Conversion of Waste Agricultural Biomass from Straw into Useful Bioproducts—Wheat Fibers and Biofuels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wheat Variety

2.2. Pretreatments and Fiber Isolation of Biomass

2.3. Testing of Fibers

3. Results and Discussion

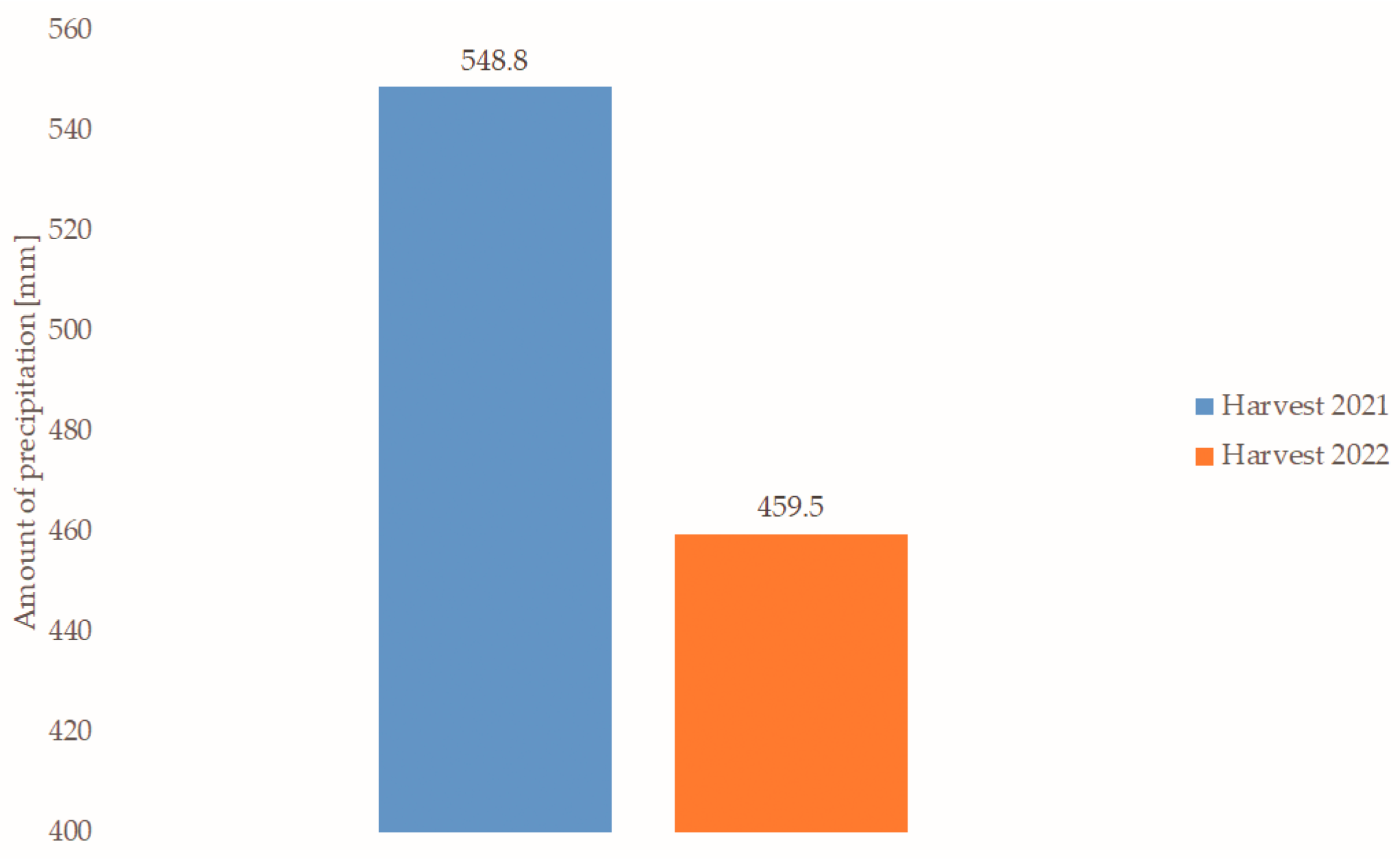

3.1. Pretreatment of Biomass

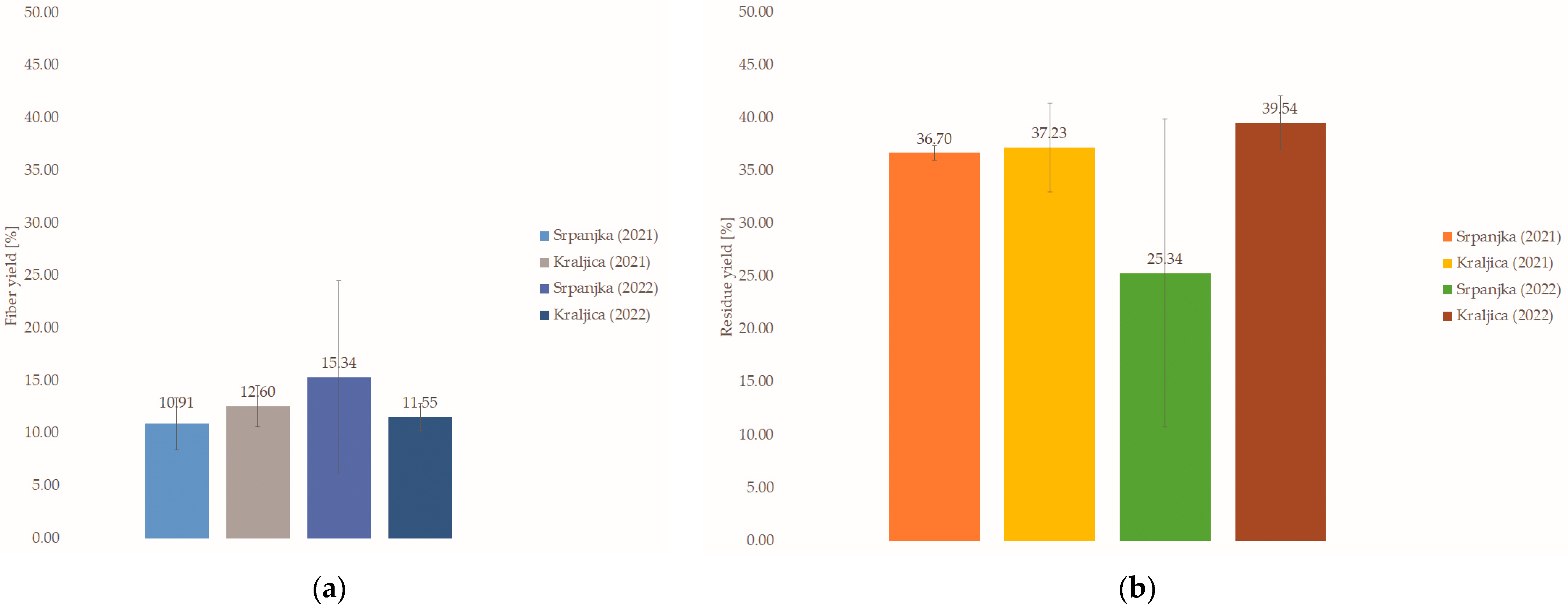

3.2. Fiber and Residue Yield

3.3. Tensile Properties

3.4. Length of Fibers

3.5. Moisture Regain and Moisture Content

3.6. Density of Fibers

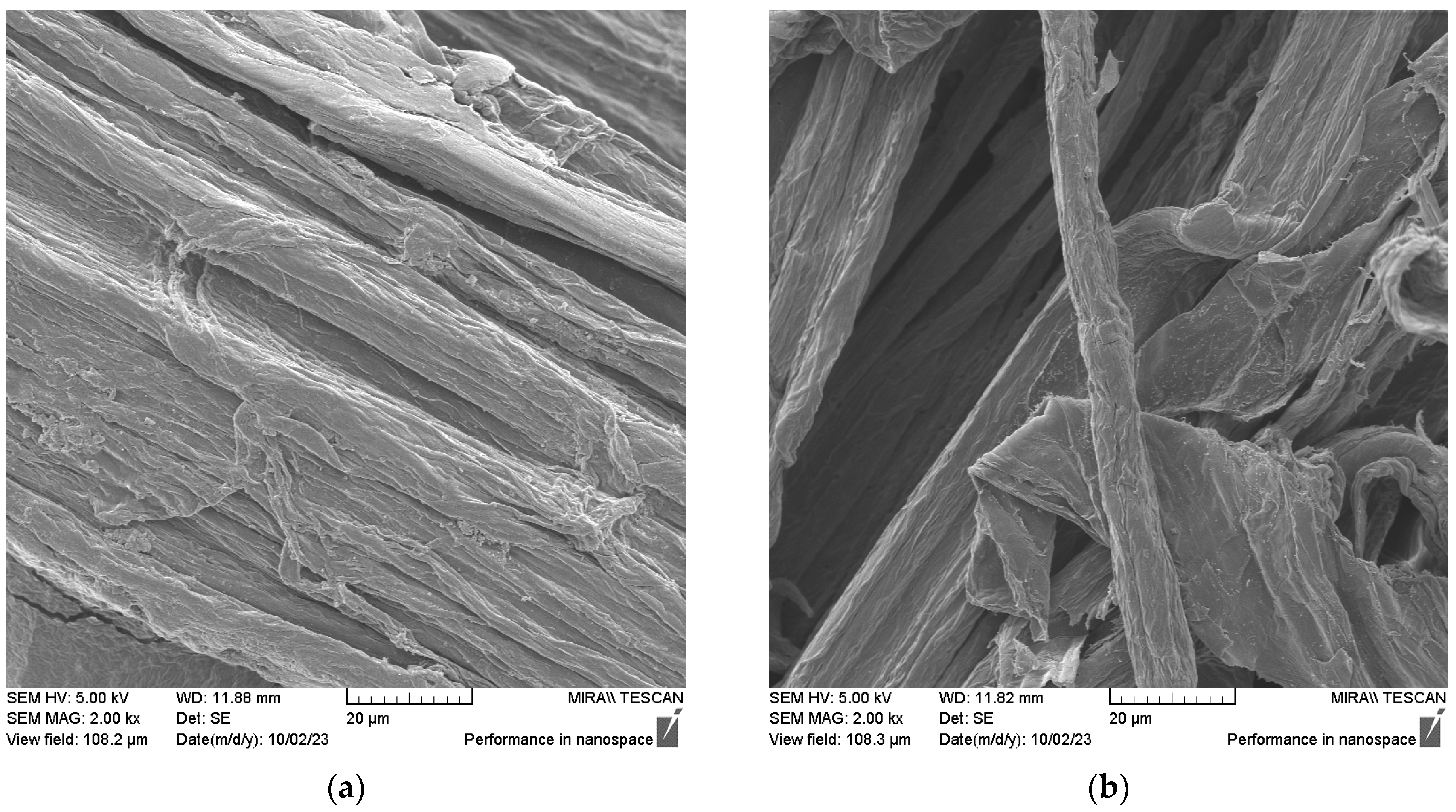

3.7. Fiber Morphology

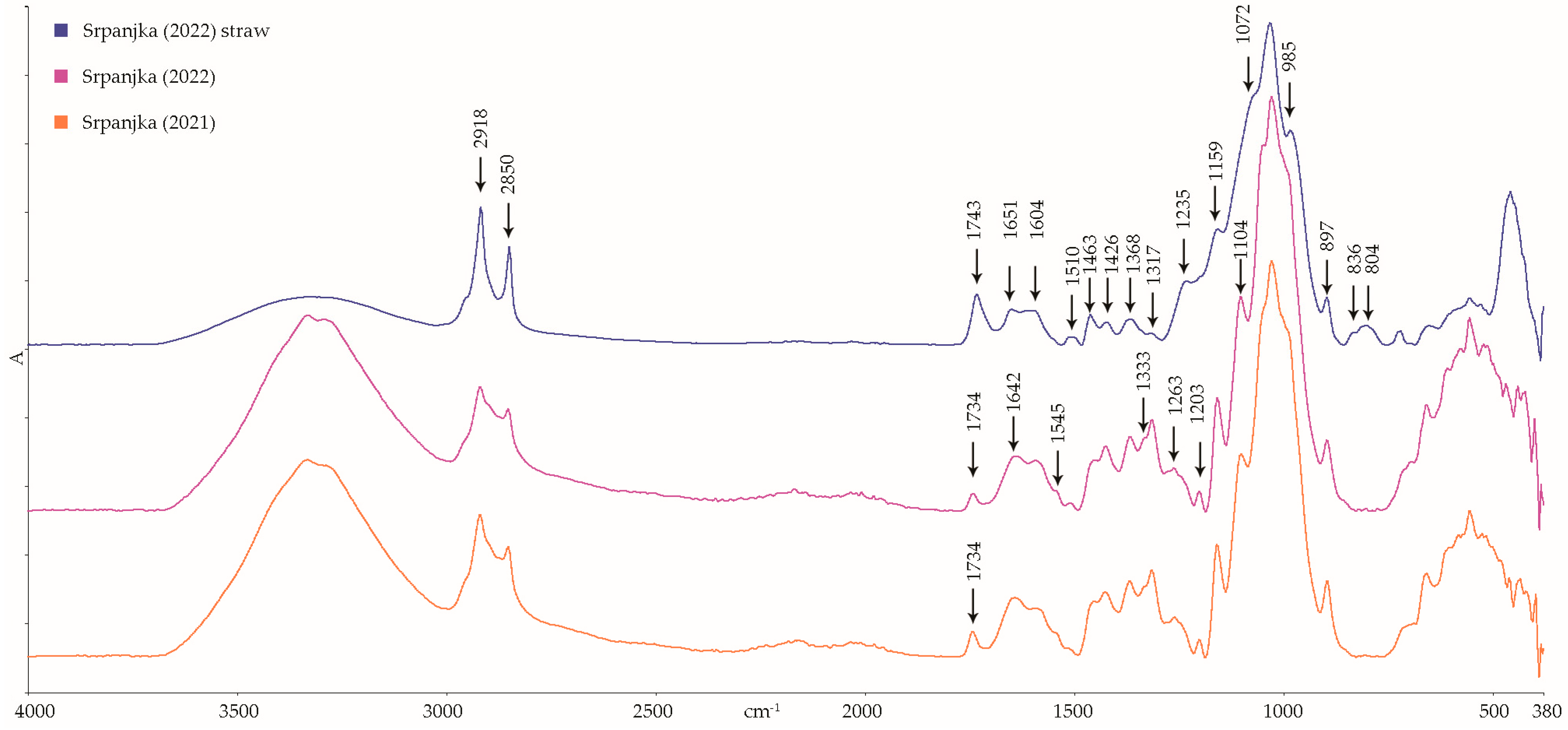

3.8. Chemical Composition

FTIR

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Preferred Fiber & Materials Market Report (October 2022). Available online: https://textileexchange.org/app/uploads/2022/10/Textile-Exchange_PFMR_2022.pdf (accessed on 24 May 2024).

- Plastic in Textiles: Towards a Circular Economy for Synthetic Textiles in Europe (2021). Available online: https://www.eea.europa.eu/publications/plastic-in-textiles-towards-a/file (accessed on 24 May 2024).

- Dalla Fontana, G.; Mossotti, R.; Montarsolo, A. Assessment of microplastics release from polyester fabrics: The impact of different washing conditions. Environ. Pollut. 2020, 264, 113960. [Google Scholar] [CrossRef] [PubMed]

- Šaravanja, A.; Pušić, T.; Dekanić, T. Microplastics in Wastewater by Washing Polyester Fabrics. Materials 2022, 15, 2683. [Google Scholar] [CrossRef] [PubMed]

