Reuse of Steel Residue in Polypropylene Matrices for the Production of Plastic Wood, Aiming at Decarbonization

Abstract

:1. Introduction

2. Materials and Methods

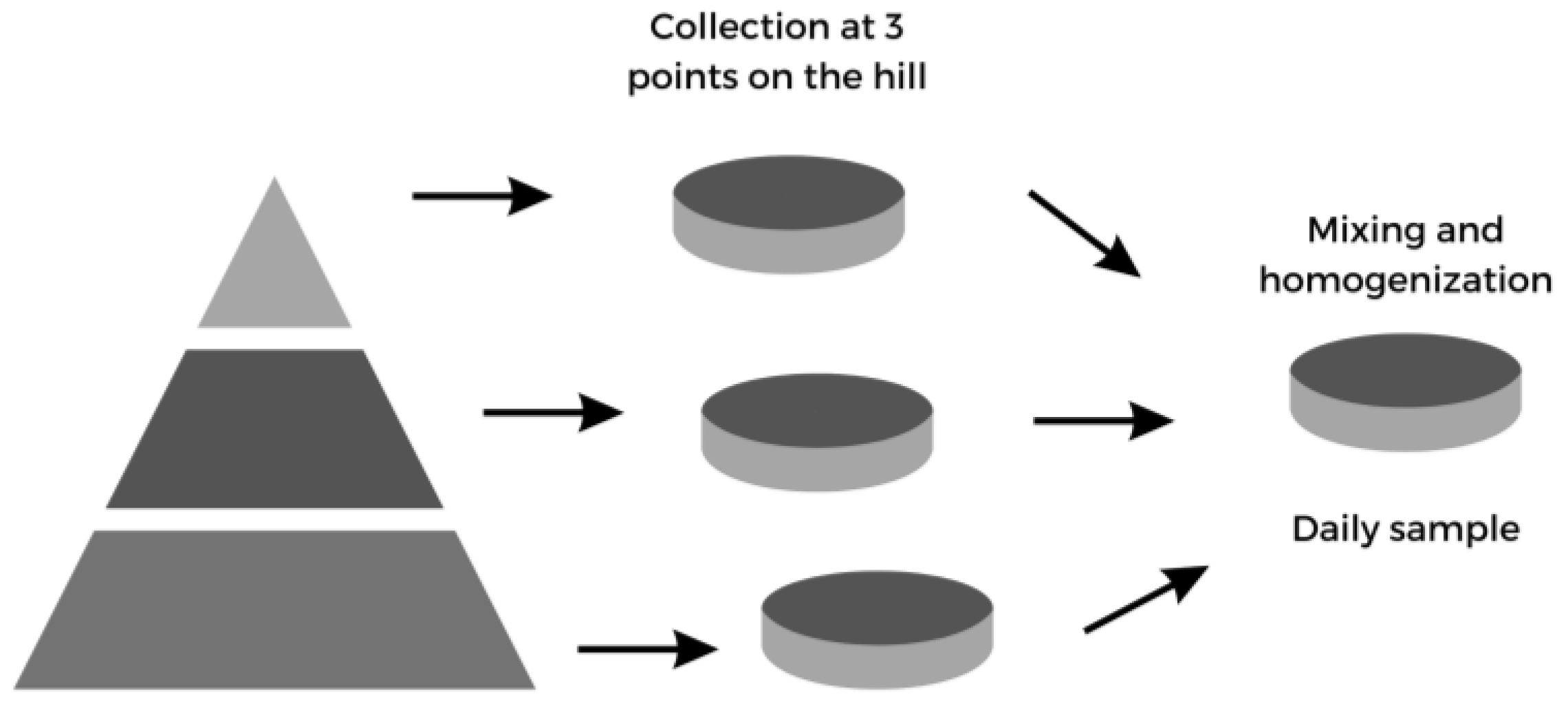

2.1. Sampling and Beneficiation of the Waste

2.2. Characterization of the Waste

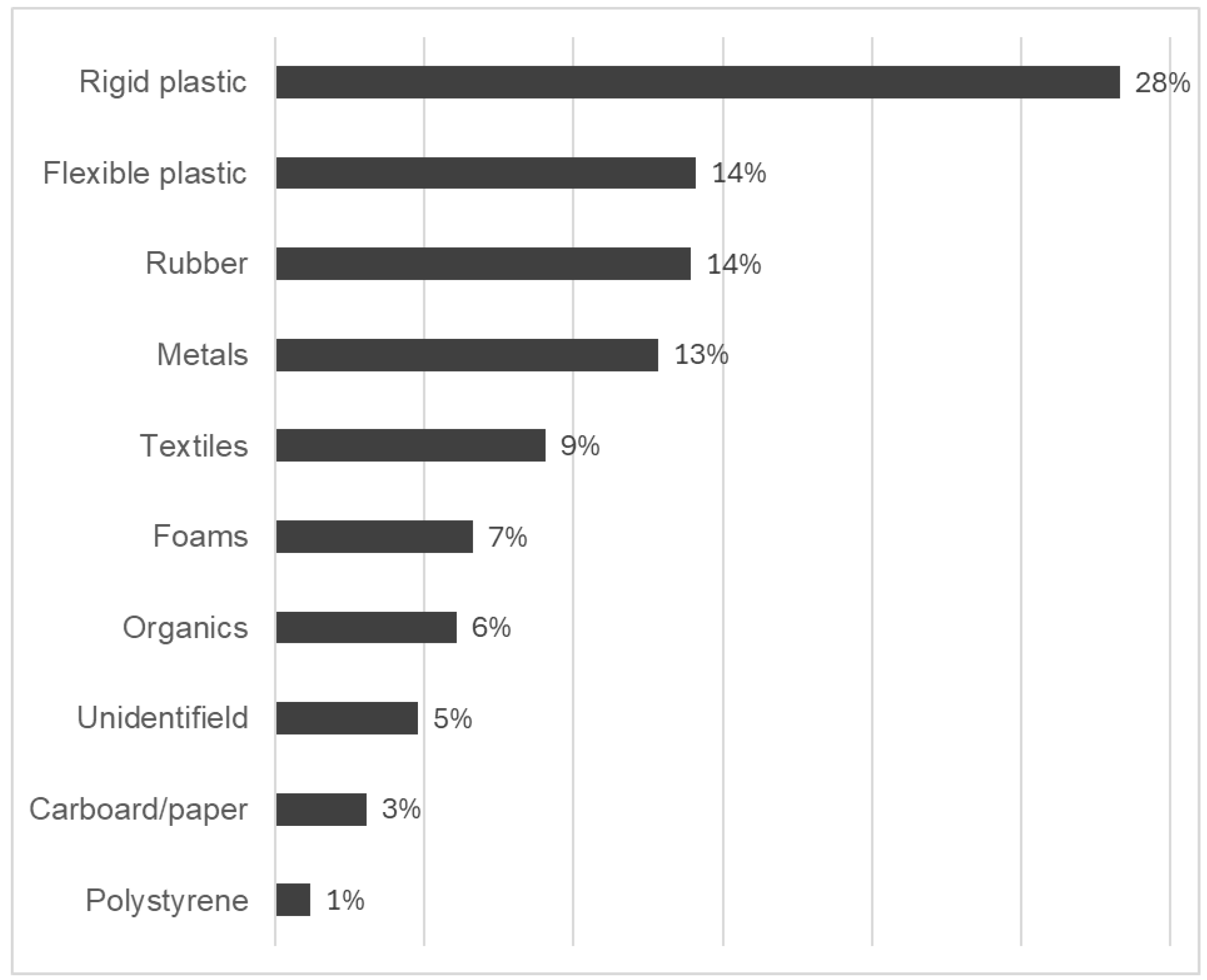

2.2.1. Gravimetry

2.2.2. Grinding

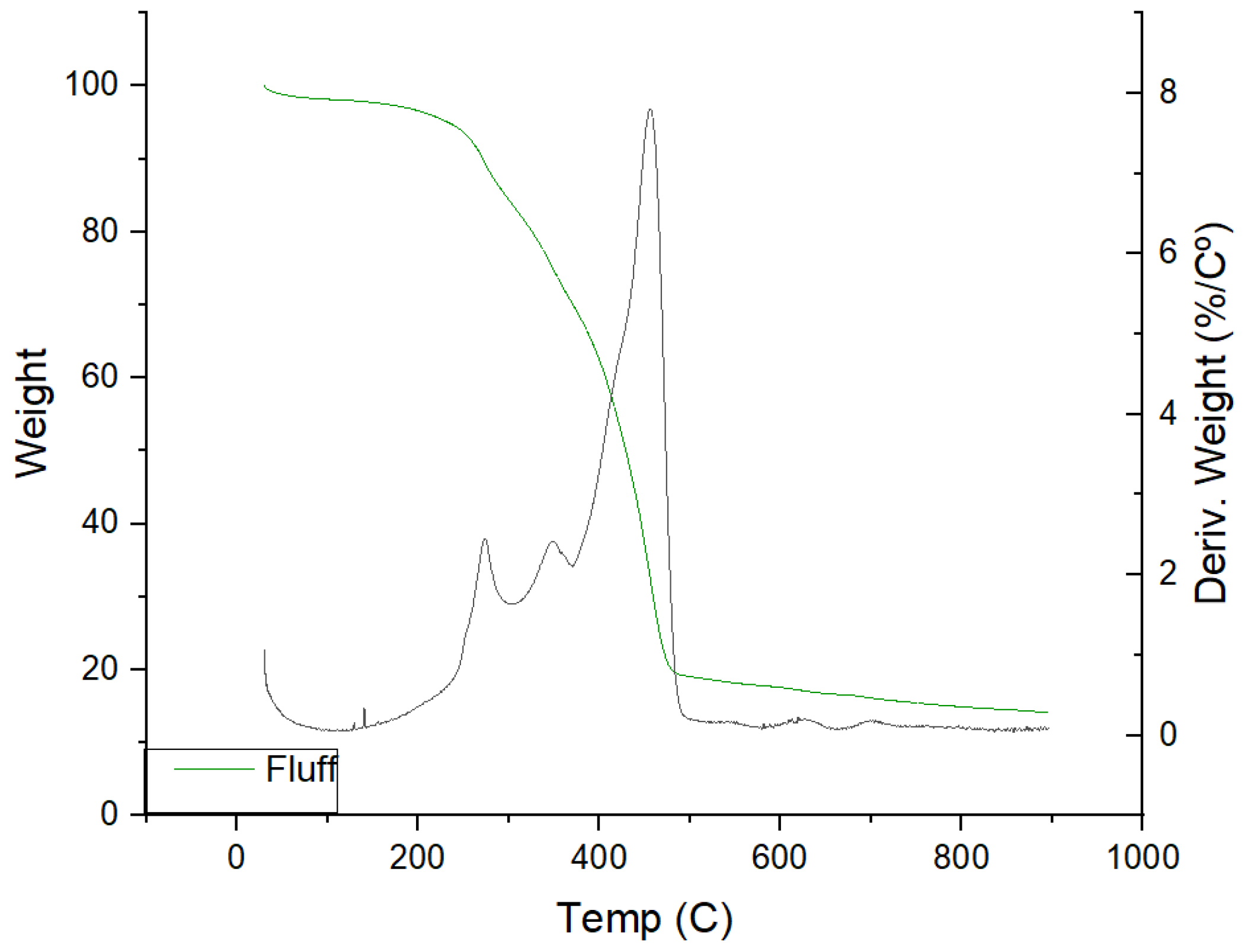

2.2.3. Thermal Behavior of the Waste

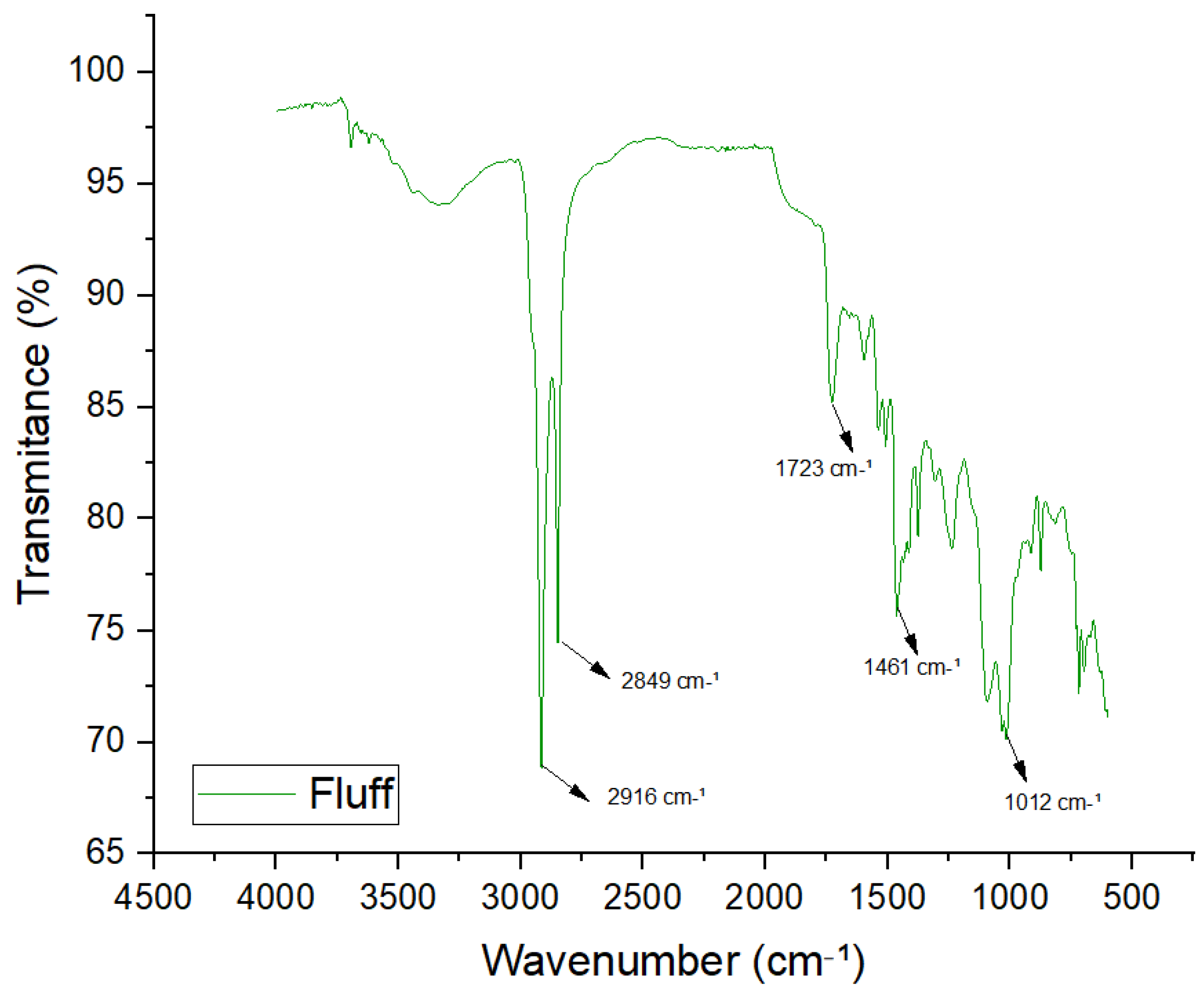

2.2.4. Fourier-Transform Infrared Spectroscopy (FTIR)

2.3. Composition Preparation

2.3.1. Preparation of the Compositions

2.3.2. Neat-PP and Composite Processing

2.3.3. Compression Molding

2.4. Characterization of the Neat-PP and Composites

2.4.1. Thermal Properties of Neat-PP, R05, and R10 Compositions

