Carbon Footprint of Greenhouse Production in EU—How Close Are We to Green Deal Goals?

Abstract

:1. Introduction

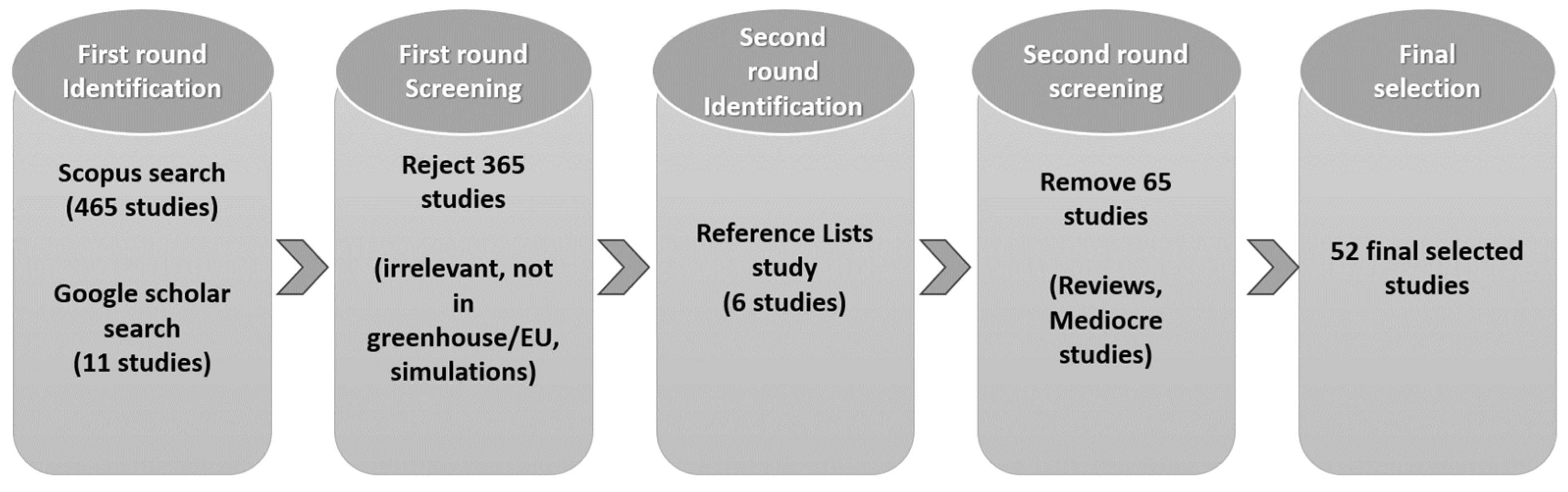

2. Systematic Review Methodology

2.1. Research Question

2.2. Eligibility Criteria

2.3. Search Strategy

2.4. Description of the Selected Studies

2.5. Bibliometric Analysis

3. Study Insights and Discussion

3.1. General Description of the Studies

3.1.1. Countries and Year

3.1.2. Plant Species—Cultivation Period—Yield

3.1.3. Protocols

3.1.4. Databases

3.1.5. Software

3.1.6. Functional Unit (FU)

3.1.7. System Boundaries

3.1.8. Impact Assessment Method

3.1.9. Impact Categories

3.1.10. Carbon Footprint Values

3.1.11. Hotspots

3.2. Bibliometric Analysis

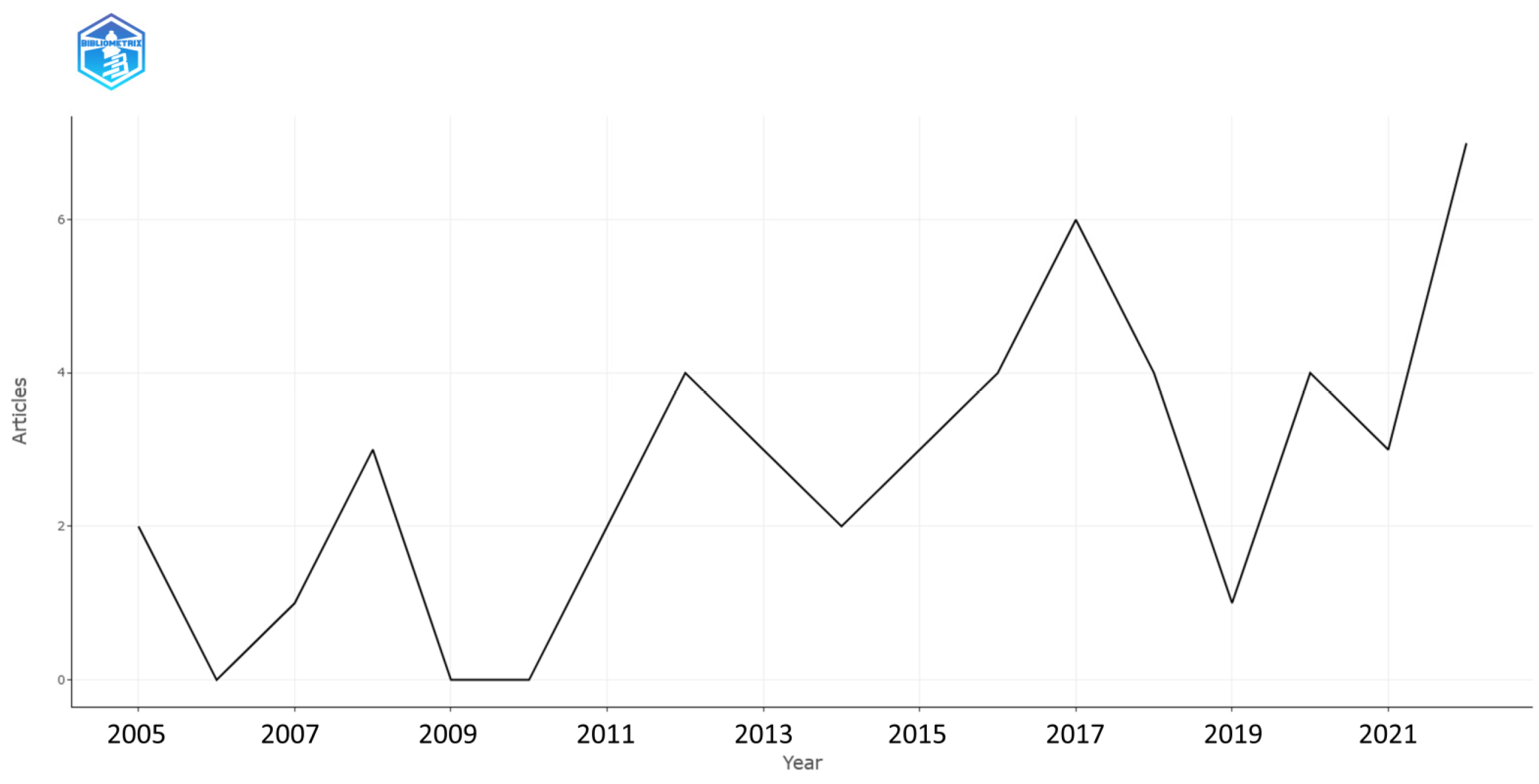

3.2.1. Descriptive Information of Collected Studies

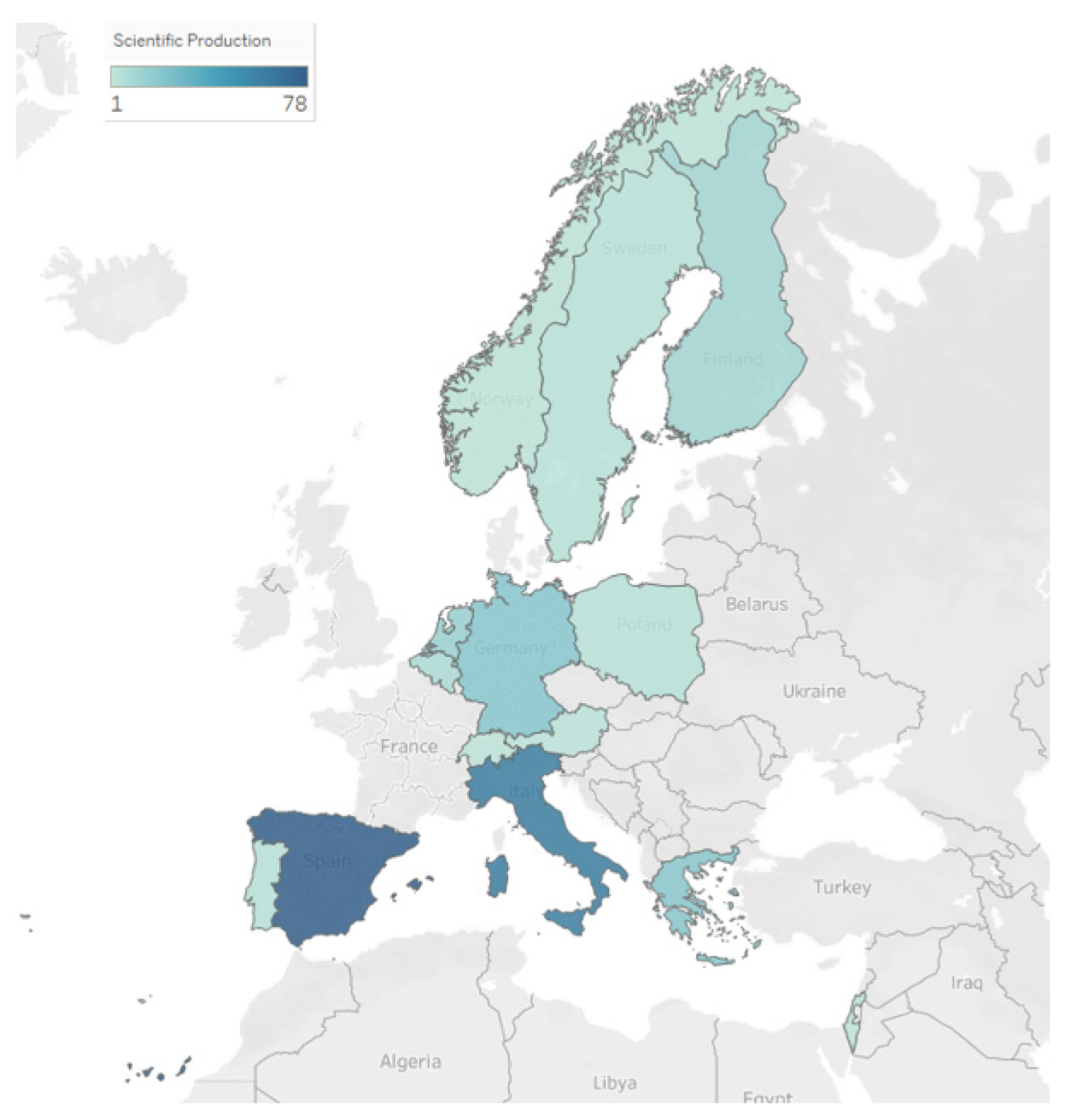

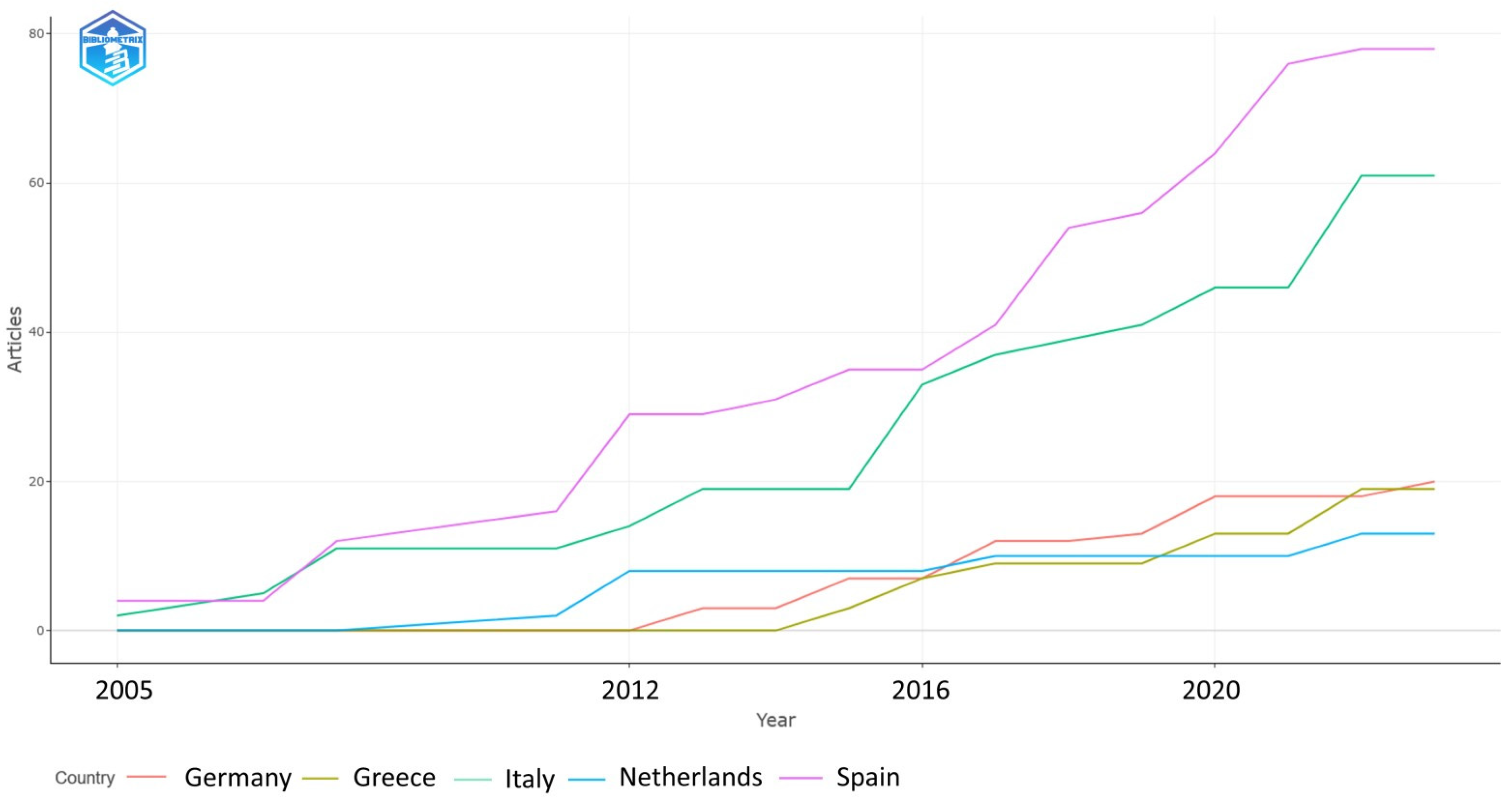

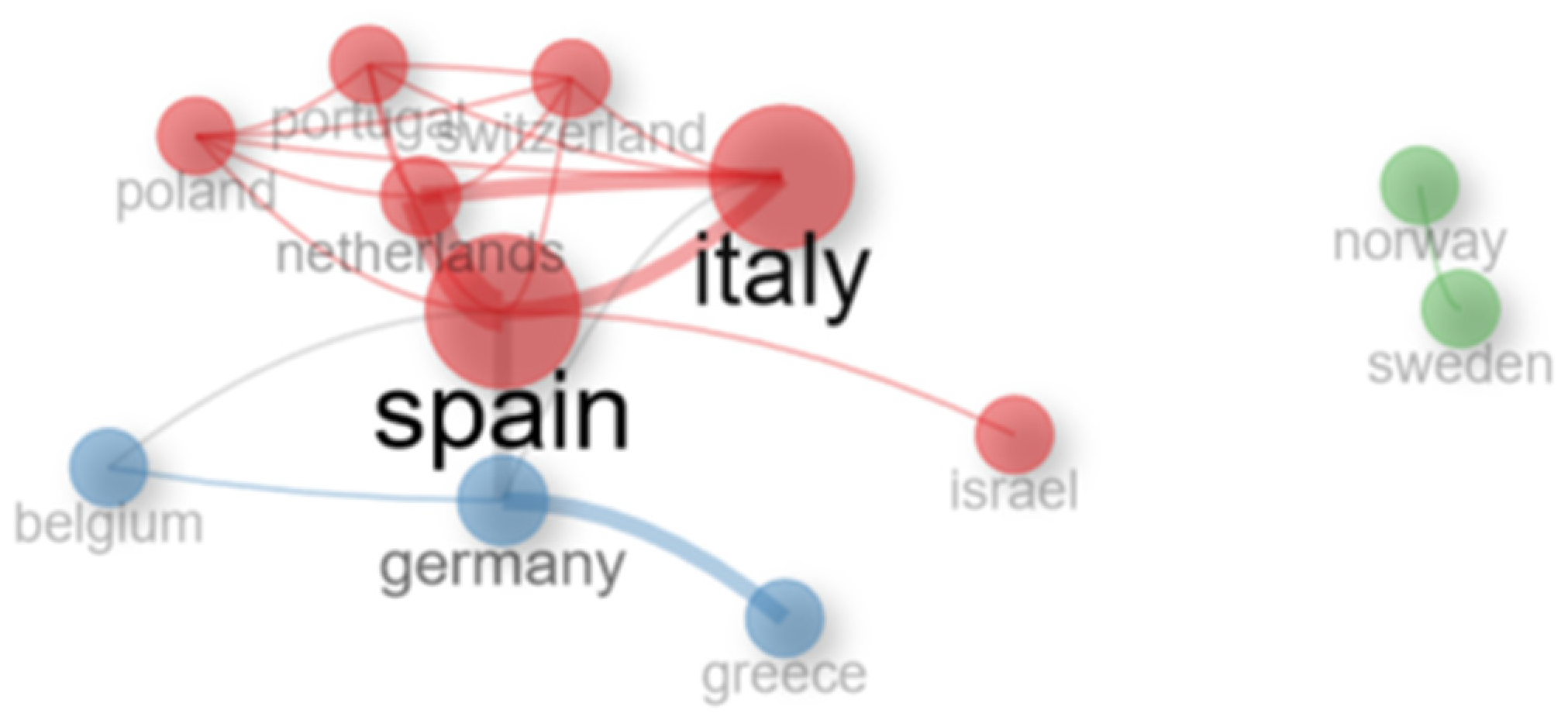

3.2.2. Country-Level Analysis

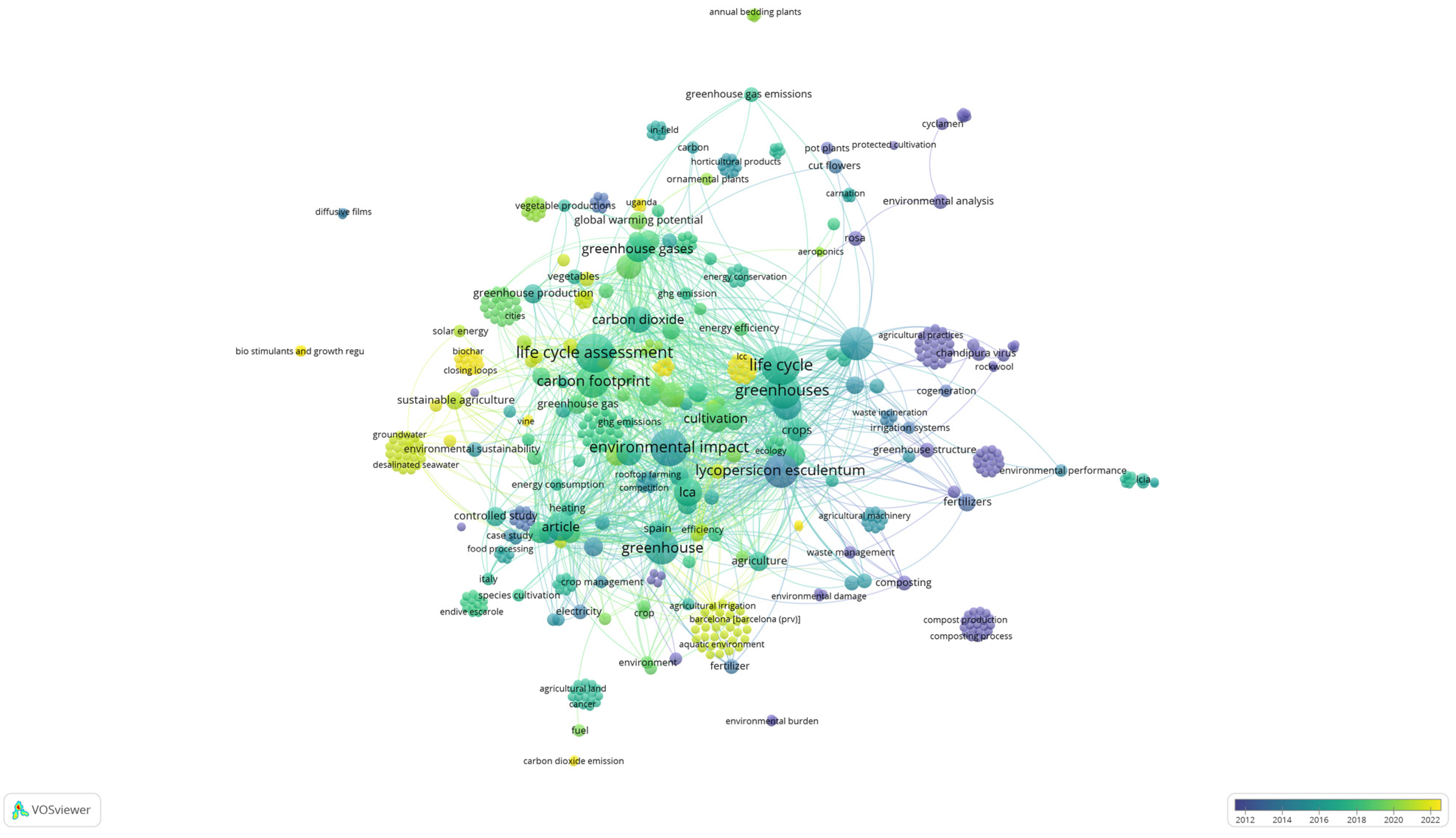

3.2.3. Thematic Axes of Collected Studies

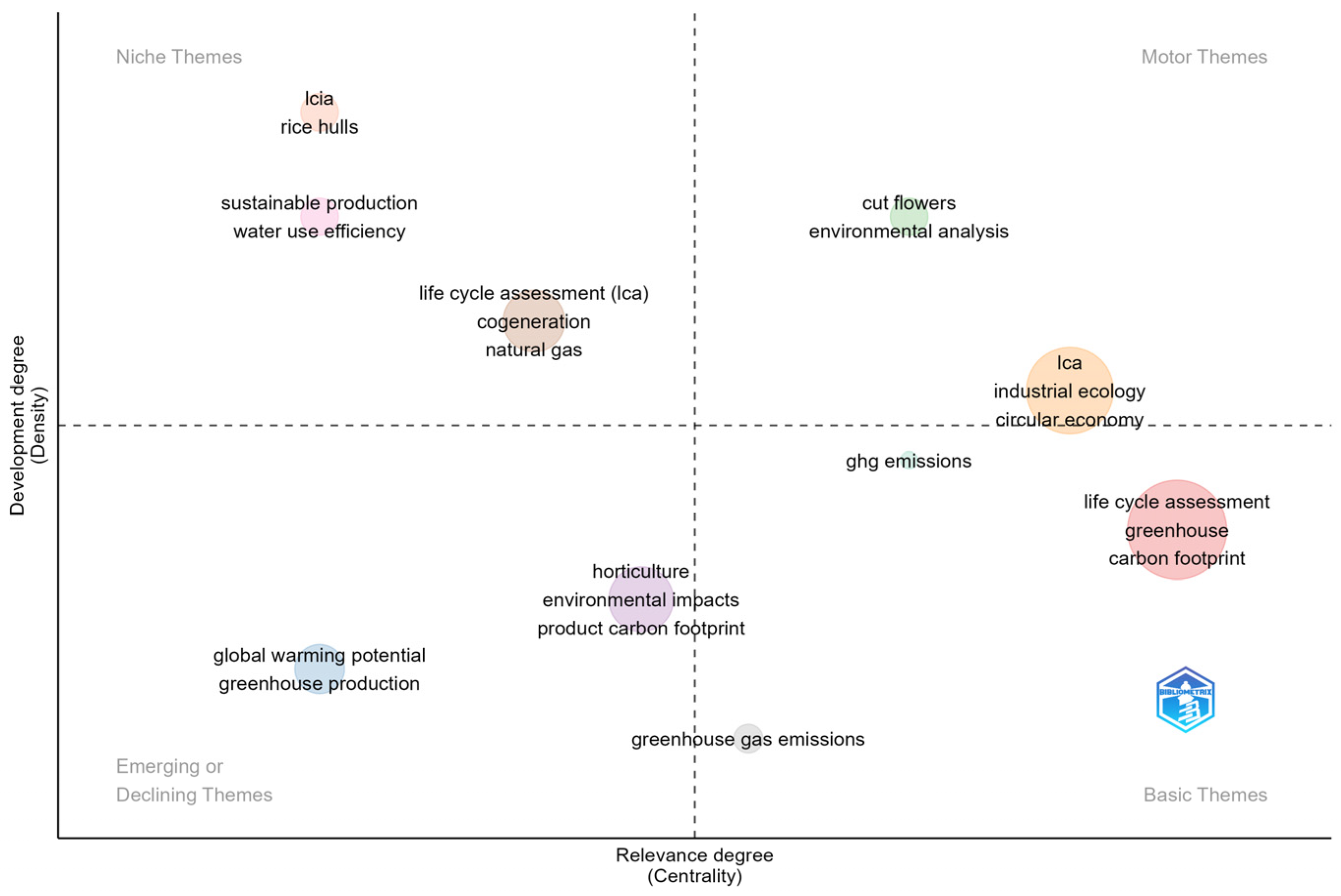

- (a)

- Themes in the upper left quadrant (high density, low centrality) represent niche themes that, while comprised of terms that are well connected to each other with strong ties, are not connected with the rest of the themes. Hence, these themes correspond to more refined areas of study that may require specific knowledge and expertise but may have important scientific impact. The themes in this cluster comprise of Theme_1 (lcia, rice hulls), Theme_2 (sustainable production, water-use efficiency), and Theme_3 (life cycle assessment (lca), cogeneration, natural gas). Within the more general subject of GH CF research, each theme in the niche cluster represents a focused and in-depth field of study. A product or process’s life cycle environmental impacts can be evaluated using the methodological technique known as life cycle impact assessment, or LCIA. The term “rice hulls” is included to show that the use of this specific agricultural input has special environmental impacts that are analyzed in impact assessment stage. Moreover, as the goal of sustainable production is to maximize resource utilization while reducing adverse effects on the environment, the inclusion of “water use efficiency” indicates that water-related issues in GH production could be the main focus. LCA is a technique for evaluating a process or product’s possible effects on the environment and environmental aspects over each stage of its life cycle. The words “cogeneration” and “natural gas” are specifically included, indicating a thorough investigation of energy-related aspects in GH production. Thus, they are a part of this cluster because of their lack of association with larger themes in the thematic map (low centrality) yet strongly interconnected terms within each subject (high density). Within their specific fields of study, this approach suggests a specialized focus, internal cohesiveness, and potential for major scientific impact.

- (b)

- Themes in the upper right quadrant (high density, high centrality) represent motor themes that comprise well interconnected terms that are also connected with other themes of other quadrants. Thus, these themes are drivers for research and have significant scientific activity surrounding them. In this cluster, the detected themes are Theme_4 (cut flowers, environmental analysis) and Theme_5 (lca, industrial ecology, circular economy) which are indeed crucial themes in the field of GH CF as they show broad links with other themes across several quadrants (high centrality) in addition to strong internal connections (high density). Regarding the environmental effects