Economic Feasibility Analysis of Greenhouse–Fuel Cell Convergence Systems

Abstract

:1. Introduction

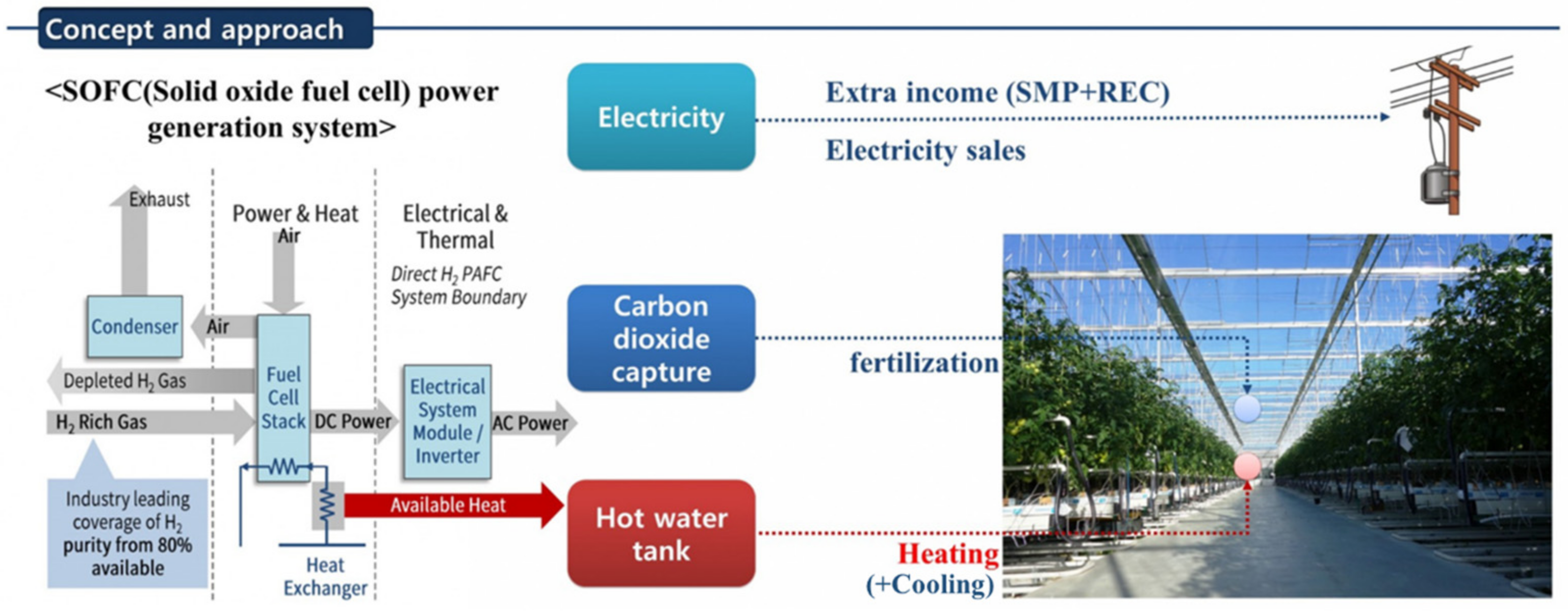

- The concept of introducing fuel cells, a new energy system, into greenhouses is presented.

- In addition to the existing combined heat and power generation method, increased crop production using carbon dioxide was considered.

- An economic evaluation was conducted using government energy policies.

- Government support methods for the expansion of the GFCS were presented.

