Sustainable Reclaimed Asphalt Emulsified Granular Mixture for Pavement Base Stabilization: Prediction of Mechanical Behavior Based on Repeated Load Triaxial Tests

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

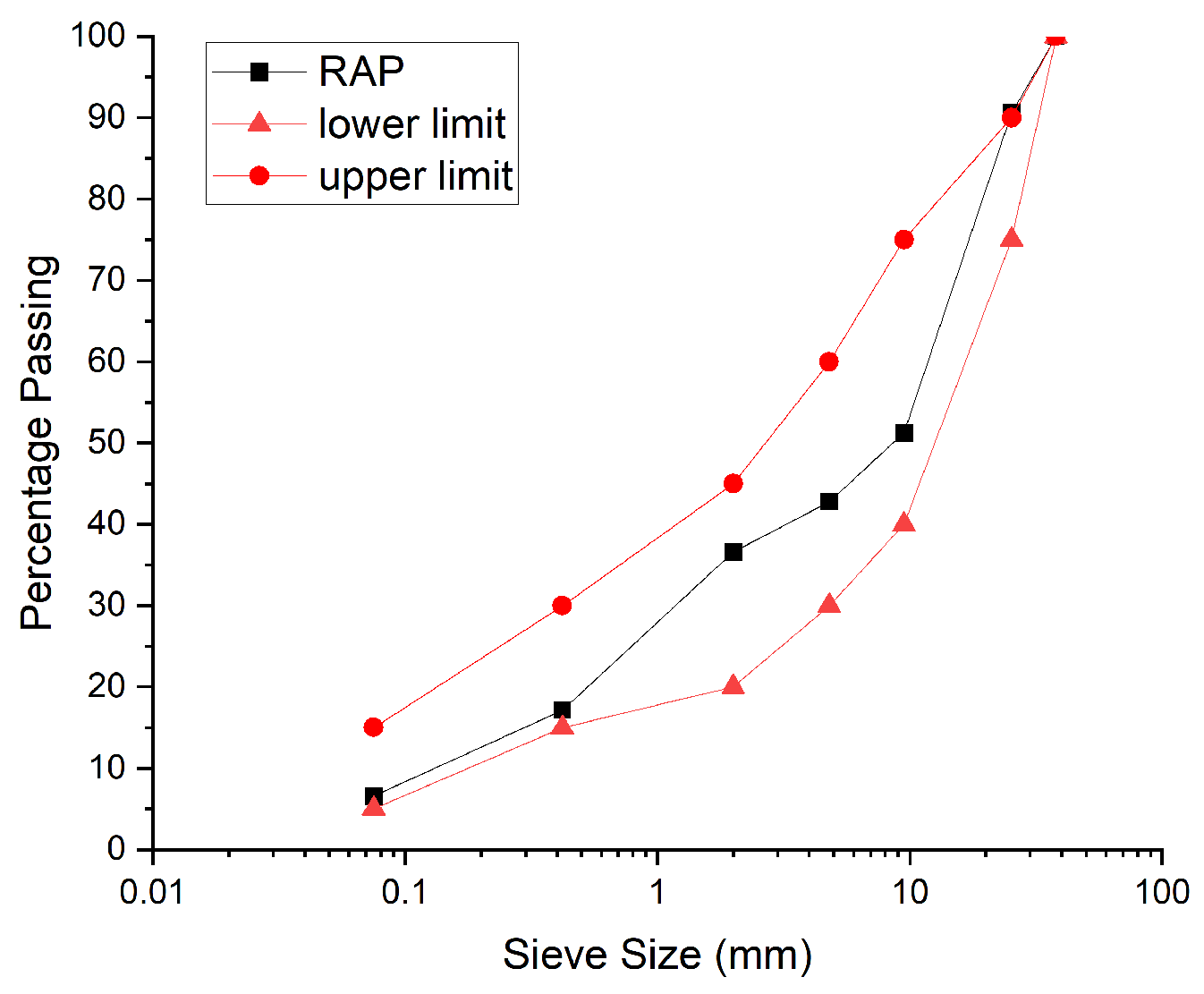

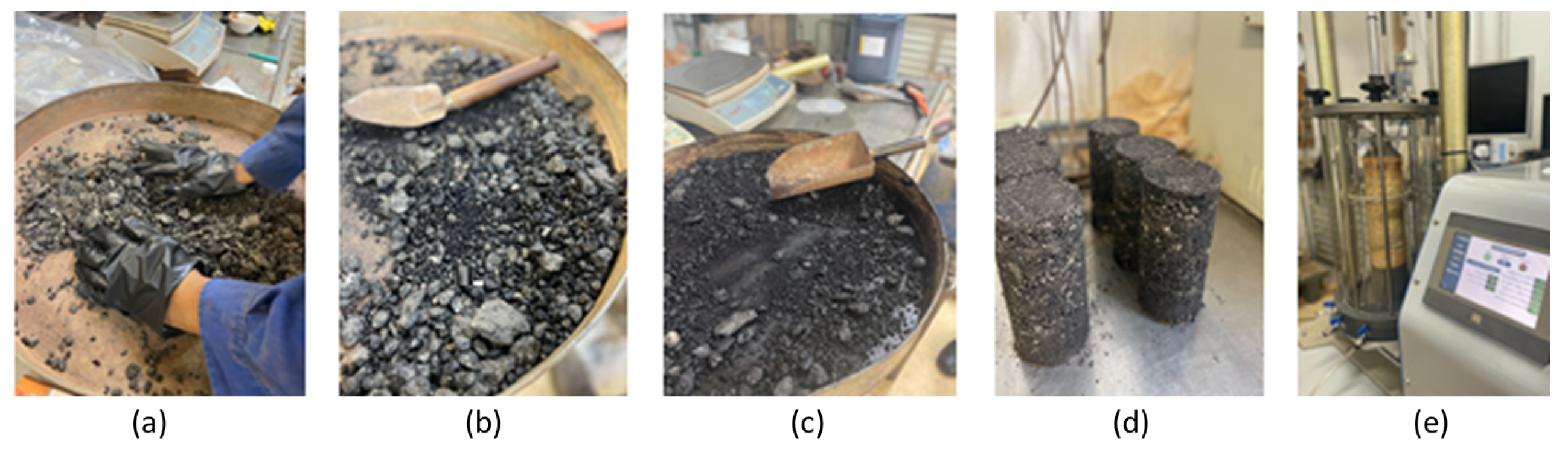

2.1.1. Reclaimed Asphalt Pavement (RAP)

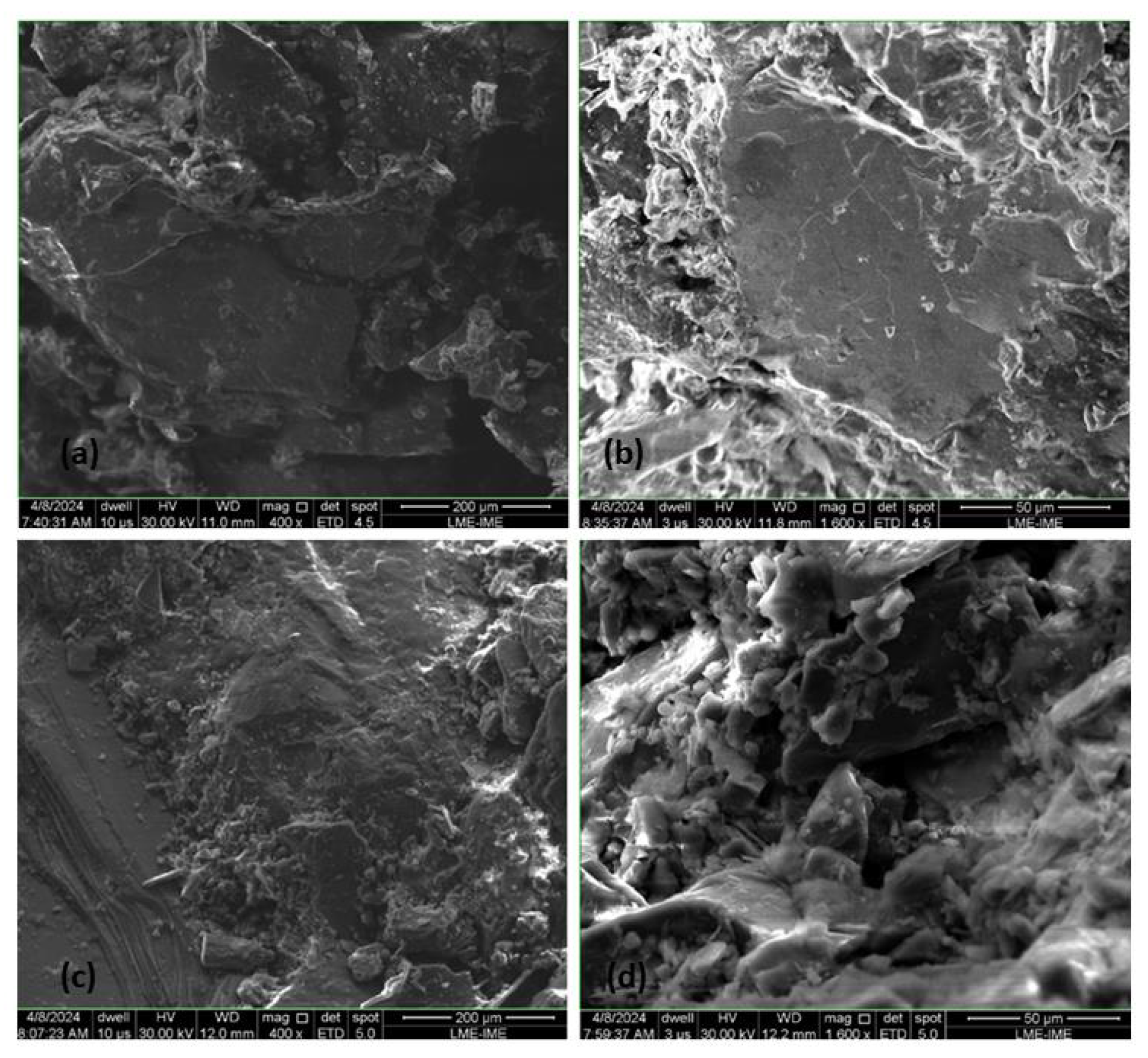

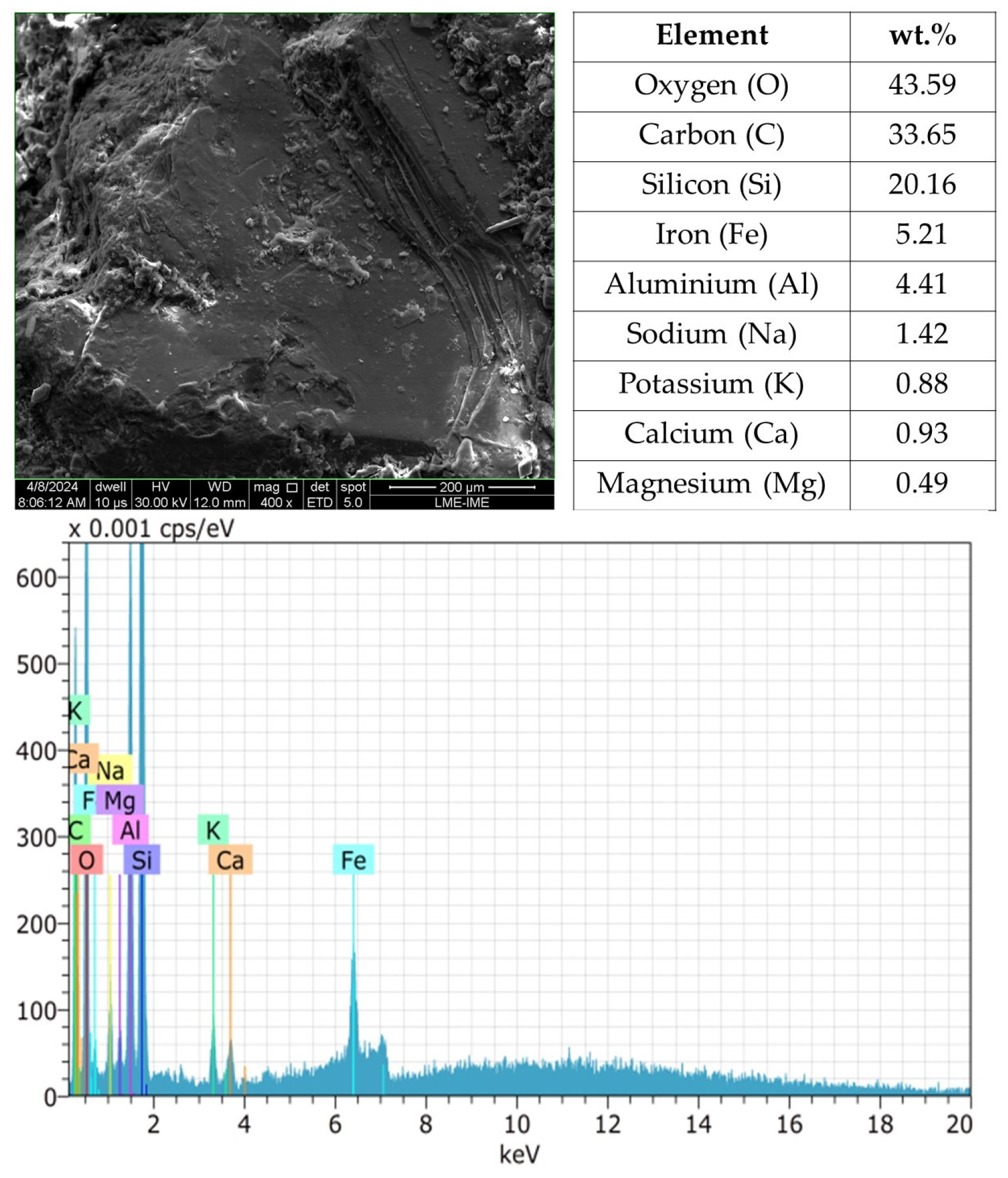

2.1.2. Mineralogical Verification and Microscopic Structure

3. Emulsion

4. Methods

4.1. Experimental Program

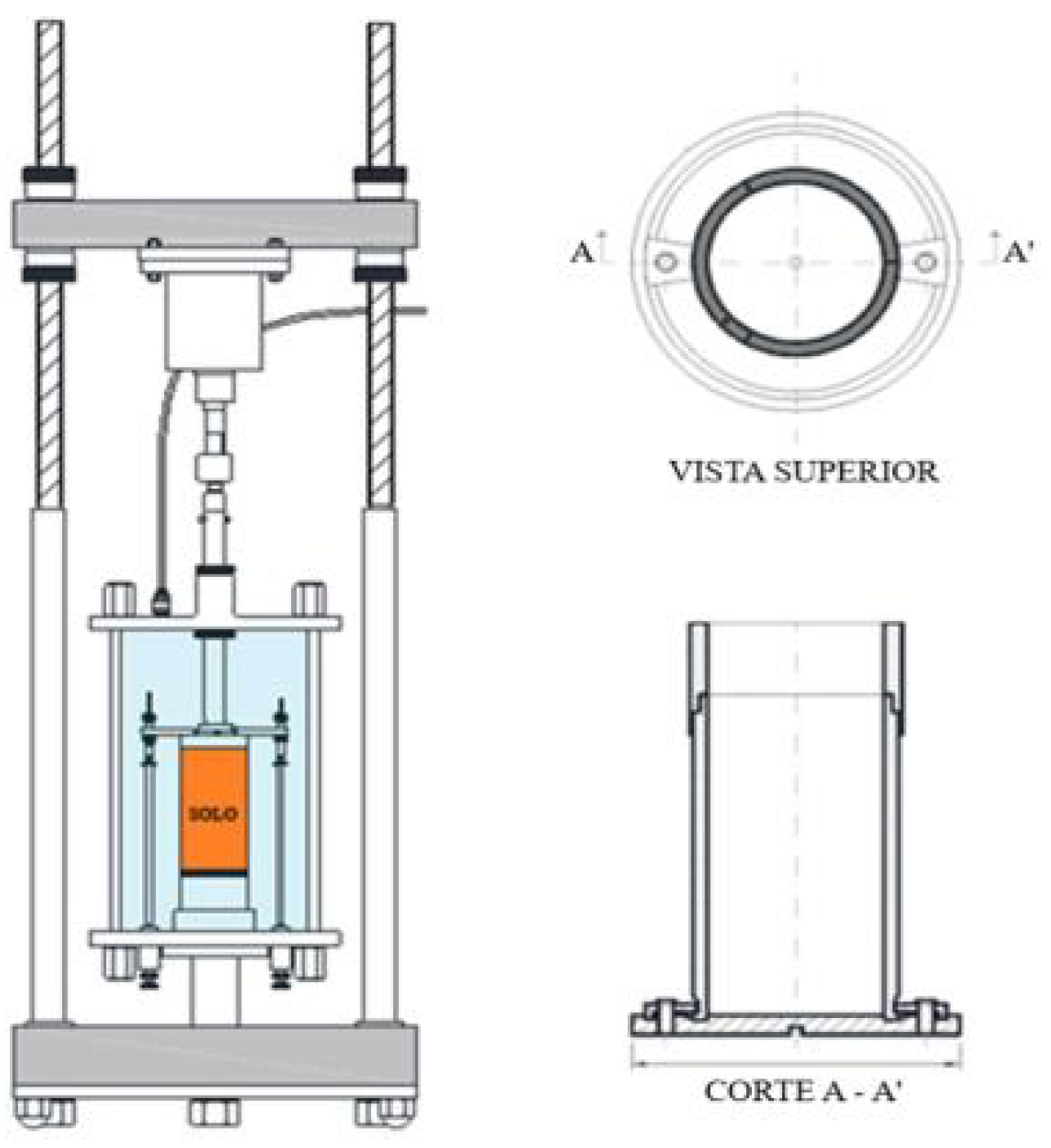

4.1.1. Triaxial Tests with Repeated Loads

4.1.2. Resilient Modulus (RM) Test

4.1.3. PD of the Multi-Stage Type

5. Results and Discussions

5.1. Mineralogical Properties and Microscopic Structure

5.2. Proctor Compaction Test

5.3. Resilient Modulus (RM)

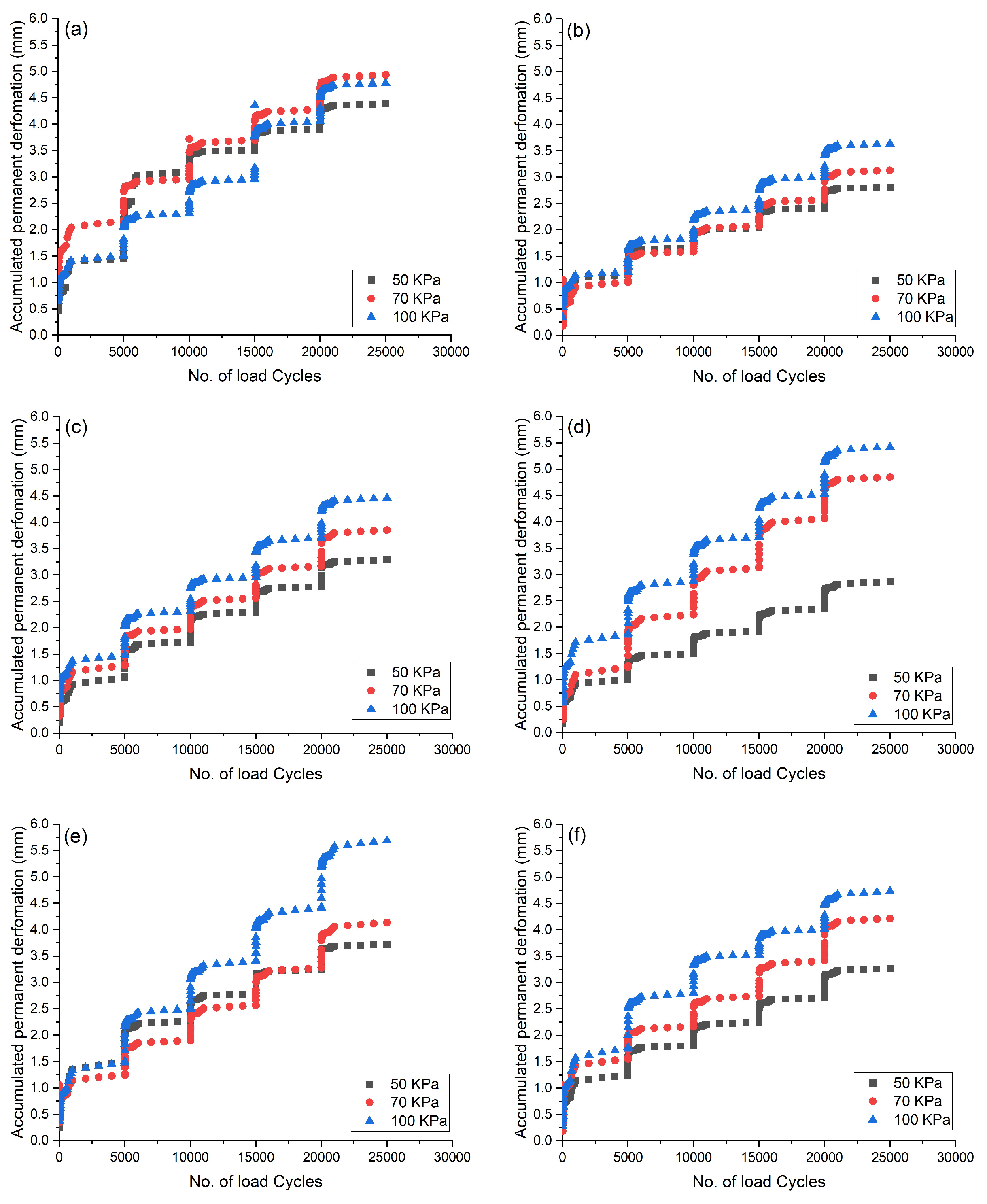