- FAOSTAT Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 29 January 2024).

- Giraldo, P.; Benavente, E.; Manzano-Agugliaro, F.; Gimenez, E. Worldwide research trends on wheat and barley: A bibliometric comparative analysis. Agronomy 2019, 9, 352. [Google Scholar] [CrossRef]

- EMEP/EEA Emission Inventory Guidebook 2013. 3. F Field Burning of Agricultural Residues. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2013/part-b-sectoral-guidance-chapters/4-agriculture/3-f-field-burning (accessed on 29 January 2024).

- Chilakamarry, C.R.; Sakinah, A.M.; Zularisam, A.W.; Sirohi, R.; Khilji, I.A.; Ahmad, N.; Pandey, A. Advances in solid-state fermentation for bioconversion of agricultural wastes to value-added products: Opportunities and challenges. Bioresour. Technol. 2022, 343, 126065. [Google Scholar] [CrossRef] [PubMed]

- Awogbemi, O.; Von Kallon, D.V. Pretreatment techniques for agricultural waste. Case Stud. Chem. Environ. Eng. 2022, 6, 100229. [Google Scholar] [CrossRef]

- Bala, S.; Garg, D.; Sridhar, K.; Inbaraj, B.S.; Singh, R.; Kamma, S.; Tripathi, M.; Sharma, M. Transformation of agro-waste into value-added bioproducts and bioactive compounds: Micro/nano formulations and application in the agri-food-pharma sector. Bioengineering 2023, 10, 152. [Google Scholar] [CrossRef] [PubMed]

