Free Vibrations of Sustainable Laminated Veneer Lumber Slabs

Abstract

1. Introduction

1.1. LVL as a Sustainable Material

1.2. Dynamic Tests of LVL Slabs

2. Materials and Methods

2.1. The LVL Panels

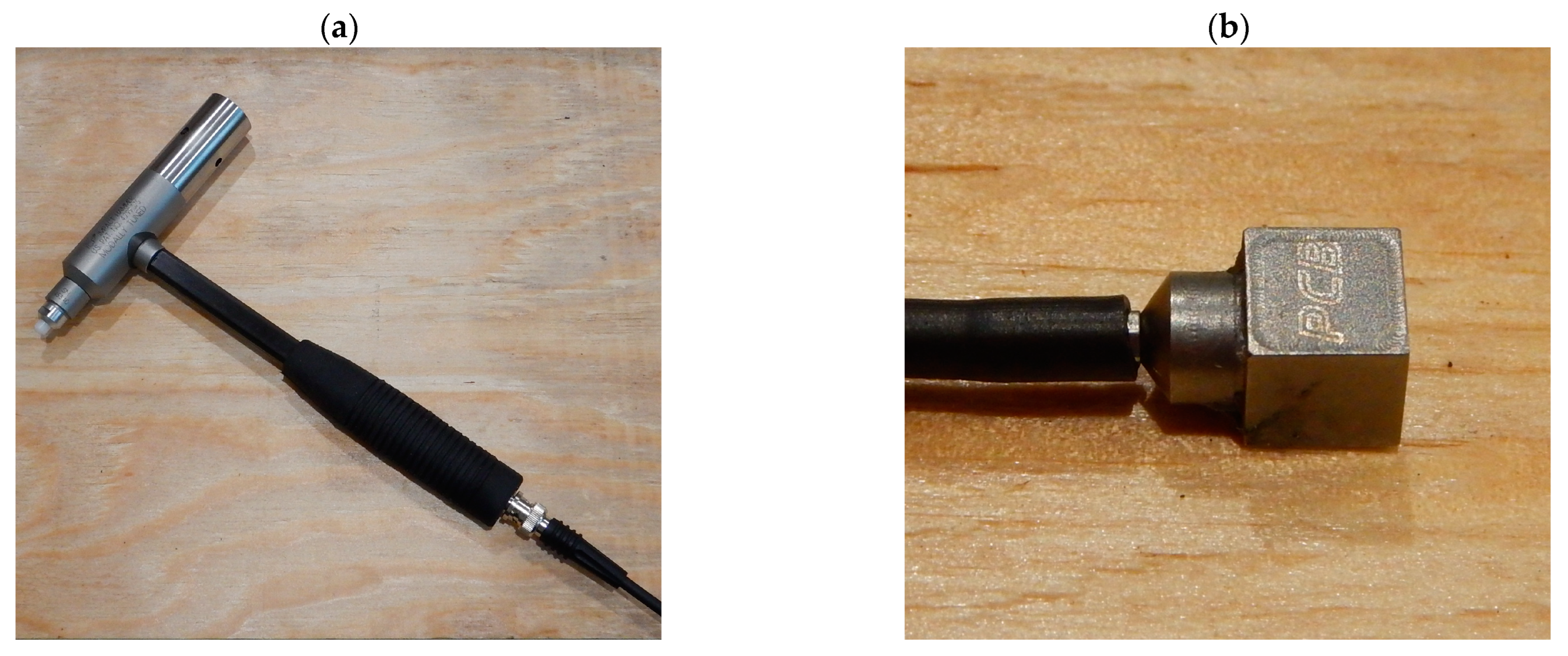

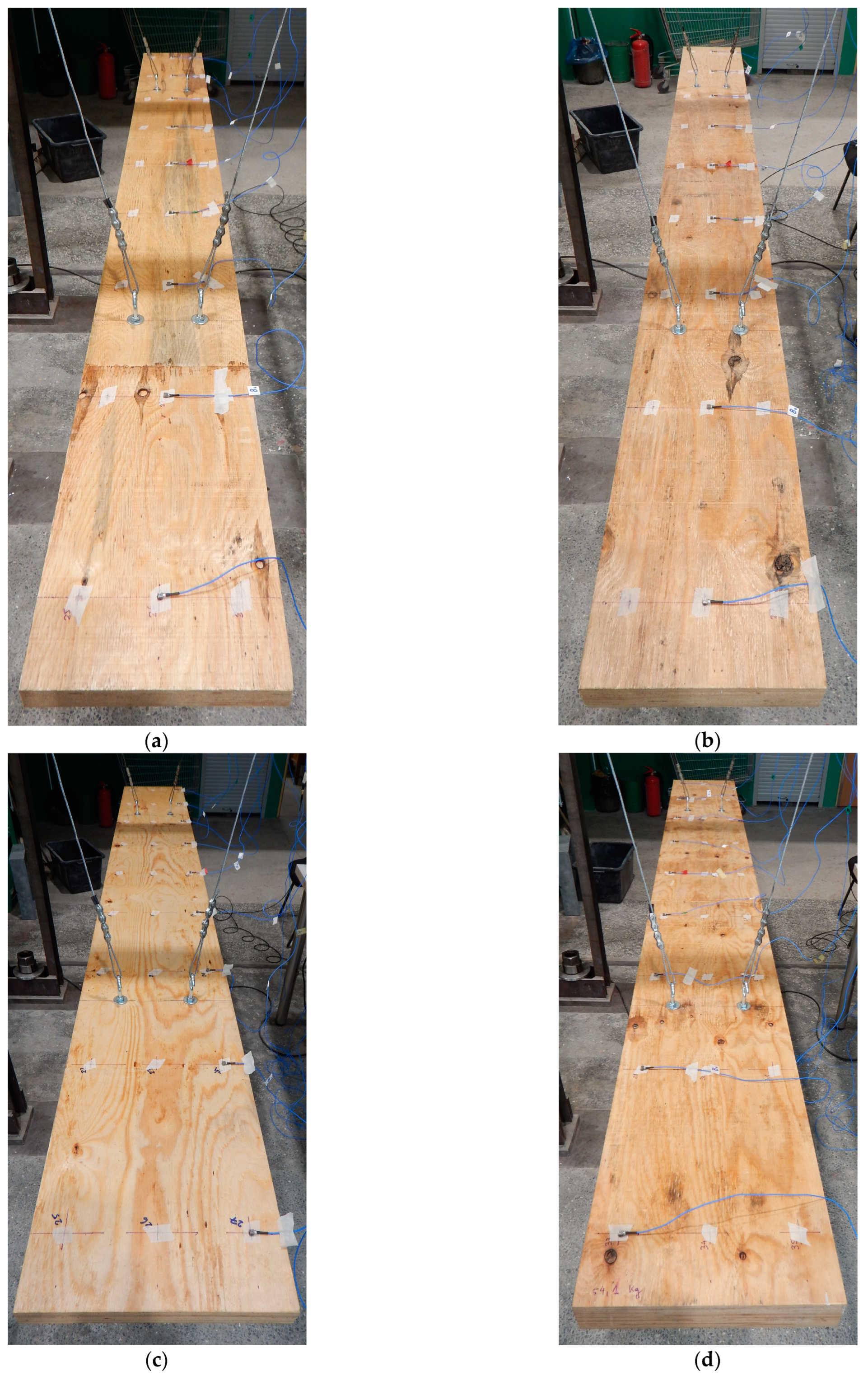

2.2. The Experimental Tests of the LVL Panels

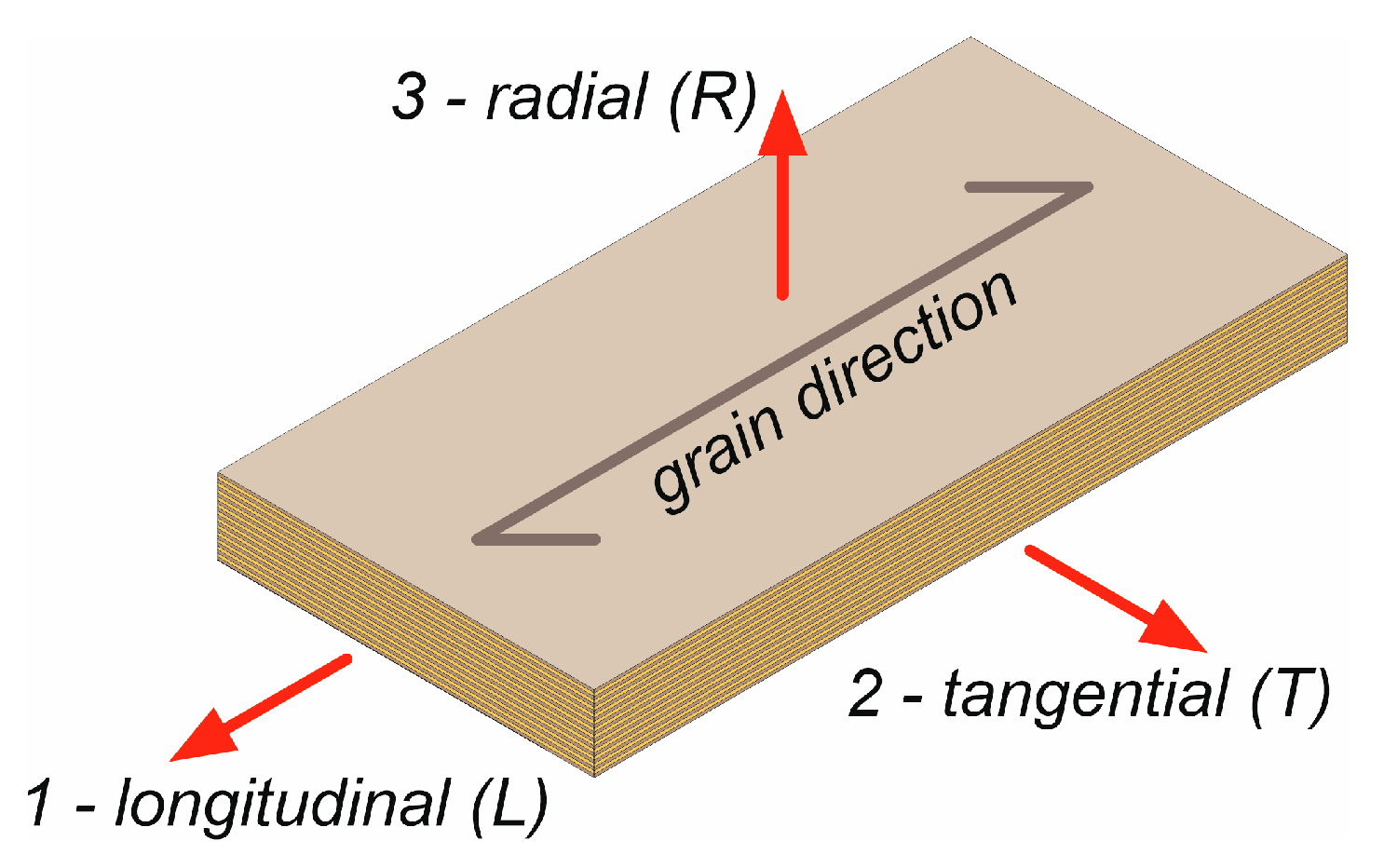

