Performance Analysis and Optimization of Solar-Coupled Mine Water-Source Heat Pump Combined Heating and Cooling System

Abstract

:1. Introduction

2. Case Study

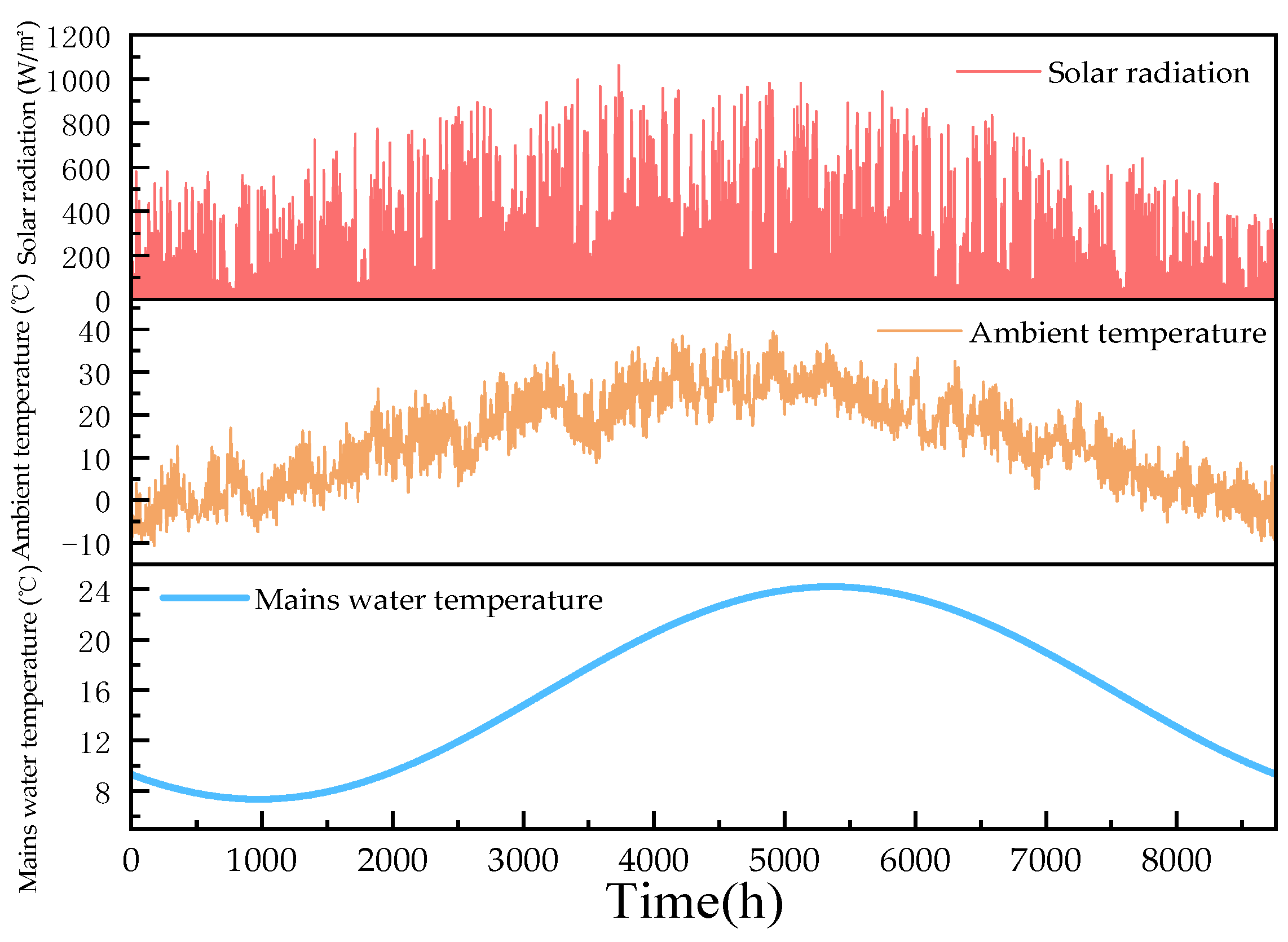

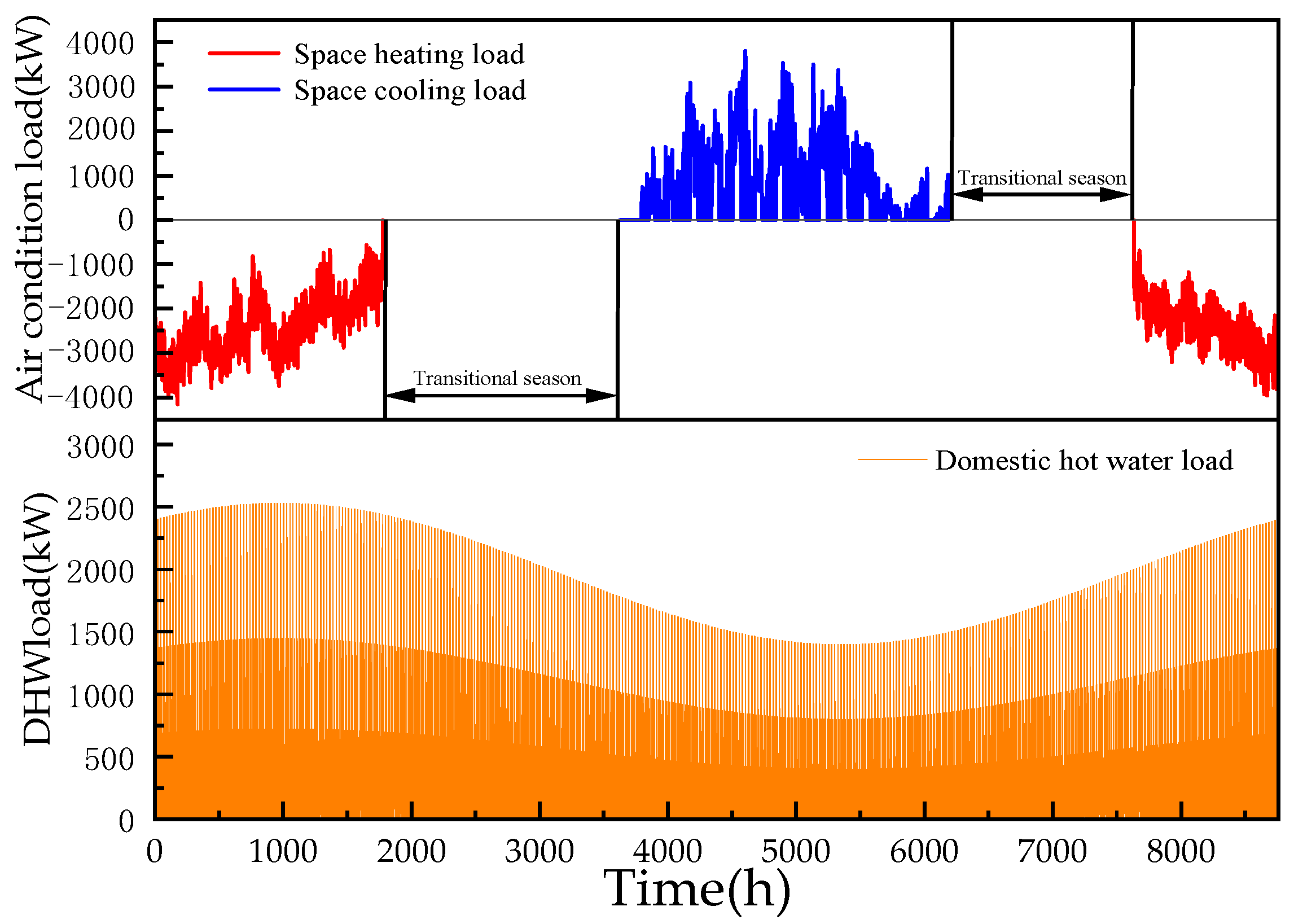

2.1. Building Space Heating, Space Cooling, and Domestic Hot Water Load

2.2. Analysis of Available Heat and Cold Energy of Mine Water

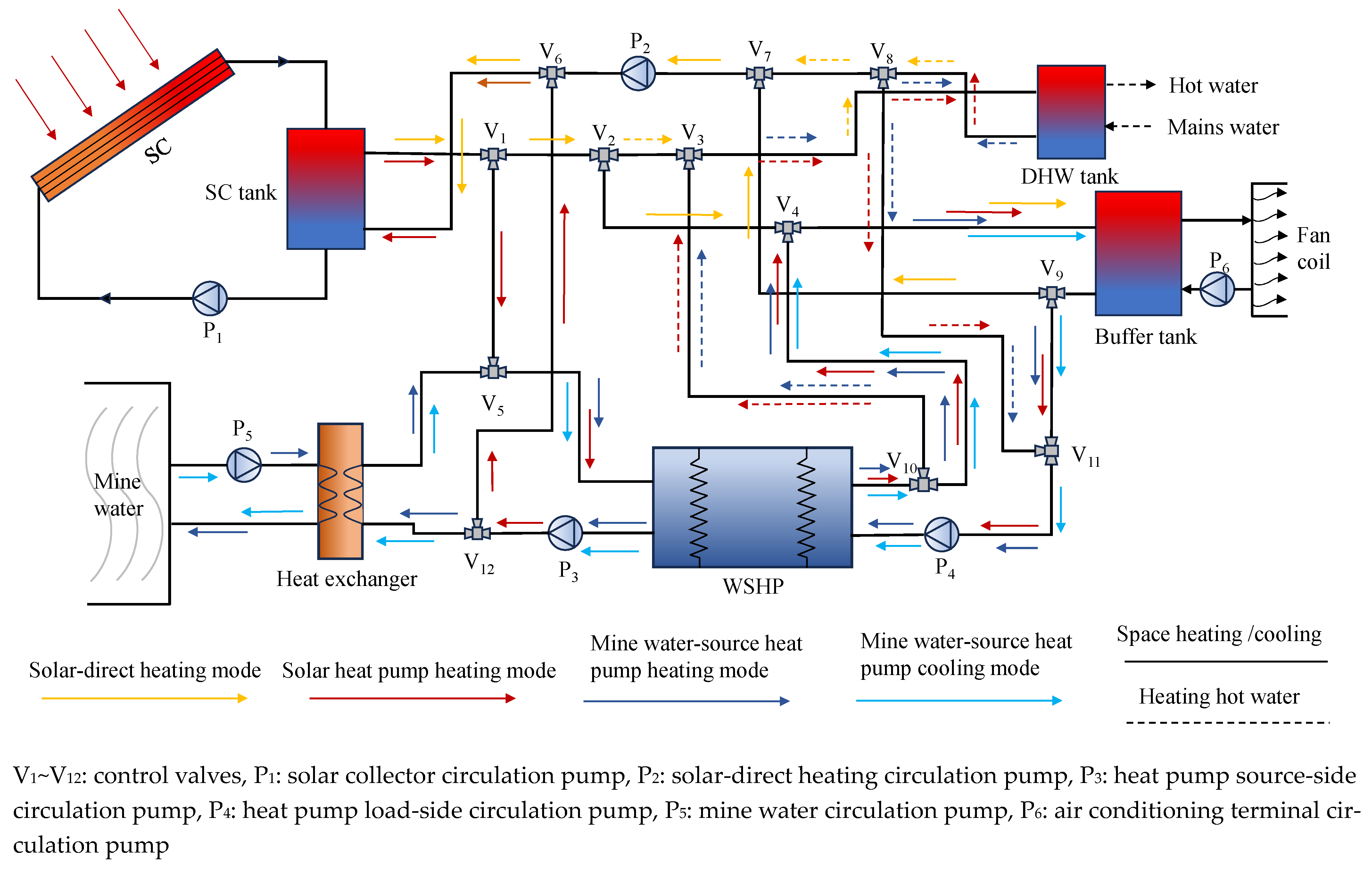

3. SMWHP-CHC System Introduction

3.1. System Principle

3.2. Operation Control Strategy

4. SMWHP-CHC System Simulation Model

4.1. Mathematical Model of Main Devices

- (1)

- Solar collector model

- (2)

- Water-source heat pump model

- (3)

- Energy storage water tank model

- (4)

- Exchanger model

4.2. Establishment of SMWHP-CHC System’s TRNSYS Simulation Model

4.3. Evaluation Index

- (1)

- System heat/cooling supply, operating power consumption:

- (2)

- Solar contribution rate:

- (3)

- Heating coefficient of performance of the system (COPsys) and cooling energy efficiency ratio of the system (EERsys):

