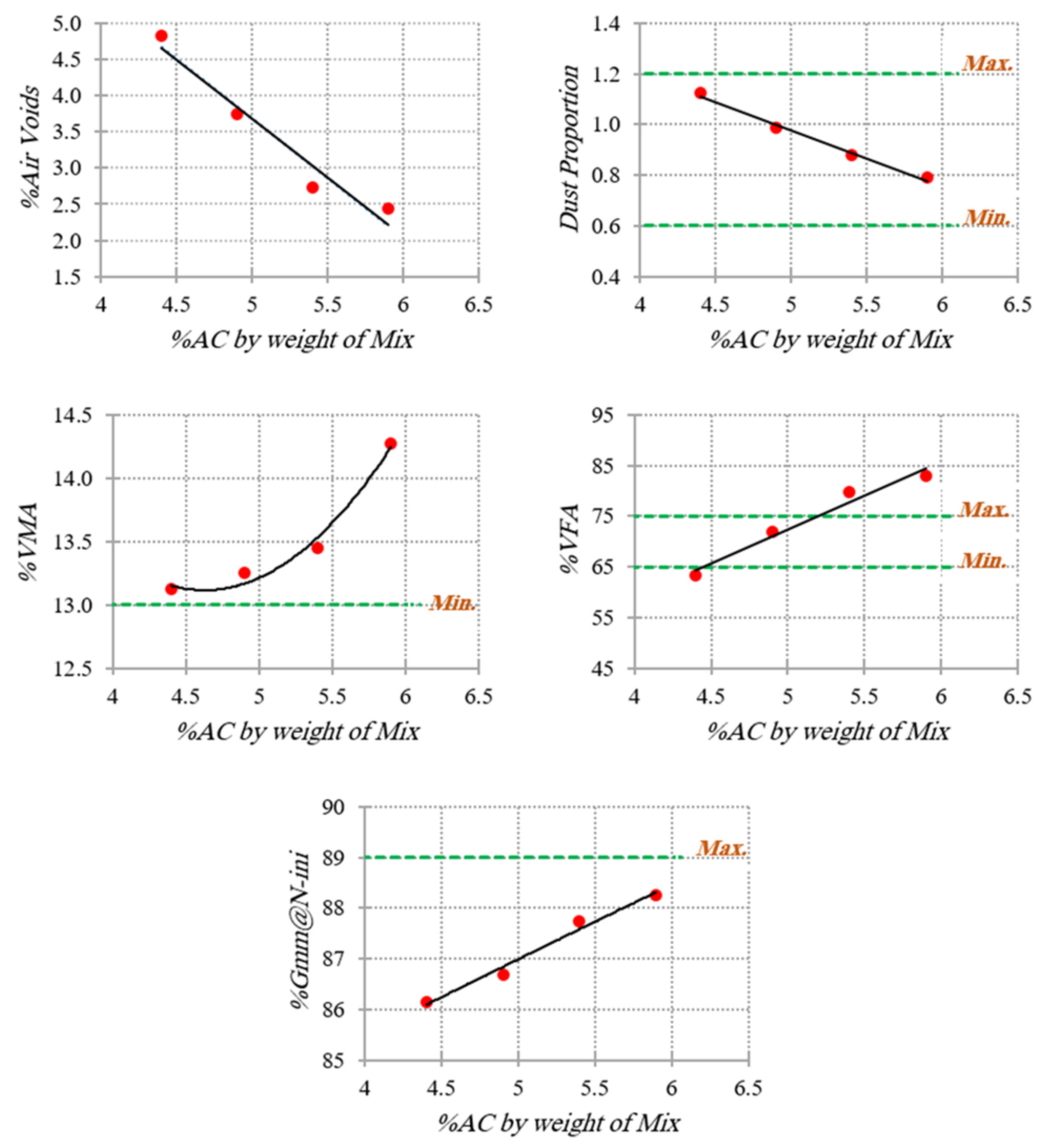

2.2. Asphalt Mix Design

2.3. Specimens and Testing Procedure

3. Results and Discussion

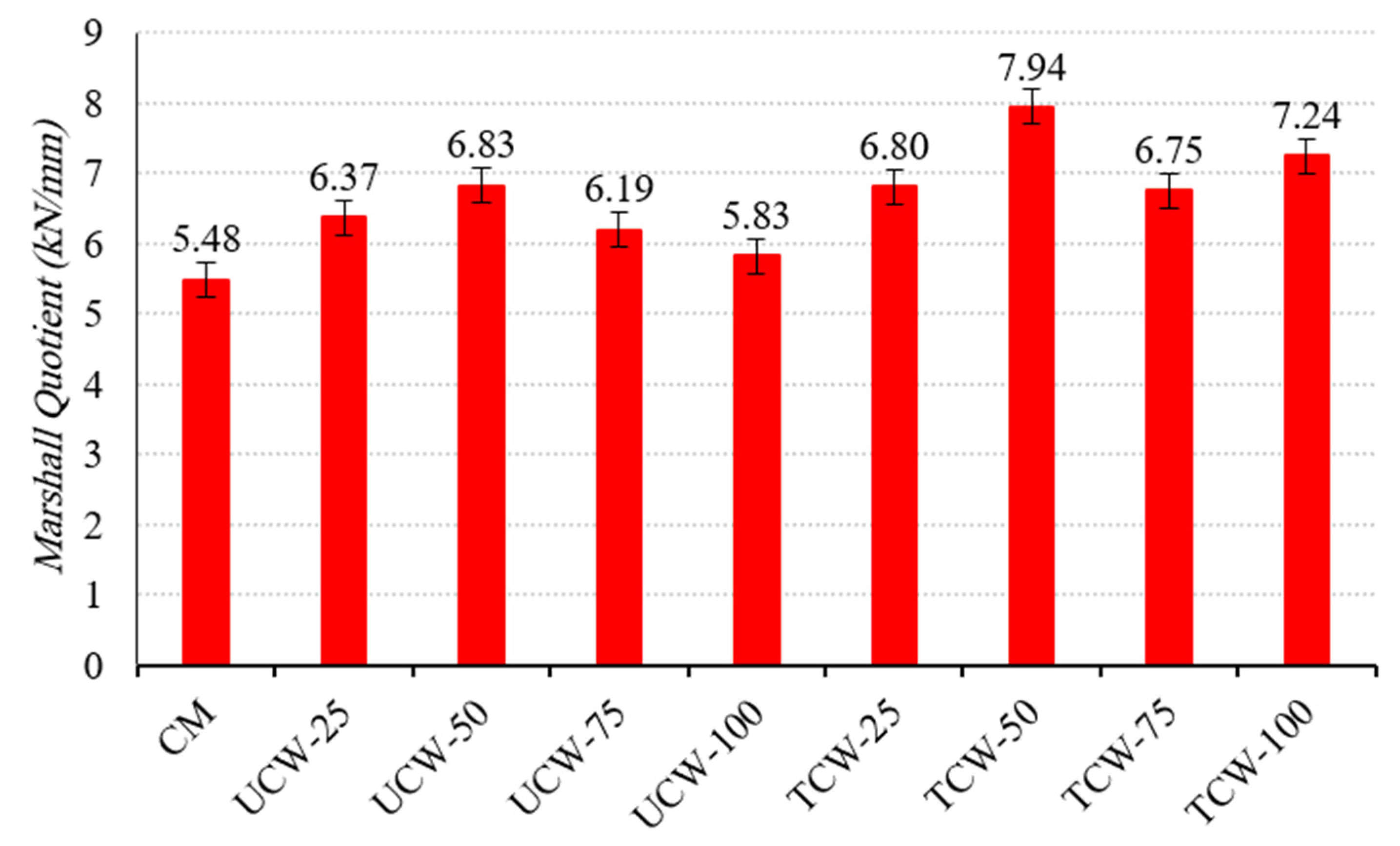

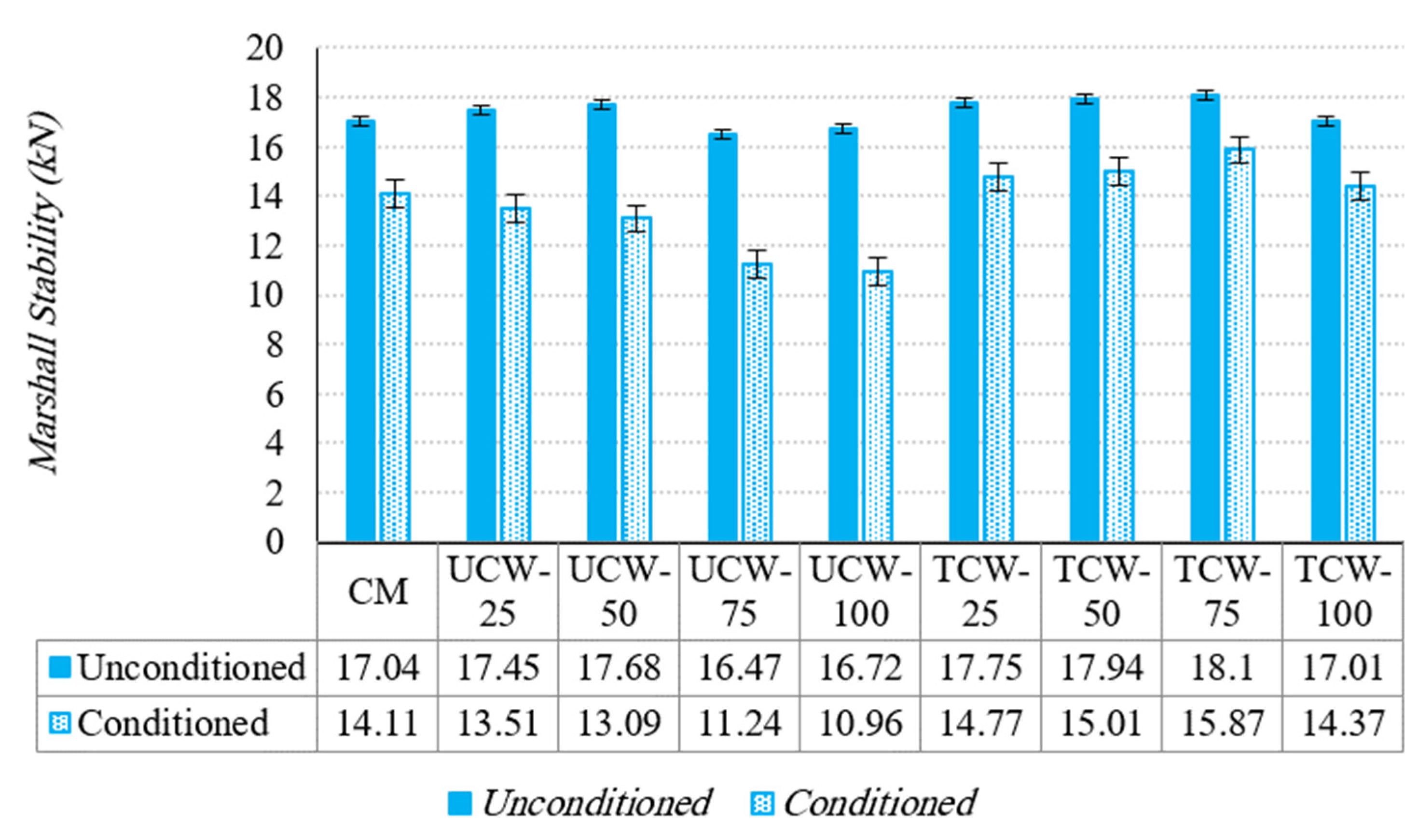

3.1. Marshall Quotient (MQ) and Retained Marshall Stability (RMS)

