Application of Biopolymers as Sustainable Cladding Materials: A Review

Abstract

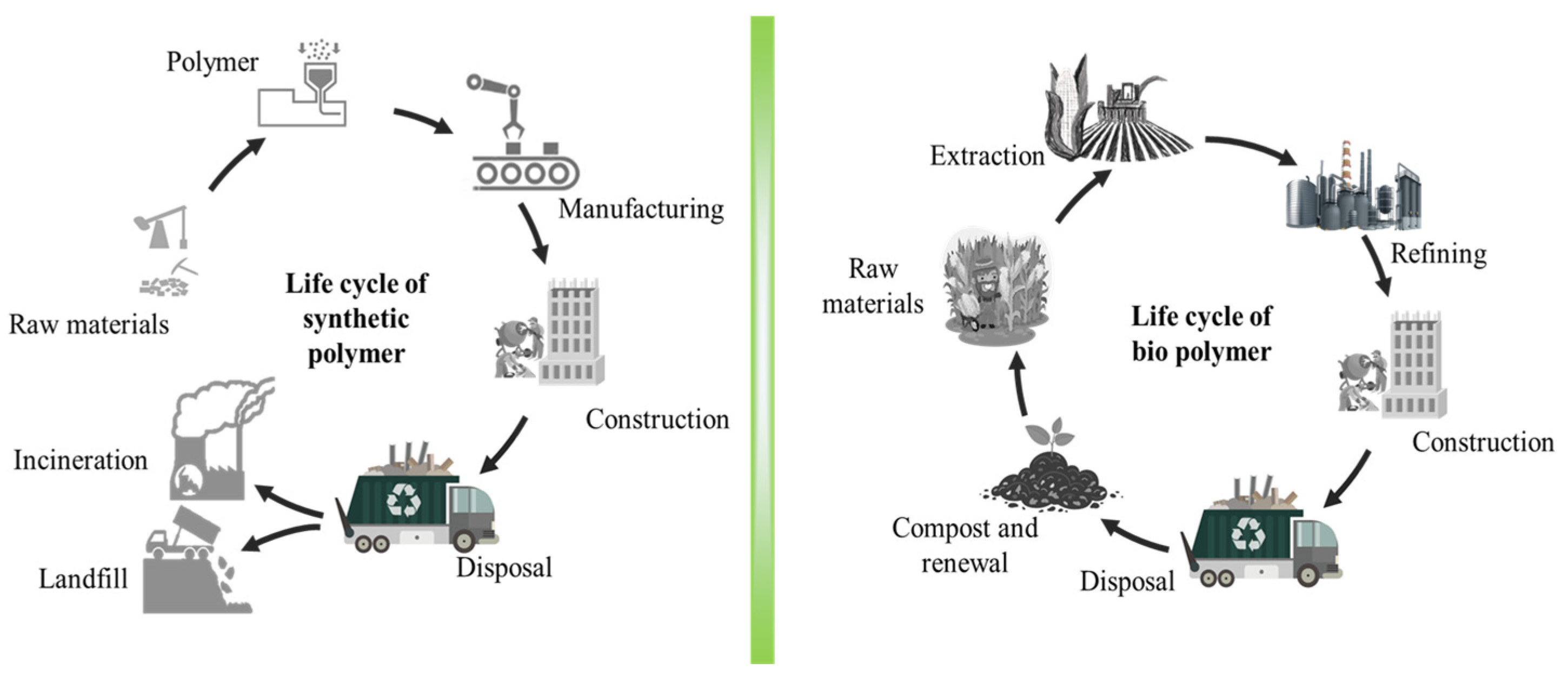

:1. Introduction

2. Research Methodology

3. Different Types of Biopolymers Used in Cladding

3.1. Polylactic Acid (PLA)

3.2. Polyhydroxyalkanoates (PHAs)

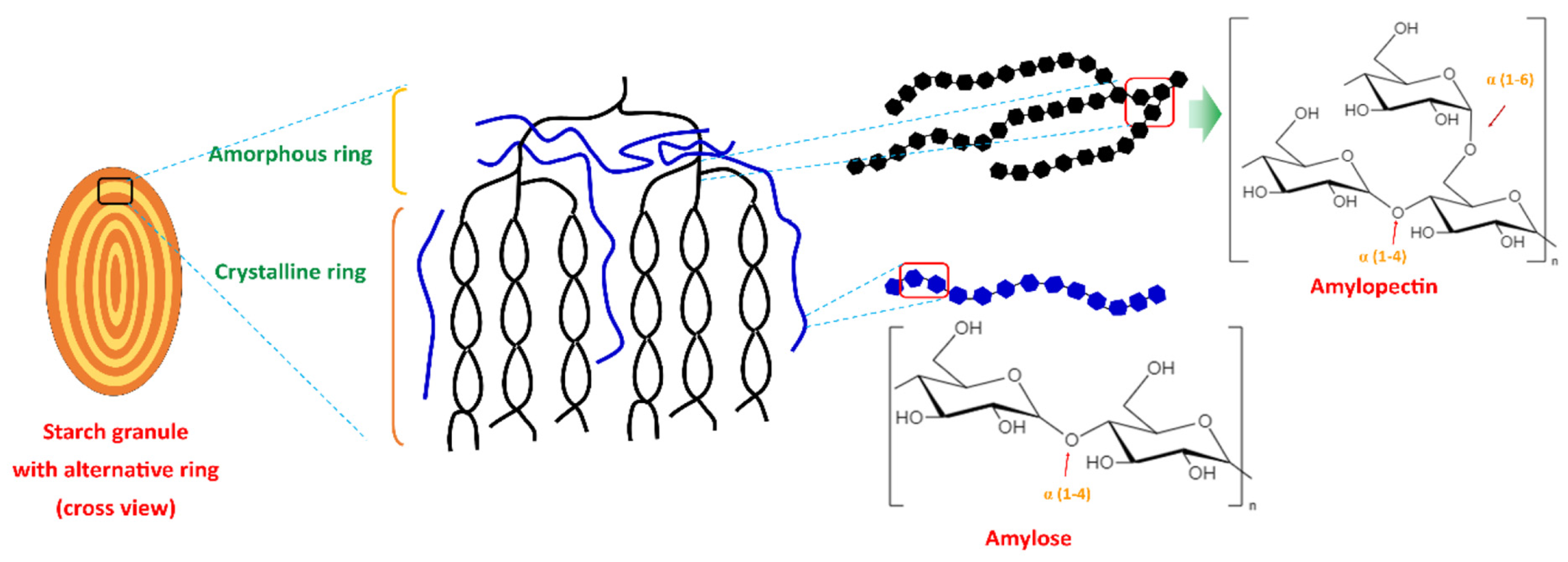

3.3. Starch-Based Polymers (SBP)

3.4. Cellulose-Based Polymers (CBP)

3.5. Polyhydroxybutyrate (PHB)

3.6. Polybutylene Adipate Terephthalate (PBAT)

3.7. Polybutylene Succinate (PBS)

3.8. Polycaprolactone (PCL)

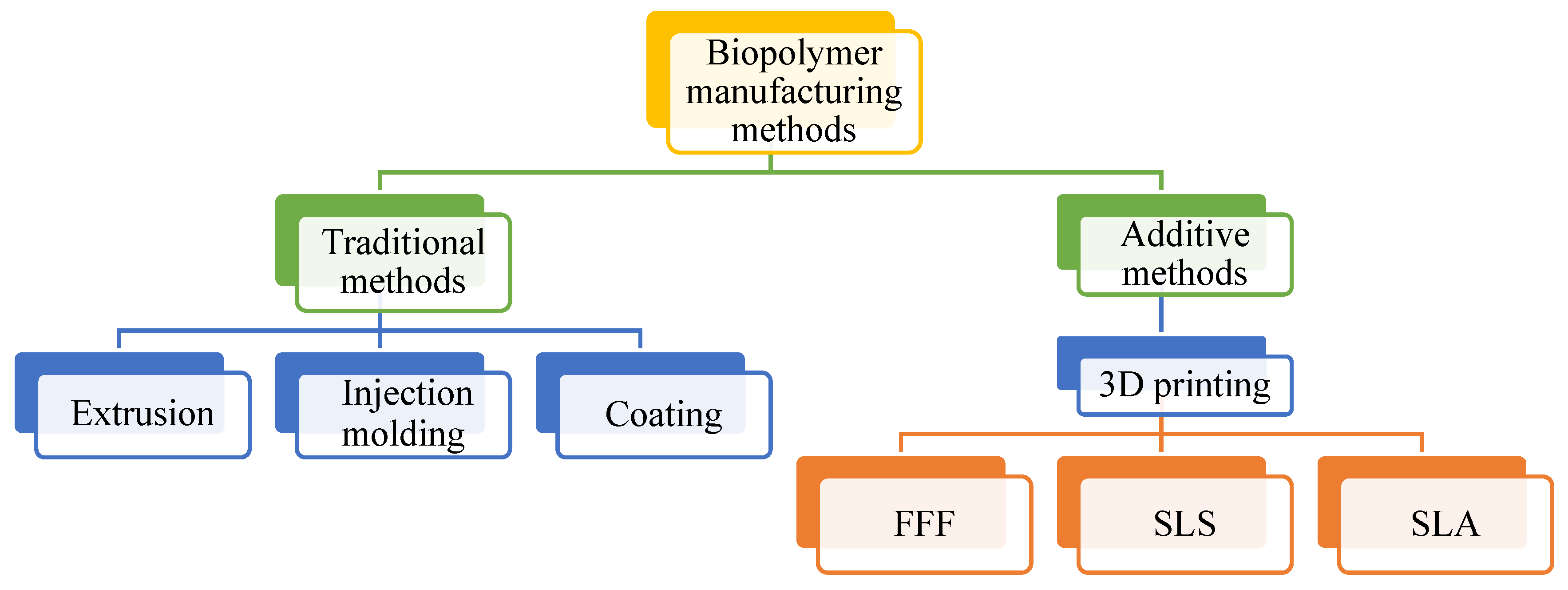

4. Manufacturing Methods for Biopolymers

4.1. Traditional Manufacturing Techniques

4.1.1. Extrusion

4.1.2. Injection Moulding

4.1.3. Coating

4.2. Additive Manufacturing Technique and 3D Printing

4.2.1. Fused Filament Fabrication (FFF)

4.2.2. Selective Laser Sintering (SLS)

4.2.3. Stereolithography (SLA)

5. Different Properties and Applications of Biopolymer Materials

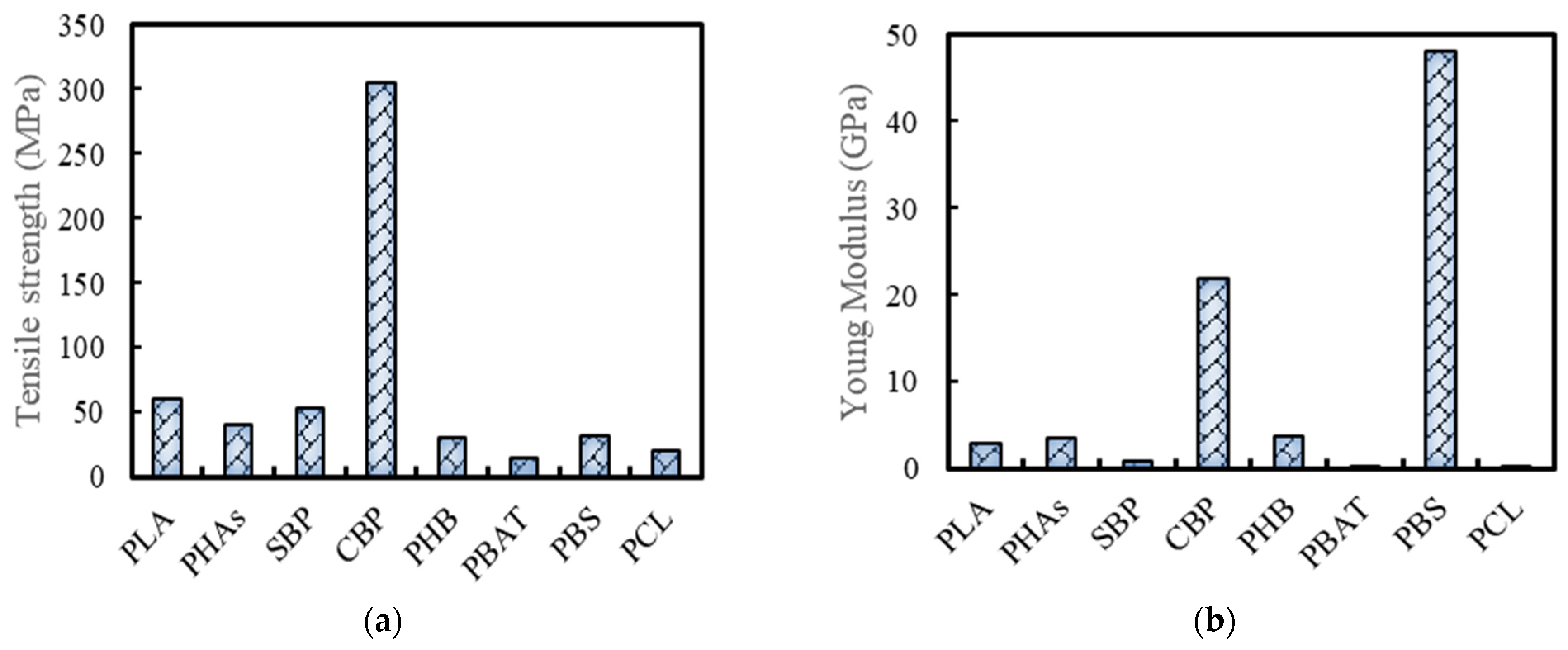

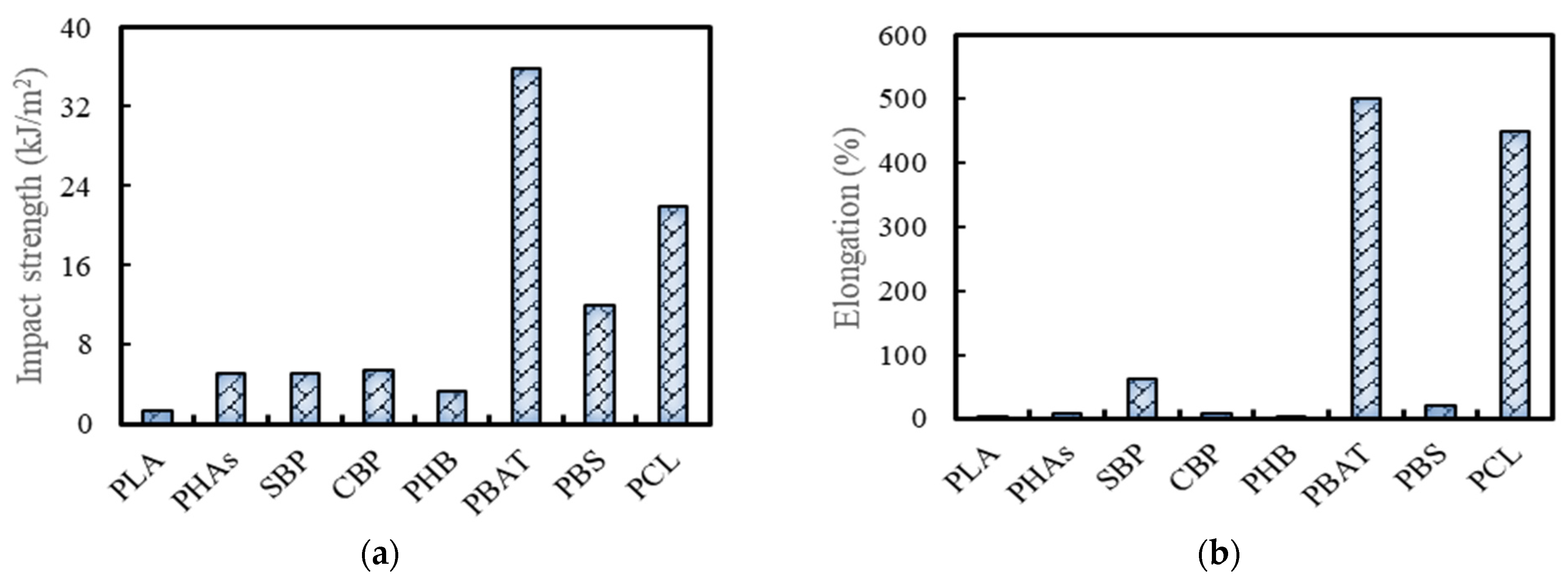

5.1. Mechanical Properties

5.2. Chemical Properties

5.3. Thermal Properties

5.4. Barrier Properties

5.5. Applications and Limitations

6. Prospectives and Future Challenges

6.1. Prospectives of Biopolymers

- (a)

- Sustainability and lower carbon footprint

- (b)

- Enhanced mechanical and thermal properties

- (c)

- Improve environmental impact

- (d)

- Regulatory support and innovation

6.2. Future Challenges of Biopolymers

- (a)

- Biodegradability vs. Durability Balance

- (b)

- Fire Properties

- (c)

- Market Acceptance

7. Conclusions

