Innovative Imaging and Analysis Techniques for Quantifying Spalling Repair Materials in Concrete Pavements

Abstract

:1. Introduction

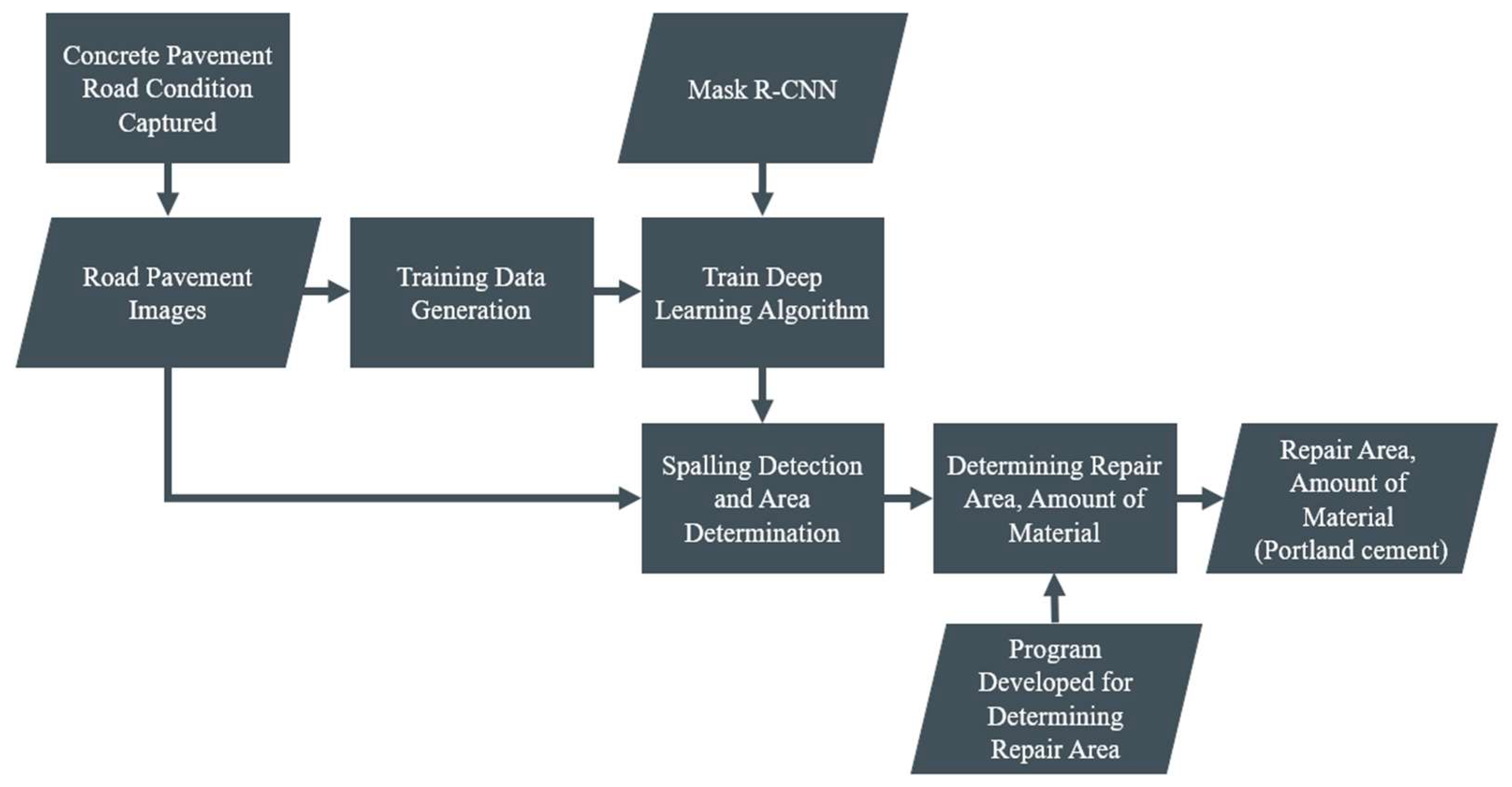

2. Materials and Methods

2.1. Dataset Formation

2.2. Training Dataset

2.3. Spalling Detection

2.4. Determining Spalling Repair Area and the Amount of Repair Material

3. Results and Discussion

4. Conclusions

- A line scan camera was utilized to capture the state of road pavements, enabling the analysis of its conditions in an indoor environment without road closures on-site.