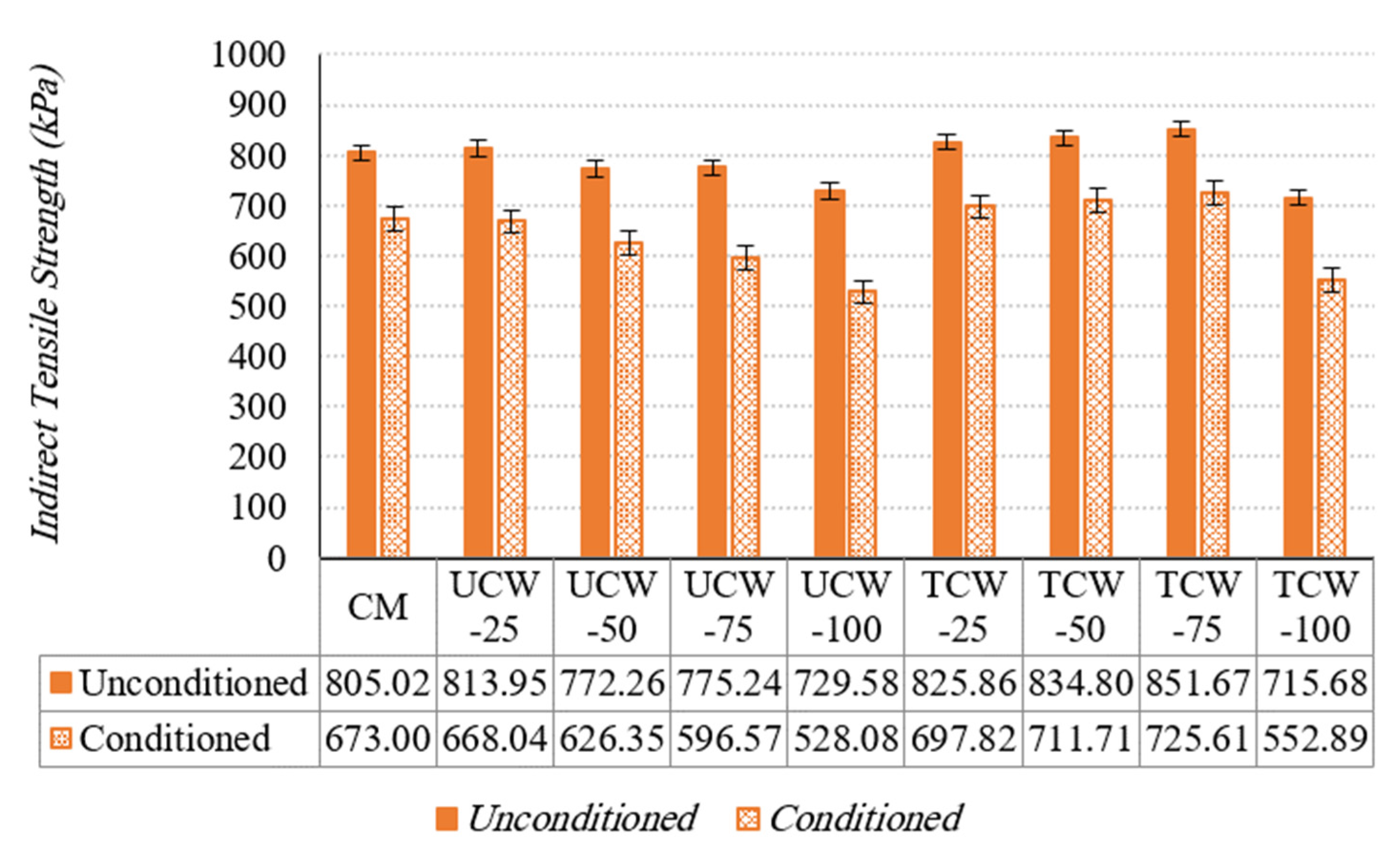

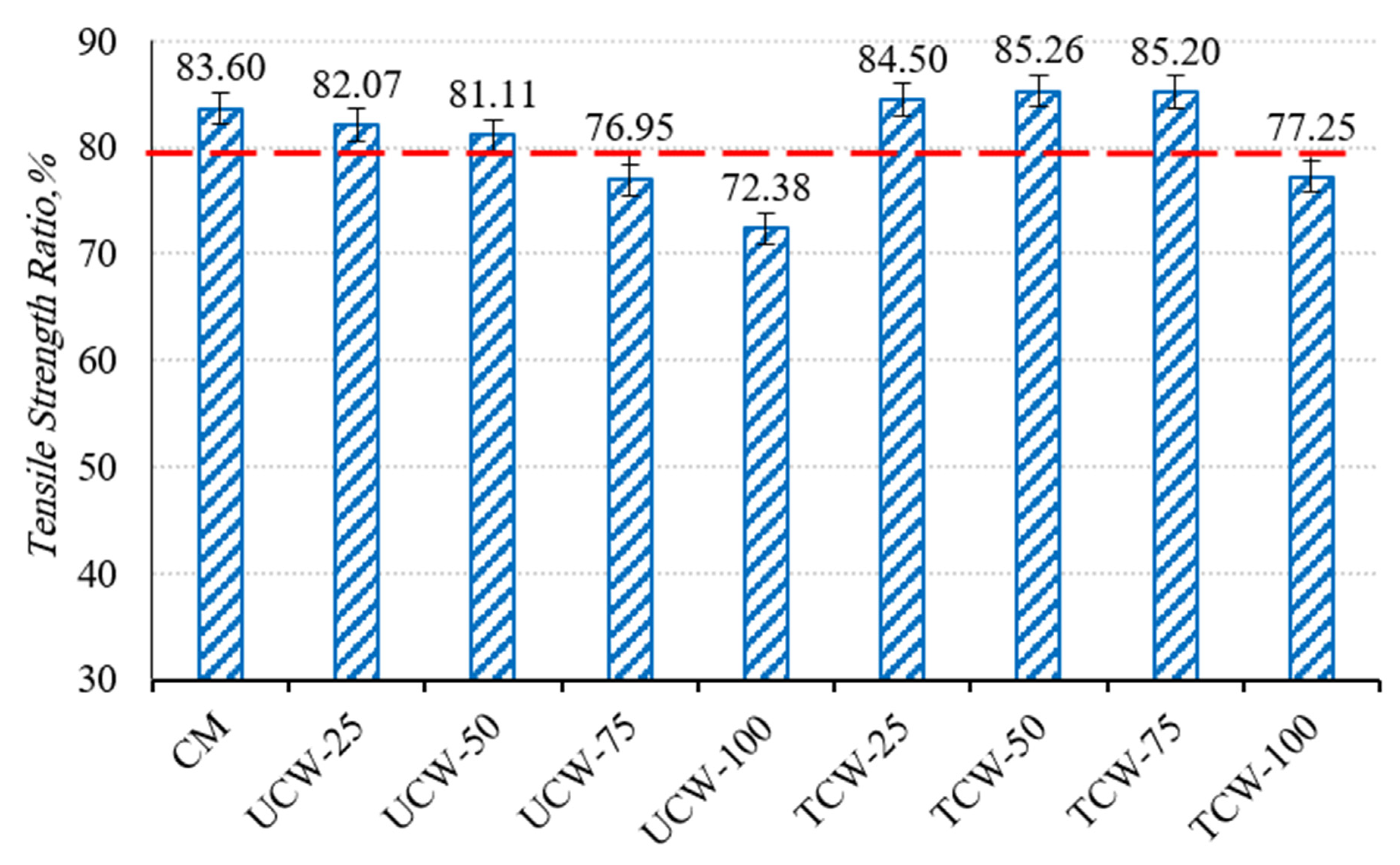

3.2. Indirect Tensile Strength (ITS) and Tensile Strength Ratio (TSR)

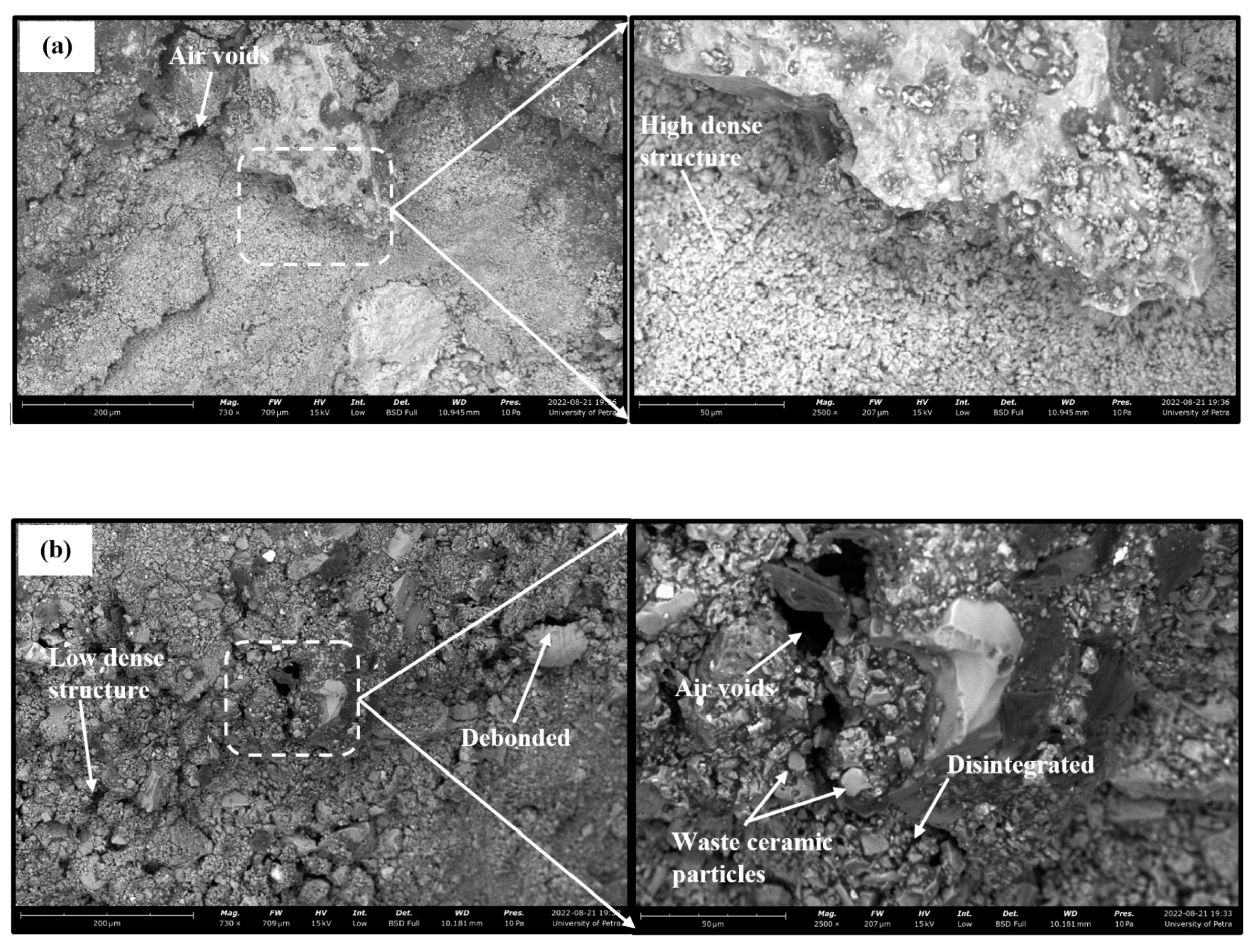

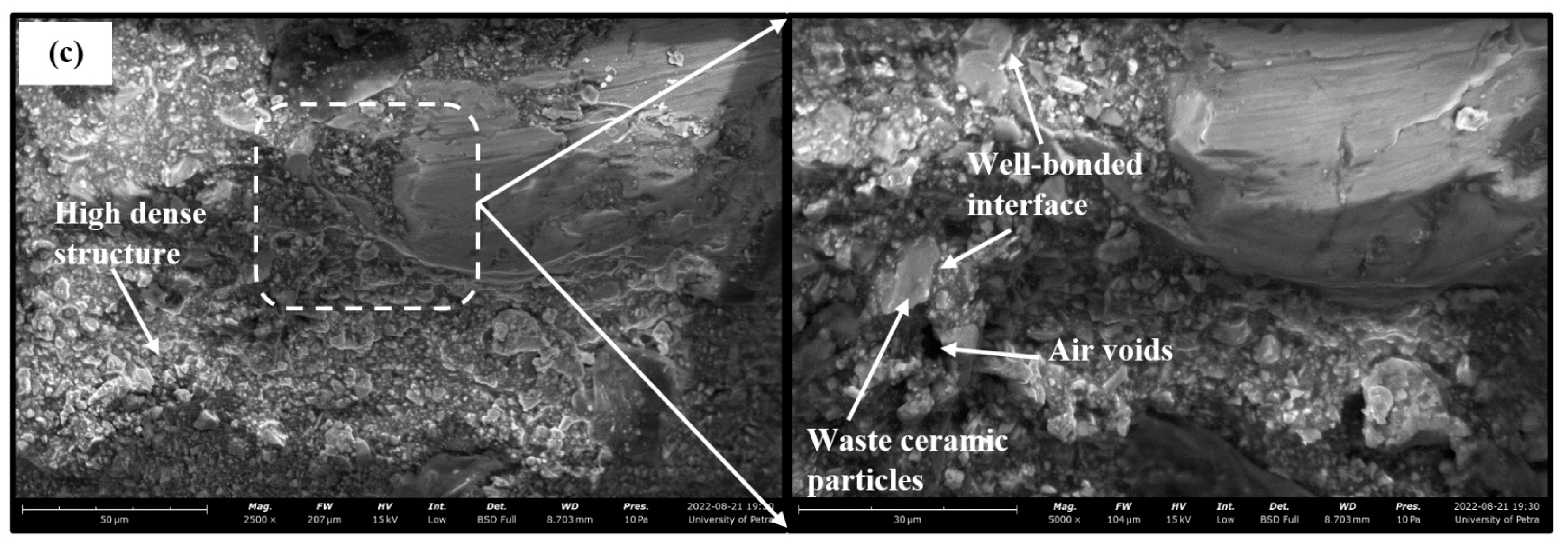