2. Concept of Greenhouse–Fuel Cell Convergence Systems

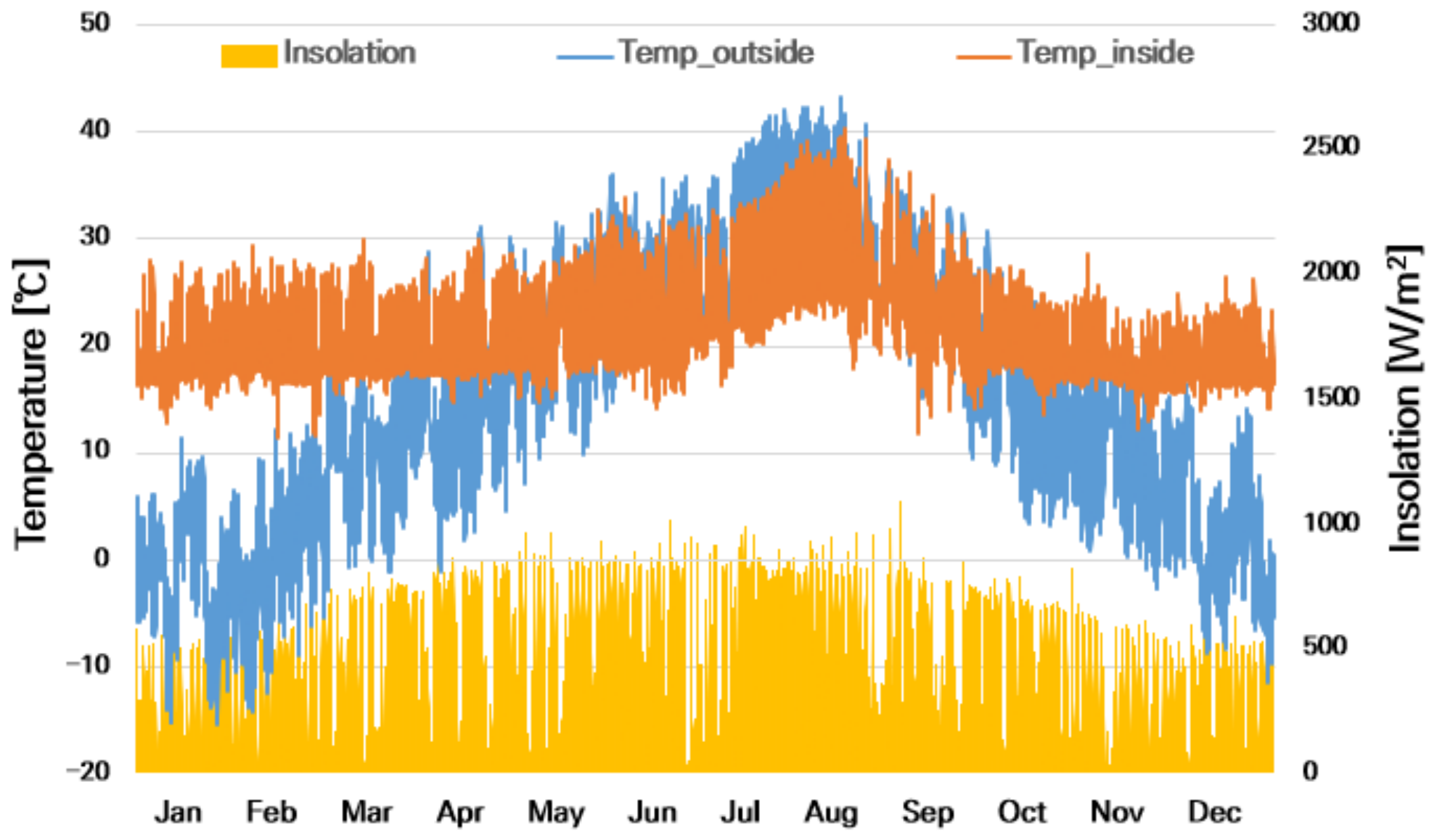

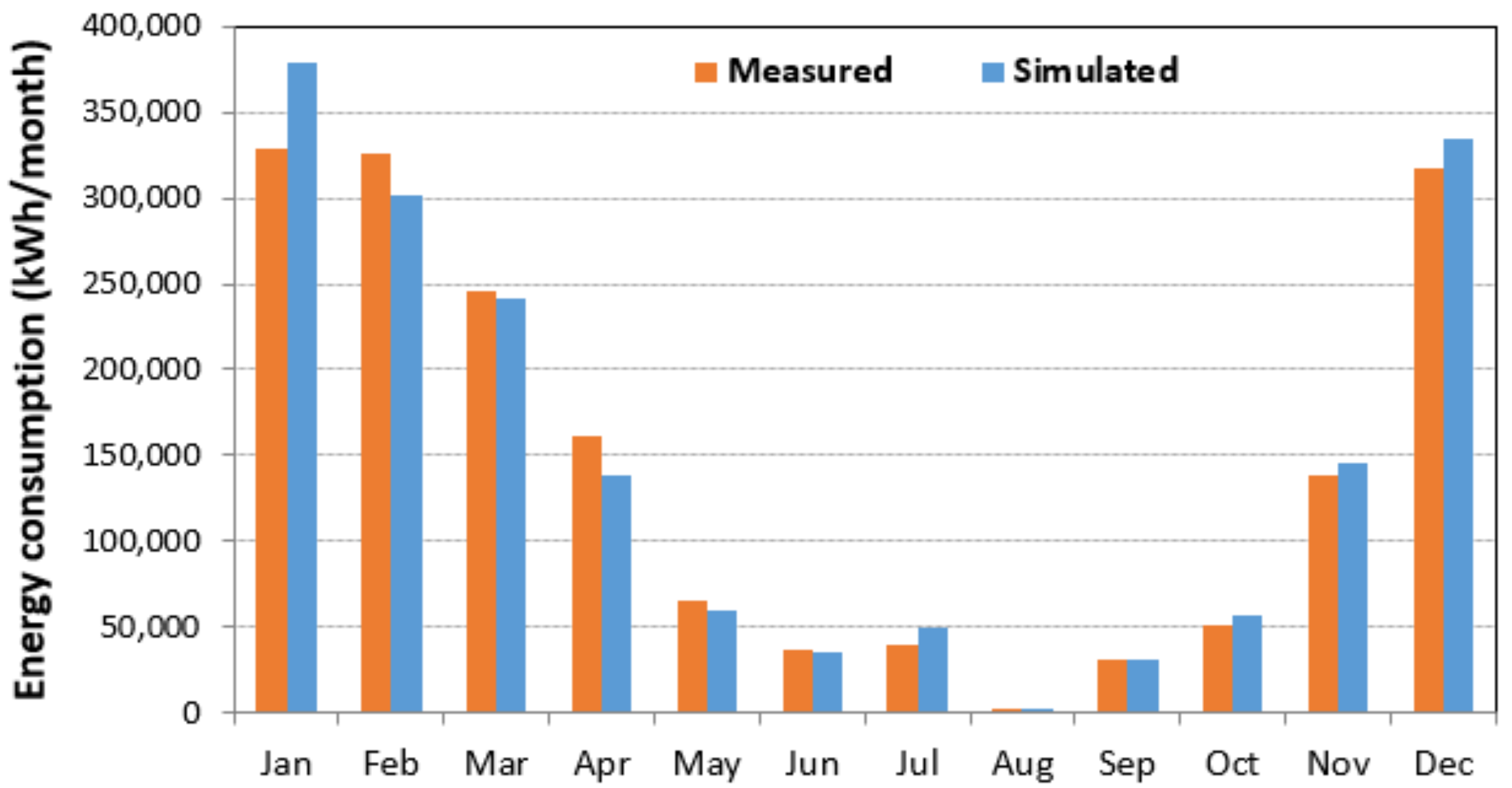

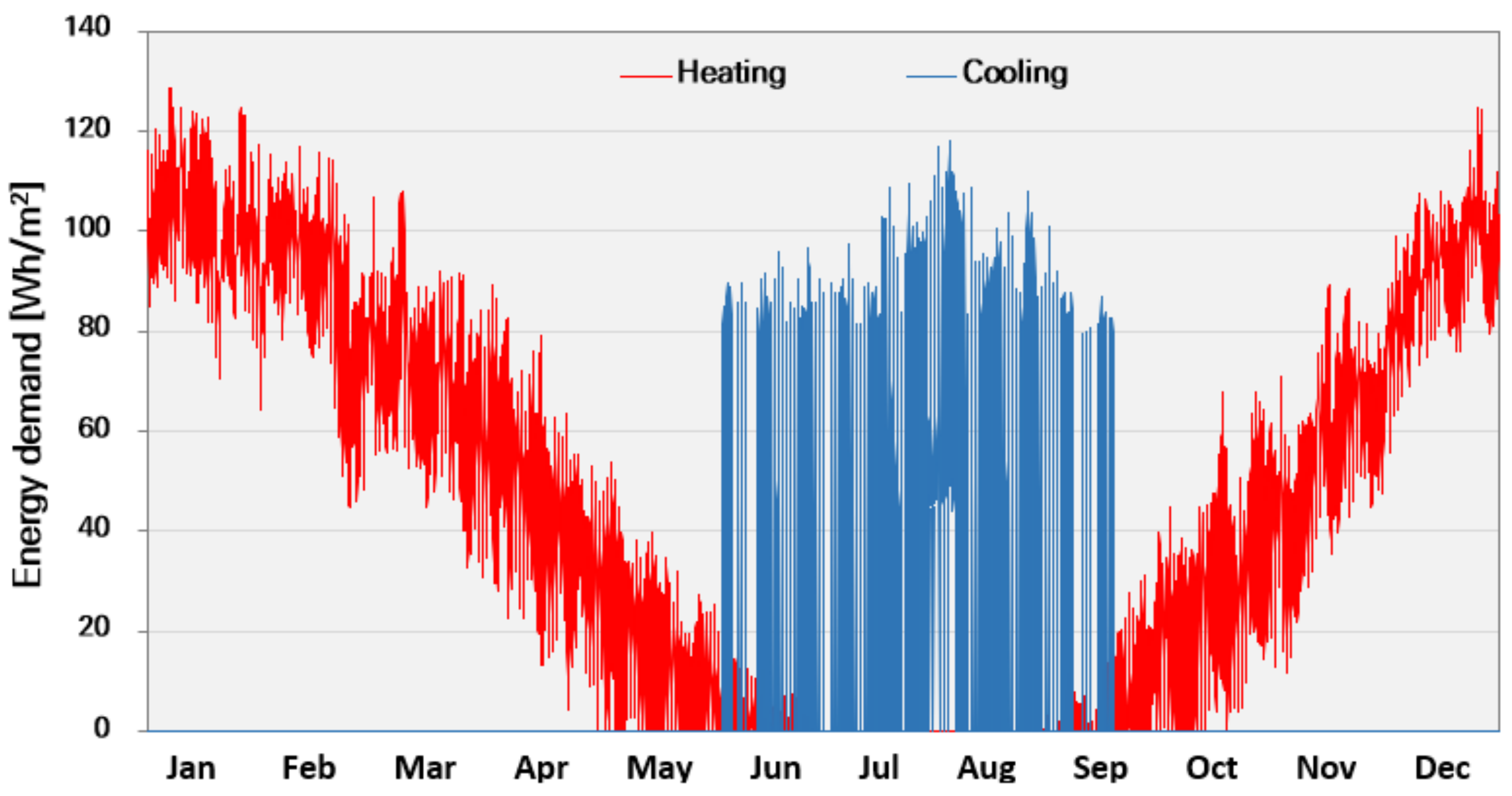

3. GFCS Energy Simulation Model and Calculation of Energy Consumption

3.1. Calibration and Establishment of the Energy Simulation Model

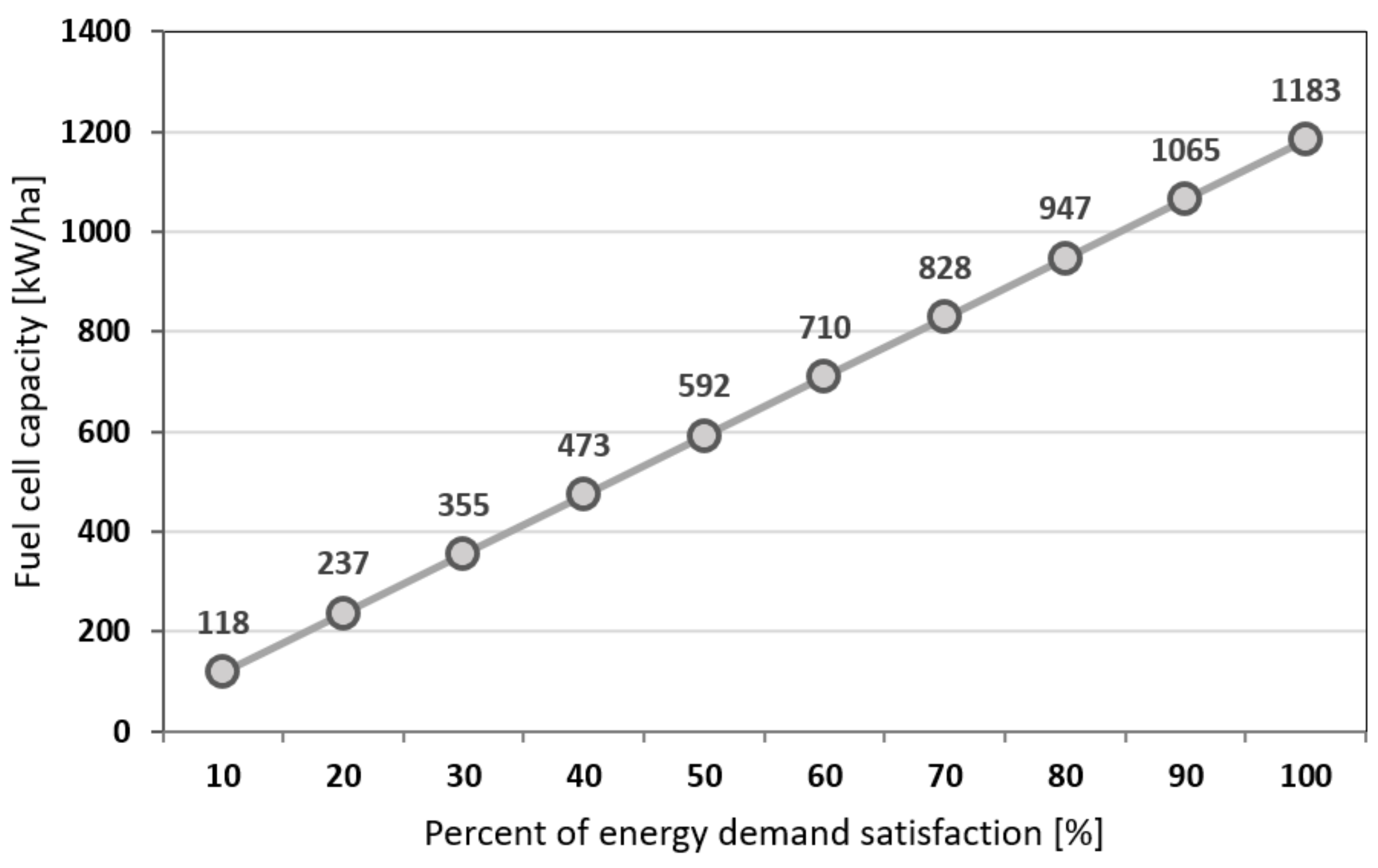

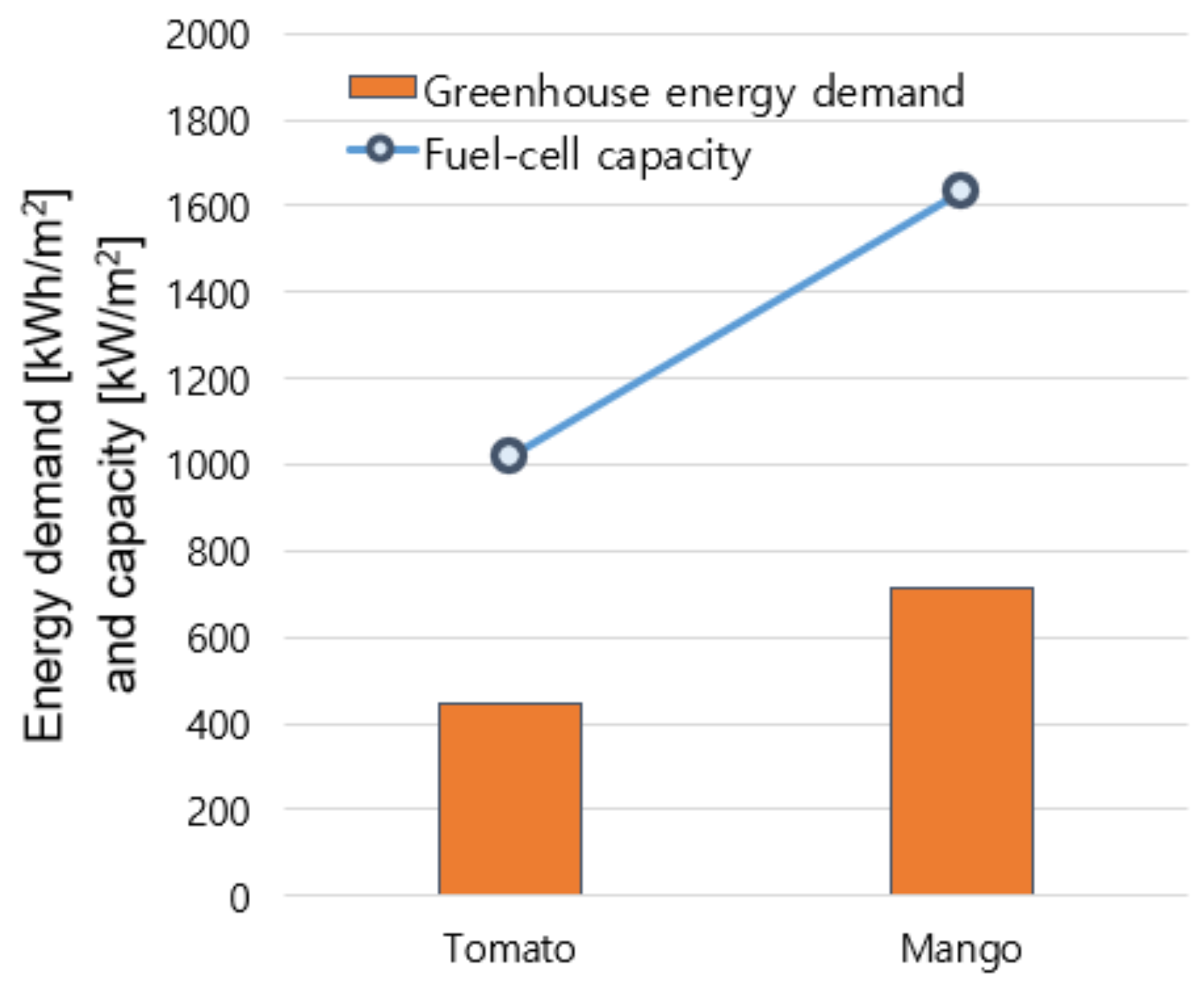

3.2. Calculation of Greenhouse Energy Consumption and Fuel Cell Capacity

4. Economic Evaluation of Business Model

4.1. Development of Business Models

4.2. Economic Evaluation

5. Strategies for Ensuring the Economic Feasibility of the Farmer-Led Model

- -

- SMP + REC: The current price is 218 KRW, and to secure the economic feasibility of each crop, SMP + REC prices need to increase by over two times, reaching 438–515 KRW.

- -

- LNG price: The gas price for B/C to become 1.0 was found to be −34 to −100 KRW/Nm3, and a negative number means that when using gas for power generation, the government provides an additional subsidy of 34~100 KRW/Nm3.

- -

- Fuel cell subsidy: This refers to the government support rate of the initial installation cost of fuel cells, and it was found to be 111~120%, which means that 100% of the initial installation cost of the fuel cell should be supported and an additional amount equivalent to 11~20% should be subsidized.

6. Discussion and Conclusions

6.1. Discussion

6.2. Conclusions

- The energy consumption of a 1 ha greenhouse was calculated using the corrected simulation analysis model. When covering 100% of the energy requirement with the fuel cell, the appropriate installation capacity of the fuel cell was determined to be 520 kW/ha for tomatoes and 820 kW/ha for mangoes.

