Using BIM and LCA to Calculate the Life Cycle Carbon Emissions of Inpatient Building: A Case Study in China

Abstract

1. Introduction

2. Materials and Methods

2.1. Life Cycle Assessment

2.2. Case Description

2.2.1. Case Introduction

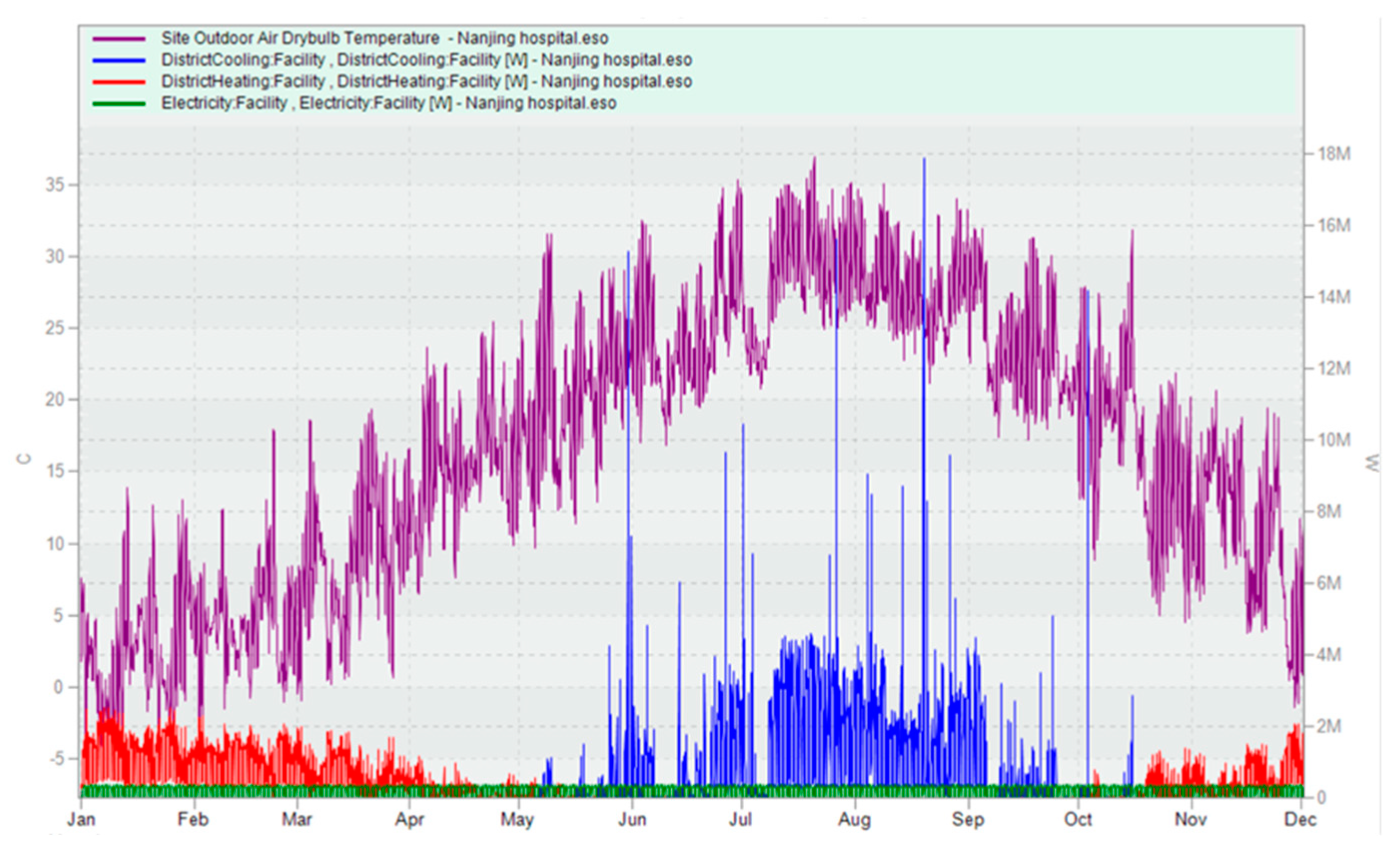

2.2.2. Simulation

2.3. Detailed Calculation Methodology

2.3.1. Total Carbon Emissions

2.3.2. Stage 1

2.3.3. Stage 2

2.3.4. Stage 3

2.4. Stock Cases