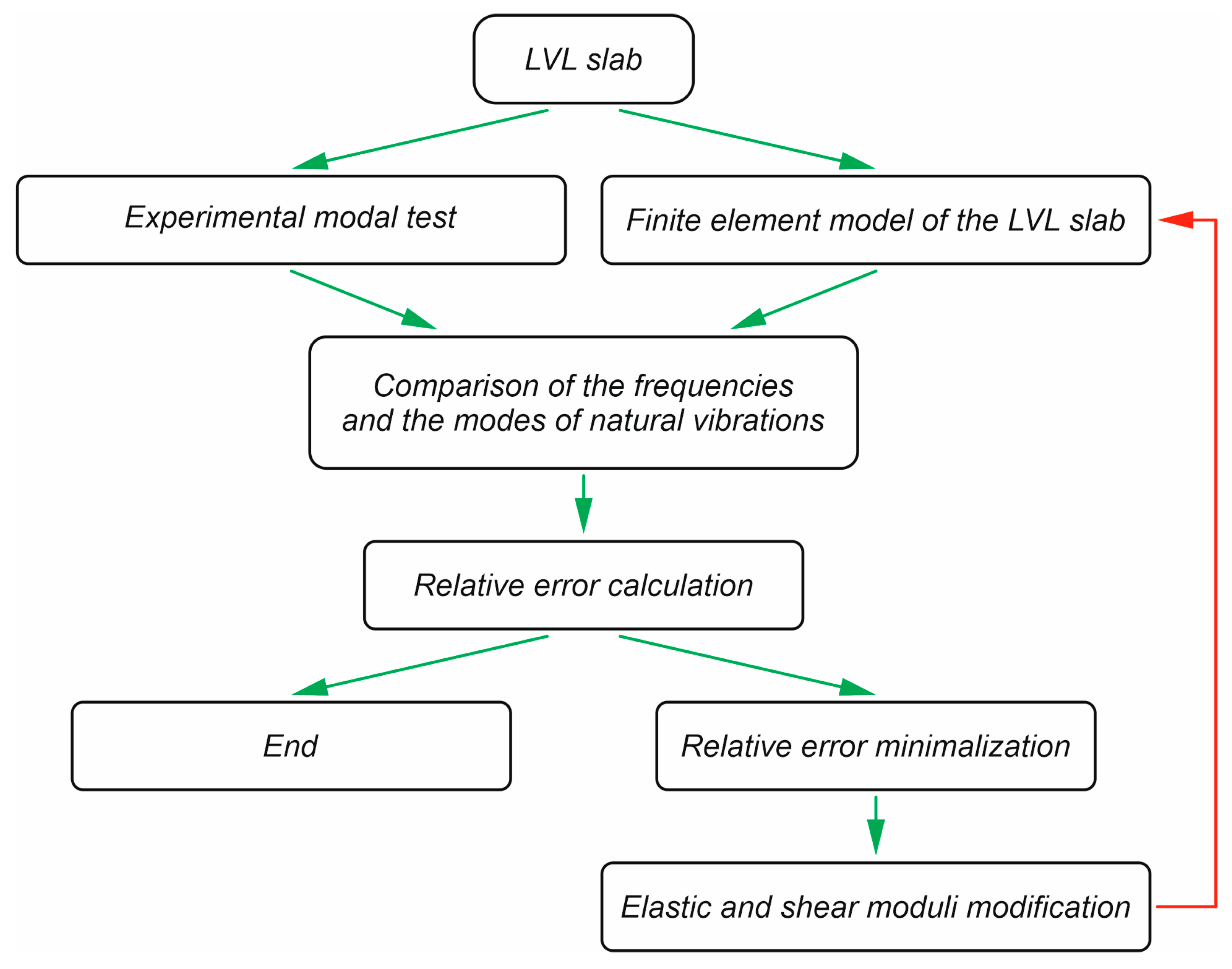

2.3. The Numerical Models of the LVL Panels

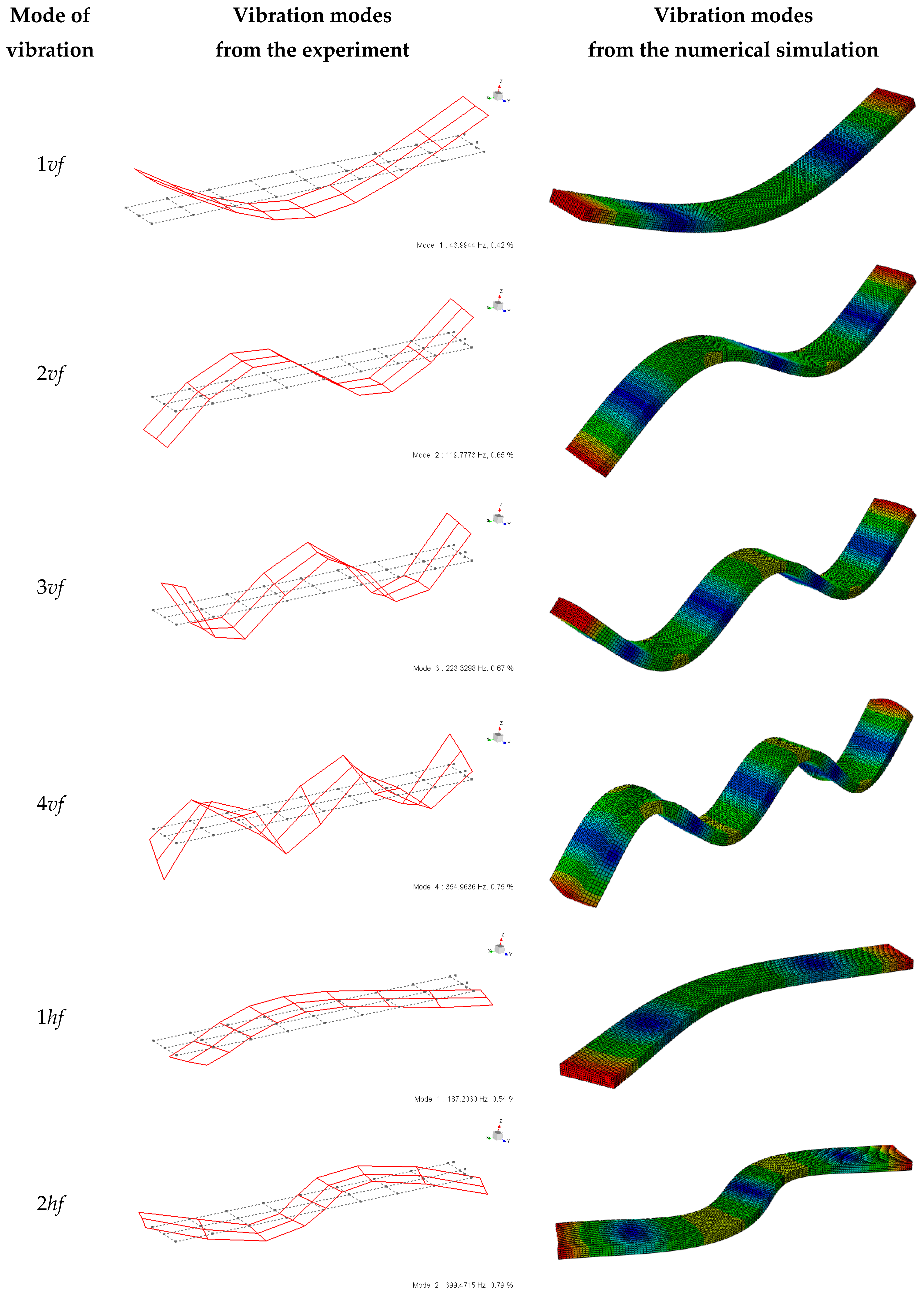

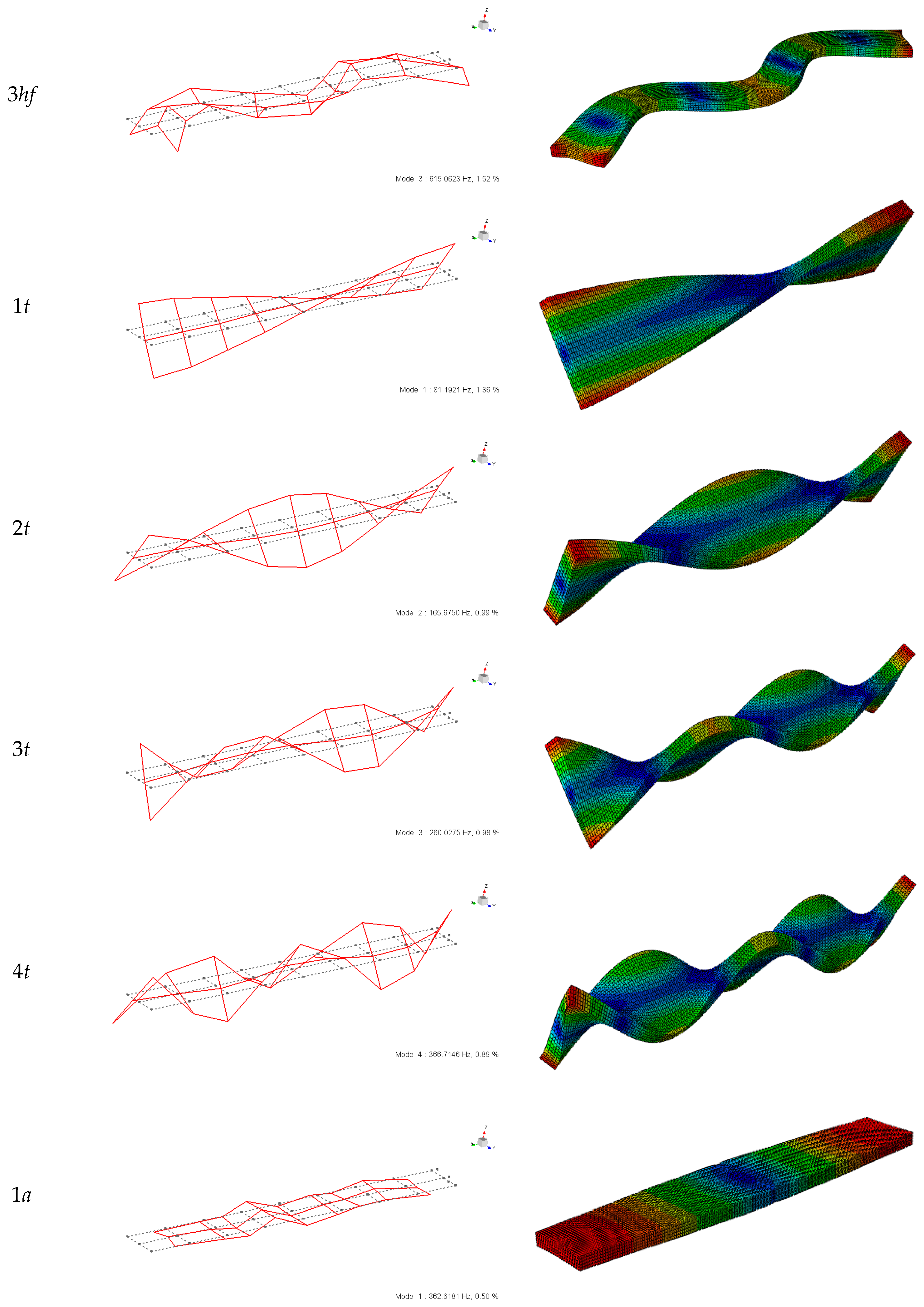