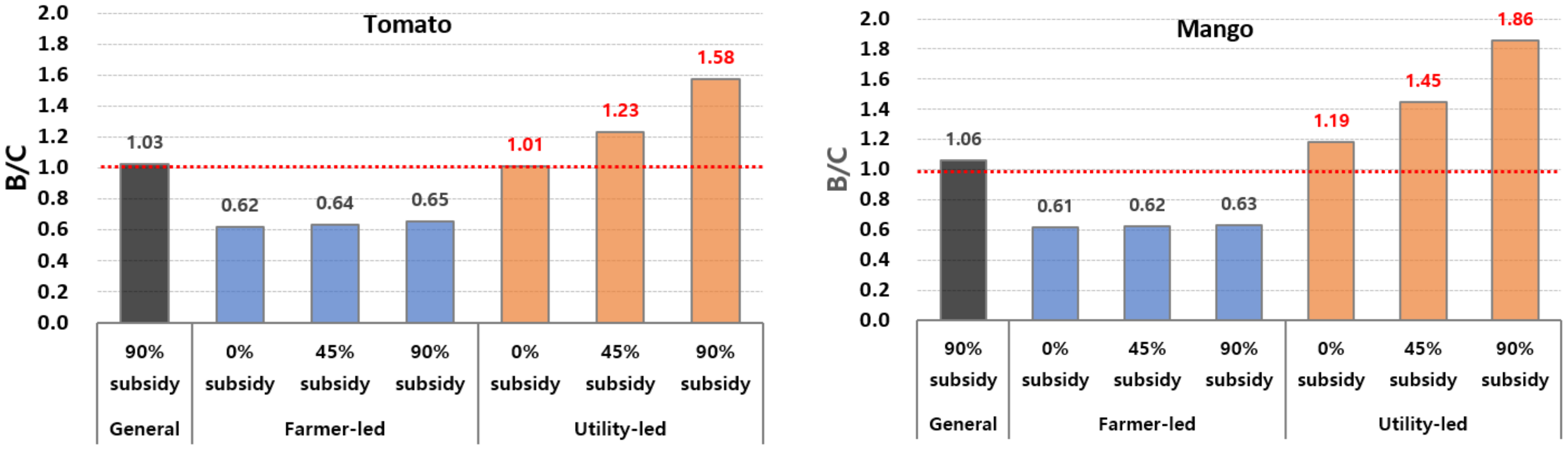

- Farmer-led and utility-led business models were proposed to evaluate the economic feasibility of introducing GFCS.

- -

- In the farmer-led model, farmers install fuel cell power generation facilities in small-scale greenhouses within their own ownership, typically ranging from 1 to 2 hectares. They then generate agricultural and non-agricultural income through electricity sales, CO2 fertilization, and waste heat utilization.

- -

- In the utility-led model, power generation companies install fuel cell power generation facilities near large greenhouses, typically around 50 hectares, or in unused land, such as reclaimed land. Farmers then increase agricultural income by utilizing CO2 fertilization and waste heat.

- The economic evaluation results of the two proposed business models are as follows:

- -

- The farmer-led model is not yet economical due to the high initial investment cost of fuel cells and the recent rise in gas prices. Even with government support for heat utilization facilities, the B/C ranged from 0.62 to 0.65, lower than the general greenhouse range of 1.03 to 1.06.

- -

- The utility-led model showed a high B/C of 1.19 to 1.86 because there was no burden on farmers’ fuel costs, and crop productivity increased because of CO2 fertilization.

- Support for SMP + REC, gas prices, and fuel cell installation costs is needed to secure the economic feasibility of the farmer-led model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ASHP | Air source heat pump |

| B/C | Benefit–cost ratio |

| BIPV | Building-integrated photovoltaics |

| CHP | Combined heat and power |

| COP | Coefficient of performance |

| GSHP | Geothermal source heat pump |

| GFCS | Greenhouse–fuel cell convergence systems |

| HGSHP | Horizontal source heat pumps |

| LCC | Life cycle cost |

| LHS | Latin hypercube sampling |

| PEMFC | Proton exchange membrane fuel cell |

| REC | Renewable energy certificate |

| RPS | Renewable portfolio standard |

| SAHP | Solar-assisted heat pump |

| SMP | System marginal price |

| SOFC | Solid oxide fuel cell |

| STPV | Semi-transparent photovoltaic |

| TMY | Typical monthly year |

| TPV | Transparent photovoltaic |

| VGSHP | Vertical source heat pumps |

References

- El-Maghlany, W.M.; Teamah, M.A.; Tanaka, H. Optimum design and orientation of the greenhouses for maximum capture of solar energy in North Tropical Region. Energy Convers. Manag. 2015, 105, 1096–1104. [Google Scholar] [CrossRef]

- Çakır, U.; Şahin, E. Using solar greenhouses in cold climates and evaluating optimum type according to sizing, position and location: A case study. Comput. Electron. Agric. 2015, 117, 245–257. [Google Scholar] [CrossRef]

- Chen, J.; Ma, Y.; Pang, Z. A mathematical model of global solar radiation to select the optimal shape and orientation of the greenhouses in southern China. Sol. Energy 2020, 205, 380–389. [Google Scholar] [CrossRef]

- Costantino, A.; Comba, L.; Sicardi, G.; Bariani, M.; Fabrizio, E. Energy performance and climate control in mechanically ventilated greenhouses: A dynamic modelling-based assessment and investigation. Appl. Energy 2021, 288. [Google Scholar] [CrossRef]

- Lim, A.-Y.; Yoon, M.; Kim, E.-H.; Kim, H.-A.; Lee, M.J.; Cheong, H.-K. Effects of mechanical ventilation on indoor air quality and occupant health status in energy-efficient homes: A longitudinal field study. Sci. Total Environ. 2021, 785, 147324. [Google Scholar] [CrossRef] [PubMed]

