Evaluation of Quality Performance in Paper Pulp vs. Polyethylene Nursery Pots for Green Sustainability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials for Greenhouse Experiment

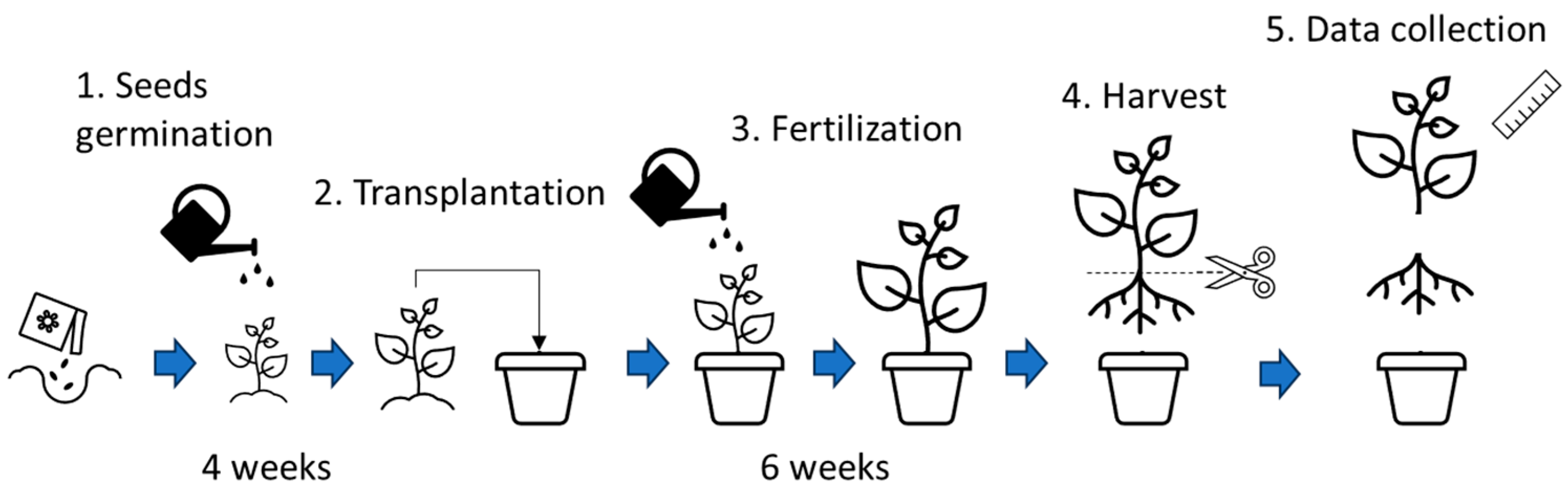

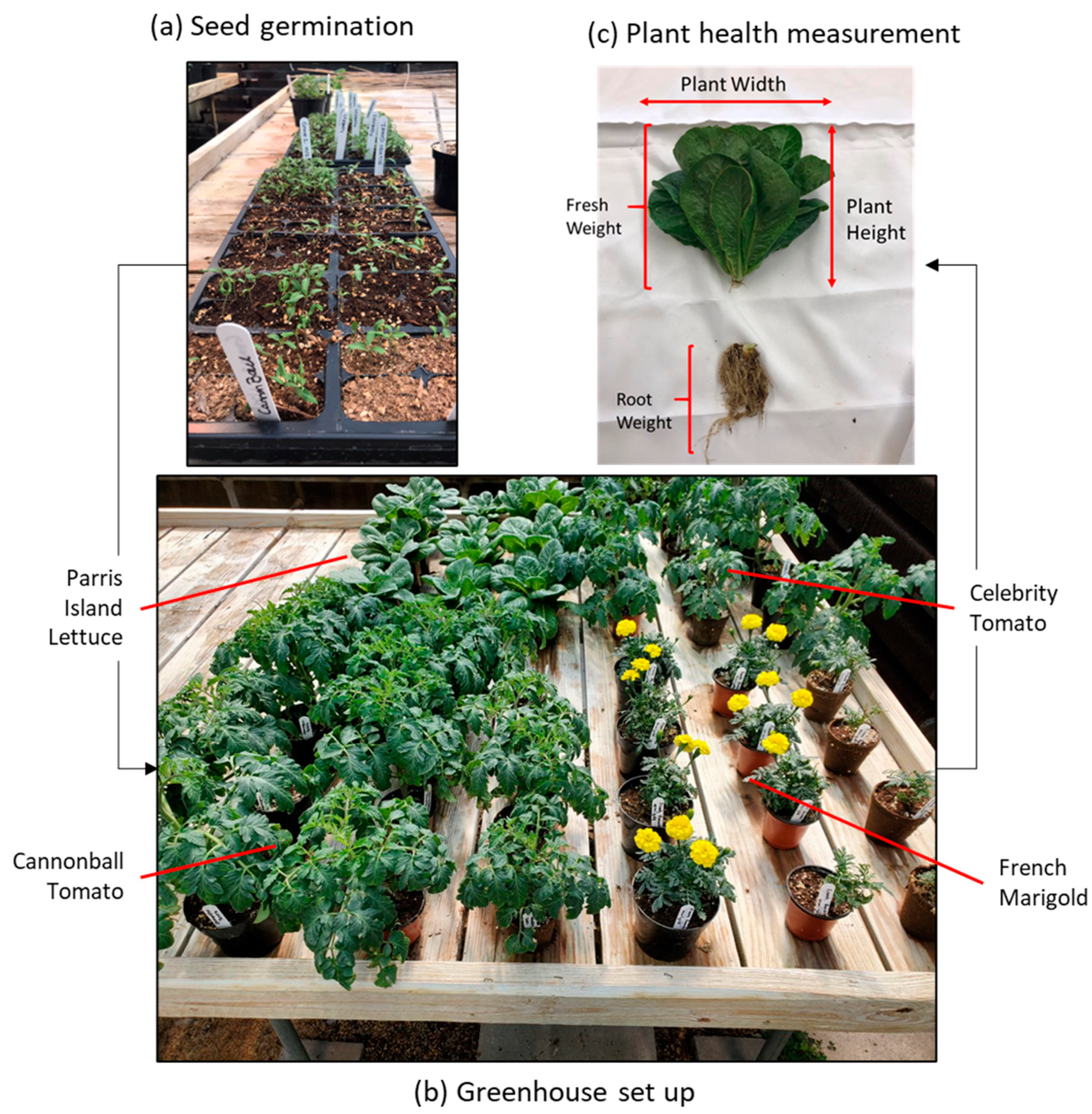

2.2. Greenhouse Experiment

2.3. Quality Performance Analysis

2.3.1. Plant Health Statistical Analysis

2.3.2. Pot Degradation Analysis

2.3.3. Techno-Economic Analysis

3. Results

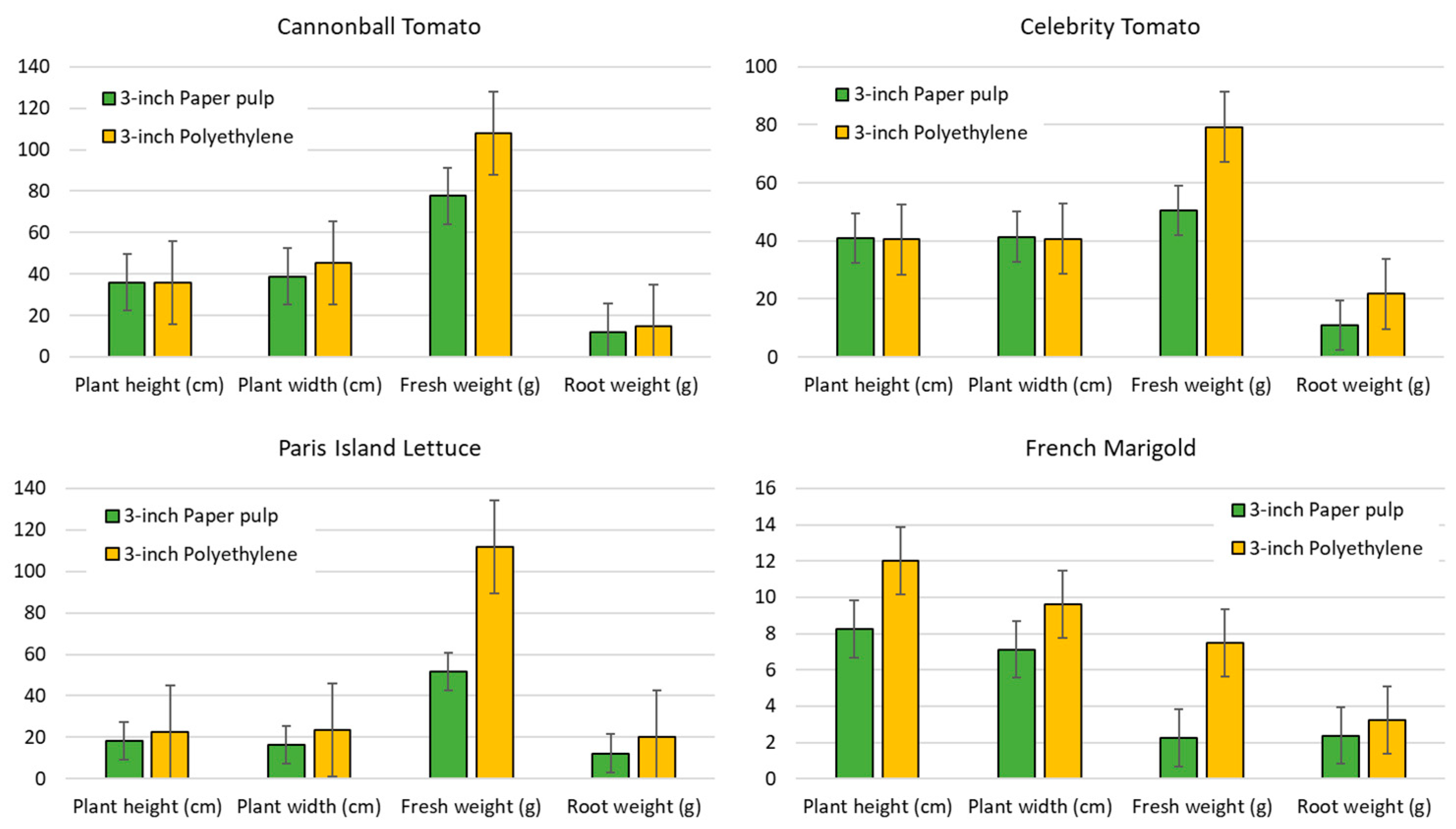

3.1. Plant Health Analysis Results

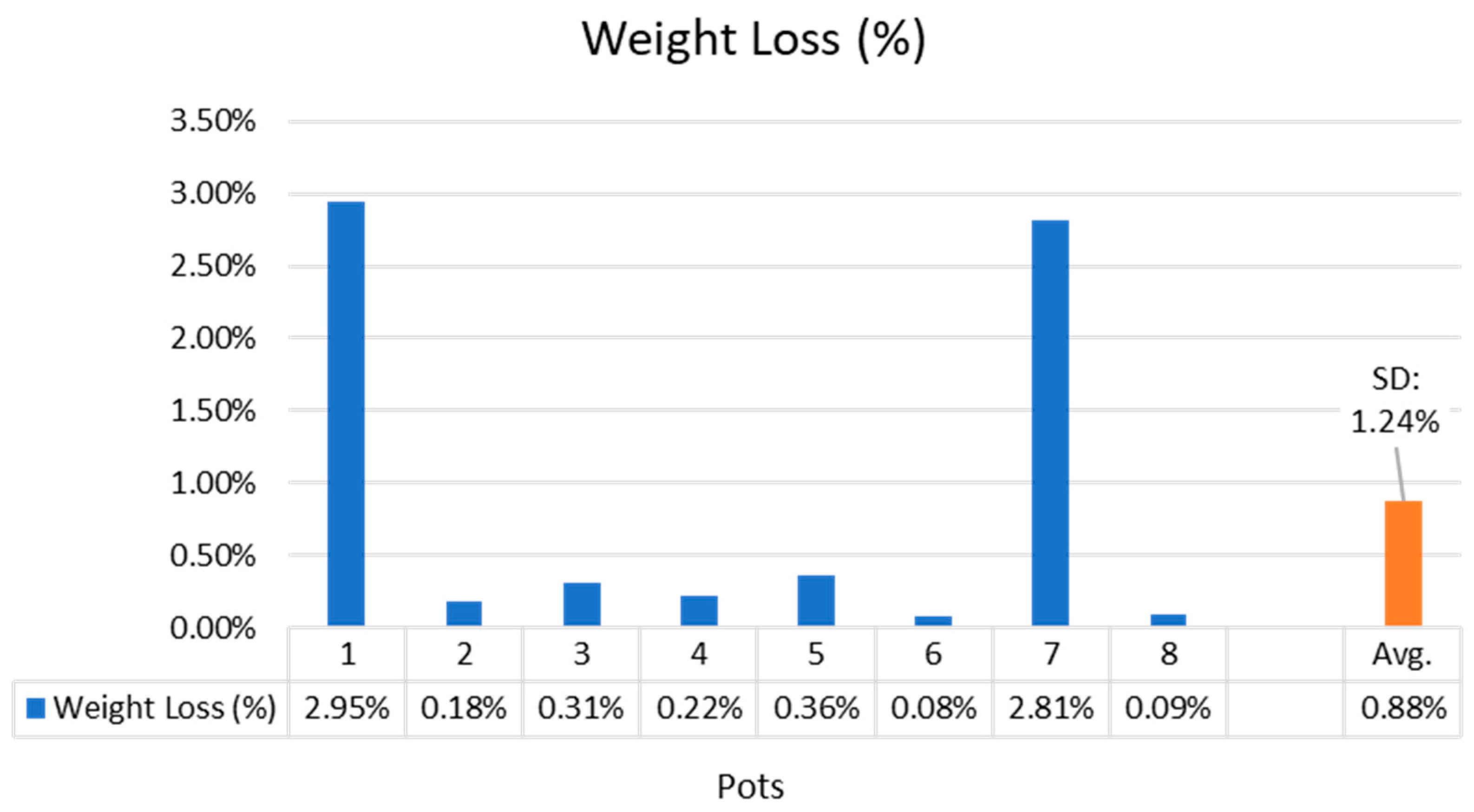

3.2. Degradation Analysis Results

3.3. Techno-Economic Analysis Results

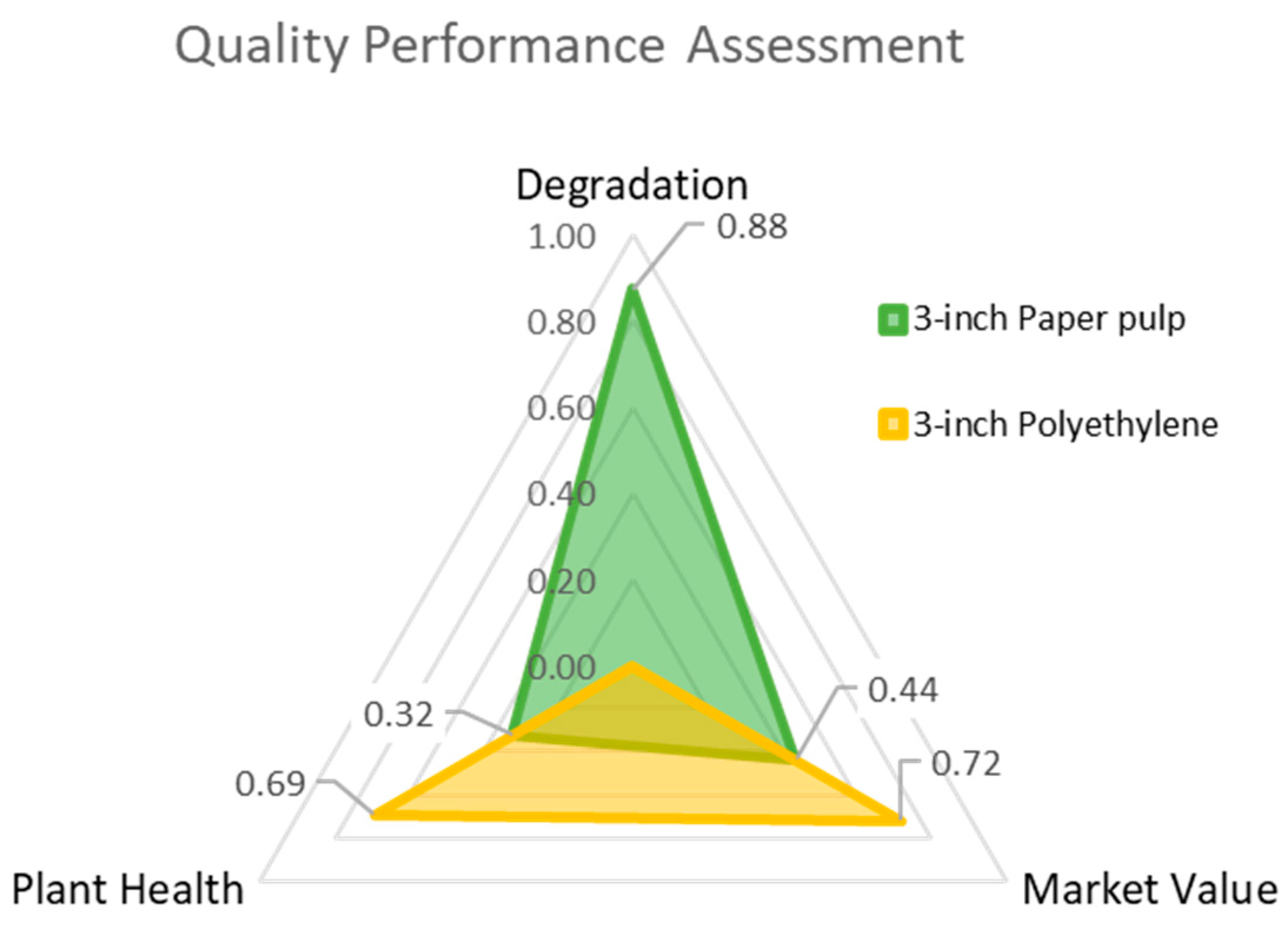

3.4. Quality Performance Assessment

4. Discussion

4.1. Long-Term Sustainability

