Evaluation of Incinerator Performance and Policy Framework for Effective Waste Management and Energy Recovery: A Case Study of South Korea

Abstract

1. Introduction

2. Materials and Methods

2.1. Target Waste and Facilities

2.2. Determination of Waste Mass, Volume, and Components through Incineration

2.3. Energy Recovery Efficiency Measurement

2.4. NOx Concentration Measurement before and after Emission Control Measures

3. Results

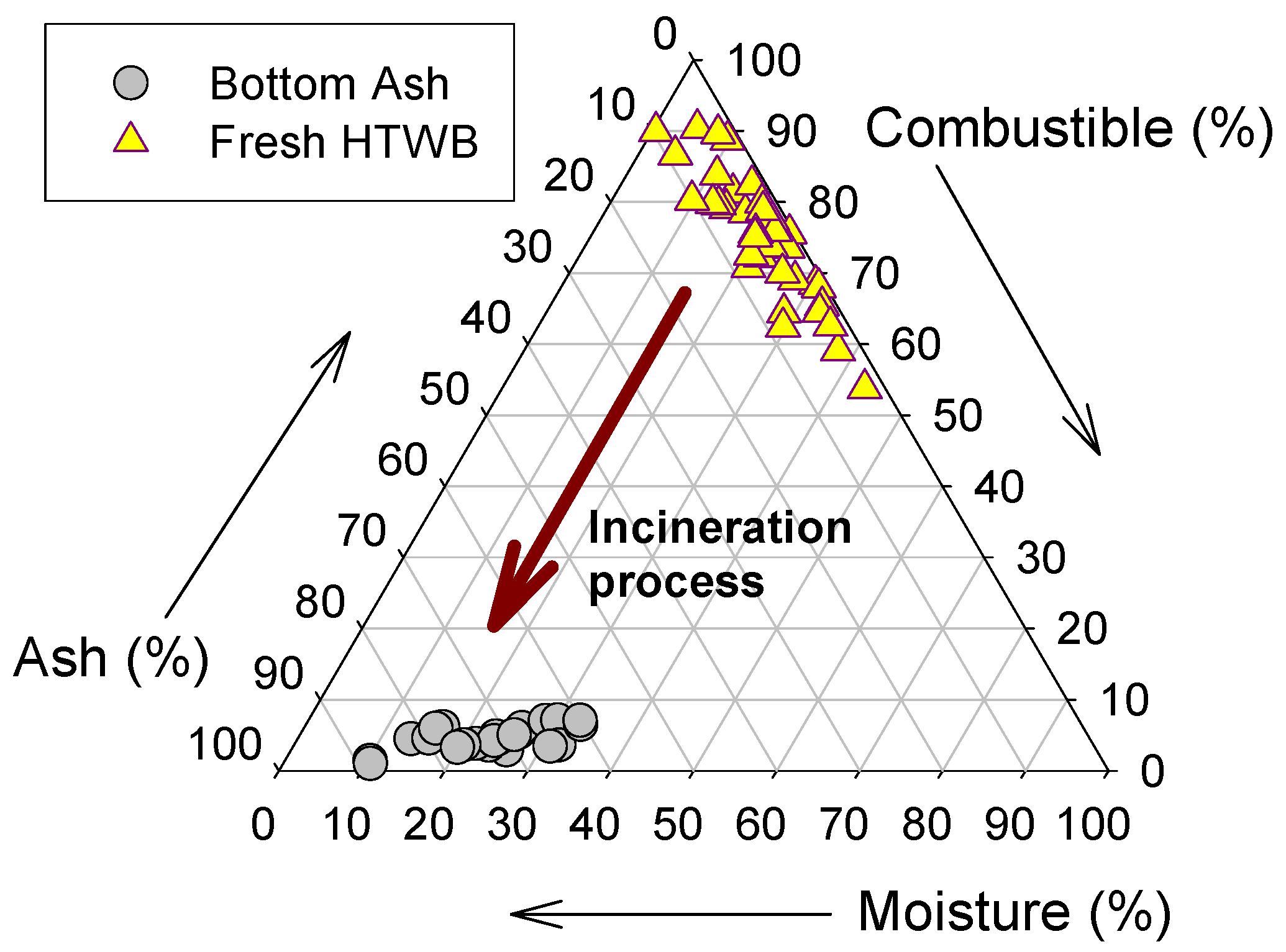

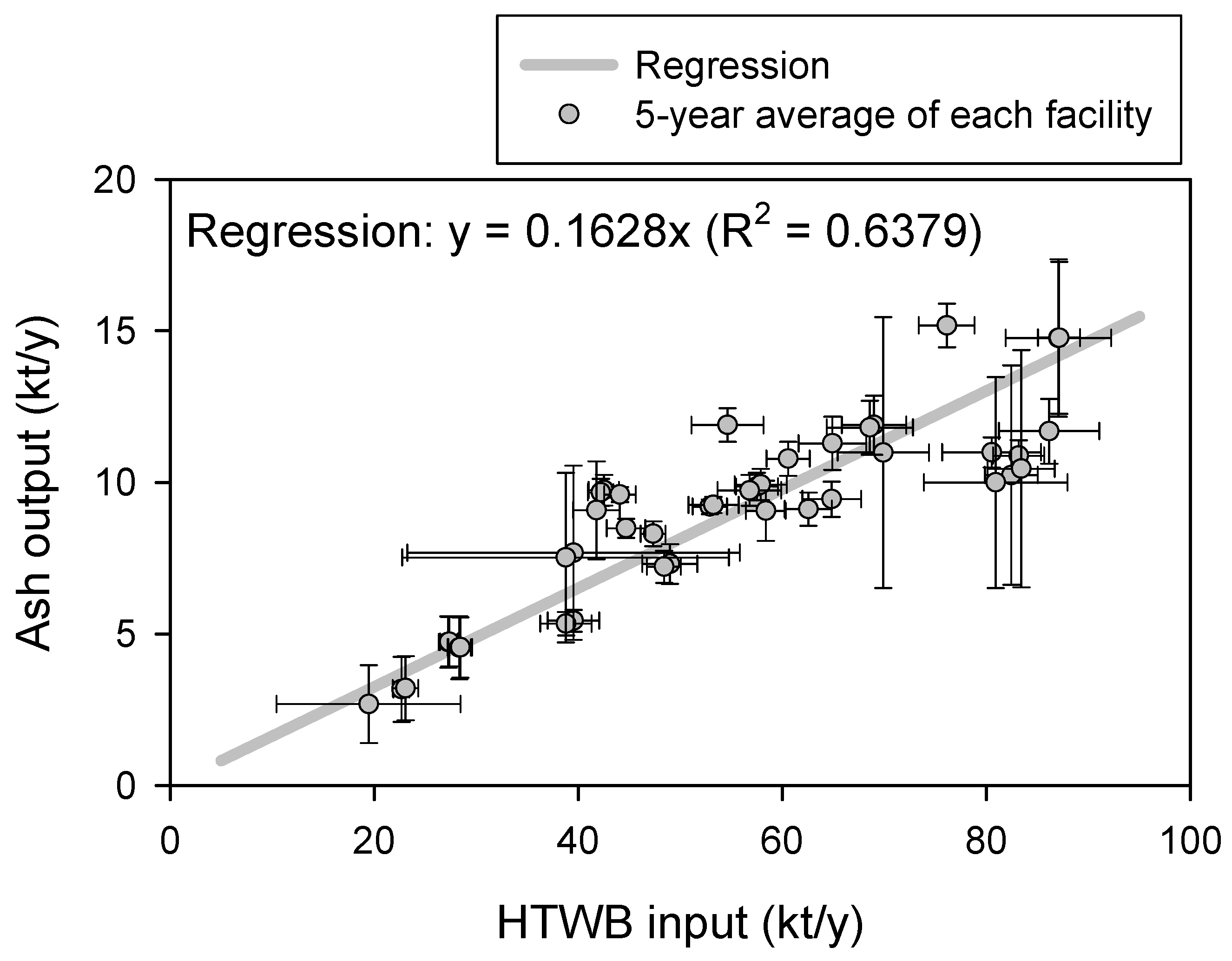

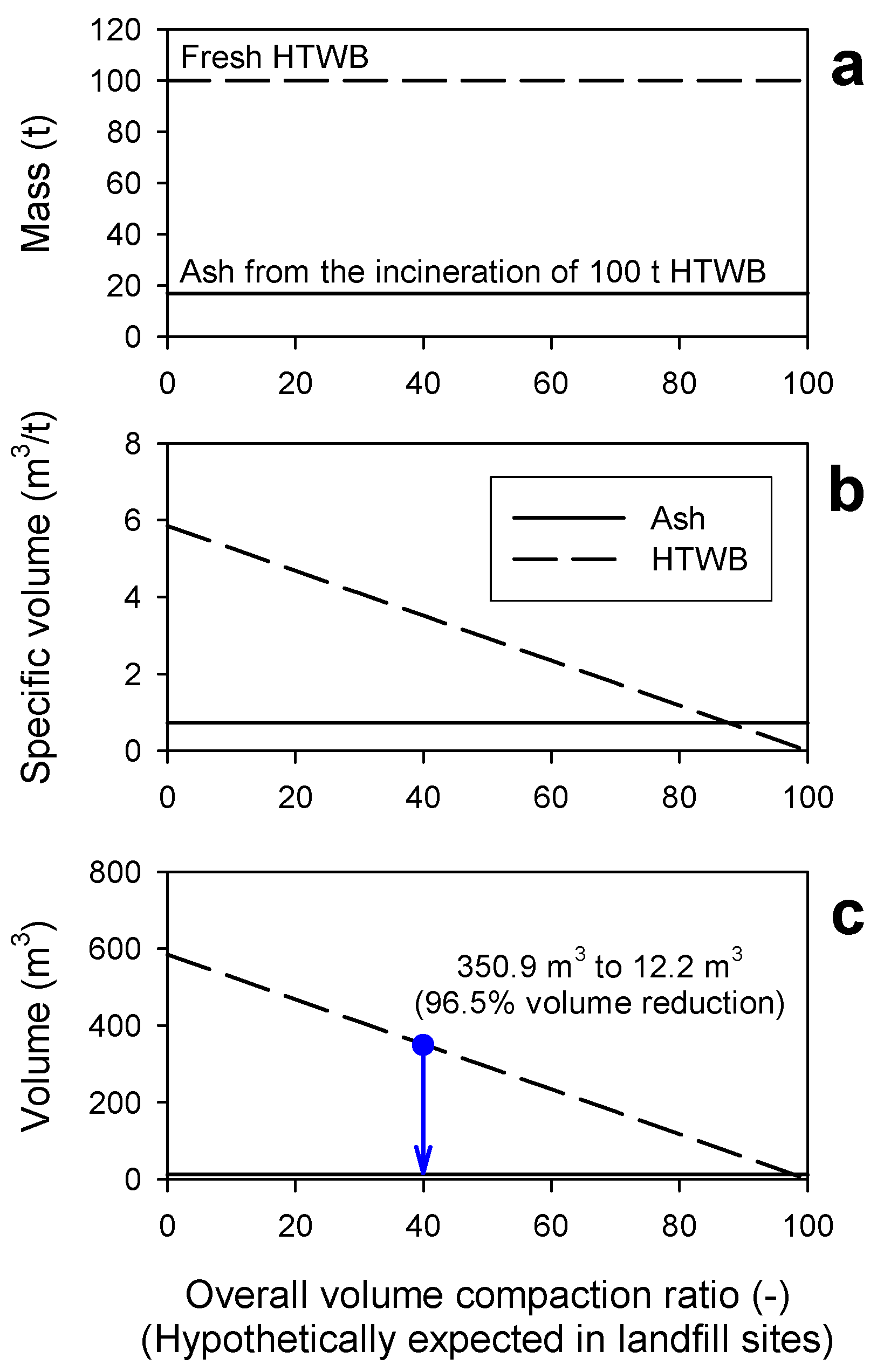

3.1. Changes in Waste Mass, Volume, and Components Due to Incineration

3.2. Energy Recovery Efficiency

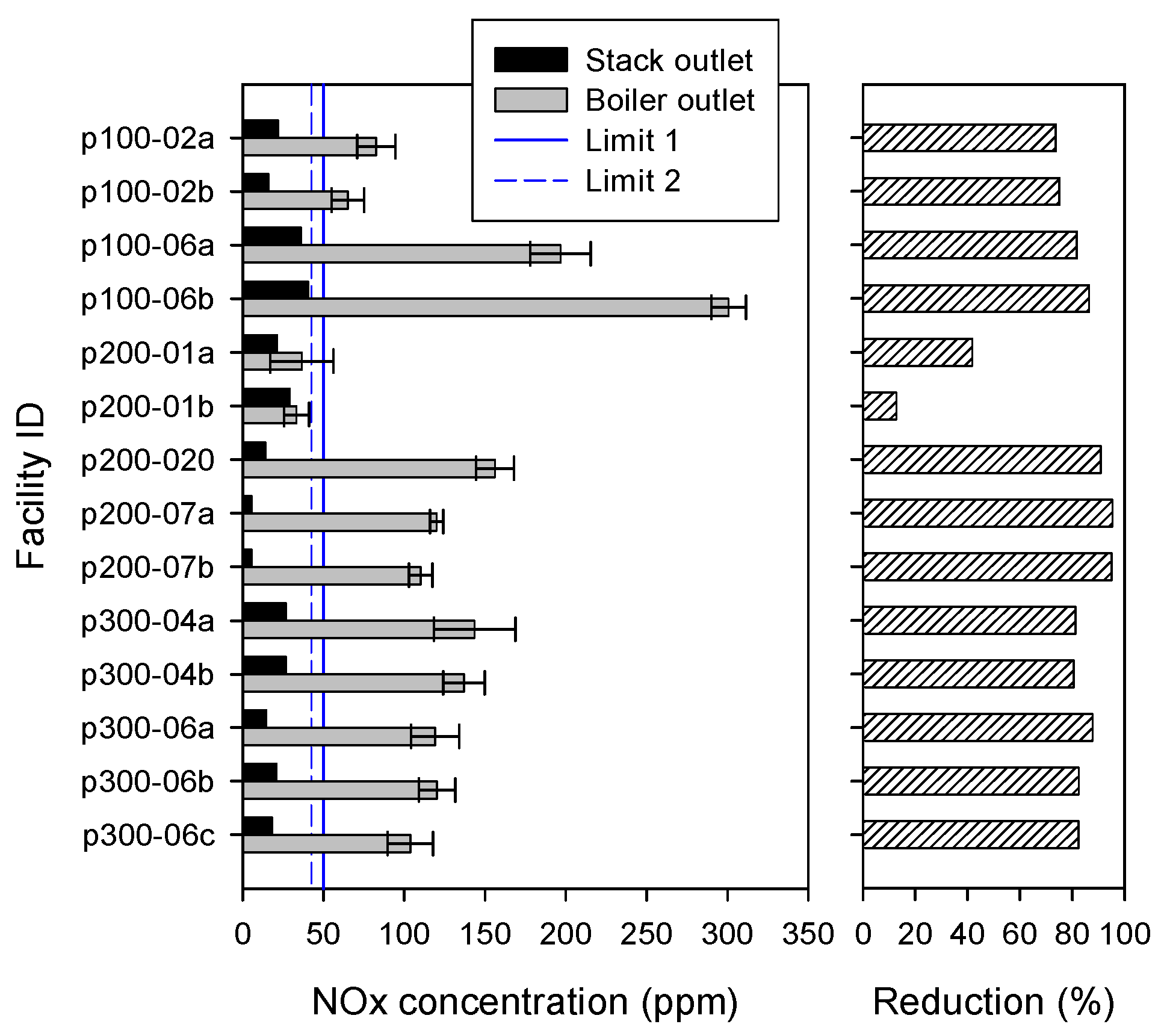

3.3. Thirty-Minute Averaged NOx Concentrations before and after Emission Control Measures