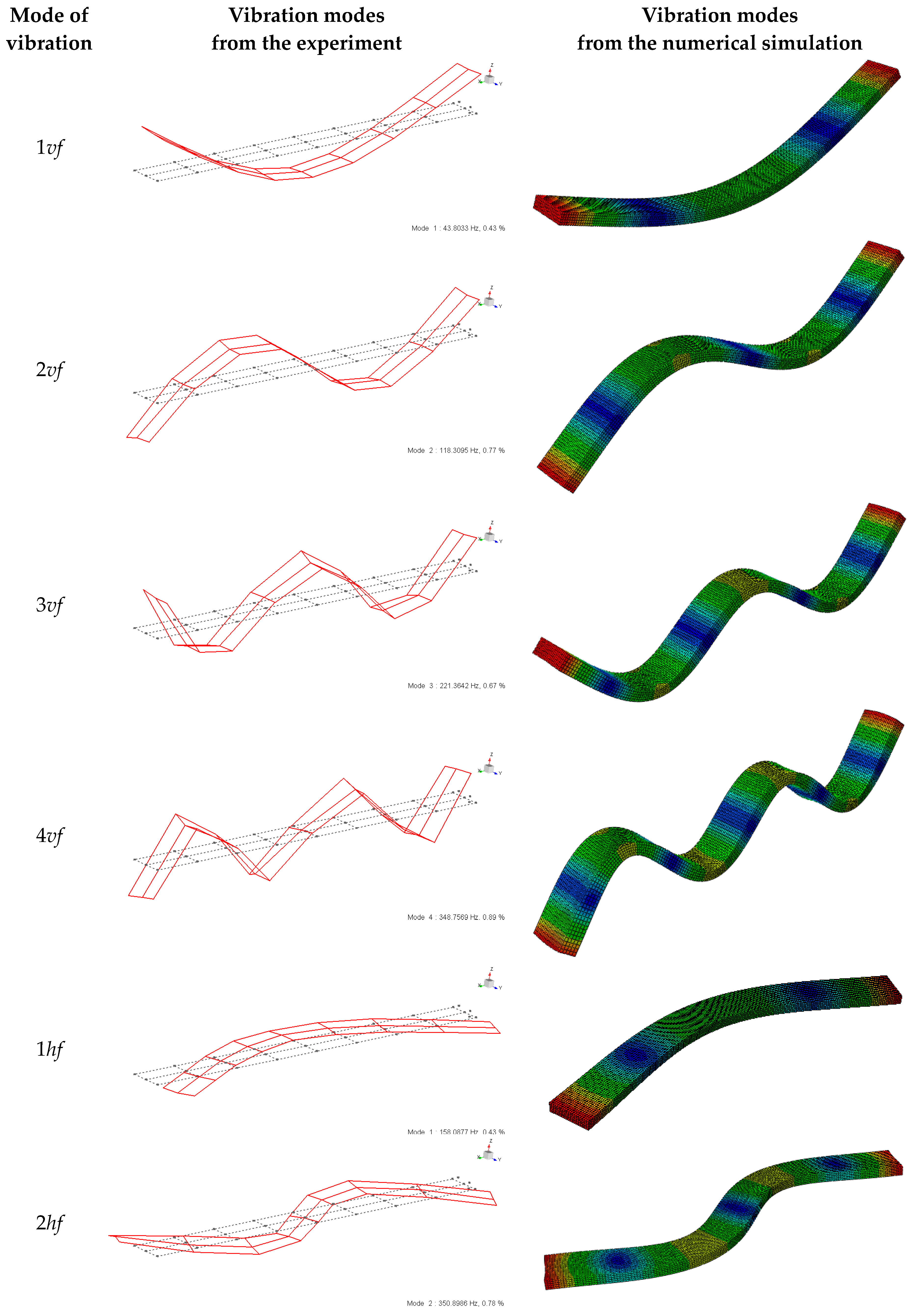

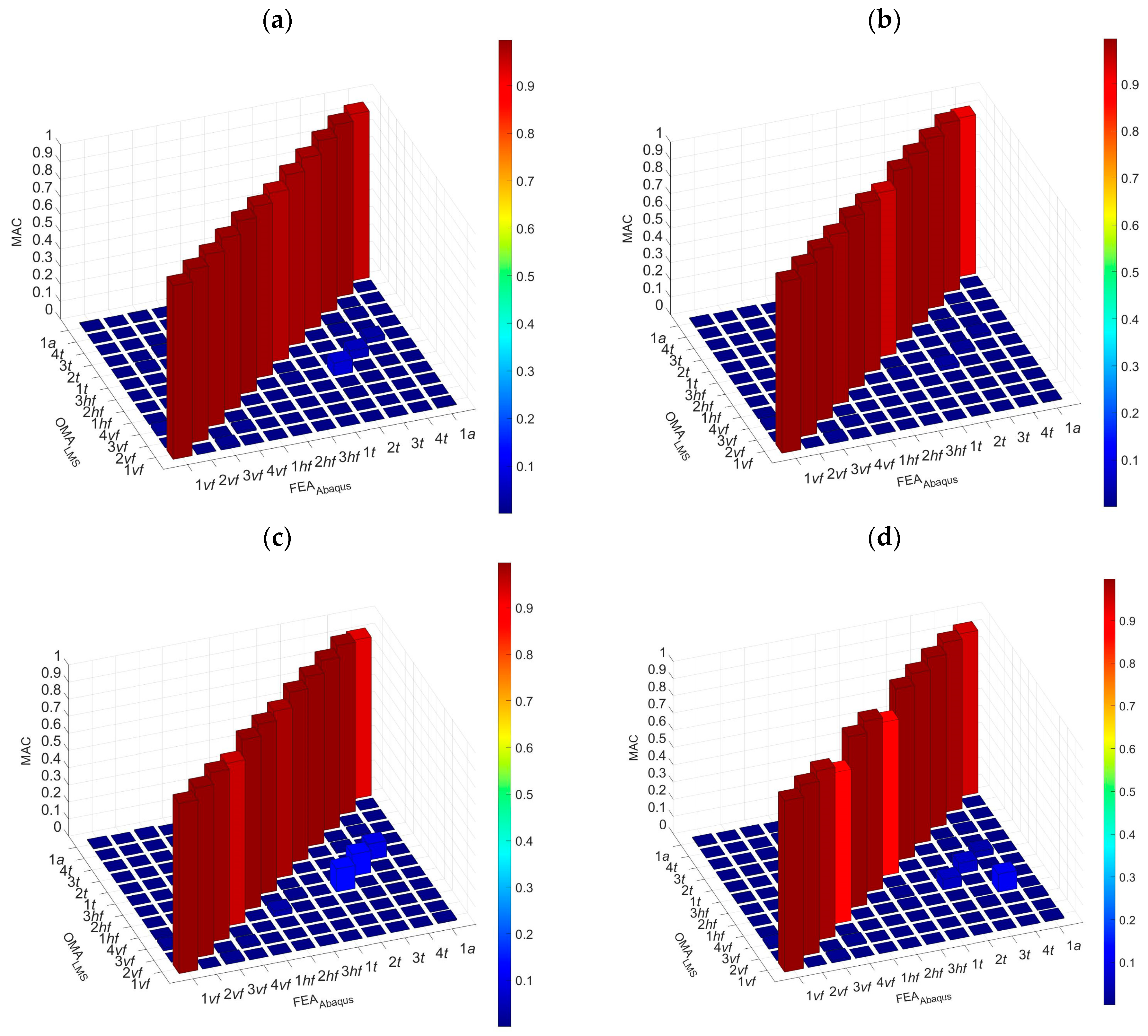

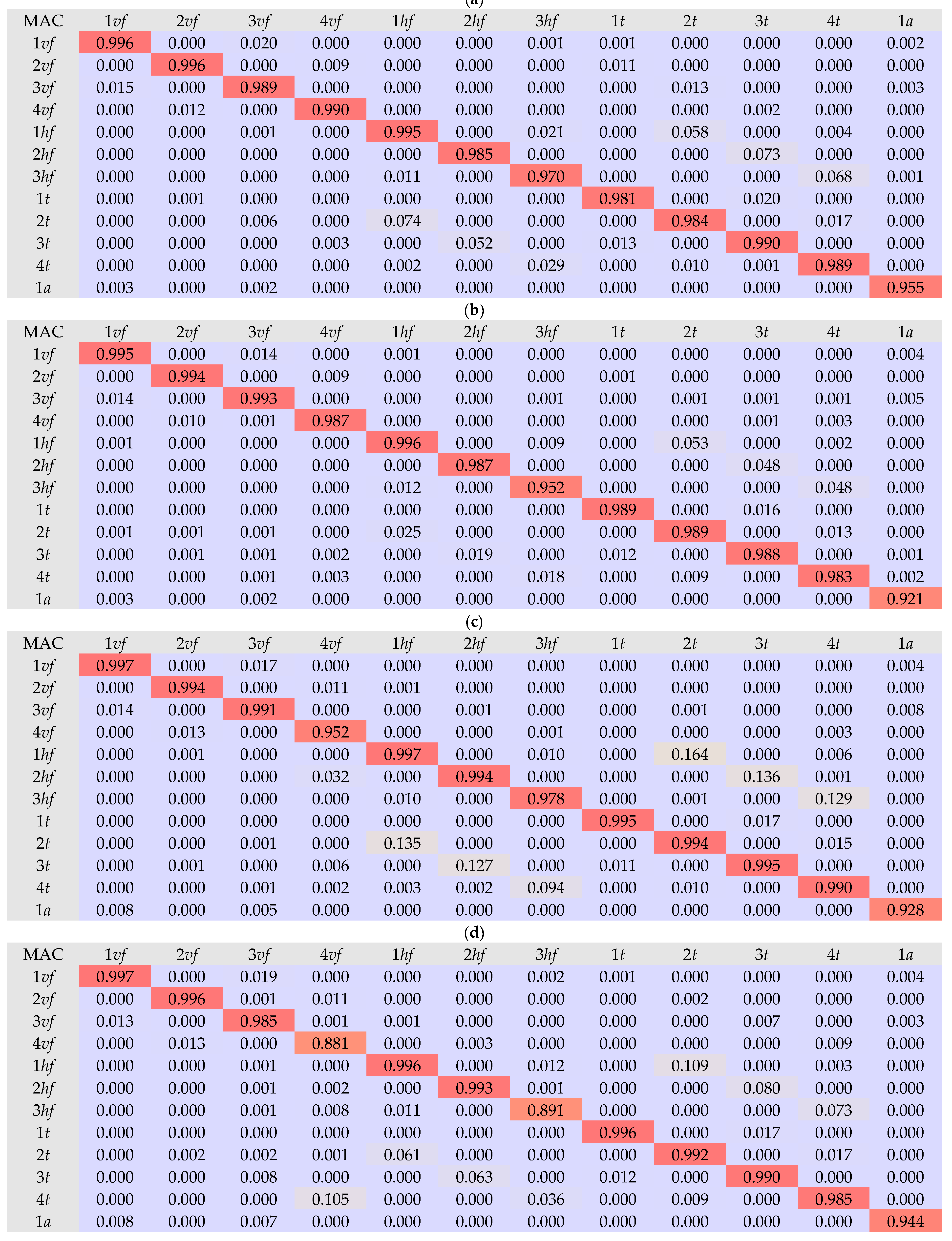

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tupenaite, L.; Kanapeckiene, L.; Naimaviciene, J.; Kaklauskas, A.; Gecys, T. Timber Construction as a Solution to Climate Change: A Systematic Literature Review. Buildings 2023, 13, 976. [Google Scholar] [CrossRef]