4.2. Limitations and Future Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beyond Plastics, Bennington College (4 May 2022) ‘REPORT: The Real Truth about the U.S. Plastics Recycling Rate’. Available online: https://static1.squarespace.com/static/5eda91260bbb7e7a4bf528d8/t/62b2238152acae761414d698/1655841666913/The-Real-Truth-about-the-US-Plastic-Recycling-Rate-2021-Facts-and-Figures-_5-4-22.pdf (accessed on 22 May 2024).

- Blanke, M.M.; Golombek, S.D. Innovative Strategy to Reduce Single-Use Plastics in Sustainable Horticulture by a Refund Strategy for Flowerpots. Sustainability 2021, 13, 8532. [Google Scholar] [CrossRef]

- Gupta, A.; Urahn, N.; Dey, A.; Yodo, N.; Grewell, D.; Lee, C.W. Sustainable bio-based planting pots as an approach to reduce plastic waste in the agriculture industry. Int. J. Agric. Innov. Technol. Glob. 2023, 3, 215–244. [Google Scholar] [CrossRef]

- USEPA (U.S. Environmental Protection Agency). Advancing Sustainable Materials Management: 2015 Factsheet. Assessing Trends in Material Generation, Recycling, Composting, Combustion with Energy Recovery and Landfilling in the United States; U.S. Environmental Protection Agency: Washington, DC, USA, 2018.

- Gedde, U.W.; Hedenqvist, M.S.; Hakkarainen, M.; Nilsson, F.; Das, O. Plastics and sustainability. In Applied Polymer Science; Springer: Cham, Switzerland, 2021; pp. 489–504. [Google Scholar]

- United States Environmental Protection Agency. National Overview: Facts and Figures on Materials, Wastes and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials#recycling (accessed on 22 May 2024).

- Tomadoni, B.; Merino, D.; Alvarez, V. Biodegradable materials for planting pots. Adv. Appl. Bio-Degrad. Green Compos. 2020, 68, 85. [Google Scholar]