- Borrega, M.; Hinkka, V.; Hörhammer, H.; Kataja, K.; Kenttä, E.; Ketoja, J.A.; Palmgren, R.; Salo, M.; Sundqvist-Andberg, H.; Tanaka, A. Utilizing and Valorizing Oat and Barley Straw as an Alternative Source of Lignocellulosic Fibers. Materials 2022, 15, 7826. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.A.B.A.; Borhana Omran, A.A.; Hasan, Z.; Ilyas, R.A.; Sapuan, S.M. Wheat Biocomposite Extraction, Structure, Properties and Characterization: A Review. Polymers 2021, 13, 3624. [Google Scholar] [CrossRef]

- Gunjan; Chopra, L.; Manikanika. Extraction of cellulose from agro-waste—A short review. Mater. Today Proc. 2023, 92, 233–239. [Google Scholar] [CrossRef]

- Feleke, K.; Thothadri, G.; Beri Tufa, H.; Rajhi, A.A.; Ahmed, G.M.S. Extraction and characterization of fiber and cellulose from Ethiopian linseed straw: Determination of retting period and optimization of multi-step alkaline peroxide process. Polymers 2023, 15, 469. [Google Scholar] [CrossRef]

- Matin, A.; Krička, T.; Grubor, M.; Jurišić, V.; Majdak, T.; Špelić, K.; Majdak, J.; Matin, B.; Jovičić, N.; Antonović, A.; et al. Energy properties of agricultural biomass after the pyrolysis. J. Proc. Energy. Agric. 2023, 27, 39–44. [Google Scholar] [CrossRef]

- Lawson, L.; Degenstein, L.M.; Bates, B.; Chute, W.; King, D.; Dolez, P.I. Cellulose Textiles from Hemp Biomass: Opportunities and Challenges. Sustainability 2022, 14, 15337. [Google Scholar] [CrossRef]

- Vervris, C.; Georghiou, K.; Christodoulakis, N.; Santas, P.; Santas, R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crops Prod. 2004, 19, 245–254. [Google Scholar] [CrossRef]