- Suitable Shift: The increasing demand for sustainable construction materials is leading towards biopolymer-based cladding applications, which help to overcome the limitations of traditional synthetic polymers.

- Environmental Compatibility: Biopolymers, with ultimate attributes of biodegradability, renewability, and low embodied energy, reduce ecological impact and offer better environmental compatibility.

- Integration for Sustainability: Integrating biopolymers with synthetic polymers such as PLA, PHA, and starch-based biopolymers improves biodegradability for sustainable waste management.

- Research Gap and Future Directions: Despite biopolymers being promising, a research gap exists in the comprehensive use of biopolymers in cladding. Further research studies are essential to assess their suitability for specific applications and promote successful integration into sustainable construction practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hossain, M.D.; Hassan, M.K.; Yuen, A.C.Y.; He, Y.; Saha, S.; Hittini, W. Flame behaviour, fire hazard and fire testing approach for lightweight composite claddings—A review. J. Struct. Fire Eng. 2021, 12, 257–292. [Google Scholar] [CrossRef]

- Hudson, F.S.; Sutrisna, M.; Chawynski, G. A certification framework for managing the risks of non-compliance and non-conformance building products: A Western Australian perspective. Int. J. Build. Pathol. Adapt. 2021, 39, 312–343. [Google Scholar] [CrossRef]

- Hill, C.A.S. The environmental consequences concerning the use of timber in the built environment. Front. Built Environ. 2019, 5, 129. [Google Scholar] [CrossRef]

- Balocco, C.; Grazzini, G.; Cavalera, A. Transient analysis of an external building cladding. Energy Build. 2008, 40, 1273–1277. [Google Scholar] [CrossRef]

