Assessing the Benefits of Electrification for the Mackinac Island Ferry from an Environmental and Economic Perspective

Abstract

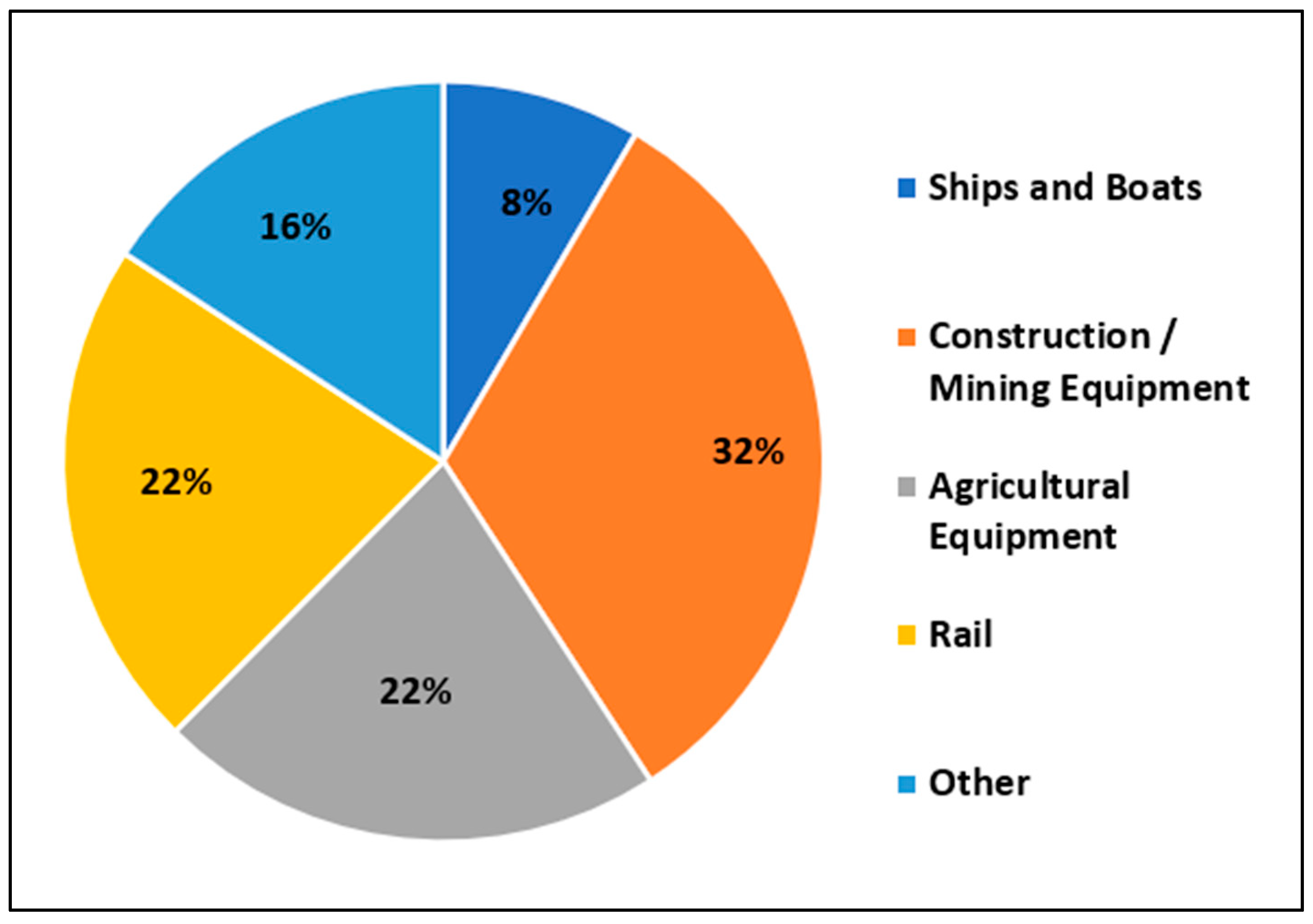

1. Introduction

2. Goal and Motivation

- Technological readiness—Is it physically possible to convert the Voyager into a battery electric vehicle based on the current commercially available technology?

- Environmental impact—Does it benefit the environment to convert the Voyager into a BEV? Will electrifying the ferry be a net benefit in terms of long-term sustainability?

- Economics—Is it economical for the ferry company to convert the Voyager into a BEV?

- (1)

- Replace the ferry’s diesel engines with modern diesel engines.

- (2)

- Convert the ferry to a BEV.

3. Methodology

- The comparison had to be between petroleum diesel IC engine propulsion and pure BEV propulsion. Hybrid electrified configurations were outside the scope of this project, as were alternative and low-carbon fuels. Analyzing these potential alternatives is, however, recommended for future work.

- The speed of the BEV configuration had to match that of the IC engine configuration, so that trip time was not impacted.

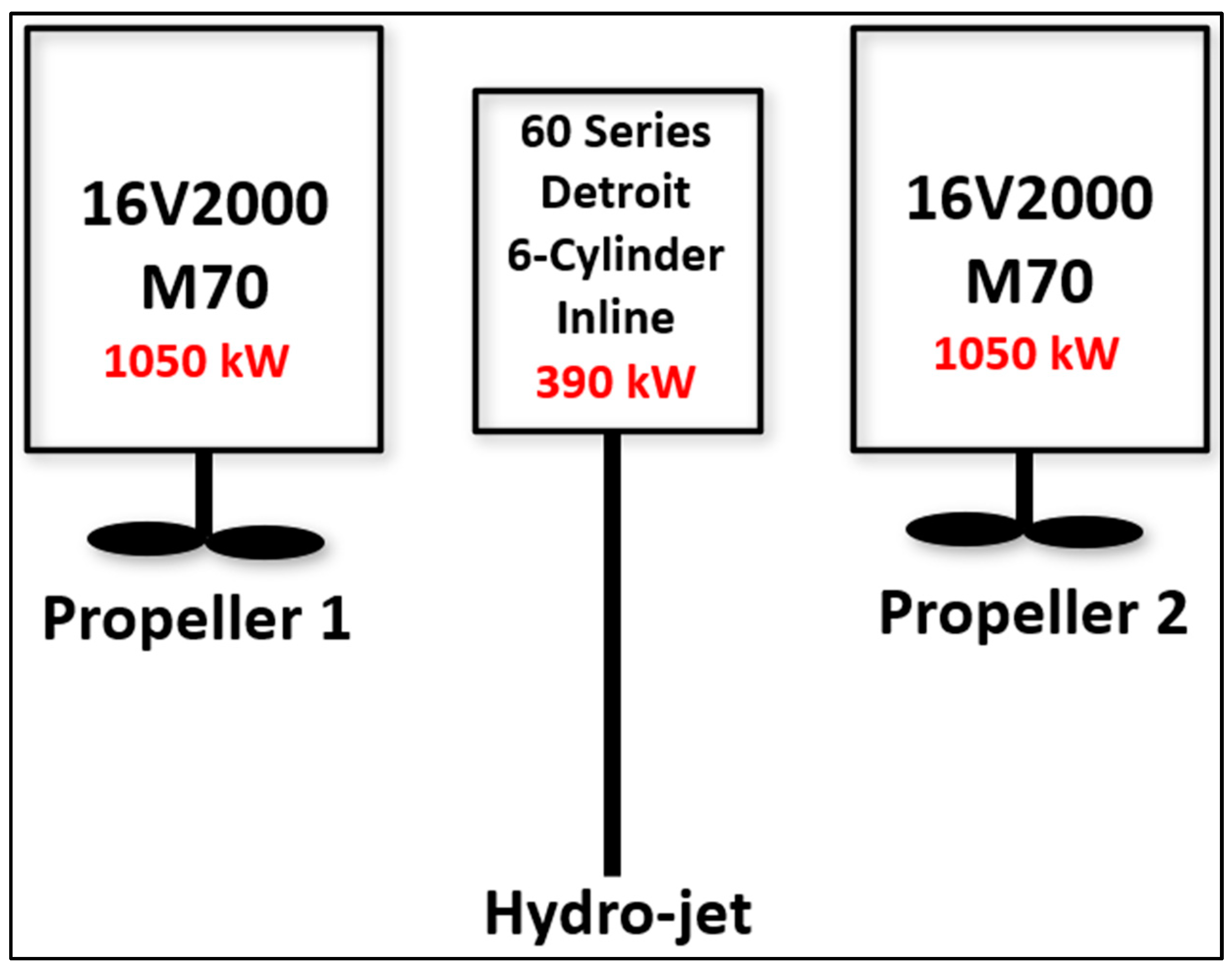

- The hydro-jet, which is a unique feature of the ferry company’s fleet, was to be included in the analysis of both the ICE and BEV configurations.