- Semple, K.E.; Zhou, C.; Rojas, O.J.; Nkeuwa, W.N.; Dai, C. Moulded pulp fibers for disposable food packaging: A state-of-the-art review. Food Packag. Shelf Life 2022, 33, 100908. [Google Scholar] [CrossRef]

- Geng, L.; Li, M.; Zhang, G.; Ye, L. Barley: A potential cereal for producing healthy and functional foods. Food Qual. Saf. 2022, 6, fyac012. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. The use of wheat straw fibres as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Faruk, O., Sain, M., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 423–453. [Google Scholar] [CrossRef]

- Fortunati, E.; Benincasa, P.; Balestra, G.M.; Luzi, F.; Mazzaglia, A.; Del Buono, D.; Puglia, D.; Torre, L. Revalorization of barley straw and husk as precursors for cellulose nanocrystals extraction and their effect on PVA_CH nanocomposites. Ind. Crops Prod. 2016, 92, 201–217. [Google Scholar] [CrossRef]

- Cruz, R.M.; Krauter, V.; Krauter, S.; Agriopoulou, S.; Weinrich, R.; Herbes, C.; Scholten, P.; Uysal-Unalan, I.; Sogut, E.; Kopacic, S.; et al. Bioplastics for Food Packaging: Environmental Impact, trends and regulatory aspects. Foods 2022, 11, 3087. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; Lv, S.; Jiang, D.; Xu, H.; Kang, H.; Song, X.; He, S. Effect of modification methods on water absorption and strength of wheat straw fiber and its cement-based composites. J. Build. Eng. 2023, 71, 106466. [Google Scholar] [CrossRef]

- Petrella, A.; Spasiano, D.; Liuzzi, S.; Ayr, U.; Cosma, P.; Petrella, M.; Di Mundo, R. Use of cellulose fibers from wheat straw for sustainable cement mortars. J. Sustain. Cem.-Based Mater. 2019, 8, 161–179. [Google Scholar] [CrossRef]

- Gidebo, F.A.; Kinoshita, N.; Yasuhara, H. Optimization of physical and strength performance of cellulose-based fiber additives stabilized expansive soil. Case Stud. Constr. Mater. 2024, 20, e02851. [Google Scholar] [CrossRef]

- Nath, B.; Chen, G.; Bowtell, L.; Mahmood, R.A. Assessment of densified fuel quality parameters: A case study for wheat straw pellet. J. Bioresour. Bioprod. 2023, 8, 45–58. [Google Scholar] [CrossRef]

- Tan, J.; Huang, J.; Yuan, J.; Chen, J.; Pei, Z.; Li, H.; Yang, S. Novel supramolecular deep eutectic solvent-enabled in-situ lignin protection for full valorization of all components of wheat straw. Bioresour. Technol. 2023, 388, 129722. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, M.I.; Sabri, A.A.; Taha, E.J. Application of Wheat Husk in Color Removal of Textile Wastewater. Eng. Technol. J. 2019, 37, 296–302. [Google Scholar] [CrossRef]

- Djafari Petroudy, S.R.; Kahagh, S.A.; Vatankhah, E. Environmentally friendly superabsorbent fibers based on electrospun cellulose nanofibers extracted from wheat straw. Carbohydr. Polym. 2021, 251, 117087. [Google Scholar] [CrossRef] [PubMed]

- Kaur, M.; Pal, J. Evaluation of efficiency of wheat straw nanocellulose as nanoadsorbent for the removal of divalent copper, lead, and zinc from aqueous solution. Carbohydr. Polym. Technol. Appl. 2023, 6, 100350. [Google Scholar] [CrossRef]

- Li, W.; Zheng, L.; Teng, D.; Ge, D.; Farha, F.I.; Xu, F. Interfacial modified unidirectional wheat straw/polylactic acid composites. J. Ind. Text. 2022, 51, 272S–284S. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Al-Kheetan, M.J.; Gecevicius, M. Wheat straw pre-treatments using eco-friendly strategies for enhancing the tensile properties of bio-based polylactc acid composites. Ind. Crops Prod. 2020, 155, 112836. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, J.; Dadi Bekele, L.; Liu, Y.; Duns, G.J.; Jin, L. Physical and Mechanical Properties of Modified Wheat Straw-Filled Polyethylene Composites. Bioresource 2016, 11, 4472–4484. [Google Scholar] [CrossRef]

- Pascoli, D.U.; Dichiara, A.; Roumeli, E.; Gustafson, R.; Bura, R. Lignocellulosic nanomaterials production from wheat straw via peracetic acid pretreatment and their application in plastic composites. Carbohydr. Polym. 2022, 295, 119857. [Google Scholar] [CrossRef]

- Hornsby, P.R.; Hinrichsen, E.; Tarverdi, K. Preparation and properties of polypropylene composites reinforced with wheat and flax straw fibres—Part I: Fibre characterization. J. Mater. Sci. 1997, 32, 443–449. [Google Scholar] [CrossRef]

- Karjalainen, M. Studies on Wheat Straw Pulp Fractionation. Ph.D. Dissertation, University of Oulu Graduate School, University of Oulu, Faculty of Technology, Oulu, Finland, 4 December 2015. [Google Scholar]

- Fang, G.; Shen, K. Wheat Straw Pulping for Paper and Paperboard Production. In Global Wheat Production; Fahad, S., Adnan, M., Eds.; Intech Open: Rijeka, Croatia, 2018. [Google Scholar] [CrossRef]

- El Messiry, M.; El Deeb, R. Analysis of the Wheat Straw/Flax Fiber Reinforced Polymer Hybrid Composites. J. Appl. Mech. Eng. 2016, 5, 1–5. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Zhao, Y.; Wang, X.; Cheng, Y.; Zeng, X. Fabrication of biodegradable materials with antibacterial and high-strength properties from wheat straw fibers. Ind. Crops Prod. 2024, 208, 117925. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Maslowski, M.; Rybinski, P.; Strzelec, K. Straw/Nano-Additive Hybrids as Functional Fillers for Natural Rubber Biocomposites. Materials 2021, 14, 321. [Google Scholar] [CrossRef] [PubMed]

- Kumar Trivedi, A.; Kumar, A.; Gupta, M.K. Extraction of nanocellulose from wheat straw and its characterization. Mater. Today 2023, 78, 48–54. [Google Scholar] [CrossRef]