of the floral sector, the inclusion of “cut flowers” implies a particular focus on matters like energy use, water use, and possible pollution. This cluster also examines the GH CF through the lenses of life cycle assessment (LCA), industrial ecology, and circular economy. In doing so, it adopts a comprehensive approach to evaluate and mitigate the environmental impact of GH production over the course of its life cycle, investigate the environmental impacts of industrial systems, and promote sustainability by reducing waste and optimizing resource usage. These topics, which are positioned as catalysts for research and are seen as essential to the corpus of literature as a whole, suggest that they are critical in forming and impacting scientific research concerning GH CF.

- (c)

- Themes in the lower left quadrant (low density, low centrality) comprise weakly connected terms that are also isolated from the rest of the quadrants. Themes in this quadrant represent declining or emerging research fields that are either saturated and with low scientific production or finding their foothold in the scientific community. The themes in this cluster are Theme_6 (global warming potential, GH production) and Theme_7 (horticulture, environmental impacts, product carbon footprint). The first can be interpreted as focusing on evaluating and comprehending the possibility of GW in relation to GHG emissions. Given its low density and centrality, it is possible that this theme is still in the preliminary stages of investigation or is producing less scientific work than other themes in the field since it is a more specialized or narrowly focused area. The second one is centered on horticulture and focuses on evaluating the CF of the products associated with horticultural practices, and presents low density and centrality, indicating that it may be an emerging or declining field of study with a narrow focus and few connections to other themes, suggesting a possible lower level of scientific output in comparison to more central themes. Although some subjects may be particularly pertinent, the way they are now positioned within the field of science suggests that they require more research or development. It should also be noted that the position of themes is relevant to the examined domain (GH CF) and similar themes may have more prestigious positions in another domain.

- (d)

- Themes in the lower right quadrant (low density, high centrality) are basic themes that are well connected with other themes in the rest of the quadrants but have a weak internal structure. These themes, while important for research are less developed than motor themes (upper right quadrant). In this cluster, two of the detected themes are relevant to GHG emissions while the other theme is relevant to Theme_8 (life cycle assessment, greenhouse, carbon footprint), which is the central research theme of this study. GHG emissions’ evaluation and analysis entails researching the different gases released during agricultural activities and how these emissions affect the environment. While this subject is well-connected to other research fields, its low density and high centrality indicates that it may have a less developed internal structure, indicating the need for more in-depth studies. The study’s primary research focus, which includes life cycle assessment, GH technology, and the total CF related to GH production, represents an integrated approach to comprehending how GH activities affect the environment over all stages of their life cycle. Located in the lower right quadrant, the low density indicates that further internal growth is necessary, while the high centrality shows that it has strong relationships with other themes. Despite having a less developed internal structure, these themes play a crucial role in interpreting various research topics belonging to other quadrants.