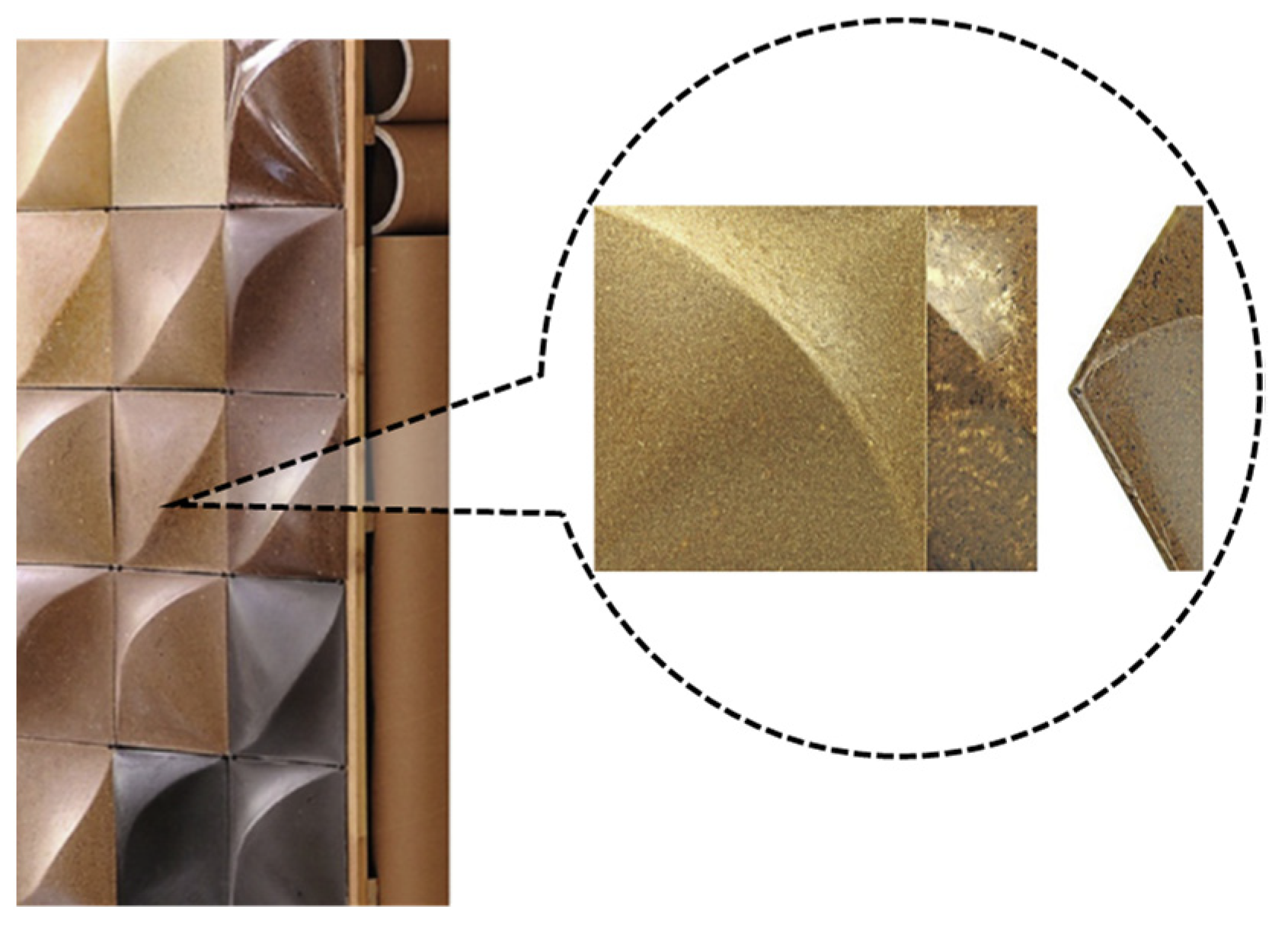

- Özdamar, E.G.; Murat, A.T.E.Ş. Rethinking sustainability: A research on starch-based bioplastic. J. Sustain. Constr. Mater. Technol. 2018, 3, 249–260. [Google Scholar]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A.; Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Designing building skins with biomaterials. In Bio-Based Building Skin; Springer: Berlin/Heidelberg, Germany, 2019; pp. 65–97. [Google Scholar]

- Telmo, O. Polymers and the environment. In Polymer Science; IntechOpen,: London, UK, 2013; Chapter 1. [Google Scholar] [CrossRef]

- Rong, L.; Chen, X.; Shen, M.; Yang, J.; Qi, X.; Li, Y.; Xie, J. The application of 3D printing technology on starch-based product: A review. Trends Food Sci. Technol. 2023, 134, 149–161. [Google Scholar] [CrossRef]

- Aziz, T.; Haq, F.; Farid, A.; Kiran, M.; Faisal, S.; Ullah, A.; Ullah, N.; Bokhari, A.; Mubashir, M.; Chuah, L.F.; et al. Challenges associated with cellulose composite material: Facet engineering and prospective. Environ. Res. 2023, 223, 115429. [Google Scholar] [CrossRef]

- Huang, K.X.; Zhou, L.Y.; Chen, J.Q.; Peng, N.; Chen, H.X.; Gu, H.Z.; Zou, T. Applications and perspectives of quaternized cellulose, chitin and chitosan: A review. Int. J. Biol. Macromol. 2023, 242, 124990. [Google Scholar] [CrossRef]

- Yano, H.; Fu, W. Hemp: A Sustainable Plant with High Industrial Value in Food Processing. Foods 2023, 12, 651. [Google Scholar] [CrossRef]

- Carvalho, V.R.; Costa, L.C.B.; Baeta, B.E.L.; Peixoto, R.A.F. Lignin-Based Admixtures: A Scientometric Analysis and Qualitative Discussion Applied to Cement-Based Composites. Polymers 2023, 15, 1254. [Google Scholar] [CrossRef]

- Tusnim, J.; Hoque, M.E.; Biswas, M.C. Biopolymers in building materials. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 185–195. [Google Scholar]

- Grigoras, A.G. Natural and synthetic polymeric antimicrobials with quaternary ammonium moieties: A review. Environ. Chem. Lett. 2021, 19, 3009–3022. [Google Scholar] [CrossRef]

- Muhammadi Shabina Afzal, M.; Hameed, S. Bacterial polyhydroxyalkanoates-eco-friendly next generation plastic: Production, biocompatibility, biodegradation, physical properties and applications. Green Chem. Lett. Rev. 2015, 8, 56–77. [Google Scholar] [CrossRef]

- García-Guzmán, L.; Cabrera-Barjas, G.; Soria-Hernández, C.G.; Castaño, J.; Guadarrama-Lezama, A.Y.; Rodríguez Llamazares, S. Progress in starch-based materials for food packaging applications. Polysaccharides 2022, 3, 136–177. [Google Scholar] [CrossRef]

- Yu, Z.; Ji, Y.; Bourg, V.; Bilgen, M.; Meredith, J.C. Chitin-and cellulose-based sustainable barrier materials: A review. Emergent Mater. 2020, 3, 919–936. [Google Scholar] [CrossRef]

- Belgacem, M.N.; Gandini, A. (Eds.) Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Barletta, M.; Aversa, C.; Ayyoob, M.; Gisario, A.; Hamad, K.; Mehrpouya, M.; Vahabi, H. Poly (butylene succinate) (PBS): Materials, processing, and industrial applications. Prog. Polym. Sci. 2022, 132, 101579. [Google Scholar] [CrossRef]

- Friedrich, D. How building experts evaluate the sustainability and performance of novel bioplastic-based textile façades: An analysis of decision making. Build. Environ. 2022, 207, 108485. [Google Scholar] [CrossRef]

- Dahy, H. Biocomposite materials based on annual natural fibres and biopolymers–Design, fabrication and customized applications in architecture. Constr. Build. Mater. 2017, 147, 212–220. [Google Scholar] [CrossRef]

- Gheorghita, R.; Anchidin-Norocel, L.; Filip, R.; Dimian, M.; Covasa, M. Applications of biopolymers for drugs and probiotics delivery. Polymers 2021, 13, 2729. [Google Scholar] [CrossRef]

- Jeon, H.J.; Kim, M.N. Biodegradation of poly (L-lactide) (PLA) exposed to UV irradiation by a mesophilic bacterium. Int. Biodeterior. Biodegrad. 2013, 85, 289–293. [Google Scholar] [CrossRef]

- Filachione, E.M.; Costello, E.J. Lactic esters by reaction of ammonium lactate with alcohols. Ind. Eng. Chem. 1952, 44, 2189–2191. [Google Scholar] [CrossRef]

- Jiménez, A.; Peltzer, M.; Ruseckaite, R. (Eds.) Poly (Lactic Acid) Science and Technology: Processing, Properties, Additives and Applications (No. 12); Royal Society of Chemistry: London, UK, 2015. [Google Scholar]

- Taib, N.A.A.B.; Rahman, M.R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bakri, M.K.B.; Bin Julaihi, M.R.M.; Khan, A. A review on poly lactic acid (PLA) as a biodegradable polymer. Polym. Bull. 2023, 80, 1179–1213. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly (lactic acid) (PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef] [PubMed]

- PLA (Polylactic Acid): Definition, Applications, and Different Types. Available online: https://www.xometry.com/resources/materials/what-is-pla (accessed on 8 August 2023).

- Galindo, S.; Ureña-Núñez, F. Enhanced surface hydrophobicity of poly (lactic acid) by Co60 gamma ray irradiation. Rev. Mex. Física 2018, 64, 1–7. [Google Scholar]

- Reddy, C.S.K.; Ghai, R.; Kalia, V. Polyhydroxyalkanoates: An overview. Bioresour. Technol. 2003, 87, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Riley, R.S.; Day, E.S. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2017, 9, e1449. [Google Scholar]

- Tomizawa, S.; Hyakutake, M.; Saito, Y.; Agus, J.; Mizuno, K.; Abe, H.; Tsuge, T. Molecular weight change of polyhydroxyalkanoate (PHA) caused by the PhaC subunit of PHA synthase from Bacillus cereus YB-4 in recombinant Escherichia coli. Biomacromolecules 2011, 12, 2660–2666. [Google Scholar] [CrossRef]

- Grigore, M.E.; Grigorescu, R.M.; Iancu, L.; Ion, R.M.; Zaharia, C.; Andrei, E.R. Methods of synthesis, properties and biomedical applications of polyhydroxyalkanoates: A review. J. Biomater. Sci. 2019, 30, 695–712. [Google Scholar] [CrossRef]

- Dalton, B.; Bhagabati, P.; De Micco, J.; Padamati, R.B.; O’Connor, K. A review on biological synthesis of the biodegradable polymers polyhydroxyalkanoates and the development of multiple applications. Catalysts 2022, 12, 319. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Udduttula, A.; Fan, Z.S.; Chen, J.H.; Sun, A.R.; Zhang, P. Microbial-Derived Polyhydroxyalkanoate-Based Scaffolds for Bone Tissue Engineering: Biosynthesis, Properties, and Perspectives. Front. Bioeng. Biotechnol. 2021, 9, 763031. [Google Scholar] [CrossRef]

- Guimarães, T.C.; Araújo, E.S.; Hernández-Macedo, M.L.; López, J.A. Polyhydroxyalkanoates: Biosynthesis from alternative carbon sources and analytic methods: A short review. J. Polym. Environ. 2022, 30, 2669–2684. [Google Scholar] [CrossRef]

- Qamruzzaman, M.; Ahmed, F.; Mondal, M.I.H. An overview on starch-based sustainable hydrogels: Potential applications and aspects. J. Polym. Environ. 2022, 30, 19–50. [Google Scholar] [CrossRef]