5.4. Permanent Derformation

6. Conclusions

- Our initial hypothesis was that the addition of emulsion to RAP could increase the resistance to deformation. However, the results showed that the resistance to PD decreased at higher emulsion contents, although the RM benefited;

- The tests showed that the addition of emulsion to RAP significantly affects the mechanical properties of paving mixes. The RM values indicated a satisfactory range of elastic deformation resistance under repeated loading, while the PD values showed a decrease in resistance with increasing emulsion content. Although the aim was not to determine the optimum binder content of the ETB with an emulsion content of 100%, it was observed that sample R1 with 1% emulsion had a satisfactory RM value and better performance in PD than RAPC (5 mm), showing cumulative PD values of up to 4 mm. In contrast, the other samples (R2, R3, R4, and R5) showed deformations of up to 6 mm. This indicates that higher additions of emulsified asphalt make the ETB with 100% RAP aggregate susceptible to PD, even at higher RM values;

- Performing multi-stage MR and PD tests proved to be an effective method for predicting the behavior of emulsion-treated pavement mixtures. The results provided valuable insight into the influence of emulsion on the resistance of mixtures to elastic and permanent deformation and contributed to a better understanding of the behavior of these materials;

- In summary, multi-stage resilient modulus and PD tests can be considered as a predictive method for the behavior of milled material in base courses. They were able to provide initial data for interpreting the behavior of ETB