Environmental and Economic Performance of Greenhouse Cropping in the Mediterranean Basin: Lessons Learnt from a Cross-Country Comparison

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope Definition

2.1.1. Case Studies

Tuscany, Italy (43°07′30″ N; 10°38′24″ E)

Almería, Spain (36°51′46″ N, 2°17′04″ W)

Monastir, Tunisia (35°45′18″ N, 10°49′16″ E)

Antalya, Turkey (36°58′13″ N, 30°56′08″ E)

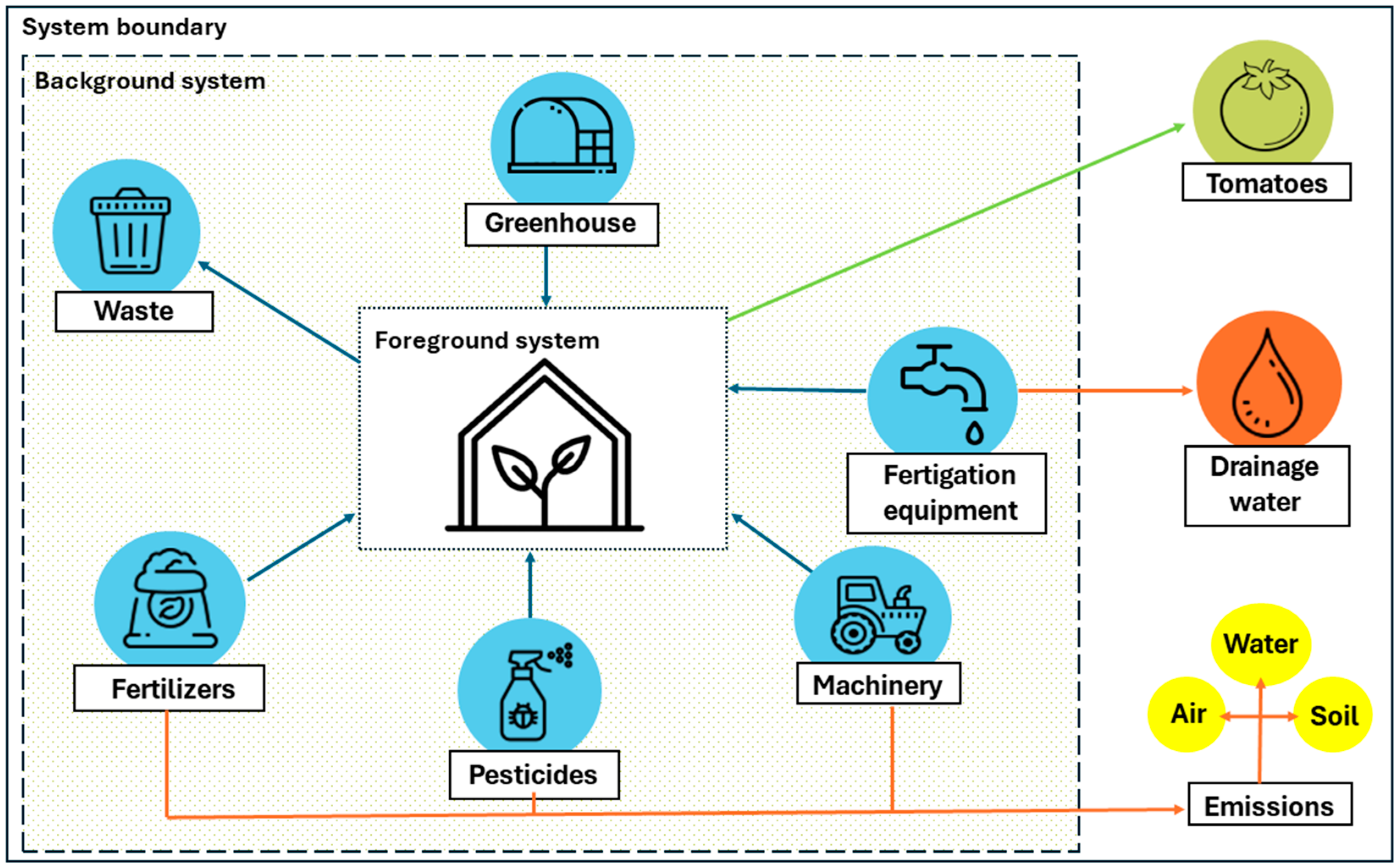

2.1.2. System Boundaries

2.2. Life Cycle Inventory Analysis

2.2.1. Materials and Resources

2.2.2. Direct Emissions

2.3. Life Cycle Impact Assessment

2.4. Interpretation, Normalization, and Hotspot Analysis

3. Results

3.1. Impact Assessment

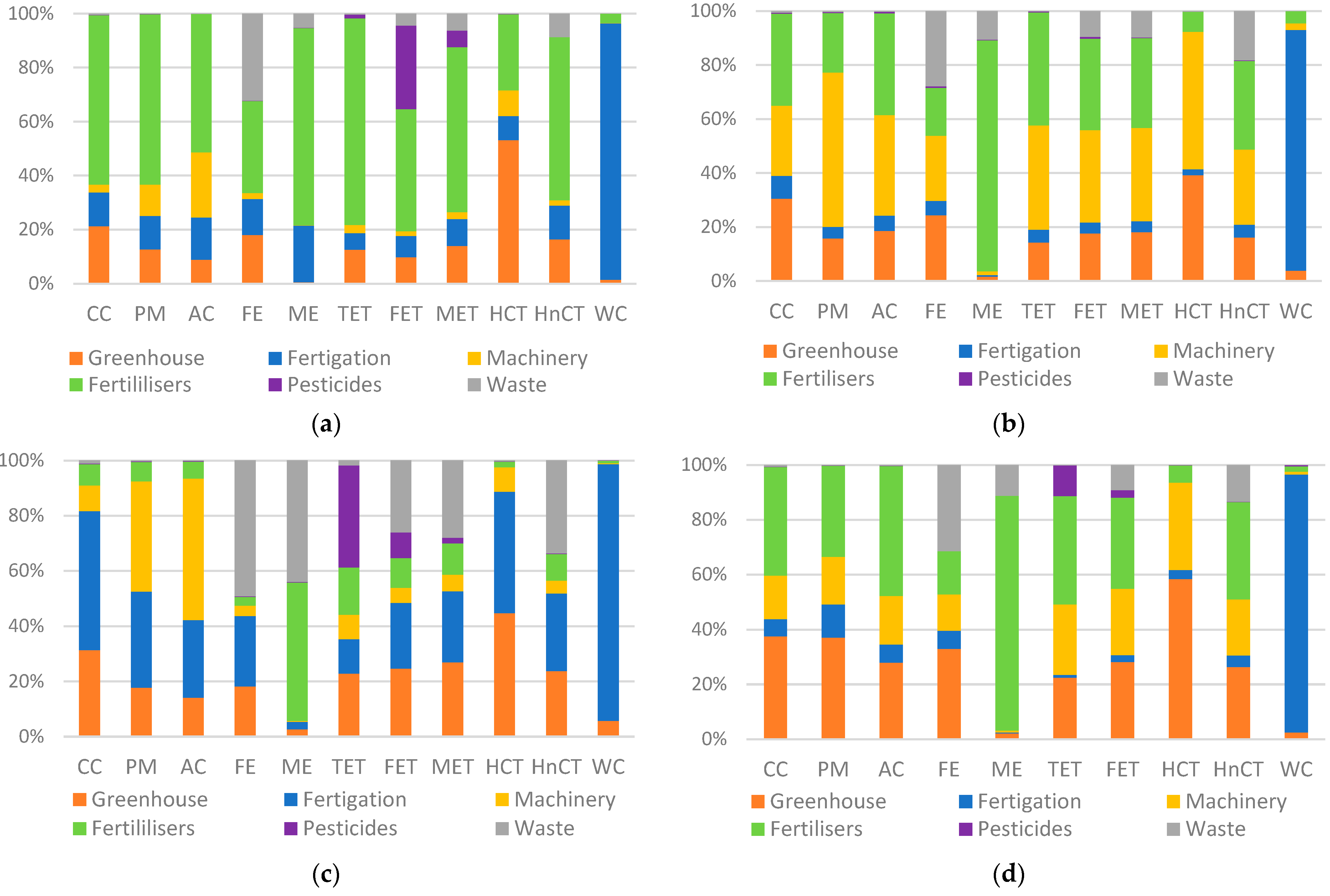

3.2. Hotspot Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AC | Terrestrial acidification |

| CC | Climate change |

| EU | European Union |

| FE | Freshwater eutrophication |

| FET | Freshwater ecotoxicity |

| HCT | Human carcinogenic toxicity |

| HnCT | Human not carcinogenic toxicity |

| IPM | Integrated Pest Management |

| LCA | Life cycle assessment |

| LCC | Life cycle costing |

| ME | Marine eutrophication |

| MET | Marine ecotoxicity |

| NPV | Net Present Value |

| PI | Profitability Index |

| PM | Fine particulate matter formation |

| TCOP | Total Cost of Production |

| TET | Terrestrial ecotoxicity |

| WC | Water consumption |

Appendix A

| Case Study | Active Ingredient (a.i) | g (a.i)/ha |

|---|---|---|

