Water Nutrient Management in Soilless Plant Cultivation versus Sustainability

Abstract

:1. Introduction

2. Water and Nutrients Management

2.1. Open-Circuit Systems

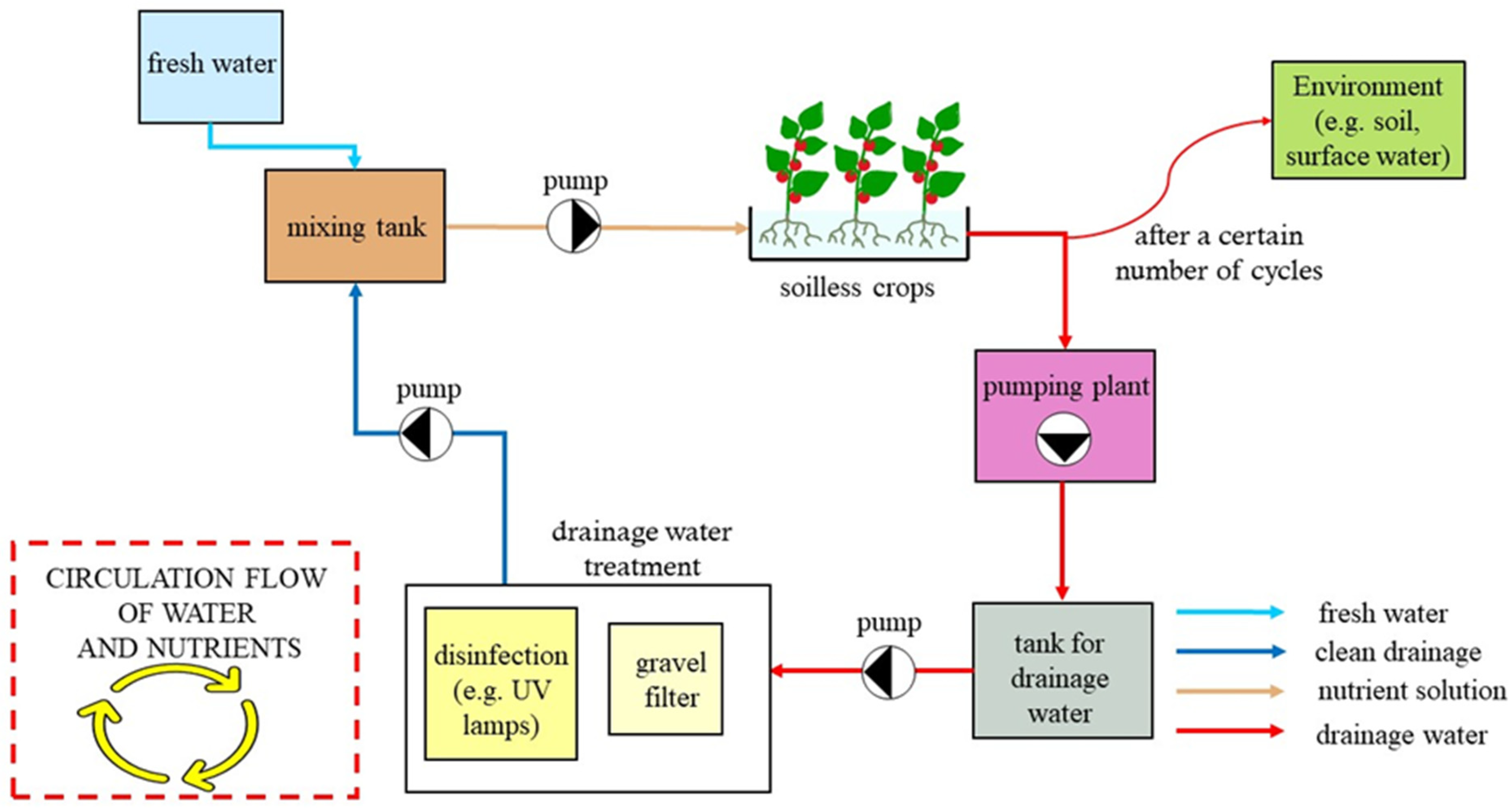

2.2. Closed-Circuit Systems

2.3. Cascade Cropping Systems

2.4. Fertilizers

3. The Impact of Soilless Cultivation on the Natural Environment

4. Methods for the Final Management of the Overflow

4.1. Nature-Based Solution

4.2. Physicochemical and Biological Methods for the Final Management of DW

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Savvas, D.; Gianquinto, G.; Tuzel, Y.; Gruda, N. Soilless Culture. In Good Agricultural Practices Principles for Greenhouse Vegetable Production in the Mediterranean Region; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; pp. 303–354. ISBN 978-92-5107649-1. [Google Scholar]