3.3. Morphological Characterization

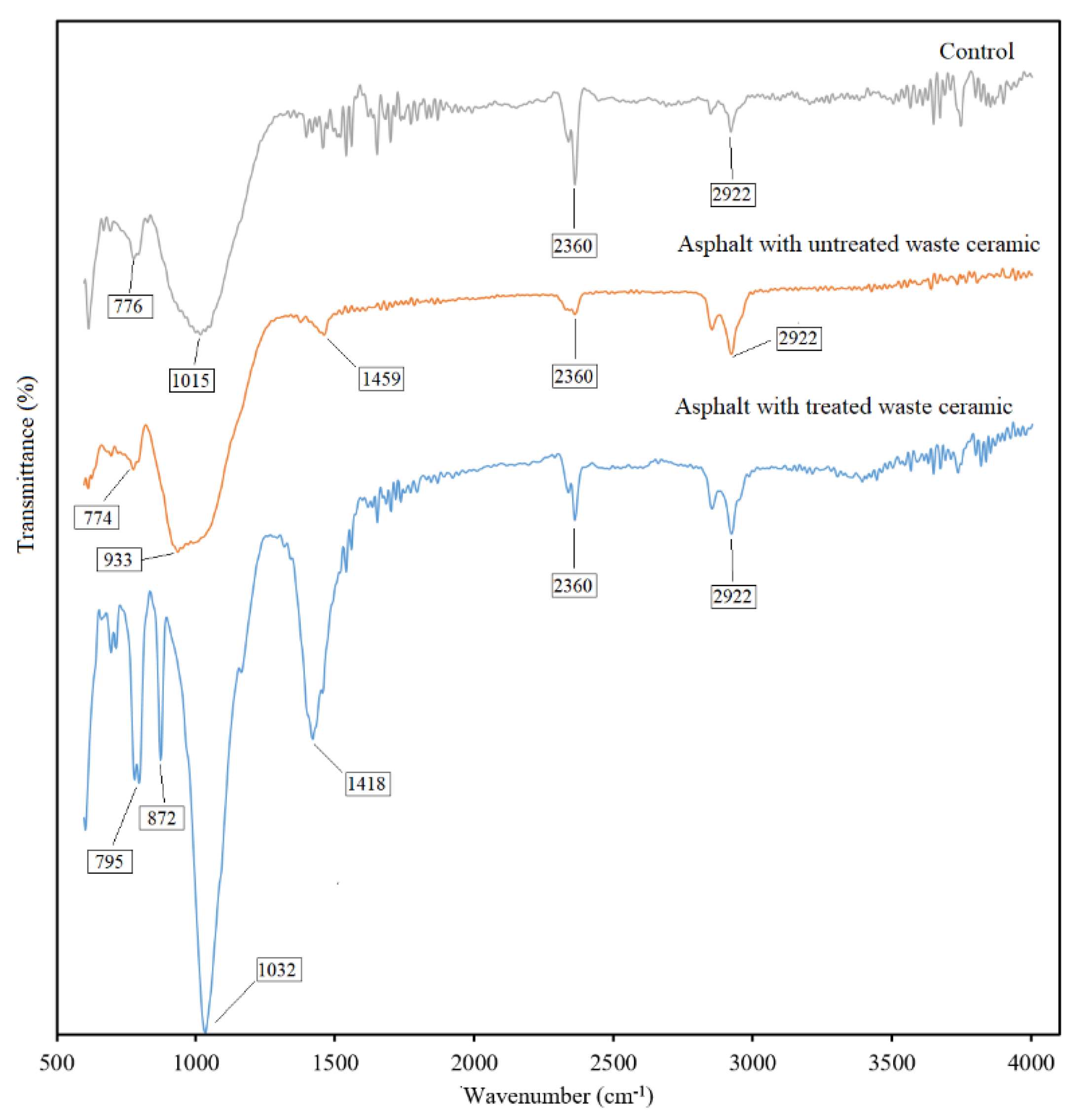

3.4. Chemical Characterization

4. Conclusions

- The MQ values revealed that incorporating waste ceramic aggregates in asphalt mixtures enhances their permanent deformation resistance. The high angularity of ceramic particles contributes to this improvement, with asphalt mixtures with treated ceramics displaying better performance than those with untreated ceramics, particularly for the TCW-50 mix.

- Using silane-treated waste ceramics in asphalt mixtures enhances their performance regarding Marshall stability and indirect tensile strength (for both conditions), with the best performance observed for asphalt mixtures with 75% treated waste ceramic (TCW-75 mix).