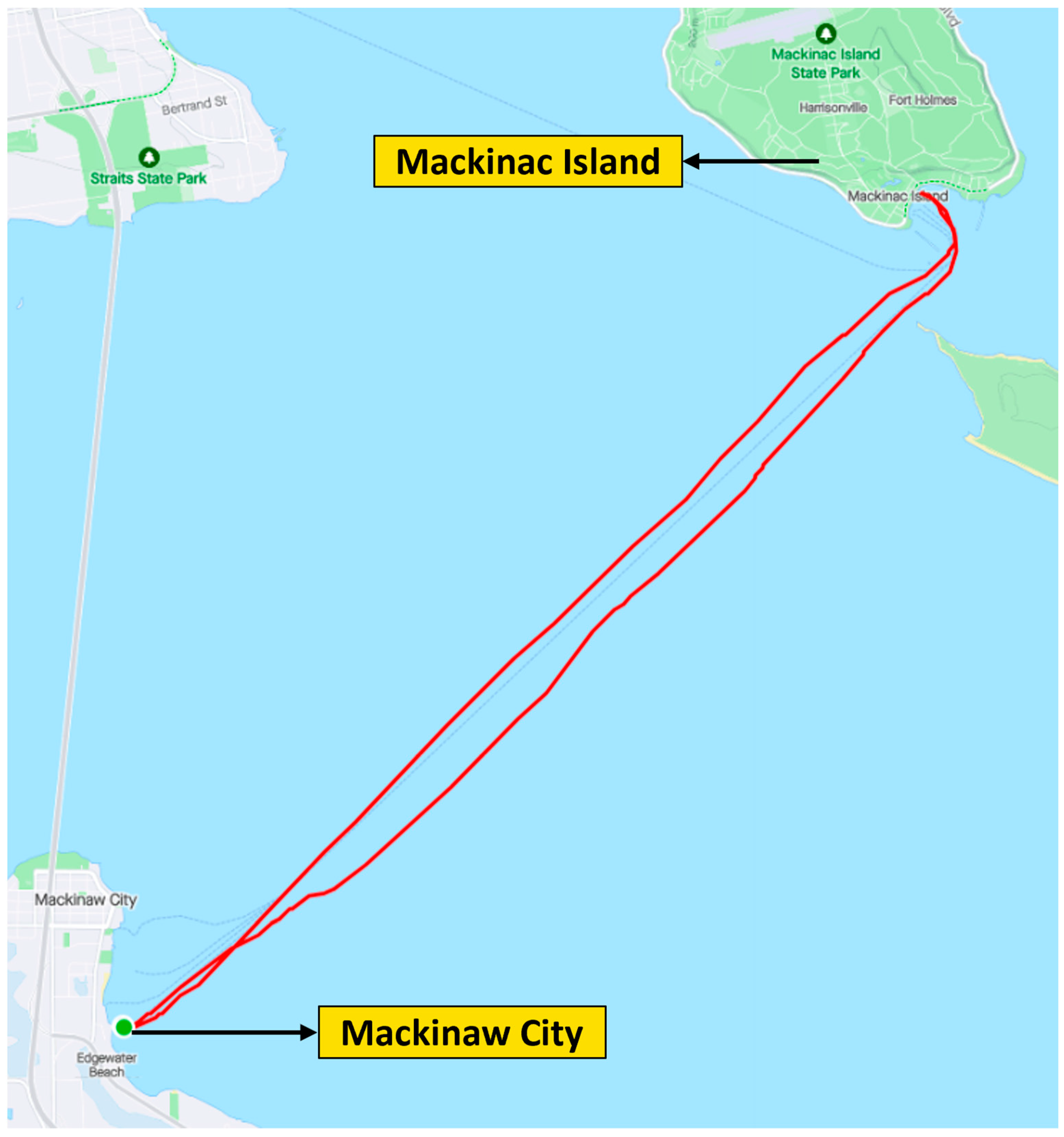

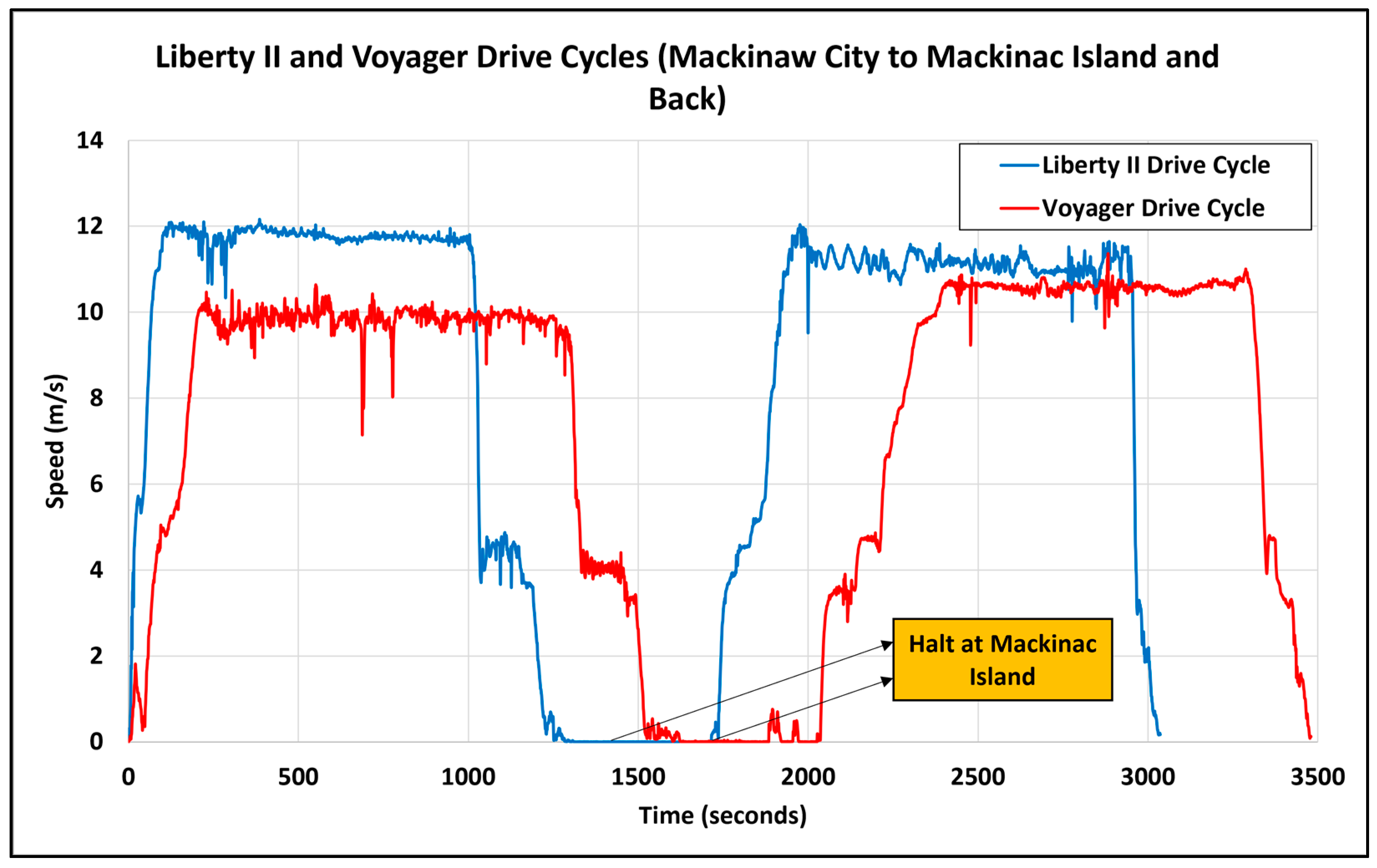

- For the majority of the drive cycle, the ferry cruises at around 12 m/s (26.8 mph or 23.3 knots).

- A total of 90% of the trip’s fuel consumption happens during the cruise portion.

- The ferry is quick to accelerate from 0 speed to cruising speed (approximately 2 min when leaving from Mackinaw City and 4 min when leaving from Mackinac Island).

- The ferry company uses a ‘turn n’ burn’ approach, where docking time is consistently 6 to 8 min. This approach helps them reduce the wait times for passengers at the dock.