- The time-intensive process of spalling detection and repair area calculation, which was previously performed by human workers, has been replaced with Mask R-CNN, enabling the analysis of road conditions for spalling detection and area calculation to be conducted using less manpower.

- A self-developed calculation program based on the spalling repair area calculation standards of the FHWA that automatically calculates spalling area and material quantity was utilized, enabling more consistent and faster calculations based on the same standard.

- The effectiveness of the proposed method was validated by showing that the obtained spalling repair area values were very close to the actual repair area values calculated by workers, as confirmed by RMSE and PCC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wilde, W.J.; Waalkes, S.; Harrison, R. Life Cycle Cost Analysis of Portland Cement Concrete Pavements; Center for Transportation Research, University of Texas at Austin: Austin, TX, USA, 1999. [Google Scholar]

- Gates, T.J.; Hawkins, H.G.; Rose, E.R. Effective Pavement Marking Materials and Applications for Portland Cement Concrete Roadways; Texas Transportation Institute, Texas A & M University System: College Station, TX, USA, 2003. [Google Scholar]

- Li, J.; Zhang, W.; Cao, Y. Laboratory evaluation of magnesium phosphate cement paste and mortar for rapid repair of cement concrete pavement. Constr. Build. Mater. 2014, 58, 122–128. [Google Scholar] [CrossRef]

- Jiang, C.; Gu, X.; Huang, Q.; Zhang, W. Carbonation depth predictions in concrete bridges under changing climate conditions and increasing traffic loads. Cem. Concr. Compos. 2018, 93, 140–154. [Google Scholar] [CrossRef]

- Ismail, Z.-A.B. Thermal comfort practices for precast concrete building construction projects: Towards BIM and IOT integration. Engineering, Constr. Archit. Manag. 2022, 29, 1504–1521. [Google Scholar] [CrossRef]

- Rollings, R.S. Joint spalling in newly constructed concrete pavements. J. Perform. Constr. Facil. 1998, 12, 137–144. [Google Scholar] [CrossRef]

- Asamoto, S.; Sato, J.; Okazaki, S.; Chun, P.-j.; Sahamitmongkol, R.; Nguyen, G.H. The Cover Depth Effect on Corrosion-Induced Deterioration of Reinforced Concrete Focusing on Water Penetration: Field Survey and Laboratory Study. Materials 2021, 14, 3478. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.; Lechner, B.; Wong, Y.D. Response-based methods to measure road surface irregularity: A state-of-the-art review. Eur. Transp. Res. Rev. 2019, 11, 43. [Google Scholar] [CrossRef]

- Ong, G.P.; Fwa, T. Wet-pavement hydroplaning risk and skid resistance: Modeling. J. Transp. Eng. 2007, 133, 590–598. [Google Scholar] [CrossRef]

- Kliethermes, J.C. Repair of spalling bridge decks. In Proceedings of the 51st Annual Meeting of the Highway Research Board, Washington, DC, USA, 17–21 January 1972. [Google Scholar]

- Yeon, J.; Kang, J.; Yan, W. Spall damage repair using 3D printing technology. Autom. Constr. 2018, 89, 266–274. [Google Scholar] [CrossRef]

- Chen, D.-H.; Lin, H.-H.; Sun, R. Field performance evaluations of partial-depth repairs. Constr. Build. Mater. 2011, 25, 1369–1378. [Google Scholar] [CrossRef]

- Russell, H.G. Adjacent Precast Concrete Box Beam Bridges: Connection Details; Transportation Research Board: Washington, DC, USA, 2009; Volume 393. [Google Scholar]

- Dekker, R.; Plasmeijer, R.P.; Swart, J.H. Evaluation of a new maintenance concept for the preservation of highways. IMA J. Manag. Math. 1998, 9, 109–156. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, L.; Yu, S.; Prokhorov, D.; Mei, X.; Ling, H. Feature pyramid and hierarchical boosting network for pavement crack detection. IEEE Trans. Intell. Transp. Syst. 2019, 21, 1525–1535. [Google Scholar] [CrossRef]