- Gamage, A.; Thiviya, P.; Mani, S.; Ponnusamy, P.G.; Manamperi, A.; Evon, P.; Merah, O.; Madhujith, T. Environmental Properties and Applications of Biodegradable Starch-Based Nanocomposites. Polymers 2022, 14, 4578. [Google Scholar] [CrossRef] [PubMed]

- Marichelvam, M.K.; Jawaid, M.; Asim, M. Corn and rice starch-based bio-plastics as alternative packaging materials. Fibers 2019, 7, 32. [Google Scholar] [CrossRef]

- Nawaz, H.; Waheed, R.; Nawaz, M.; Shahwar, D. Physical and chemical modifications in starch structure and reactivity. Chem. Prop. Starch 2020, 9, 13–35. [Google Scholar]

- Mary, S.K.; Koshy, R.R.; Arunima, R.; Thomas, S.; Pothen, L.A. A review of recent advances in starch-based materials: Bio nanocomposites, pH sensitive films, aerogels and carbon dots. Carbohydr. Polym. Technol. Appl. 2022, 3, 100190. [Google Scholar] [CrossRef]

- Lu, D.R.; Xiao, C.M.; Xu, S.J. Starch-based completely biodegradable polymer materials. Express Polym. Lett. 2009, 3, 366–375. [Google Scholar] [CrossRef]

- Surendren, A.; Mohanty, A.K.; Liu, Q.; Misra, M. A review of biodegradable thermoplastic starches, their blends and composites: Recent developments and opportunities for single-use plastic packaging alternatives. Green Chem. 2022, 24, 8606–8636. [Google Scholar] [CrossRef]

- Bao, J.; Xing, J.; Phillips, D.L.; Corke, H. Physical properties of octenyl succinic anhydride modified rice, wheat, and potato starches. J. Agric. Food Chem. 2003, 51, 2283–2287. [Google Scholar] [CrossRef]

- Mischnick, P.; Momcilovic, D. Chemical structure analysis of starch and cellulose derivatives. Adv. Carbohydr. Chem. Biochem. 2010, 64, 117–210. [Google Scholar]

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Yang, Z. Recent progress in polymer-based building materials. Int. J. Polym. Sci. 2020, 2020, 8838160. [Google Scholar] [CrossRef]

- Galiano, F.; Briceño, K.; Marino, T.; Molino, A.; Christensen, K.V.; Figoli, A. Advances in biopolymer-based membrane preparation and applications. J. Membr. Sci. 2018, 564, 562–586. [Google Scholar] [CrossRef]

- Li, B.; Konecke, S.; Wegiel, L.A.; Taylor, L.S.; Edgar, K.J. Both solubility and chemical stability of curcumin are enhanced by solid dispersion in cellulose derivative matrices. Carbohydr. Polym. 2013, 98, 1108–1116. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Wang, Q.; Cai, J.; Zhang, L.; Xu, M.; Cheng, H.; Han, C.C.; Kuga, S.; Xiao, J.; Xiao, R. A bioplastic with high strength constructed from a cellulose hydrogel by changing the aggregated structure. J. Mater. Chem. A 2013, 1, 6678–6686. [Google Scholar] [CrossRef]

- Guan, Q.F.; Yang, H.B.; Han, Z.M.; Ling, Z.C.; Yu, S.H. An all-natural bioinspired structural material for plastic replacement. Nat. Commun. 2020, 11, 5401. [Google Scholar] [CrossRef] [PubMed]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Felgueiras, C.; Azoia, N.G.; Gonçalves, C.; Gama, M.; Dourado, F. Trends on the cellulose-based textiles: Raw materials and technologies. Front. Bioeng. Biotechnol. 2021, 9, 608826. [Google Scholar] [CrossRef]

- Gurieff, N.; Lant, P. Comparative life cycle assessment and financial analysis of mixed culture polyhydroxyalkanoate production. Bioresour. Technol. 2007, 98, 3393–3403. [Google Scholar] [CrossRef]

- Yu, P.H.; Chua, H.; Huang, A.L.; Lo, W.; Chen, G.Q. Conversion of food industrial wastes into bioplastics. Appl. Biochem. Biotechnol. 1998, 70, 603–614. [Google Scholar] [CrossRef]

- Rajan, K.P.; Thomas, S.P.; Gopanna, A.; Chavali, M. Polyhydroxybutyrate (PHB): A standout biopolymer for environmental sustainability. In Handbook of Ecomaterials; Springer: Berlin/Heidelberg, Germany, 2019; p. 4. [Google Scholar]

- Vasudevan, M.; Natarajan, N. Towards achieving sustainable bioplastics production and nutrient recovery from wastewater—A comprehensive overview on polyhydroxybutyrate. Biomass Convers. Biorefinery 2022, 1–20. [Google Scholar] [CrossRef]

- McAdam, B.; Brennan Fournet, M.; McDonald, P.; Mojicevic, M. Production of polyhydroxybutyrate (PHB) and factors impacting its chemical and mechanical characteristics. Polymers 2020, 12, 2908. [Google Scholar] [CrossRef] [PubMed]

- Wongmoon, C.; Napathorn, S.C. Optimization for the efficient recovery of poly (3-hydroxybutyrate) using the green solvent 1, 3-dioxolane. Front. Bioeng. Biotechnol. 2022, 10, 1086636. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.; Sasikumar, S.C.; Balakumaran, M.D. Optimization, purification and characterization of polyhydroxybutyrate (PHB) produced by Bacillus cereus isolated from sewage. Int. J. Chem. Tech. Res. 2017, 10, 884–904. [Google Scholar]

- Mahitha, G.; Madhuri, R. Purification and characterization of polyhydroxybutyrate produced from marine bacteria. Int. J. Sci. Eng. Res 2015, 6, 71–75. [Google Scholar]

- The Biodegradable Polymer PBAT Is Hitting the Big Time. 2022.Acs.org. 2022. Available online: https://cen.acs.org/business/biobased-hemicals/biodegradable-polymer-PBAT-hitting-big/99/i34 (accessed on 19 July 2023).

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable biodegradable coffee grounds filler and its effect on the hydrophobicity, mechanical and thermal properties of biodegradable PBAT composites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Park, H.Y.; Kim, S.S.; Kim, S.G.; Seo, K.H. Modification of physical properties of PBAT by using TPS. Int. Proc. Chem. Biol. Environ. Eng. 2012, 46, 67–71. [Google Scholar]

- Zhao, P.; Liu, W.; Wu, Q.; Ren, J. Preparation, mechanical, and thermal properties of biodegradable polyesters/poly (lactic acid) blends. J. Nanomater. 2010, 2010, 287082. [Google Scholar] [CrossRef]

- Barrino, F.; De La Rosa-Ramírez, H.; Schiraldi, C.; López-Martínez, J.; Samper, M.D. Preparation and Characterization of New Bioplastics Based on Polybutylene Succinate (PBS). Polymers 2023, 15, 1212. [Google Scholar] [CrossRef]

- Liu, L.; Yu, J.; Cheng, L.; Qu, W. Mechanical properties of poly (butylene succinate) (PBS) bio composites reinforced with surface modified jute fibre. Compos. Part A Appl. Sci. Manuf. 2009, 40, 669–674. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B.H. Microbial succinic acid, its polymer poly (butylene succinate), and applications. In Plastics from Bacteria: Natural Functions and Applications; Springer: Berlin/Heidelberg, Germany, 2010; pp. 347–388. [Google Scholar]

- AL-Oqla, F.M.; Omari, M.A. Sustainable bio composites: Challenges, potential and barriers for development. In Green Bio Composites: Manufacturing and Properties; Springer: Berlin/Heidelberg, Germany, 2017; pp. 13–29. [Google Scholar]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.; Lee, C.H. A review on properties and application of bio-based poly (butylene succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef]

- Bikiaris, D.N.; Papageorgiou, G.Z.; Achilias, D.S.; Pavlidou, E.; Stergiou, A. Miscibility and enzymatic degradation studies of poly (ε-caprolactone)/poly (propylene succinate) blends. Eur. Polym. J. 2007, 43, 2491–2503. [Google Scholar] [CrossRef]

- Krasowska, K.; Heimowska, A.; Morawska, M. Environmental degradability of polycaprolactone under natural conditions. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2016; Volume 10, p. 00048. [Google Scholar]

- Abbah, S.A.; Lam, C.X.; Hutmacher, D.W.; Goh, J.C.; Wong, H.K. Biological performance of a polycaprolactone-based scaffold used as fusion cage device in a large animal model of spinal reconstructive surgery. Biomaterials 2009, 30, 5086–5093. [Google Scholar] [CrossRef]

- Lu, H.F.; Zhang, K.; Yi, J.L.; Wei, A.C. Study on mechanical properties of polycaprolactone modified cement-based material. Int. J. Concr. Struct. Mater. 2022, 16, 24. [Google Scholar] [CrossRef]

- Azimi, B.; Nourpanah, P.; Rabiee, M.; Arbab, S. Poly (∊-caprolactone) fiber: An overview. J. Eng. Fibers Fabr. 2014, 9, 155892501400900309. [Google Scholar] [CrossRef]

- Raina, N.; Pahwa, R.; Khosla, J.K.; Gupta, P.N.; Gupta, M. Polycaprolactone-based materials in wound healing applications. Polym. Bull. 2021, 79, 7041–7063. [Google Scholar] [CrossRef]

- Archer, E.; Torretti, M.; Madbouly, S. Biodegradable polycaprolactone (PCL) based polymer and composites. Phys. Sci. Rev. 2021, 8, 4391–4414. [Google Scholar] [CrossRef]

- Wu, C.; Xu, F.; Wang, H.; Liu, H.; Yan, F.; Ma, C. Manufacturing technologies of polymer composites—A Review. Polymers 2023, 15, 712. [Google Scholar] [CrossRef]

- Puertas-Bartolomé, M.; Mora-Boza, A.; García-Fernández, L. Emerging bio fabrication techniques: A review on natural polymers for biomedical applications. Polymers 2021, 13, 1209. [Google Scholar] [CrossRef]

- Pal, A.K.; Mohanty, A.K.; Misra, M. Additive manufacturing technology of polymeric materials for customized products: Recent developments and future prospective. RSC Adv. 2021, 11, 36398–36438. [Google Scholar] [CrossRef] [PubMed]

- Nanda, S.; Patra, B.R.; Patel, R.; Bakos, J.; Dalai, A.K. Innovations in applications and prospects of bioplastics and biopolymers: A review. Environ. Chem. Lett. 2022, 20, 379–395. [Google Scholar] [CrossRef] [PubMed]

- Baranwal, J.; Barse, B.; Fais, A.; Delogu, G.L.; Kumar, A. Biopolymer: A sustainable material for food and medical applications. Polymers 2022, 14, 983. [Google Scholar] [CrossRef]

- Extruding Biopolymers: Packaging Reaps Cost Benefit of Going ‘Green’. 2007. Available online: https://www.ptonline.com/articles/extruding-biopolymers-packaging-reaps-cost-benefit-of-going-green (accessed on 1 September 2023).