4. Research Questions Resolved

4.1. Research Question 1—What Is the Research Landscape of Carbon Footprint Analysis in the European Union Countries, Based on Bibliometric Indicators?

4.2. Research Question 2—What Is the Value of the Carbon Footprint Indicator of Greenhouse Crops in European Union Countries?

4.3. Research Question 3—Are Renewable Energy Sources Being Implemented in European Union Greenhouses and How Does This Affect Carbon Footprint Values?

4.4. Research Question 4—Based on Current Data, Is It Possible for Greenhouse Production to Meet the Green Deal’s Directive Fit for 55 to Reduce the European Union’s Greenhouse Gas Emissions by 55% by 2030, and in What Ways?

5. Threads to Validity

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| No. | Authors | Country | Year | Plant Species | Protocol | Functional Unit | System Boundaries | Software | LCI Method | Impact Categories |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Abeliotis et al. | Greece | 2016 | carnation | ISO 14044 | 1.5 million carnation stems | cradle-to-gate | n.d. | CML 2 baseline 2000 | AD, OLD, GWP100, MAE, FAE, TECc, HT, PO, AC, ET |

| 2 | Almeida et al. | Italy | 2014 | tomato | ISO 14040/44 | 1 kg | cradle-to- gate | SimaPro | IPCC GWP 2007 100y | CF, WF, ED |

| 3 | Antón et al. | Netherlands | 2012 | tomato | ISO 14040/44 | 1 t | cradle-to-grave | SimaPro v.7.2 | CML2001 | AD, AC, ET, GW, PO |

| 4 | Antón et al. | Spain | 2005 | tomato | ISO 14040 | 1 kg | cradle-to-grave | TEAM 3.0 | n.d. | ET, AC, CC, OLD, PO, NRRD, HT, AET, TET, WR |

| 5 | Baptista et al. | Portugal | 2017 | tomato | n.d. | 1 t | gate -to- gate | n.d. | n.d. | GHG emissions |

| 6 | Barla et. al. | Greece | 2020 | lettuce | ISO 14044 | 1 kg | cradle-to-farm gate | SimaPro v.7 | CML 2 baseline 2000 | GWP100 |

| 7 | Bartzas et al. | Spain, Italy | 2015 | lettuce | ISO 14040/44 | 1 kg | cradle-to-gate | GaBi 6 | CML2001 | AC, ET, GWP, OLD, PO, CED |

| 8 | Blom et al. | Netherlands | 2022 | lettuce | IPCC | 1 kg | cradle-to-grave | SimaPro v.9.0.0 | IPCC GWP 100a | GWP100 |

| 9 | Bonaguro et al. | Italy | 2017 | cyclamen | ISO 14044 | 1 potted plant | gate-to-gate | n.d. | CML2001 | AD, OLD, GWP100, MAE, FAE, TECc, HT, PO, AC, ET |

| 10 | Bonaguro et al. | Italy | 2016 | 4 ornamental plants | PAS2050, ISO 14044 | 1 plant in its container | cradle-to-gate | SimaPro v.7.3.3 | n.d. | GWP |

| 11 | Bosona et al. | Sweden | 2018 | tomato | n.d. | 1 t | cradle-to-consumer gate | SimaPro v.8.2 | ReCiPe (H) | CED, GWP100 |

| 12 | Canaj et al. | Italy | 2022 | zucchini | n.d. | 1 t | cradle-to-farm gate | OpenLCA v.1.10.3 | ReCiPe (H) | FPMF, FRS, FEC, FE, GW, HCT, HNCT, IR, LU, MEC, ME, MRS, OFHH, OFTE, SOD, TA, TEC, WC |

| 13 | Cellura et al. | Italy | 2012 | 5 fruit vegetables | ISO 14040 | 1000 kg of packaged vegetable | cradle-to-grave | SimaPro v.7 | CML2001 | GW, OLD, PO, AC, ET, HT, FAE, MAE, TECc |

| 14 | Chatzigeorgiou et al. | Greece | 2022 | grapevine | ISO 14067 | 1 kg of vine leaves | cradle-to-farm gate | SimaPro v.9.2.0. | n.d. | CF |

| 15 | Corcelli et al. | Spain | 2019 | tomato | ISO 14040/44 | 1 m2 of flat rooftop | cradle-to-grave | SimaPro v.8.0.5 | ReCiPe Midpoint (H) | CC, SOD, TA, FE, POF, TEC, WD, MD, FRS |

| 16 | De Lucia et al. | Italy | 2013 | Bougainvillea | ISO 14040 | 1 kg | cradle-to-grave | GaBi 4 | CML2010 | AD, GWP100, OLD, AC, ET, PO, EC |

| 17 | Falla et al. | Italy | 2020 | begonias, violas | ISO 14040/44 | 1 g of fresh edible flowers | cradle-to-gate | SimaPro v.8.5.0.0 | n.d. | GWP, AC, ET, PO |