- De Brito, J.; Branco, F.; Thoft-Christensen, P.; Sørensen, J.D. An expert system for concrete bridge management. Eng. Struct. 1997, 19, 519–526. [Google Scholar] [CrossRef]

- Jumaat, M.Z.; Kabir, M.; Obaydullah, M. A review of the repair of reinforced concrete beams. J. Appl. Sci. Res. 2006, 2, 317–326. [Google Scholar]

- Rasmussen, J. Human errors. A taxonomy for describing human malfunction in industrial installations. J. Occup. Accid. 1982, 4, 311–333. [Google Scholar] [CrossRef]

- Lea, F.C.; Middleton, C. Reliability of Visual Inspection of Highway Bridges; Department of Engineering, University of Cambridge: Cambridge, UK, 2002. [Google Scholar]

- Kee, S.-H.; Gucunski, N. Interpretation of flexural vibration modes from impact-echo testing. J. Infrastruct. Syst. 2016, 22, 04016009. [Google Scholar] [CrossRef]

- Dry, C. Three designs for the internal release of sealants, adhesives, and waterproofing chemicals into concrete to reduce permeability. Cem. Concr. Res. 2000, 30, 1969–1977. [Google Scholar] [CrossRef]

- Assaf, S.A.; Al-Hejji, S. Causes of delay in large construction projects. Int. J. Proj. Manag. 2006, 24, 349–357. [Google Scholar] [CrossRef]

- Polder, R.; Peelen, W.; Courage, W. Non-traditional assessment and maintenance methods for aging concrete structures–technical and non-technical issues. Mater. Corros. 2012, 63, 1147–1153. [Google Scholar] [CrossRef]

- Long, N.D.; Ogunlana, S.; Quang, T.; Lam, K.C. Large construction projects in developing countries: A case study from Vietnam. Int. J. Proj. Manag. 2004, 22, 553–561. [Google Scholar] [CrossRef]

- Samal, S.R.; Mohanty, M.; Santhakumar, S.M. Adverse effect of congestion on economy, health and environment under mixed traffic scenario. Transp. Dev. Econ. 2021, 7, 15. [Google Scholar] [CrossRef]

- Retallack, A.E.; Ostendorf, B. Current understanding of the effects of congestion on traffic accidents. Int. J. Environ. Res. Public Health 2019, 16, 3400. [Google Scholar] [CrossRef] [PubMed]

- Kaliba, C.; Muya, M.; Mumba, K. Cost escalation and schedule delays in road construction projects in Zambia. Int. J. Proj. Manag. 2009, 27, 522–531. [Google Scholar] [CrossRef]

- Grădinaru, C.M.; Muntean, R.; Șerbănoiu, A.A.; Ciocan, V.; Burlacu, A. Sustainable development of human society in terms of natural depleting resources preservation using natural renewable raw materials in a novel ecological material production. Sustainability 2020, 12, 2651. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Morrow, W.; Masanet, E.; Sathaye, J.; Xu, T. Energy efficiency improvement and CO2 emission reduction opportunities in the cement industry in China. Energy Policy 2013, 57, 287–297. [Google Scholar] [CrossRef]

- France-Mensah, J.; O’Brien, W.J. Developing a sustainable pavement management plan: Tradeoffs in road condition, user costs, and greenhouse gas emissions. J. Manag. Eng. 2019, 35, 04019005. [Google Scholar] [CrossRef]

- Wu, W.; Qurishee, M.A.; Owino, J.; Fomunung, I.; Onyango, M.; Atolagbe, B. Coupling deep learning and UAV for infrastructure condition assessment automation. In Proceedings of the 2018 IEEE International Smart Cities Conference (ISC2), Kansas City, MO, USA, 16–19 September 2018. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. Comparison of deep convolutional neural networks and edge detectors for image-based crack detection in concrete. Constr. Build. Mater. 2018, 186, 1031–1045. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, C.; Huang, C.; Liu, L.; Yang, Y. Phishing email detection using improved RCNN model with multilevel vectors and attention mechanism. IEEE Access 2019, 7, 56329–56340. [Google Scholar] [CrossRef]