- Rabbi, M.S.; Islam, T.; Islam, G.S. Injection-molded natural fiber-reinforced polymer composites—A review. Int. J. Mech. Mater. Eng. 2021, 16, 15. [Google Scholar] [CrossRef]

- Sáez-Comet, C.; Muntada, O.; Lozano, N.; Fontdecaba, E.; Sousa, P.; Llobet, J.; Perez-Murano, F.; Puiggali, J.; del Valle, L.J. Three-level hierarchical micro/nanostructures on biopolymers by injection moulding using low-cost polymeric inlays. Int. J. Adv. Manuf. Technol. 2023, 124, 1527–1535. [Google Scholar] [CrossRef]

- Nathanael, A.J.; Oh, T.H. Biopolymer coatings for biomedical applications. Polymers 2020, 12, 3061. [Google Scholar] [CrossRef]

- Rastogi, V.K.; Samyn, P. Bio-based coatings for paper applications. Coatings 2015, 5, 887–930. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Jabeen, R.; Kärki, T. The Modelling of Extrusion Processes for Polymers—A Review. Polymers 2020, 12, 1306. [Google Scholar] [CrossRef]

- Formela, K.; Zedler, L.; Hejna, A.; Tercjak, A. Reactive Extrusion of Bio-Based Polymer Blends and Composites–Current Trends and Future Developments. Express Polym. Lett. 2018, 12, 24–57. [Google Scholar] [CrossRef]

- Biopolymers for Paperboard Extrusion Coating and Converting-SPE FlexPackCon 2016. Available online: https://www.slideshare.net/CCareyYangPhD/yang-biopolymer-extrusion-coating-flexpackcon2016 (accessed on 11 September 2023).

- Ranjan, S. Plastic Extrusion Process. Available online: https://polymeracademy.com/plastic-extrusion-process/ (accessed on 16 September 2023).

- Maghsoudi, K.; Vazirinasab, E.; Momen, G.; Jafari, R. Advances in the fabrication of superhydrophobic polymeric surfaces by polymer molding processes. Ind. Eng. Chem. Res. 2020, 59, 9343–9363. [Google Scholar] [CrossRef]

- Song, J.; Winkeljann, B.; Lieleg, O. Biopolymer-based coatings: Promising strategies to improve the biocompatibility and functionality of materials used in biomedical engineering. Adv. Mater. Interfaces 2020, 7, 2000850. [Google Scholar] [CrossRef]

- Park, S.; Han, U.; Choi, D.; Hong, J. Layer-by-layer assembled polymeric thin films as prospective drug delivery carriers: Design and applications. Biomater. Res. 2018, 22, 29. [Google Scholar] [CrossRef]

- Hussain, S.A.; Dey, B.; Bhattacharjee, D.; Mehta, N. Unique supramolecular assembly through Langmuir–Blodgett (LB) technique. Heliyon 2018, 4, e01038. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Jung, J. Polymer brush: A promising grafting approach to scaffolds for tissue engineering. BMB Rep. 2016, 49, 655. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, M.S.; Muneer, M.A.; Zafar, M.Q.; Arif, M.; Hussain, G.; Siddiqui, F.A. Process parameter optimization for Fused Filament Fabrication additive manufacturing of PLA/PHA biodegradable polymer blend. Int. Polym. Process. 2022, 37, 1–14. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Mihankhah, P.; Azdast, T.; Aghaiee, S.; Park, C.B. Optimization of Process Parameters of Fused Filament Fabrication of Polylactic Acid Composites Reinforced by Aluminum Using Taguchi Approach. Metals 2023, 13, 1013. [Google Scholar] [CrossRef]

- Wasti, S.; Adhikari, S. Use of biomaterials for 3D printing by fused deposition modeling technique: A review. Front. Chem. 2020, 8, 315. [Google Scholar] [CrossRef] [PubMed]

- Santoni, S.; Gugliandolo, S.G.; Sponchioni, M.; Moscatelli, D.; Colosimo, B.M. 3D bioprinting: Current status and trends-a guide to the literature and industrial practice. Bio-Des. Manuf. 2022, 5, 14–42. [Google Scholar] [CrossRef]

- Schappo, H.; Giry, K.; Salmoria, G.; Damia, C.; Hotza, D. Polymer/calcium phosphate biocomposites manufactured by selective laser sintering: An overview. Prog. Addit. Manuf. 2023, 8, 285–301. [Google Scholar] [CrossRef]

- Riza, S.H.; Masood, S.H.; Rashid, R.A.R.; Chandra, S. Selective laser sintering in biomedical manufacturing. In Metallic Biomaterials Processing and Medical Device Manufacturing; Woodhead Publishing: Sawston, UK, 2020; pp. 193–233. [Google Scholar]

- Duan, B.; Wang, M. Selective laser sintering and its application in biomedical engineering. MRS Bull. 2011, 36, 998–1005. [Google Scholar] [CrossRef]

- Charoo, N.A.; Barakh Ali, S.F.; Mohamed, E.M.; Kuttolamadom, M.A.; Ozkan, T.; Khan, M.A.; Rahman, Z. Selective laser sintering 3D printing—An overview of the technology and pharmaceutical applications. Drug Dev. Ind. Pharm. 2020, 46, 869–877. [Google Scholar] [CrossRef]

- Skoog, S.A.; Goering, P.L.; Narayan, R.J. Stereolithography in tissue engineering. J. Mater. Sci. Mater. Med. 2014, 25, 845–856. [Google Scholar] [CrossRef]

- Martinez, J.S.; Peterson, S.; Hoel, C.A.; Erno, D.J.; Murray, T.; Boyd, L.; Her, J.H.; Mclean, N.; Davis, R.; Ginty, F.; et al. High resolution DLP stereolithography to fabricate biocompatible hydroxyapatite structures that support osteogenesis. PLoS ONE 2022, 17, e0272283. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Górski, F.; Wichniarek, R.; Kuczko, W.; Andrzejewski, J. Experimental determination of critical orientation of ABS parts manufactured using fused deposition modelling technology. J. Mach. Eng. 2015, 15, 121–132. [Google Scholar]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the mechanical properties of FFF structures and materials: A review on the experimental, computational and theoretical approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef]

- Ahmadifar, M.; Benfriha, K.; Shirinbayan, M.; Tcharkhtchi, A. Additive manufacturing of polymer-based composites using fused filament fabrication (FFF): A review. Appl. Compos. Mater. 2021, 28, 1335–1380. [Google Scholar] [CrossRef]

- Jasiuk, I.; Abueidda, D.W.; Kozuch, C.; Pang, S.; Su, F.Y.; McKittrick, J. An overview on additive manufacturing of polymers. JOM 2018, 70, 275–283. [Google Scholar] [CrossRef]

- Berry, E.; Brown, J.M.; Connell, M.; Craven, C.M.; Efford, N.D.; Radjenovic, A.; Smith, M.A. Preliminary experience with medical applications of rapid prototyping by selective laser sintering. Med. Eng. Phys. 1997, 19, 90–96. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B.; Khorasani, M.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021; Volume 17, pp. 160–186. [Google Scholar]

- Gibson, I.; Shi, D. Material properties and fabrication parameters in selective laser sintering process. Rapid Prototyp. J. 1997, 3, 129–136. [Google Scholar] [CrossRef]

- Khanna, N.; Mistry, S.; Rashid, R.R.; Gupta, M.K. Investigations on density and surface roughness characteristics during selective laser sintering of Invar-36 alloy. Mater. Res. Express 2019, 6, 086541. [Google Scholar] [CrossRef]

- Verma, A.; Rai, R. Energy Efficient Modeling and Optimization of Additive Manufacturing Process. In 2013 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2013. [Google Scholar]

- Selective Laser Sintering, CustomPartNet. 2020. Available online: https://www.custompartnet.com/wu/selective-laser-sintering (accessed on 10 September 2023).

- 3D Systems, sPro 230. 2019. Available online: https://au.3dsystems.com/3d-printers/spro-230 (accessed on 10 September 2023).