mixtures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andrews, J.; Radhakrishnan, V.; Koshy, R. Laboratory Evaluation of Emulsion-Treated Base Layer Mixes Incorporating Reclaimed Asphalt Pavement Materials. J. Mater. Civ. Eng. 2023, 35. [Google Scholar] [CrossRef]

- Pi, Y.; Huang, Z.; Pi, Y.; Li, G.; Li, Y. Composition Design and Performance Evaluation of Emulsified Asphalt Cold Recycled Mixtures. Materials 2019, 12, 2682. [Google Scholar] [CrossRef]

- Xiao, F.; Yao, S.; Wang, J.; Li, X.; Amirkhanian, S. Composition Design and A Literature Review on Cold Recycling Technology of Asphalt Pavement. Constr. Build. Mater. 2018, 180, 579–604. [Google Scholar] [CrossRef]

- Guduru, G.; Tavva, T.; Kuna, K. Estimation of Reclaimed Asphalt Pavement (RAP) Characteristics Using Simple Indicative Tests. Road Mater. Pavement Des. 2022, 23, 822–848. [Google Scholar] [CrossRef]

- Chelelgo, K.; Abiero Gariy, Z.; Muse Shitote, S. Laboratory Mix Design of Cold Bitumen Emulsion Mixtures Incorporating Reclaimed Asphalt and Virgin Aggregates. Buildings 2018, 8, 177. [Google Scholar] [CrossRef]

- Lima, C.; Motta, L.; Guimarães, A. Estudo da deformação permanente de britas granito-gnaisse para uso em base e sub-base de pavimentos. Transportes 2017, 25, 41. [Google Scholar] [CrossRef]

- Lima, C.; Motta, L.; Aragão, F. Analysis of Stresses Applied in Permanent Deformation Tests of Soils and Aggregates for Empirical Mechanistic Pavement Design. In Proceedings of the 33rd Congress of Research and Teaching in Transportation of ANPET, Balneário Camboriú, SC, Brazil, 10–14 November 2019. [Google Scholar]

- Guimarães, A.; Motta, L.; Castro, C. Permanent deformation parameters of fine–grained tropical soils. Road Mater. Pavement Des. 2019, 20, 1664–1681. [Google Scholar] [CrossRef]