- Qu, R.; Tang, M.; Wang, Y.; Li, D.; Wang, L. TEMPO-oxidized cellulose fibers from wheat straw: Effect of ultrasonic pretreatment and concentration on structure and rheological properties of suspensions. Carbohydr. Polym. 2021, 255, 117386. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-M.; Wan, J.-Q.; Huang, M.-Z.; Ma, Y.-W.; Wang, Y.; Lv, H.-L.; Yang, J. Influence of drying temperature and duration on fiber properties of unbleached wheat straw pulp. Carbohydr. Polym. 2011, 85, 759–764. [Google Scholar] [CrossRef]

- Liu, Q.; He, W.-Q.; Aguedo, M.; Xia, X.; Bai, W.-B.; Dong, Y.-Y.; Song, J.-Q.; Richel, A.; Goffin, D. Microwave-assisted alkali hydrolysis for cellulose isolation from wheat straw: Influence of reaction conditions and non-thermal effects of microwave. Carbohydr. Polym. 2020, 253, 117170. [Google Scholar] [CrossRef] [PubMed]

- Sain, M.; Panthapulakkal, S. Bioprocess preparation of wheat straw fibers and their characterization. Ind. Crops Prod. 2006, 23, 1–8. [Google Scholar] [CrossRef]

- Jaiswal, D.; Devnani, G.L.; Rajeshkumar, G.; Sanjay, M.R.; Siengchin, S. Review on extraction, characterization, surface treatment and thermal degradation analysis of new cellulosic fibers as sustainable reinforcement in polymer composites. Curr. Res. Green Sustain. Chem. 2022, 5, 100271. [Google Scholar] [CrossRef]

- Franck, R.R. Overview. In Bast and Other Plant Fibres; Franck, R.R., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2005; pp. 1–23. [Google Scholar]

- Sisti, L.; Totaro, G.; Vannini, M.; Celli, A. Retting Process as a Pretreatment of Natural Fibers for the Development of Polymer Composites. In Lignocellulosic Composite Materials; Kalia, S., Ed.; Springer International Publishing AG: Basingstoke, UK, 2018; pp. 97–135. [Google Scholar]

- Konczewicz, W.; Zimniewska, M.; Valera, M.A. The selection of a retting method for the extraction of bast fibres as response to challenges in composite reinforcement. Text. Res. J. 2017, 88, 2104–2119. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Lee, S.H.; Liu, M. A Comprehensive Review on Bast Fibre Retting Process for Optimal Performance in Fibre-Reinforced Polymer Composites. Adv. Mater. Sci. Eng. 2020, 2020, 6074063. [Google Scholar] [CrossRef]

- Sfiligoj Smole, M.; Hribernik, S.; Stana Kleinschek, K.; Kreže, T. Plant Fibres for Textile and Technical Applications. In Advances in Agrophysical Research; Grundas, S., Stepniewski, A., Eds.; IntechOpen: Rijeka, Croatia, 2013; pp. 369–398. [Google Scholar] [CrossRef]

- Čunko, R.; Andrassy, M. Vlakna; Zrinski d.d.: Čakovec, Croatia, 2005; pp. 1–341. [Google Scholar]

- Agricultural Institute Osijek. Available online: https://www.poljinos.hr/en/ (accessed on 17 January 2024).

- Bilandžija, D.; Zgorelec, Ž.; Bilandžija, N.; Zdunić, Z.; Krička, T. Contribution of Winter Wheat and Barley Cultivars to Climate Change via Soil Respiration in Continental Croatia. Agronomy 2021, 11, 2127. [Google Scholar] [CrossRef]

- Češek, I. Analysis of Distinctness, Uniformity and Stability in Croatian Wheat Varieties. Master’s Thesis, Josip Juraj Strossmayer University of Osijek Faculty of Agriculture, Osijek, Croatia, 2016. [Google Scholar]

- Aaditaa, A.; Jahan, S. Extraction and processing of bast fibres from Ficus glomerata—A new source for non-conventional fibres. J. App. Natur. Sci. 2018, 10, 661–666. [Google Scholar] [CrossRef]

- Kovačević, Z.; Strgačić, S.; Bischof, S. Barley Straw Fiber Extraction in the Context of a Circular Economy. Fibers 2023, 11, 108. [Google Scholar] [CrossRef]

- Bangar, S.P.; Ilyas, R.A.; Chaudhary, N.; Dhull, S.B.; Chowdhury, A.; Lorenzo, J.M. Plant-Based Natural Fibers For Food Packaging: A Green Approach To The Reinforcement of Biopolymers. J. Polym. Environ. 2023, 31, 5029–5049. [Google Scholar] [CrossRef]

- Manian, A.P.; Braun, D.E.; Široká, B.; Bechtold, T. Distinguishing liquid ammonia from sodium hydroxide mercerization in cotton textiles. Cellulose 2022, 29, 4183–4202. [Google Scholar] [CrossRef]

- Sari, N.H.; Wardana, I.N.G.; Irawan, Y.S.; Siswanto, E. The effect of sodium hydroxide on chemical and mechanical properties of corn husk fiber. Orient. J. Chem. 2017, 33, 3037–3042. [Google Scholar] [CrossRef]

- Gao, F.; Yang, F.; De, Y.; Tao, Y.; Ta, N.; Wang, H.; Sun, Q. Dilute alkali pretreatment and subsequent enzymatic hydrolysis of amur silvergrass for ethanol production. Bioresources 2020, 15, 4823–4834. [Google Scholar] [CrossRef]

- Hansen, M.A.T.; Ahl, L.I.; Pedersen, H.L.; Westereng, B.; Willats, W.G.T.; Jorgensen, H.; Felby, C. Extractability and digestibility of plant cell wall polysaccharides during hydrothermal and enzymatic degradation of wheat straw (Triticum aestivum L.). Ind. Crops Prod. 2014, 55, 63–69. [Google Scholar] [CrossRef]

- Right to Know, Hazardous Fact Sheet. Available online: https://nj.gov/health/eoh/rtkweb/documents/fs/1706.pdf (accessed on 17 January 2024).

- Croatian Meteorological and Hydrological Service. Available online: https://meteo.hr/klima.php?section=klima_podaci¶m=k2_1&Godina=2020 (accessed on 17 January 2024).