| 18 | Frem et al. | Italy | 2022 | ornamental plants | ISO 14040/44 | 1000 potted plants | cradle-to-farm gate | OpenLCA | ReCiPe Midpoint (H) | LU, GWP100, FRS, WD |

| 19 | Fusi et al. | Italy | 2016 | lamb’s lettuce | ISO 14040/44 | 1 bag with 130 gr lamb’s lettuce | cradle-to-gate | SimaPro v.7.3.3 | IPCC 2006, Recipe Midpoint (H)/Europe | CC, SOD, HT, PO, TA, FE, ME, TEC, FEC, MEC, WD, FFD |

| 20 | García García and García García | Spain | 2022 | pepper | ISO 14040 | 1 t | cradle-to-grave | SimaPro v.9.1 | CML-IA Baseline 4.7 | AD, GW, OLD, HT, FAE, MAE, TECc, PO, AC, ET |

| 21 | Grabarczyk et al. | Poland | 2022 | potted flowers | ISO 14040/44 | (a) potted plants, (b) 1 m2 area | cradle-to-farm gate | n.d. | IPCC 2006 | CF, CED |

| 22 | Ilari et al. | Italy | 2018 | 4 leafy vegetables | ISO 14040/44 | 1 plant in tray | cradle-to-nursery gate | SimaPro v.8.1 | CML 2 baseline 2000 v.2.05 | AD, AC, ET, GWP100, OLD, HT, FAE, MAE, TECc, PO |

| 23 | Jukka et.al. | Finland | 2022 | tomato | ISO 14040/44/67 | 1 t | cradle-to-gate | GaBi v.9.2.1.68 | n.d. | CF |

| 24 | Lampert and Menrad | Germany | 2023 | poinsettia | PAS 2050-1, ISO 14067 | 1 potted poinsettia | cradle-to-grave | Umberto NXT CO2 | PCF | CF |

| 25 | Lazzerini et al. | Italy | 2016 | ornamental plants | ISO 14044, PAS 2050 | 1 m2 area | cradle-to-gate | GaBi 6 | CML2011 | GWP100 |

| 26 | Martínez-Blanco et al. | Spain | 2011 | tomato | ISO 14044 | 1 t | system expansion | SimaPro v.7.2.4 | CML2001 | AD, AC, ET, GW, OLD, PO, CED |

| 27 | Martin-Gorriz et al. | Spain | 2021 | tomato | ISO 14040/44 | (a) 1 m2 cultivation area, (b) 1 kg of marketable tomato | cradle-to-gate | SimaPro v.9.1 | CML2001 | AD, AC, ET, GW |

| 28 | Marttila et al. | Finland | 2021 | tomato, cucumber | ISO 14040/44/67 | (a) 1 t tomatoes, (b) 1 t cucumber | cradle-to- gate | GaBi ts 9.5 | CML2001, GWP100 | GWP100 |

| 29 | Montero et al. | Spain | 2014 | tomato | ISO 14040 | 1 t | n.d. | SimaPro v.7 | n.d. | CED, AD, GW, AC, ET, PO |

| 30 | Mugnozza et al. | Italy | 2007 | rose | ISO 14040/43/20 | 100 cut stems | cradle-to-gate | GaBi 4 | CML2001 | AD, AC, ET, GWP100, OLD |

| 31 | Muñoz et al. | Spain | 2007 | tomato | ISO 14040/44 | 1 kg | cradle-to-farm gate | v.7.0, 2006 | CML2001 | NRRD, GW, OLD, AC, ET, WC, EC |

| 32 | Ntinas et al. | Greece, Germany | 2017 | tomato | ISO 14040/44 | (a) 1 kg tomatoes, (b) 1 m2 area | cradle-to-farm gate | n.d. | IPCC 2006 | GWP100, CED |

| 33 | Ntinas et al. | Germany | 2020 | tomato | ISO 14040/44 | (a) 1 kg tomato, (b) 1 m2 area | cradle-to-farm gate | n.d. | IPCC 2007 | CF, CED, WUE |

| 34 | Palma et al. | France, Turkey | 2014 | processed tomato | n.d. | (a) 1 kg tomatoes, (b) 1 kg packed processed tomatoes | cradle-to-grave | SimaPro | CML 2 baseline V2.05 world | CF, HT, ET |

| 35 | Parada et al. | Spain | 2021 | tomato | ISO 14040 | 1 kg | cradle-to-grave | SimaPro v.9 | ReCiPe (H) | GW, TA, FE, ME, FRS, CED, ECT |

| 36 | Pérez Neira et al. | Spain | 2018 | tomato | IPCC | 1 kg tomatoes delivered | (a) cradle-to-regional distributional center; (b) cradle-to-farm gate | n.d. | equations | CF, CED |

| 37 | Röös et al. | Sweden | 2013 | tomato | IPCC | 10.4 kg | cradle-to-farm gate | SimaPro v.7.3.3 | IPCC 2007 GWP 100a | CF |

| 38 | Rufí-Salís et al. | Spain | 2020 | common bean | ISO 14040 | 1 kg | cradle-to-grave | SimaPro v.9.0 | ReCiPe (H) | GW, TA, FE, ME, FRS, MEC, TEC, FEC |

| 39 | Russo and Mugnozza | Italy | 2005 | tomato | ISO 14040/43/49/47/48 | 1 kg | cradle-to-gate | n.d. | CML2, 2000 | AD, GWP100, OLD, HT, FAE, TECc, PO, AC, ET |

| 40 | Russo et al. | Italy | 2008 | rose, cyclamen | ISO | 100 cut stems | cradle-to-gate | GaBi 4 | CML2001 | AD, AC, ET, GWP100, OLD, PO, EC |

| 41 | Russo et al. | Italy | 2008 | roses and cyclamens | ISO 14040/44 | (a) 100 cut stems (roses), (b) 6 pots of cyclamens | cradle-to-gate | GaBi 4 | CML2001 | AD, CC, OLD, AC, ET, PO, EC |

| 42 | Sanjuan-Delmas et al. | Spain | 2018 | tomato | ISO 14040/44 | 1 kg tomatoes delivered | cradle-to-grave | SimaPro v.8.2 | ReCiPe (H) | CC, ECT, TA, FE, ME, FFD, TEC, FEC, MEC |

| 43 | Sanyé-Mengual et.al. | Spain | 2015 | tomato | ISO 14044 | 1 kg | (a) cradle-to-grave; (b) cradle-to-farm gate; (c) cradle-to-consumer | SimaPro v.7.3.3 | ReCiPe Midpoint (H) | GWP, CED, norm-ReCiPe |

| 44 | Soode et al. | Germany | 2015 | strawberries | PAS 2050/1 | 1 kg | cradle-to-grave | GaBi v.6.0, SPSS | n.d. | GWP100 |

| 45 | Soode et al. | Germany | 2013 | poinsettia | PAS 2050, ISO 14067 | 1 potted plant | cradle-to-grave | GaBi 5 | IPCC 2007 GWP 100a | GWP100 |

| 46 | Soode-Schimonsky et al. | Germany, Estonia | 2017 | strawberry | ISO 14040/44/67 | 1 kg | cradle to the point of sale | GaBi 6 | PEF | TEP, ME, POF, WD, HNCT, CC, OLD, AC, FE, FPMF, LT, HCT, IR, FAE, FFD |

| 47 | Stajnko et al. | Slovenia | 2016 | tomato | SPI | 1 kg | n.d. | SPIonWeb | n.d. | GWP |

| 48 | Torellas et al. | Spain | 2012 | tomato | ISO 14040 | 1 t of loose tomatoes | cradle-to-grave | SimaPro v.7.2 | CML2001 | AD, AC, ET, GWP100, PO, CED |

| 49a | Torrellas et al. | Spain | 2012 | tomato | ISO 14040, ILCD | 1 t | cradle-to-farm gate | SimaPro v.7.2 | CML2001 | CED, AD, AC, ET, GW, PO |

| 49b | \\ | Hungary | \\ | tomato | \\ | 1 t | \\ | \\ | \\ | \\ |

| 49c | \\ | Netherlands | \\ | tomato | \\ | 1 t | \\ | \\ | \\ | \\ |

| 49d | \\ | Netherlands | \\ | rose | \\ | 1000 rose stems | \\ | \\ | \\ | \\ |

| 50 | Torres et al. | Spain | 2017 | 4 vegetables | ISO 14067, PAS 2050-1 | 1 kg of each product | cradle-to-farm gate | eFoodPrint Env | IPCC 2006 | CF |

| 51 | Vermeulen and van der Lans | Netherlands | 2010 | tomato | DNSF2009 | 1 t | cradle-to-gate | n.d. | n.d. | CF |

| 52 | Wandl and Haberl | Austria | 2017 | ornamental plants | ISO 14040/44 | (a) piece of product, (b) days of flowering | cradle-to-grave, gate-to-gate | n.d. | IPCC 2006 | GWP |

| No. | Authors | CF Value (kg CO2 eq) per Selected FU | Hotspots | Heating | Ref. |

|---|---|---|---|---|---|

| 1 | Abeliotis et al. | 47,400 kg | electricity for the flowers’ preservation | No | [105] |

| 2 | Almeida et al. | Current: 2.28 kg; Conventional with natural gas: 3.59 kg; Waste Valorization scenario: 1.37 kg; Cogen: 2.69 kg; | heating and CO2 fertilization, construction, coupled heating and CO2 provision, construction | Yes | [50] |

| 3 | Antón et al. | Avoided product method: 780 kg; Allocation method: 2000 kg | climate control system (natural gas for heating) | Yes | [102] |

| 4 | Antón et al. | Closed: 81.4 g; Open vs Closed: 1.12 (ratio) | waste of biomass and plastics | No | [104] |

| 5 | Baptista et al. | Organic: 105.9 kg; Conventional: 122.18 kg | GH materials, fertilizers, electricity | No | [40] |

| 6 | Barla et al. | Winter: 3.549 kg; Spring: 2.775 kg; Winter–Spring: 2.173 kg | electricity | No | [47] |

| 7 | Bartzas et al. | GH Lettuce Italy: 0.205 kg; GH Lettuce Spain: 0.225 kg | compost production, GH construction, energy consumption for climate control | Yes | [37] |

| 8 | Blom et al. | GH (soil): 1.211 kg; GH (hydroponic): 1.451 kg | electricity and fuel use, energy and resources used to produce the seedlings | Yes | [53] |

| 9 | Bonaguro et al. | Base scenario: 0.157 kg; Scenario 1—peat shipped from Germany: 0.177 kg; Scenario 2—peat shipped from Lithuania and Estonia: 0.139 kg | plastic pot, GH structure, peat transport | No | [100] |

| 10 | Bonaguro et al. | Poinsettia: 0.0619 kg; Zonal geranium: 0.0295 kg; Cyclamen: 0.0217 kg | pot containers and diesel for heating | Yes | [61] |

| 11 | Bosona et al. | Fresh tomato value chain: 547.13 kg; Dried tomato value chain: 467.44 kg | cultivation stage: energy for GH heating, irrigation and GH construction materials. post-harvest stage: packaging and drying activities; transport stage: fuel consumption | Yes | [90] |

| 12 | Canaj et al. | Farmer irrigation: 785.62 kg; Cloud-based DSS irrigation: 770.46 kg; Sensor-based irrigation: 770.45 kg | irrigation, mechanization | No | [91] |

| 13 | Cellura et al. | Melon: 1427.5 kg; Pepper: 915.5 kg; Zucchini: 1571 kg; Tomato: 740 kg; Cherry tomato: 1245.9 kg | GH materials, packaging and transportations | No | [107] |

| 14 | Chatzigeorgiou et al. | 1.7P: 10.35 kg; S treatment: 79.2 kg | energy consumption, construction materials, perlite-zeolite substrate | No | [121] |

| 15 | Corcelli et al. | 17 kg | fertilizers, substrate, RTG structure | No | [122] |