| Tuscany | Bacillus thuringiensis var. kurstaki (*) | 2150.0 |

| Chlorantraniliprole | 116.7 | |

| Copper oxychloride | 2886.3 | |

| Cyprodinil | 416.7 | |

| Deltamethrin | 29.9 | |

| Emamectin benzoate | 23.8 | |

| Fludioxonil | 277.8 | |

| Indoxacarb | 66.7 | |

| Metaflumizone | 244.4 | |

| Methomyl | 268.6 | |

| Methoxyfenozide | 500.0 | |

| Spinosad | 128.9 | |

| Sulfoxaflor | 26.4 | |

| Almería | Azoxistrobine | 200.0 |

| Bacillus amyloliquefaciens (*) | 3750.0 | |

| Cimoxanile 45% | 500.0 | |

| Sulfur | 5000.0 | |

| Monastir | Abamectin | 162.1 |

| Chlorantraniliprole | 364.2 | |

| Copper | 800.4 | |

| Copper sulfate | 533.6 | |

| Emamectin Benzoate | 26.7 | |

| Flubendiamide | 40.0 | |

| Flupyradifurone | 68.4 | |

| Folpet | 1200.6 | |

| Fosetyl-Al | 1600.8 | |

| Mancozeb | 133.4 | |

| Metalaxyl-M | 1217.3 | |

| Orange essential oil (*) | 235.3 | |

| Spinosad | 353.8 | |

| Sulfur | 2134.4 | |

| Antalya | Abamectin | 24.0 |

| Ametoctradine | 642.9 | |

| Cyprodinil | 120.5 | |

| Dimetomorf | 483.3 | |

| Emamectin benzoate | 238.1 | |

| Fludioxonil | 80.4 | |

| Orange essential oil (*) | 280.0 | |

| Spinetoram | 17.1 | |

| Spirotetramat | 107.9 |

| Emissions (kg/ha) | Case Studies | |||

|---|---|---|---|---|

| Tuscany | Almería | Monastir | Antalya | |

| Machinery (to air) | ||||

| HC | 1.1 | 1.1 | 3.5 | 0.04 |

| NOx | 12.5 | 12.1 | 39.6 | 0.47 |

| CO | 1.6 | 1.5 | 4.9 | 0.06 |

| CO2 | 346.3 | 676.7 | 2735.5 | 9.73 |

| SO2 | 0.1 | 0.2 | 0.9 | 0.003 |