- Kovačević, Z. Development of Advanced Polylactide Nanobiocomposite Reinforced with Spartium junceum L. Fibres. Ph.D. Dissertation, University of Zagreb Faculty of Textile Technology, Zagreb, Croatia, 25 October 2019. [Google Scholar]

- Madueke, C.I.; Mbah, O.M.; Umunakwe, R. A review on the limitations of natural fibres and natural fibre composites with emphasis on tensile strength using coir as a case study. Polym. Bull. 2023, 80, 3489–3506. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Nasir, M.; Abdan, K. A Review on Pineapple Leaves Fibre and Its Composites. Int. J. Polym. Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef]

- Vujasinović, E.; Pavunc Samaržija, M. Održivi dizajn biokompozita—Skrivena prilika za kružno gospodarstvo. In Proizvodnja Hrane, Biokompozita i Biogoriva iz Žitarica u Kružnom Gospodarstvu; Krička, T., Ed.; University of Zadar: Zadar, Croatia, 2023; pp. 193–220. [Google Scholar]

- Madić, M.; Knežević, D.; Paunović, A.; Đurović, D. Plant height and internode length as components of lodging resistance in barley. Acta Agric. Serb. 2016, 21, 99–106. [Google Scholar] [CrossRef]

- Pavkić, M. Differences in the Ear Length and Stem Height of Different Croatian Wheat Cultivars. Bachelor’s Thesis, Josip Juraj Strossmayer University of Osijek, Faculty of Agrobiotechnical Sciences, Osijek, Croatia, 2019. [Google Scholar]

- Plazonić, I.; Barbarić-Mikočević, Ž.; Španić, N. Effect of Agricultural Residue Fibers on Newsprint Strength Properties. Wood Res. 2020, 65, 437–446. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Wheat and Rice Straw Fibers. In Innovative Biofibers from Renewable Resources; Springer: Berlin/Heidelberg, Germany, 2015; pp. 9–10. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Preparation and Characterization of Long Natural Cellulose Fibers from Wheat Straw. J. Agric. Food Chem. 2007, 55, 8570–8575. [Google Scholar] [CrossRef] [PubMed]

- Bartl, A.; Mihalyi, B.; Marini, I. Applications of Renewable Fibrous Materials. Chem. Biochem. Eng. Q. 2004, 18, 21–28. [Google Scholar]

- Djafari Petroudy, S.R. Physical and mechanical properties of natural fibers. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 59–83. [Google Scholar] [CrossRef]

- Madueke, C.I.; Umunakwe, R.; Mbah, O.M. A review on the factors affecting the properties of natural fibre polymer composites. Niger. J. Technol. 2022, 41, 55–64. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Julián, F.; Espinosa, E.; Rodríguez, A.; Espinach, F.X.; Vilaseca, F. Feasibility of Barley Straw Fibers as Reinforcement in Fully Biobased Polyethylene Composites: Macro and Micro Mechanics of the Flexural Strength. Molecules 2020, 25, 2242. [Google Scholar] [CrossRef] [PubMed]

- Bismarck, A.; Mishra, S.; Lampke, T. Plant Fibers as Reinforcement for Green Composites. In Natural Fibers, Biopolymers and Biocomposites; Mohanty, A.K., Misra, M., Drzal, L.T., Eds.; CRC Press: Boca Raton, FL, USA, 2005; pp. 37–108. [Google Scholar]

- Sweygers, N.; Depuydt, D.E.; Eyley, S.; Thielemans, W.; Mosleh, Y.; Ivens, J.; Dewil, R.; Appels, L.; Van Vuure, A.W. Prediction of the equilibrium moisture content based on the chemical composition and crystallinity of natural fibres. Ind. Crops Prod. 2022, 186, 115187. [Google Scholar] [CrossRef]

- Garat, W.; Le Moigne, N.; Corn, S.; Beaugrand, J.; Bergeret, A. Swelling of natural fibre bundles under hygro-and hydrothermal conditions: Determination of hydric expansion coefficients by automated laser scanning. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105803. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Ismadi; Amin, Y.; Damayanti, R.; Lubis, M.A.R.; Wulandari, A.P.; Nurindah; Iswanto, A.H.; et al. A comprehensive review on natural fibers: Technological and socio-economical aspects. Polymers 2021, 13, 4280. [Google Scholar] [CrossRef]

- Sfiligoj Smole, M.; Hribernik, S.; Kurečič, M.; Krajnc, A.U.; Kreže, T.; Kleinschek, K.S. Surface Properties of Non-Conventional Cellulose Fibres; Springer Nature Switzerland AG: Cham, Switzerland, 2019; pp. 1–88. [Google Scholar] [CrossRef]

- Zuhudi, N.Z.M.; Zulkifli, A.F.; Zulkifli, M.; Yahaya, A.N.A.; Nur, N.M.; Aris, K.D.M. Void and moisture content of fiber reinforced composites. J. Adv. Res. Fluid Mech. Therm. Sci. 2021, 87, 78–93. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, S.M.; Ishak, M.R.; Nuraini, A.A. A novel evaluation tool for enhancing the selection of natural fibers for polymeric composites based on fiber moisture content criterion. Bioresources 2015, 10, 299–312. [Google Scholar] [CrossRef]

- Ansell, M.P.; Mwaikambo, L.Y. The structure of cooton and other plant fibres. In Handbook of Textile Fibre Structure, Natural, Regenerated, Inorganic and Specialist Fibres; Eichorn, S.J., Hearle, J.W.S., Jaffe, M., Kikutani, T., Eds.; Woodhead Publishing: Sawston, UK, 2009; pp. 62–94. [Google Scholar]

- Yuksel, I. Fiber Length Measurement by Image Processing. Ph.D. Dissertation, Graduate Faculty of North Carolina State University, Raleigh, NC, USA, 2000. [Google Scholar]

- Batara, A.G.N.; Llanos, P.S.P.; de Yro, P.A.N.; Sanglay, G.C.D.; Magdaluyo, E.R. Surface modification of abaca fibers by permanganate and alkaline treatment via factorial design. In Proceedings of the 7th International Conference on Nano and Materials Science ICNMS 2019, San Francisco, CA, USA, 4–7 January 2019; AIP Publishing: Melville, NY, USA, 2019; Volume 2083, pp. 1–5. [Google Scholar] [CrossRef]

- Martina, T.; Wardiningsih, W.; Rianti, A.; Rudy, R.; Pradana, S.M. An investigation into the potential of water retted fiber from agricultural waste of Curcuma longa plant for textile application. Res. J. Text. Appar. [CrossRef]