- Tüzel, Y.; Gül, A.; Tüzel, I.H.; Öztekin, G.B. Different Soilless Culture Systems and Their Management. J. Agric. Food Environ. Sci. 2019, 73, 7–12. [Google Scholar] [CrossRef]

- EI-Kazzaz, A. Soilless Agriculture a New and Advanced Method for Agriculture Development: An Introduction. Agric. Res. Technol. Open Access J. 2017, 3, 555610. [Google Scholar] [CrossRef]

- Raviv, M.; Lieth, J.H.; Bar-Tal, A. Soilless Culture: Theory and Practice: Theory and Practice; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 0444636978. [Google Scholar]

- Gruda, N.S. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef]

- Putra, P.A.; Yuliando, H. Soilless Culture System to Support Water Use Efficiency and Product Quality: A Review. Agric. Agric. Sci. Procedia 2015, 3, 283–288. [Google Scholar] [CrossRef]

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153. [Google Scholar] [CrossRef] [PubMed]

- Fatel, K. Nowoczesna Uprawa Szklarniowa—Monitorowanie, Rejestracja, Wspieranie Decyzji. Available online: https://www.podoslonami.pl/nawozenie/nawozenie-warzyw/nowoczesna-uprawa-szklarniowa-monitorowanie/ (accessed on 26 August 2023).

- D’Amico, A.; De Boni, A.; Ottomano Palmisano, G.; Acciani, C.; Roma, R. Environmental Analysis of Soilless Tomato Production in a High-Tech Greenhouse. Clean. Environ. Syst. 2023, 11, 100137. [Google Scholar] [CrossRef]

- Palmitessa, O.D.; Pantaleo, M.A.; Santamaria, P. Applications and Development of LEDs as Supplementary Lighting for Tomato at Different Latitudes. Agronomy 2021, 11, 835. [Google Scholar] [CrossRef]

- Gullino, M.; Gilardi, G.; Garibaldi, A. Ready-to-Eat Salad Crops: A Plant Pathogen’s Heaven. Plant Dis. 2019, 103, 2153–2170. [Google Scholar] [CrossRef]

- Pod Osłonami Powierzchnia Uprawy i Produkcja Warzyw Pod Osłonami w 2022 r. Available online: https://www.podoslonami.pl/przeglad-informacji/powierzchnia-uprawy-i-produkcja-warzyw-pod-oslonami-w-2022-r/ (accessed on 24 August 2023).

- Costa, J.M.; Berkmoes, E.; Beerling, E.; Nicol, S.; Jose, J.; Garcia, J.; Cáceres, R. Water Use in Greenhouse Horticulture: Efficiency and Circularity; EIP-AGRI Focus Group—Circular Horticulture Mini-Paper; EIP-AGRI: Brussels, Belgium, 2019; Available online: https://ec.europa.eu/eip/agriculture/sites/agri-eip/files/fg27_mini-paper_water_2019_en.pdf (accessed on 24 August 2023).

- Zacharof, M.P.; Lovitt, R.W. Adding Value to Wastewater by Resource Recovery and Reformulation as Growth Media: Current Prospects and Potential. J. Water Reuse Desalination 2015, 5, 473–479. [Google Scholar] [CrossRef]

- Kleiber, T. Pollution of the Natural Environment in Intensive Cultures under Greenhouses. Arch. Environ. Prot. 2012, 38, 45–53. [Google Scholar] [CrossRef]

- Breś, W. Estimation of Nutrient Losses from Open Fertigation Systems to Soil during Horticultural Plant Cultivation. Pol. J. Environ. Stud. 2009, 18, 341–345. [Google Scholar]

- Cordell, D.; Drangert, J.O.; White, S. The Story of Phosphorus: Global Food Security and Food for Thought. Glob. Environ. Chang. 2009, 19, 292–305. [Google Scholar] [CrossRef]

- What Are the Prospects for the Global Fertilizer Market? Available online: https://agronews.com.pl/artykul/jakie-perspektywy-dla-swiatowego-rynku-nawozow/ (accessed on 1 April 2023). (In Polish).