- Ullah, A.; Xie, H.; Farooq, M.O.; Sun, Z. Pedestrian detection in infrared images using fast RCNN. In Proceedings of the 2018 Eighth International Conference on Image Processing Theory, Tools and Applications (IPTA), Xi’an, China, 7–10 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, A.; Kota, S.R. Automatic multiclass instance segmentation of concrete damage using deep learning model. IEEE Access 2021, 9, 90330–90345. [Google Scholar] [CrossRef]

- Mandal, V.; Uong, L.; Adu-Gyamfi, Y. Automated road crack detection using deep convolutional neural networks. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 5212–5215. [Google Scholar] [CrossRef]

- Chitta, K.; Álvarez, J.M.; Haussmann, E.; Farabet, C. Training data subset search with ensemble active learning. IEEE Trans. Intell. Transp. Syst. 2021, 23, 14741–14752. [Google Scholar] [CrossRef]

- Li, G.; Xie, Y.; Lin, L. Weakly supervised salient object detection using image labels. In Proceedings of the AAAI Conference on Artificial Intelligence, New Orleans, LA, USA, 2–7 February 2018. [Google Scholar] [CrossRef]

- Xu, Y.; Goodacre, R. On splitting training and validation set: A comparative study of cross-validation, bootstrap and systematic sampling for estimating the generalization performance of supervised learning. J. Anal. Test. 2018, 2, 249–262. [Google Scholar] [CrossRef]

- Jiao, L.; Dong, S.; Zhang, S.; Xie, C.; Wang, H. AF-RCNN: An anchor-free convolutional neural network for multi-categories agricultural pest detection. Comput. Electron. Agric. 2020, 174, 105522. [Google Scholar] [CrossRef]

- Chiao, J.-Y.; Chen, K.-Y.; Liao, K.Y.-K.; Hsieh, P.-H.; Zhang, G.; Huang, T.-C. Detection and classification the breast tumors using mask R-CNN on sonograms. Medicine 2019, 98, e15200. [Google Scholar] [CrossRef] [PubMed]

- Girshick, R. Fast r-cnn. In Proceedings of the IEEE International Conference on Computer Vision, Santiago, Chile, 11–18 December 2015; pp. 1440–1448. [Google Scholar] [CrossRef]

- Sumida, I.; Magome, T.; Kitamori, H.; Das, I.J.; Yamaguchi, H.; Kizaki, H.; Aboshi, K.; Yamashita, K.; Yamada, Y.; Seo, Y. Deep convolutional neural network for reduction of contrast-enhanced region on CT images. J. Radiat. Res. 2019, 60, 586–594. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Wei, S.; Yan, M.; Wang, C.; Shi, J.; Zhang, X. Object detection and instance segmentation in remote sensing imagery based on precise mask R-CNN. In Proceedings of the IGARSS 2019-2019 IEEE International Geoscience and Remote Sensing Symposium, Yokohama, Japan, 28 July–2 August 2019; pp. 1454–1457. [Google Scholar] [CrossRef]

- Gao, X.; Chen, L.; Wang, K.; Xiong, X.; Wang, H.; Li, Y. Improved Traffic Sign Detection Algorithm Based on Faster R-CNN. Appl. Sci. 2022, 12, 8948. [Google Scholar] [CrossRef]

- He, K.; Gkioxari, G.; Dollár, P.; Girshick, R. Mask r-cnn. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017; pp. 2961–2969. [Google Scholar] [CrossRef]

- Dey, B.; Goswami, D.; Halder, S.; Khalil, K.; Leray, P.; Bayoumi, M.A. Deep Learning-Based Defect Classification and Detection in SEM Images, Metrology, Inspection, and Process Control XXXVI, 2022; SPIE: Washington, DC, USA, 2022; p. PC120530Y. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, M.; Shi, P.; Ren, R.; He, X.; Wei, X.; Yang, H. Crack detection and comparison study based on faster R-CNN and mask R-CNN. Sensors 2022, 22, 1215. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Tian, Y.; Luo, R.; Zhang, Z.; Lian, J.; Zheng, Y. Detection and segmentation of overlapped fruits based on optimized mask R-CNN application in apple harvesting robot. Comput. Electron. Agric. 2020, 172, 105380. [Google Scholar] [CrossRef]