- Juanga-Labayen, J.P.; Yuan, Q. Making biodegradable seedling pots from textile and paper waste—Part B: Development and evaluation of seedling pots. Int. J. Environ. Res. Public Health 2021, 18, 7609. [Google Scholar] [CrossRef] [PubMed]

- Paudel, B.; Basak, J.K.; Kaushalya Madhavi, B.G.; Kim, N.-E.; Lee, G.-H.; Choi, G.-M.; Choi, Y.-W.; Kim, H.T. Properties of paper-based biodegradable pots for growing seedlings. Hortic. Environ. Biotechnol. 2022, 63, 793–807. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Kim, C.-H.; Lee, G.-S.; Jo, H.-S.; Nam, H.-G.; Park, H.-H.; Moon, S.-O. Physico-chemical characteristics of biodegradable seedling pots made of paper mill sludges. J. Korea Tech. Assoc. Pulp Pap. Ind. 2014, 46, 9–18. [Google Scholar] [CrossRef]

- Fuentes, R.A.; Berthe, J.A.; Barbosa, S.E.; Castillo, L.A. Development of biodegradable pots from different agroindustrial wastes and byproducts. Sustain. Mater. Technol. 2021, 30, e00338. [Google Scholar] [CrossRef]

- Lopez, R.G.; Camberato, D.M. Growth and development of ‘Eckespoint Classic Red’poinsettia in biodegradable and compostable containers. HortTechnology 2011, 21, 419–423. [Google Scholar] [CrossRef]

- Seo, T.C.; An, S.W.; Kim, S.M.; Nam, C.W.; Chun, H.; Kim, Y.C.; Kang, T.K.; Kim, S.W.; Jeon, S.G.; Jang, K.-S. Effect of the seedlings difference in cylindrical paper pot trays on initial root growth and yield of pepper. J. Bio-Environ. Control 2017, 26, 368–377. [Google Scholar] [CrossRef]

- Nambuthiri, S.S.; Ingram, D.L. Evaluation of plantable containers for groundcover plant production and their establishment in a landscape. HortTechnology 2014, 24, 48–52. [Google Scholar] [CrossRef]