- Ampim, P.A.Y.; Obeng, E.; Olvera-Gonzalez, E. Indoor Vegetable Production: An Alternative Approach to Increasing Cultivation. Plants 2022, 11, 2843. [Google Scholar] [CrossRef] [PubMed]

- Pignata, G.; Casale, M.; Nicola, S. Water and Nutrient Supply in Horticultural Crops Grown in Soilless Culture: Resource Efficiency in Dynamic and Intensive Systems. In Advances in Research on Fertilization Management of Vegetable Crops; Springer: Cham, Switzerland, 2017; pp. 183–219. ISBN 978-3-319-53624-8. [Google Scholar]

- Massa, D.; Magán, J.J.; Montesano, F.F.; Tzortzakis, N. Minimizing Water and Nutrient Losses from Soilless Cropping in Southern Europe. Agric. Water Manag. 2020, 241, 106395. [Google Scholar] [CrossRef]

- Rani, R.S.; Kumar, H.V.H.; Mani, A.; Reddy, B.S.; Rao, C.S. Soilless Cultivation Technique, Hydroponics—A Review. Curr. J. Appl. Sci. Technol. 2022, 41, 22–30. [Google Scholar] [CrossRef]

- Parada, F.; Gabarrell, X.; Rufí-Salís, M.; Arcas-Pilz, V.; Muñoz, P.; Villalba, G. Optimizing Irrigation in Urban Agriculture for Tomato Crops in Rooftop Greenhouses. Sci. Total Environ. 2021, 794, 148689. [Google Scholar] [CrossRef]

- Dyśko, J. Recyrkulacja Pożywki w Bezglebowej Uprawie Pomidora. Owoce Warzywa Kwiaty 2004, 7, 8–9. [Google Scholar]

- Dyśko, J.; Kaniszewski, S.; Kowalczyk, W. The Influence of Drainage Water from Greenhouse Soilless Culture on Pollution of Shallow Groundwater. Infrastrukt. I Ekol. Teren. Wiej. 2013, 2/I/2013, 127–135. [Google Scholar]

- Muñoz, P.; Flores, J.S.; Antón, A.; Montero, J.I. Combination of Greenhouse and Open-Field Crop Fertigation Can Increase Sustainability of Horticultural Crops in the Mediterranean Region. Acta Hortic. 2017, 1170, 627–633. [Google Scholar] [CrossRef]

- Kwon, M.J.; Hwang, Y.; Lee, J.; Ham, B.; Rahman, A.; Azam, H.; Yang, J.S. Waste Nutrient Solutions from Full-Scale Open Hydroponic Cultivation: Dynamics of Effluent Quality and Removal of Nitrogen and Phosphorus Using a Pilot-Scale Sequencing Batch Reactor. J. Environ. Manag. 2021, 281, 111893. [Google Scholar] [CrossRef]

- Mielcarek, A.; Rodziewicz, J.; Janczukowicz, W.; Dobrowolski, A. Analysis of Wastewater Generated in Greenhouse Soilless Tomato Cultivation in Central Europe. Water 2019, 11, 2538. [Google Scholar] [CrossRef]

- García-Caparrós, P.; Llanderal, A.; Maksimovic, I.; Lao, M.T. Cascade Cropping System with Horticultural and Ornamental Plants under Greenhouse Conditions. Water 2018, 10, 125. [Google Scholar] [CrossRef]

- Thompson, R.B.; Gallardo, M.; Rodríguez, J.S.; Sánchez, J.A.; Magán, J.J. Effect of N Uptake Concentration on Nitrate Leaching from Tomato Grown in Free-Draining Soilless Culture under Mediterranean Conditions. Sci. Hortic. 2013, 150, 387–398. [Google Scholar] [CrossRef]

- Santos, M.G.; Moreira, G.S.; Pereira, R.; Carvalho, S.M.P. Assessing the Potential Use of Drainage from Open Soilless Production Systems: A Case Study from an Agronomic and Ecotoxicological Perspective. Agric. Water Manag. 2022, 273, 107906. [Google Scholar] [CrossRef]

- Ahn, T.I.; Yang, J.S.; Park, S.H.; Im, Y.H.; Lee, J.Y. Nutrient Recirculating Soilless Culture System as a Predictable and Stable Way of Microbial Risk Management. J. Clean. Prod. 2021, 298, 126747. [Google Scholar] [CrossRef]

- Dyśko, J.; Szczech, M.; Kaniszewski, S.; Kowalczyk, W. Parameters of Drainage Waters Collected during Soilless Tomato Cultivation in Mineral and Organic Substrates. Agronomy 2020, 10, 2009. [Google Scholar] [CrossRef]

- Richa, A.; Touil, S.; Fizir, M.; Martinez, V. Recent Advances and Perspectives in the Treatment of Hydroponic Wastewater: A Review. Rev. Environ. Sci. Biotechnol. 2020, 19, 945–966. [Google Scholar] [CrossRef]