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Circularity Gap Reporting Initiative, the Circularity Gap Report. 2023. Available online: https://www.circularity-gap.world/2023#download (accessed on 10 August 2023).

- Shin, S.K.; Um, N.; Kim, Y.J.; Cho, N.H.; Jeon, T.W. New Policy Framework with Plastic Waste Control Plan for Effective Plastic Waste Management. Sustainability 2020, 12, 6049. [Google Scholar] [CrossRef]

- Ministry of the Environment. Act on the Promotion of Transformation Toward Circular Economy Society. 2023. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=254899&ancYd=&ancNo=&efYd=20240101&nwJoYnInfo=Y&ancYnChk=0&efGubun=Y&vSct=*#0000 (accessed on 10 August 2023). (In Korean).

- European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Off. J. Eur. Union 2018. Available online: http://data.europa.eu/eli/dir/2008/98/2018-07-05 (accessed on 10 August 2023).

- US Environmental Protection Agency. Sustainable Materials Management: Nonhazardous Materials and Waste Management Hierarchy; (Last Updated on 19 June 2023); US Environmental Protection Agency: Washington, DC, USA, 2023. [Google Scholar]

- Ministry of the Environment. Wastes Control Act. 2023. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=254087&ancYd=&ancNo=&efYd=20240817&nwJoYnInfo=N&ancYnChk=0&efGubun=Y&vSct=*#0000 (accessed on 10 August 2023). (In Korean).

- Ministry of the Environment. Act on the Promotion of Saving and Recycling of Resources. 2023. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=249347&ancYd=&ancNo=&efYd=20240329&nwJoYnInfo=N&ancYnChk=0&efGubun=Y&vSct=*#0000 (accessed on 10 August 2023). (In Korean).