- Bharati, P.; Pramanik, A. Deep Learning Techniques—R-CNN to Mask R-CNN: A Survey. In Computational Intelligence in Pattern Recognition: Proceedings of CIPR 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 657–668. [Google Scholar] [CrossRef]

- Attard, L.; Debono, C.J.; Valentino, G.; Di Castro, M.; Masi, A.; Scibile, L. Automatic crack detection using mask R-CNN. In Proceedings of the 2019 11th International Symposium on Image and Signal Processing and Analysis (ISPA), Dubrovnik, Croatia, 23–25 September 2019; pp. 152–157. [Google Scholar] [CrossRef]

- Wilson, T.P.; Romine, A.; Smith, K. Materials and Procedures for Rapid Repair of Partial-Depth Spalls in Concrete Pavements: Manual of Practice; Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2000.

- Willmott, C.J.; Matsuura, K. Advantages of the mean absolute error (MAE) over the root mean square error (RMSE) in assessing average model performance. Clim. Res. 2005, 30, 79–82. [Google Scholar] [CrossRef]

- Cohen, I.; Huang, Y.; Chen, J.; Benesty, J. Pearson correlation coefficient. Noise Reduct. Speech Process. 2009, 1–4. [Google Scholar] [CrossRef]

| Location of Spalling | Minimum Dimensions of Repair Area | ||

|---|---|---|---|

| Depth (m) | Length/Height (m) | Width (m) | |

| At one joint | 0.05 | 0.25 or length of spalled area + 0.1 Whichever is greater | 0.1 or width of spalled area + 0.05 Whichever is greater |

| At two joints | 0.05 | 0.2 or length of spalled area + 0.05 Whichever is greater | 0.1 or width of spalled area + 0.05 Whichever is greater |

| Away from joints | 0.05 | 0.25 or length of spalled area + 0.1 Whichever is greater | 0.14 or width of spalled area + 0.1 Whichever is greater |

| Actual Min. Spalling Repair Area (m2) | Actual Max. Spalling Repair Area (m2) | Program Min. Spalling Repair Area (m2) | Program Max. Spalling Repair Area (m2) |

|---|---|---|---|

| 0.053795 | 0.104015 | 0.05215 | 0.0957 |

| 0.22827 | 0.3531 | 0.207774 | 0.329574 |

| 0.04239 | 0.08892 | 0.044148 | 0.085248 |

| 0.187224 | 0.288834 | 0.164226 | 0.260626 |

| 0.079373 | 0.140933 | 0.075296 | 0.130946 |

| 0.091924 | 0.159874 | 0.075088 | 0.137088 |

| 0.189312 | 0.291732 | 0.176448 | 0.282948 |

| 0.0882 | 0.14976 | 0.107316 | 0.165466 |

| 0.056922 | 0.109752 | 0.048363 | 0.093613 |

| 0.046046 | 0.093296 | 0.041385 | 0.080835 |

| Min. Spalling Repair Material (m3) | Max. Spalling Repair Material (m3) |

|---|---|

| 0.003511 | 0.006444 |

| 0.01399 | 0.022191 |

| 0.002973 | 0.00574 |

| 0.011058 | 0.017549 |

| 0.00507 | 0.008817 |

| 0.005056 | 0.009231 |

| 0.011881 | 0.019052 |

| 0.007226 | 0.011141 |

| 0.003256 | 0.006303 |

| 0.002787 | 0.005443 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, J.; Kang, J.; Song, Y.; Lee, S.; Yeon, J. Innovative Imaging and Analysis Techniques for Quantifying Spalling Repair Materials in Concrete Pavements. Sustainability 2024, 16, 112. https://doi.org/10.3390/su16010112

Cho J, Kang J, Song Y, Lee S, Yeon J. Innovative Imaging and Analysis Techniques for Quantifying Spalling Repair Materials in Concrete Pavements. Sustainability. 2024; 16(1):112. https://doi.org/10.3390/su16010112

Chicago/Turabian StyleCho, Junhwi, Julian Kang, Yooseob Song, Seungjoo Lee, and Jaeheum Yeon. 2024. "Innovative Imaging and Analysis Techniques for Quantifying Spalling Repair Materials in Concrete Pavements" Sustainability 16, no. 1: 112. https://doi.org/10.3390/su16010112