2.4.2. Melt Flow Index (MFI)

2.4.3. Tensile Properties

2.4.4. Fourier-Transform Infrared Spectroscopy (FTIR)

2.5. Calculation of Avoided Greenhouse Gas Emissions

- Scenario 1: Disposal of waste in landfills without gas capture and utilization;

- Scenario 2: Disposal of waste in landfills with gas capture and utilization for energy generation.

- For the calculations, an annual waste disposal volume of 20,000 tons was utilized. Emission Factors: The emission factors assumed in the calculator consider that 50% of the organic carbon in the waste decomposes into landfill biogas over the landfill’s lifespan. This decomposition rate is higher in landfills than in anaerobic biodigestion processes due to the longer degradation period. Additionally, it is assumed that 55% of the decomposed organic carbon converts to methane, while 45% converts to biogenic CO2, which is considered climate-neutral [27];

- Gas Capture: The efficiency of gas collection is crucial for calculating GHG emissions from the final disposal of waste. Effective gas capture and utilization reduce fuel consumption and enter the mass balance. Gas collection efficiency rates in landfill recovery projects vary widely, from 9% to over 90%. However, it is estimated that, over the landfill’s entire lifespan, only half of the potentially generated methane can be captured, even with advanced gas collection techniques. The average gas collection efficiency used for these calculations was 50% [27];

- Energy Generation: Generating electricity from landfill gas significantly reduces methane emissions. Additionally, this approach offers extra benefits, such as replacing conventional energy sources like the average Brazilian grid electricity. The calculator assumes a methane energy content of 10 kWh/m3. Avoided GHG emissions for electricity are calculated based on a GHG emission rate of 338 g CO2-eq./kWh for the replaced diesel [27];

- Landfill Oxidation Layer: Concerning the oxidation layer, which reflects the amount of CH4 oxidized in a landfill soil cover or other cover material when properly managed, an oxidation factor of 0.1 is used to estimate methane oxidation during its diffusion through the top layer and through openings and fissures. Therefore, an oxidation factor of 10%, as suggested by the Greenhouse Gas Emission Calculation Tool (GEE) methodology in the Management of Solid Waste in Brazil, was adapted [27].