- Saxena, P.; Bassi, A. Removal of Nutrients from Hydroponic Greenhouse Effluent by Alkali Precipitation and Algae Cultivation Method. J. Chem. Technol. Biotechnol. 2013, 88, 858–863. [Google Scholar] [CrossRef]

- Bryszewski, K.Ł.; Rodziewicz, J.; Janczukowicz, W. Effect of Bio-Electrochemical Treatment of Hydroponic Effluent on the Nutrient Content. Appl. Sci. 2022, 12, 9540. [Google Scholar] [CrossRef]

- Putri, F.E.; Hung, T.-C. Comparison of Nutrient Removal and Biomass Production between Macrophytes and Microalgae for Treating Artificial Citrus Nursery Wastewater. J. Environ. Manag. 2020, 264, 110303. [Google Scholar] [CrossRef]

- Bryszewski, K.Ł.; Rodziewicz, J.; Mielcarek, A.; Janczukowicz, W.; Jóźwiakowski, K. Investigation on the Improved Electrochemical and Bio-Electrochemical Treatment Processes of Soilless Cultivation Drainage (SCD). Sci. Total Environ. 2021, 783, 146846. [Google Scholar] [CrossRef] [PubMed]

- Mielcarek, A.; Bryszewski, K.Ł.; Rodziewicz, J.; Janczukowicz, W. Single-Stage or Two-Stages Bio-Electrochemical Treatment Process of Drainage from Soilless Tomato Cultivation with Alternating Current. Sep. Purif. Technol. 2022, 299, 121762. [Google Scholar] [CrossRef]

- Malorgio, F.; Scacco, M.; Tognoni, F.; Dipartimento, A.P.; Vegetale, D.P. Effect of Nutrient Concentration and Water Regime on Cut Rose Production Grown in Hydroponic System. Acta Hortic. 2001, 559, 313–317. [Google Scholar] [CrossRef]

- Massa, D.; Incrocci, L.; Maggini, R.; Carmassi, G.; Campiotti, C.A.; Pardossi, A. Strategies to Decrease Water Drainage and Nitrate Emission from Soilless Cultures of Greenhouse Tomato. Agric. Water Manag. 2010, 97, 971–980. [Google Scholar] [CrossRef]

- Rufí-Salís, M.; Parada, F.; Arcas-Pilz, V.; Petit-Boix, A.; Villalba, G.; Gabarrell, X. Closed-Loop Crop Cascade to Optimize Nutrient Flows and Grow Low-Impact Vegetables in Cities. Front. Plant Sci. 2020, 11, 596550. [Google Scholar] [CrossRef] [PubMed]

- Richa, A.; Fizir, M.; Touil, S. Advanced Monitoring of Hydroponic Solutions Using Ion-Selective Electrodes and the Internet of Things: A Review. Environ. Chem. Lett. 2021, 19, 3445–3463. [Google Scholar] [CrossRef]

- Savvas, D.; Gruda, N. Application of Soilless Culture Technologies in the Modern Greenhouse Industry—A Review. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Thompson, R.B.; Incrocci, L.; van Ruijven, J.; Massa, D. Reducing Contamination of Water Bodies from European Vegetable Production Systems. Agric. Water Manag. 2020, 240, 106258. [Google Scholar] [CrossRef]

- Pomiar i Regulacja PH i EC w Ogrodnictwie. Available online: https://royalbrinkman.pl/bank-wiedzy/pielegnacja/nawozy/regulacja-ph-i-ec-wskazowki (accessed on 28 August 2023).

- Wójcik, P.; Dyśko, J.; Kaniszewski, S.; Kowalczyk, W.; Nowak, J.S. Zrównoważone Nawożenie Roślin Ogrodniczych: Opracowanie Zbiorowe; Instytut Ogrodnictwa: Skierniewice, Poland, 2014; ISBN 9788389800572. [Google Scholar]

- Tola, E.K.; Al-Gaadi, K.A.; Madugundu, R.; Patil, V.C.; Sygrimis, N. Impact of Water Salinity Levels on the Spectral Behavior and Yield of Tomatoes in Hydroponics. J. King Saud Univ. Sci. 2023, 35, 102515. [Google Scholar] [CrossRef]

- Czerwińska-Nowak, A. Ile Kosztuje i Jakie Są Korzyści Zamkniętego Obiegu Pożywki w Uprawie Warzyw Szklarniowych? Available online: https://www.warzywa.pl/warzywa-pod-oslonami/ile-kosztuje-zamkniety-obieg-pozywki-w-uprawie-warzyw-szklarniowych-ile-wody-i-nawozow-mozemy-przez-to-zaoszczedzic/ (accessed on 26 August 2023).