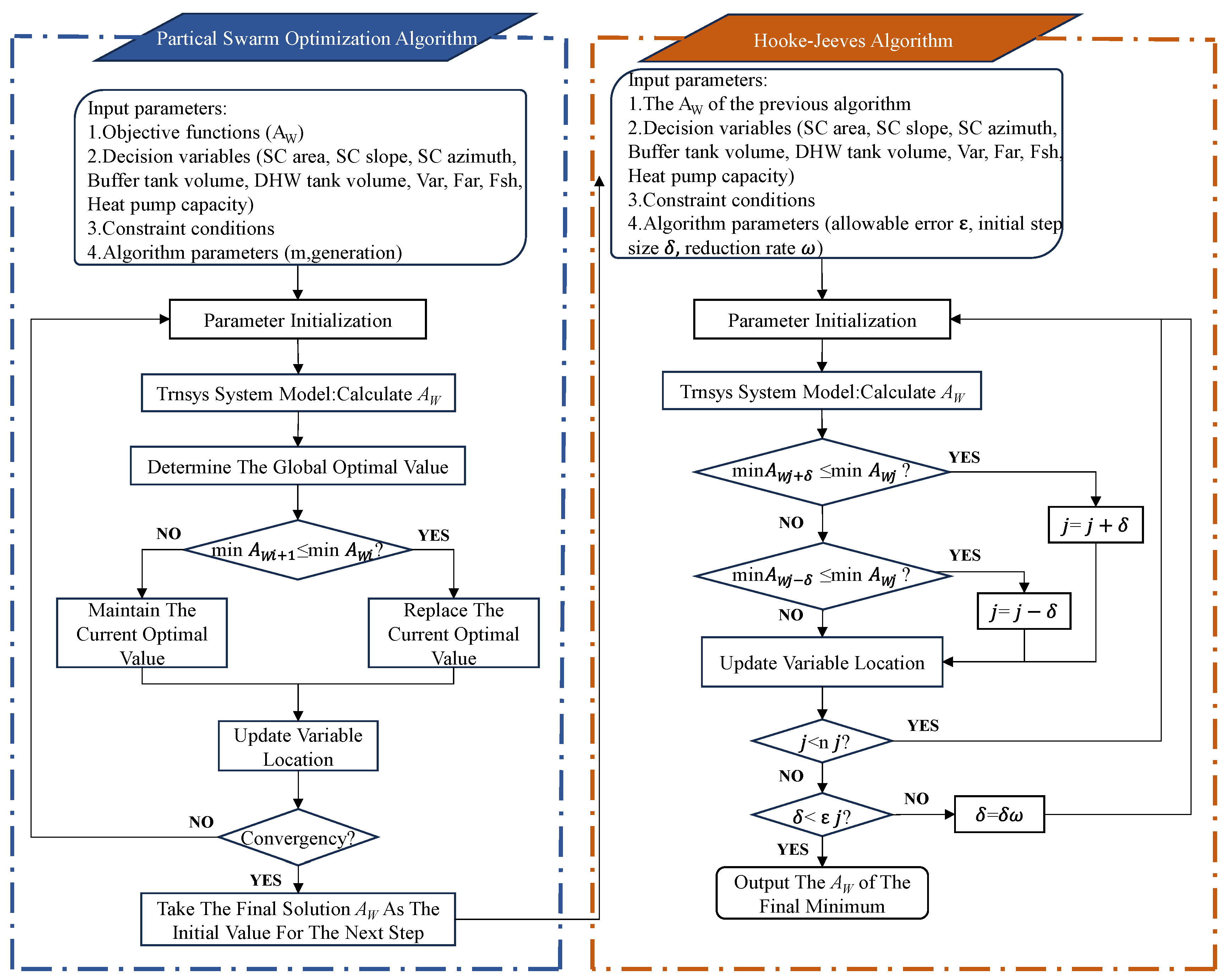

5. SMWHP-CHC System Optimization Scheme

5.1. Optimization Objective

5.2. Optimization Variable

5.3. Optimization Algorithm

6. Results and Discussion

6.1. SMWHP-CHC System Performance Analysis

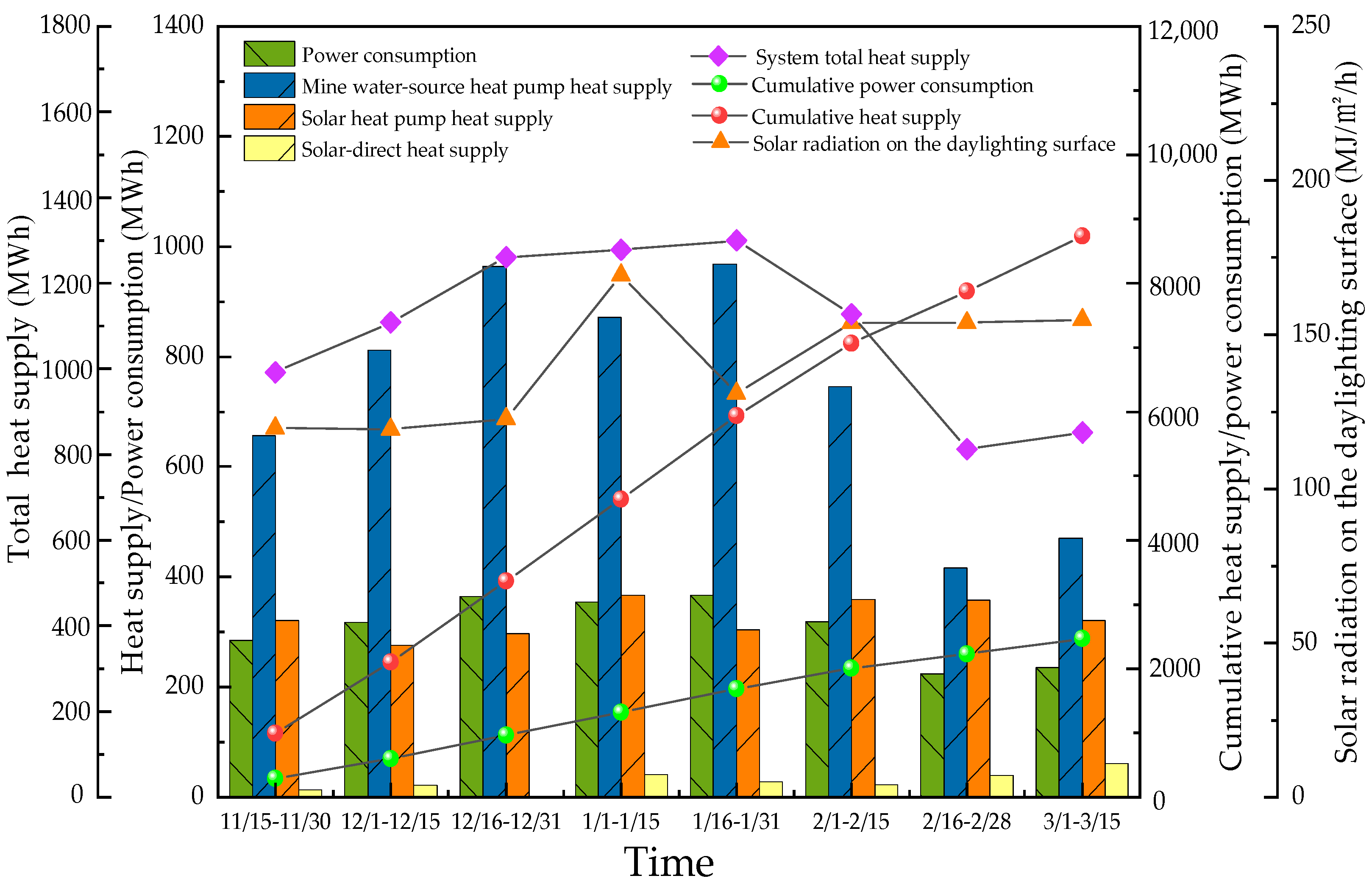

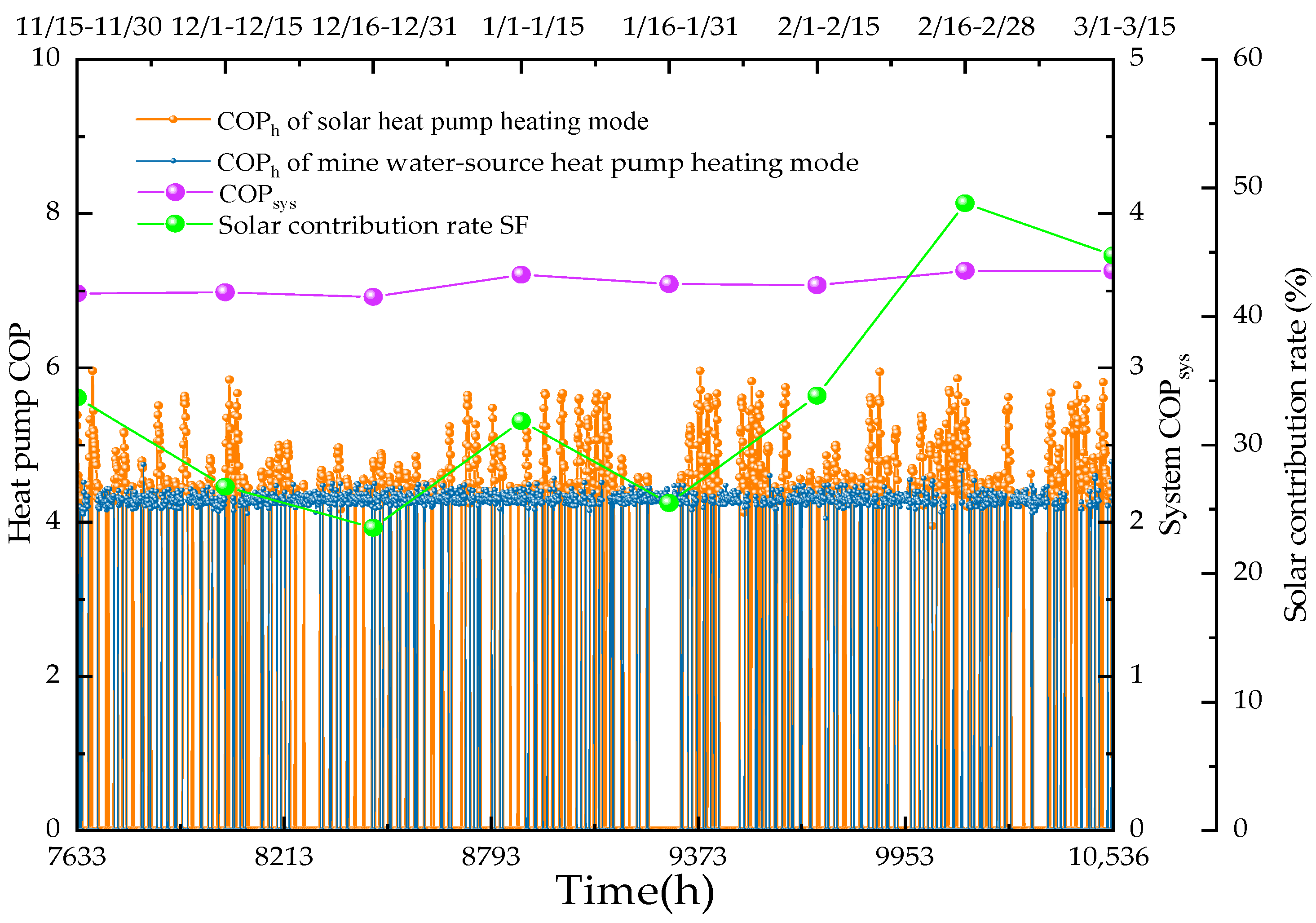

6.1.1. Analysis of System Performance during the Space Heating Season

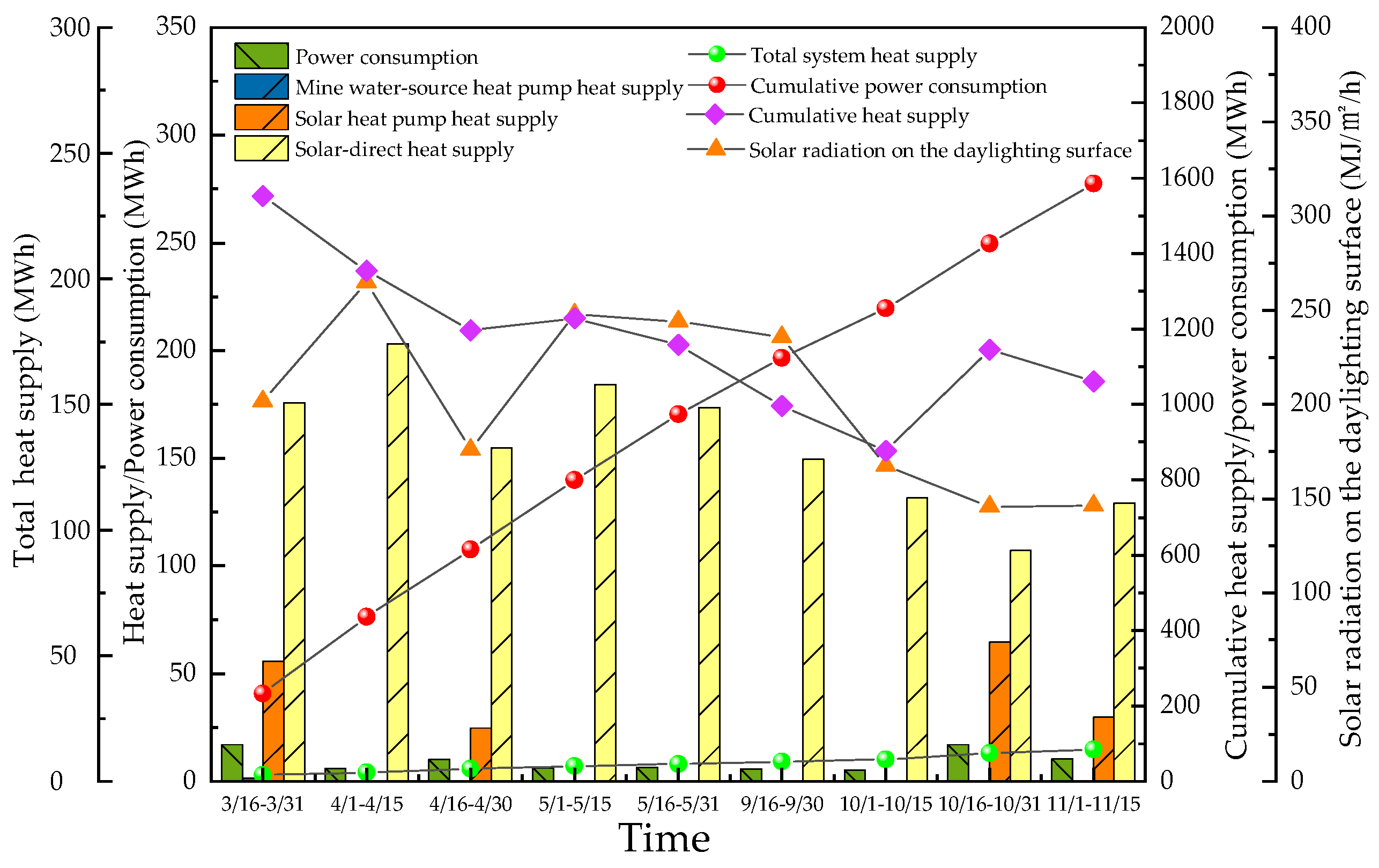

