Predictive and Prescriptive Analytics in Identifying Opportunities for Improving Sustainable Manufacturing

Abstract

1. Introduction

2. Literature Review

2.1. Sustainable Manufacturing

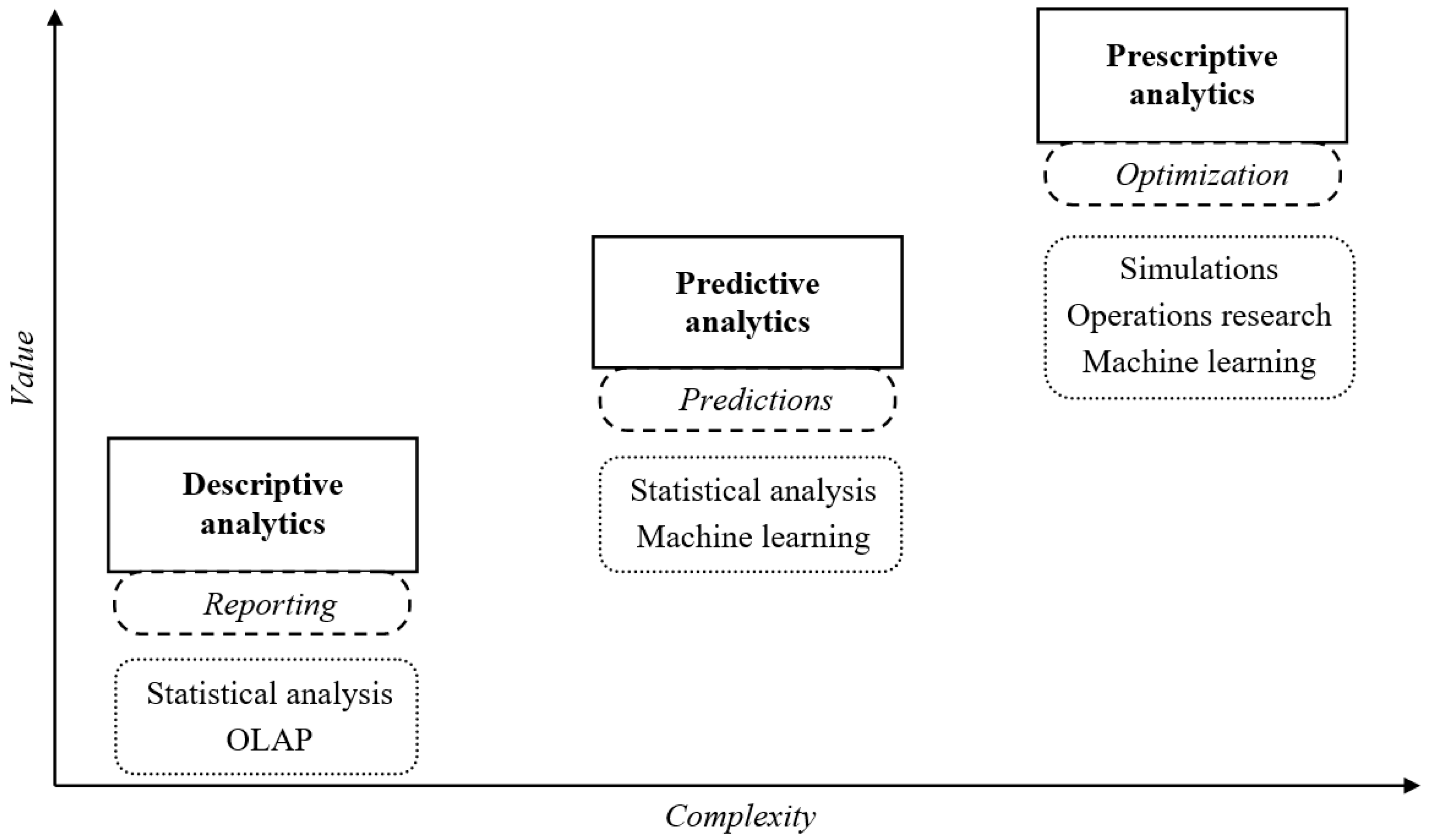

2.2. Data-Driven Approaches and Business Analytics