3. Results and Discussions

3.1. Waste Characterization

3.1.1. Thermogravimetric Analysis (TGA)

3.1.2. Fourier-Transform Infrared Spectroscopy (FTIR) Analysis

3.2. Neat-PP and Composite Processing

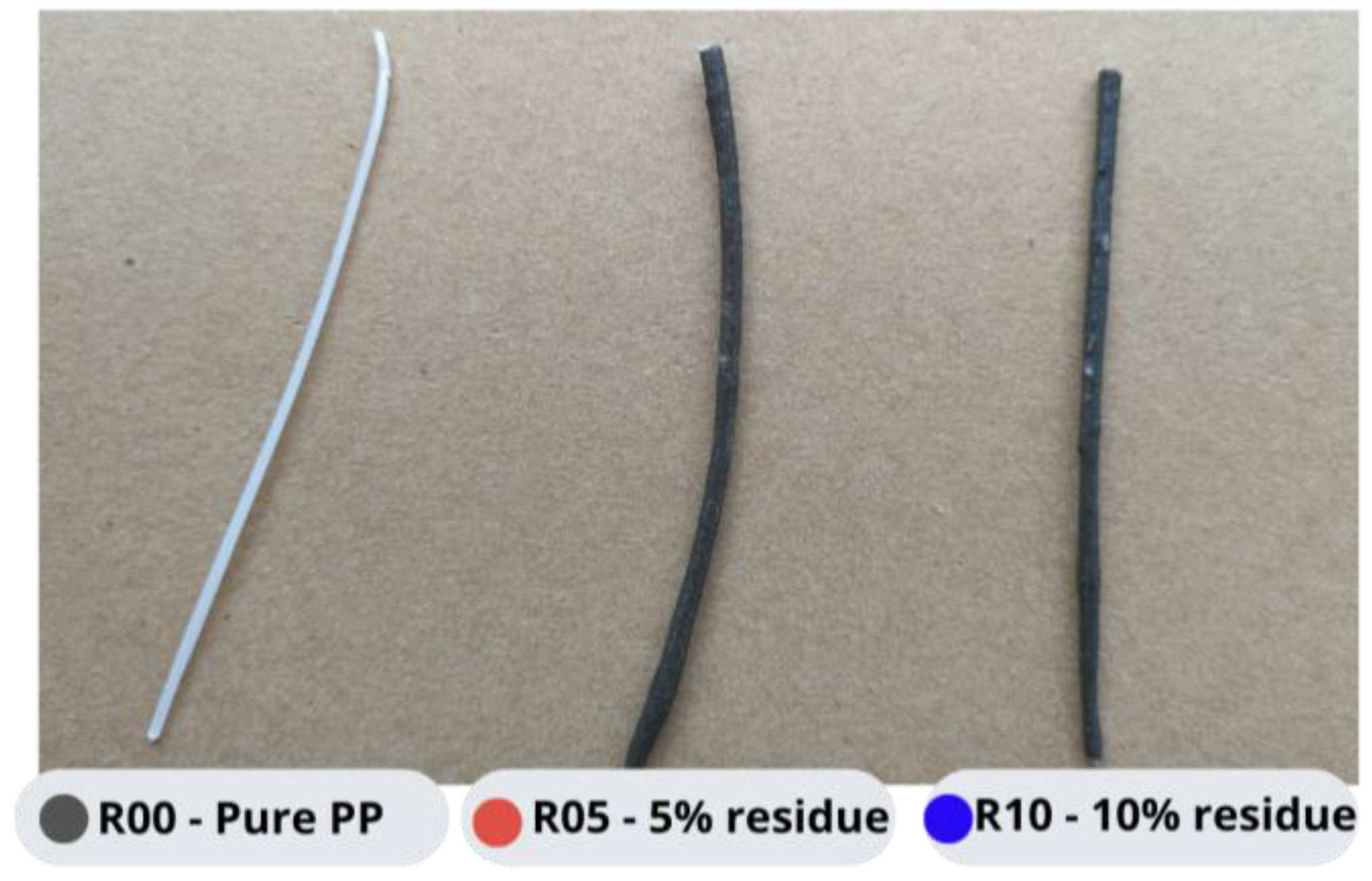

3.2.1. Granulation Process of Extruded Materials—Pelletization

3.2.2. Compression Molding

3.3. Characterization of the Neat-PP and Composites

3.3.1. Melt Flow Index (MFI)

3.3.2. Thermogravimetric Analysis (TGA)

3.3.3. Differential Scanning Calorimetry (DSC) Analysis

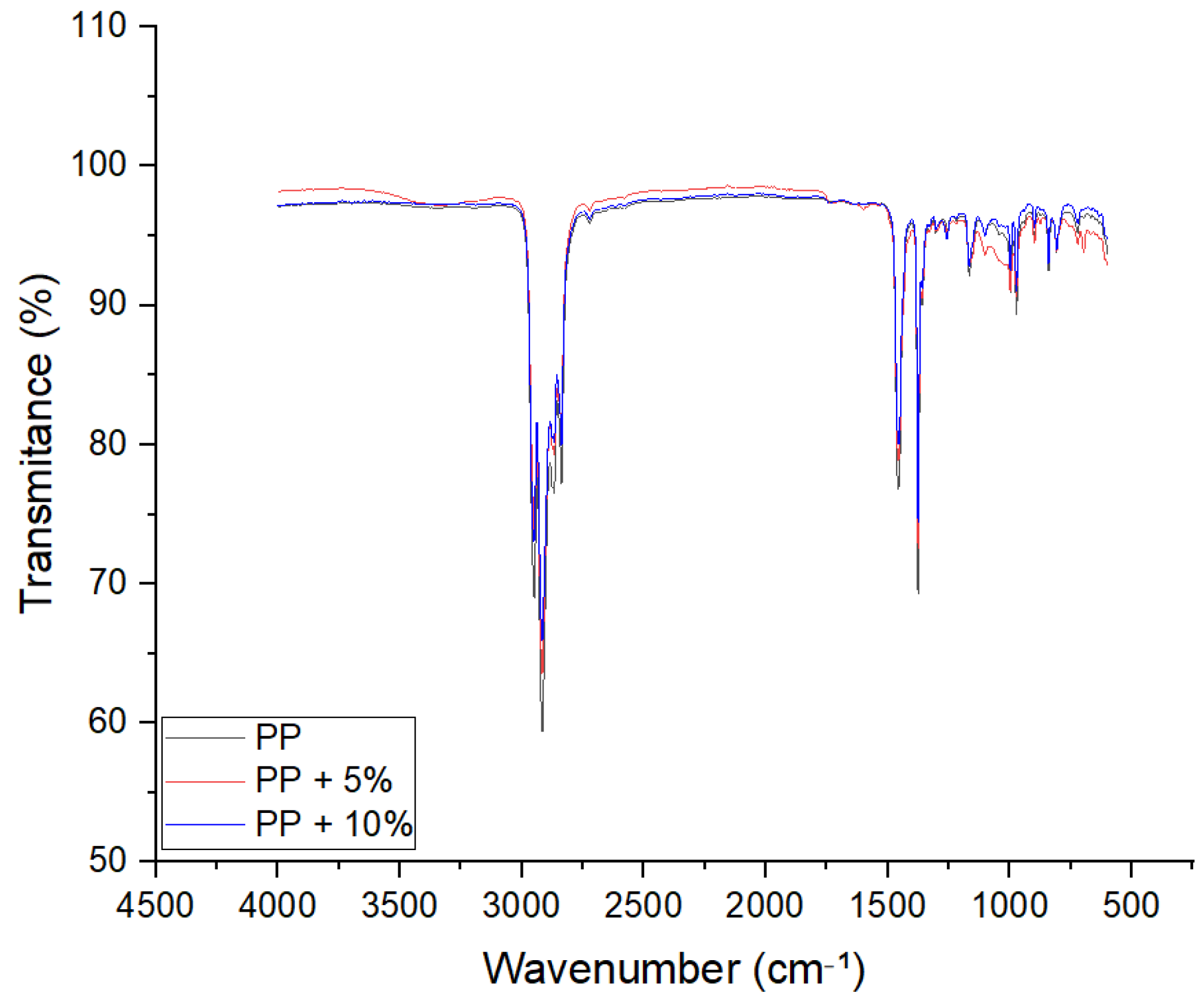

3.3.4. FTIR Analysis

3.3.5. Tensile Properties

3.4. Calculation of Avoided GHG Emissions through Application

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- WEF. Global Risk Report 2024; WEF: Cologny, Switzerland, 2024; Volume 2. [Google Scholar]

- IPCC. Synthesis Report of The IPCC Sixth Assessment Report; IPCC: Geneva, Switzerland, 2023; pp. 2–5. [Google Scholar]

- Pipatti, R.; Svardal, P.; Alves, J.W.S.; Gao, Q.; Cabrera, C.L.; Mareckova, K.; Oonk, H.; Scheehle, E.; Sharma, C.; Smith, A.; et al. Waste generation and compositon and management data. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006; Volume 5, p. 23. [Google Scholar]

- Martin, R.; De Melo, B.; Crippa, M.; Guizzardi, D.; Pagani, F.; Banja, M.; Muentan, M.; Schaaf, E.; Becker, W.; Monforti-Ferrario, F.; et al. GHG Emissions of All World Countries; European Commission: Brussels, Belgium, 2023; ISBN 978-92-68-07550-0. [Google Scholar]

- Observatório do Clima SEEG—Sistema de Estimativa de Emissões e Remoções de Gases de Efeito Estufa. Available online: https://seeg.eco.br/ (accessed on 1 February 2024).