| CH4 | 0.014 | 0.028 | 0.113 | 0.0004 |

| NH3 | 0.002 | 0.004 | 0.018 | 0.0001 |

| PM2.5 | 4.6 | 27.4 | 45.9 | 0.08 |

| Fertilizers (to air) | ||||

| N2O | 16.0 | 7.5 | 4.7 | 18.6 |

| NH3 | 25.6 | 12.0 | 7.5 | 29.7 |

| NOx | 3.4 | 1.6 | 1.0 | 3.9 |

| Fertilizers (to soil) | ||||

| NO3 | 384.7 | 179.5 | 113.1 | 445.5 |

| K2O | 2.6 | 0.04 | 0.05 | 0.9 |

References

- De Pascale, S.; Maggio, A. Sustainable protected cultivation at a mediterranean climate. Perspectives and challenges. Acta Hortic. 2005, 691, 29–42. [Google Scholar] [CrossRef]

- EIP-AGRI. EIP-AGRI Focus Group Circular Horticulture; EIP-AGRI: Saint-Josse-ten-Noode, Belgium, 2019; pp. 1–36. [Google Scholar]

- Maaoui, M.; Boukchina, R.; Hajjaji, N. Environmental life cycle assessment of Mediterranean tomato: Case study of a Tunisian soilless geothermal multi-tunnel greenhouse. Environ. Dev. Sustain. 2021, 23, 1242–1263. [Google Scholar] [CrossRef]

- Solimene, S.; Coluccia, D.; Bernardo, A. Environmental Impact of Different Business Models: An LCA Study of Fresh Tomato Production in Italy. Sustainability 2023, 15, 365. [Google Scholar] [CrossRef]

- IGUESSMED. Innovative Greenhouse Support System in the Mediterranean Region Efficient Fertigation and Pest Management through IoT Based Climate Control; iGUESS-MED: 2020. Available online: https://www.iguessmed.com/ (accessed on 20 January 2024).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 26 March 2024).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 26 March 2024).