- Al-Maharma, A.Y.; Al-Huniti, N. Critical review of the parameters affecting the effectiveness of moisture absorption treatments used for natural composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Shuvo, I.I. Fibre attributes and mapping the cultivar influence of different industrial cellulosic crops (cotton, hemp, flax, and canola) on textile properties. Bioresour. Bioprocess. 2020, 7, 51. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: A comprehensive review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Hussain, M.; Levacher, D.; Leblanc, N.; Zmamou, H.; Djeran-Maigre, I.; Razakamanantsoa, A.; Saouti, L. Analysis of physical and mechanical characteristics of tropical natural fibers for their use in civil engineering applications. J. Nat. Fibers 2023, 20, 2164104. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of mercerization/alkali surface treatment of natural fibres and their utilization in polymer composites: Mechanical and morphological studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Valášek, P.; Müller, M.; Šleger, V.; Kolář, V.; Hromasová, M.; D’Amato, R.; Ruggiero, A. Influence of Alkali Treatment on the Microstructure and Mechanical Properties of Coir and Abaca Fibers. Materials 2021, 14, 2636. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Liu, R.; Shen, D.; Wu, Z.; Huang, Y. Arrangement of cellulose microfibrils in the wheat straw cell wall. Carbohydr. Polym. 2008, 72, 122–127. [Google Scholar] [CrossRef]

- Zhang, L.; Larsson, A.; Moldin, A.; Edlund, U. Comparison of lignin distribution, structure, and morphology in wheat straw and wood. Ind. Crops Prod. 2022, 187, 115432. [Google Scholar] [CrossRef]

- Chen, H.; Wu, J.; Shi, J.; Zhang, W.; Wang, H. Effect of alkali treatment on microstructure and thermal stability of parenchyma cell compared with bamboo fiber. Ind. Crops Prod. 2021, 164, 113380. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M.K. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Marcuello, C.; Foulon, L.; Chabbert, B.; Molinari, M.; Aguié-Béghin, V. Langmuir-Blodgett Procedure to Precisely Control the Coverage of Functionalized AFM Cantilevers for SMFS Measurements: Application with Cellulose Nanocrystals. Langmuir 2018, 34, 9376–9386. [Google Scholar] [CrossRef] [PubMed]

- Fazeli, M.; Florez, J.P.; Simão, R.A. Improvement in adhesion of cellulose fibers to the thermoplastic starch matrix by plasma treatment modification. Compos. B Eng. 2019, 163, 207–216. [Google Scholar] [CrossRef]

- Salim, R.M.; Asik, J.; Sani Sarjadi, M. Chemical functional groups of extractives, cellulose and lignin extracted from native Leucaena leucocephala bark. Wood Sci. Technol. 2021, 55, 295–313. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L.; Chao, Y.; Nawawi, D.S.; Akiyama, T.; Yokoyama, T.; Matsumoto, Y. Analysis of lignin aromatic structure in wood based on the IR spectrum. J. Wood Chem. Technol. 2012, 32, 294–303. [Google Scholar] [CrossRef]

- Suciyati, S.W.; Manurung, P.; Sembiring, S.; Situmeang, R. Comparative study of Cladophora sp. Cellulose by using FTIR and XRD. J. Phys. Conf. Ser. 2021, 1751, 012075. [Google Scholar] [CrossRef]

- Hansen, M.A.T.; Hidayat, B.J.; Mogensen, K.K.; Jeppesen, M.D.; Jorgensen, M.D.; Johansen, K.S.; Thygesen, L.G. Enzyme affinity to cell types in wheat straw (Triticum aestivum L.) before and after hydrothermal pretreatment. Biotechnol. Biofuels 2013, 6, 54. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing cellulose structures with vibrational spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

- Cai, H.; Du, F.; Li, B.; Shi, H. A practical approach based on FTIR spectroscopy for identification of semi-synthetic and natural celluloses in microplastic investigation. Sci. Total Environ. 2019, 669, 692–7014. [Google Scholar] [CrossRef]

- Abidi, N.; Hequet, E.; Cabrales, L.; Wilkins, T.; Wells, L.W. Evaluating Cell Wall Structure and Composition of Developing Cotton Fibers using Fourier Transform Infrared Spectroscopy and Thermogravimetric Analysis. J. Appl. Polym. Sci. 2008, 107, 476–486. [Google Scholar] [CrossRef]

- Fellak, S.; Rafik, M.; Haidara, H.; Boukir, A.; Lhassani, A. Study of natural degradation effect on lignocellulose fibers of archeological cedar wood: Monitoring by Fourier Transform Infrared (FTIR) spectroscopy. MATEC Web Conf. 2022, 360, 00006. [Google Scholar] [CrossRef]

- Hospodarova, V.; Singovszka, E.; Stevulova, N. Characterization of Cellulosic Fibers by FTIR Spectroscopy for their Further Implementation to Building Materials. Am. J. Anal. Chem. 2018, 9, 303–310. [Google Scholar] [CrossRef]

- Zeng, Y.; Himmel, M.E.; Ding, S.-Y. Visualizing chemical functionality in plant cell walls. Biotechnol. Biofuels 2017, 10, 263. [Google Scholar] [CrossRef]

- Oriez, V.; Peydecastaing, J.; Pontalier, P.-Y. Lignocellulosic Biomass Mild Alkaline Fractionation and Resulting Extract Purification Processes: Conditions, Yields, and Purities. Clean Technol. 2020, 2, 91–115. [Google Scholar] [CrossRef]

- Durot, N.; Gaudard, F.; Kurek, B. The unmasking of lignin structures in wheat straw by alkali. Phytochemistry 2003, 63, 617–623. [Google Scholar] [CrossRef]

| Fiber | Total Production (%) |

|---|---|

| Cotton | 22 |

| Other plant fibers | 5.9 |

| Wool | 3 |

| Other animal fibers | 0.71 |

| Polyester | 54 |

| Polyamide | 5 |

| Polypropylene, acrylics, and elastane | 5.2 |

| Manufactured cellulosics | 64 |

| Plant (Stalk/Straw) | Cellulose Content (%) | Reference |

|---|---|---|

| Cotton | 40.1 | [17] |

| Kenaf | 40.2 | [17] |

| Flax | 68 | [14] |

| Hemp | 70 | [16] |

| Bamboo | 48 | [16] |

| Corn | 42.2 | [15] |

| Barley | 47.1 | [15] |

| Rye | 52 | [15] |

| Rice | 38.3 | [14] |

| Description | References |

|---|---|

| Wheat straw infused with animal glue as reinforcement in composite materials | [38] |

| Wheat fibers isolated by mechanical process and microbial retting (fiber length is up to 4 mm) | [45] |

| Wheat straw as reinforcement in composite materials (chopped to the size 18–20 cm, 5 to 15 mm, and 2.5 cm; milled to the particle size up to 1 mm) | [31,32,33,35] |