- The RMS results recommend using less than 50% untreated waste ceramic aggregates in asphalt mixtures. Nonetheless, all mixtures incorporating silane-treated waste ceramic exhibited better moisture resistance than the other mixtures, with the highest value recorded for the TWC-75 mix, approximately 87.7%.

- The TSR test results confirm that the most suitable replacement percentages for the untreated and silane-treated ceramic aggregates in the Superpave asphalt mixtures are 50% and 75%, respectively.

- In mixtures with untreated ceramic aggregates, inadequate bonding between waste ceramic particles and the binder, coupled with limited asphalt binder coverage, was observed. However, incorporating silane-treated ceramic aggregates into asphalt mixtures resulted in a highly dense structure with few air voids and excellent bonding between ceramic particles and the asphalt binder.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, S.; Kant Sharma, S.; Abdul Akbar, M. Developing Zero Carbon Emission Pavements with Geopolymer Concrete: A Comprehensive Review. Transp. Res. Part D Transp. Environ. 2022, 110, 103436. [Google Scholar] [CrossRef]

- Al-Raqeb, H.; Ghaffar, S.H.; Al-Kheetan, M.J.; Chougan, M. Understanding the Challenges of Construction Demolition Waste Management towards Circular Construction: Kuwait Stakeholder’s Perspective. Clean. Waste Syst. 2023, 4, 100075. [Google Scholar] [CrossRef]

- Tefa, L.; Bianco, I.; Blengini, G.A.; Bassani, M. Integrated and Comparative Structural-LCA Analysis of Unbound and Cement-Stabilized Construction and Demolition Waste Aggregate for Subbase Road Pavement Layers Formation. J. Clean. Prod. 2022, 352, 131599. [Google Scholar] [CrossRef]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular Economy of Construction and Demolition Waste: A Literature Review on Lessons, Challenges, and Benefits. Materials 2021, 15, 76. [Google Scholar] [CrossRef]

- Galán, B.; Viguri, J.R.; Cifrian, E.; Dosal, E.; Andres, A. Influence of Input Streams on the Construction and Demolition Waste (CDW) Recycling Performance of Basic and Advanced Treatment Plants. J. Clean. Prod. 2019, 236, 117523. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, L.; Li, F.; Peng, J. Recycled Aggregates from Construction and Demolition Wastes as Alternative Filling Materials for Highway Subgrades in China. J. Clean. Prod. 2020, 255, 120223. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to Circular Construction: An Integrated Management of Construction and Demolition Waste for Resource Recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Wong, T.L.X.; Mohd Hasan, M.R.; Peng, L.C. Recent Development, Utilization, Treatment and Performance of Solid Wastes Additives in Asphaltic Concrete Worldwide: A Review. J. Traffic Transp. Eng. 2022, 9, 693–724. [Google Scholar] [CrossRef]

- Muniandy, R.; Ismail, D.H.; Hassim, S. Performance of Recycled Ceramic Waste as Aggregates in Asphalt Mixtures. J. Traffic Transp. Eng. 2019, 7, 237–245. [Google Scholar] [CrossRef]

- Ossa, A.; García, J.L.; Botero, E. Use of Recycled Construction and Demolition Waste (CDW) Aggregates: A Sustainable Alternative for the Pavement Construction Industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Hassan, D.I.; Abdulnafaa, M.D. Use of Waste Ceramic Tiles for Road Pavement Subgrade. Road Mater. Pavement Des. 2017, 18, 882–896. [Google Scholar] [CrossRef]

- Silvestre, R.; Medel, E.; García, A.; Navas, J. Using Ceramic Wastes from Tile Industry as a Partial Substitute of Natural Aggregates in Hot Mix Asphalt Binder Courses. Constr. Build. Mater. 2013, 45, 115–122. [Google Scholar] [CrossRef]

- Liu, F.; Pan, B.; Bian, J.; Zhou, C. Experimental Investigation on the Performance of the Asphalt Mixture with Ceramic Fiber. J. Clean. Prod. 2023, 384, 135585. [Google Scholar] [CrossRef]

- Aburkaba, E.; Muniandy, R. Experimental Study of High Temperature Properties and Rheological Behavior of Ceramic Modified Asphalt. Aust. J. Basic Appl. Sci. 2016, 10, 150–161. [Google Scholar]

- Ali, A.M.; Al-Mansoori, T. Investigation of Asphalt Binder Performance Modified with Ceramic Waste Powder. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1090, 012055. [Google Scholar] [CrossRef]

- Feng, D.; Yi, J.; Wang, D. Performance and Thermal Evaluation of Incorporating Waste Ceramic Aggregates in Wearing Layer of Asphalt Pavement. J. Mater. Civ. Eng. 2013, 25, 857–863. [Google Scholar] [CrossRef]

- Caro, S.; Masad, E.; Airey, G.; Bhasin, A.; Little, D. Probabilistic Analysis of Fracture in Asphalt Mixtures Caused by Moisture Damage. Transp. Res. Rec. J. Transp. Res. Board 2008, 2057, 28–36. [Google Scholar] [CrossRef]

- Peng, C.; Chen, P.; You, Z.; Lv, S.; Zhang, R.; Xu, F.; Zhang, H.; Chen, H. Effect of Silane Coupling Agent on Improving the Adhesive Properties between Asphalt Binder and Aggregates. Constr. Build. Mater. 2018, 169, 591–600. [Google Scholar] [CrossRef]

- Ameri, M.; Kouchaki, S.; Roshani, H. Laboratory Evaluation of the Effect of Nano-Organosilane Anti-Stripping Additive on the Moisture Susceptibility of HMA Mixtures under Freeze–Thaw Cycles. Constr. Build. Mater. 2013, 48, 1009–1016. [Google Scholar] [CrossRef]

- Yang, M.; Huang, T.; Lv, S.; Zheng, J. Effect and Mechanism of Acidic Aggregate Surface Silane Modification on Water Stability of Asphalt Mixture. Road Mater. Pavement Des. 2021, 22, 1654–1666. [Google Scholar] [CrossRef]

- Mirzababaei, P.; Moghadas Nejad, F.; Naderi, K. Effect of Liquid Silane-Based Anti-Stripping Additives on Rheological Properties of Asphalt Binder and Hot Mix Asphalt Moisture Sensitivity. Road Mater. Pavement Des. 2020, 21, 570–585. [Google Scholar] [CrossRef]