- ISO 15686-5:2017; Buildings and Constructed Assets—Service Life Planning—Part 5: Life-cycle Costing. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/61148.html (accessed on 26 March 2024).

- Richterová, E.; Richter, M.; Palkovič, J. World’s 24 Biggest Agricultural Producers ‘Eco-Efficiency Considering Undesirable Outputs. Agris On-Line Pap. Econ. Inform. 2021, 13, 89–100. [Google Scholar] [CrossRef]

- Garcìa, J.G.; Garcìa, B.G. Sustainability Assessment of Greenhouse Pepper Production Scenarios in Southeastern Spain. Agronomy 2022, 12, 1254. [Google Scholar] [CrossRef]

- Canaj, K.; Mehmeti, A.; Berbel, J. The Economics of Fruit and Vegetable Production Irrigated with Reclaimed Water Incorporating the Hidden Costs of Life Cycle Environmental Impacts. Resources 2021, 10, 90. [Google Scholar] [CrossRef]

- Tamburini, E.; Pedrini, P.; Marchetti, M.G.; Fano, E.A.; Castaldelli, G. Life cycle based evaluation of environmental and economic impacts of agricultural productions in the Mediterranean area. Sustainability 2015, 7, 2915–2935. [Google Scholar] [CrossRef]

- Sanyé-Mengual, E.; Oliver-Solà, J.; Montero, J.I.; Rieradevall, J. An environmental and economic life cycle assessment of rooftop greenhouse (RTG) implementation in Barcelona, Spain. Assessing new forms of urban agriculture from the greenhouse structure to the final product level. Int. J. Life Cycle Assess. 2015, 20, 350–366. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; Ruijs, M.; Victoria, N.G.; Stanghellini, C.; Montero, J.I. Environmental and economic assessment of protected crops in four European scenarios. J. Clean. Prod. 2012, 28, 45–55. [Google Scholar] [CrossRef]

- Gava, O.; Antón, A.; Carmassi, G.; Pardossi, A.; Incrocci, L.; Bartolini, F. Reusing drainage water and substrate to improve the environmental and economic performance of Mediterranean greenhouse cropping. J. Clean. Prod. 2023, 413, 137510. [Google Scholar] [CrossRef]

- Gava, O.; Ardakani, Z.; Delalic, A.; Monaco, S. Environmental Impacts of Rice Intensification Using High-Yielding Varieties: Evidence from Mazandaran, Iran. Sustainability 2024, 16, 2563. [Google Scholar] [CrossRef]

- Zampori, L.; Saouter, E.; Schau, E.; Cristobal, J.; Castellani, V.; Sala, S. Guide Forinterpreting Life Cycle Assessment Result; Publications Office of the European Union: Luxembourg, 2016; p. 60. [Google Scholar] [CrossRef]

- D’Amico, A.; De Boni, A.; Palmisano, G.O.; Acciani, C.; Roma, R. Environmental analysis of soilless tomato production in a high-tech greenhouse. Clean. Environ. Syst. 2023, 11, 100137. [Google Scholar] [CrossRef]

- IRPET. L’Agricoltura Toscana e le Sue Interazioni Con il Resto del Sistema Economico; IRPET: Firenze, Italy, 2021; pp. 1–165. [Google Scholar]

- RICA. Le Aziende Agricole in Italia: Risultati Economici e Produttivi, Caratteristiche Strutturali, Sociali ed Ambientali; Rapporto RICA 2021; RICA: Roma, Italy, 2021; ISBN 9788833851396. [Google Scholar]

- Parra, J.P.; Baeza, E.; Montero, J.I.; Bailey, B.J. Natural Ventilation of Parral Greenhouses. Biosyst. Eng. 2004, 87, 355–366. [Google Scholar] [CrossRef]

- Bonachela, S.; López, J.C.; Granados, M.R.; Magán, J.J.; Hernández, J.; Baille, A. Effects of gravel mulch on surface energy balance and soil thermal regime in an unheated plastic greenhouse. Biosyst. Eng. 2020, 192, 1–13. [Google Scholar] [CrossRef]

- APIA. Agency for the Promotion of Agricultural Investments: Report of Study of the Promotion of Investments and Development of Production of Vegetables under Greenhouses; APIA: El Khadra, Tunisia, 2015. [Google Scholar]