- Arena, U. From Waste-to-Energy to Waste-to-Resources: The New Role of Thermal Treatments of Solid Waste in the Recycling Society. Waste Manag. 2015, 37, 1–2. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Waste to Energy–Key Element for Sustainable Waste Management. Waste Manag. 2015, 37, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Lopes, E.J.; Queiroz, N.; Yamamoto, C.I.; da Costa Neto, P.R. Evaluating the Emissions from the Gasification Processing of Municipal Solid Waste Followed by Combustion. Waste Manag. 2018, 73, 504–510. [Google Scholar] [CrossRef] [PubMed]

- Ministry of the Environment. Press Release. Direct Disposal of Pay-as-You-Throw Trash in Metropolitan Landfills Will Be Banned Starting in 2026. 2021. Available online: https://me.go.kr/home/web/board/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=&menuId=10525&orgCd=&condition.fromDate=2021-07-05&condition.toDate=2021-07-05&boardId=1464280&boardMasterId=1&boardCategoryId=&decorator= (accessed on 10 August 2023). (In Korean).

- Ministry of the Environment. Press Release. The Mayors of 10 Cities in the Seoul Metropolitan Area Need to Expand Incineration Capacity Before Their Terms End. 2022. Available online: https://me.go.kr/home/web/board/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=&menuId=10525&orgCd=&condition.fromDate=2022-07-01&condition.toDate=2022-07-01&boardId=1534530&boardMasterId=1&boardCategoryId=&decorator= (accessed on 10 August 2023). (In Korean).