- Xiong, L.; Gong-xun, W.; Xiao-zhi, J.; Hu Zhi, Z. Investigation of Performance and Modification Mechanism of Ceramic-Polishing-Powder-Modified Asphalt Mastic. Road Mater. Pavement Des. 2022, 24, 919–934. [Google Scholar] [CrossRef]

- Guo, X.; Chen, X.; Li, Y.; Li, Z.; Guo, W. Using Sustainable Oil Shale Waste Powder Treated with Silane Coupling Agent for Enriching the Performance of Asphalt and Asphalt Mixture. Sustainability 2019, 11, 4857. [Google Scholar] [CrossRef]

- Min, Y.; Fang, Y.; Huang, X.; Zhu, Y.; Li, W.; Yuan, J.; Tan, L.; Wang, S.; Wu, Z. Surface Modification of Basalt with Silane Coupling Agent on Asphalt Mixture Moisture Damage. Appl. Surf. Sci. 2015, 346, 497–502. [Google Scholar] [CrossRef]

- Han, X.; Cao, Z.; Wang, R.; He, P.; Zhang, Y.; Yu, J.; Ge, Y. Effect of Silane Coupling Agent Modified Zeolite Warm Mix Additives on Properties of Asphalt. Constr. Build. Mater. 2020, 259, 119713. [Google Scholar] [CrossRef]

- Directorate of Planning and Development. Specifications for Highway and Bridge Construction; Directorate of Planning and Development: Amman, Jordan, 1991; Volume 2.

- ASTM D 946; Standard Specification for Penetration-Graded Asphalt Cement for Use in Pavement Construction. American Society for Testing and Materials: West Conshohocken, PA, USA, 2009.

- ASTM D 6373; Standard Specification for Performance Graded Asphalt Binder. American Society for Testing and Materials: West Conshohocken, PA, USA, 2007.

- Asi, I.M. Performance Evaluation of SUPERPAVE and Marshall Asphalt Mix Designs to Suite Jordan Climatic and Traffic Conditions. Constr. Build. Mater. 2007, 21, 1732–1740. [Google Scholar] [CrossRef]

- Louzi, N. Modification of Hot Asphalt Mixtures in Jordan and Syria by Using Steel Slag. Jordan J. Civ. Eng. 2012, 6, 279–292. [Google Scholar]

- Jweihan, Y.S. Performance of Aged Asphalt Mixes Containing Waste Oil Shale Filler. Int. J. Pavement Res. Technol. 2023; online ahead of print. [Google Scholar] [CrossRef]

- AASHTO R 35; Standard Practice for Superpave Volumetric Design for Asphalt Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T 283; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Al-Kheetan, M.J.; Byzyka, J.; Ghaffar, S.H. Sustainable Valorisation of Silane-Treated Waste Glass Powder in Concrete Pavement. Sustainability 2021, 13, 4949. [Google Scholar] [CrossRef]

- AASHTO R 30; Standard Practice for Laboratory Conditioning of Asphalt Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T 312; Standard Method of Test for Preparing and Determining the Density of Asphalt Mixture Specimens by Means of the Superpave Gyratory Compactor. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- ASTM D6927-15; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- Kok, B.V.; Yilmaz, M. The Effects of Using Lime and Styrene–Butadiene–Styrene on Moisture Sensitivity Resistance of Hot Mix Asphalt. Constr. Build. Mater. 2009, 23, 1999–2006. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, F.; Jiang, Y.; Xie, Q. Influence of Water Saturated State on Moisture Susceptibility of Asphalt Mixture. In Proceedings of the Performance Modeling and Evaluation of Pavement Systems and Materials, American Society of Civil Engineers, Reston, VA, USA, 13 July 2009; pp. 109–114. [Google Scholar]

- Aksoy, A.; Şamlioglu, K.; Tayfur, S.; Özen, H. Effects of Various Additives on the Moisture Damage Sensitivity of Asphalt Mixtures. Constr. Build. Mater. 2005, 19, 11–18. [Google Scholar] [CrossRef]

- Cominsky, R.J.; Huber, G.A.; Kennedy, T.W.; Anderson, M. The Superpave Mix Design Manual for New Construction and Overlays; Strategic Highway Research Program: Washington, DC, USA, 1994.

- Pérez, I.; Pasandín, A.R.; Medina, L. Hot Mix Asphalt Using C&D Waste as Coarse Aggregates. Mater. Des. 2012, 36, 840–846. [Google Scholar] [CrossRef]

- Apeagyei, A.K.; Grenfell, J.R.A.; Airey, G.D. Influence of Aggregate Absorption and Diffusion Properties on Moisture Damage in Asphalt Mixtures. Road Mater. Pavement Des. 2015, 16, 404–422. [Google Scholar] [CrossRef]

- Zhang, J.; Airey, G.D.; Grenfell, J.; Apeagyei, A.K. Moisture Damage Evaluation of Aggregate–Bitumen Bonds with the Respect of Moisture Absorption, Tensile Strength and Failure Surface. Road Mater. Pavement Des. 2017, 18, 833–848. [Google Scholar] [CrossRef]

- Plueddemann, E.P. Chemistry of Silane Coupling Agents. In Silane Coupling Agents; Plueddemann, E.P., Ed.; Springer: Boston, MA, USA, 1991; pp. 31–54. [Google Scholar]

- Liang, X.; Guo, X.D.; Wang, H.; Yu, X.S. The Effect and Characterization of Modified Asphalt by Coupling Agent. Appl. Mech. Mater. 2011, 105–107, 1773–1778. [Google Scholar] [CrossRef]

- Yu, R.; Zhu, X.; Zhang, M.; Fang, C. Investigation on the Short-Term Aging-Resistance of Thermoplastic Polyurethane-Modified Asphalt Binders. Polymers 2018, 10, 1189. [Google Scholar] [CrossRef]

- Ren, R.; Fan, W.; Zhao, P.; Zhou, H.; Meng, W.; Ji, P. Crude Oil Source Identification of Asphalt via ATR-FTIR Approach Combined with Multivariate Statistical Analysis. Adv. Mater. Sci. Eng. 2020, 2020, 1–13. [Google Scholar] [CrossRef]