- Li, T.; Bi, G.; Harkess, R.L.; Denny, G.C.; Blythe, E.K.; Zhao, X. Nitrogen rate, irrigation frequency, and container type affect plant growth and nutrient uptake of Encore azalea ‘Chiffon’. HortScience 2018, 53, 560–566. [Google Scholar] [CrossRef]

- Dey, A.; Rahman, M.M.; Gupta, A.; Yodo, N.; Lee, C.W. A Performance Study on 3D-Printed Bioplastic Pots from Soybean By-Products. Sustainability 2023, 15, 10535. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, C.; Bokka, S.K.; He, Z.; Ni, Y. Molded fiber and pulp products as green and sustainable alternatives to plastics: A mini review. J. Bioresour. Bioprod. 2022, 7, 14–25. [Google Scholar] [CrossRef]

- Gabellini, S.; Scaramuzzi, S. Evolving consumption trends, marketing strategies, and governance settings in ornamental horticulture: A grey literature review. Horticulturae 2022, 8, 234. [Google Scholar] [CrossRef]

- Rahman, M.M.; Dey, A.; Yodo, N.; Lee, C.W.; Grewell, D. Soybean By-Products Bioplastic (Polylactic Acid)-Based Plant Containers: Sustainable Development and Performance Study. Sustainability 2023, 15, 5373. [Google Scholar] [CrossRef]

- Mendenhall, W.M.; Sincich, T.L. Statistics for Engineering and the Sciences, 6th ed.; Taylor & Francis: Abingdon, UK, 2015. [Google Scholar]

- Kim, T.K. T test as a parametric statistic. Korean J. Anesthesiol. 2015, 68, 540. [Google Scholar] [CrossRef]

- Razza, F.; Cerutti, A.K. Life cycle and environmental cycle assessment of biodegradable plastics for agriculture. In Soil Degradable Bioplastics for a Sustainable Modern Agriculture; Springer: Berlin/Heidelberg, Germany, 2017; pp. 169–185. [Google Scholar]

- Liew, K.C.; Khor, L.K. Effect of different ratios of bioplastic to newspaper pulp fibres on the weight loss of bioplastic pot. J. King Saud. Univ.-Eng. Sci. 2015, 27, 137–141. [Google Scholar] [CrossRef]

- Folino, A.; Pangallo, D.; Calabrò, P.S. Assessing bioplastics biodegradability by standard and research methods: Current trends and open issues. J. Environ. Chem. Eng. 2023, 11, 109424. [Google Scholar] [CrossRef]

- Pires, J.R.A.; Souza, V.G.L.; Fuciños, P.; Pastrana, L.; Fernando, A.L. Methodologies to assess the biodegradability of bio-based polymers—Current knowledge and existing gaps. Polymers 2022, 14, 1359. [Google Scholar] [CrossRef]

- Schrader, J.A.; McCabe, K.G.; Srinivasan, G.; Haubrich, K.; Grewell, D.; Madbouly, S.; Graves, W. Development and evaluation of bioplastic containers for sustainable greenhouse and nursery production. Acta Hort. 2015, 1104, 79–88. [Google Scholar] [CrossRef]

- Havardi-Burger, N.; Mempel, H.; Bitsch, V. Sustainability challenges and innovations in the value chain of flowering potted plants for the German market. Sustainability 2020, 12, 1905. [Google Scholar] [CrossRef]

- Koeser, A.; Kling, G.; Miller, C.; Warnock, D. Compatibility of biocontainers in commercial greenhouse crop production. HortTechnology 2013, 23, 149–156. [Google Scholar] [CrossRef]

- Awuku, B.; Huang, Y.; Yodo, N. Predicting Natural Gas Pipeline Failures Caused by Natural Forces: An Artificial Intelligence Classification Approach. Appl. Sci. 2023, 13, 4322. [Google Scholar] [CrossRef]

- McCabe, K.G.; Schrader, J.A.; Madbouly, S.; Grewell, D.; Graves, W.R. Evaluation of biopolymer-coated fiber containers for container-grown plants. HortTechnology 2014, 24, 439–448. [Google Scholar] [CrossRef]

- Kratsch, H.A.; Schrader, J.A.; McCabe, K.G.; Srinivasan, G.; Grewell, D.; Graves, W.R. Performance and biodegradation in soil of novel horticulture containers made from bioplastics and biocomposites. HortTechnology 2015, 25, 119–131. [Google Scholar] [CrossRef]