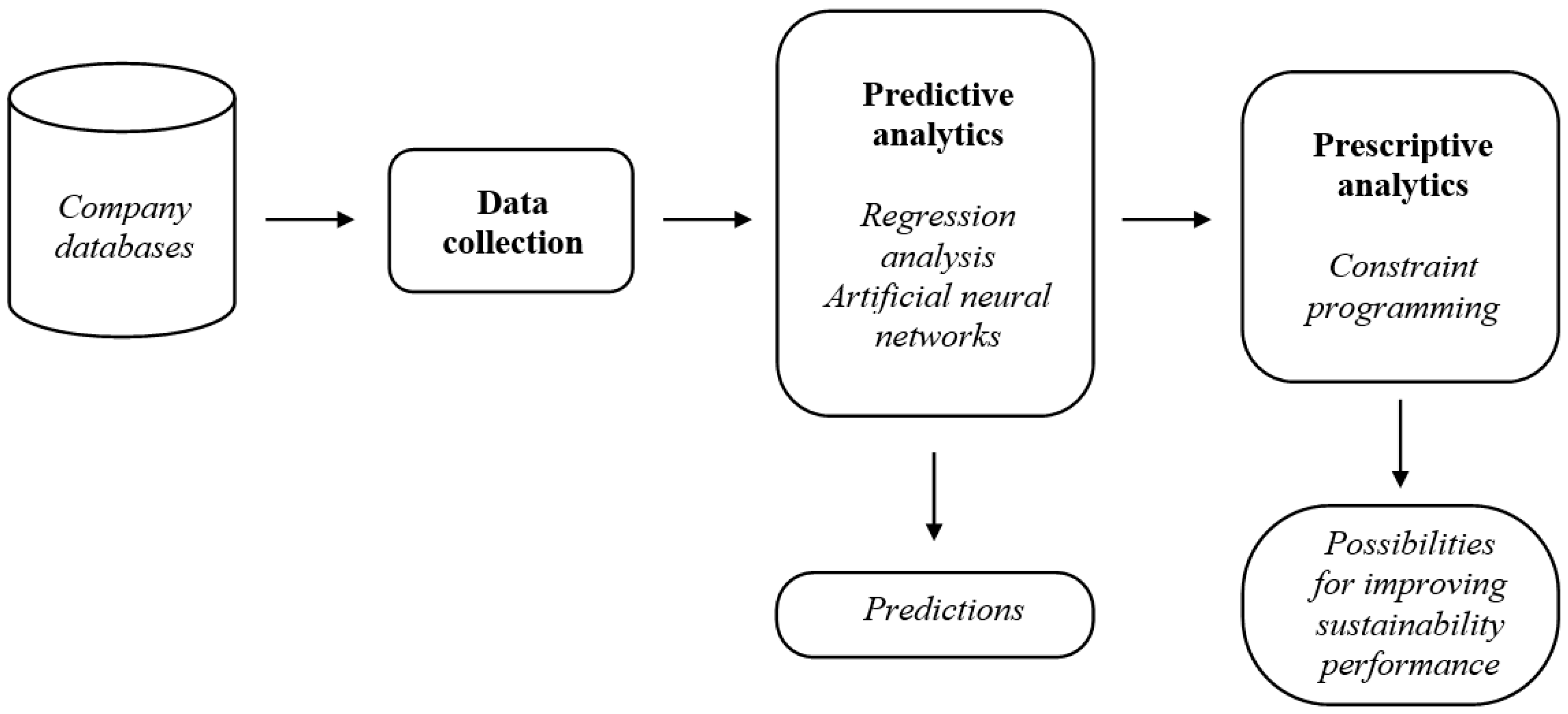

3. A Method for Supporting Sustainable Manufacturing

3.1. Data Collection

3.2. Predictive Analytics

3.3. Prescriptive Analytics

- What is the number of defective products predicted during the production process?