- Based on the data collected from the drive cycle of the Liberty II, the fuel consumption was calculated to be 320 L (84.6 gallons) per round trip to and from the island. This included fuel used by the two propulsion engines as well as the hydro-jet engine. The ferry is fueled once at the end of each day and does not require refueling in the middle of operations.

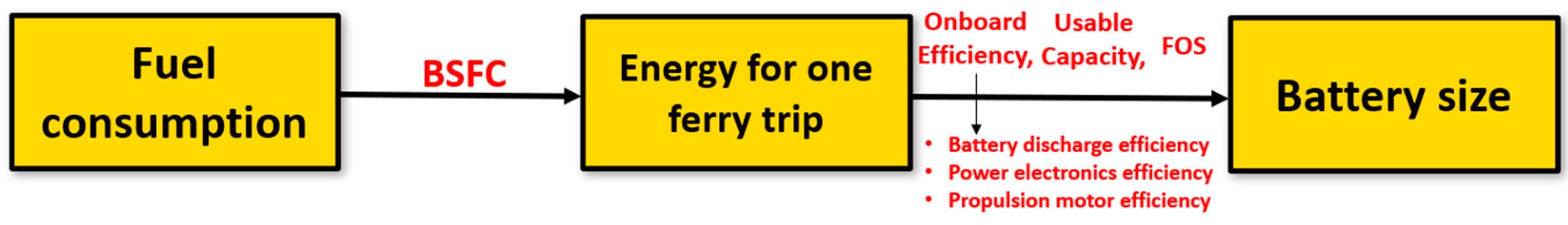

3.1. Battery Sizing

3.2. Motor Sizing

4. Results

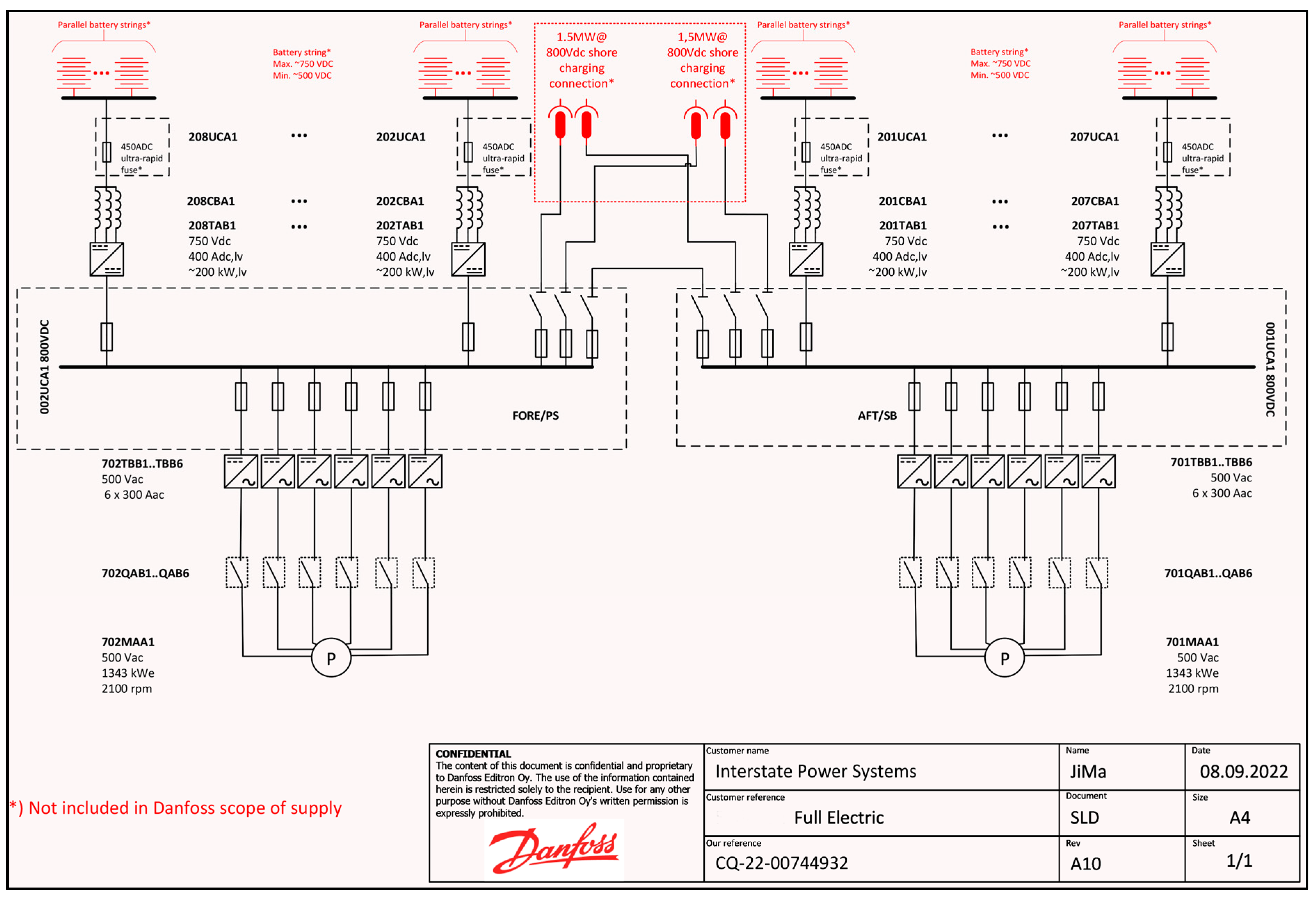

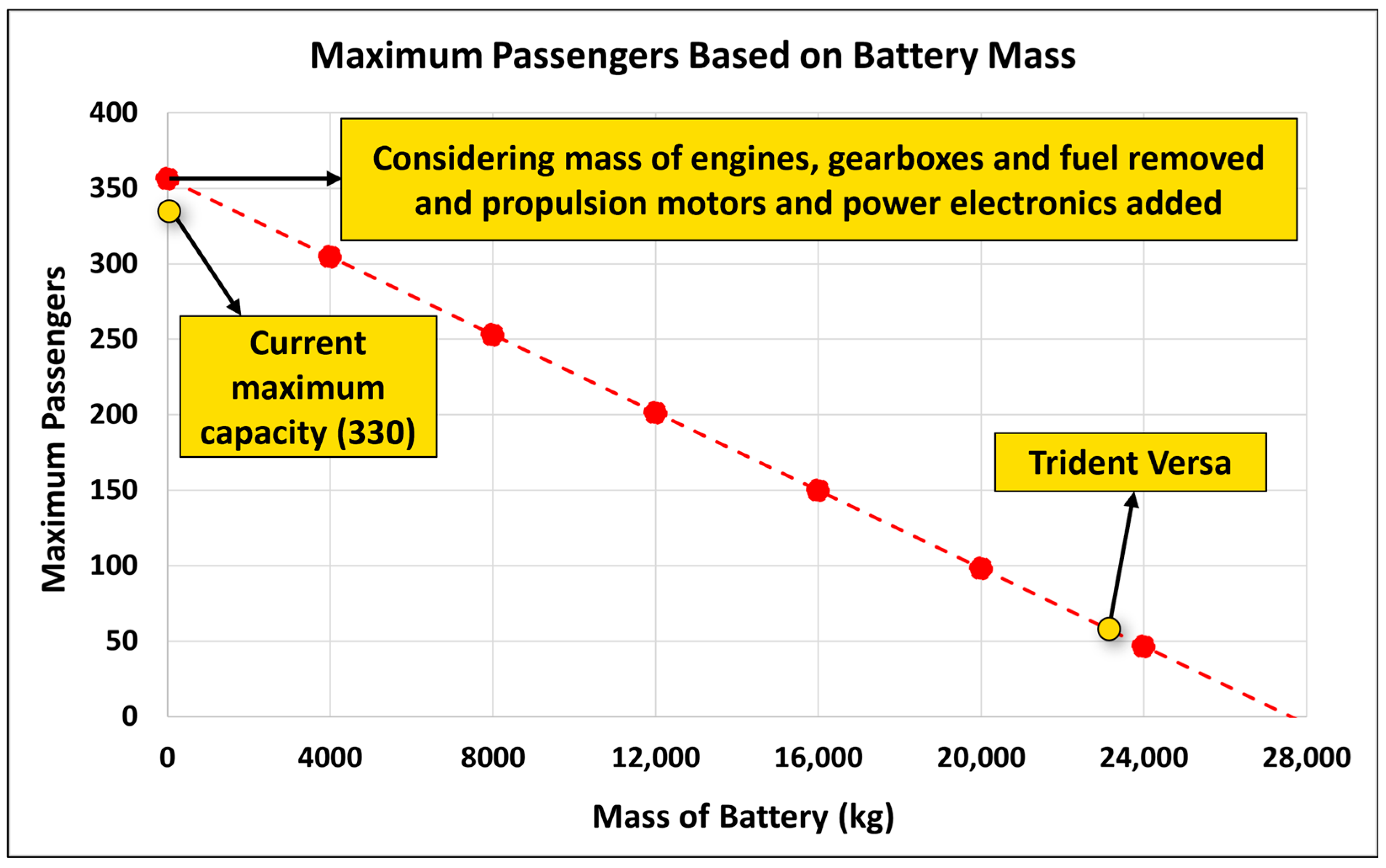