- MARHP—République Tunisienne Ministère de l’Agriculture, des Ressources Hydrauliques et de la Pêche. Projet Annuel de Performance des Programmes des Missions Agriculture, Ressources Hydrauliques et Pêche Année 2020; MARHP: Tunis, Tunisia, 2020. [Google Scholar]

- MARHP—Ministère de l’Agriculture, des Ressources Hydrauliques et de la Pêche. Rapport National du Sector de L’eau; MARHP: Tunis, Tunisia, 2021. [Google Scholar]

- Karaca, C.; Situation, C. Problems and Solution of Protected Cultivation in Antalya; Duvar Publishing: Sariyer, Turkey, 2020; pp. 7–34. [Google Scholar]

- Ekvall, T.; Tillman, A.M. Open-loop recycling: Criteria for allocation procedures. Int. J. Life Cycle Assess. 1997, 2, 155–162. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Durlinger, B.; Koukouna, E.; Broekema, R.; Van Paassen, M.; Scholten, J. Agri-Footprint. 2017. Available online: www.agri-footprint.com (accessed on 26 March 2024).

- Rowe, G.E.; Margaritis, A. Bioprocess design and economic analysis for the commercial production of environmentally friendly bioinsecticides from Bacillus thuringiensis HD-1 kurstaki. Biotechnol. Bioeng. 2004, 86, 377–388. [Google Scholar] [CrossRef] [PubMed]

- Beccali, M.; Cellura, M.; Iudicello, M.; Mistretta, M. Resource consumption and environmental impacts of the agrofood sector: Life cycle assessment of italian citrus-based products. Environ. Manag. 2009, 43, 707–724. [Google Scholar] [CrossRef]

- Nemecek, T.; Kägi, T. Life Cycle Inventories of agricoltural production system. Nature 2007, 111, 787. [Google Scholar]

- Erickson, J.E.; Cisar, J.L.; Volin, J.C.; Snyder, G.H. Comparing Nitrogen Runoff and Leaching between Newly Established St. Augustinegrass Turf and an Alternative Residential Landscape. Crop. Sci. 2001, 41, 1889–1895. [Google Scholar] [CrossRef]

- Masoni, A. Riduzione Dell’inquinamento delle Acque dai Nitrati Provenienti Dall’agricoltura; WorldCat.org: San Giuliano Terme, Italy, 2010. [Google Scholar]

- Audsley, E.; Alber, S.; Clift, R.; Cowell, S.; Crettaz, P.; Gaillard, G.; Hausheer, J.; Jolliet, O.; Kleijn, R.; Morten-sen, B.; et al. Harmonisation of Environmental Life Cycle Assessment for Agriculture; Final Report, Concerted Action AIR3-CT94-2028; European Commission: Brussels, Belgium, 1997; researchgate.net; Available online: https://www.researchgate.net/profile/Eric_Audsley/publication/258966401_EU_Concerted_Action_report_HARMONISATION_OF_ENVIRONMENTAL_LIFE_CYCLE_ASSESSMENT_FOR_AGRICULTURE_Final_Report_Concerted_Action_AIR3-CT94-2028/links/00463529865607368b000000/EU-Concerted-Action-report-HARMONISATION-OF-ENVIRONMENTAL-LIFE-CYCLE-ASSESSMENT-FOR-AGRICULTURE-Final-Report-Concerted-Action-AIR3-CT94-2028 (accessed on 26 March 2024).

- Margni, M.; Rossier, D.; Crettaz, P.; Jolliet, O. Life cycle impact assessment of pesticides on human health and ecosystems. Agric. Ecosyst. Environ. 2002, 93, 379–392. [Google Scholar] [CrossRef]

- Juraske, R.; Antón, A.; Castells, F.; Huijbregts, M.A.J. Human intake fractions of pesticides via greenhouse tomato consumption: Comparing model estimates with measurements for Captan. Chemosphere 2007, 67, 1102–1107. [Google Scholar] [CrossRef] [PubMed]

- Lovarelli, D.; Bacenetti, J.; Fiala, M. Effect of local conditions and machinery characteristics on the environmental impacts of primary soil tillage. J. Clean. Prod. 2017, 140, 479–491. [Google Scholar] [CrossRef]

- Manko, I.; Shuba, Y.; Korpach, A.; Gutarevyc, S.; Ragulskiene, J.; Pauliukas, A. Measurement of fuel consumption and harmful emissions of cars when using different types of fuel. J. Meas. Eng. 2020, 8, 182–196. [Google Scholar] [CrossRef]