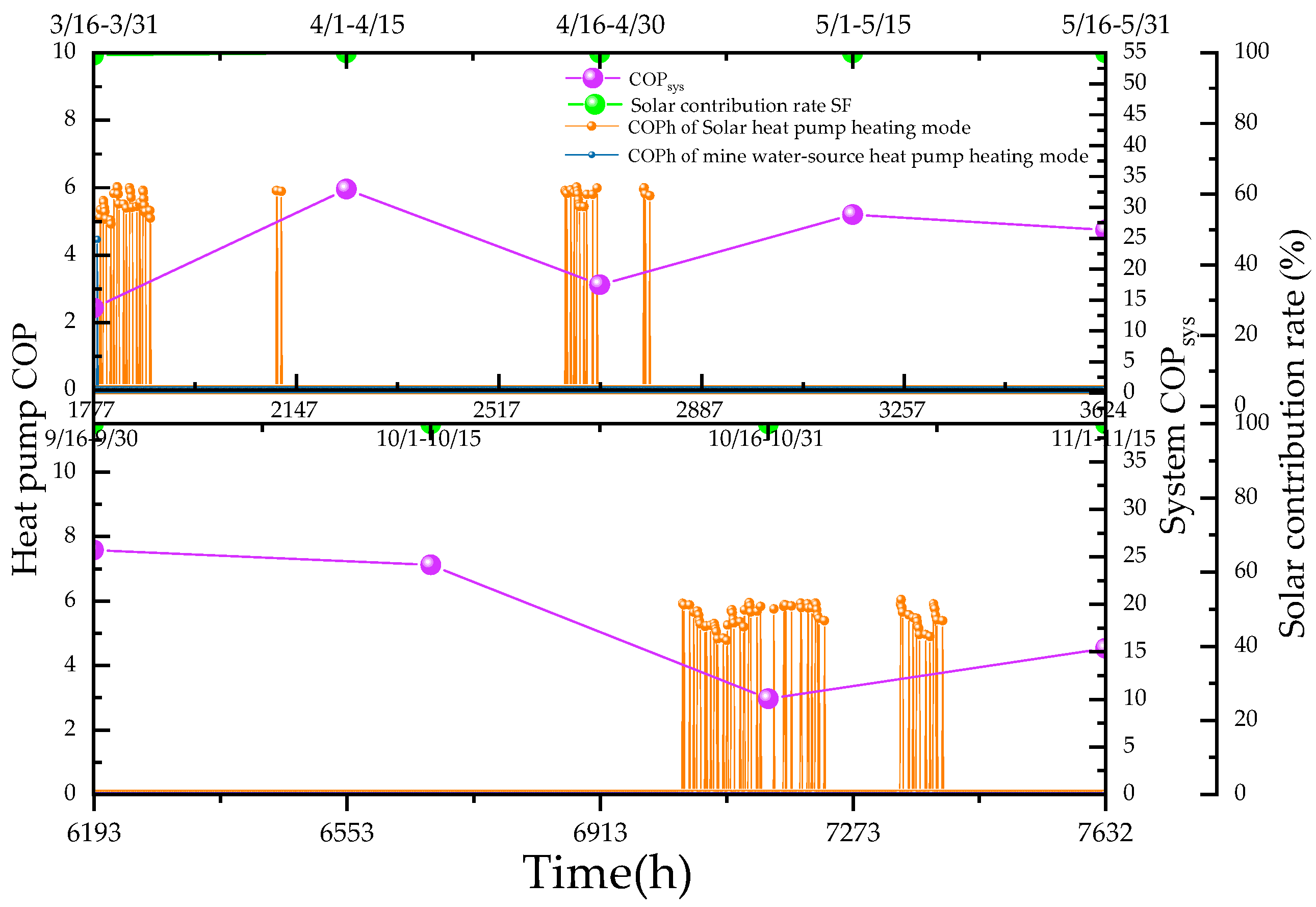

6.1.2. Analysis of System Performance during the Transition Season

6.1.3. Analysis of System Performance during the Space Cooling Season

6.2. Analysis of SMWHP-CHC System Optimization Results

7. Conclusions

- (1)

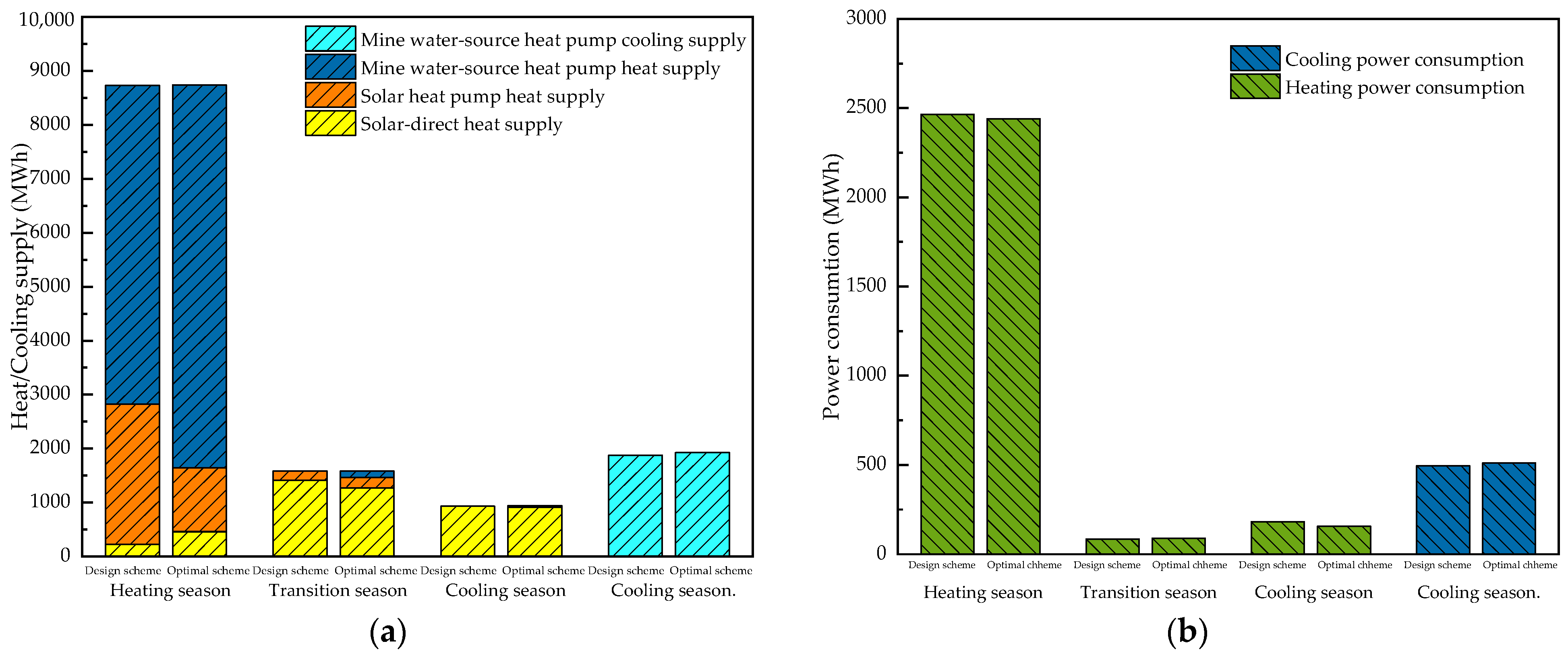

- The system was capable of meeting the space heating, space cooling, and annual hot water load demands of the case buildings. The system’s cumulative total heat supply in the heating season was 8.728 × 106 kWh, 1.585 × 106 kWh in the transition season, and 9.397 × 105 kWh in the cooling season. The system’s cumulative cooling supply was 1.878 × 106 kWh. The system’s power consumption was 2.465 × 106 kWh in the heating season, 8.506 × 104 kWh in the transition season, 6.768 × 105 kWh in the cooling season.