- Saradara, S.M.; Khalfan, M.M.A.; Rauf, A.; Qureshi, R. On The Path towards Sustainable Construction—The Case of the United Arab Emirates: A Review. Sustainability 2023, 15, 14652. [Google Scholar] [CrossRef]

- Syariah, K.B.; Ilmu, G. American Iron and Steel Institute Profile; American Iron and Steel Institute: Washington, DC, USA, 2023. [Google Scholar]

- Batista, D.C. Classificação e caracterização dos resíduos do beneficiamento da sucata de ferro e aço utilizada no processo siderúrgico para identificação de viabilidade de aplicações. Master’s Thesis, Escola de Engenharia de São Carlos, São Carlos, Brazil, 2014. [Google Scholar] [CrossRef]

- Landmark, M.E. The Newell Shredder; The American Society of Mechanical Engineers: San Antonio, TX, USA, 1994. [Google Scholar]

- ArcelorMittal Catálogo de Coprodutos 2022, Juiz de Fora, Minas Gerais. 27. Available online: https://brasil.arcelormittal.com/produtos-solucoes/coprodutos/catalogo-de-coprodutos-juiz-de-fora (accessed on 1 February 2024).

- Vijayan, S.K.; Kibria, M.A.; Uddin, M.H.; Bhattacharya, S. Pretreatment of automotive shredder residues, their chemical characterisation, and pyrolysis kinetics. Sustainability 2021, 13, 10549. [Google Scholar] [CrossRef]

- Gonzalez-Fernandez, O.; Hidalgo, M.; Margui, E.; Carvalho, M.L.; Queralt, I. Heavy metals’ content of automotive shredder residues (ASR): Evaluation of environmental risk. Environ. Pollut. 2008, 153, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Morselli, L.; Santini, A.; Passarini, F.; Vassura, I. Automotive shredder residue (ASR) characterization for a valuable management. Waste Manag. 2010, 30, 2228–2234. [Google Scholar] [CrossRef] [PubMed]