- Heräjärvi, H. Wooden buildings as carbon storages–Mitigation or oration? Wood Mater. Sci. Eng. 2019, 14, 291–297. [Google Scholar] [CrossRef]

- Musselman, E.S.; Dinehart, D.W.; Walker, S.M.; Mancini, M.L. The effect of holes on the creep behavior and flexural capacity of laminated veneer lumber (LVL) beams. Constr. Build. Mater. 2018, 180, 167–176. [Google Scholar] [CrossRef]

- Komorowski, M. Podręcznik Projektowania i Budowania w Systemie STEICO. Podstawy. Fizyka Budowli. Zalecenia Wykonawcze; Forestor Communication: Warsaw, Poland, 2020. (In Polish) [Google Scholar]

- Hammad, M.W.; Valipour, H.R.; Ghanbari-Ghazijahani, T.; Bradford, M.A. Timber-timber composite (TTC) beams subjected to hogging moment. Constr. Build. Mater. 2022, 321, 126295. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Wu, P.; Li, Y. Experimental investigation on the flexural and shear behaviour of LVL I-beam strengthened with steel channels. Constr. Build. Mater. 2022, 341, 127719. [Google Scholar] [CrossRef]

- Hiziroglu, S. Laminated Veneer Lumber (LVL) as a Construction Material. In Food Technology Fact Sheet; FAPC-163; Oklahoma State University: Stillwater, OK, USA, 2016. [Google Scholar]

- Chiniforush, A.A.; Valipour, H.R.; Ataei, A. Timber-timber composite (TTC) connections and beams: An experimental and numerical study. Constr. Build. Mater. 2021, 303, 124493. [Google Scholar] [CrossRef]

- Hassan, O.A.B.; Johansson, C.J. Glued laminated timber and steel beams. A comparative study of structural design, economic and environmental consequences. Eng. Des. Technol. 2018, 16, 398–417. [Google Scholar] [CrossRef]

- Wilson, J.B.; Dancer, E.R. Gate-to-gate life-cycle inventory of laminated veneer lumber production. Wood Fiber Sci. 2005, 37, 114–127. [Google Scholar]

- Mirdad, M.A.H.; Daneshvar, H.; Joyce, T.; Chu, Y.H. Sustainability Design Considerations for Timber-Concrete Composite Floor Systems. Hindawi Adv. Civ. Eng. 2021, 2021, 6688076. [Google Scholar] [CrossRef]

- United Nations; the Food and Agriculture Organization of the United Nations. Circularity Concepts in Wood Construction; ECE/TIM/DP/95; Forestry and Timber Section: Geneva, Switzerland, 2023.

- Annual and Sustainability Report; Metsä Group: Espoo, Finland, 2022.

- Sustainability Report; STEICO: Feldkirchen, Germany, 2020.

- The LVL Kitset Portal Frame Solution, hyFRAME LVL Kitset Brochure; Carter Holt Harvey, Futurebuild LVL: Auckland, New Zealand, 2018.

- Winchester, N.; Reilly, J.M. The economic and emissions benefits of engineered wood products in a low-carbon future. Energy Econ. 2020, 85, 104596. [Google Scholar] [CrossRef]

- Upton, B.; Miner, R.; Spinney, M.; Heath, L.S. The greenhouse gas and energy impacts of using wood instead of alternatives in residential construction in the United States. Bio-Mass Bioenergy 2008, 32, 1–10. [Google Scholar] [CrossRef]

- Tellnes, L.G.F.; Eide, S.; Kristjansdottir, T.F.; Kron, M. Assessment of carbon footprint of laminated veneer lumber elements in a six story housing–comparison to a steel and concrete solution. In Proceedings of the International Conference Portugal SB13-Contribution of Sustainable Building to Meet EU 20-20-20 Targets, Guimarães, Portugal, 30 October–1 November 2013; Bragança, L., Mateus, R., Pinheiro, M., Eds.; MULTICOMP-Artes Gráficas, Lda: Estoril, Portugal, 2013; pp. 817–824. [Google Scholar]

- Lu, H.R.; El Hanandeh, A.; Gilbert, B.; Bailleres, H. A comparative life cycle assessment (LCA) of alternative material for Australian building construction. MATEC Web Conf. 2017, 120, 02013. [Google Scholar] [CrossRef]

- Bakalarz, M.M.; Kossakowski, P.G. Application of Transformed Cross-Section Method for Analytical Analysis of Laminated Veneer Lumber Beams Strengthened with Composite Materials. Fibers 2023, 11, 24. [Google Scholar] [CrossRef]

- Hassanieh, A.; Valipour, H.R.; Bradford, M.A. Experimental and analytical behaviour of steel-timber composite connections. Constr. Build. Mater. 2016, 118, 63–75. [Google Scholar] [CrossRef]

- Romero, A.; Yang, J.; Hanus, F.; Odenbreit, C. Numerical Investigation of Steel-LVL Timber Composite Beams. Ce/Papers 2022, 5, 21–30. [Google Scholar] [CrossRef]

- Chybiński, M.; Polus, Ł. Experimental and numerical investigations of aluminium-timber composite beams with bolted connections. Structures 2021, 34, 1942–1960. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, Y.; Wang, C.-L.; Zhou, Y.; Zheng, J. Experimental study of the shear performance of H-shaped aluminum-timber composite connections. Constr. Build. Mater. 2022, 334, 127421. [Google Scholar] [CrossRef]

- Nie, Y.; Valipour, H.R. Experimental and numerical study of long-term behaviour of timber-timber composite (TTC) connections. Constr. Build. Mater. 2021, 304, 124672. [Google Scholar] [CrossRef]

- Nie, Y.; Karimi-Nobandegani, A.; Valipour, H.R. Experimental behaviour and numerical modelling of timber-timber composite (TTC) joints. Constr. Build. Mater. 2021, 290, 123273. [Google Scholar] [CrossRef]

- Khorsandnia, N.; Valipour, H.R.; Crews, K. Experimental and analytical investigation of short-term behaviour of LVL–concrete composite connections and beams. Constr. Build. Mater. 2012, 37, 229–238. [Google Scholar] [CrossRef]

- Khorsandnia, N.; Valipour, H.; Bradford, M. Deconstructable timber-concrete composite beams with panelised slabs: Finite element analysis. Constr. Build. Mater. 2018, 163, 798–811. [Google Scholar] [CrossRef]

- Jaaranen, J.; Fink, G. Experimental and numerical investigations of two-way LVL–concrete composite plates with various support conditions. Eng. Struct. 2022, 256, 114019. [Google Scholar] [CrossRef]

- Chorlton, B.; Gales, J. Mechanical performance of laminated veneer lumber and Glulam beams after short-term incident heat exposure. Constr. Build. Mater. 2020, 263, 120129. [Google Scholar] [CrossRef]

- Hamm, P.; Richter, A.; Winter, S. Floor vibrations–new results. In Proceedings of the 11th World Conference on Timber Engineering 2010 (WCTE 2010); Ceccotti, A., Ed.; Trees and Timber Institute, National Research Council: Sesto Fiorentino, Italy, 2010. [Google Scholar]