- (2)

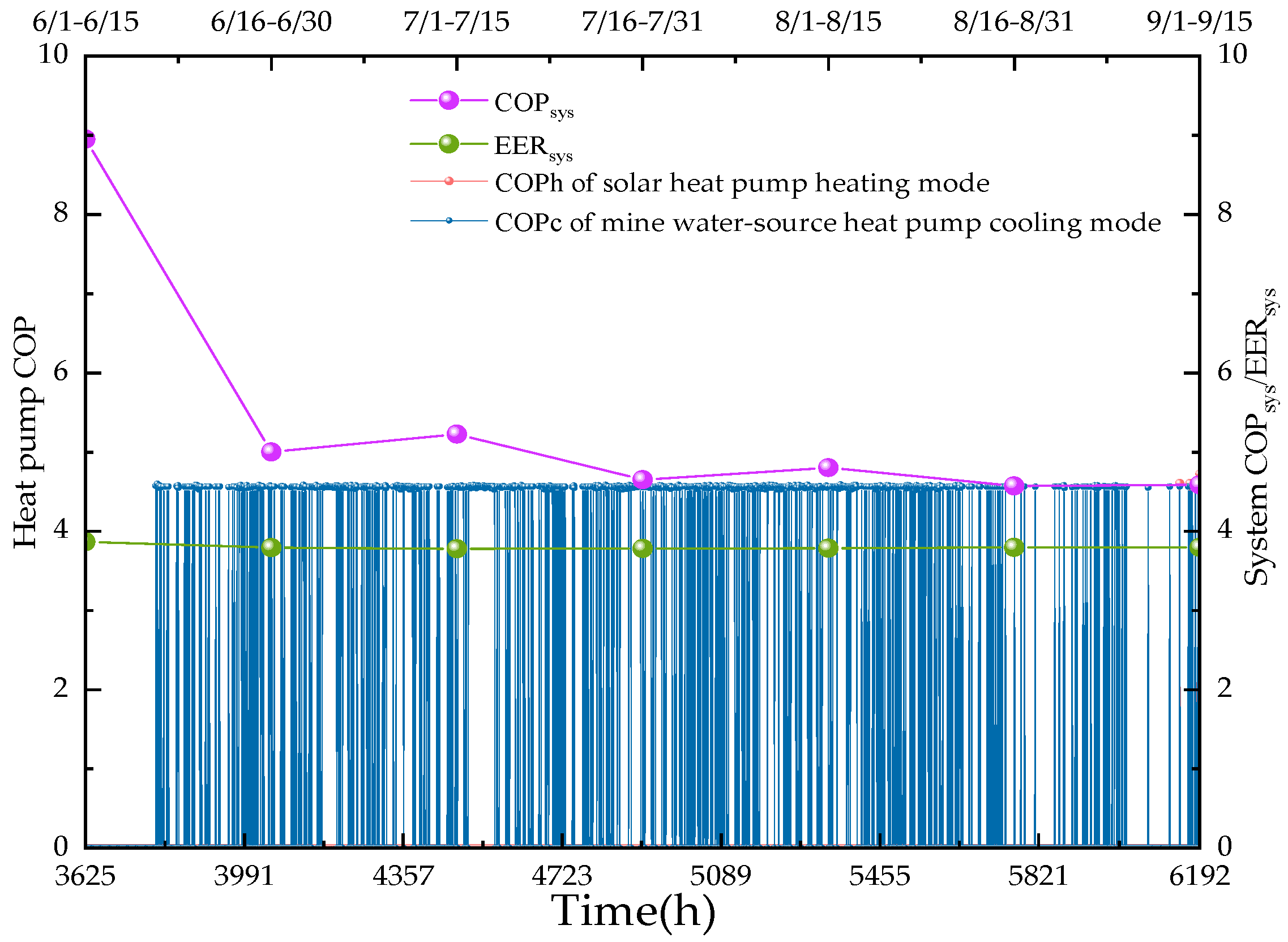

- The utilization of solar energy could enhance the performance of the heat pump system. During the space heating season, the COPh of the solar heat pump heating mode was significantly higher than that of the mine water-source heat pump heating mode. The average COPh of the solar heat pump heating mode was 4.75, while that of the mine water-source heat pump heating mode was 4.29. During the transition season, the average COPh of the solar heat pump heating mode was 5.58. The average COPc of the mine water-source heat pump cooling mode was 4.56.

- (3)

- The solar contribution rate SF reached up to 32.4% in the entire space heating season. In the non-space heating season, nearly the entire domestic hot water demand was met by solar energy. The performance of the system improved with the increase in the SF. The COPsys values during the space heating season, transitional season, and cooling season were 3.54, 18.6, and 5.14, respectively, and the EERsys was 3.79, demonstrating excellent performance throughout the year.

- (4)

- According to the system optimization results, it is evident that the PSO-HJ hybrid optimization algorithm effectively enhanced the convergence of the optimization. The system’s annual cost reached a minimum when the SC area was 10,531m2, the SC slope was 41.1°, the SC azimuth was 35.4°, the Var was 0.011 m3/m2, the Far was 20.9 m3/h·m2, the Fsh was 156.4 m3/h, the heat pump capacity was 6017 kW, the buffer tank volume was 947 m3, and the DHW tank volume was 381 m3.

- (5)

- Compared with before optimization, the optimized system’s annual cost decreased by 8.82%, and the investment cost decreased by 21.7%. Additionally, the optimized system’s annual cumulative total heat supply was 0.11% higher than that before optimization, the cooling supply was 2.5% higher than that before optimization, and the annual cumulative power consumption was 0.84% lower than that before optimization. After optimization, the investment cost of the system was significantly reduced, and the performance of the system was also improved.

- (1)

- The control the of system in this study was primarily constant frequency control; research can be conducted on variable frequency control and optimization of the system to further improve the system performance in the future.

- (2)

- This study only used the main parameters of devices as optimization variables, but the system operating parameters in the control strategy of the system also have an impact on the optimization objectives. Further research on this aspect can be conducted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hoang, A.T.; Foley, A.M.; Nizetic, S.; Huang, Z.; Ong, H.C.; Olcer, A.I.; Pham, V.V.; Nguyen, X.P. Energy-related approach for reduction of CO2 emissions: A critical strategy on the port-to-ship pathway. Clean. Prod. 2022, 355, 131772. [Google Scholar] [CrossRef]

- Liu, Z.J.; Zhang, Y.L.; Xu, W.; Yang, X.Y.; Liu, Y.W.; Jin, G.Y. Suitability and feasibility study on the application of groundwater source heat pump (GWSHP) system in residential buildings for different climate zones in China. Energy Rep. 2020, 6, 2587–2603. [Google Scholar] [CrossRef]

- Amasyali, K.; El-Gohary, N.M. A review of data-driven building energy consumption prediction studies. Renew. Sustain. Energy Rev. 2018, 81, 1192–1205. [Google Scholar] [CrossRef]