4.1. Technological Readiness and Feasibility of Retrofit

4.2. Environmental Impact

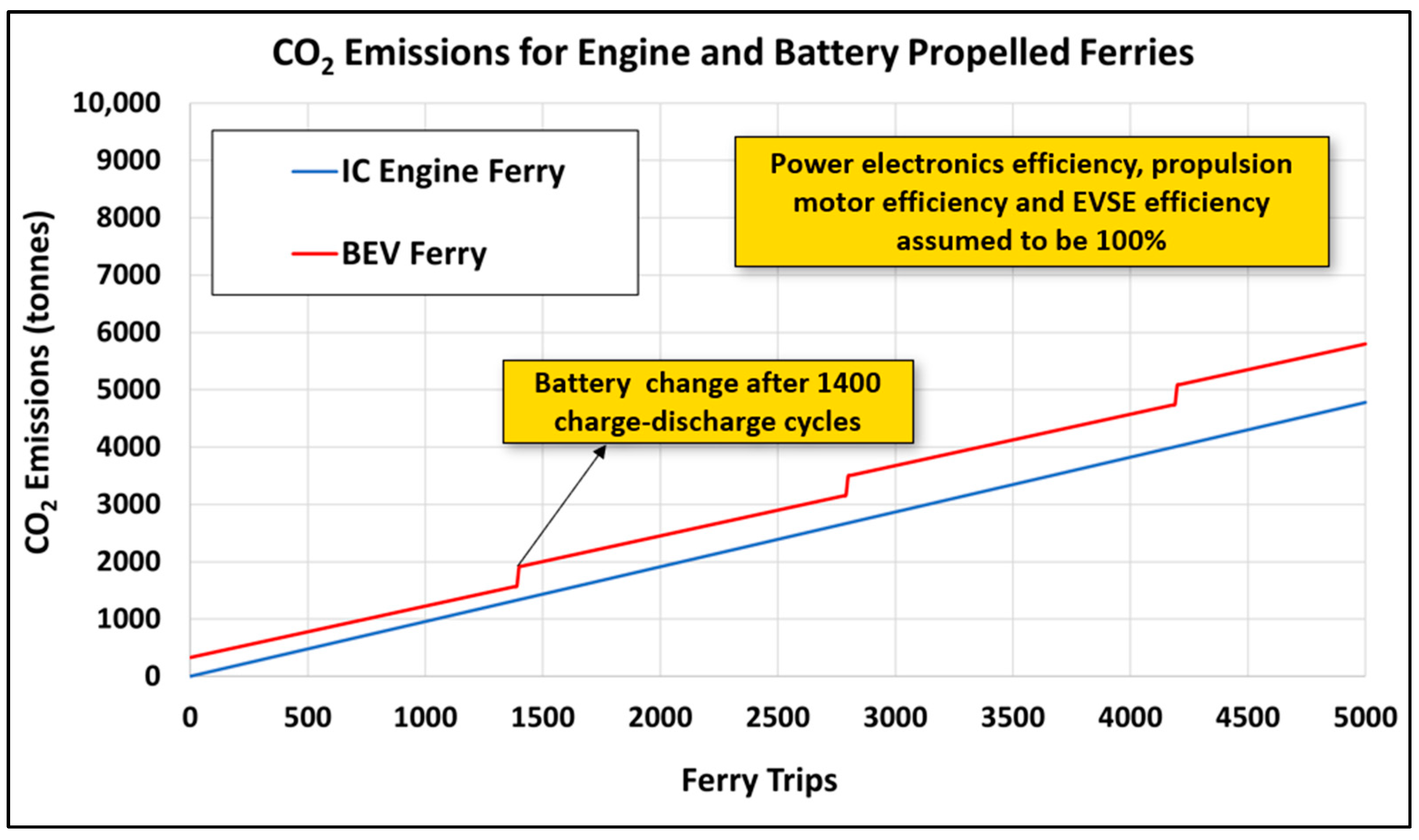

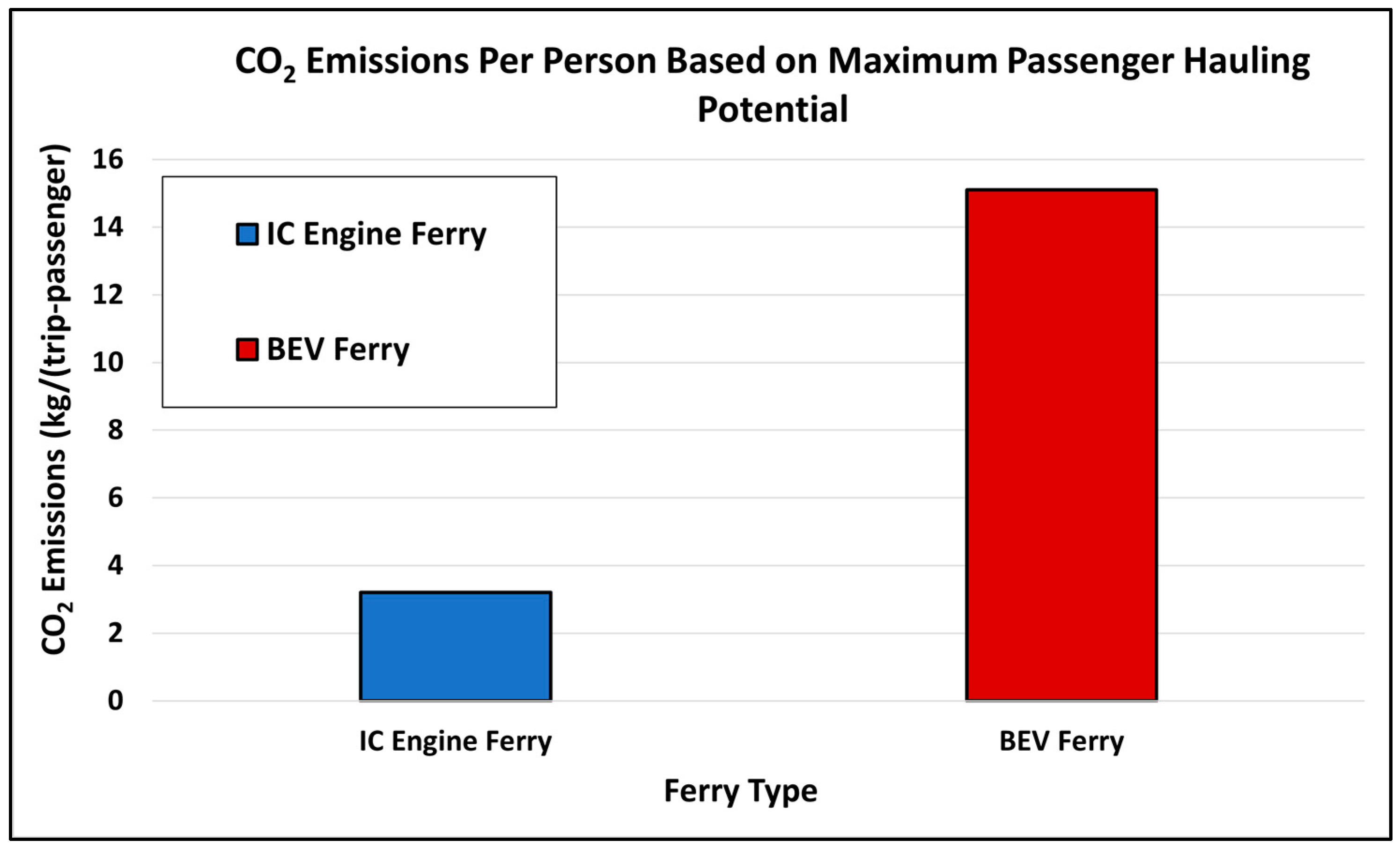

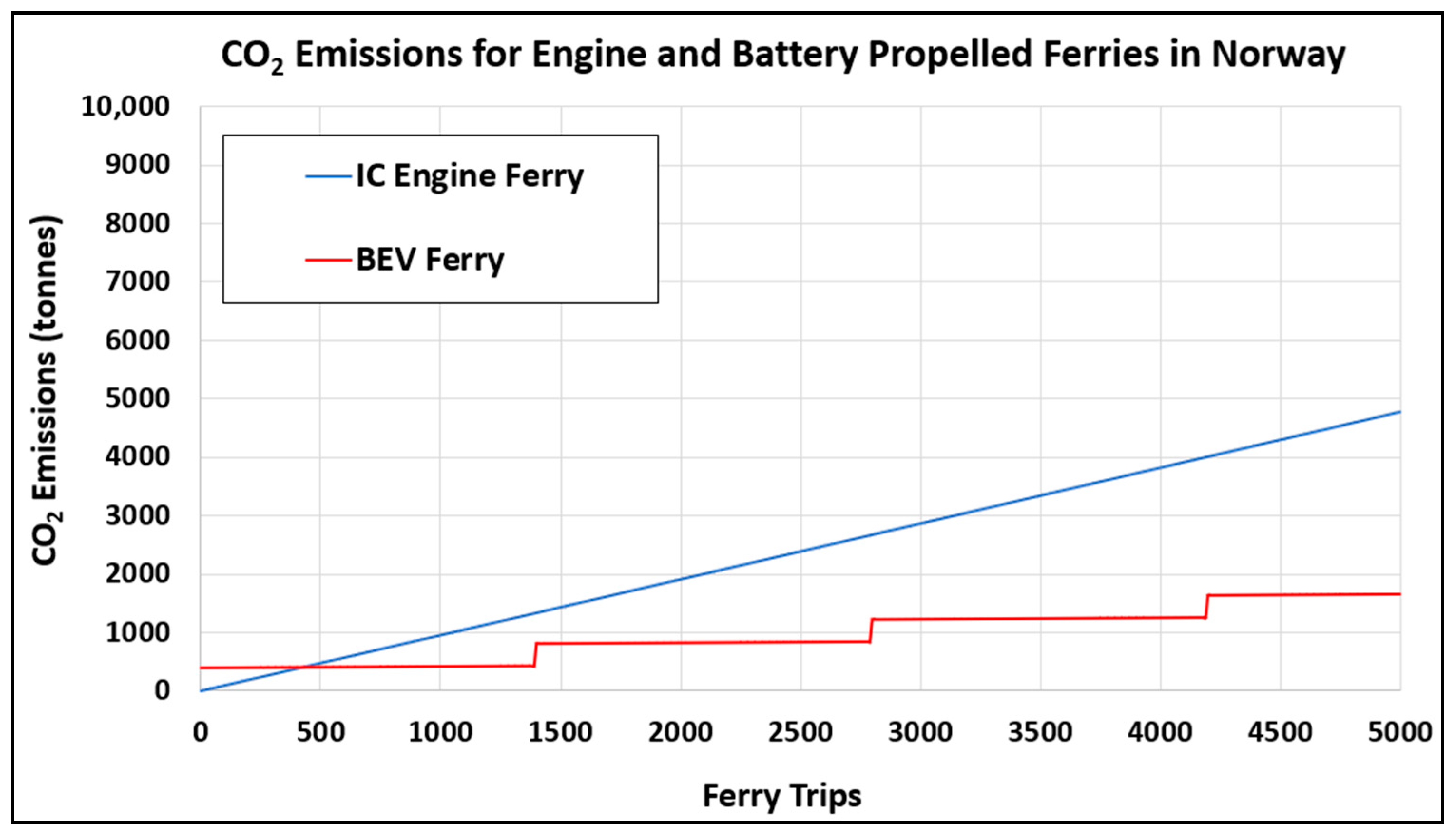

4.2.1. Carbon Dioxide (CO2) Emissions

- (1)

- IC Engine Ferry—955 kg CO2 per ferry trip to and from Mackinac Island.

- (2)

- Fully Electric Ferry—1103 kg CO2 per ferry trip to and from Mackinac Island.

- (1)

- IC Engine Ferry—811 kg CO2 per ferry trip to and from Mackinac Island.

- (2)

- Fully Electric Ferry—1057 kg CO2 per ferry trip to and from Mackinac Island.