- Sagrilo, A.; Pascoal, P.T.; Baroni, M.; Back, A.; Pinheiro, R.; Specht, L.; Guimarães, A. Contribution to resilient and permanent deformation investigation of unbound granular materials with different geological origins from Rio Grande do Sul, Brazil. Soils Rocks 2023, 46, e2023009822. [Google Scholar] [CrossRef]

- Guimarães, A.; Lima, C.; Aragão, F.T.S.; Motta, L.; Tanabe, J. Mechanical characterization of an alternative laterite gravel used as pavement material. Soils Rocks 2023, 47, e2024010622. [Google Scholar] [CrossRef]

- Stolle, D.; Guo, P.; Emery, J. Mechanical Properties of Reclaimed Asphalt Pavement—Natural Aggregate. Can. J. Civ. Eng. 2014, 41, 493–499. [Google Scholar] [CrossRef]

- Thakur, J.; Han, J. Recent Development of Recycled Asphalt Pavement (RAP) Bases Treated for Roadway Applications. Transp. Infrastruct. Geotechnol. 2015, 2, 1–19. [Google Scholar] [CrossRef]

- AASTHO. Mechanistic-Empirical Pavement Design Guide: A Manual of Practice, 3rd ed.; AASTHO: Washington, DC, USA, 2020. [Google Scholar]

- DNIT 179; IE—Pavimentação—Solos—Determinação da Deformação Permanente. National Department of Transportation Infrastructure: Rio de Janeiro, RJ, Brazil, 2018.

- BS EN 13286-7; Unbound and Hydraulically Bound Mixtures-Cyclic Load Triaxial Test for Unbound Mixtures. British Standards Institution: London, UK, 2004.

- AG:PT/T053; Determination of Permanent Deformation and Resilient Modulus Characteristics of Unbound Granular Materials under Drained Conditions. Austroads Working Group: Sydney, Australia, 2006.

- NZTA T15: 2014; Specification for Repeated load Triaxial Testing (RLT) for Pavement Materials. New Zealand Transport Agency: Wellington, New Zealand, 2014.

- DNIT 141-ES; Pavement—Granulometrically Stabilized Base. National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2022.

- DNER ME 53; Bituminous Mixtures—Bitumen Percentage. National Department of Roads and Highways: Rio de Janeiro, Brazil, 1994.

- Brazilian Standard NBR14376 DE 01/2019; Asphaltic Emulsions—Determination of the Solids Content of Conventional or Modified Asphalt Emulsions—Expeditious Methods. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2019.

- Brazilian Standard NBR14491 DE 04/2007; Asphalt Emulsions—Determination of Saybolt Furol Viscosity. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2007.

- Brazilian Standard NBR14393 de 11/2012; Asphalt Emulsions—Determination of Sieving. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2012.

- Brazilian Standard NBR6570 de 05/2016; Asphalt Binders—Determination of Sedimentation and Storage Stability of Asphalt Emulsion. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2016.

- Brazilian Standard NBR6567 de 01/2015; Asphalt Binders—Asphalt Emulsions—Determination of Particle Charge. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2015.

- Brazilian Standard NBR6569 de 12/2008; Cationic Emulsified Asphalts—Determination of Demulsibility. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2008.

- Brazilian Standard NBR14249 de 07/2007; Cationic Emulsified Asphalt—Quick Determination of Water Resistance (Ability to Coat Coarse Aggregate). Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2007.

- Brazilian Standard NBR6568 de 09/2005; Asphaltic Emulsions—Determination of Distillation Residue. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2005.

- DNIT 443ME; Pavement-Soils-Compaction Test Using Tripartite Molds. National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2023.

- Zhen, K.; Yang, Q.; Qiu, X.; Xu, W.; Liu, H.; Chen, Z. An Investigation of Behaviors and Characteristics of the Interfacial Bonding Capacity Between Emulsified Asphalt Cement Composite Binder and Recovered Asphalt Pavement. Buildings 2024, 14, 1217. [Google Scholar] [CrossRef]

- Lekarp, F.; Isacsson, U.; Dawson, A. State of the Art. II: Permanent Strain Response of Unbound Aggregates. J. Transp. Eng. 2000, 126, 76–83. [Google Scholar] [CrossRef]

- Medina, J.; Motta, L. Mecânica dos Pavimentos, 3rd ed.; Editora Interciência: Rio de Janeiro, Brazil, 2015; p. 572. [Google Scholar]

- Motta, L. Flexible Pavement Design Method: Reliability Criteria and Repeated Load Tests. Ph.D. Thesis, Federal University of Rio de Janeiro, Rio de Janeiro, Brazil, 1991. [Google Scholar]

- DNIT Pavement-Soils-Determination of Resilience Modulus; Technical report; National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2018.