| 16 | De Lucia et al. | Sewage sludge compost 70%: 150%; Sewage sludge compost 55%: 138%; Sewage sludge compost 40%: 120%; Sewage sludge compost 25%: 100%; Sewage sludge compost 0%: 48% | SSC70 (peat free substrate) | No | [123] |

| 17 | Falla et al. | Begonia: 24.94 g (potted plant); 28.03 g (large container); 29.47 g (small container) Viola: 26.99 g (potted plant), 29.81 g (large container), 31.25 g (small container) | small containers, propagation phase and young plant cultivation phase for begonia, young plant cultivation phase for viola | Yes | [124] |

| 18 | Frem et al. | Novel and sustainable production model (NSM): 660.67 kg; Conventional production model (CM): 665.42 kg | peat moss production, diesel, burned in agricultural machinery | Yes | [103] |

| 19 | Fusi et al. | 0.346 kg | agricultural level: GH production processing stage: high consumptions of energy, use of water | No | [46] |

| 20 | García García and García García | 122 kg | electricity associated with the supply of water for irrigation, GH infrastructure | No | [125] |

| 21 | Grabarczyk et al. | Coal: 366.6 kg/m2 and 1.245 kg/pot; Natural gas: 170.1 kg/m2 and 0.578 kg/pot; Wood pellets: 20.5 kg/m2 and 0.07 kg/pot; Wood chips: 18.4 kg/m2 and 0.063 kg/pot | heating with coal, heating with natural gas | Yes | [75] |

| 22 | Ilari et al. | 0.00253 kg | thermoplastic and plastic materials, substrates extraction, fertilizers, pesticides | No | [126] |

| 23 | Jukka et al. | 888 kg | electricity consumption, infrastructure, heating | Yes | [127] |

| 24 | Lampert and Menrad | 1.27–2.31 kg | young plant phase: transport by airplane and the rooting of cuttings; horticultural production and distribution: packaging, potting substrate, and electrical power; consumer stage: small basket of goods and a non-combined shopping trip | Yes | [60] |

| 25 | Lazzerini et al. | Quercus fellus: 0.5612 kg; Wisteria floribunda: 1.0197 kg; Nandina domestica: 3.7763 kg; Magnolia stellata: 2.8506 kg; Cupressocyparis leylandii: 2.0678 kg; Photinia fraseri red robin: 5.0107 kg; Pinus pinea 5.2969 kg CO2 eq/plant/year | farm and container structures, diesel, fertilizers, potting mix, pots, transport, soil tillage | No | [43] |

| 26 | Martínez-Blanco et al. | Mineral fertilizers: 153 kg; Compost and mineral: 119% more | compost production, mineral fertilizers production | No | [49] |

| 27 | Martin-Gorriz et al. | 1.75–2.05 kg | production and management of fertilizers, GH structure, and irrigation system | No | [74] |

| 28 | Marttila et al. | Tomato: 857–6523 kg; Cucumber: 1379–2951 kg | heating with oil boiler and natural gas boiler, electricity, peat | Yes | [128] |

| 29 | Montero et al. | (Avoided CF) PE recycling: −0.7012 kg; Valorization: −8.7557 kg | GH structure, fertilizers, auxiliary equipment | No | [129] |

| 30 | Mugnozza et al. | Soilless GH, Pesticides: 85%, Soil cultivation GH, Pesticides: 53% | Soil-less GH: heating systems, fertilizers; Soil-cultivation GH: pesticides, heating systems, fertilizers | Yes | [92] |

| 31 | Muñoz et al. | 0.0744 kg | GH structure | No | [109] |

| 32 | Ntinas et al. | Conventional heating system (Greece): 58.7 kg/m2 and 10.1 kg/kg; Hybrid solar energy saving system (Greece): 46.2 kg/m2 and 7.2 kg/kg. Standard variant (Germany): 10.6 kg/m2 and 0.7 kg/kg; IsoMax (Germany): 7.9 kg/m2 and 0.7 kg/kg; F-clean (Germany): 7.6 kg/m2 and 0.4 kg/kg | natural gas for heating, electricity, structure, electricity, fuel | Yes | [20] |

| 33 | Ntinas et al. | Scenario 1—Conventional GH: 48.3 kg/m2, 2.5 kg/kg tomato; Scenario 2—Solar collector GH (no reused energy): 99.4 kg/m2, 4.1 kg/kg tomato; Scenario 3—Solar collector GH (reused energy): 47.5 kg/m2, 1.9 kg/kg tomato; Scenario 4—Solar collector GH (reused energy + excess energy transfer): −17.5 kg/m2, −0.7 kg/kg tomato | heating and structure | Both | [45] |

| 34 | Palma et al. | France: 2.6987 kg; Turkey: 3.0635 kg | packaging and energy for steam production, fertilization (agriculture stage) | Yes | [35] |

| 35 | Parada et al. | Open management: 0.862 kg; Recirculated management: 0.764 kg; Recirculated management with further 15% freshwater input: 0.778 kg | fertilizers, energy, rainwater harvesting system, auxiliary equipment, structure | No | [39] |

| 36 | Pérez Neira et al. | (Cradle-to-farm-gate) Heated: 1.33 kg; Unheated: 0.39 kg. (Cradle to regional distribution center) Heated: 2.07 kg; Unheated: 1.13 kg | use of energy, infrastructure, fertilizers | Both | [42] |

| 37 | Röös et al. | Sweden unheated: 0.22 kg CO2 eq/kg tomato; Sweden heated: 0.29 kg CO2 eq/kg tomato; Netherlands: 0.95 kg CO2 eq/kg tomato; Spain: 0.54 kg CO2 eq/kg tomato | eating non-seasonal, heated GH production, long-distance transport | Yes | [54] |

| 38 | Rufí-Salís et al. | Closed-loop S0: 3.92 kg; Closed-loop S1: 2.42 kg; Closed-loop S2: 3.16 kg; Closed-loop S3: 1.91 kg; Linear system (no nutrient/water recovery): 2.58 kg | closed-loop system: iRTG structure, leachates system linear system: rainwater harvesting surface, iRTG structure | No | [130] |

| 39 | Russo and Mugnozza | GH soil: 90%; GH hydroponic: 100% | energy consumption, steel, and glass | No | [51] |

| 40 | Russo et al. | Rose soilless: 83% fossil fuel; Rose soil: 90%; Cyclamen: 63% baby plant production | heating fuel, baby plant production | Yes | [131] |

| 41 | Russo et al. | Farm A, Roses: 64% fuel; Farm B, Roses: 84% fuel; Farm C, Roses: 73% fuel; Farm D, Roses: 48%fuel, 45% structure; Farm E, Roses: 90% fuel; Farm F, Cyclamens: 62% Baby plant; Farm G, Cyclamens: 64% Baby plant | roses: heating fuel, electricity, fertilizers, packaging, pesticides. cyclamen: baby plant, electricity, fertilizers, packaging, pesticides | Yes | [41] |

| 42 | Sanjuan-Delmas et al. | Spring crop 1: 0.61 kg; Winter crop: 1.41 kg; Spring crop 2: 0.56 kg | construction of the rainwater harvesting system, and fertilizers | No | [38] |

| 43 | Sanyé-Mengual et al. | (a) 2.42 kg (b) 0.216 kg (c) 0.78 kg | structure materials, maintenance stages | No | [48] |

| 44 | Soode et al. | 0.1–10.2 kg | customer shopping trip by private car, energy for product cleaning, electricity, heating, soil management | Yes | [132] |

| 45 | Soode et al. | PAS 2050:2011: 0.45–0.5 kg; ISO 14067: 0.53–0.58 kg; PARS 2011: 0.53–0.59 kg | production of poinsettia plant, electricity | Yes | [59] |

| 46 | Soode-Schimonsky et al. | 3.53 kg | electricity for cooling/heating and the use of agricultural machinery including fuel burning | Yes | [36] |

| 47 | Stanjko et al. | Geothermal: 0.018 kg; Natural gas: 0.5255 kg | heating with natural gas | Yes | [65] |

| 48 | Torrellas et al. | 250 kg | structure, fertilizers, auxiliary equipment | No | [108] |

| 49a | Torrellas et al. | 250 kg | structure, climate control system, auxiliary equipment, and fertilizers | Yes | [89] |

| 49b | \\ | Thermal energy: 440 kg; Natural gas; 5000 kg | \\ | \\ | \\ |

| 49c | \\ | Avoided electricity at CHP: 780 kg; Energy allocation at CHP: 2000 kg | \\ | \\ | \\ |

| 49d | \\ | 1600 kg | \\ | \\ | \\ |

| 50 | Torres et al. | GH tomato: 293 g | GH structure, fertilizers, and transport | No | [62] |

| 51 | Vermeulen and van der Lans | Organic with CHP: 888 kg; Conventional with CHP: 784 kg; Conventional: 1760 kg; Organic: 1941 kg | gas boiler, gas CHP, fertilizer, transport | Yes | [52] |

| 52 | Wandl and Haberl | Cyclamen: 5.6 kg/piece; Amaryllis–Azalea: 3.6 kg/piece; Iris: 0.4 kg/day of flowering | heating energy requirements, substrate, fuel | Yes | [76] |

References

- Steer, A. Resource Depletion, Climate Change, and Economic Growth. In Towards a Better Global Economy: Policy Implications for Citizens Worldwide in the 21st Century; University of Oxford: Oxford, UK, 2014; Volume 381. [Google Scholar]

- Fetting, C. The European Green Deal, ESDN Report; ESDN Office: Vienna, Austria, 2020. [Google Scholar]

- Chen, J.; Chepeliev, M.; Garcia-Marcia, D.; Iakova, D.; Roaf, J.; Shabunina, A.; van der Mensbrugghe, D.; Wingender, P. EU Climate Mitigation Policy; International Monetary Fund: Washington, DC, USA, 2020; ISBN 9781513552569. [Google Scholar]

- Bohringer, C. The Kyoto Protocol: A Review and Perspectives. Oxf. Rev. Econ. Policy 2003, 19, 451–466. [Google Scholar] [CrossRef]

- Parker, L. CRS Report for Congress Climate Change and the EU Emissions Trading Scheme (ETS): Looking to 2020; Congressional Research Service: Washington, DC, USA, 2010.

- European Environment Agency Technical Background Document-Accompanying the Report Trends and Projections in Europe 2021. 2021. Available online: https://www.eea.europa.eu/publications/trends-and-projections-in-europe-2021/technical-background-document (accessed on 5 October 2023).

- United Nations/Framework Convention on Climate Change. Adoption of the Paris Agreement. In Proceedings of the 21st Conference of the Parties, Paris, France, 30 November–12 December 2015. [Google Scholar]

- European Commission. The European Green Deal; European Commission: Luxembourg, 2019. [Google Scholar]

- Sikora, A. European Green Deal–Legal and Financial Challenges of the Climate Change. ERA Forum 2021, 21, 681–697. [Google Scholar] [CrossRef]

- Cifuentes-Faura, J. European Union Policies and Their Role in Combating Climate Change over the Years. Air. Qual. Atmos Health 2022, 15, 1333–1340. [Google Scholar] [CrossRef] [PubMed]

- European Council European Green Deal. Consilium. Available online: https://www.consilium.europa.eu/en/policies/green-deal/ (accessed on 30 October 2023).

- Dyrhauge, H.; Kurze, K. Making the European Green Deal Work; Taylor & Francis Ltd.: London, UK, 2023. [Google Scholar]

- Sandri, S.; Hussein, H.; Alshyab, N.; Sagatowski, J. The European Green Deal: Challenges and Opportunities for the Southern Mediterranean. In Mediterranean Politics; Taylor & Francis Ltd.: London, UK, 2023. [Google Scholar] [CrossRef]

- European Environment Agency Greenhouse Gas Emissions from Agriculture in Europe. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emissions-from-agriculture?activeAccordion= (accessed on 30 October 2023).