- Makarichi, L.; Jutidamrongphan, W.; Techato, K.A. The Evolution of Waste-to-Energy Incineration: A Review. Renew. Sustain. Energy Rev. 2018, 91, 812–821. [Google Scholar] [CrossRef]

- Zhao, X.-G.; Jiang, G.-W.; Li, A.; Li, Y. Technology, Cost, a Performance of Waste-to-Energy Incineration Industry in China. Renew. Sustain. Energy Rev. 2016, 55, 115–130. [Google Scholar] [CrossRef]

- Ministry of the Environment. Enforcement Decree of the Framework Act on Resources Circulation. 2023. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=257037&ancYd=&ancNo=&efYd=20240101&nwJoYnInfo=Y&ancYnChk=0&efGubun=Y&vSct=*#0000 (accessed on 10 August 2023). (In Korean).

- Shah, H.H.; Amin, M.; Pepe, F. Maximizing Resource Efficiency: Opportunities for Energy Recovery from Municipal Solid Waste in Europe. J. Mater. Cycles Waste Manag. 2023, 25, 2766–2782. [Google Scholar] [CrossRef]

- Hwang, K.L.; Choi, S.M.; Kim, M.K.; Heo, J.B.; Zoh, K.D. Emission of Greenhouse Gases from Waste Incineration in Korea. J. Environ. Manag. 2017, 196, 710–718. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Y.; Chen, G.; Zuo, J.; Yan, B.; Yin, P. Effectiveness of Waste-to-Energy Approaches in China: From the Perspective of Greenhouse Gas Emission Reduction. J. Clean. Prod. 2017, 163, 99–105. [Google Scholar] [CrossRef]

- Istrate, I.R.; Galvez-Martos, J.L.; Vázquez, D.; Guillén-Gosálbez, G.; Dufour, J. Prospective Analysis of the Optimal Capacity, Economics and Carbon Footprint of Energy Recovery from Municipal Solid Waste Incineration. Resour. Conserv. Recycl. 2023, 193, 106943. [Google Scholar] [CrossRef]

- Han, M.; Wu, Y.; Sun, J.; Geng, X.; Gao, X.; Zhou, T.; Lu, J. Carbon feasibility of terminating plastic waste leakage by landfill mining: A case study based on practical projects in China. Sci. Total Environ. 2024, 906, 167461. [Google Scholar] [CrossRef] [PubMed]

- Ministry of the Environment. Persistent Organic Pollutants Control Act. 2022. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=243003&ancYd=&ancNo=&efYd=20230611&nwJoYnInfo=Y&ancYnChk=0&efGubun=Y&vSct=*#0000 (accessed on 10 August 2023). (In Korean).

- Ministry of the Environment. Clean Air Conservation Act. 2022. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=246843&ancYd=&ancNo=&efYd=20230628&nwJoYnInfo=Y&ancYnChk=0&efGubun=Y&vSct=*#0000 (accessed on 10 August 2023). (In Korean).

- Korean Environment Corporation. Clean Sys: Smokestack Tele-Monitoring System. 2023. Available online: https://cleansys.or.kr/introSystem.do (accessed on 10 August 2023).

- Gohlke, O.; Weber, T.; Seguin, P.; Laborel, Y. A New Process for NOx Reduction in Combustion Systems for the Generation of Energy from Waste. Waste Manag. 2010, 30, 1348–1354. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lou, H.H.; Yang, F.; Cheng, F. Numerical Simulation of a Decoupling and Re-burning Combinative Low-NOx Coal Grate Boiler. J. Clean. Prod. 2018, 188, 977–988. [Google Scholar] [CrossRef]

- Van Caneghem, J.; De Greef, J.; Block, C.; Vandecasteele, C. NOx Reduction in Waste Incinerators by Selective Catalytic Reduction (SCR) Instead of Selective Non Catalytic Reduction (SNCR) Compared from a Life Cycle Perspective: A Case Study. J. Clean. Prod. 2016, 112, 4452–4460. [Google Scholar] [CrossRef]