- Muñoz, P.; Antón, A.; Nuñez, M.; Paranjpe, A.; Ariño, J.; Castells, X.; Montero, J.; Rieradevall, J. Comparing the environmental impacts of greenhouse versus open-field tomato production in the Mediterranean region. Acta Hortic. 2008, 801, 1591–1596. [Google Scholar] [CrossRef]

- Boulard, T.; Raeppel, C.; Brun, R.; Lecompte, F.; Hayer, F.; Carmassi, G.; Gaillard, G. Environmental impact of greenhouse tomato production in France. Agron. Sustain. Dev. 2011, 31, 757–777. [Google Scholar] [CrossRef]

- Rivera, X.C.S.; Bacenetti, J.; Fusi, A.; Niero, M. The influence of fertiliser and pesticide emissions model on life cycle assessment of agricultural products: The case of Danish and Italian barley. Sci. Total Environ. 2017, 592, 745–757. [Google Scholar] [CrossRef] [PubMed]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Parada, F.; Gabarrell, X.; Rufí-Salís, M.; Arcas-Pilz, V.; Muñoz, P.; Villalba, G. Optimizing irrigation in urban agriculture for tomato crops in rooftop greenhouses. Sci. Total Environ. 2021, 794, 148689. [Google Scholar] [CrossRef]

- Norris, G.A. The Requirement for Congruence in Normalization. Int. J. Life Cycle Assess. 2001, 6, 85–88. [Google Scholar] [CrossRef]

- Sleeswijk, A.W.; van Oers, L.F.C.M.; Guinée, J.B.; Struijs, J.; Huijbregts, M.A.J. Normalisation in product life cycle assessment: An LCA of the global and European economic systems in the year 2000. Sci. Total Environ. 2008, 390, 227–240. [Google Scholar] [CrossRef] [PubMed]

- TURKSTAT. Agricultural Input Price Index, January 2022. 2022. Available online: https://data.tuik.gov.tr/Bulten/Index?p=Agricultural-Input-Price-Index-January-2022-45773&dil=2 (accessed on 27 February 2024).

- Hasan, M.; Mani, I.; Kumar, L.; Sagar, A.; Paradkar, V.; Gavhane, K.P.; Ameta, T. IoT e gestione dell’acqua e dei nutrienti basata su sensori per la tecnologia di coltivazione protetta [IoT and sensor-based water and nutrient management for protected cultivation technology]. In Progress. Nella Gest. Dell’acqua nel Contesto dei Cambiamenti Clim. [Advances in Water Management Under Climate Chan]; CRC Press: Boca Raton, FL, USA, 2023; pp. 168–188. [Google Scholar] [CrossRef]

- Gallardo, M.; Elia, A.; Thompson, R.B. Decision support systems and models for aiding irrigation and nutrient management of vegetable crops. Agric. Water Manag. 2020, 240, 106209. [Google Scholar] [CrossRef]

- Zinkernagel, J.; Maestre-Valero, J.F.; Seresti, S.Y.; Intrigliolo, D.S. New technologies and practical approaches to improve irrigation management of open field vegetable crops. Agric. Water Manag. 2020, 242, 106404. [Google Scholar] [CrossRef]

- Incrocci, L.; Thompson, R.B.; Fernandez-Fernandez, M.D.; De Pascale, S.; Pardossi, A.; Stanghellini, C.; Rouphael, Y.; Gallardo, M. Irrigation management of European greenhouse vegetable crops. Agric. Water Manag. 2020, 242, 106393. [Google Scholar] [CrossRef]

- Massa, D.; Magán, J.J.; Montesano, F.F.; Tzortzakis, N. Minimizing water and nutrient losses from soilless cropping in southern Europe. Agric. Water Manag. 2020, 241, 106395. [Google Scholar] [CrossRef]

- Rufí-Salís, M.; Petit-Boix, A.; Villalba, G.; Sanjuan-Delmás, D.; Parada, F.; Ercilla-Montserrat, M.; Arcas-Pilz, V.; Muñoz-Liesa, J.; Rieradevall, J.; Gabarrell, X. Recirculating water and nutrients in urban agriculture: An opportunity towards environmental sustainability and water use efficiency? J. Clean. Prod. 2020, 261, 121213. [Google Scholar] [CrossRef]

- De Lucia, C.; Pazienza, P. Market-based tools for a plastic waste reduction policy in agriculture: A case study in the south of Italy. J. Environ. Manag. 2019, 250, 109468. [Google Scholar] [CrossRef]

- European Environment Agency. European Climate Risk Assessment; European Environment Agency: Copenhagen, Denmark, 2024; Available online: https://www.eea.europa.eu/en/about/who-we-are/projects-and-cooperation-agreements/european-climate-risk-assessment (accessed on 15 May 2024).