- Davenport, T.H.; Short, J.E. The New Industrial Engineering: Information Technology and Business Process Redesign; Forgotten Books: London, UK, 1990. [Google Scholar]

- Bornman, J.F.; Barnes, P.W.; Robinson, S.A.; Ballaré, C.L.; Flint, S.D.; Caldwell, M.M. Solar ultraviolet radiation and ozone depletion-driven climate change: Effects on terrestrial ecosystems. Photochem. Photobiol. Sci. 2015, 14, 88–107. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Fernandez, R.T.; Cregg, B.M.; Auras, R.; Fulcher, A.; Cochran, D.R.; Niu, G.; Sun, Y.; Bi, G.; Nambuthiri, S. Multistate evaluation of plant growth and water use in plastic and alternative nursery containers. HortTechnology 2015, 25, 42–49. [Google Scholar] [CrossRef]

| Refs. | Research Highlights | Results |

|---|---|---|

| Section A. Research on paper pulp pots manufacturing-related characteristics | ||

| Juanga-Labayen and Yuan [8] | Investigated the effectiveness of blending textile waste with paper waste to create biodegradable seedling pots, demonstrating comparable strength and biodegradability to commercial alternatives. | The bio-composite blend, consisting of cotton and polycotton with newspaper and corrugated cardboard, exhibited optimal mechanical properties and anaerobic biodegradability while achieving 100% seed germination, highlighting its potential as an environmentally friendly alternative. |

| Paudel et al. [9] | Investigated the properties of paper-based seedling pots with varying additives in pot production. | Results indicated that while water absorption and tensile strength differed among the pots, additives improved pot strength in wet conditions without affecting seedling germination and growth. |

| Lee et al. [10] | Developed a biodegradable seedling pot by blending paper mill sludge with old newspaper at varying ratios, resulting in rapid organic matter deterioration due to a low carbon-to-nitrogen (C:N) ratio below 20. | Increasing paper content enhanced pot thickness and decreased pot density, while cellulose fibers in paper facilitated water absorption, with the addition of alkyl ketene dimer (AKD) aiding in water repellency during seedling growth. Incorporating wet strength additives improved breaking length and burst strength, albeit slightly diminishing air permeability, and accelerated biodegradation in soil, leading to complete degradation within 150 days. |

| Fuentes et al. [11] | Paper-based bio-composites, alongside other waste-derived materials, like gelatin, corn and wheat waste flour, and sunflower and rice husk, were utilized to develop biodegradable seedling pots. | Tests on water absorption, solubility, tensile strength, and biodegradation were conducted, with gelatin-based bio-composites exhibiting high solubility and water absorption rates. However, paper-based bio-composites showed slower biodegradation rates compared to gelatin-based ones, indicating their potential for prolonged use as compostable containers. |

| Section B. Research highlighting plant growth indices in paper pulp pots | ||

| Lopez and Camberato [12] | Examined various bio-based pots for appearance and durability in greenhouse cultivation. | While wood pulp, sphagnum peat moss, rice straw, and coco fiber pots were susceptible to algae growth and breakage, molded fiber containers (composition: minimum 74% recycled paper; supplier: Western Pulp Products) remained intact and displayed superior plant growth characteristics, including greater shoot and root dry weights and an enhanced bract area index compared to other container types, thus highlighting the advantage of using molded fiber/paper pots for greenhouse crop production. |

| Seo et al. [13] | Assessed the viability of cylindrical paper pot seedlings for hot pepper cultivation, examining seedling growth and fruit yield under various tray types and fertigation methods. | Results showed comparable growth patterns and fruit yields between paper pot seedlings and conventional plug seedlings, indicating the potential applicability of paper pots for pepper cultivation. |

| Nambuthiri and Ingram [14] | Conducted plant growth studies to evaluate plantable pots for different types of groundcover plants. | Plants cultivated in paper and bioplastic containers exhibited comparable growth to those in standard plastic containers, and these plantable pots underwent almost complete bio-degradation after four months in the field. |

| Li et al. [15] | Transplanted Encore azalea ‘Chiffon’ liners into one-gallon containers of black plastic and biodegradable paper, respectively, for growth indices comparison. | Results showed that plants grown in paper containers exhibited increased growth indices, dry weights, leaf area, and root growth compared to those in plastic containers, particularly with nitrogen rates ranging from 10 to 20 mm. Additionally, plants in paper containers had higher nitrogen content despite lower tissue concentrations, suggesting better nutrient uptake efficiency compared to plastic containers. |

| Plant Species | t-Test Results * | Plant Height (cm) | Plant Width (cm) | Fresh Weight (g/plant) | Root Weight (g) |