- Czarnecka, A. Metody Dezynfekcji Pożywki Do Fertygacji, Cz.2. Available online: https://www.podoslonami.pl/technika/metody-dezynfekcji-pozywki-do-fertygacji-cz-2/ (accessed on 31 August 2023).

- Czarnecka, A. Dezynfekcja Pożywki i Wody Promieniami UV. Available online: https://www.podoslonami.pl/nawozenie/nawozenie-warzyw/dezynfekcja-wody-i-pozywki-promieniami-uv/ (accessed on 31 August 2023).

- Ogrodinfo Dezynfekcja Wód Lub Pożywki w Szkółkach. Available online: https://www.ogrodinfo.pl/ogrodinfo/dezynfekcja-wody-lub-pozywki-w-szkolkach/ (accessed on 1 September 2023).

- Kumar, R.R.; Cho, J.Y. Reuse of Hydroponic Waste Solution. Environ. Sci. Pollut. Res. 2014, 21, 9569–9577. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Maestre-Valero, J.F.; Gallego-Elvira, B.; Marín-Membrive, P.; Terrero, P.; Martínez-Alvarez, V. Recycling Drainage Effluents Using Reverse Osmosis Powered by Photovoltaic Solar Energy in Hydroponic Tomato Production: Environmental Footprint Analysis. J. Environ. Manag. 2021, 297, 113326. [Google Scholar] [CrossRef] [PubMed]

- Zamora-Izquierdo, M.A.; Santa, J.; Martínez, J.A.; Martínez, V.; Skarmeta, A.F. Smart Farming IoT Platform Based on Edge and Cloud Computing. Biosyst. Eng. 2019, 177, 4–17. [Google Scholar] [CrossRef]

- Rufí-Salís, M.; Petit-Boix, A.; Villalba, G.; Sanjuan-Delmás, D.; Parada, F.; Ercilla-Montserrat, M.; Arcas-Pilz, V.; Muñoz-Liesa, J.; Rieradevall, J.; Gabarrell, X. Recirculating Water and Nutrients in Urban Agriculture: An Opportunity towards Environmental Sustainability and Water Use Efficiency? J. Clean. Prod. 2020, 261, 121213. [Google Scholar] [CrossRef]

- Incrocci, L.; Thompson, R.B.; Fernandez-Fernandez, M.D.; De Pascale, S.; Pardossi, A.; Stanghellini, C.; Rouphael, Y.; Gallardo, M. Irrigation Management of European Greenhouse Vegetable Crops. Agric. Water Manag. 2020, 242, 106393. [Google Scholar] [CrossRef]

- Beerling, E.A.M.; Blok, C.; Van Der Maas, A.A.; Van Os, E.A. Closing the Water and Nutrient Cycles in Soilless Cultivation Systems. Acta Hortic. 2014, 1034, 49–55. [Google Scholar] [CrossRef]

- Breś, W.; Trelka, T. Effect of Fertigation on Soil Pollution during Greenhouse Plant Cultivation. Arch. Environ. Prot. 2015, 41, 75–81. [Google Scholar] [CrossRef]

- Karatsivou, E.; Elvanidi, A.; Faliagka, S.; Naounoulis, I.; Katsoulas, N. Performance Evaluation of a Cascade Cropping System. Horticulturae 2023, 9, 802. [Google Scholar] [CrossRef]

- Hussain, A.; Iqbal, K.; Aziem, S.; Mahato, P.; Negi, A. A Review on the Science of Growing Crops without Soil (Soilless Culture)-a Novel Alternative for Growing Crops. Int. J. Agric. Sci. 2014, 7, 833. [Google Scholar]

- Nawożenie Pomidorów w Tunelu i Szklarni. Available online: https://royalbrinkman.pl/bank-wiedzy/pielegnacja/nawozenie-pomidorow (accessed on 28 August 2023).

- Filipiak, B.; Centrum Doradztwa Rolniczego w Brwinowie; Zespół Rolnictwa i Środowiska. Analiza Rynku Nawozów Mineralnych Oraz Cen Nawozów w Grudniu 2022r. 2023. Available online: https://www.cdr.gov.pl/informacje-branzowe/informatory/informacja-o-rynku-nawozow-mineralnych/4274-analiza-rynku-nawozow-mineralnych-oraz-cen-nawozow-we-wrzesniu-2022r (accessed on 26 August 2023).