- MAPA. National Report of the Water Sector; 2019. Available online: http://www.onagri.tn/uploads/secteur-eau/RNE_2021_V-Anglaise.pdf (accessed on 15 February 2024).

- Rossi, V.; Caffi, T.; Salotti, I.; Fedele, G. Sharing decision-making tools for pest management may foster implementation of Integrated Pest Management. Food Secur. 2023, 15, 1459–1474. [Google Scholar] [CrossRef]

| Inputs (ha/year) | Unit | Case Studies | |||

|---|---|---|---|---|---|

| Tuscany | Almería | Monastir | Antalya | ||

| Concrete | m3 | 5.0 | 3.9 | 2.5 | 5.0 |

| Metals | kg | 881 | 1248 | 1257 | 2082 |

| Plastics | kg | 1900 | 1499 | 7459 | 2095 |

| Electronic component | kg | 9.5 | 0.1 | 1.2 | 0.2 |

| Growing substrate | kg | 2604 | - | - | - |

| Agricultural machinery | kg | 180 | 2000 | 1470 | 5053 |

| Fuel | L | 1986 | 127 | 1050 | 365 |

| Water | m3 | 10125 | 5142 | 6160 | 13,170 |

| Electricity | kWh | 777 | 431 | 1800 | 6481 |

| N | kg | 1282 | 603 * | 377 | 1485 |

| K2O | kg | 2072 | 1057 | 707 | 2525 |

| P2O5 | kg | 484 | 460 | 464 | 853 |

| Other nutrients | kg | 1056 | 1179 | 312 | 664 |

| Chemical pesticides (a.i) | kg | 7.1 | 5.7 | 8.6 | 1.7 |

| Biopesticides (a.i.) | Kg | 2.2 | 3.8 | 0.2 | 0.3 |

| Production Stages | Breakdown of Costs | Price (€/ha/year) | |||

|---|---|---|---|---|---|

| Tuscany | Almería | Monastir | Antalya | ||

| Greenhouse infrastructure | Investment (construction materials and transport, project design) | 14,733 | 6542 | 6280 | 4266 |

| Investment (heating system and transport) * | 3518 | - | - | - | |

| Maintenance | 6191 | 1041 | 359 | 1766 | |

| Consumables and packaging | 29,733 | 17,129 | 17,287 | 3272 | |

| Transport (consumables only) | 49 | 29 | 208 | 19 | |

| Electricity | 53 | 637 | - | 139 | |

| Fertigation system | Investment | 3780 | 3514 | 2729 | 1648 |

| Maintenance | 1682 | 2207 | 469 | 1199 | |

| Electricity | 64 | 350 | 360 | 21 | |

| Substate | 15,000 | - | - | - | |

| Water tax | - | - | 288 | - | |

| Machinery | Investment (rent or purchase) | 1100 | 1100 | 1541 | 368 |

| Fuel and maintenance | 657 | 193 | 726 | 200 | |

| Fertilizers | Consumables (and transport) | 14,592 | 10,308 | 2587 | 13,107 |

| Manure treatment (every 3 years) | - | 929 | - | - | |

| Pesticides | Chemical consumables (and transport) | 1844 | 2500 | 1185 | 342 |

| Biocontrol consumables | 1190 | 1241 | 1026 | - | |

| Waste | Waste management and demolition | 547 | 585 | 1188 | 1337 |

| Labor and services | Labor ** | 52,060 | 27,531 | 11,326 | 6665 |

| Advisory services, taxes, and administration | 8500 | 1630 | 984 | 60 | |

| Emissions | Formulas | Description | Source |

|---|---|---|---|

| Machinery (to air) | |||

| CO, HC, NOx | =ERCO,HC,NOx × ot | ER = reference emissions from field operation (g/h); ot = operation time (hours) DC = diesel consumption EF = emission factor (g/kgdiesel) MP = mean power during fieldwork | [32] |

| CO2, CH4, NH3, SO2 | =DC × EFCO2,CH4,NH3,SO2 | ||

| PM2.5 | =EFPM2.5 × 0.854 ×MP × ot | ||

| Fertilizers (to water) | |||

| N2O | =1.25% of Nf | Nf = total N applied with fertilizers (kg/ha) | [32] |

| NH3 | =2% of Nf | ||

| NOx | =0.21 × emissions of N2O | ||

| Fertilizers (to soil) | |||

| NO3 | =0.3 × Nf | Kpl = amount of potentially leachable potassium oxide (kg/ha) Kl = leaching coefficient | [33,34] |