- Dolomatov, M.; Gafurov, M.; Rodionov, A.; Mamin, G.; González, L.M.; Vakhin, A.; Petrov, A.; Bakhtizin, R.; Khairudinov, I.; Orlinskii, S. Low-Temperature Thermal Decomposition of Heavy Petroleum Distillates: Interconnection between the Electrical Properties and Concentration of Paramagnetic Centres. IOP Conf. Ser. Earth Environ. Sci. 2018, 155, 012007. [Google Scholar] [CrossRef]

- Van der Weerd, J.; van Loon, A.; Boon, J.J. FTIR Studies of the Effects of Pigments on the Aging of Oil. Stud. Conserv. 2005, 50, 3–22. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Peng, J. Silane Modification of Crumb Rubber on the Rheological Properties of Rubberized Asphalt. Appl. Sci. 2019, 9, 4831. [Google Scholar] [CrossRef]

- Rathore, M.; Haritonovs, V.; Merijs Meri, R.; Zaumanis, M. Rheological and Chemical Evaluation of Aging in 100% Reclaimed Asphalt Mixtures Containing Rejuvenators. Constr. Build. Mater. 2022, 318, 126026. [Google Scholar] [CrossRef]

- Omar, H.A.; Katman, H.Y.; Bilema, M.; Ahmed, M.K.A.; Milad, A.; Md Yusoff, N.I. The Effect of Ageing on Chemical and Strength Characteristics of Nanoclay-Modified Bitumen and Asphalt Mixture. Appl. Sci. 2021, 11, 6709. [Google Scholar] [CrossRef]

- Ma, L.; Varveri, A.; Jing, R.; Erkens, S. Chemical Characterisation of Bitumen Type and Ageing State Based on FTIR Spectroscopy and Discriminant Analysis Integrated with Variable Selection Methods. Road Mater. Pavement Des. 2023, 1–15. [Google Scholar] [CrossRef]

- Anbalagan, G.; Prabakaran, A.R.; Gunasekaran, S. Spectroscopic Characterization of Indian Standard Sand. J. Appl. Spectrosc. 2010, 77, 86–94. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.; Chen, W.; Li, Y.; Sun, M.; Dai, W. Laboratory Assessment of Deteriorating Performance of Nano Hydrophobic Silane Silica Modified Asphalt in Spring-Thaw Season. Appl. Sci. 2019, 9, 2305. [Google Scholar] [CrossRef]

| Property | Result | Criterion |

|---|---|---|

| Bulk specific gravity of coarse aggregates | 2.635 | na |

| Bulk specific gravity of fine aggregates | 2.557 | na |

| Bulk specific gravity of ceramic | 2.501 | na |

| Coarse aggregates’ absorption (%) | 1.9% | na |

| Fine aggregates’ absorption (%) | 2.7% | na |

| Ceramic absorption (%) | 4.9% | na |

| Coarse aggregates’ abrasion loss (500 revolutions),% | 27.2% | ≤35% |

| Coarse aggregates’ ratio of wear loss (100/500)% | 22.3% | ≤25% |

| Angularity of coarse aggregates (%) | 100% | 100% |

| Angularity of fine aggregates (%) | 67% | ≥45% |

| Sand equivalent | 62 | ≥45 |

| Coarse aggregates’ flat/elongated particles | 0.6% | ≤10% |

| Coarse aggregates’ soundness by sodium sulfate (%) | 1.4% | ≤9% |

| Property | Result | ASTM D946 Requirements for 60/70 Penetration Asphalt | ASTM D6373 Criterion | |

|---|---|---|---|---|

| Min. | Max. | |||

| Penetration (0.1 mm) | 66.5 | 60 | 70 | na |

| Specific gravity at 25 °C | 1.02 | 1.01 | 1.06 | na |

| Flash point (°C) | 310 | 232 | na | 230 °C min. |

| Ductility at 25 °C, cm | 120 | 100 | na | na |

| Softening point (°C) | 50 | 48 | 56 | na |

| Heating loss (%) | 0.3 | na | 0.8 | 0.8 max. |

| Penetration of residue, % of original | 64.3 | 54 | na | na |

| Rotational viscosity at 135 °C, Pa.s | 0.468 | na | na | 3.0 Pa.s max. |

| Rotational viscosity at 165 °C, Pa.s | 0.142 | na | na | na |

| Blend | Estimated AC% | VMA% | Criterion | VFA% | Criterion | %Gmm@Nini | Criterion | D.P | Criterion |

|---|---|---|---|---|---|---|---|---|---|

| A | 4.4 | 12.02 | 13 min. | 66.72 | 65–75 | 86.03 | ≤89.0 | 1.43 | 0.6–1.2 |

| B | 4.9 | 13.43 | 13 min. | 70.21 | 65–75 | 87.49 | ≤89.0 | 1.03 | 0.6–1.2 |

| C | 5.0 | 13.05 | 13 min. | 69.35 | 65–75 | 86.70 | ≤89.0 | 1.09 | 0.6–1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Kheetan, M.J. Waste Not, Want Not: Sustainable Use of Anti-Stripping-Treated Waste Ceramic in Superpave Asphalt Mixtures. Sustainability 2023, 15, 7579. https://doi.org/10.3390/su15097579

Al-Kheetan MJ. Waste Not, Want Not: Sustainable Use of Anti-Stripping-Treated Waste Ceramic in Superpave Asphalt Mixtures. Sustainability. 2023; 15(9):7579. https://doi.org/10.3390/su15097579

Chicago/Turabian StyleAl-Kheetan, Mazen J. 2023. "Waste Not, Want Not: Sustainable Use of Anti-Stripping-Treated Waste Ceramic in Superpave Asphalt Mixtures" Sustainability 15, no. 9: 7579. https://doi.org/10.3390/su15097579

APA StyleAl-Kheetan, M. J. (2023). Waste Not, Want Not: Sustainable Use of Anti-Stripping-Treated Waste Ceramic in Superpave Asphalt Mixtures. Sustainability, 15(9), 7579. https://doi.org/10.3390/su15097579