- Is there a possibility for incorporating changes during the design process to increase sustainability performance, and if so, what changes are admissible?

4. An Example of Applying the Proposed Method

4.1. Model Specification

- V1—the total time of material processing (in minutes);

- V2—the size of components for material processing (in cm3);

- V3—the material density (in g/cm3);

- V4—the number of defective products;

- V5—the unit cost related to defective products (in EUR);

- V6—the unit production cost (in EUR);

- V7—the material cost per product (in EUR);

- V8—the labor cost per product (in EUR);

- V9—the energy cost per product (in EUR);

- V10—the overhead cost per product (in EUR).

4.2. Predictive Analytics

4.3. Prescriptive Analytics

5. Discussion

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davenport, T.; Harris, J. Competing on Analytics: Updated, with a New Introduction: The New Science of Winning; Harvard Business Press: Brighton, MA, USA, 2017. [Google Scholar]

- Kristoffersen, E.; Blomsma, F.; Mikalef, P.; Li, J. The smart circular economy: A digital-enabled circular strategies framework for manufacturing companies. J. Bus. Res. 2020, 120, 241–261. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Pigosso, D.C.; McAloone, T.C. The emergent role of digital technologies in the circular economy: A review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How smart, connected products are transforming competition. Harv. Bus. Rev. 2014, 92, 64–88. [Google Scholar]

- Romero, D.; Noran, O. Towards green sensing virtual enterprises: Interconnected sensing enterprises, intelligent assets and smart products in the cyber-physical circular economy. IFAC PapersOnLine 2017, 50, 11719–11724. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, Y.; Xiao, Y.; Chen, X.; Zeng, H. The optimization of reverse logistics cost based on value flow analysis–a case study on automobile recycling company in China. J. Intell. Fuzzy Syst. 2018, 34, 807–818. [Google Scholar] [CrossRef]

- Molka-Danielsen, J.; Engelseth, P.; Wang, H. Large scale integration of wireless sensor network technologies for air quality monitoring at a logistics shipping base. J. Ind. Inf. Integr. 2018, 10, 20–28. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Wang, K.S. Intelligent predictive maintenance for fault diagnosis and prognosis in machine centers: Industry 4.0 scenario. Adv. Manuf. 2017, 5, 377–387. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, Q.; Wei, F.; Rao, W.; Liu, J.; Hu, J.; Cai, W. A review on remanufacturing assembly management and technology. Int. J. Adv. Manuf. Technol. 2019, 105, 4797–4808. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring how usage-focused business models enable circular economy through digital technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Yang, S.; Araving Raghavendra, M.R.; Kaminski, J.; Pepin, H. Opportunities for industry 4.0 to support remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Lin, K.P.; Yu, C.M.; Chen, K.S. Production data analysis system using novel process capability indices-based circular economy. Ind. Manag. Data Syst. 2019, 119, 1655–1668. [Google Scholar] [CrossRef]

- Lieder, M.; Asif, F.M.; Rashid, A. A choice behavior experiment with circular business models using machine learning and simulation modeling. J. Clean. Prod. 2020, 258, 120894. [Google Scholar] [CrossRef]

- Charnley, F.; Tiwari, D.; Hutabarat, W.; Moreno, M.; Okorie, O.; Tiwari, A. Simulation to enable a data-driven circular economy. Sustainability 2019, 11, 3379. [Google Scholar] [CrossRef]

- Gbededo, M.A.; Liyanage, K.; Garza-Reyes, J.A. Towards a life cycle sustainability analysis: A systematic review of approaches to sustainable manufacturing. J. Clean. Prod. 2018, 184, 1002–1015. [Google Scholar] [CrossRef]