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. Int. Sch. Res. Not. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Szilvśi-Nagy, M.; Matyasi, G.Y. Analysis of STL files. Math. Comput. Model. 2003, 38, 945–960. [Google Scholar] [CrossRef]

- Bianconi, F. Bridging the gap between CAD and CAE using STL files. Int. J. Cad/Cam 2002, 2, 55. [Google Scholar]

- Olayan, H.B.; Hami, H.S.; Owen, E.D. Photochemical and thermal crosslinking of polymers. J. Macromol. Sci. Part C Polym. Rev. 1996, 36, 671–719. [Google Scholar] [CrossRef]

- Gillham, J.K. Award address formation and properties of network polymeric materials. Polym. Eng. Sci. 1979, 19, 676–682. [Google Scholar] [CrossRef]

- Bártolo, P.J. (Ed.) Stereolithography: Materials, Processes and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Domínguez, J.C.; Alonso, M.V.; Oliet, M.; Rodríguez, F. Chemorheological study of the curing kinetics of a phenolic resol resin gelled. Eur. Polym. J. 2010, 46, 50–57. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread appli-cations—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Fortelny, I.; Ujcic, A.; Fambri, L.; Slouf, M. Phase structure, compatibility, and toughness of PLA/PCL blends: A review. Front. Mater. 2019, 6, 206. [Google Scholar] [CrossRef]

- Chaléat, C.; Halley, P.J.; Truss, R.W. Mechanical properties of starch-based plastics. In Starch Polymers; Elsevier: Amsterdam, The Netherlands, 2014; pp. 187–209. [Google Scholar]

- Eichhorn, S.J.; Young, R.J. The Young’s modulus of a microcrystalline cellulose. Cellulose 2001, 8, 197–207. [Google Scholar] [CrossRef]

- Dhandapani, S.; Nayak, S.K.; Mohanty, S. Analysis and evaluation of biobased polyester of PTT/PBAT blend: Thermal, dy-namic mechanical, interfacial bonding, and morphological properties. Polym. Adv. Technol. 2016, 27, 938–945. [Google Scholar] [CrossRef]

- Hu, X.; Su, T.; Pan, W.; Li, P.; Wang, Z. Difference in solid-state properties and enzymatic degradation of three kinds of poly (butylene succinate)/cellulose blends. RSC Adv. 2017, 7, 35496–35503. [Google Scholar] [CrossRef]

- Ganapathy, V.; Muthukumaran, G.; Sudhagar, P.E.; Rashedi, A.; Norrrahim, M.N.F.; Ilyas, R.A.; Goh, K.L.; Jawaid, M.; Naveen, J. Mechanical properties of cellulose-based multiscale composites: A review. Polym. Compos. 2023, 44, 734–756. [Google Scholar] [CrossRef]

- Wang, Y.S.; Koo, W.M.; Kim, H.D. Preparation and properties of new regenerated cellulose fibers. Text. Res. J. 2003, 73, 998–1004. [Google Scholar] [CrossRef]

- Xu, Z.; Zhou, Q.; Wang, L.; Xia, G.; Ji, X.; Zhang, J.; Nawaz, H.; Wang, J.; Peng, J. Transparent cellulose-based films prepared from used disposable paper cups via an ionic liquid. Polymers 2021, 13, 4209. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Yu, C.; Wongwiwattana, P.; Thomas, N.L. Optimising ductility of poly (lactic acid)/poly (butylene adipate-co-terephthalate) blends through co-continuous phase morphology. J. Polym. Environ. 2018, 26, 3802–3816. [Google Scholar] [CrossRef]

- Wang, R.; Sun, X.; Chen, L.; Liang, W. Morphological and mechanical properties of biodegradable poly (glycolic acid)/poly (butylene adipate-co-terephthalate) blends with in situ compatibilization. RSC Adv. 2021, 11, 1241–1249. [Google Scholar] [CrossRef] [PubMed]

- Tejada-Oliveros, R.; Balart, R.; Ivorra-Martinez, J.; Gomez-Caturla, J.; Montanes, N.; Quiles-Carrillo, L. Improvement of impact strength of polylactide blends with a thermoplastic elastomer compatibilized with biobased maleinized linseed oil for ap-plications in rigid packaging. Molecules 2021, 26, 240. [Google Scholar] [CrossRef] [PubMed]

- Akinmulewo, A.B.; Nwinyi, O.C. Polyhydroxyalkanoate: A biodegradable polymer (a mini review). In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; Volume 1378, p. 042007. [Google Scholar]

- Park, H.J.; Weller, C.L.; Vergano, P.J.; Testin, R.F. Permeability and mechanical properties of cellulose-based edible films. J. Food Sci. 1993, 58, 1361–1364. [Google Scholar] [CrossRef]

- Rudnik, E.; Briassoulis, D. Degradation behaviour of poly (lactic acid) films and fibres in soil under Mediterranean field conditions and laboratory simulations testing. Ind. Crops Prod. 2011, 33, 648–658. [Google Scholar] [CrossRef]

- McKeown, P.; Jones, M.D. The chemical recycling of PLA: A review. Sustain. Chem 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Samorì, C.; Martinez, G.A.; Bertin, L.; Pagliano, G.; Parodi, A.; Torri, C.; Galletti, P. PHB into PHB: Recycling of polyhydroxybutyrate by a tandem “thermolytic distillation-microbial fermentation” process. Resour. Conserv. Recycl. 2022, 178, 106082. [Google Scholar] [CrossRef]

- Jbilou, F.; Dole, P.; Degraeve, P.; Ladavière, C.; Joly, C. A green method for polybutylene succinate recycling: Depolymerization catalyzed by lipase B from Candida antarctica during reactive extrusion. Eur. Polym. J. 2015, 68, 207–215. [Google Scholar] [CrossRef]

- Vu, D.H.; Åkesson, D.; Taherzadeh, M.J.; Ferreira, J.A. Recycling strategies for polyhydroxyalkanoate-based waste materials: An overview. Bioresour. Technol. 2020, 298, 122393. [Google Scholar] [CrossRef] [PubMed]

- Encalada, K.; Aldás, M.B.; Proaño, E.; Valle, V. An overview of starch-based biopolymers and their biodegradability. Cienc. E Ing. 2018, 39, 245–258. [Google Scholar]

- Fredi, G.; Dorigato, A. Recycling of bioplastic waste: A review. Adv. Ind. Eng. Polym. Res. 2021, 4, 159–177. [Google Scholar] [CrossRef]

- Su, J.; Xu, G.; Dong, B.; Yang, R.; Sun, H.; Wang, Q. Closed-loop chemical recycling of poly (ε-caprolactone) by tuning reaction parameters. Polym. Chem. 2022, 13, 5897–5904. [Google Scholar] [CrossRef]

- Li, J.; He, Y.; Inoue, Y. Thermal and mechanical properties of biodegradable blends of poly (L-lactic acid) and lignin. Polym. Int. 2003, 52, 949–955. [Google Scholar] [CrossRef]

- Perego, G.; Cella, G.D.; Bastioli, C. Effect of molecular weight and crystallinity on poly (lactic acid) mechanical properties. J. Appl. Polym. Sci. 1996, 59, 37–43. [Google Scholar] [CrossRef]

- Ishii-Hyakutake, M.; Mizuno, S.; Tsuge, T. Biosynthesis and characteristics of aromatic polyhydroxyalkanoates. Polymers 2018, 10, 1267. [Google Scholar] [CrossRef]

- Eesaee, M.; Ghassemi, P.; Nguyen, D.D.; Thomas, S.; Elkoun, S.; Nguyen-Tri, P. Morphology and crystallization behaviour of polyhydroxyalkanoates-based blends and composites: A review. Biochem. Eng. J. 2022, 187, 108588. [Google Scholar] [CrossRef]

- Zhang, Y.; Rempel, C.; Liu, Q. Thermoplastic starch processing and characteristics—A review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1353–1370. [Google Scholar] [CrossRef]

- Amin, M.R.; Chowdhury, M.A.; Kowser, M.A. Characterization and performance analysis of composite bioplastics synthesized using titanium dioxide nanoparticles with corn starch. Heliyon 2019, 5, e02009. [Google Scholar] [CrossRef] [PubMed]

- Dome, K.; Podgorbunskikh, E.; Bychkov, A.; Lomovsky, O. Changes in the crystallinity degree of starch having different types of crystal structure after mechanical pretreatment. Polymers 2020, 12, 641. [Google Scholar] [CrossRef] [PubMed]

- Erdmann, R.; Kabasci, S.; Heim, H.P. Thermal properties of plasticized cellulose acetate and its β-relaxation phenomenon. Polymers 2021, 13, 1356. [Google Scholar] [CrossRef] [PubMed]

- Szcześniak, L.; Rachocki, A.; Tritt-Goc, J. Glass transition temperature and thermal decomposition of cellulose powder. Cellulose 2008, 15, 445–451. [Google Scholar] [CrossRef]

- Danjo, T.; Iwata, T. Syntheses of cellulose branched ester derivatives and their properties and structure analyses. Polymer 2018, 137, 358–363. [Google Scholar] [CrossRef]

- Zhou, X.; Hao, Y.; Zhang, X.; He, X.; Zhang, C. Cellulose-based polymers. Phys. Sci. Rev. 2021, 000010151520200067. [Google Scholar]

- Anbukarasu, P.; Sauvageau, D.; Elias, A. Tuning the properties of polyhydroxybutyrate films using acetic acid via solvent casting. Sci. Rep. 2015, 5, 17884. [Google Scholar] [CrossRef]

- Hench, L.; Jones, J. (Eds.) Biomaterials, Artificial Organs and Tissue Engineering; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Sousa, J.C.; Arruda, S.A.; Lima, J.C.; Wellen, R.M.R.; Canedo, E.L.; Almeida, Y.M.B.D. Crystallization kinetics of poly (butylene adipate terephthalate) in biocomposite with coconut fiber. Matéria 2019, 24, e12419. [Google Scholar] [CrossRef]

- Sharafi Zamir, S.; Fathi, B.; Ajji, A.; Robert, M.; Elkoun, S. Crystallinity and Gas Permeability of Poly (Lactic Acid)/Starch Nanocrystal Nanocomposite. Polymers 2022, 14, 2802. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly (butylene succinate) (PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef]

- Lule, Z.C.; Wondu Shiferaw, E.; Kim, J. Thermomechanical properties of SiC-filled polybutylene succinate composite fabricated via melt extrusion. Polymers 2020, 12, 418. [Google Scholar] [CrossRef] [PubMed]

- Righetti, M.C.; Di Lorenzo, M.L.; Cinelli, P.; Gazzano, M. Temperature dependence of the rigid amorphous fraction of poly (butylene succinate). RSC Adv. 2021, 11, 25731–25737. [Google Scholar] [CrossRef]

- McKeen, L.W. The Effect of Long-Term Thermal Exposure on Plastics and Elastomers; William Andrew: Norwich, NY, USA, 2021. [Google Scholar]

- Babaie, A.; Rezaei, M.; Sofla, R.L.M. Investigation of the effects of polycaprolactone molecular weight and graphene content on crystallinity, mechanical properties and shape memory behavior of polyurethane/graphene nanocomposites. J. Mech. Behav. Biomed. Mater. 2019, 96, 53–68. [Google Scholar] [CrossRef] [PubMed]