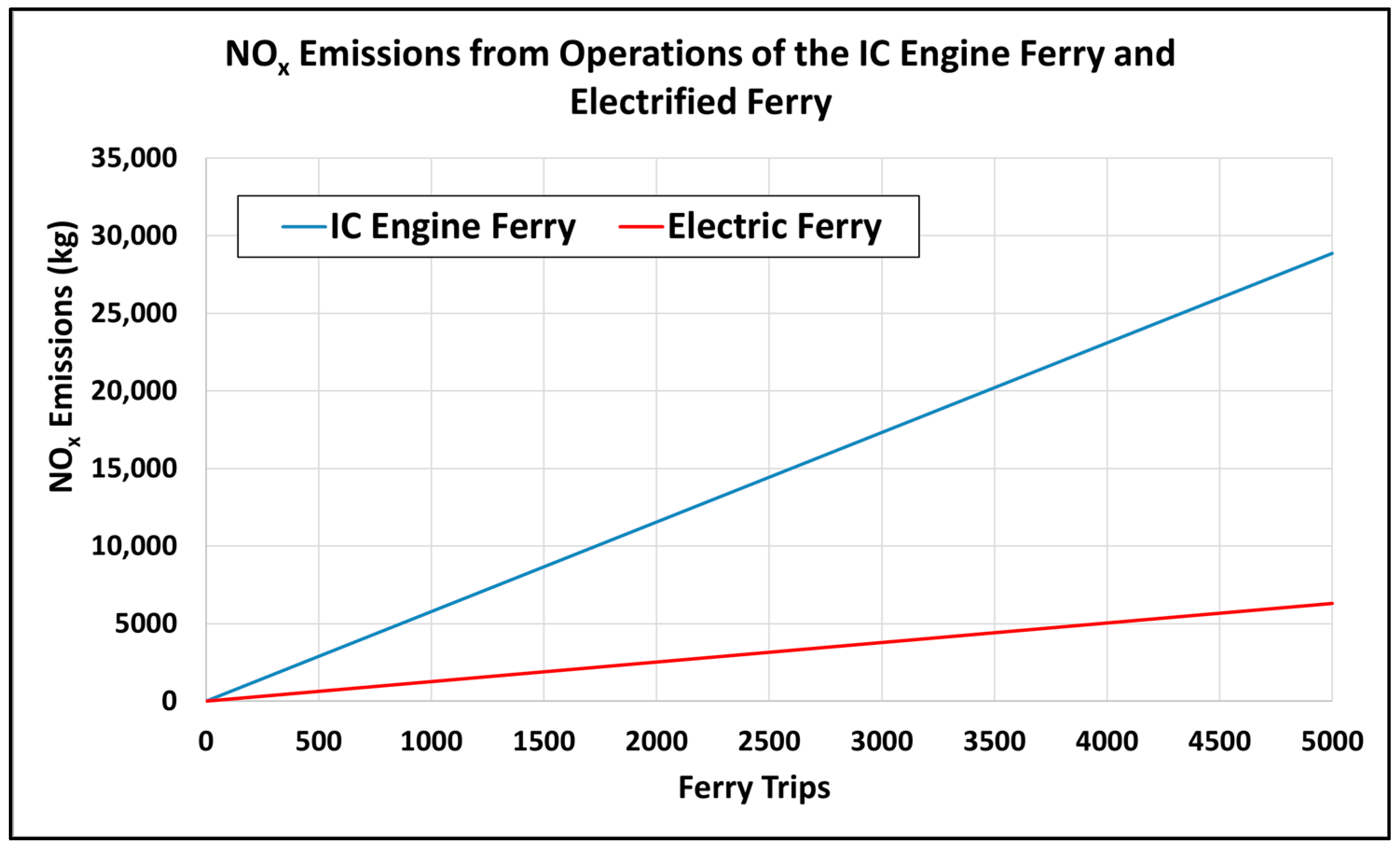

4.2.2. Nitrogen Oxides (NOx) and Sulphur Dioxide (SO2) Emissions

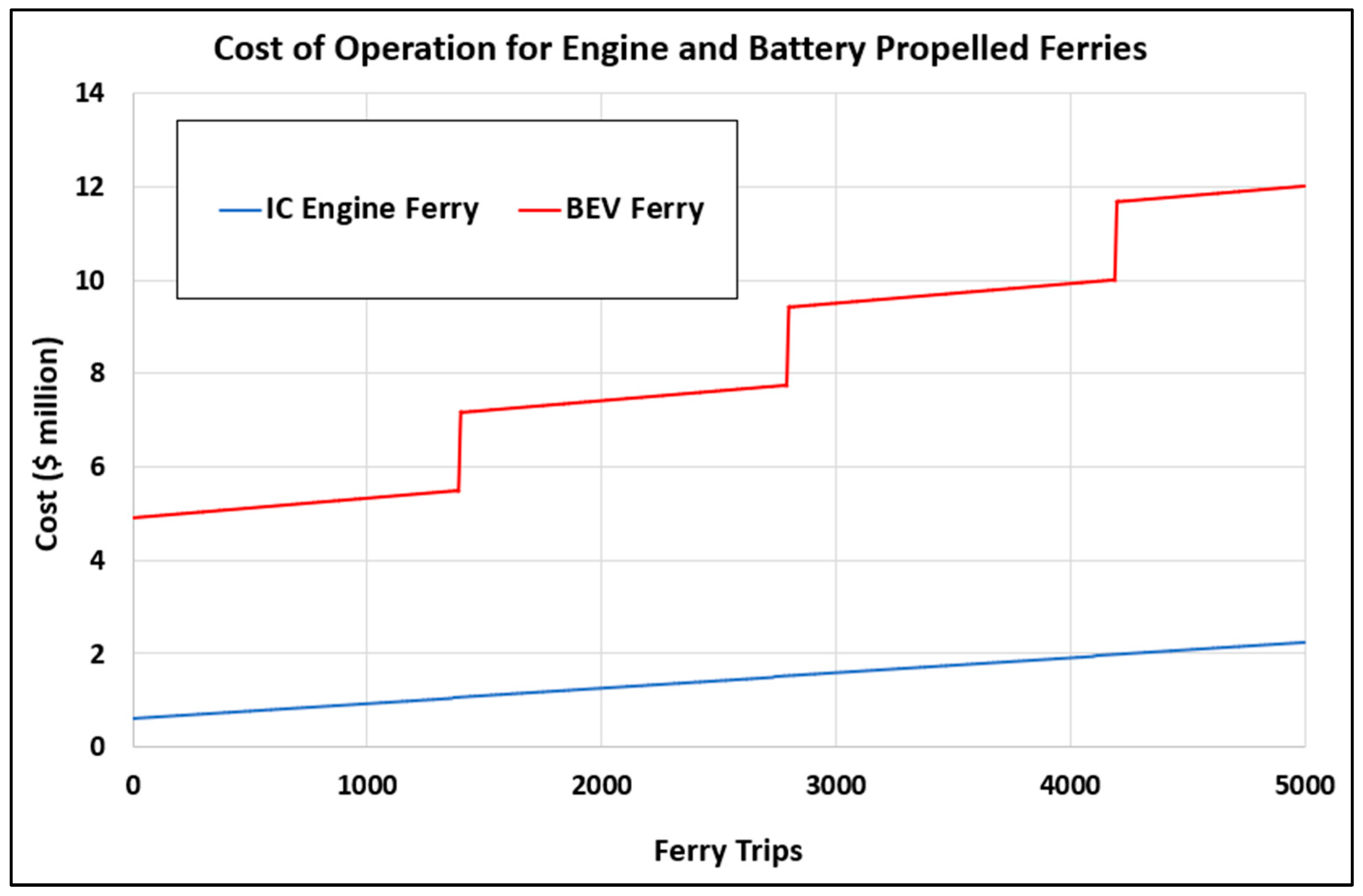

4.3. Economic Analysis

- Initial capital—This includes the cost of engines for the IC engine ferry and cost of the battery, motors, power electronics, and charging infrastructure for the BEV ferry.

- Running costs—Running costs include cost of fuel and electricity. For the IC engine ferry, it includes yearly engine maintenance and oil changes. For the BEV ferry, it includes regular battery changes.

5. Discussion

6. Conclusions

- Technological feasibility

- Environmental impact

- Economic analysis

- Technological feasibility—It is possible to retrofit the current IC engine ferry into an electric ferry. The required components currently exist in the market. This assumes that the charging infrastructure required for the electrification of the ferry can be made available at the location.