- Li, M.; Lou, S.; Gao, Y.; Zheng, H.; Hu, B.; Tan, J. A cerebellar operant conditioning-inspired constraint satisfaction approach for product design concept generation. Int. J. Prod. Res. 2022, 1–20. [Google Scholar] [CrossRef]

- Relich, M. Computational intelligence for estimating cost of new product development. Found. Manag. 2016, 8, 21–34. [Google Scholar] [CrossRef]

- Wang, J.; Li, R.; Ding, G.; Qin, S.; Cai, Z. Product-service system engineering characteristics design for life cycle cost based on constraint satisfaction problem and Bayesian network. Adv. Eng. Inform. 2022, 52, 101573. [Google Scholar] [CrossRef]

- Lahri, V.; Shaw, K.; Ishizaka, A. Sustainable supply chain network design problem: Using the integrated BWM, TOPSIS, possibilistic programming, and ε-constrained methods. Expert Syst. Appl. 2021, 168, 114373. [Google Scholar] [CrossRef]

- Shahparvari, S.; Soleimani, H.; Govindan, K.; Bodaghi, B.; Fard, M.T.; Jafari, H. Closing the loop: Redesigning sustainable reverse logistics network in uncertain supply chains. Comput. Ind. Eng. 2021, 157, 107093. [Google Scholar] [CrossRef]

- Sartal, A.; Bellas, R.; Mejías, A.M.; García-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020, 12, 1687814020925232. [Google Scholar] [CrossRef]

- Andersen, A.L.; Brunoe, T.D.; Bockholt, M.T.; Napoleone, A.; Kristensen, J.H.; Colli, M.; Nielsen, K. Changeable closed-loop manufacturing systems: Challenges in product take-back and evaluation of reconfigurable solutions. Int. J. Prod. Res. 2023, 61, 839–858. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Zarte, M.; Pechmann, A.; Nunes, I.L. Decision support systems for sustainable manufacturing surrounding the product and production life cycle: A literature review. J. Clean. Prod. 2019, 219, 336–349. [Google Scholar] [CrossRef]

- Hapuwatte, B.M.; Jawahir, I.S. Closed-loop sustainable product design for circular economy. J. Ind. Ecol. 2021, 25, 1430–1446. [Google Scholar] [CrossRef]

- Agrawal, R.; Wankhede, V.A.; Kumar, A.; Upadhyay, A.; Garza-Reyes, J.A. Nexus of circular economy and sustainable business performance in the era of digitalization. Int. J. Product. Perform. Manag. 2022, 71, 748–774. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2022, 30, 864–898. [Google Scholar] [CrossRef]

- Diego-Mas, J.A.; Poveda-Bautista, R.; Alcaide-Marzal, J. Designing the appearance of environmentally sustainable products. J. Clean. Prod. 2016, 135, 784–793. [Google Scholar] [CrossRef]

- Rau, H.; Lagapa, M.D.; Chen, P.H. Anticipatory non-green-phenomena determination for designing eco-design products. Sustainability 2021, 13, 621. [Google Scholar] [CrossRef]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A big data-driven framework for sustainable and smart additive manufacturing. Robot. Comput. Integr. Manuf. 2021, 67, 102026. [Google Scholar] [CrossRef]

- Ma, S.; Ding, W.; Liu, Y.; Ren, S.; Yang, H. Digital twin and big data-driven sustainable smart manufacturing based on information management systems for energy-intensive industries. Appl. Energy 2022, 326, 119986. [Google Scholar] [CrossRef]

- Tsai, F.M.; Bui, T.D.; Tseng, M.L.; Ali, M.H.; Lim, M.K.; Chiu, A.S. Sustainable supply chain management trends in world regions: A data-driven analysis. Resour. Conserv. Recycl. 2021, 167, 105421. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Saad, E. Design for sustainable manufacturing: Approach, implementation, and assessment. Sustainability 2018, 10, 3604. [Google Scholar] [CrossRef]