- Thanos Bourtsalas, A.C.; Seo, Y.; Tanvir Alam, M.; Seo, Y.C. The Status of Waste Management and Waste to Energy for District Heating in South Korea. Waste Manag. 2019, 85, 304–316. [Google Scholar] [CrossRef] [PubMed]

- Villani, K.; De Greef, J.; Goethals, J.; Montauban, I.; Van Langenhove, H. Exploring the performance limits of non-catalytic de-NOx in waste-to-energy plants. In Proceedings of the Fourth International Symposium on Energy from Biomass and Waste, Venice, Italy, 12–15 November 2012; CISA Publisher: Padova, Italy, 2012. [Google Scholar]

- Gómez-García, M.A.; Pitchon, V.; Kiennemann, A. Pollution by nitrogen oxides: An approach to NOx abatement by using sorbing catalytic materials. Environ. Int. 2005, 31, 445–467. [Google Scholar] [CrossRef] [PubMed]

- Goemans, M.; Clarysse, P.; Joannès, J.; De Clercq, P.; Lenaerts, S.; Matthys, K.; Boels, K. Catalytic NOx reduction with simultaneous dioxin and furan oxidation. Chemosphere 2004, 54, 1357–1365. [Google Scholar] [CrossRef]

- Ministry of the Environment. 6th Nationwide Statistical Survey on Waste. 2023. Available online: https://library.me.go.kr/#/search/detail/5883548?offset=1 (accessed on 10 August 2023). (In Korean).

- Martin, J.J.; Koralewska, R.; Wohlleben, A. Advanced Solutions in Combustion-Based WtE Technologies. Waste Manag. 2015, 37, 147–156. [Google Scholar] [CrossRef]

- Lynn, C.J.; Ghataora, G.S.; Obe, R.K. Municipal incinerated bottom ash (MIBA) characteristics and potential for use in road pavements. Int. J. Pavement Res. Technol. 2017, 10, 185–201. [Google Scholar] [CrossRef]

- Gourc, J.P.; Staub, M.J.; Conte, M. Decoupling MSW Settlement into Mechanical and Biochemical Processes–Modelling and Validation on Large-Scale Setups. Waste Manag. 2010, 30, 1556–1568. [Google Scholar] [CrossRef]

- Pi, X.; Fei, X.; Wang, Y.; Sun, X.; Guo, Y. Global Void Ratio of Municipal Solid Waste for Compression Indices Estimation. Waste Manag. 2023, 160, 69–79. [Google Scholar] [CrossRef] [PubMed]

- National Institute of Environmental Research. Method ES 06303.1a, Humidity and Total Solid-Gravimetry; National Institute of Environmental Research: Incheon, Republic of Korea, 2022. (In Korean) [Google Scholar]

- National Institute of Environmental Research. Method ES 06301.1d, Loss on Ignition and Total Organics-Gravimetry; National Institute of Environmental Research: Incheon, Republic of Korea, 2022. (In Korean) [Google Scholar]

- Confederation of European Waste-to-Energy Plants. CEWEP Energy Report (Status 2001–2004) Results of Specific Data for Energy, Efficiency Rates and Coefficients, Plant Efficiency Factors and NCV of 97 European W-t-E Plants and Determination of the Main Energy Results; Confederation of European Waste-to-Energy Plants: Brussels, Belgium, 2006. [Google Scholar]

- Grosso, M.; Motta, A.; Rigamonti, L. Efficiency of Energy Recovery from Waste Incineration, in the Light of the New Waste Framework Directive. Waste Manag. 2010, 30, 1238–1243. [Google Scholar] [CrossRef] [PubMed]

- IPCC. IPCC Guideline for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2007; Volume 2006. [Google Scholar]

- National Institute of Environmental Research. Method ES 01308.1b, Nitrogen Oxides in Flue Gas–NOx–Automated Measuring Method; National Institute of Environmental Research: Incheon, Republic of Korea, 2021. (In Korean) [Google Scholar]