- Diao, Y.; Qi, N.; Wang, Z.; Zhao, Y.; Wang, Z. Thermal performance analysis of a solar air collection–cascade storage system integrated with micro-heat pipe arrays. Sol. Energy 2021, 224, 1271–1290. [Google Scholar] [CrossRef]

- Nagpal, H.; Spriet, J.; Murali, M.K.; McNabola, A. Heat Recovery from Wastewater-A Review of Available Resource. Water 2021, 13, 1274. [Google Scholar] [CrossRef]

- Hepbasli, A.; Biyik, E.; Ekren, O.; Gunerhan, H.; Araz, M. A key review of wastewater source heat pump (WWSHP) systems. Energy Conv. Manag. 2014, 88, 700–722. [Google Scholar] [CrossRef]

- Menéndez, J.; Ordónez, A.; Fernández-Oro, J.M.; Loredo, J.; Díaz-Aguado, M.B. Feasibility analysis of using mine water from abandoned coal mines in Spain for heating and cooling of buildings. Renew. Energy 2020, 146, 1166–1176. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, P.; Ren, P.; Bao, L.; Liang, C. The Application of Sewage Source Heat Pump Technology in Oilfield Station. Energy Conserv. Pet. Petrochem. Ind. 2017, 7, 7–9. [Google Scholar]

- Kim, Y.; Lim, J.; Shim, J.Y.; Hong, S.; Lee, H.; Cho, H. Optimization of Heat Exchanger Network via Pinch Analysis in Heat Pump-Assisted Textile Industry Wastewater Heat Recovery System. Energies 2022, 15, 3090. [Google Scholar] [CrossRef]

- Liu, L.; Fu, L.; Jiang, Y. Application of an exhaust heat recovery system for domestic hot water. Energy 2009, 35, 1476–1481. [Google Scholar] [CrossRef]

- Bai, B. Simulation and Analysis of Solar-Assist Sewage Source Heat Pump Coupling System Operating Characteristics. Master’s Thesis, Shenyang Architectural University, Shenyang, China, 2016. [Google Scholar]

- Starke, A.R.; Cardemil, J.M.; Escobar, R.; Colle, S. Thermal analysis of solar-assisted heat pumps for swimming pool heating. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2289–2306. [Google Scholar] [CrossRef]

- Xie, X. Optimization and Operation Analysis of Sewage Source Heat Pump Combined with Solar Heating System. Master’s Thesis, Harbin Engineering University, Harbin, China, 2018. [Google Scholar]

- Mi, P.Y.; Ma, L.D.; Zhang, J.L. Integrated optimization study of hot water supply system with multi-heat-source for the public bath based on PVT heat pump and water source heat pump. Appl. Therm. Eng. 2020, 176, 11. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, D.; Luo, J.; Liu, H.; Yang, T. Research on optimization of solar-assist sewage source heat pump coupling hot water system based on taguchi method. Renew. Energy Resour. 2021, 39, 1463–1469. [Google Scholar]

- Cheng, C.; Jiang, Y.; Wang, F. Continuous Operation Analysis of New Solar Sewage Dual-source Heat Pump for Nearly Zero-energy Buildings. J. Refrig. 2022, 43, 142–149. [Google Scholar]

- Zhang, D.W.; Gao, Z.; Fang, C.L.; Shen, C.; Li, H.; Qin, X. Simulation and analysis of hot water system with comprehensive utilization of solar energy and wastewater heat. Energy 2022, 253, 11. [Google Scholar] [CrossRef]

- Ren, Q.; Jia, J.; Tian, Q. Status and development direction of heat pump technology in mine waste heat recovery. Dist. Heat. 2023, 102–108. [Google Scholar] [CrossRef]

- Gu, D.; Li, J.; Cao, Z.; Wu, B.; Jiang, B.; Yang, Y.; Yang, J.; Chen, Y. Technology and engineering development strategy of water protection and utilization of coal mine in China. J. China Coal Soc. 2021, 46, 3079–3089. [Google Scholar]

- Xiang, Y.; Yang, Y. Advances on waste heat utilization technologies of low-temperature water resources in coal mines. Coal Qual. Technol. 2023, 38, 27–32. [Google Scholar]

- Liu, Y.F.; Zhao, Y.T.; Chen, Y.W.; Wang, D.J.; Li, Y.; Yuan, X.P. Design optimization of the solar heating system for office buildings based on life cycle cost in Qinghai-Tibet plateau of China. Energy 2022, 246, 16. [Google Scholar] [CrossRef]

- Yue, H.; Xu, Z.; Wang, N.; Zhang, H.; Chen, H. Performance Analysis and Optimization of Photovoltaic/thermal Tri-generation System. J. North China Electr. Power Univ. 2024, 1–8. [Google Scholar] [CrossRef]

- Liu, Y.F.; Zhou, W.H.; Luo, X.; Wang, D.J.; Hu, X.X.; Hu, L. Design and operation optimization of multi-source complementary heating system based on air source heat pump in Tibetan area of Western Sichuan, China. Energy Build. 2021, 242, 17. [Google Scholar] [CrossRef]

- Gök, O.; Atmaca, A.U.; Erek, A.; Altay, H.M. TRNSYS Model of the combi boiler domestic hot water circuit with a focus on the parameter definition of the plat heat exchanger. ISI Bilim. Tek. Derg. 2023, 43, 191–205. [Google Scholar] [CrossRef]

- Zheng, R.; He, T. Technical Code for Solar Heating System, 2nd ed.; China Academy of Building Sciences: Beijing, China, 2019. [Google Scholar]

- Xu, W.; Zou, Y. Design Code for Heating Ventilation and Air Conditioning of Civil Buildings, 2nd ed.; China Academy of Building Sciences: Beijing, China, 2012. [Google Scholar]

- Jiang, J.J.; Wei, W.X.; Shao, W.L.; Liang, Y.F.; Qu, Y.Y. Research on Large-Scale Bi-Level Particle Swarm Optimization Algorithm. IEEE Access 2021, 9, 56364–56375. [Google Scholar] [CrossRef]

- Litvinas, L. A hybrid of Bayesian-based global search with Hooke-Jeeves local refinement for multi-objective optimization problems. Nonlinear Anal.-Model Control 2022, 27, 534–555. [Google Scholar] [CrossRef]

| Heat transfer coefficient of the building envelope W(m2·K) | Exterior wall | Interior wall | Roof | Exterior window |

| 0.621 | 0.947 | 0.402 | 2.04 | |

| Air conditioning design set parameters | Indoor | Terminal inlet water | Period | |

| Space heating season | 20 °C | 45 °C | 11.15~next year 3.15 | |

| Space cooling season | 26 °C | 7 °C | 6.1~9.15 | |

| Mode | Judging Condition | Operating Devices |

|---|---|---|

| Solar-direct heating mode. | During the space heating season, when TS1 ≥ 45 °C, heat both the DHW tank and the buffer tank concurrently; when TS1 < 45 °C, turn off. | P2, V1, V2, V3, V4, V6, V7, V8, and V9. |

| During the non-space heating season, when TS1 ≥ 45 °C, heat the DHW tank; when TS1 < 45 °C or Tdhw1 > TS1, turn off. | P2, V1, V2, V3, V6, V7, and V8. | |