- Chiniforush, A.A.; Akbarnezhad, A.; Valipour, H.; Dackermann, U. Dynamic response of steel-timber composite (STC) beams. In Proceedings of the 24th International Congress on Sound and Vibration, London, UK, 23–27 July 2017. [Google Scholar]

- Wen, B.; Tao, H.; Shi, B.; Yang, H. Dynamic Properties of Timber–Concrete Composite Beams with Crossed Inclined Coach Screw Connections: Experimental and Theoretical Investigations. Buildings 2023, 13, 2268. [Google Scholar] [CrossRef]

- Meng, Z.B.; Ren, X.C.; Chai, S.Q.; Wang, X.; Zhao, T.F.; Gao, F.F.; Wang, S.; Liu, Y. Wood Beam Damage Identification Based on the Curvature Mode and Wavelet Transform. Adv. Civ. Eng. 2023, 1, 2238021. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, X.; Wang, Y.; Yang, R.; Wang, G.; Wang, Z. Measurement of the Poisson’s ratio of materials based on the bending mode of the cantilever plate. BioResources 2016, 11, 5703–5721. [Google Scholar] [CrossRef]

- Ross, R.J. Nondestructive Evaluation of Wood; General Technical Report FPL-GTR-238; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2015.

- Berczyński, S.; Wróblewski, T. Vibration of Steel–Concrete Composite Beams Using the Timoshenko Beam Model. J. Vib. Control 2005, 11, 829–848. [Google Scholar] [CrossRef]

- Berczyński, S.; Wróblewski, T. Experimental Verification of Natural Vibration Models of Steel-Concrete Composite. J. Vib. Control 2010, 16, 2057–2081. [Google Scholar] [CrossRef]

- NA to BS EN 1991-1-1:2002; UK National Annex to Eurocode 1: Actions on Structures. British Standards Institution: London, UK, 2005.

- EN 1995-1-1; Eurocode 5: Design of Timber Structures-Part 1-1: General-Common Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- EKS 10: BFS 2015:6; Swedish National Annex for Application of Eurocodes. The National Board of Housing, Building and Planning: Karlskrona, Sweden, 2015.

- Schirén, W.; Swahn, T. Vibrations in Residential Timber Floors. A Comparison Between the Current and the Revised Eurocode 5. Master’s Thesis, Linnaeus University, Växjö, Sweden, 2019. [Google Scholar]

- Wróblewski, T.; Pełka-Sawenko, A.; Abramowicz, M.; Berczyński, B. Modeling and analysis of free vibration of steel-concrete composite beams by finite element method. Adv. Manuf. Sci. Technol. 2012, 36, 85–96. [Google Scholar]

- Huang, Y.; Chen, S.; Dauletbek, A.; Yang, X.; Wang, J.; Sun, X.; Xie, W.; Wang, Z. Dynamic testing of the elastic modulus and shear modulus of full-scale laminated veneer lumber. BioResources 2021, 16, 8273–8288. [Google Scholar] [CrossRef]

- Timoshenko, S. Mechanical Vibration Science; China Machine Press: Beijing, China, 1965. [Google Scholar]

- Timoshenko, S. Vibration Problems in Engineering; D. Van Nostrand Company: New York, NY, USA, 1937. [Google Scholar]

- Kawrza, M.; Furtmüller, T.; Adam, C. Experimental and numerical modal analysis of a cross laminated timber floor system in different construction states. Constr. Build. Mater. 2022, 344, 128032. [Google Scholar] [CrossRef]

- Kouroussis, G.; Fekih, L.B.; Descamps, T. Assessment of timber element mechanical properties using experimental modal analysis. Constr. Build. Mater. 2017, 134, 254–261. [Google Scholar] [CrossRef]

- Gsell, D.; Feltrin, G.; Schubert, S.; Steiger, R.; Motavalli, M. Cross-laminated timber plates: Evaluation and verification of homogenized elastic properties. J. Struct. Eng. 2007, 133, 132–138. [Google Scholar] [CrossRef]

- Jarosińska, M.; Berczyński, S. Changes in Frequency and Mode Shapes Due to Damage in Steel–Concrete Composite Beam. Materials 2021, 14, 6232. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.-J. Comparison of Mode Shapes of Carbon-Fiber-Reinforced Plastic Material Considering Carbon Fiber Direction. Crystals 2021, 11, 311. [Google Scholar] [CrossRef]

- Pastor, M.; Binda, M.; Harčarik, T. Modal Assurance Criterion. Procedia Eng. 2012, 48, 543–548. [Google Scholar] [CrossRef]

- Shabani, A.; Feyzabadi, M.; Kioumarsi, M. Model updating of a masonry tower based on operational modal analysis: The role of soil-structure interaction. Case Stud. Constr. Mater. 2022, 16, e00957. [Google Scholar] [CrossRef]

- Marwala, T. Finite-Element-Model Updating Using Computational Intelligence Techniques; Springer: London, UK, 2010. [Google Scholar]

- Abramowicz, M.; Berczyński, S.; Wróblewski, T. Parameter estimation of a discrete model of a reinforced concrete slab. J. Theor. Appl. Mech. 2017, 55, 407–420. [Google Scholar] [CrossRef][Green Version]

- Pełka-Sawenko, A. Zastosowanie Metod Dostrajania Modeli Dyskretnych oraz Transformaty Falkowej do Diagnostyki Uszkodzeń Belek Zespolonych [Application an Identification Technique of Discrete Models and Wavelet Transform for Damage Diagnostics of Composite Beams]; West Pomeranian University of Technology in Szczecin: Szczecin, Poland, 2019. (In Polish) [Google Scholar]

- Abramowicz, M.; Berczyński, S.; Wróblewski, T. Modelling and parameter identifcation of steel–concrete composite beams in 3D rigid fnite element method. Arch. Civ. Mech. Eng. 2020, 20, 103. [Google Scholar] [CrossRef]

- Szewczyk, P. Wzmacnianie Pod Obciążeniem Stalowo-Betonowych Belek Zespolonych w Analizie Numerycznej i Badaniach Doświadczalnych [Strenghtening of Steel-Concrete Composite Beams under Load in a Numerical Analysis and a Physical Experiment]; West Pomeranian University of Technology in Szczecin: Szczecin, Poland, 2019. (In Polish) [Google Scholar]

- Szewczyk, P.; Szumigała, M. Optimal Design of Steel–Concrete Composite Beams Strengthened under Load. Materials 2021, 14, 4715. [Google Scholar] [CrossRef]

- Hassanieh, A.; Valipour, H.R.; Bradford, M.A.; Sandhaas, C. Modelling of steel-timber composite connections: Validation of finite element model and parametric study. Eng. Struct. 2017, 138, 35–49. [Google Scholar] [CrossRef]