- National Institute of Environmental Research. A Study on Improvement of Energy Recovery Efficiency Factors for Waste Incineration Facilities in Korea; National Institute of Environmental Research: Incheon, Republic of Korea, 2022. (In Korean) [Google Scholar]

- Vakalis, S.; Moustakas, K.; Loizidou, M. Energy Efficiency of Waste-to-Energy Plants with a Focus on the Comparison and the Constraints of the 3T Method and the R1 Formula. Renew. Sustain. Energy Rev. 2019, 108, 323–329. [Google Scholar] [CrossRef]

| Plant Group | Incineration Capacity (t/d) | Numbers | Performance Overview | ||

|---|---|---|---|---|---|

| Sites | Facilities | Mass Reduction (%, Mean ± Standard Deviation) | R1 Recovery Efficiency (%, Mean ± Standard Deviation) | ||

| p100 | 80–170 | 9 | 15 | 83.0 ± 4.0 | 68.2 ± 15.5 |

| p200 | 200–270 | 10 | 17 | 81.8 ± 2.5 | 75.6 ± 14.9 |

| p300 | 300–400 | 6 | 12 | 85.0 ± 3.4 | 68.0 ± 7.0 |

| Overall | 25 | 44 | 83.1 ± 3.6 | 71.0 ± 13.9 | |

| Plant Group | Facility ID | Incineration Capacity (t/d) | Emission Control Measures |

|---|---|---|---|

| p100 | p100-02a | 100 | SDR + BF + SCR |

| p100-02b | 100 | SDR + BF + SCR | |

| p100-06a | 170 | AC + EP + WS + SCR | |

| p100-06b | 170 | AC + EP + WS + SCR | |

| p200 | p200-01a | 200 | SNCR + SDR + AC + BF |

| p200-01b | 200 | SNCR + SDR + AC + BF | |

| p200-020 | 200 | SDR + AC + BF + SCR | |

| p200-07a | 270 | SNCR + SDR + BF + AC + BF | |

| p200-07b | 270 | SNCR + SDR + BF + AC + BF | |

| p300 | p300-04a | 300 | EP + WS + SCR |

| p300-04b | 300 | EP + WS + SCR | |

| p300-06a | 300 | SNCR + WS + SDR + AC + BF + SCR | |

| p300-06b | 300 | SNCR + WS + SDR + AC + BF + SCR | |

| p300-06c | 300 | SNCR + WS + SDR + AC + BF + SCR |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwon, Y.; Lee, S.; Bae, J.; Park, S.; Moon, H.; Lee, T.; Kim, K.; Kang, J.; Jeon, T. Evaluation of Incinerator Performance and Policy Framework for Effective Waste Management and Energy Recovery: A Case Study of South Korea. Sustainability 2024, 16, 448. https://doi.org/10.3390/su16010448

Kwon Y, Lee S, Bae J, Park S, Moon H, Lee T, Kim K, Kang J, Jeon T. Evaluation of Incinerator Performance and Policy Framework for Effective Waste Management and Energy Recovery: A Case Study of South Korea. Sustainability. 2024; 16(1):448. https://doi.org/10.3390/su16010448

Chicago/Turabian StyleKwon, Younghyun, Suyoung Lee, Jisu Bae, Sein Park, Heesung Moon, Taewoo Lee, Kyuyeon Kim, Jungu Kang, and Taewan Jeon. 2024. "Evaluation of Incinerator Performance and Policy Framework for Effective Waste Management and Energy Recovery: A Case Study of South Korea" Sustainability 16, no. 1: 448. https://doi.org/10.3390/su16010448

APA StyleKwon, Y., Lee, S., Bae, J., Park, S., Moon, H., Lee, T., Kim, K., Kang, J., & Jeon, T. (2024). Evaluation of Incinerator Performance and Policy Framework for Effective Waste Management and Energy Recovery: A Case Study of South Korea. Sustainability, 16(1), 448. https://doi.org/10.3390/su16010448