| Solar heat pump heating mode | When TS1 ≥ 15 °C and TS2 ≥ 10 °C and Tdhw < 43 °C, heat the DHW tank; when TS1 < 15 °C or TS2 < 10 °C or Tdhw ≥ 45 °C, turn off. | WHSP, P3, P4, V1, V3, V5, V6, V8, V10, V11, and V12. |

| During the space heating season, when TS1 ≥ 15 °C and TS2 ≥ 10 °C and Tn < 20 °C and TL < 45 °C, heat the buffer tank; when TS1 < 15 °C or TS2 < 10 °C or TL ≥ 48 °C, turn off. | WHSP, P3, P4, V1, V4, V5, V6, V9, V10, V11, and V12. | |

| During the space heating season, when TS1 ≥ 15 °C and TS2 ≥ 10 °C and Tn < 20 °C and TL < 45 °C and Tdhw < 43 °C, heat both the DHW tank and buffer tank concurrently; when TS1 < 15 °C or TS2 < 10 °C or TL ≥ 48 °C or Tdhw ≥ 45 °C, turn off. | WHSP, P3, P4, V1, V3, V4, V5, V6, V8, V9, V10, V11, and V12. | |

| Mine water-source heat pump heating mode. | When TS1 < 15 °C or TS2 < 10 °C, and Tdhw < 43 °C, heat the DHW tank; when TS1 ≥ 15 °C and TS2 ≥ 10 °C, or Tdhw ≥ 45 °C, turn off. | WHSP, P3, P4, P5, V3, V5, V8, V10, V11, and V12. |

| During the space heating season, when TS1 < 15 °C or TS2 < 10 °C, and TL < 45 °C and Tdhw < 43 °C, heat the buffer tank; when TS1 ≥ 15 °C and TS2 ≥ 10 °C, or TL ≥ 48 °C, turn off. | WHSP, P3, P4, P5, V4, V5, V9, V10, V11, and V12. | |

| During the space heating season, when TS1 < 15 °C or TS2 < 10 °C, and Tn < 20 °C and TL < 45 °C and Tdhw < 43 °C, heat both the DHW tank and the buffer tank concurrently; when TS1 ≥ 15 °C and TS2 ≥ 10 °C, or Tdhw ≥ 45 °C or TL ≥ 4 °C, turn off. | WHSP, P3, P4, P5, V3, V4, V5, V8, V9, V10, V11, and V12. | |

| Mine water-source heat pump cooling mode. | During air conditioning operation in the space cooling season, when Tn > 26 °C and TL > 7 °C, cool the buffer tank; when Tn ≤ 26 °C or TL ≤ 5 °C, turn off. | WHSP, P3, P4, P5, V4, V5, V9, V10, V11, and V12. |

| Other related operation strategies: 1. The solar collector cycle is controlled by monitoring the temperature difference ΔTS between the inlet and outlet of the collector, so that when ΔTS ≤ 2 °C, P1 is off, and when ΔTS > 8 °C, P1 is open. 2. The terminal circulation of the system is controlled by monitoring the temperature Tn, so that when Tn < 20 °C during the space heating season or Tn > 26 °C during the space cooling season, P6 is open, otherwise it remains off. | ||

| Device | Parameters/Unit | Value |

|---|---|---|

| SC | Thermal efficiency/% | 80 |

| Area/m2 | 14,656 | |

| Slope/° | 34.5 | |

| Azimuth/° | 0 | |

| WSHP | Rated heating capacity/kW | 6688 |

| Rated heating power/kW | 1486 | |

| Rated cooling capacity/kW | 6431 | |

| Rated cooling power/kW | 1340 | |

| SC tank | Volume/m3 | 586 |

| Buffer tank | Volume/m3 | 700 |

| DHW tank | Volume/m3 | 330 |

| Exchanger | Area/m2 | 526 |

| Heat transfer coefficient/kW·m−2·K−1 | 3 | |

| Solar collector circulation pump | Rated flow/kg·h−1 | 439.68 |

| Rated power/kW | 25.67 | |

| Solar-direct heating circulation pump | Rated flow/kg·h−1 | 439.68 |

| Rated power/kW | 25.67 | |

| Heat pump source-side circulation pump | Rated flow/kg·h−1 | 977.92 |

| Rated power/kW | 57.1 | |

| Heat pump load-side circulation pump | Rated flow/kg·h−1 | 1105.04 |

| Rated power/kW | 64.5 | |

| Mine water circulation pump | Rated flow/kg·h−1 | 488.96 |

| Rated power/kW | 38 | |

| Air conditioning terminal circulation pump | Rated flow/kg·h−1 | 714.25 |

| Rated power/kW | 166.8 |

| Device | SC | Tank | WSHP | Exchanger | Pump |

|---|---|---|---|---|---|

| Unit Price | 500 CNY/m2 | 650 CNY/m3 | 400 CNY/m2 | 350 CNY/m2 | 0.18 CNY/kg·h−1 |

| Optimization Variable | Value Range | Optimization Step Size |

|---|---|---|

| SC area/m2 | (9771, 19,541) | 50 |

| SC slope/° | (0, 60) | 1 |

| SC azimuth/° | (−20, 60) | 1 |

| Var/m3·m−2 | (0.005, 0.1) | 0.001 |

| Far/m3·h−1·m−2 | (5, 50) | 1 |

| Fsh/m3·h−1 | (100, 600) | 20 |

| Heat pump capacity/kW | (4000, 9000) | 50 |

| Buffer tank volume/m3 | (500, 1200) | 10 |

| DHW tank volume/m3 | (150, 600) | 10 |

| Parameter | Initial Value | PSO | PSO-HJ | Variation Rate |

|---|---|---|---|---|

| SC area/m2 | 14,656 | 10,981 | 10,531 | −28.1% |

| SC slope/° | 34.5 | 40.7 | 41.1 | −19.1% |

| SC azimuth/° | 0 | 42.3 | 35.4 | ______ |

| Var/m3·m−2 | 0.04 | 0.011 | 0.011 | −72.5% |

| Far/m3·h−1·m−2 | 30 | 17.9 | 20.9 | −30.3% |

| Fsh/m3·h−1 | 439.7 | 318.9 | 156.4 | −64.4% |

| Heat pump capacity/kW | 6688 | 6273 | 6017 | −10% |

| Buffer tank volume/m3 | 700 | 984 | 947 | +35.3% |

| DHW tank volume/m3 | 300 | 335 | 381 | +15.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Zhao, J.; Wang, M. Performance Analysis and Optimization of Solar-Coupled Mine Water-Source Heat Pump Combined Heating and Cooling System. Sustainability 2024, 16, 4752. https://doi.org/10.3390/su16114752

Zhao C, Zhao J, Wang M. Performance Analysis and Optimization of Solar-Coupled Mine Water-Source Heat Pump Combined Heating and Cooling System. Sustainability. 2024; 16(11):4752. https://doi.org/10.3390/su16114752

Chicago/Turabian StyleZhao, Chang, Jianhui Zhao, and Mei Wang. 2024. "Performance Analysis and Optimization of Solar-Coupled Mine Water-Source Heat Pump Combined Heating and Cooling System" Sustainability 16, no. 11: 4752. https://doi.org/10.3390/su16114752