- Furxhi, I.; Perucca, M.; Blosi, M.; Lopez de Ipiña, J.; Oliveira, J.; Murphy, F.; Costa, A.L. ASINA Project: Towards a Methodological Data-Driven Sustainable and Safe-by-Design Approach for the Development of Nanomaterials. Front. Bioeng. Biotechnol. 2022, 9, 1456. [Google Scholar] [CrossRef]

- Sun, H.; Guo, W.; Wang, L.; Lin, M. A data-driven adaptive design for achieving sustainable product. Procedia CIRP 2022, 109, 316–321. [Google Scholar] [CrossRef]

- Nigro, M.; Ferrara, M.; De Vincentis, R.; Liberto, C.; Valenti, G. Data driven approaches for sustainable development of E-mobility in urban areas. Energies 2021, 14, 3949. [Google Scholar] [CrossRef]

- Ocampo, L.A.; Vergara, V.G.; Impas, C.; Tordillo, J.A.; Pastoril, J. Identifying critical indicators in sustainable manufacturing using analytic hierarchy process (AHP). J. Manuf. Ind. Eng. 2015, 14, 1–8. [Google Scholar] [CrossRef]

- Askary, Z.; Singh, A.; Gupta, S.; Shukla, R.K.; Jaiswal, P. Development of AHP Framework of Sustainable Product Design and Manufacturing of Electric Vehicle. In Advances in Engineering Design. Lecture Notes in Mechanical Engineering; Prasad, A., Gupta, S., Tyagi, R., Eds.; Springer: Singapore, 2019; pp. 415–422. [Google Scholar]

- Deshmukh, R.A.; Hiremath, R. Analyzing the Key Performance Indicators of Advanced Sustainable Manufacturing System Using AHP Approach. In Techno-Societal 2018; Pawar, P., Ronge, B., Balasubramaniam, R., Vibhute, A., Apte, S., Eds.; Springer: Cham, Switzerland, 2020; pp. 745–750. [Google Scholar]

- Saraf, C.; Agrawal, S.; Barodiya, D.; Shrivastava, P.; Verma, T.N. AHP-based Identification of Tools for Sustainable Product Development. In Advancement in Materials, Manufacturing and Energy Engineering; Springer Nature: Singapore, 2022; pp. 543–552. [Google Scholar]

- Kluczek, A. An overall multi-criteria approach to sustainability assessment of manufacturing processes. Procedia Manuf. 2017, 8, 136–143. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Gnanavelbabu, A.; Lokesh Prabhuraj, B. A sustainable assessment model for material selection in construction industries perspective using hybrid MCDM approaches. J. Adv. Manag. Res. 2019, 16, 234–259. [Google Scholar] [CrossRef]

- Bhanot, N.; Qaiser, F.H.; Alkahtani, M.; Rehman, A.U. An integrated decision-making approach for cause-and-effect analysis of sustainable manufacturing indicators. Sustainability 2020, 12, 1517. [Google Scholar] [CrossRef]

- Hichem, A.; Mohyeddine, S.; Abdessamed, K. Benchmarking framework for sustainable manufacturing based MCDM techniques. Benchmarking Int. J. 2022, 29, 87–117. [Google Scholar] [CrossRef]

- Guebsi, W.; Zouari, A. Investigation on multi-criteria decision making methods application in sustainable product design. SPEKTA 2022, 3, 91–104. [Google Scholar] [CrossRef]

- Vidgen, R.; Shaw, S.; Grant, D.B. Management challenges in creating value from business analytics. Eur. J. Oper. Res. 2017, 261, 626–639. [Google Scholar] [CrossRef]

- Singh, S.K.; El-Kassar, A.N. Role of big data analytics in developing sustainable capabilities. J. Clean. Prod. 2019, 213, 1264–1273. [Google Scholar] [CrossRef]