- Barksdale, R. Laboratory Evaluation of Rutting in Base Course Materials. In Proceedings of the 3rd International Conference on the Structural Design of Asphalt Pavements, London, UK, 11–15 September 1972; pp. 161–174. [Google Scholar]

- Barksdale, R.; Itani, S. Influence of Aggregate Shape on Base Behavior. Transp. Res. Rec. 1989, 1227, 173–182. [Google Scholar]

- Ullah, S.; Tanyu, B.; Dawson, A. Reclaimed Asphalt Pavement (RAP) as an Unbound Base Course Material: A Mechanistic Design Approach Based on Multi-stage Repeated Load Triaxial Tests. Transp. Geotech. 2022, 33, 100729. [Google Scholar] [CrossRef]

- Brown, S.; Hyde, A. Significance of Cyclic Confining Stress in Repeated Load Triaxial Testing of Granular Material. Transp. Res. Rec. 1975, 537, 49–58. [Google Scholar]

- Pinto, M.; Cervo, T.; Pereira, D. Reuse of Milled Material on Shoulders as a Smoothing and Leveling Agent. Paving 2013, 6, 27–35. [Google Scholar]

- Specht, L.P.; Pires, G.M.; Vitorelo, T.; Hirsh, F.; Cronst, F.; Bergmann, E.; Tiefensee, M. Use of Milled Material as Pavement Layer: Laboratory Study and Field Application. In Proceedings of the 42nd Annual Paving Meeting (RAPv), Gramado (RS), Brazil, 12–14 November 2013. [Google Scholar]

- Silva, M.R.D.A.; Cervo, T.C.; Baroni, M.; Duarte, F. Study of the Granulometric and Chemical Stabilization of Milled Material for Use in Pavement Layers. Rev. Eng. Civ. Imed Passo Fundo 2018, 5, 20–31. [Google Scholar]

- Santos, E.F. Recycling of Milled Materials from Different Sources in Stabilized Mixtures for Use in Granular Layers of Pavements. Master’s Thesis, Federal University of Santa Maria, Center for Technology, Graduate Program in Civil Engineering, Santa Maria, RS, Brazil, 2021. [Google Scholar]

- Bernucci, L.B.; Ceratti, J.A.P.; Soares, J.B.; da Motta, L.M.G. Asphalt Pavement, Basic Training for Engineers, 2nd ed.; PETROBRAS, ABEDA: Rio de Janeiro, Brazil, 2006; p. 504. [Google Scholar]

- Balbo, J.T. Pavimentação Asfáltica: Materiais, Projeto e Restauração, 1st ed.; Oficina de Textos: São Paulo, Brazil, 2007; p. 560. [Google Scholar]

- Lima, C.D.A.; Motta, L.M.G.; Aragão, F.T.S. Permanent deformation tests: Effect of the number of loading cycles on the interpretation of the behavior of soils and gravels. Rev. MatéRia 2021, 26. [Google Scholar]

- Puppala, A.J.; Hoyos, L.R.; Potturi, A.K. Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J. Mater. Civil Eng. 2011, 23, 990–998. [Google Scholar] [CrossRef]

- Arulrajah, A.; Jegatheesan, P.; Disfani, M.M.; Bo, M.W. Geotechnical and Geo-environmental Properties of Recycled Construction and Demolition Materials in Pavement Subbase Applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Leite, F.C. Mechanical Behavior of Recycled Solid Waste Construction Aggregate in Base and Sub-Base Layers of Pavements. Master’s Thesis, University of São Paulo, São Paulo, Brazil, 2007. [Google Scholar]

- Arshad, M. Development of a Correlation between the Resilient Modulus and CBR value for granular blends containing Natural Aggregates and RAP/RCA material. Adv. Mater. Sci. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Chakravarthi, S.; Kumar, G.; Shankar, S.; Vishnu, R. Effect of Emulsified Asphalt Content on Creep Behavior and Mechanical Properties of Cold Recycled Emulsified Asphalt Bases. J. Rehabil. Civ. Eng. 2021, 9, 133–147. [Google Scholar]

- Plati, C.; Tsakoumaki, M.; Gkyrtis, K. Physical and Mechanical Properties of Reclaimed Asphalt Pavement (RAP) Incorporated in Unbound Pavement Layers. Appl. Sci. 2023, 13, 362. [Google Scholar] [CrossRef]

- Jin, D.; Gé, D.; Chen, S.; Che, T.; Liu, H.; Malburgo, L.; Você, Z. On-site Cold Recycling Asphalt Mixtures: Laboratory Performance and Preliminary ME Design Analysis. Materials 2021, 14, 2036. [Google Scholar] [CrossRef]

- Meena, P.; Naga, G.; Kumar, P. Effect of Mechanical Properties on Performance of Cold Asphalt Mixture with Recycled Aggregates Incorporating Filler Additives. Sustainability 2024, 16, 4908. [Google Scholar] [CrossRef]

| % Passing | RAP1 | RAP 2 | RAP 3 | DNIT 141 [18] | Adopted Curve | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| # (pol.) | (mm) | Sample | Attempt | Sample | Attempt | Sample | Attempt | Range B | ||