- Revathi, S.; Sivakumaran, N.; Radhakrishnan, T.K. Design of solar-powered forced ventilation system and energy-efficient thermal comfort operation of greenhouse. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; pp. 9893–9900. [Google Scholar] [CrossRef]

- Kuijpers, W.J.; Katzin, D.; van Mourik, S.; Antunes, D.J.; Hemming, S.; van de Molengraft, M.J. Lighting systems and strategies compared in an optimally controlled greenhouse. Biosyst. Eng. 2021, 202, 195–216. [Google Scholar] [CrossRef]

- Katzin, D.; van Mourik, S.; Kempkes, F.; van Henten, E.J. GreenLight—An open source model for greenhouses with supplemental lighting: Evaluation of heat requirements under LED and HPS lamps. Biosyst. Eng. 2020, 194, 61–81. [Google Scholar] [CrossRef]

- Katzin, D.; Marcelis, L.F.; van Mourik, S. Energy savings in greenhouses by transition from high-pressure sodium to LED lighting. Appl. Energy 2020, 281, 116019. [Google Scholar] [CrossRef]

- Tong, Y.; Kozai, T.; Nishioka, N.; Ohyama, K. Greenhouse heating using heat pumps with a high coefficient of performance (COP). Biosyst. Eng. 2010, 106, 405–411. [Google Scholar] [CrossRef]

- Xi, X.; Duan, D.; Xu, X.; Liu, F.; Zhang, B. Performance assessment of a novel combined heating mode integrated greenhouse and closed drying system with a dual-temperature steam jet heat pump. Sustain. Energy Technol. Assess. 2022, 53, 102470. [Google Scholar] [CrossRef]

- Badji, A.; Benseddik, A.; Boukhelifa, A.; Bensaha, H.; Erregani, R.; Bendriss, A.; Bouhoun, S.; Nettari, C.; Kaouane, M.; Lalmi, D. Solar air heater with underground latent heat storage system for greenhouse heating: Performance analysis and machine learning prediction. J. Energy Storage 2023, 74, 109548. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Yin, F. The integration of semi-transparent photovoltaics on greenhouse roof for energy and plant production. Renew. Energy 2018, 121, 377–388. [Google Scholar] [CrossRef]

- Bambara, J.; Athienitis, A.K. Energy and economic analysis for the design of greenhouses with semi-transparent photovoltaic cladding. Renew. Energy 2019, 131, 1274–1287. [Google Scholar] [CrossRef]

- Kavga, A.; Strati, I.F.; Sinanoglou, V.J.; Fotakis, C.; Sotiroudis, G.; Christodoulou, P.; Zoumpoulakis, P. Evaluating the experimental cultivation of peppers in low-energy-demand greenhouses. An interdisciplinary study. J. Sci. Food Agric. 2018, 99, 781–789. [Google Scholar] [CrossRef] [PubMed]

- Chahidi, L.O.; Fossa, M.; Priarone, A.; Mechaqrane, A. Energy saving strategies in sustainable greenhouse cultivation in the mediterranean climate—A case study. Appl. Energy 2020, 282, 116156. [Google Scholar] [CrossRef]

- Benli, H. A performance comparison between a horizontal source and a vertical source heat pump systems for a greenhouse heating in the mild climate Elaziğ, Turkey. Appl. Therm. Eng. 2013, 50, 197–206. [Google Scholar] [CrossRef]

- Reda, F.; Paiho, S.; Pasonen, R.; Helm, M.; Menhart, F.; Schex, R.; Laitinen, A. Comparison of solar assisted heat pump solutions for office building applications in Northern climate. Renew. Energy 2019, 147, 1392–1417. [Google Scholar] [CrossRef]

- Besagni, G.; Croci, L.; Nesa, R.; Molinaroli, L. Field study of a novel solar-assisted dual-source multifunctional heat pump. Renew. Energy 2018, 132, 1185–1215. [Google Scholar] [CrossRef]

- Arsalis, A. A comprehensive review of fuel cell-based micro-combined-heat-and-power systems. Renew. Sustain. Energy Rev. 2019, 105, 391–414. [Google Scholar] [CrossRef]

- Choudhury, A.; Chandra, H.; Arora, A. Application of solid oxide fuel cell technology for power generation—A review. Renew. Sustain. Energy Rev. 2013, 20, 430–442. [Google Scholar] [CrossRef]

- Huangfu, Y.; Wu, J.; Wang, R.; Kong, X.; Wei, B. Evaluation and analysis of novel micro-scale combined cooling, heating and power (MCCHP) system. Energy Convers. Manag. 2007, 48, 1703–1709. [Google Scholar] [CrossRef]

- Sonar, D.; Soni, S.; Sharma, D. Micro-trigeneration for energy sustainability: Technologies, tools and trends. Appl. Therm. Eng. 2014, 71, 790–796. [Google Scholar] [CrossRef]

- Vadiee, A.; Yaghoubi, M.; Sardella, M.; Farjam, P. Energy analysis of fuel cell system for commercial greenhouse application—A feasibility study. Energy Convers. Manag. 2015, 89, 925–932. [Google Scholar] [CrossRef]

- Lee, C.-S.; Hoes, P.; Cóstola, D.; Hensen, J. Assessing the performance potential of climate adaptive greenhouse shells. Energy 2019, 175, 534–545. [Google Scholar] [CrossRef]

- ASHRAE Guideline 14-2014; Measurement of Energy, Demand, and Water Savings. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE): Atlanta, GA, USA, 2014.