- Sandhaas, C. Mechanical Behaviour of Timber Joints with Slotted-in Steel Plates. Ph.D. Thesis, Delft University of Technology, Delf, Netherlands, 2012. [Google Scholar]

- Wdowiak-Postulak, A. Numerical, theoretical and experimental models of the static performance of timber beams reinforced with steel, basalt and glass pre-stressed bars. Compos. Struct. 2023, 305, 116479. [Google Scholar] [CrossRef]

- Wdowiak-Postulak, A.; Bahleda, F.; Prokop, J. An Experimental and Numerical Analysis of Glued Laminated Beams Strengthened by Pre-Stressed Basalt Fibre-Reinforced Polymer Bars. Materials 2023, 16, 2776. [Google Scholar] [CrossRef] [PubMed]

- Van Beerschoten, W.A. Structural Performance of Post-Tensioned Timber Frames under Gravity Loading. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2013. [Google Scholar]

- Design Guide STEICO LVL/Laminated Veneer Lumber; STEICO: Feldkirchen, Germany, 2019.

| Panel | Dimensions [mm] | LVL | Density [kg/m3] |

|---|---|---|---|

| P_45_300 | 45 × 300 × 3000 | R | 587.7 |

| P_45_370X | 45 × 370 × 3000 | X | 616.6 |

| P_75_300 | 75 × 300 × 3000 | R | 665.2 |

| P_75_370 | 75 × 370 × 3000 | R | 649.8 |

| Panel | LVL | Elastic Modulus [MPa] | Poisson’s Ratio [–] | Shear Modulus [MPa] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| E1 | E2 | E3 | υ12 | υ13 | υ23 | G12 | G13 | G23 | ||

| P_45_300 | R | 15,600 | 400 | 400 | 0.48 | 0.48 | 0.22 | 870 | 870 | 90 |

| P_45_370X | X | 13,400 | 700 | 700 | 0.48 | 0.48 | 0.22 | 900 | 900 | 90 |

| P_75_300 | R | 17,550 | 500 | 500 | 0.48 | 0.48 | 0.22 | 1000 | 1000 | 100 |

| P_75_370 | R | 17,400 | 500 | 500 | 0.48 | 0.48 | 0.22 | 1070 | 1070 | 100 |

| Panel | LVL | Elastic Modulus [MPa] | ||

|---|---|---|---|---|

| E1i | E1e | E1e/E1i | ||

| P_45_300 | R | 15,600 | 15,487 | 0.99 |

| P_45_370X | X | 13,400 | 13,180 | 0.98 |

| P_75_300 | R | 17,550 | 17,390 | 0.99 |

| P_75_370 | R | 17,400 | 17,136 | 0.98 |

| Panel | Mode of Vibration | Experimental Frequency fexp [Hz] | Computational Frequency fcom [Hz] | Relative Error Δ = 100 × (fexp − fcom)/fexp [%] |

|---|---|---|---|---|

| P_45_300 | 1vf | 26.387 | 26.408 | −0.08 |

| 2vf | 73.442 | 72.323 | 1.52 | |

| 3vf | 136.910 | 140.380 | −2.53 | |

| 4vf | 222.013 | 228.990 | −3.14 | |

| 1hf | 153.238 | 157.730 | −2.93 | |

| 2hf | 345.102 | 354.660 | −2.77 | |

| 3hf | 541.408 | 562.720 | −3.94 | |

| 1t | 60.544 | 57.841 | 4.46 | |

| 2t | 122.993 | 119.270 | 3.03 | |

| 3t | 190.931 | 187.620 | 1.73 | |

| 4t | 263.068 | 265.990 | −1.11 | |

| 1a | 859.937 | 858.750 | 0.14 | |

| P_45_370X | 1vf | 23.765 | 23.907 | −0.60 |

| 2vf | 65.494 | 65.560 | −0.10 | |

| 3vf | 122.550 | 127.480 | −4.02 | |

| 4vf | 196.190 | 208.380 | −6.21 | |

| 1hf | 174.117 | 171.130 | 1.72 | |

| 2hf | 374.978 | 372.570 | 0.64 | |

| 3hf | 589.589 | 586.720 | 0.49 | |

| 1t | 48.319 | 47.364 | 1.98 | |

| 2t | 97.279 | 98.402 | −1.15 | |

| 3t | 152.465 | 156.560 | −2.69 | |

| 4t | 215.757 | 225.110 | −4.33 | |

| 1a | 776.164 | 776.560 | −0.05 | |

| P_75_300 | 1vf | 43.803 | 43.660 | 0.33 |

| 2vf | 118.309 | 118.150 | 0.13 | |

| 3vf | 221.364 | 225.430 | −1.84 | |

| 4vf | 348.757 | 359.890 | −3.19 | |

| 1hf | 158.088 | 157.530 | 0.35 | |

| 2hf | 350.899 | 355.240 | −1.24 | |

| 3hf | 557.664 | 570.750 | −2.35 | |

| 1t | 91.843 | 91.522 | 0.35 | |

| 2t | 187.673 | 187.100 | 0.31 | |

| 3t | 288.364 | 290.610 | −0.78 | |

| 4t | 397.100 | 405.860 | −2.21 | |

| 1a | 857.270 | 856.210 | 0.12 | |

| P_75_370 | 1vf | 43.994 | 44.009 | −0.02 |

| 2vf | 119.777 | 119.250 | 0.38 | |

| 3vf | 223.330 | 227.930 | −2.07 | |

| 4vf | 354.964 | 364.520 | −2.76 | |

| 1hf | 187.203 | 188.170 | −0.63 | |

| 2hf | 399.471 | 404.350 | −1.34 | |

| 3hf | 615.062 | 631.920 | −2.74 | |

| 1t | 81.192 | 80.133 | 1.17 | |

| 2t | 165.675 | 165.260 | 2.60 | |

| 3t | 260.028 | 260.550 | −0.21 | |

| 4t | 366.715 | 371.180 | −1.23 | |

| 1a | 862.618 | 861.460 | 0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abramowicz, M.; Chybiński, M.; Polus, Ł.; Wróblewski, T. Free Vibrations of Sustainable Laminated Veneer Lumber Slabs. Sustainability 2024, 16, 166. https://doi.org/10.3390/su16010166

Abramowicz M, Chybiński M, Polus Ł, Wróblewski T. Free Vibrations of Sustainable Laminated Veneer Lumber Slabs. Sustainability. 2024; 16(1):166. https://doi.org/10.3390/su16010166

Chicago/Turabian StyleAbramowicz, Małgorzata, Marcin Chybiński, Łukasz Polus, and Tomasz Wróblewski. 2024. "Free Vibrations of Sustainable Laminated Veneer Lumber Slabs" Sustainability 16, no. 1: 166. https://doi.org/10.3390/su16010166

APA StyleAbramowicz, M., Chybiński, M., Polus, Ł., & Wróblewski, T. (2024). Free Vibrations of Sustainable Laminated Veneer Lumber Slabs. Sustainability, 16(1), 166. https://doi.org/10.3390/su16010166