| min | max | |||||||||

| 50.8 | 100 | 50 | 100 | 45 | 100 | 5 | 100 | 100 | 100 | |

| 25.0 | 81.2 | 40.6 | 100 | 45 | 100 | 5 | 75 | 90 | 90.6 | |

| 3/ | 9.5 | 2.5 | 1.25 | 100 | 45 | 100 | 5 | 40 | 75 | 51.25 |

| n.° 4 | 4.8 | 1.7 | 0.85 | 82.1 | 36.94 | 99.95 | 4.99 | 30 | 60 | 42.79 |

| n.° 10 | 2.0 | 1.6 | 0.8 | 69.4 | 31.23 | 91.3 | 4.56 | 20 | 45 | 36.59 |

| n.° 40 | 0.42 | 1.4 | 0.7 | 33.8 | 15.21 | 25 | 1.25 | 15 | 30 | 17.16 |

| n.° 200 | 0.07 | 0.75 | 0.37 | 13.6 | 6.12 | 1.87 | 0.09 | 5 | 15 | 6.58 |

| Characteristics | Unit | Test Method (Brazilian Standard) | Results | Limits (Min–Max) |

|---|---|---|---|---|

| Asphalt residue | % (m/m) | NBR 14376 [20] | 62.0 | Min 62.0 |

| Viscosity Saybolt Furol, 50 °C | SSF | NBR 14491 [21] | 22.0 | 20–200 |

| Sieved, retained on the 0.84 mm . | % (m/m) | NBR 14393 [22] | 0 | Max 0.1 |

| Settlement, 5 days, difference in residue between top and bottom | % (m/m) | NBR 6570 [23] | 1.2 | Max 5 |

| Particle load | % (m/m) | NBR 6567 [24] | Positive | Positive |

| De-emulsification | - | NBR 6569 [25] | 17.9 | Max 50.0 |

| Water resistance | % | NBR 14249 [26] | 85.0 | Min 80.0 |

| Distilled solvent | % (v/v) | NBR 6568 [27] | 0 | Max 12.0 |

| Conditioning phase | |||

| Pair | (KPa) | (KPa) | / |

| 1 | 70 | 70 | 2 |

| 2 | 70 | 210 | 4 |

| 3 | 105 | 315 | 4 |

| Loading phase | |||

| Pair | (KPa) | (KPa) | / |

| 1 | 20 | 20 | 2 |

| 2 | 40 | 3 | |

| 3 | 60 | 4 | |

| 4 | 35 | 35 | 2 |

| 5 | 70 | 3 | |

| 6 | 105 | 4 | |

| 7 | 50 | 50 | 3 |

| 8 | 100 | 2 | |

| 9 | 150 | 3 | |

| 10 | 70 | 70 | 2 |

| 11 | 140 | 3 | |

| 12 | 210 | 4 | |

| 13 | 105 | 105 | 2 |

| 14 | 210 | 3 | |

| 15 | 315 | 4 | |

| 16 | 140 | 140 | 2 |

| 17 | 280 | 3 | |

| 18 | 420 | 4 | |

| Test N° | Stage | / | ||

|---|---|---|---|---|

| Test I | I | 50 | 50 | 1.0 |

| II | 75 | 50 | 1.5 | |

| III | 100 | 50 | 2.0 | |

| IV | 125 | 50 | 2.5 | |

| V | 150 | 50 | 3.0 | |

| Test II | Ia | 70 | 70 | 1.0 |

| IIa | 105 | 70 | 1.5 | |

| IIIa | 100 | 70 | 2.0 | |

| IVa | 125 | 70 | 2.5 | |

| Va | 150 | 70 | 3.0 | |

| Test III | Ib | 100 | 100 | 1.0 |

| IIb | 150 | 100 | 1.5 | |

| IIIb | 200 | 100 | 2.0 | |

| IVb | 250 | 100 | 2.5 | |

| Vb | 300 | 100 | 3.0 |

| Data RAPC | |

| W Optimum (%) | Density (g/cm3) |

| 4.54 | 1.98 |

| Data R1 à R5 | |

| EAP (%) | Density (g/cm3) |

| 1% | 1.86 |

| 2% | 1.85 |

| 3% | 1.84 |

| 4% | 1.85 |

| 5% | 1.94 |

| Sample | Average RM (MPa) |

|---|---|

| RAPC | 339.20 |

| R1 | 441.22 |

| R2 | 428.41 |

| R3 | 412.23 |

| R4 | 422.13 |

| R5 | 496.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coelho, L.M.; Guimarães, A.C.R.; Azevedo, A.R.G.d.; Monteiro, S.N. Sustainable Reclaimed Asphalt Emulsified Granular Mixture for Pavement Base Stabilization: Prediction of Mechanical Behavior Based on Repeated Load Triaxial Tests. Sustainability 2024, 16, 5335. https://doi.org/10.3390/su16135335

Coelho LM, Guimarães ACR, Azevedo ARGd, Monteiro SN. Sustainable Reclaimed Asphalt Emulsified Granular Mixture for Pavement Base Stabilization: Prediction of Mechanical Behavior Based on Repeated Load Triaxial Tests. Sustainability. 2024; 16(13):5335. https://doi.org/10.3390/su16135335

Chicago/Turabian StyleCoelho, Lisley Madeira, Antônio Carlos Rodrigues Guimarães, Afonso Rangel Garcez de Azevedo, and Sergio Neves Monteiro. 2024. "Sustainable Reclaimed Asphalt Emulsified Granular Mixture for Pavement Base Stabilization: Prediction of Mechanical Behavior Based on Repeated Load Triaxial Tests" Sustainability 16, no. 13: 5335. https://doi.org/10.3390/su16135335