- Rovinaru, F.I.; Rovinaru, M.D.; Rus, A.V. The economic and ecological impacts of dismantling end-of-life vehicles in Romania. Sustainability 2019, 11, 6446. [Google Scholar] [CrossRef]

- Lima, H.B.V. Análise Energética do Resíduo da Sucata Tipo Fluff de Uma Planta Shredder no Recife. Bachelor’s Thesis, Universidade Federal de Pernambuco, Recife, Brazil, 2019. [Google Scholar]

- Lee, J.J.S.; Mo, J.P.T.; Wu, D.Y. Polymer recovery from auto shredder residue by projectile separation method. Sustainability 2012, 4, 643–655. [Google Scholar] [CrossRef]

- Caetano, J.A. Reaproveitamento do resíduo Terra da Shredder através da técnica de solidificação/estabilização em matrizes de cimento Portland para aplicação na construção civil. Master’s Thesis, Universidade de São Paulo, São Paulo, Brazil, 2017. [Google Scholar]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood–Plastic Composite Technology. Curr. For. Reports 2015, 1, 139–150. [Google Scholar] [CrossRef]

- Schwarzkopf, M.J.; Burnard, M.D. Wood-Plastic Composites—Performance and Environmental Impacts. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts. Environmental Footprints and Eco-design of Products and Processes; Springer: Singapore, 2016; pp. 19–43. [Google Scholar]

- Zhou, H.; Li, W.; Hao, X.; Zong, G.; Yi, X.; Xu, J.; Ou, R.; Wang, Q. Recycling end-of-life WPC products into ultra-high-filled, high-performance wood fiber/polyethylene composites: A sustainable strategy for clean and cyclic processing in the WPC industry. J. Mater. Res. Technol. 2022, 18, 1–14. [Google Scholar] [CrossRef]

- Owen, M.M.; Achukwu, E.O.; Romli, A.Z.; Abdullah, A.H.B.; Ramlee, M.H.; Shuib, S.B. Thermal and mechanical characterization of composite materials from industrial plastic wastes and recycled nylon fibers for floor paving tiles application. Waste Manag. 2023, 166, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Nneka Anosike-Francis, E.; Ijeoma Obianyo, I.; Wasiu Salami, O.; Odochi Ihekweme, G.; Ikpi Ofem, M.; Olajide Olorunnisola, A.; Peter Onwualu, A. Physical-Mechanical properties of wood based composite reinforced with recycled polypropylene and cowpea (Vigna unguiculata Walp.) husk. Clean. Mater. 2022, 5, 100101. [Google Scholar] [CrossRef]

- Martinez Lopez, Y.; Paes, J.B.; Gustave, D.; Gonçalves, F.G.; Méndez, F.C.; Theodoro Nantet, A.C. Production of wood-plastic composites using cedrela odorata sawdust waste and recycled thermoplastics mixture from post-consumer products—A sustainable approach for cleaner production in Cuba. J. Clean. Prod. 2020, 244, 118723. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. Amostragem de Resíduos Sólidos. Norma 10007. 2004, 17. Available online: https://www.abntcatalogo.com.br/pnm.aspx?Q=SW9hWFlpU1RoZ2hNWTdodGM0WldUTlhja2lRamprRmwzTVIxT21zczZ5dz0= (accessed on 1 February 2024).

- Parenteau, T.; Ausias, G.; Grohens, Y.; Pilvin, P. Structure, mechanical properties and modelling of polypropylene for different degrees of crystallinity. Polymer 2012, 53, 5873–5884. [Google Scholar] [CrossRef]

- Giegrich, J. Manual Da Calculadora De Emissões De GEE Para Resíduos; IFEU—Institut für Energie und Umweltforschung Heidelberg GmbH. 2021; Volume 1, p. 134. Available online: https://www.gov.br/cidades/pt-br/acesso-a-informacao/acoes-e-programas/saneamento/protegeer/copy_of_ManualdaFerramentadeGEE_02.08.2021.pdf (accessed on 1 February 2024).

- Dos Reis, C.E. Estudo da eficácia da amoxicilina incorporada em membranas de látex. Master’s Thesis, Fundação Educacional do Municipio de Assis, Assis, Brazil, 2015. [Google Scholar]

- Rosa, R.V.D.S. Modificação das Propriedades dos Polímeros de NBR Carboxilado Comerciais a Partir da Incorporação de Nanopartículas Sintéticas. Master’s Thesis, Universidade Federal de São Carlos, São Carlos, Brazil, 2014. [Google Scholar]

- Ramos, S.M.L.S.; Carvalho, L.H.D.; Spieth, E.; Rivadula, R.S.M. Efeitos da estabilização do Polipropileno nas propriedades térmicas, mecânicas e termo-mecânicas de compósitos de Propileno/Atapulgita. Polímeros Ciência e Tecnol. 1993, 3, 26–31. [Google Scholar]