| K2O | =Kpl × (Kl/100) | ||

| Pesticides | |||

| To air | =5% total a.i. | a.i. = active ingredient (g/ha) | [35,36,37] |

| To water | =8.5% total a.i. | ||

| To soil | =76.5% total a.i. | ||

| Impact Categories | Unit | Tuscany | Almería | Monastir | Antalya |

|---|---|---|---|---|---|

| CC | kg CO2 eq | 34,393 | 28,678 | 54,087 | 53,818 |

| PM | kg PM2.5 eq | 75.6 | 74.4 | 150 | 124 |

| AC | kg SO2 eq | 257 | 136 | 390 | 206 |

| FE | kg P eq | 15.5 | 14.7 | 36.6 | 33.6 |

| ME | kg N eq | 36.2 | 14.5 | 15.3 | 35.5 |

| TET | kg 1,4-DCB | 211,211 | 175,547 | 167,203 | 328,531 |

| FET | kg 1,4-DCB | 3806 | 2169 | 2453 | 3799 |

| MET | kg 1,4-DCB | 3663 | 2901 | 3077 | 5022 |

| HCT | kg 1,4-DCB | 3589 | 7440 | 8305 | 14,617 |

| HnCT | kg 1,4-DCB | 50,749 | 39,999 | 53,139 | 67,593 |

| WC | m3 | 8276 | 3475 | 3775 | 11,283 |

| Economic Indicators | Unit | Tuscany | Almería | Monastir | Antalya |

|---|---|---|---|---|---|

| TCOP | €/ha/yr | 155,332 | 77,436 | 48,543 | 34,408 |

| NPV | €/ha (20 years) | 463,123 | 254,007 | 162,013 | 90,759 |

| PI | (20 years) | 1.28 | 1.59 | 1.26 | 1.05 |

| Impact Categories | Tuscany | Almería | Monastir | Antalya |

|---|---|---|---|---|

| CC | 4 | 4 | 7 | 7 |

| PM | 3 | 3 | 6 | 5 |

| AC | 6 | 3 | 10 | 5 |

| FE | 24 | 23 | 56 | 52 |

| ME | 8 | 3 | 3 | 8 |

| TET | 14 | 12 | 11 | 22 |

| FET | 151 | 86 | 97 | 151 |

| MET | 84 | 67 | 71 | 116 |

| HCT | 348 | 722 | 806 | 1419 |

| HnCT | 2 | 1 | 2 | 2 |

| WC | 31 | 13 | 14 | 42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sturiale, S.; Gava, O.; Gallardo, M.; Buendía Guerrero, D.; Buyuktas, D.; Aslan, G.E.; Laarif, A.; Bouslama, T.; Navarro, A.; Incrocci, L.; et al. Environmental and Economic Performance of Greenhouse Cropping in the Mediterranean Basin: Lessons Learnt from a Cross-Country Comparison. Sustainability 2024, 16, 4491. https://doi.org/10.3390/su16114491

Sturiale S, Gava O, Gallardo M, Buendía Guerrero D, Buyuktas D, Aslan GE, Laarif A, Bouslama T, Navarro A, Incrocci L, et al. Environmental and Economic Performance of Greenhouse Cropping in the Mediterranean Basin: Lessons Learnt from a Cross-Country Comparison. Sustainability. 2024; 16(11):4491. https://doi.org/10.3390/su16114491

Chicago/Turabian StyleSturiale, Sara, Oriana Gava, Marisa Gallardo, Dolores Buendía Guerrero, Dursun Buyuktas, Gulcin Ece Aslan, Asma Laarif, Thameur Bouslama, Alejandra Navarro, Luca Incrocci, and et al. 2024. "Environmental and Economic Performance of Greenhouse Cropping in the Mediterranean Basin: Lessons Learnt from a Cross-Country Comparison" Sustainability 16, no. 11: 4491. https://doi.org/10.3390/su16114491

APA StyleSturiale, S., Gava, O., Gallardo, M., Buendía Guerrero, D., Buyuktas, D., Aslan, G. E., Laarif, A., Bouslama, T., Navarro, A., Incrocci, L., & Bartolini, F. (2024). Environmental and Economic Performance of Greenhouse Cropping in the Mediterranean Basin: Lessons Learnt from a Cross-Country Comparison. Sustainability, 16(11), 4491. https://doi.org/10.3390/su16114491