- European Commission Effort Sharing 2021–2030: Targets and Flexibilities. Available online: https://climate.ec.europa.eu/eu-action/effort-sharing-member-states-emission-targets/effort-sharing-2021-2030-targets-and-flexibilities_en#documents (accessed on 30 October 2023).

- Dar, A.A.; Hameed, J.; Huo, C.; Sarfraz, M.; Albasher, G.; Wang, C.; Nawaz, A. Recent Optimization and Panelizing Measures for Green Energy Projects; Insights into CO2 Emission Influencing to Circular Economy. Fuel 2022, 314, 123094. [Google Scholar] [CrossRef]

- Pomoni, D.I.; Koukou, M.K.; Vrachopoulos, M.G.; Vasiliadis, L. A Review of Hydroponics and Conventional Agriculture Based on Energy and Water Consumption, Environmental Impact, and Land Use. Energies 2023, 16, 1690. [Google Scholar] [CrossRef]

- Vatistas, C.; Avgoustaki, D.D.; Bartzanas, T. A Systematic Literature Review on Controlled-Environment Agriculture: How Vertical Farms and Greenhouses Can Influence the Sustainability and Footprint of Urban Microclimate with Local Food Production. Atmosphere 2022, 13, 1258. [Google Scholar] [CrossRef]

- Fernández, J.A.; Orsini, F.; Baeza, E.; Oztekin, G.B.; Muñoz, P.; Contreras, J.; Montero, J.I. Current Trends in Protected Cultivation in Mediterranean Climates. Eur. J. Hortic. Sci. 2018, 83, 294–305. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon Footprint and Cumulative Energy Demand of Greenhouse and Open-Field Tomato Cultivation Systems under Southern and Central European Climatic Conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Morin, A.; Katsoulas, N.; Desimpelaere, K.; Karkalainen, S.; Schneegans, A. EIP-AGRI Focus Group Circular Horticulture. 2017. Available online: https://ec.europa.eu/eip/agriculture/sites/default/files/eip-agri_fg_circular_horticulture_starting_paper_2017_en.pdf (accessed on 5 November 2023).

- Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; García-Arca, D.; López-Felices, B. Identification of Opportunities for Applying the Circular Economy to Intensive Agriculture in Almería (South-East Spain). Agronomy 2020, 10, 1499. [Google Scholar] [CrossRef]

- Timpanaro, G.; Urso, A.; Prato, C.; Foti, V.T. Evaluating the Potential for Development of Vegetable Nursery Industry: Analysis in an Important Vegetable Region in Italy. Am. J. Agric. Biol. Sci. 2015, 10, 74–82. [Google Scholar] [CrossRef]

- Girgenti, V.; Peano, C.; Baudino, C.; Tecco, N. From “Farm to Fork” Strawberry System: Current Realities and Potential Innovative Scenarios from Life Cycle Assessment of Non-Renewable Energy Use and Green House Gas Emissions. Sci. Total Environ. 2014, 473–474, 48–53. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040:2006; Environmental Management-Life Cycle Assessment-Principles and Framework (ISO 14040). International Organization for Standardization: Geneva, Switzerland, 2006.

- Chainho, P.; Matos, H.A. Process Analysis Using Umberto Carbon Footprint Tool. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2012; pp. 810–814. [Google Scholar]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to Conduct a Bibliometric Analysis: An Overview and Guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Grant, M.J.; Booth, A. A Typology of Reviews: An Analysis of 14 Review Types and Associated Methodologies. Health Inf. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef] [PubMed]

- Bibliometrix Biblioshiny. Available online: https://www.bibliometrix.org/home/index.php/layout/biblioshiny (accessed on 31 October 2023).

- K-Synth Srl Bibliometrix. Available online: https://www.bibliometrix.org/home/index.php (accessed on 31 October 2023).

- Leiden University Visualizing Scientific Landscapes. Available online: https://www.vosviewer.com/ (accessed on 31 October 2023).

- Callon, M.; Courtial, J.P.; Laville, F. Co-Word Analysis as a Tool for Describing the Network of Interactions between Basic and Technological Research: The Case of Polymer Chemsitry. Scientometrics 1991, 22, 155–205. [Google Scholar] [CrossRef]

- Zhang, Y.; Hua, W.; Yuan, S. Mapping the Scientific Research on Open Data: A Bibliometric Review. Learn. Publ. 2018, 31, 95–106. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. An Approach for Detecting, Quantifying, and Visualizing the Evolution of a Research Field: A Practical Application to the Fuzzy Sets Theory Field. J. Informetr. 2011, 5, 146–166. [Google Scholar] [CrossRef]

- Palma, G.; Padilla, M.; Saheb, M.; Tatar, Y.; Tugulay, A.; Kellou, I.; Colvine, S. Environmental Impact of Processed Tomato in France and in Turkey. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector (LCA Food 2014), San Francisco, CA, USA, 8–10 October 2014. [Google Scholar]

- Soode-Schimonsky, E.; Richter, K.; Weber-Blaschke, G. Product Environmental Footprint of Strawberries: Case Studies in Estonia and Germany. J. Environ. Manag. 2017, 203, 564–577. [Google Scholar] [CrossRef]

- Bartzas, G.; Zaharaki, D.; Komnitsas, K. Life Cycle Assessment of Open Field and Greenhouse Cultivation of Lettuce and Barley. Inf. Process. Agric. 2015, 2, 191–207. [Google Scholar] [CrossRef]

- Sanjuan-Delmás, D.; Llorach-Massana, P.; Nadal, A.; Ercilla-Montserrat, M.; Muñoz, P.; Montero, J.I.; Josa, A.; Gabarrell, X.; Rieradevall, J. Environmental Assessment of an Integrated Rooftop Greenhouse for Food Production in Cities. J. Clean. Prod. 2018, 177, 326–337. [Google Scholar] [CrossRef]

- Parada, F.; Gabarrell, X.; Rufí-Salís, M.; Arcas-Pilz, V.; Muñoz, P.; Villalba, G. Optimizing Irrigation in Urban Agriculture for Tomato Crops in Rooftop Greenhouses. Sci. Total Environ. 2021, 794, 148689. [Google Scholar] [CrossRef]

- Baptista, F.J.; Murcho, D.; Silva, L.L.; Stanghellini, C.; Montero, J.I.; Kempkes, F.; Munoz, P.; Gilli, C.; Giuffrida, F.; Stepowska, A. Assessment of Energy Consumption in Organic Tomato Greenhouse Production-a Case Study. In Proceedings of the Acta Horticulturae: III International Symposium on Organic Greenhouse Horticulture, Izmir, Turkey, 30 June 2017; Volume 1164, pp. 453–460. [Google Scholar]

- Russo, G.; Buttol, P.; Tarantini, M. LCA (Life Cycle Assessment) of Roses and Cyclamens in Greenhouse Cultivation. In Proceedings of the International Symposium on High Technology for Greenhouse System Management: Greensys 2007, Naples, Italy, 4–6 October 2007; Volume 801, pp. 359–366. [Google Scholar]

- Pérez Neira, D.; Soler Montiel, M.; Delgado Cabeza, M.; Reigada, A. Energy Use and Carbon Footprint of the Tomato Production in Heated Multi-Tunnel Greenhouses in Almeria within an Exporting Agri-Food System Context. Sci. Total Environ. 2018, 628–629, 1627–1636. [Google Scholar] [CrossRef] [PubMed]

- Lazzerini, G.; Lucchetti, S.; Nicese, F.P. Green House Gases(GHG) Emissions from the Ornamental Plant Nursery Industry: A Life Cycle Assessment(LCA) Approach in a Nursery District in Central Italy. J. Clean. Prod. 2016, 112, 4022–4030. [Google Scholar] [CrossRef]

- European Commission. The Tomato Market in the EU. In Vol. 1: Production and Area Statistics; European Commission: Luxembourg, 2022. [Google Scholar]

- Ntinas, G.K.; Dannehl, D.; Schuch, I.; Rocksch, T.; Schmidt, U. Sustainable Greenhouse Production with Minimised Carbon Footprint by Energy Export. Biosyst. Eng. 2020, 189, 164–178. [Google Scholar] [CrossRef]

- Fusi, A.; Castellani, V.; Bacenetti, J.; Cocetta, G.; Fiala, M.; Guidetti, R. The Environmental Impact of the Production of Fresh Cut Salad: A Case Study in Italy. Int. J. Life Cycle Assess. 2016, 21, 162–175. [Google Scholar] [CrossRef]

- Barla, S.A.; Salachas, G.; Abeliotis, K. Assessment of the Greenhouse Gas Emissions from Aeroponic Lettuce Cultivation in Greece. EuroMediterr. J. Env. Integr. 2020, 5, 29. [Google Scholar] [CrossRef]

- Sanyé-Mengual, E.; Oliver-Solà, J.; Montero, J.I.; Rieradevall, J. An Environmental and Economic Life Cycle Assessment of Rooftop Greenhouse (RTG) Implementation in Barcelona, Spain. Assessing New Forms of Urban Agriculture from the Greenhouse Structure to the Final Product Level. Int. J. Life Cycle Assess. 2015, 20, 350–366. [Google Scholar] [CrossRef]

- Martínez-Blanco, J.; Muñoz, P.; Antón, A.; Rieradevall, J. Assessment of Tomato Mediterranean Production in Open-Field and Standard Multi-Tunnel Greenhouse, with Compost or Mineral Fertilizers, from an Agricultural and Environmental Standpoint. J. Clean. Prod. 2011, 19, 985–997. [Google Scholar] [CrossRef]

- Almeida, J.; Achten, W.M.J.; Verbist, B.; Heuts, R.F.; Schrevens, E.; Muys, B. Carbon and Water Footprints and Energy Use of Greenhouse Tomato Production in Northern Italy. J. Ind. Ecol. 2014, 18, 898–908. [Google Scholar] [CrossRef]

- Russo, G.; Scarascia Mugnozza, G. LCA Methodology Applied to Various Typology of Greenhouses. In Proceedings of the International Conference on Sustainable Greenhouse Systems-Greensys 2004, Leuven, Belgium, 12–16 September 2005; Volume 691, pp. 837–844. [Google Scholar]

- Vermeulen, P.C.M.; Van Der Lans, C.J.M. Combined Heat and Power (CHP) as a Possible Method for Reduction of the CO2 Footprint of Organic Greenhouse Horticulture. In Proceedings of the I International Conference on Organic Greenhouse Horticulture, Bleiswijk, The Netherlands, 25 November 2011; Volume 915, pp. 61–68. [Google Scholar]

- Blom, T.; Jenkins, A.; Pulselli, R.M.; van den Dobbelsteen, A.A.J.F. The Embodied Carbon Emissions of Lettuce Production in Vertical Farming, Greenhouse Horticulture, and Open-Field Farming in The Netherlands. J. Clean. Prod. 2022, 377, 134443. [Google Scholar] [CrossRef]

- Röös, E.; Karlsson, H. Effect of Eating Seasonal on the Carbon Footprint of Swedish Vegetable Consumption. J. Clean. Prod. 2013, 59, 63–72. [Google Scholar] [CrossRef]

- ISO 14043; Environmental Management, Life Cycle Assessment, Life Cycle Interpretation. International Organisation for Standardisation: Geneva, Switzerland, 2000.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organisation for Standardisation: Geneva, Switzerland, 2006.

- ISO 14067:2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. International Organisation for Standardisation: Geneva, Switzerland, 2018.