- OneBuilding.org. Climate. Available online: https://climate.onebuilding.org/WMO_Region_2_Asia/KOR_South_Korea/index.html (accessed on 6 June 2023).

| Action | Advantages |

|---|---|

| Use of captured CO2 for greenhouse enrichment | Higher CO2 levels (from 600 ppm to 1000 ppm) in greenhouses boost fruit and vegetable yield and quality, leading to increased farm profits. |

| Use of waste heat for greenhouse heating | Using wasted heat from power generation to save on heating costs in the greenhouse |

| Selling generated electricity | Selling electricity and renewable energy supply certificates to secure additional agricultural income |

| Category | Farmer-Led Model | Utility-Led Model |

|---|---|---|

| Concept |

|

|

| Scale |

|

|

| Operator |

|

|

| Advantages |

|

|

| Business Model | General Greenhouse | Farmer-Led | Utility-Led | |

|---|---|---|---|---|

| Crops | Cucumbers, Mangoes. | |||

| Features |

|

|

| |

| Heat Source |

|

|

| |

| Costs | Direct Costs |

|

|

|

| Indirect Costs |

|

|

| |

| Benefits |

|

|

| |

| (Unit: Million KRW) | General | Farmer-Led Model | Utility-Led Model | |||||

|---|---|---|---|---|---|---|---|---|

| Tomatoes | Mangoes | Tomatoes | Mangoes | Tomatoes | Mangoes | |||

| Costs | Direct Costs | Greenhouse construction costs | 1500.0 | 1500.0 | 1500.0 | 1500.0 | 1500.0 | 1500.0 |

| Heat utilization facility construction costs | - | - | 1500.0 | 1500.0 | 1500.0 | 1500.0 | ||

| Fuel cell installation costs | - | - | 6351.3 | 10,196.9 | - | - | ||

| HP (geothermal) installation costs | 107.8 | 173.1 | - | - | - | - | ||

| Total | 1607.8 | 1673.1 | 9351.3 | 13,196.9 | 3000.0 | 3000.0 | ||

| Indirect Costs | Operating expenses | 68.3 | 66.7 | 43.3 | 41.7 | 43.3 | 41.7 | |

| Heat utilization facility maintenance costs | - | - | 15.0 | 15.0 | 15.0 | 15.0 | ||

| Fuel cell maintenance costs | - | - | 236.1 | 379.1 | - | - | ||

| HP maintenance costs | 9.0 | 14.4 | - | - | ||||

| Fuel costs (electricity/gas) | 35.6 | 57.2 | 1131.3 | 1816.2 | - | - | ||

| Total | 112.9 | 138.3 | 1425.7 | 2252.0 | 58.3 | 56.7 | ||

| Benefit | Crop sales | 243.2 | 283.9 | 243.2 | 283.9 | 243.2 | 283.9 | |

| Power sales | - | - | 530.5 | 851.6 | - | - | ||

| REC sales | - | - | 507.4 | 814.6 | - | - | ||

| Yield increase | - | - | 73.0 | 85.2 | 73.0 | 85.2 | ||

| Total | 243.2 | 283.9 | 2800.2 | 4352.1 | 58.3 | 56.7 | ||

| Variable | Input Range |

|---|---|

| SMP + REC (KRW/kWh) | 100~500 |

| Gas supply price (KRW/Nm³) | 500~1000 |

| Subsidy for fuel cell installation cost (%) | 10~90 |

| Subsidy for fuel cell maintenance cost (%) | 10~90 |

| Subsidy for heat utilization facility cost (%) | 10~90 |

| Subsidy for heat utilization facility maintenance cost (%) | 10~90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-s.; Shin, H.; Park, C.; Park, M.-L.; Choi, Y. Economic Feasibility Analysis of Greenhouse–Fuel Cell Convergence Systems. Sustainability 2024, 16, 74. https://doi.org/10.3390/su16010074

Lee C-s, Shin H, Park C, Park M-L, Choi Y. Economic Feasibility Analysis of Greenhouse–Fuel Cell Convergence Systems. Sustainability. 2024; 16(1):74. https://doi.org/10.3390/su16010074

Chicago/Turabian StyleLee, Chul-sung, Hyungjin Shin, Changi Park, Mi-Lan Park, and Young Choi. 2024. "Economic Feasibility Analysis of Greenhouse–Fuel Cell Convergence Systems" Sustainability 16, no. 1: 74. https://doi.org/10.3390/su16010074

APA StyleLee, C. -s., Shin, H., Park, C., Park, M. -L., & Choi, Y. (2024). Economic Feasibility Analysis of Greenhouse–Fuel Cell Convergence Systems. Sustainability, 16(1), 74. https://doi.org/10.3390/su16010074