- Castilla-Cortázar, I.; Vidaurre, A.; Marí, B.; Campillo-Fernández, A.J. Morphology, crystallinity, and molecular weight of poly (ε-caprolactone)/graphene oxide hybrids. Polymers 2019, 11, 1099. [Google Scholar] [CrossRef]

- Bikiaris, N.D.; Koumentakou, I.; Samiotaki, C.; Meimaroglou, D.; Varytimidou, D.; Karatza, A.; Kalantzis, Z.; Roussou, M.; Bikiaris, R.D.; Papageorgiou, G.Z. Recent Advances in the Investigation of Poly (lactic acid) (PLA) Nanocomposites: Incorporation of Various Nanofillers and their Properties and Applications. Polymers 2023, 15, 1196. [Google Scholar] [CrossRef] [PubMed]

- Cherpinski, A.; Torres-Giner, S.; Vartiainen, J.; Peresin, M.S.; Lahtinen, P.; Lagaron, J.M. Improving the water resistance of nanocellulose-based films with polyhydroxyalkanoates processed by the electrospinning coating technique. Cellulose 2018, 25, 1291–1307. [Google Scholar] [CrossRef]

- Masood, F. Polyhydroxyalkanoates in the food packaging industry. In Nanotechnology Applications in Food; Academic Press: Cambridge, MA, USA, 2017; pp. 153–177. [Google Scholar]

- Bertuzzi, M.A.; Vidaurre, E.C.; Armada, M.; Gottifredi, J.C. Water vapor permeability of edible starch-based films. J. Food Eng. 2007, 80, 972–978. [Google Scholar] [CrossRef]

- Bras, J.; Vaca-Garcia, C.; Borredon, M.E.; Glasser, W. Oxygen and water vapor permeability of fully substituted long chain cellulose esters (LCCE). Cellulose 2007, 14, 367–374. [Google Scholar] [CrossRef]

- Saedi, S.; Garcia, C.V.; Kim, J.T.; Shin, G.H. Physical and chemical modifications of cellulose fibers for food packaging applications. Cellulose 2021, 28, 8877–8897. [Google Scholar] [CrossRef]

- Tajeddin, B. Cellulose-based polymers for packaging applications. In Lignocellulosic Polymer Composites: Processing, Characterization, and Properties; Wiley: Hoboken, NJ, USA, 2014; pp. 477–498. [Google Scholar]

- Melendez-Rodriguez, B.; Torres-Giner, S.; Angulo, I.; Pardo-Figuerez, M.; Hilliou, L.; Escuin, J.M.; Cabedo, L.; Nevo, Y.; Prieto, C.; Lagaron, J.M. High-oxygen-barrier multilayer films based on polyhydroxyalkanoates and cellulose nanocrystals. Nanomaterials 2021, 11, 1443. [Google Scholar] [CrossRef]

- Ragaert, P.; Buntinx, M.; Maes, C.; Vanheusden, C.; Peeters, R.; Wang, S.; D’Hooge, D.R.; Cardon, L. Polyhydroxyalkanoates for food packaging applications. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Bumbudsanpharoke, N.; Wongphan, P.; Promhuad, K.; Leelaphiwat, P.; Harnkarnsujarit, N. Morphology and permeability of bio-based poly (butylene adipate-co-terephthalate) (PBAT), poly (butylene succinate) (PBS) and linear low-density polyethylene (LLDPE) blend films control shelf-life of packaged bread. Food Control 2022, 132, 108541. [Google Scholar] [CrossRef]

- Xing, Q.; Ruch, D.; Dubois, P.; Wu, L.; Wang, W.J. Biodegradable and high-performance poly (butylene adipate-co-terephthalate)–lignin UV-blocking films. ACS Sustain. Chem. Eng. 2017, 5, 10342–10351. [Google Scholar] [CrossRef]

- Aziman, N.; Kian, L.K.; Jawaid, M.; Sanny, M.; Alamery, S. Morphological, structural, thermal, permeability, and antimicrobial activity of PBS and PBS/TPS films incorporated with biomaster-silver for food packaging application. Polymers 2021, 13, 391. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.W.; Chowdhury, A. Polybutylene succinate based bionanocomposites for food packaging applications. In Bionanocomposites for Food Packaging Applications; Woodhead Publishing: Sawston, UK, 2022; pp. 165–180. [Google Scholar]

- Ding, Y.; Han, A.; Zhou, H.; Zhou, Q.; Song, H.; Chen, R.; Guo, S. Preparation of poly (ε-caprolactone) based composites through multistage biaxial-stretching extrusion with excellent oxygen and water vapor barrier performance. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106494. [Google Scholar] [CrossRef]

- Thakur, M.; Majid, I.; Hussain, S.; Nanda, V. Poly (ε-caprolactone): A potential polymer for biodegradable food packaging applications. Packag. Technol. Sci. 2021, 34, 449–461. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, D.Y.; Haurie, L.; Liu, Z.; Zhang, L. Combination of corn pith fiber and biobased flame retardant: A novel method toward flame retardancy, thermal stability, and mechanical properties of polylactide. Polymers 2021, 13, 1562. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Haurie, L.; Wang, D.Y. Bio-based materials for fire-retardant application in construction products: A review. J. Therm. Anal. Calorim. 2021, 147, 6563–6582. [Google Scholar] [CrossRef]

- Narayanan, D.; Giffin, M.T.; Neetha, P.S.; Jose, C.; Thomas, S. Natural Fiber-Reinforced Biopolymers as Construction Materials. In Handbook of Biopolymers; Springer Nature: Singapore, 2023; pp. 1173–1193. [Google Scholar] [CrossRef]

- Abdullah Cai, J.; Hafeez, M.A.; Wang, Q.; Farooq, S.; Huang, Q.; Tian, W.; Xiao, J. Biopolymer-based functional films for packaging applications: A review. Front. Nutr. 2022, 9, 1000116. [Google Scholar] [CrossRef]

- Hu, B. Biopolymer-Based Lightweight Materials for Packaging Applications. ACS Symp. Ser. 2014, 239–255. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Banerjee, A.; Saurabh, C.K.; Tye, Y.Y.; Suriani, A.B.; Mohamed, A.; Karim, A.A.; Rizal, S.; Paridah, M.T. Biodegradable films for fruits and vegetables packaging application: Preparation and properties. Food Eng. Rev. 2018, 10, 139–153. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, F.; Zhai, W.; Cheng, S.; Li, J.; Wang, Y. Unraveling of advances in 3D-printed polymer-based bone scaffolds. Polymers 2022, 14, 566. [Google Scholar] [CrossRef] [PubMed]

- Barkhad, M.S.; Abu-Jdayil, B.; Iqbal, M.Z.; Mourad, A.H.I. Thermal insulation using biodegradable poly (lactic acid)/date pit composites. Constr. Build. Mater. 2020, 261, 120533. [Google Scholar] [CrossRef]

- DeStefano, V.; Khan, S.; Tabada, A. Applications of PLA in modern medicine. Eng. Regen. 2020, 1, 76–87. [Google Scholar] [CrossRef]

- Bouzouita, A.; Notta-Cuvier, D.; Raquez, J.M.; Lauro, F.; Dubois, P. Poly (lactic acid)-based materials for automotive applications. In Industrial Applications of Poly (Lactic Acid); Springer: Berlin/Heidelberg, Germany, 2018; pp. 177–219. [Google Scholar]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly (butylene succinate)-based polyesters for biomedical applications: A review. Eur. Polym. J. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- Poltronieri, P.; Kumar, P. Polyhydroxyalkanoates (PHAs) in industrial applications. Handb. Ecomater. 2017, 4, 2843–2872. [Google Scholar]

- Bonartsev, A.P.; Bonartseva, G.A.; Reshetov, I.V.; Kirpichnikov, M.P.; Shaitan, K.V. Application of polyhydroxyalkanoates in medicine and the biological activity of natural poly (3-hydroxybutyrate). Acta Naturae (Aнглoязычная Bерсия) 2019, 11, 4–16. [Google Scholar] [CrossRef]

- Popa, M.S.; Frone, A.N.; Panaitescu, D.M. Polyhydroxybutyrate blends: A solution for biodegradable packaging? Int. J. Biol. Macromol. 2022, 207, 263–277. [Google Scholar] [CrossRef] [PubMed]

- Vieyra, H.; Molina-Romero, J.M.; Calderón-Nájera, J.D.D.; Santana-Díaz, A. Engineering, recyclable, and biodegradable plastics in the automotive industry: A review. Polymers 2022, 14, 3412. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, W.; Cheng, S.; Li, J.; Zhang, H. Surface-functionalized design of blood-contacting biomaterials for preventing coagulation and promoting hemostasis. Friction 2023, 11, 1371–1394. [Google Scholar] [CrossRef]

- Lu, J.; Chen, Y.; Ding, M.; Fan, X.; Hu, J.; Chen, Y.; Li, J.; Li, Z.; Liu, W. A 4arm-PEG macromolecule crosslinked chitosan hydrogels as antibacterial wound dressing. Carbohydr. Polym. 2022, 277, 118871. [Google Scholar] [CrossRef]

- Reddy, T.R.K.; Kim, H.J.; Park, J.W. Renewable bio composite properties and their applications. In Composites from Renewable and Sustainable Materials; InTech: London, UK, 2016; Chapter 10. [Google Scholar] [CrossRef]

- Ranjbar, Z.; Ranjbar, B.; Foroughirad, S. Biopolymers in Automotive Industry. In Biopolymers: Recent Updates; Challenges and Opportunities; Springer International Publishing: Cham, Switzerland, 2022; pp. 271–288. [Google Scholar]

- Dahal, R.K.; Acharya, B.; Dutta, A. Mechanical, Thermal, and Acoustic Properties of Hemp and Biocomposite Materials: A Review. J. Compos. Sci. 2022, 6, 373. [Google Scholar] [CrossRef]

- Alfaro, M.E.C.; Stares, S.L.; de Oliveira Barra, G.M.; Hotza, D. Estimation of shelf life of 3D-printed PLA scaffolds by accelerated weathering. Mater. Today Commun. 2022, 32, 104140. [Google Scholar] [CrossRef]

- Biopolymers: Properties, Processing, and Applications-Matmatch. 2023. Available online: https://matmatch.com/learn/material/biopolymers (accessed on 20 July 2023).