- Elvanidi, A.; Reascos, C.M.B.; Gourzoulidou, E.; Kunze, A.; Max, J.F.J.; Katsoulas, N. Implementation of the Circular Economy Concept in Greenhouse Hydroponics for Ultimate Use of Water and Nutrients. Horticulturae 2020, 6, 83. [Google Scholar] [CrossRef]

- Komosa, A.; Roszyk, J. Przydatność Wody Do Fertygacji–Wapń. In Proceedings of the Ogólnopolska Konferencja Naukowa–Efektywność Stosowania Nawozów w Uprawach Ogrodniczych, AR Lublin, Lublin, Poland, 8–9 June 1998; pp. 9–10. [Google Scholar]

- Kowalczyk, W.; Dyśko, J.; Felczyńska, A. Ocena Stopnia Zanieczyszczenia Składnikami Nawozowymi Wody z Ujęć Głębinowych Na Terenach o Skoncentrowanej Produkcji Szklarniowej. Nowości Warzywnicze 2010, 51, 29–34. [Google Scholar]

- Komosa, A. Podłoża Inertne-Postęp Czy Inercja? Zesz. Probl. Postępów Nauk Rol. 2002, 485, 147–167. [Google Scholar]

- Dyśko, J.; Kaniszewski, S. Contamination of Shallow Groundwater by the Soilless Tomato Culture. J. Agric. Sci. Technol. 2018, 20, 121–128. [Google Scholar]

- Kowalczyk, W.; Dyśko, J.; Felczynska, A. Tendencje Zmian Zawartości Wybranych Składników Mineralnych w Wodach Stosowanych Do Fertygacji Warzyw Uprawianych Pod Osłonami. Infrastrukt. I Ekol. Teren. Wiej. 2013, 2/I/2013, 167–175. [Google Scholar]

- Pogăcean, M.O.; Gavrilescu, M. Plant Protection Products and Their Sustainable and Environmentally Friendly Use. Environ. Eng. Manag. J. 2009, 8, 608–627. [Google Scholar]

- Vermeulen, T.; van Os, E.; Linden, A.M.A.; Wipfler, E.L. Need for Clean Water and Recirculation to Reduce Emissions of Plant Protection Products from Soilless Cultivation. Acta Hortic. 2017, 1176, 87–94. [Google Scholar] [CrossRef]

- Obarska-Pempkowiak, H.; Gajewska, M.; Wojciechowska, E. Hydrofitowe Oczyszczanie Wód i Ścieków; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2010; ISBN 9788301164201. [Google Scholar]

- Zubair, M.; Wang, S.; Zhang, P.; Ye, J.; Liang, J.; Nabi, M.; Zhou, Z.; Tao, X.; Chen, N.; Sun, K.; et al. Biological Nutrient Removal and Recovery from Solid and Liquid Livestock Manure: Recent Advance and Perspective. Bioresour. Technol. 2020, 301, 122823. [Google Scholar] [CrossRef] [PubMed]

- Gagnon, V.; Maltais-Landry, G.; Puigagut, J.; Chazarenc, F.; Brisson, J. Treatment of Hydroponics Wastewater Using Constructed Wetlands in Winter Conditions. Water Air Soil Pollut. 2010, 212, 483–490. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, S.H.; Delaune, R.D.; Cho, J.S.; Heo, J.S.; Ok, Y.S.; Seo, D.C. Enhancement of Nitrate Removal in Constructed Wetlands Utilizing a Combined Autotrophic and Heterotrophic Denitrification Technology for Treating Hydroponic Wastewater Containing High Nitrate and Low Organic Carbon Concentrations. Agric. Water Manag. 2015, 162, 1–14. [Google Scholar] [CrossRef]

- Rozema, E.; Gordon, R.; Zheng, Y. Plant Species for the Removal of Na+ and Cl− from Greenhouse Nutrient Solution. HortScience 2014, 49, 1071–1075. [Google Scholar] [CrossRef]

- Li, K.; Liu, Q.; Fang, F.; Luo, R.; Lu, Q.; Zhou, W.; Huo, S.; Cheng, P.; Liu, J.; Addy, M.; et al. Microalgae-Based Wastewater Treatment for Nutrients Recovery: A Review. Bioresour. Technol. 2019, 291, 121934. [Google Scholar] [CrossRef]

- Aravinthan, V.; Story, N.; Yusaf, T. Nutrient Removal of Nursery and Municipal Wastewater Using Chlorella Vulgaris Microalgae for Lipid Extraction. Desalination Water Treat. 2014, 52, 727–736. [Google Scholar] [CrossRef]