| Wheat straw fiber-based hand sheets (unbleached wheat straw fibers, fiber length < 0.58 mm) | [39,43] |

| Wheat straw fibers as building material (milled and sieved straw, particle size 0.3 mm, and chopped straw up to 32 mm in length) | [23,24] |

| Milled wheat straw as reinforcement for biocomposites. | [40] |

| Nanocellulose derived from wheat straw as reinforcement in composite materials | [34,41] |

| Milled and sieved straw (fiber/particle size 75 to 300 µm) as a soil stabilizer | [25] |

| Chopped and grounded wheat straw for pellet production | [26] |

| Wheat cellulose nanofibers as superabsorbent material | [29] |

| Crushed wheat straw as a source of cellulose fibers | [42] |

| Wheat nanocellulose as nanoadsorbent for metal ions removal from wastewater | [30] |

| Cellulose fiber isolation from the dried and milled wheat straw powder (particle size < 1 mm) | [44] |

| Wheat cellulose pulp for paper production | [37] |

| Srpanjka (2021) | Srpanjka (2022) | Kraljica (2021) | Kraljica (2022) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T [cN/tex] | YM [cN/tex] | E [%] | T [cN/tex] | YM [cN/tex] | E [%] | T [cN/tex] | YM [cN/tex] | E [%] | T [cN/tex] | YM [cN/tex] | E [%] | |

| Average | 20.69 | 396.82 | 4.81 | 21.10 | 273.48 | 6.00 | 25.66 | 460.71 | 5.35 | 25.28 | 405.52 | 5.52 |

| SD | 5.98 | 221.17 | 1.25 | 8.49 | 185.69 | 1.19 | 10.53 | 328.63 | 1.21 | 11.25 | 287.50 | 1.55 |

| CV [%] | 28.93 | 55.73 | 25.94 | 40.22 | 67.90 | 19.88 | 41.04 | 71.33 | 22.65 | 44.51 | 70.90 | 28.14 |

| SE [%] | 1.66 | 61.31 | 0.35 | 2.35 | 51.47 | 0.33 | 2.92 | 91.09 | 0.34 | 3.12 | 79.69 | 0.43 |

| Tensile Properties | Cotton | Flax | Hemp | Jute | Spanish Broom | Wheat | Barley | Sisal | Coir |

|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | 287–597 | 345–900 | 300–800 | 200–800 | 500–1100 | 190–380 | 190–380 | 100–800 | 13–220 |

| Young’s Modulus (GPa) | 5.5–12.6 | 27–80 | 30–70 | 10–55 | 15–20 | 3–7 | 3–10 | 9–28 | 4–6 |

| Elongation (%) | 3–10 | 1.2–1.6 | 1.3–1.6 | 1.4–1.8 | 3–9 | 4–6 | 3–7 | 2–3 | 15–40 |

| Reference | [67] | [68] | [65] | This study | [57] | [68] | |||

| Srpanjka (2021) | Srpanjka (2022) | Kraljica (2021) | Kraljica (2022) | |

|---|---|---|---|---|

| Average [cm] | 2.95 | 2.30 | 2.76 | 2.38 |

| Standard deviation [cm] | 0.86 | 0.83 | 0.76 | 0.78 |

| Coefficient of variation [%] | 29.08 | 35.91 | 27.49 | 32.86 |

| Standard error [%] | 0.17 | 0.16 | 0.15 | 0.15 |

| Moisture Content of Wheat Fibers [%] | ||||

|---|---|---|---|---|

| Srpanjka (2021) | Srpanjka (2022) | Kraljica (2021) | Kraljica (2022) | |

| Average [%] | 8.93 | 6.58 | 9.61 | 7.21 |

| Standard deviation [%] | 0.13 | 0.02 | 0.02 | 0.07 |

| Coefficient of variation [%] | 1.43 | 0.30 | 0.25 | 0.98 |

| Standard error [%] | 0.14 | 0.02 | 0.03 | 0.08 |

| Moisture Regain of Wheat Fibers [%] | ||||

|---|---|---|---|---|

| Srpanjka (2021) | Srpanjka (2022) | Kraljica (2021) | Kraljica (2022) | |

| Average [%] | 11.18 | 9.72 | 11.40 | 11.10 |

| Standard deviation [%] | 0.21 | 0.05 | 0.04 | 0.19 |

| Coefficient of variation [%] | 1.86 | 0.48 | 0.39 | 1.68 |

| Standard error [%] | 0.24 | 0.05 | 0.05 | 0.21 |

| Fiber Category | Fiber | Diameter (µm) | Length (mm) | Moisture Regain (%) | Density (g/cm3) | Reference |

|---|---|---|---|---|---|---|

| Seed fiber | Cotton | 10–22 | 12–64 | 8.5 | 1.55 | [85,86] |

| Stem fiber | Flax | 40–600 | 5–900 | 7 | 1.4–1.5 | [65,68] |

| Hemp | 10–500 | 5–56 | 8 | 1.3–1.6 | ||

| Jute | 25–200 | 1.5–120 | 12 | 1.4–1.8 | ||

| Spanish broom | 10–200 | 5–900 | 8 | 1.55–1.6 | [65] | |

| Straw/stem fiber | Wheat | 10–350 | 10–60 | 9–12 | 1.4–1.6 | This study |

| Barley | 10–350 | 5–100 | 10–11 | 1.4–1.5 | [57] | |

| Leaf fiber | Sisal | 8–200 | 900 | 11 | 1.2–1.5 | [68,85] |

| Fruit fiber | Coir | 10–460 | 20–150 | 13 | 1.1–1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovačević, Z.; Bischof, S.; Bilandžija, N.; Krička, T. Conversion of Waste Agricultural Biomass from Straw into Useful Bioproducts—Wheat Fibers and Biofuels. Sustainability 2024, 16, 4739. https://doi.org/10.3390/su16114739

Kovačević Z, Bischof S, Bilandžija N, Krička T. Conversion of Waste Agricultural Biomass from Straw into Useful Bioproducts—Wheat Fibers and Biofuels. Sustainability. 2024; 16(11):4739. https://doi.org/10.3390/su16114739

Chicago/Turabian StyleKovačević, Zorana, Sandra Bischof, Nikola Bilandžija, and Tajana Krička. 2024. "Conversion of Waste Agricultural Biomass from Straw into Useful Bioproducts—Wheat Fibers and Biofuels" Sustainability 16, no. 11: 4739. https://doi.org/10.3390/su16114739