- Arikan, E.B.; Ozsoy, H.D. A review: Investigation of bioplastics. J. Civ. Eng. Arch 2015, 9, 188–192. [Google Scholar]

- Hasnat, M.R.; Hassan, M.K.; Saha, S. Flame Retardant Polymer Composite and Recent Inclusion of Magnesium Hydroxide Filler Material: A Bibliometric Analysis towards Further Study Scope. Fire 2023, 6, 180. [Google Scholar] [CrossRef]

- Riedel, U.; Nickel, J. Natural fibre-reinforced biopolymers as construction materials–New discoveries. Die Angew. Makromol. Chem. 1999, 272, 34–40. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Z.; Zhou, G.; Leng, W.; Mei, C. Understanding the interaction between bonding strength and strain distribution of plywood. Int. J. Adhes. Adhes. 2020, 98, 102506. [Google Scholar] [CrossRef]

- Cho, G.C.; Chang, I.; Im, J. Microbial Biopolymers as an Alternative Construction Binder. In Microbial Polymers: Applications and Ecological Perspectives; Springer: Berlin/Heidelberg, Germany, 2021; pp. 581–617. [Google Scholar]

- Jayakumar, A.; Radoor, S.; Siengchin, S.; Shin, G.H.; Kim, J.T. Recent progress of bioplastics in their properties, standards, certifications and regulations: A review. Sci. Total Environ. 2023, 878, 163156. [Google Scholar] [CrossRef]

- Aaliya, B.; Sunooj, K.V.; Lackner, M. Biopolymer composites: A review. Int. J. Biobased Plast. 2021, 3, 40–84. [Google Scholar] [CrossRef]

- Saini, P.; Singh, A.; Ahmed, M.; Iqbal, U.; Srivastava, U. Sustainability of Biodegradable Polymers for the Environment: An Alternative Approach for the Future. In Eco-Friendly Energy Processes and Technologies for Achieving Sustainable Development; IGI Global: Hershey, PA, USA, 2021; pp. 65–87. [Google Scholar]

- Biswas, M.C.; Jony, B.; Nandy, P.K.; Chowdhury, R.A.; Halder, S.; Kumar, D.; Hassan, M.; Ahsan, M.A.; Hoque, M.E.; Imam, M.A. Recent advancement of biopolymers and their potential biomedical applications. J. Polym. Environ. 2022, 30, 51–74. [Google Scholar] [CrossRef]

- Taherimehr, M.; YousefniaPasha, H.; Tabatabaeekoloor, R.; Pesaranhajiabbas, E. Trends and challenges of biopolymer-based nanocomposites in food packaging. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5321–5344. [Google Scholar] [CrossRef]

- Vahabi, H.; Rastin, H.; Movahedifar, E.; Antoun, K.; Brosse, N.; Saeb, M.R. Flame retardancy of bio-based polyurethanes: Opportunities and challenges. Polymers 2020, 12, 1234. [Google Scholar] [CrossRef] [PubMed]

- Idumah, C.I.; Hassan, A. Emerging trends in flame retardancy of biofibers, biopolymers, biocomposites, and bionanocomposites. Rev. Chem. Eng. 2016, 32, 115–148. [Google Scholar] [CrossRef]

- Bio-Based Flame Retardants-Fraunhofer IAP.”Fraunhofer Institute for Applied Polymer Research IAP. Available online: https://www.iap.fraunhofer.de/en/press_releases/2023/bio-based-flame-retardants.html (accessed on 22 August 2023).

- Econcore-Bio-Based Panels. Available online: https://econcore.com/en/technology/technology-for-licensing/bio-based-panels (accessed on 16 August 2023).

- Parkes, J. The Dezeen Guide to Biomaterials in Architecture, Design and Interiors. Dezeen. Available online: https://www.dezeen.com/2021/12/09/dezeen-guide-biomaterials-architecture-design-interiors/ (accessed on 22 August 2023).

| Manufacturing Process | Advantages | Limitations | Biopolymers | Ref. |

|---|---|---|---|---|

| Extrusion |

|

| Polylactic acid (PLA), Polyhydroxyalkanoates (PHA), and starch-based polymers | [81,82,83] |

| Injection Molding |

|

| Polyhydroxyalkanoates (PHA), polylactic acid (PLA), and polyethylene furanoate (PEF) 910 | [84,85] |

| Coating |

|

| Cellulose, chitosan, Alginate, and collagen | [86,87] |

| Manufacturing Process | Advantages | Limitations | Biopolymers | Ref. |

|---|---|---|---|---|

| FFF |

|

| Polylactic acid (PLA), polyhydroxyalkanoates (PHA), polyethylene furanoate (PEF), and starch-based polymers. | [97,98,99,100] |

| SLS |

|

| Polyamide 11 (PA 11), polycaprolactone (PCL), and poly-3-hydroxybutyrate (PHB) | [101,102,103,104] |

| SLA |

|

| Polyethylene glycol diacrylate (PEGDA), gelatin methacrylate (GelMA), and cellulose acetate | [105,106,107] |

| Biopolymers | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (GPa) | Impact Strength (kJ/m2) | References |

|---|---|---|---|---|---|

| PLA | 50–70 | 7.3 | 3 | 1.3 | [126,137] |

| PHAs | 15–40 | 1–15 | 3.5 | 0.1–10 | [27,138] |

| SBP | 38–69 | — | — | 0.1–10 | [128,137] |

| CBP | ∼305 | 5–10 | ∼22 | 1–10 | [129,133,134,139] |

| PHB | 40 | 5–8 | 3.5–4 | 3.36 | [27] |

| PBAT | 8.31 | — | 0.02592 | 26.2–45.3 | [130] |

| PBS | 32.0 | 21.5 | 48 | 12 | [131] |

| PCL | 12–30 | — | 0.21–0.44 | 6–38 | [27,74,128] |

| Biopolymer | Biodegradability (Composting) | Biodegradability | Recyclability | Compatibility with Other Polymers | Reference |

|---|---|---|---|---|---|

| PLA | Yes | Slow | Yes | Yes | [141] |

| PHAs | Yes | Yes | Yes | Yes | [144] |

| SBP | Yes | Yes | Yes | Yes | [145] |

| CBP | Yes | Yes | Yes | Yes | [146] |

| PHB | Yes | Yes | Yes | Yes | [142] |

| PBAT | Yes | Slow | Yes | Yes | [146] |

| PBS | Yes | Slow | Yes | Yes | [143] |

| PCL | Yes | Yes | Yes | Yes | [147] |

| Biopolymer | Glass Transition Temperature (°C) | Melting Temperature (°C) | Crystallinity (%) | Coefficient of Thermal Expansion (10−6/K) | References |

|---|---|---|---|---|---|

| PLA | 55 to 65 | 60 to 180 | 30 to 60 | 55 to 75 | [136,137,138,139,140,141,142,143,144,145,146,147,148,149] |

| PHAs | −20 to 50 | 40 to 180 | 10 to 70 | 60 to 100 | [150,151] |

| SBP | 40 to 80 | 130 to 180 | 10 to 60 | 30 to 70 | [152,153] |

| CBP | 220 to 250 | 260 to 350 | 40 to 80 | ~10 | [154,155,156,157,158] |

| PHB | 4 to 7 | 175 to 180 | 50 to 90 | 15 to 20 | [159,160] |

| PBAT | −30 to −20 | 120 to 130 | 20 to 60 | 10 to 20 | [135,161] |

| PBS | −32 | 113 to 115 | 30 to 70 | 15 to 20 | [163,164,165] |

| PCL | −60 to −65 | 58 to 60 | 35 to 75 | 15 to 20 | [162,166,167,168] |

| Biopolymers | Construction Industry | Medical Industry | Automotive Industry | Packaging Industry | Limitations | References |

|---|---|---|---|---|---|---|

| PLA (Polylactic Acid) | Eco-friendly exterior cladding panels, interior wall panels, roofing materials | Biodegradable medical facility components, drug delivery devices | Sustainable automotive interior trim dashboards, door panels | Compostable food packaging, disposable cutlery, cups and containers | low gas-barrier properties | [183,191,192,193] |

| PBS (Polybutylene Succinate) | Weather-resistant cladding materials, siding, insulation panel | Biodegradable medical devices, drug delivery systems, tissue, engineering scaffolds | Biodegradable medical devices, drug delivery systems, tissue engineering scaffolds | Eco-friendly automotive parts, interior trim panels | brittle and low thermal stability | [19,194] |

| PHA (Polyhydroxyalkanoates) | Green cladding solutions with biodegradability, thermal insulation properties | Biodegradable sutures, tissue engineering scaffolds, drug delivery systems | Environmentally friendly automotive components, door trims | Biodegradable and compostable packaging materials, food containers | High production cost | [171,195,196,197,198] |

| PHB (Polyhydroxybutyrate) | Environmentally friendly cladding materials, resistant to weather and UV degradation | Biodegradable medical packaging, drug delivery devices | Sustainable automotive components and parts | Biodegradable and compostable packaging materials, single-use food packaging | rigid, brittle, low elongation, high crystallinity properties | [58,196,197,198] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazrun, T.; Hassan, M.K.; Hossain, M.D.; Ahmed, B.; Hasnat, M.R.; Saha, S. Application of Biopolymers as Sustainable Cladding Materials: A Review. Sustainability 2024, 16, 27. https://doi.org/10.3390/su16010027

Nazrun T, Hassan MK, Hossain MD, Ahmed B, Hasnat MR, Saha S. Application of Biopolymers as Sustainable Cladding Materials: A Review. Sustainability. 2024; 16(1):27. https://doi.org/10.3390/su16010027

Chicago/Turabian StyleNazrun, Touha, Md Kamrul Hassan, Md Delwar Hossain, Bulbul Ahmed, Md Rayhan Hasnat, and Swapan Saha. 2024. "Application of Biopolymers as Sustainable Cladding Materials: A Review" Sustainability 16, no. 1: 27. https://doi.org/10.3390/su16010027

APA StyleNazrun, T., Hassan, M. K., Hossain, M. D., Ahmed, B., Hasnat, M. R., & Saha, S. (2024). Application of Biopolymers as Sustainable Cladding Materials: A Review. Sustainability, 16(1), 27. https://doi.org/10.3390/su16010027