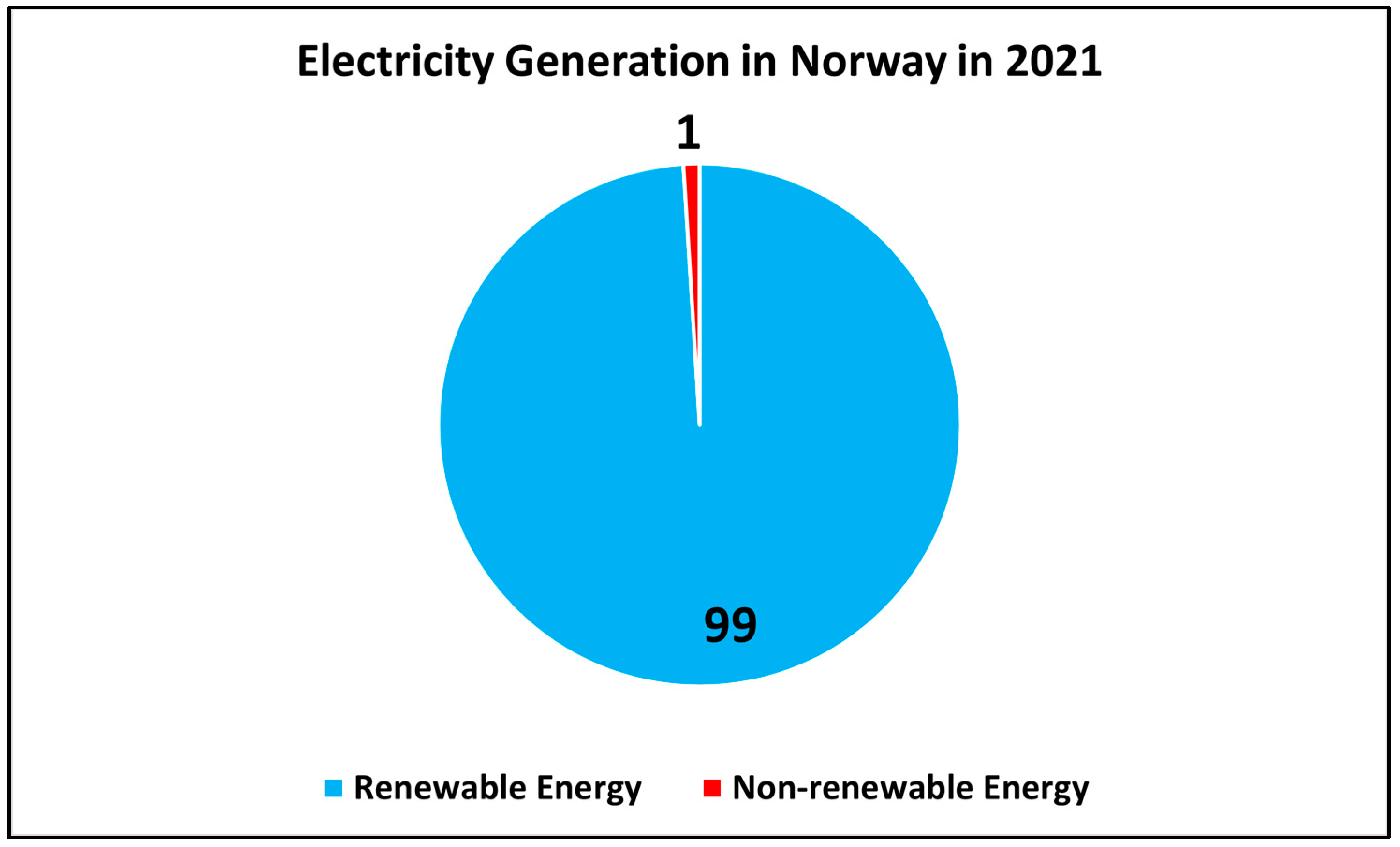

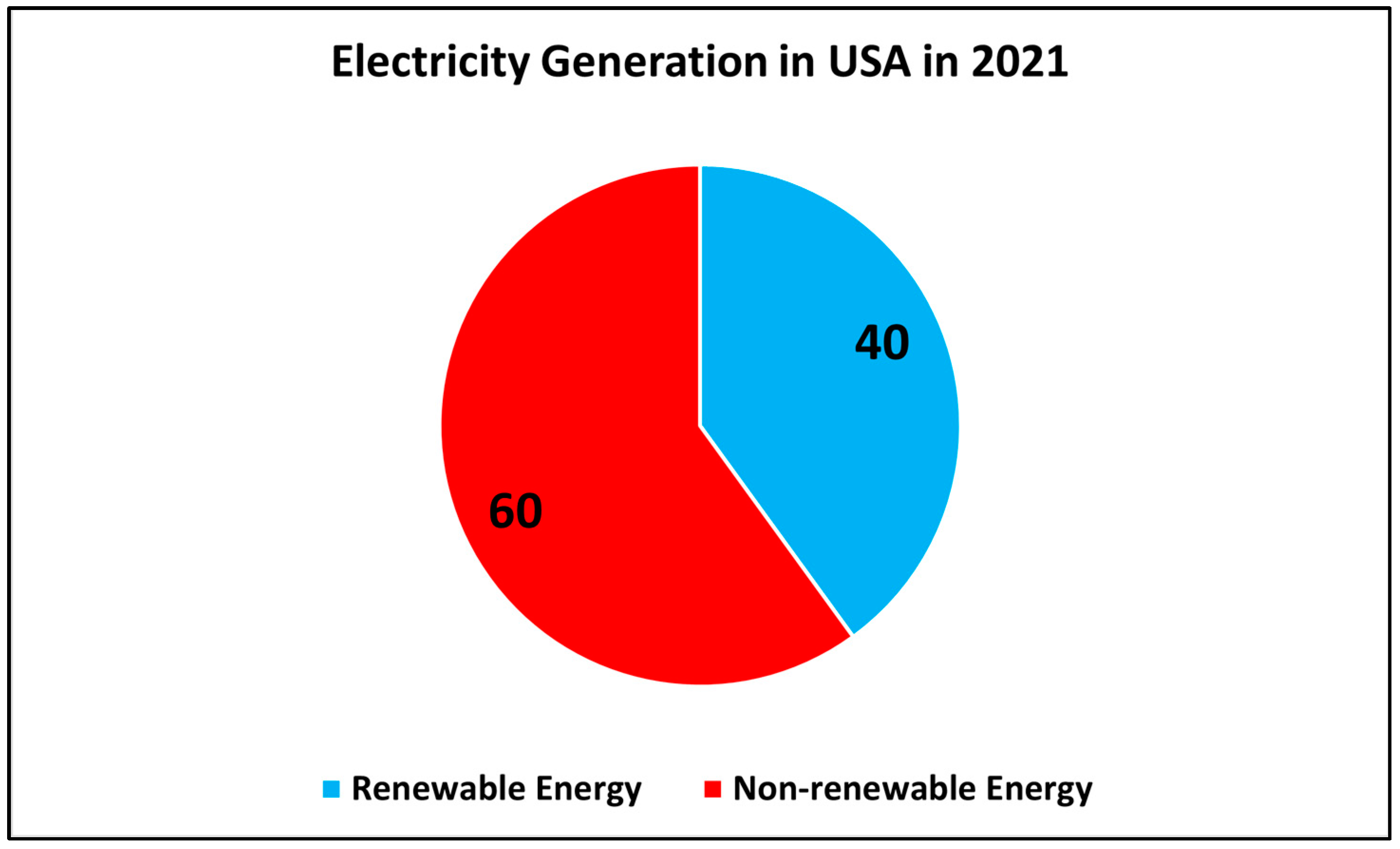

- Environmental impact

- ○

- Electrification will increase the CO2 emissions of the ferry, due to the mix of power generation in Michigan and the energy intensive Li-ion battery manufacturing process. Over 5000 ferry trips (3.5 seasons), the BEV ferry will have 48% higher CO2 emissions than the IC engine ferry.

- ○

- From a decarbonization perspective, full electrification of the ferry is not the most sustainable solution.

- ○

- There is an 80% reduction in NOx emissions with electrification but a significant rise in SO2 emissions.

- ○

- Recyclability/reusability of the spent Li-ion batteries were not within the scope of this project.

- Economic analysis

- ○

- Based on a simplistic model and without the including the potential government grants, an electrified ferry is unlikely to be as profitable as an ICE-powered ferry due to increased costs of demand charge, regular changes to the Li-ion battery, initial infrastructure costs, and reduced passengers.

- ○

- The revenue from the BEV ferry will be 23.5% lower than that of the IC engine ferry.

- ○

- Battery mass will have a significant impact on passenger count and, in turn, the overall revenue and profit.

7. Potential for Future Work

- The analysis conducted in this study should be repeated every few years. With technological advancements and decarbonization of the grid, there is a possibility of the scales tipping in favor of electrification in the future.

- A similar analysis should be conducted for alternative configurations such as ultracapacitors, fuel cells, or a hybrid approach.

- Alternative fuels such as hydrogen, natural gas, and low-carbon fuels should be considered for the IC engine configuration of the ferry for reducing CO2 emissions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BEV | Battery Electric Vehicle |

| BOM | Bill of Materials |

| BSFC | Brake Specific Fuel Consumption |

| CO2 | Carbon Dioxide |

| DoD | Depth of Discharge |

| EIA | Energy Information Administration |

| Eff. | Efficiency |

| EVSE | Electric Vehicle Supply Equipment |

| FOS | Factor of Safety |

| IMO | International Maritime Organization |

| MEA | Mackinac Economic Alliance |

| MEDC | Michigan Economic Development Corporation |

| GHG | Greenhouse Gas |

| GREET | Greenhouse Gases, Regulated Emissions, and Energy use in Technologies |

| ICE | Internal Combustion Engine |

| LCA | Life-cycle Assessment |

| LHV | Lower Heating Value |

| NG | Natural Gas |

| NOx | Oxides of Nitrogen |

| SLD | Single-Line Diagram |

| SO2 | Sulfur Dioxide |

| USCG | United States Coast Guard |

| ULSD | Ultra-Low-Sulfur Diesel |

| USA | United States of America |

Appendix A

Appendix B

| Parameter | Value |

|---|---|

| Li-ion battery manufacture emissions (kg CO2-eq/kWh) [14,15] | 162 |

| NG power plant efficiency (%) [17] | 44 |

| Coal-fired power plant efficiency (%) [17] | 32 |