- British Standards Institution. The Guide to PAS 2050:2011: How to Carbon Footprint Your Products, Identify Hotspots and Reduce Emissions in Your Supply Chain; BSI: London, UK, 2011; ISBN 9780580774324. [Google Scholar]

- Soode, E.; Weber-Blaschke, G.; Richter, K. Comparison of Product Carbon Footprint Standards with a Case Study on Poinsettia (Euphorbia Pulcherrima). Int. J. Life Cycle Assess. 2013, 18, 1280–1290. [Google Scholar] [CrossRef]

- Lampert, P.; Menrad, K. Sustainable Star? The Carbon Footprint of Christmas Stars and Its Variability along the Value Chain. Sustainability 2023, 15, 82. [Google Scholar] [CrossRef]

- Bonaguro, J.E.; Coletto, L.; Samuele, B.; Zanin, G.; Sambo, P. Environmental Impact in Floriculture: LCA Approach at Farm Level. In Proceedings of the XXIX International Horticultural Congress on Horticulture, Brisbane, Australia, 22 March 2016; Volume 1112, pp. 419–424. [Google Scholar]

- Torres, C.M.; Antón, A.; Ferrer, F.; Castells, F. Greenhouse Gas Calculator at Farm Level Addressed to the Growers. Int. J. Life Cycle Assess. 2017, 22, 537–545. [Google Scholar] [CrossRef]

- European Commission. Joint Research Centre. Institute for Environment and Sustainability. In International Reference Life Cycle Data System (ILCD) Handbook General Guide for Life Cycle Assessment: Detailed Guidance; Publications Office: Luxembourg, 2010; ISBN 9789279190926. [Google Scholar]

- Buendia, C.; Tanabe, E.; Kranjc, K.; Baasansuren, A.; Fukuda, J.; Ngarize, M.; Osako, S.; Pyrozhenko, A. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories Task Force on National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019; ISBN 978-4-88788-232-4.

- Stajnko, D.; Berk, P.; Vindis, P.; Lakota, M. Decreasing Impact of Tomato Production by Introducing Renewable Energy. In DAAAM International Scientific Book; EBSCO: Ipswich, MA, USA, 2016; pp. 49–58. [Google Scholar]

- Narodoslawsky, M. Sustainable Process Index. In Assessing and Measuring Environmental Impact and Sustainability; Elsevier: Amsterdam, The Netherlands, 2015; pp. 73–86. [Google Scholar]

- Swiss Centre for Life Cycle Inventories Ecoinvent Database. Available online: https://ecoinvent.org/ (accessed on 10 November 2023).

- Sphera Solutions GaBi Software. Available online: https://sphera.com/ (accessed on 10 November 2023).

- Lopes Silva, D.A.; Nunes, A.O.; Piekarski, C.M.; da Silva Moris, V.A.; de Souza, L.S.M.; Rodrigues, T.O. Why Using Different Life Cycle Assessment Software Tools Can Generate Different Results for the Same Product System? A Cause–Effect Analysis of the Problem. Sustain. Prod. Consum. 2019, 20, 304–315. [Google Scholar] [CrossRef]

- Speck, R.; Selke, S.; Auras, R.; Fitzsimmons, J. Life Cycle Assessment Software: Selection Can Impact Results. J. Ind. Ecol. 2016, 20, 18–28. [Google Scholar] [CrossRef]

- Herrmann, I.T.; Moltesen, A. Does It Matter Which Life Cycle Assessment (LCA) Tool You Choose?—A Comparative Assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Schau, E.M.; Fet, A.M. LCA Studies of Food Products as Background for Environmental Product Declarations. Int. J. Life Cycle Assess. 2008, 13, 255–264. [Google Scholar] [CrossRef]

- Weidema, B.; Wenzel, H.; Econet, C.P.; Hansen, K. The Product, Functional Unit and Reference Flows in LCA; Danish Ministry of the Environment: København, Denmark, 2004.

- Martin-Gorriz, B.; Maestre-Valero, J.F.; Gallego-Elvira, B.; Marín-Membrive, P.; Terrero, P.; Martínez-Alvarez, V. Recycling Drainage Effluents Using Reverse Osmosis Powered by Photovoltaic Solar Energy in Hydroponic Tomato Production: Environmental Footprint Analysis. J. Environ. Manag. 2021, 297, 113326. [Google Scholar] [CrossRef]

- Grabarczyk, R.; Grabarczyk, S. Cumulative Energy Demand and Carbon Footprint of the Greenhouse Cultivation System. Appl. Sci. 2022, 12, 8786. [Google Scholar] [CrossRef]

- Wandl, M.T.; Haberl, H. Greenhouse Gas Emissions of Small Scale Ornamental Plant Production in Austria-A Case Study. J. Clean. Prod. 2017, 141, 1123–1133. [Google Scholar] [CrossRef]

- Kim, S.J.; Kara, S.; Hauschild, M. Functional Unit and Product Functionality—Addressing Increase in Consumption and Demand for Functionality in Sustainability Assessment with LCA. Int. J. Life Cycle Assess. 2017, 22, 1257–1265. [Google Scholar] [CrossRef]

- Ross, S.A.; Topp, C.F.E.; Ennos, R.A.; Chagunda, M.G.G. Relative Emissions Intensity of Dairy Production Systems: Employing Different Functional Units in Life-Cycle Assessment. Animal 2017, 11, 1381–1388. [Google Scholar] [CrossRef] [PubMed]

- Kokare, S.; Oliveira, J.P.; Godina, R. Life Cycle Assessment of Additive Manufacturing Processes: A Review. J. Manuf. Syst. 2023, 68, 536–559. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H.; Liu, Z.; Ke, Q.; Alting, L. A System Boundary Identification Method for Life Cycle Assessment. Int. J. Life Cycle Assess. 2014, 19, 646–660. [Google Scholar] [CrossRef]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System Boundary Selection in Life-Cycle Inventories Using Hybrid Approaches. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Roer, A.G.; Korsaeth, A.; Henriksen, T.M.; Michelsen, O.; Strømman, A.H. The Influence of System Boundaries on Life Cycle Assessment of Grain Production in Central Southeast Norway. Agric. Syst. 2012, 111, 75–84. [Google Scholar] [CrossRef]

- Cherubini, E.; Franco, D.; Zanghelini, G.M.; Soares, S.R. Uncertainty in LCA Case Study Due to Allocation Approaches and Life Cycle Impact Assessment Methods. Int. J. Life Cycle Assess. 2018, 23, 2055–2070. [Google Scholar] [CrossRef]

- Renou, S.; Thomas, J.S.; Aoustin, E.; Pons, M.N. Influence of Impact Assessment Methods in Wastewater Treatment LCA. J. Clean. Prod. 2008, 16, 1098–1105. [Google Scholar] [CrossRef]

- Rejane, M.R.; Zortea, R.; Mendez, M.C.A.; Espinoza, M.R.C. New Frontiers on Life Cycle Assessment-Theory and Application; Petrillo, A., De Felice, F., Eds.; IntechOpen: London, UK, 2019; ISBN 978-1-83880-693-4. [Google Scholar]

- Alhashim, R.; Deepa, R.; Anandhi, A. Environmental Impact Assessment of Agricultural Production Using Lca: A Review. Climate 2021, 9, 164. [Google Scholar] [CrossRef]

- European Commission. Joint Research Centre. Institute for Environment and Sustainability. In International Reference Life Cycle Data System (ILCD) Handbook General Guide for Life Cycle Assessment: Provisions and Action Steps; Publications Office: Luxembourg, 2011; ISBN 9789279174513. [Google Scholar]

- Antón, A.; Torrellas, M.; Núñez, M.; Sevigné, E.; Amores, M.J.; Muñoz, P.; Montero, J.I. Improvement of Agricultural Life Cycle Assessment Studies through Spatial Differentiation and New Impact Categories: Case Study on Greenhouse Tomato Production. Environ. Sci. Technol. 2014, 48, 9454–9462. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; Ruijs, M.; García Victoria, N.; Stanghellini, C.; Montero, J.I. Environmental and Economic Assessment of Protected Crops in Four European Scenarios. J. Clean. Prod. 2012, 28, 45–55. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G. Life Cycle Analysis of Organic Tomato Production and Supply in Sweden. J. Clean. Prod. 2018, 196, 635–643. [Google Scholar] [CrossRef]

- Canaj, K.; Parente, A.; D’imperio, M.; Boari, F.; Buono, V.; Toriello, M.; Mehmeti, A.; Montesano, F.F. Can Precise Irrigation Support the Sustainability of Protected Cultivation? A Life-Cycle Assessment and Life-Cycle Cost Analysis. Water 2022, 14, 6. [Google Scholar] [CrossRef]

- Mugnozza, G.S.; Russo, G.; De, B.; Zeller, L. LCA Methodology Application in Flower Protected Cultivation. In Proceedings of the XXVII International Horticultural Congress-IHC 2006: International Symposium on Advances in Environmental Control, Automation, Seoul, Republic of Korea, 13 August 2007. [Google Scholar]

- Ouazzani Chahidi, L.; Fossa, M.; Priarone, A.; Mechaqrane, A. Energy Saving Strategies in Sustainable Greenhouse Cultivation in the Mediterranean Climate–A Case Study. Appl. Energy 2021, 282, 116156. [Google Scholar] [CrossRef]

- Barbaresi, A.; Maioli, V.; Bovo, M.; Tinti, F.; Torreggiani, D.; Tassinari, P. Application of Basket Geothermal Heat Exchangers for Sustainable Greenhouse Cultivation. Renew. Sustain. Energy Rev. 2020, 129, 109928. [Google Scholar] [CrossRef]

- Boulard, T.; Raeppel, C.; Brun, R.; Lecompte, F.; Hayer, F.; Carmassi, G.; Gaillard, G. Environmental Impact of Greenhouse Tomato Production in France. Agron. Sustain. Dev. 2011, 31, 757–777. [Google Scholar] [CrossRef]

- Benis, K.; Reinhart, C.; Ferrão, P. Building-Integrated Agriculture (Bia) in Urban Contexts: Testing a Simulation-Based Decision Support Workflow. In Proceedings of the Building Simulation Conference Proceedings, San Francisco, CA, USA, 7–9 August 2017; Volume 5, pp. 2337–2346. [Google Scholar]

- Antón, A.; Torrellas, M.; Raya, V.; Montero, J.I. Modelling the Amount of Materials to Improve Inventory Datasets of Greenhouse Infrastructures. Int. J. Life Cycle Assess. 2014, 19, 29–41. [Google Scholar] [CrossRef]

- Nadal, A.; Llorach-Massana, P.; Cuerva, E.; López-Capel, E.; Montero, J.I.; Josa, A.; Rieradevall, J.; Royapoor, M. Building-Integrated Rooftop Greenhouses: An Energy and Environmental Assessment in the Mediterranean Context. Appl. Energy 2017, 187, 338–351. [Google Scholar] [CrossRef]

- Katzin, D.; Marcelis, L.F.M.; van Mourik, S. Energy Savings in Greenhouses by Transition from High-Pressure Sodium to LED Lighting. Appl. Energy 2021, 281, 116019. [Google Scholar] [CrossRef]

- Bonaguro, J.E.; Coletto, L.; Zanin, G. Environmental and Agronomic Performance of Fresh Rice Hulls Used as Growing Medium Component for Cyclamen persicum L. Pot Plants. J. Clean. Prod. 2017, 142, 2125–2132. [Google Scholar] [CrossRef]

- Vinci, G.; Rapa, M. Hydroponic Cultivation: Life Cycle Assessment of Substrate Choice. Br. Food J. 2019, 121, 1801–1812. [Google Scholar] [CrossRef]

- Antón, A.; Torrellas, M.; Montero, J.I.; Ruijs, M.; Vermeulen, P.; Stanghellini, C. Environmental Impact Assessment of Dutch Tomato Crop Production in a Venlo Glasshouse. In Proceedings of the XXVIII International Horticultural Congress on Science and Horticulture for People (IHC2010), Lisbon, Portugal, 22–27 August 2010. [Google Scholar]

- Frem, M.; Fucilli, V.; Petrontino, A.; Acciani, C.; Bianchi, R.; Bozzo, F. Nursery Plant Production Models under Quarantine Pests’ Outbreak: Assessing the Environmental Implications and Economic Viability. Agronomy 2022, 12, 2964. [Google Scholar] [CrossRef]