- Lepenioti, K.; Bousdekis, A.; Apostolou, D.; Mentzas, G. Prescriptive analytics: Literature review and research challenges. Int. J. Inf. Manag. 2020, 50, 57–70. [Google Scholar] [CrossRef]

- Relich, M.; Bzdyra, K. Knowledge discovery in enterprise databases for forecasting new product success. Lect. Notes Comput. Sci. 2015, 9375, 121–129. [Google Scholar]

- Krumeich, J.; Werth, D.; Loos, P. Prescriptive control of business processes. Bus. Inf. Syst. Eng. 2016, 58, 261–280. [Google Scholar] [CrossRef]

- Sun, K.; Li, Y.; Roy, U. A PLM-based data analytics approach for improving product development lead time in an engineer-to-order manufacturing firm. Math. Model. Eng. Probl. 2017, 4, 69–74. [Google Scholar] [CrossRef]

- Bertsimas, D.; Kallus, N. From predictive to prescriptive analytics. Manag. Sci. 2020, 66, 1025–1044. [Google Scholar] [CrossRef]

- Jiang, Z.; Ding, Z.; Zhang, H.; Cai, W.; Liu, Y. Data-driven ecological performance evaluation for remanufacturing process. Energy Convers. Manag. 2019, 198, 111844. [Google Scholar] [CrossRef]

- Li, T.; Yeo, J. Strengthening the sustainability of additive manufacturing through data-driven approaches and workforce development. Adv. Intell. Syst. 2021, 3, 2100069. [Google Scholar] [CrossRef]

- Perdeli Demirkan, C.; Smith, N.M.; Duzgun, H.S.; Waclawski, A. A data-driven approach to evaluation of sustainability reporting practices in extractive industries. Sustainability 2021, 13, 8716. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Z. Data-driven product design evaluation method based on multi-stage artificial neural network. Appl. Soft Comput. 2021, 103, 107117. [Google Scholar] [CrossRef]

- Li, M.; Li, L.; Ma, Y. Integration of well-defined BIM external module with CAD via associative feature templates. Comput. Aided Des. Appl. 2019, 16, 878–893. [Google Scholar] [CrossRef]

- Dezdar, S. An integrative model for realising benefits from enterprise resource planning implementation. Int. J. Bus. Inf. Syst. 2017, 24, 423–451. [Google Scholar] [CrossRef]

- Menon, S. Benefits and process improvements for ERP implementation: Results from an exploratory case study. Int. Bus. Res. 2019, 12, 124–132. [Google Scholar] [CrossRef]

- Ghedira, K. Constraint Satisfaction Problems: CSP Formalisms and Techniques; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Relich, M.; Świć, A. Parametric estimation and constraint programming-based planning and simulation of production cost of a new product. Appl. Sci. 2020, 10, 6330. [Google Scholar] [CrossRef]

- Rossi, F.; Van Beek, P.; Walsh, T. Constraint programming. Found. Artif. Intell. 2008, 3, 181–211. [Google Scholar]

- Relich, M. Identifying project alternatives with the use of constraint programming. Adv. Intell. Syst. Comput. 2016, 521, 3–13. [Google Scholar]

- Hassan, M.F.; Saman, M.Z.; Sharif, S.; Omar, B. Integration of morphological analysis theory and artificial neural network approach for sustainable product design: A case study of portable vacuum cleaner. Int. J. Sustain. Manuf. 2012, 2, 293–316. [Google Scholar] [CrossRef]

- Lahmar, H.; Dahane, M.; Mouss, N.K.; Haoues, M. Production planning optimisation in a sustainable hybrid manufacturing remanufacturing production system. Procedia Comput. Sci. 2022, 200, 1244–1253. [Google Scholar] [CrossRef]