- da Silva, A.L.N.; Bertolino, L.C.; Nasser, R.O.; da Costa, L.S.; de Melo, A.A.; Marquezine, L.P.S.; de Silva, A.H.M.d.F.T.; Alves, V.O.; Nascimento, C.R.V. Aplicação de um planejamento fatorial para a avaliação das propriedades mecânicas, térmicas, morfológicas e de escoamento de compósitos à base de PEAD e CaCO3. Rev. Mater. 2013, 18, 1382–1394. [Google Scholar] [CrossRef]

- Bispo, S.J.L.; Freire Júnior, R.C.S.; Aquino, E.M.F. de Mechanical Properties Analysis of Polypropylene Biocomposites Reinforced with Curaua Fiber. Mater. Res. 2015, 18, 833–837. [Google Scholar] [CrossRef]

- Rosário, F.; Pachekoski, W.M.; Silveira, A.P.J.; Santos, S.F.d.; Júnior, H.S.; Casarin, S.A. Resíduos de sisal como reforço em compósitos de polipropileno virgem e reciclado. Polímeros 2011, 21, 90–97. [Google Scholar] [CrossRef]

| Composition (PP/Fluff), % wt/wt | Code |

|---|---|

| 100/0 (Neat-PP) | R00 |

| 95/5 | R05 |

| 90/10 | R10 |

| Sample | Initial Degradation Temperature (TONSET) (°C) | Temperature at Maximum Degradation Rate (TMAX) (°C) | Residue (%) |

|---|---|---|---|

| Fluff | 205 | 455 | 14 |

| Sample | Peak (cm−1) | Bond | Suggested Group | Suggested Material |

|---|---|---|---|---|

| Fluff | 2916 and 2849 | C-H | Hydrocarbons | Plastics, rubbers, and other polymeric materials |

| 1723 and 1596 | C=O | Carbonyl | Plastics and other polymeric materials | |

| 1462 | C-H | Methyl | Polymers such as polyethylene and polypropylene | |

| 1237 | C-O | Ethers and alcohols | Plastics and organic materials | |

| 1016 | C-H | Aromatic rings and aliphatic chains | Polymeric and organic materials |

| Composition PP/Fluff | Melt Flow Index (g/10 min) |

|---|---|

| R00 R05 R10 | 3.42 ± 0.005 |

| 3.26 ± 0.006 | |

| 3.12 ± 0.009 |

| Sample | Initial Degradation Temperature (TONSET) (°C) | Temperature at Maximum Degradation Rate (TMAX) (°C) | Residue (%) |

|---|---|---|---|

| R00 (PP) R05 (PP + 5%) R10 (PP + 10%) | 268 | 434 | 0.05 |

| 270 | 452 | 0.23 | |

| 270 | 457 | 1.63 |

| Sample | Melting Temperature (Tm) (°C) | Crystallization Temperature (Tc) (°C) | ΔHf (J/g) | Crystallinity Degree (χc) (%) |

|---|---|---|---|---|

| R00 (PP) R05 (PP + 5%) R10 (PP + 10%) | 119 | 155 | 105.80 | 51 |

| 126 | 154 | 111.10 | 54 | |

| 127 | 155 | 114.70 | 55 |

| Composite | Young’s Modulus (MPa) | Stress at Break (MPa) | Strain at Break (%) |

|---|---|---|---|

| R00 (PP) | 1082 ± 213 | 19.85± 1.63 | 14.69 ± 3.66 |

| R05 (PP + 5%) | 1058 ± 227 | 18.96 ± 2.86 | 11.43 ± 2.65 |

| R10 (PP + 10%) | 1087 ± 233 | 20.63 ± 1.28 | 15.29 ± 4.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribeiro, L.S.; Silva, A.L.N.d.; Amario, M.; Stolz, C.M.; Haddad, A.N.; Boer, D.T. Reuse of Steel Residue in Polypropylene Matrices for the Production of Plastic Wood, Aiming at Decarbonization. Sustainability 2024, 16, 4505. https://doi.org/10.3390/su16114505

Ribeiro LS, Silva ALNd, Amario M, Stolz CM, Haddad AN, Boer DT. Reuse of Steel Residue in Polypropylene Matrices for the Production of Plastic Wood, Aiming at Decarbonization. Sustainability. 2024; 16(11):4505. https://doi.org/10.3390/su16114505

Chicago/Turabian StyleRibeiro, Leticia S., Ana Lúcia Nazareth da Silva, Mayara Amario, Carina M. Stolz, Assed N. Haddad, and Dieter Thomas Boer. 2024. "Reuse of Steel Residue in Polypropylene Matrices for the Production of Plastic Wood, Aiming at Decarbonization" Sustainability 16, no. 11: 4505. https://doi.org/10.3390/su16114505

APA StyleRibeiro, L. S., Silva, A. L. N. d., Amario, M., Stolz, C. M., Haddad, A. N., & Boer, D. T. (2024). Reuse of Steel Residue in Polypropylene Matrices for the Production of Plastic Wood, Aiming at Decarbonization. Sustainability, 16(11), 4505. https://doi.org/10.3390/su16114505