- Antón, A.; Montero, J.I.; Muñoz, P.; Castells, F. LCA and Tomato Production in Mediterranean Greenhouses. Int. J. Agric. Resour. Gov. Ecol. 2005, 4, 102–112. [Google Scholar] [CrossRef]

- Abeliotis, K.; Barla, S.A.; Detsis, V.; Malindretos, G. Life Cycle Assessment of Carnation Production in Greece. J. Clean. Prod. 2016, 112, 32–38. [Google Scholar] [CrossRef]

- Rasines, L.; Miguel, G.S.; Molina-García, Á.; Artés-Hernández, F.; Hontoria, E.; Aguayo, E. Optimizing the Environmental Sustainability of Alternative Post-Harvest Scenarios for Fresh Vegetables: A Case Study in Spain. Sci. Total Environ. 2023, 860, 160422. [Google Scholar] [CrossRef] [PubMed]

- Cellura, M.; Longo, S.; Mistretta, M. Life Cycle Assessment (LCA) of Protected Crops: An Italian Case Study. J. Clean. Prod. 2012, 28, 56–62. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; López, J.C.; Baeza, E.J.; Parra, J.P.; Muñoz, P.; Montero, J.I. LCA of a Tomato Crop in a Multi-Tunnel Greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Muñoz, P.; Antón, A.; Nuñez, M.; Paranjpe, A.; Ariño, J.; Castells, X.; Montero, J.I.; Rieradevall, J. Comparing the Environmental Impacts of Greenhouse versus Open-Field Tomato Production in the Mediterranean Region. Acta Hortic. 2008, 801, 1591–1596. [Google Scholar] [CrossRef]

- Mendoza-Fernández, A.J.; Peña-Fernández, A.; Molina, L.; Aguilera, P.A. The Role of Technology in Greenhouse Agriculture: Towards a Sustainable Intensification in Campo de Dalías (Almería, Spain). Agronomy 2021, 11, 101. [Google Scholar] [CrossRef]

- Schuch, I.; Dannehl, D.; Miranda-Trujillo, L.; Rocksch, T.; Schmidt, U. ZINEG Project-Energetic Evaluation of a Solar Collector Greenhouse with above-Ground Heat Storage in Germany. Acta Hortic. 2014, 1037, 195–201. [Google Scholar] [CrossRef]

- Khan, J.; Johansson, B.; Hildingsson, R. Strategies for Greening the Economy in Three Nordic Countries. Environ. Policy Gov. 2021, 31, 592–604. [Google Scholar] [CrossRef]

- Narayanan, V.K.; O’Connor, G.C. Encyclopedia of Technology and Innovation Management; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2010; ISBN 978-1-405-16049-0. [Google Scholar]

- Donati, F.; Tukker, A. Environmental Pressures and Value Added Related to Imports and Exports of the Dutch Agricultural Sector. Sustainability 2022, 14, 6057. [Google Scholar] [CrossRef]

- Zhang, X.; Lazin, F.A. The Agricultural Cooperation Between China and Israel-Case Study of Projects in Shandong Province. Asian J. Middle East. Islam. Stud. 2023, 17, 106–126. [Google Scholar] [CrossRef]

- Costa, J.M.; Reis, M.; Passarinho, J.A.; Ferreira, M.E.; Almeida, D.P.F. Microeconomic and Environmental Sustainability of Portuguese Greenhouse Horticulture: A Critical Assessment. International Symposium on New Technologies and Management for Greenhouses-GreenSys 2015, Evora, Portugal, 19–23 July 2015; Volume 1170, pp. 1117–1123. [Google Scholar]

- Bogoslov, I.A.; Lungu, A.E.; Stoica, E.A.; Georgescu, M.R. European Green Deal Impact on Entrepreneurship and Competition: A Free Market Approach. Sustainability 2022, 14, 12335. [Google Scholar] [CrossRef]

- Ampatzoglou, A.; Ampatzoglou, A.; Chatzigeorgiou, A.; Avgeriou, P. The Financial Aspect of Managing Technical Debt: A Systematic Literature Review. Inform. Softw. Technol. 2015, 64, 52–73. [Google Scholar] [CrossRef]

- R Core Team R: A Language and Environment for Statistical Computing; R Core Team R: Vienna, Austria, 2013.

- Laurent, A.; Olsen, S.I.; Hauschild, M.Z. Limitations of Carbon Footprint as Indicator of Environmental Sustainability. Environ. Sci. Technol. 2012, 46, 4100–4108. [Google Scholar] [CrossRef]

- Chatzigeorgiou, I.; Liantas, G.; Spanos, P.; Gkriniari, V.; Maloupa, E.; Ntinas, G.K. Hydroponic Cultivation of Vine Leaves with Reduced Carbon Footprint in a Mediterranean Greenhouse. Sustainability 2022, 14, 8011. [Google Scholar] [CrossRef]

- Corcelli, F.; Fiorentino, G.; Petit-Boix, A.; Rieradevall, J.; Gabarrell, X. Transforming Rooftops into Productive Urban Spaces in the Mediterranean. An LCA Comparison of Agri-Urban Production and Photovoltaic Energy Generation. Resour. Conserv. Recycl. 2019, 144, 321–336. [Google Scholar] [CrossRef]

- De Lucia, B.; Cristiano, G.; Vecchietti, L.; Rea, E.; Russo, G. Nursery Growing Media: Agronomic and Environmental Quality Assessment of Sewage Sludge-Based Compost. Appl. Environ. Soil. Sci. 2013, 2013, 565139. [Google Scholar] [CrossRef]

- Falla, N.M.; Contu, S.; Demasi, S.; Caser, M.; Scariot, V. Environmental Impact of Edible Flower Production: A Case Study. Agronomy 2020, 10, 579. [Google Scholar] [CrossRef]

- García, J.G.; García, B.G. Sustainability Assessment of Greenhouse Pepper Production Scenarios in Southeastern Spain. Agronomy 2022, 12, 1254. [Google Scholar] [CrossRef]

- Ilari, A.; Duca, D. Energy and Environmental Sustainability of Nursery Step Finalized to “Fresh Cut” Salad Production by Means of LCA. Int. J. Life Cycle Assess. 2018, 23, 800–810. [Google Scholar] [CrossRef]

- Jukka, L.; Miika, M.; Lauri, L.; Mirja, M.; Ville, U.; Lassi, L. A Financial and Environmental Sustainability of Circular Bioeconomy: A Case Study of Short Rotation Coppice, Biochar and Greenhouse Production in Southern Finland. Biomass Bioenergy 2022, 163, 106524. [Google Scholar] [CrossRef]

- Marttila, M.P.; Uusitalo, V.; Linnanen, L.; Mikkilä, M.H. Agro-Industrial Symbiosis and Alternative Heating Systems for Decreasing the Global Warming Potential of Greenhouse Production. Sustainability 2021, 13, 9040. [Google Scholar] [CrossRef]

- Montero, J.I.; Teitel, M. Developments in Covering Materials for Intensive Horticulture: Technical Properties and Recycling Opportunities. Acta Hortic. 2014, 1015, 269–280. [Google Scholar] [CrossRef]

- Rufí-Salís, M.; Petit-Boix, A.; Villalba, G.; Sanjuan-Delmás, D.; Parada, F.; Ercilla-Montserrat, M.; Arcas-Pilz, V.; Muñoz-Liesa, J.; Rieradevall, J.; Gabarrell, X. Recirculating Water and Nutrients in Urban Agriculture: An Opportunity towards Environmental Sustainability and Water Use Efficiency? J. Clean. Prod. 2020, 261, 121213. [Google Scholar] [CrossRef]

- Russo, G.; Scarascia, G.; De, M.B.; Zeller, L. Environmental Improvements of Greenhouse Flower Cultivation by Means of LCA Methodology. Acta Hortic 2008, 801, 301–308. [Google Scholar] [CrossRef]

- Soode, E.; Lampert, P.; Weber-Blaschke, G.; Richter, K. Carbon Footprints of the Horticultural Products Strawberries, Asparagus, Roses and Orchids in Germany. J. Clean. Prod. 2015, 87, 168–179. [Google Scholar] [CrossRef]

| Goal | Methodology | Metadata |

|---|---|---|

| Descriptive information regarding collected studies | Descriptive statistics, plots | Document number, sources, publication year, document citations, author keywords, keywords plus |

| Country-wise research landscape | Descriptive statistics | Author countries |

| Citation analysis | Document citations | |

| Collaboration networks | Author countries | |

| Thematic axes from collected studies | Co-word analysis clustering | Author keywords |

| Cooccurrence networks | Author keywords, keywords plus |

| Main Information | |

|---|---|

| Timespan | 2005:2023 |

| Sources (Journals, Books, etc.) | 17 |

| Documents | 50 |

| Document Average Age | 7 |

| Annual Growth Rate (%) | −3.78 |

| Average Citations Per Document | 37.1 |

| Total References | 2008 |

| Journal Papers | 41 |

| Conference Papers | 9 |

| Document Contents | |

| Keywords Plus | 450 |

| Author Keywords | 187 |

| Authors and Author Collaboration | |

| Total Authors | 164 |

| Authors of Single-Authored Docs | 0 |

| Single-authored docs | 0 |

| Co-Authors Per Document | 4.44 |

| Journal Name | Number of Articles |

|---|---|

| Journal of Cleaner Production | 14 |

| Acta Horticulturae | 10 |

| The International Journal of Life Cycle Assessment | 6 |

| Agronomy | 3 |

| Sustainability | 3 |

| Journal of Environmental Management | 2 |

| Science of the Total Environment | 2 |

| Applied and Environmental Soil Science | 1 |

| Applied Sciences | 1 |

| Article | Number of Citations |

|---|---|

| CELLURA M, 2012, J CLEAN PROD [107] | 149 |

| TORRELLAS M, 2012, INT J LIFE CYCLE ASSESS [108] | 141 |

| SANYÉ-MENGUAL E, 2015, INT J LIFE CYCLE ASSESS [48] | 133 |

| MARTÍNEZ-BLANCO J, 2011, J CLEAN PROD [49] | 131 |

| TORRELLAS M, 2012, J CLEAN PROD [89] | 109 |

| SANJUAN-DELMÁS D, 2018, J CLEAN PROD [38] | 95 |

| ANTÓN A, 2005, INT J AGRIC RESOUR GOV ECOL [104] | 86 |

| NTINAS GK, 2017, J CLEAN PROD [20] | 82 |

| BARTZAS G, 2015, INF PROCESS AGRIC [37] | 71 |

| MUÑOZ P, 2008, ACTA HORTIC [109] | 64 |

| Country | Number of Citations |

|---|---|

| Spain | 835 |

| Italy | 359 |

| Germany | 167 |

| Greece | 112 |

| Sweden | 108 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ravani, M.; Georgiou, K.; Tselempi, S.; Monokrousos, N.; Ntinas, G.K. Carbon Footprint of Greenhouse Production in EU—How Close Are We to Green Deal Goals? Sustainability 2024, 16, 191. https://doi.org/10.3390/su16010191

Ravani M, Georgiou K, Tselempi S, Monokrousos N, Ntinas GK. Carbon Footprint of Greenhouse Production in EU—How Close Are We to Green Deal Goals? Sustainability. 2024; 16(1):191. https://doi.org/10.3390/su16010191

Chicago/Turabian StyleRavani, Maria, Konstantinos Georgiou, Stefania Tselempi, Nikolaos Monokrousos, and Georgios K. Ntinas. 2024. "Carbon Footprint of Greenhouse Production in EU—How Close Are We to Green Deal Goals?" Sustainability 16, no. 1: 191. https://doi.org/10.3390/su16010191

APA StyleRavani, M., Georgiou, K., Tselempi, S., Monokrousos, N., & Ntinas, G. K. (2024). Carbon Footprint of Greenhouse Production in EU—How Close Are We to Green Deal Goals? Sustainability, 16(1), 191. https://doi.org/10.3390/su16010191