|---|---|---|---|---|---|

| Cannonball Tomato | p-value | 0.975 | 0.182 | 0.006 | 0.230 |

| Decision | Accept H0 | Accept H0 | Reject H0 | Accept H0 | |

| Celebrity Tomato | p-value | 0.910 | 0.932 | 0.012 | 0.036 |

| Decision | Accept H0 | Accept H0 | Reject H0 | Reject H0 | |

| Parris Island Lettuce | p-value | 0.017 | 0.001 | 0.007 | 0.039 |

| Decision | Reject H0 | Reject H0 | Reject H0 | Reject H0 | |

| French Marigold | p-value | 0.029 | 0.272 | 0.115 | 0.646 |

| Decision | Reject H0 | Accept H0 | Accept H0 | Accept H0 |

| Study Period | Refs. | Pot Materials * | Degradation (%) |

|---|---|---|---|

| Experiment and data analysis results | Paper pulp (%Lin) | 3.04% | |

| Paper pulp (%Exp) | 23.38% | ||

| Paper pulp (%Log) | 21.03% | ||

| Paper pulp (%Pwr) | 10.96% | ||

| Schrader et al. [26] | Paper (uncoated) | 14% | |

| 6 months | Paper—single-coated with PU | 19% | |

| Paper—double-coated with PU | 12% | ||

| McCabe et al. [30] | Paper fiber | 53% | |

| Paper fiber—PA coat | 34% | ||

| Paper fiber—PLA coat | 27% | ||

| Paper fiber—PU coat | 31% | ||

| Paper fiber—TO coat | 27% | ||

| Experiment and data analysis results | Paper Pulp (%Lin) | 9.2% | |

| Paper Pulp (%Exp) | 55.5% | ||

| Paper Pulp (%Log) | 44.73% | ||

| Paper Pulp (%Pwr) | 17.32% | ||

| 1.5 years | McCabe et al. [30] | Paper fiber | 60% |

| Paper fiber—PA coat | 42% | ||

| Paper fiber—PLA coat | 36% | ||

| Paper fiber—PU coat | 51% | ||

| Paper fiber—TO coat | 34% | ||

| Kratsch et al. [31] | Paper fiber | 60% |

| Quote | Paper Pulp ($) | Qty | Unit Price ($)/ea | Polyethylene ($) | Qty | Unit Price ($)/ea |

|---|---|---|---|---|---|---|

| 1 | $8.99 | 50 | $0.18 | $9.90 | 50 | $0.20 |

| 2 | $14.99 | 100 | $0.15 | $9.99 | 100 | $0.10 |

| 3 | $17.99 | 120 | $0.15 | $16.99 | 200 | $0.08 |

| 4 | $14.99 | 60 | $0.25 | $23.99 | 200 | $0.12 |

| 5 | $15.99 | 100 | $0.16 | $11.99 | 100 | $0.12 |

| 6 | $16.99 | 100 | $0.17 | $18.99 | 100 | $0.19 |

| 7 | $17.99 | 100 | $0.18 | $8.80 | 80 | $0.11 |

| 8 | $9.99 | 50 | $0.20 | $12.99 | 100 | $0.13 |

| 9 | $20.99 | 200 | $0.10 | $9.99 | 100 | $0.10 |

| 10 | $13.99 | 60 | $0.23 | $7.99 | 50 | $0.16 |

| Average | $0.18 | Average | $0.13 |

| Pots | BPH | BD | CMP | BCratio |

|---|---|---|---|---|

| 3-inch paper pulp | 0.32 | 0.875 | $0.18 | 6.74 |

| 3-inch polyethylene | 0.69 | 0.000 * | $0.13 | 5.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, A.; Dey, A.; Lee, C.W.; Yodo, N. Evaluation of Quality Performance in Paper Pulp vs. Polyethylene Nursery Pots for Green Sustainability. Sustainability 2024, 16, 4800. https://doi.org/10.3390/su16114800

Gupta A, Dey A, Lee CW, Yodo N. Evaluation of Quality Performance in Paper Pulp vs. Polyethylene Nursery Pots for Green Sustainability. Sustainability. 2024; 16(11):4800. https://doi.org/10.3390/su16114800

Chicago/Turabian StyleGupta, Anunay, Arup Dey, Chiwon W. Lee, and Nita Yodo. 2024. "Evaluation of Quality Performance in Paper Pulp vs. Polyethylene Nursery Pots for Green Sustainability" Sustainability 16, no. 11: 4800. https://doi.org/10.3390/su16114800