- Baglieri, A.; Sidella, S.; Barone, V.; Fragalà, F.; Silkina, A.; Nègre, M.; Gennari, M. Cultivating Chlorella Vulgaris and Scenedesmus Quadricauda Microalgae to Degrade Inorganic Compounds and Pesticides in Water. Environ. Sci. Pollut. Res. 2016, 23, 18165–18174. [Google Scholar] [CrossRef] [PubMed]

- Pinho, S.M.; David, L.H.; Garcia, F.; Keesman, K.J.; Portella, M.C.; Goddek, S. South American Fish Species Suitable for Aquaponics: A Review. Aquac. Int. 2021, 29, 1427–1449. [Google Scholar] [CrossRef]

- Knaus, U.; Palm, H.W. Effects of the Fish Species Choice on Vegetables in Aquaponics under Spring-Summer Conditions in Northern Germany (Mecklenburg Western Pomerania). Aquaculture 2017, 473, 62–73. [Google Scholar] [CrossRef]

- Yang, T.; Kim, H.J. Comparisons of Nitrogen and Phosphorus Mass Balance for Tomato-, Basil-, and Lettuce-Based Aquaponic and Hydroponic Systems. J. Clean. Prod. 2020, 274, 122619. [Google Scholar] [CrossRef]

- Yildiz, H.Y.; Robaina, L.; Pirhonen, J.; Mente, E.; Domínguez, D.; Parisi, G. Fish Welfare in Aquaponic Systems: Its Relation to Water Quality with an Emphasis on Feed and Faeces-A Review. Water 2017, 9, 13. [Google Scholar] [CrossRef]

- Hu, Z.; Lee, J.W.; Chandran, K.; Kim, S.; Brotto, A.C.; Khanal, S.K. Effect of Plant Species on Nitrogen Recovery in Aquaponics. Bioresour. Technol. 2015, 188, 92–98. [Google Scholar] [CrossRef]

- Wongkiew, S.; Popp, B.N.; Khanal, S.K. Nitrogen Recovery and Nitrous Oxide (N2O) Emissions from Aquaponic Systems: Influence of Plant Species and Dissolved Oxygen. Int. Biodeterior. Biodegrad. 2018, 134, 117–126. [Google Scholar] [CrossRef]

- Janczukowicz, W.; Rodziewicz, J.; Czaplicka, K.; Kłodowska, I.; Mielcarek, A. The Effect of Volatile Fatty Acids (VFAs) on Nutrient Removal in SBR with Biomass Adapted to Dairy Wastewater. J. Environ. Sci. Health A Toxic/Hazard. Subst. Environ. Eng. 2013, 48, 809–816. [Google Scholar] [CrossRef]

- Wu, L.; Wei, W.; Xu, J.; Chen, X.; Liu, Y.; Peng, L.; Wang, D.-B.; Ni, B.-J. Denitrifying Biofilm Processes for Wastewater Treatment: Developments and Perspectives. Environ. Sci. 2020, 7, 40–67. [Google Scholar] [CrossRef]

- Park, J.B.K.; Craggs, R.J.; Sukias, J.P.S. Treatment of Hydroponic Wastewater by Denitrification Filters Using Plant Prunings as the Organic Carbon Source. Bioresour. Technol. 2008, 99, 2711–2716. [Google Scholar] [CrossRef] [PubMed]

- Castellar, J.A.C.; Formosa, J.; Fernández, A.I.; Jové, P.; Bosch, M.G.; Morató, J.; Brix, H.; Arias, C.A. Cork as a Sustainable Carbon Source for Nature-Based Solutions Treating Hydroponic Wastewaters—Preliminary Batch Studies. Sci. Total Environ. 2019, 650, 267–276. [Google Scholar] [CrossRef] [PubMed]

- Bryszewski, K.; Rodziewicz, J.; Mielcarek, A. Usuwanie w Reaktorze Typu Sequencing Batch Biofilm Reactor (SBBR) Azotu i Fosforu Ze Ścieków Pochodzących z Bezglebowej Uprawy Pomidorów. Gaz Woda Tech. Sanit. 2018, Nr 5, 26–28. [Google Scholar] [CrossRef]

- Rodziewicz, J.; Mielcarek, A.; Janczukowicz, W.; Jóźwiak, T.; Struk–Sokołowska, J.; Bryszewski, K. The Share of Electrochemical Reduction, Hydrogenotrophic and Heterotrophic Denitrification in Nitrogen Removal in Rotating Electrobiological Contactor (REBC) Treating Wastewater from Soilless Cultivation Systems. Sci. Total Environ. 2019, 683, 21–28. [Google Scholar] [CrossRef] [PubMed]