- Cica, D.; Sredanovic, B.; Tesic, S.; Kramar, D. Predictive modeling of turning operations under different cooling/lubricating conditions for sustainable manufacturing with machine learning techniques. Appl. Comput. Inform. 2020. ahead of print. [Google Scholar] [CrossRef]

- Grezmak, J.; Zhang, J.; Wang, P.; Gao, R.X. Multi-stream convolutional neural network-based fault diagnosis for variable frequency drives in sustainable manufacturing systems. Procedia Manuf. 2020, 43, 511–518. [Google Scholar] [CrossRef]

- Abidi, M.H.; Mohammed, M.K.; Alkhalefah, H. Predictive maintenance planning for industry 4.0 using machine learning for sustainable manufacturing. Sustainability 2022, 14, 3387. [Google Scholar] [CrossRef]

- Gue, I.H.; Ubando, A.T.; Tseng, M.L.; Tan, R.R. Artificial neural networks for sustainable development: A critical review. Clean Technol. Environ. Policy 2020, 22, 1449–1465. [Google Scholar] [CrossRef]

- Goodall, P.; Sharpe, R.; West, A. A data-driven simulation to support remanufacturing operations. Comput. Ind. 2019, 105, 48–60. [Google Scholar] [CrossRef]

- He, P. Optimization and simulation of remanufacturing production scheduling under uncertainties. Int. J. Simul. Model. 2018, 17, 734–743. [Google Scholar] [CrossRef]

- Garwood, T.L.; Hughes, B.R.; Oates, M.R.; O’Connor, D.; Hughes, R. A review of energy simulation tools for the manufacturing sector. Renew. Sustain. Energy Rev. 2018, 81, 895–911. [Google Scholar] [CrossRef]

- Relich, M.; Gola, A.; Jasiulewicz-Kaczmarek, M. Identifying improvement opportunities in product design for reducing energy consumption. Energies 2022, 15, 9611. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

| Prediction Model | Learning Set | Testing Set |

|---|---|---|

| LR | 13.11 | 14.97 |

| PR | 11.84 | 12.73 |

| NN-GD | 12.04 | 10.83 |

| NN-LM | 6.59 | 12.31 |

| AV | 19.71 | 23.08 |

| Variables | V4 | V5 | V7 | V6 |

|---|---|---|---|---|

| V1 = 85, V3 = 7.3 | 21 | 63.1 | 148.1 | 246.9 |

| … | … | … | … | … |

| V1 = 94, V3 = 7.3 | 26 | 73.8 | 148.9 | 254.8 |

| … | … | … | … | … |

| V1 = 85, V3 = 7.4 | 20 | 62.5 | 150.2 | 248.8 |

| … | … | … | … | … |

| V1 = 94, V3 = 7.4 | 25 | 73.2 | 151.0 | 256.7 |

| … | … | … | … | … |

| V1 = 85, V3 = 8.2 | 17 | 55.6 | 166.8 | 263.6 |

| … | … | … | … | … |

| V1 = 94, V3 = 8.2 | 22 | 65.8 | 172.0 | 271.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Relich, M. Predictive and Prescriptive Analytics in Identifying Opportunities for Improving Sustainable Manufacturing. Sustainability 2023, 15, 7667. https://doi.org/10.3390/su15097667

Relich M. Predictive and Prescriptive Analytics in Identifying Opportunities for Improving Sustainable Manufacturing. Sustainability. 2023; 15(9):7667. https://doi.org/10.3390/su15097667

Chicago/Turabian StyleRelich, Marcin. 2023. "Predictive and Prescriptive Analytics in Identifying Opportunities for Improving Sustainable Manufacturing" Sustainability 15, no. 9: 7667. https://doi.org/10.3390/su15097667

APA StyleRelich, M. (2023). Predictive and Prescriptive Analytics in Identifying Opportunities for Improving Sustainable Manufacturing. Sustainability, 15(9), 7667. https://doi.org/10.3390/su15097667