| CO2 emissions from the combustion of 1 kg diesel (kg) [13] | 2.9937 |

| CO2 emissions from 1 kWh of electricity on the grid from combustion of NG (kg) [13] | 0.4090 |

| CO2 emissions from 1 kWh of electricity on the grid from combustion of coal (kg) [13] | 1.0487 |

| Well-to-pump emissions from 1 kWh energy on the grid from natural gas (kg) [13] | 0.0419 |

| Well-to-pump emissions from 1 kWh energy on the grid from coal (kg) [13] | 0.0171 |

Appendix C

| Parameter | Cost (USD) |

|---|---|

| Cost of new engines (two engines) (discussions with Interstate Power Systems) | 600,000 |

| Cost of offroad diesel per gallon (purchased in bulk) (discussions with Interstate Power Systems) | 3.75 |

| Yearly cost of engine maintenance for the IC engine ferry (discussions with Interstate Power Systems) | 10,000 |

| Yearly cost of oil changes for the IC engine ferry (discussions with Interstate Power Systems) | 5000 |

| Parameter | Cost (USD) |

|---|---|

| Cost of a battery per kWh (discussions with Spear Power Systems) | 700 |

| Commercial electricity cost in Mackinaw City and St. Ignace per kWh [29] | 0.1089 |

| Demand charge in Mackinaw City and St. Ignace per kW | 16.4 |

| Battery engineering cost (discussions with Spear Power Systems) | 100,000 |

| Propulsion engineering cost (discussions with Principal Investigators from current and previous APS LABS projects) | 100,000 |

| Control engineering cost (discussions with Principal Investigators from current and previous APS LABS projects) | 50,000 |

| High voltage system engineering cost (discussions with Principal Investigators from current and previous APS LABS projects) | 50,000 |

| Cost motors (for propulsion) (emails with ABB) | 200,000 |

| Cost of motor (for the tail jet) (discussions with Principal Investigators from current and previous APS LABS projects) | 23,000 |

| Cost of inverters and power electronics (discussions with Principal Investigators from current and previous APS LABS projects) | 200,000 |

| Cost of shore power upgrades (discussions with Principal Investigators from current and previous APS LABS projects) | 1,530,000 |

| Shipyard costs for retrofitting the ferry (discussions with Interstate Power Systems) | 1,000,000 |

| Component | Mass (kg) |

|---|---|

| Battery mass (discussions with Spear Power Systems) | 23,553 |

| Mass of propulsion motors (two motors) (discussions with Interstate Power Systems) | 5000 |

| Mass of propulsion power electronics (discussions with Interstate Power Systems) | 2822 |

| Mass of motor (tail jet) (discussions with Interstate Power Systems) | 190 |

| Mass of power electronics for charging (discussions with Interstate Power Systems) | 1740 |

| Mass of 16V92 [30] | 2200 |

| Mass of 12V71 [31] | 1610 |

| Mass of fuel [12] | 4163 |

Appendix D

References

- Schnurr, R.E.J.; Walker, T.R. Marine transportation and energy use. Ref. Modul. Earth Syst. Environ. Sci. 2019, 1–9. [Google Scholar] [CrossRef]