- Dunets, C.S.; Zheng, Y. Removal of Phosphate from Greenhouse Wastewater Using Hydrated Lime. Environ. Technol. 2014, 35, 2852–2862. [Google Scholar] [CrossRef]

- Mielcarek, A.; Jóźwiak, T.; Rodziewicz, J.; Bryszewski, K.; Janczukowicz, W.; Kalisz, B.; Tavares, J.M.R. Recovery of Phosphorus and Other Minerals from Greenhouse Wastewater Generated during Soilless Tomato Cultivation by Means of Alkalizing Agents. Sci. Total Environ. 2023, 892, 164757. [Google Scholar] [CrossRef]

- Jóźwiak, T.; Mielcarek, A.; Janczukowicz, W.; Rodziewicz, J.; Majkowska-Gadomska, J.; Chojnowska, M. Hydrogel Chitosan Sorbent Application for Nutrient Removal from Soilless Plant Cultivation Wastewater. Environ. Sci. Pollut. Res. 2018, 25, 18484–18497. [Google Scholar] [CrossRef]

| Parameters | Tomato [36] | Tomato [24] | Citrus Nursery [37] | Tomato [38] | Hydroponic Vegetable Greenhouse [35] | Tomato [27] | Tomato [39] | Tomato [28] | ||

|---|---|---|---|---|---|---|---|---|---|---|

| pH | - | 5.35 | 6.22 | 6.4 | 5.40 | 5.5 | 6.5 | 5.43 | - | - |

| EC | mS/cm | 7.57 | 4.60 | 3.6 | 6.09 | - | 3.0 | 6.15 | 4.4–6.9 | 4.9–6.9 |

| Total nitrogen | mg/L | 592.3 | 439 | 514.5 | 501.8 | 466 | 242 | 504.7 | 403.6–614.8 | 270.0–577.4 |

| Total phosphorus | 145.9 | 76 | 161.7 | 81 | 370 | 106 | 79.3 | 35.4–78.0 | 54.1–104.0 | |

| Ca | 797.0 | 402 | 9.28 | 588.8 | 539 | 334 | - | - | - | |

| Mg | 181.1 | 121 | 2.33 | 261.6 | - | 140 | - | - | - | |

| S-SO4 | 475.0 | 194.3 | 51.1 | - | 61 | - | - | - | ||

| K | 1276.9 | 522 | - | - | 163 | - | - | - | ||

| Cl | 91.8 | 17 | - | - | - | - | - | |||

| Fe | 0.127 | 3.51 | 1.49 | 0.592 | 0.22 | - | 0.492 | - | - | |

| Cu | 0.13 | 0.38 | 0.52 | 0.03 | - | - | - | - | ||

| Zn | 1.65 | 2.60 | 1.16 | 0.76 | - | - | - | - | ||

| Mn | 0.738 | 0.61 | 0.90 | 0.03 | - | - | - | - | ||

| B | 1.75 | 0.68 | - | 0.01 | - | - | - | - | ||

| Al | <0.02 | - | - | 0.017 | - | - | 0.016 | - | - | |

| Mo | 2.87 | - | - | - | - | - | - | - | ||

| Parameters | Concentration [mg/L] |

|---|---|

| N-NO3 | 220–230 |

| P | 30–60 |

| K | 360 |

| Mg | 50–80 |

| Ca | 200–210 |

| SO4 | 80–100 |

| Fe | 1.2–1.6 |

| Mn | 0.5–0.1 |

| B | 0.3–0.5 |

| Zn | 0.3–0.35 |

| Cu | 0.12 |

| Mo | 0.05–0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mielcarek, A.; Kłobukowska, K.; Rodziewicz, J.; Janczukowicz, W.; Bryszewski, K.Ł. Water Nutrient Management in Soilless Plant Cultivation versus Sustainability. Sustainability 2024, 16, 152. https://doi.org/10.3390/su16010152

Mielcarek A, Kłobukowska K, Rodziewicz J, Janczukowicz W, Bryszewski KŁ. Water Nutrient Management in Soilless Plant Cultivation versus Sustainability. Sustainability. 2024; 16(1):152. https://doi.org/10.3390/su16010152

Chicago/Turabian StyleMielcarek, Artur, Karolina Kłobukowska, Joanna Rodziewicz, Wojciech Janczukowicz, and Kamil Łukasz Bryszewski. 2024. "Water Nutrient Management in Soilless Plant Cultivation versus Sustainability" Sustainability 16, no. 1: 152. https://doi.org/10.3390/su16010152