- DNV GL. Maritime Forecast to 2050, Energy Transition Outlook 2019; DNV GL: Høvik, Norway, 2019. [Google Scholar]

- Yuan, Y.; Wang, J.; Yan, X.; Li, Q.; Long, T. A design and experimental investigation of a large-scale solar energy/diesel generator powered hybrid ship. Energy 2018, 165, 965–978. [Google Scholar] [CrossRef]

- Hansen, J.F.; Wendt, F. History and state of the art in commercial electric ship propulsion, integrated power systems, and future trends. Proc. IEEE 2015, 103, 2229–2242. [Google Scholar] [CrossRef]

- Dedes, E.K.; Hudson, D.A.; Turnock, S.R. Assessing the potential of hybrid energy technology to reduce exhaust emissions from global shipping. Energy Policy 2012, 40, 204–218. [Google Scholar] [CrossRef]

- Anwar, S.; Zia, M.Y.; Rashid, M.; Rubens, G.Z.; Enevoldsen, P. Towards ferry electrification in the maritime sector. Energies 2020, 13, 6506. [Google Scholar] [CrossRef]

- Statista. Available online: https://www.statista.com/statistics/264036/number-of-passenger-ships-in-the-world-merchant-fleet/ (accessed on 20 December 2022).

- Statista. Available online: https://www.statista.com/statistics/1025497/distribution-of-electricity-production-in-norway-by-source/ (accessed on 20 December 2022).

- Statista. Available online: https://www.statista.com/statistics/528603/distribution-electricity-net-generation-in-the-us-by-fuel-type/ (accessed on 20 December 2022).

- Energy Information Administration (EIA). Available online: https://www.eia.gov/state/?sid=MI#tabs-4 (accessed on 20 December 2022).

- Energy Information Administration (EIA). Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2020 (accessed on 20 December 2022).

- Engineering Toolbox. Available online: https://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html (accessed on 20 December 2022).

- Energy Information Administration (EIA). Available online: https://www.eia.gov/environment/emissions/co2_vol_mass.php (accessed on 20 December 2022).

- GREET®, 2020. Life-Cycle Assessment Tool. Argonne National Lab: Chicago, IL, USA, 2020.

- Kim, H.C.; Wallington, T.J.; Arsenault, R.; Bae, C.; Ahn, S.; Lee, J. Cradle-to-gate emissions from a commercial electric vehicle Li-ion battery: A comparative analysis. Environ. Sci. Technol. 2016, 50, 7715–7722. [Google Scholar] [CrossRef] [PubMed]

- Energy Information Administration (EIA). Available online: https://www.eia.gov/tools/faqs/faq.php?id=105&t=3 (accessed on 20 December 2022).

- Energy Information Administration (EIA). Available online: https://www.eia.gov/electricity/annual/html/epa_08_01.html (accessed on 20 December 2022).

- Environmental Protection Agency (EPA). Available online: https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=P100ZP4H.pdf (accessed on 20 December 2022).

- DieselNet. Available online: https://dieselnet.com/standards/us/marine.php (accessed on 20 December 2022).

- Energy Information Administration (EIA). Available online: https://www.eia.gov/electricity/state/michigan/ (accessed on 20 December 2022).

- US Department of Health and Human Services. Available online: https://www.cdc.gov/nchs/data/series/sr_03/sr03-046-508.pdf (accessed on 20 December 2022).

- Sundvor, I.; Thorne, R.J.; Danebergs, J.; Aarskog, F.; Weber, C. Estimating the replacement potential of Norwegian high-speed passenger vessels with zero-emission solutions. Transp. Res. Part D Transp. Environ. 2021, 99, 103019. [Google Scholar] [CrossRef]

- Stoke, E.A. Volume 4 Naval Architecture for Marine Engineers; Thomas Reed Publications: Boston, MA, USA, 1963. [Google Scholar]

- Otsason, R.; Tapaninen, U. Decarbonizing City Water Traffic: Case of Comparing Electric and Diesel-Powered Ferries. Sustainability 2023, 15, 16170. [Google Scholar] [CrossRef]

- Statista. Available online: https://www.statista.com/statistics/1234898/belgium-distribution-of-electricity-production-by-source/ (accessed on 20 December 2022).

- Trieste, S.; Hmam, S.; Olivier, J.C.; Bourguet, S.; Loron, L. Techno-economic optimization of a supercapacitor-based energy storage unit chain: Application on the first quick charge plug-in ferry. Appl. Energy 2015, 153, 3–14. [Google Scholar] [CrossRef]

- Cha, M.; Enshaei, H.; Nguyen, H.; Jayasinghe, S.G. Towards a future electric ferry using optimisation-based power management strategy in fuel cell and battery vehicle application—A review. Renew. Sustain. Energy Rev. 2023, 183, 113470. [Google Scholar] [CrossRef]

- Burton, T.; Powers, S.; Burns, C.; Conway, G.; Leach, F.; Senecal, K. A data-driven greenhouse gas emission rate analysis for vehicle comparisons. SAE Int. J. Electrified Veh. 2023, 12, 91–127. [Google Scholar] [CrossRef]

- Find Energy. Available online: https://findenergy.com/mi/mackinac-county-electricity/ (accessed on 20 December 2022).

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Detroit_Diesel_Series_92 (accessed on 20 December 2022).

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Detroit_Diesel_Series_71 (accessed on 20 December 2022).

| Type | Electricity Generation (GWh) | Percentage |

|---|---|---|

| Natural gas | 3523 | 35.6% |

| Coal | 2984 | 30.1% |

| Nuclear | 2296 | 23.2% |

| Renewable | 1104 | 11.1% |

| Parameter | Value |

|---|---|

| Engine BSFC (g/kWh) | 205 |

| Fuel lower heating value MJ/kg [12] | 42.6 |

| Battery discharge efficiency (%) (discussions with Spear Power Systems) | 96.9 |

| Power electronics efficiency (%) (no sources were found for these parameters for this application specifically; values have been chosen based on other current projects being conducted at APS LABS) | 95 |

| Propulsion motor efficiency (%) (discussions with Spear Power Systems) | 90 |

| Electric vehicle supply equipment (EVSE) efficiency | 95 |

| Usable capacity/depth of discharge (%) | 80 |

| Factor of Safety | 1.2 |

| IC Engine Ferry | Electric Ferry | ||

|---|---|---|---|

| Average Weekday Passengers | Average Weekend Passengers | Average Weekday Passengers | Average Weekend Passengers |

| 35 | 50 | 35 | 50 |

| 70 | 100 | 70 | 73 |

| 95 | 150 | 73 | 73 |

| 95 | 150 | 73 | 73 |

| 95 | 150 | 73 | 73 |

| 70 | 100 | 70 | 73 |

| 35 | 50 | 35 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gopujkar, S.; Worm, J. Assessing the Benefits of Electrification for the Mackinac Island Ferry from an Environmental and Economic Perspective. Sustainability 2024, 16, 4297. https://doi.org/10.3390/su16104297

Gopujkar S, Worm J. Assessing the Benefits of Electrification for the Mackinac Island Ferry from an Environmental and Economic Perspective. Sustainability. 2024; 16(10):4297. https://doi.org/10.3390/su16104297

Chicago/Turabian StyleGopujkar, Siddharth, and Jeremy Worm. 2024. "Assessing the Benefits of Electrification for the Mackinac Island Ferry from an Environmental and Economic Perspective" Sustainability 16, no. 10: 4297. https://doi.org/10.3390/su16104297

APA StyleGopujkar, S., & Worm, J. (2024). Assessing the Benefits of Electrification for the Mackinac Island Ferry from an Environmental and Economic Perspective. Sustainability, 16(10), 4297. https://doi.org/10.3390/su16104297