2.5. Evaluation Indices for Carbon Emissions

3. Results

3.1. Embodied Carbon Emissions

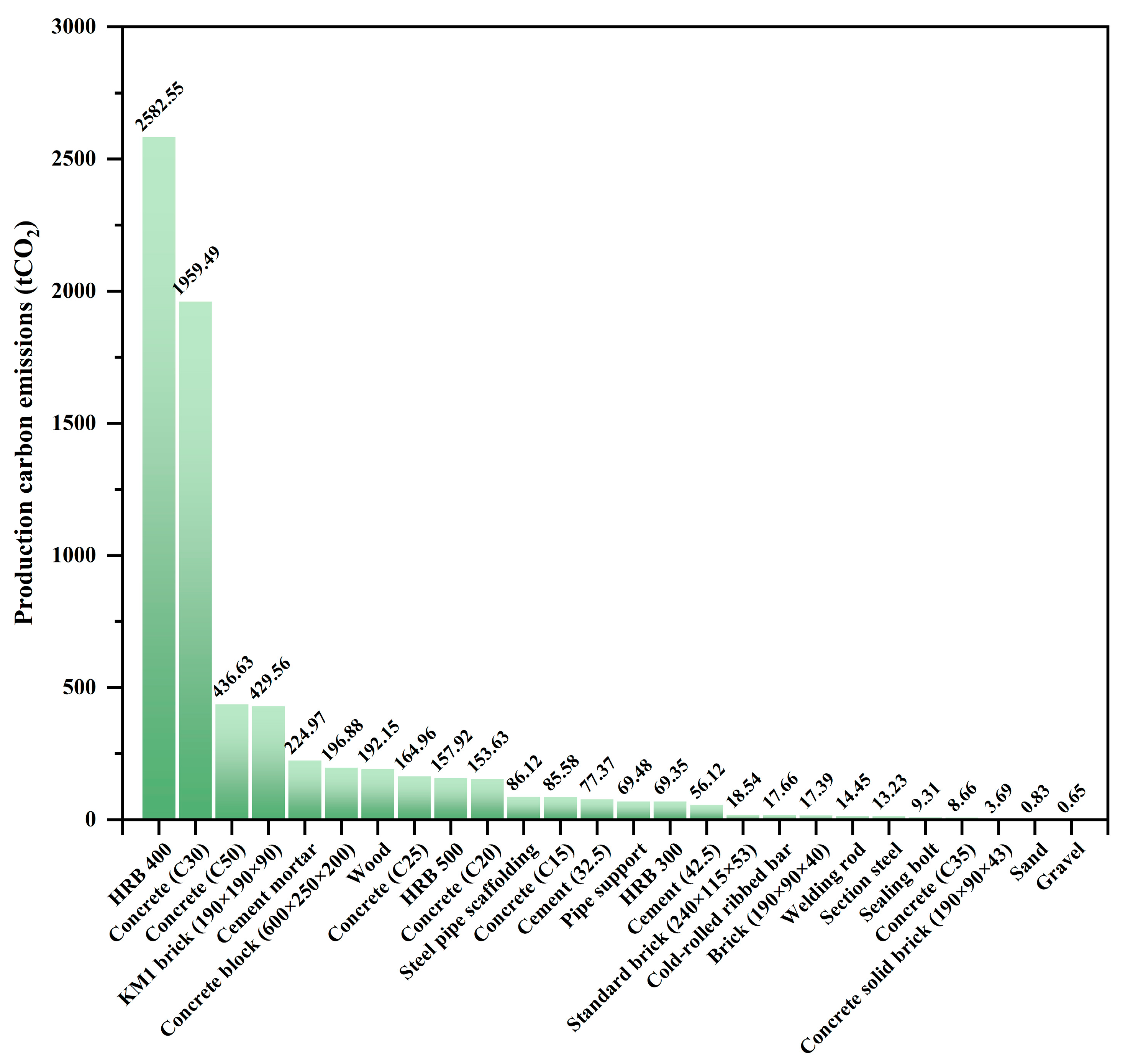

3.1.1. Building Materials Production

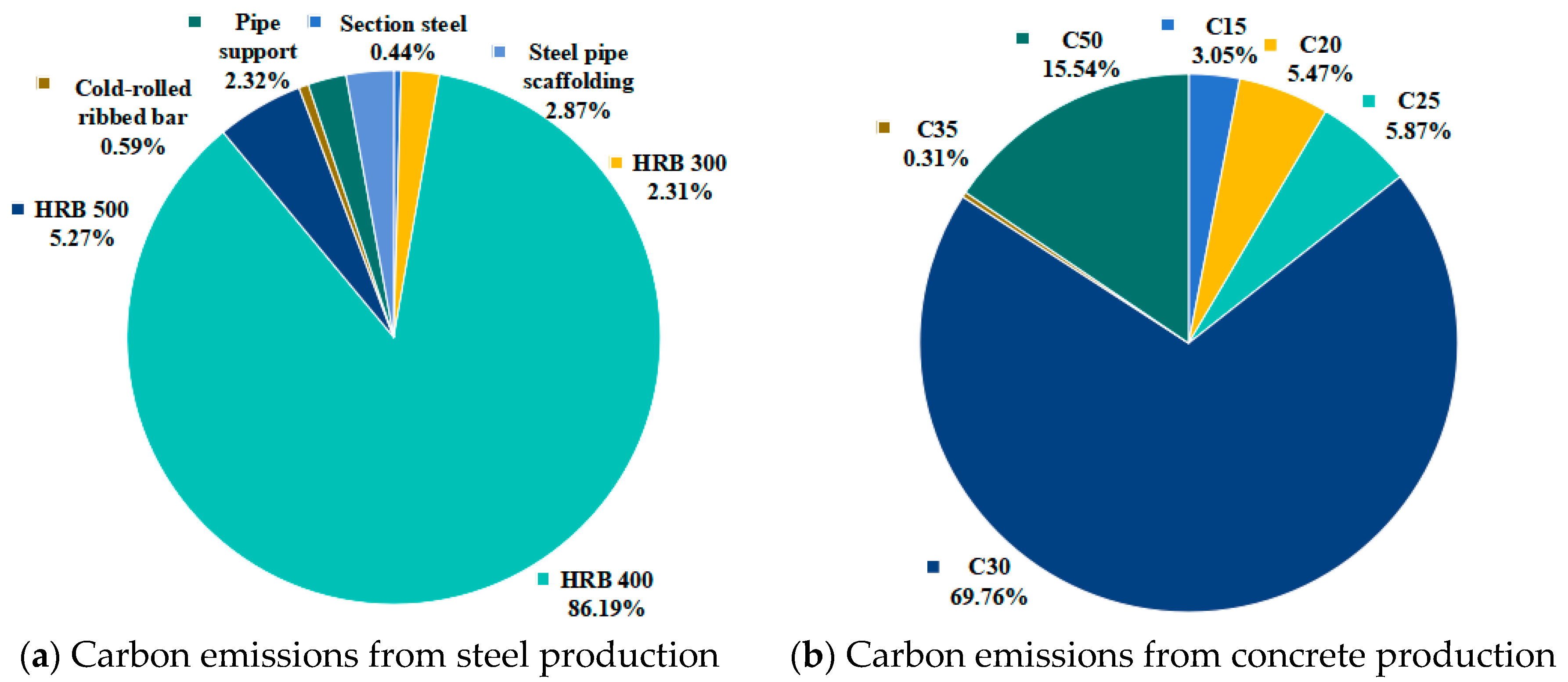

- The carbon emissions from the production of all steel materials were 2996.31 tCO2, accounting for 42.52%. Among them, the carbon emissions of HRB400 steel were 2582.55 tCO2, as shown in Figure 4a.

- The carbon emissions from the production of all concrete amounted to 2808.95 tCO2, accounting for 39.86%. The carbon emissions of C30 concrete and C50 concrete were 2396.12 tCO2, which were the two largest concrete materials (85.32% of all concrete) in terms of carbon emissions, as shown in Figure 4b.

- The two most carbon-intensive building materials were HRB400 steel and C30 concrete, accounting for 64.42% of the carbon emissions from the production of building materials.

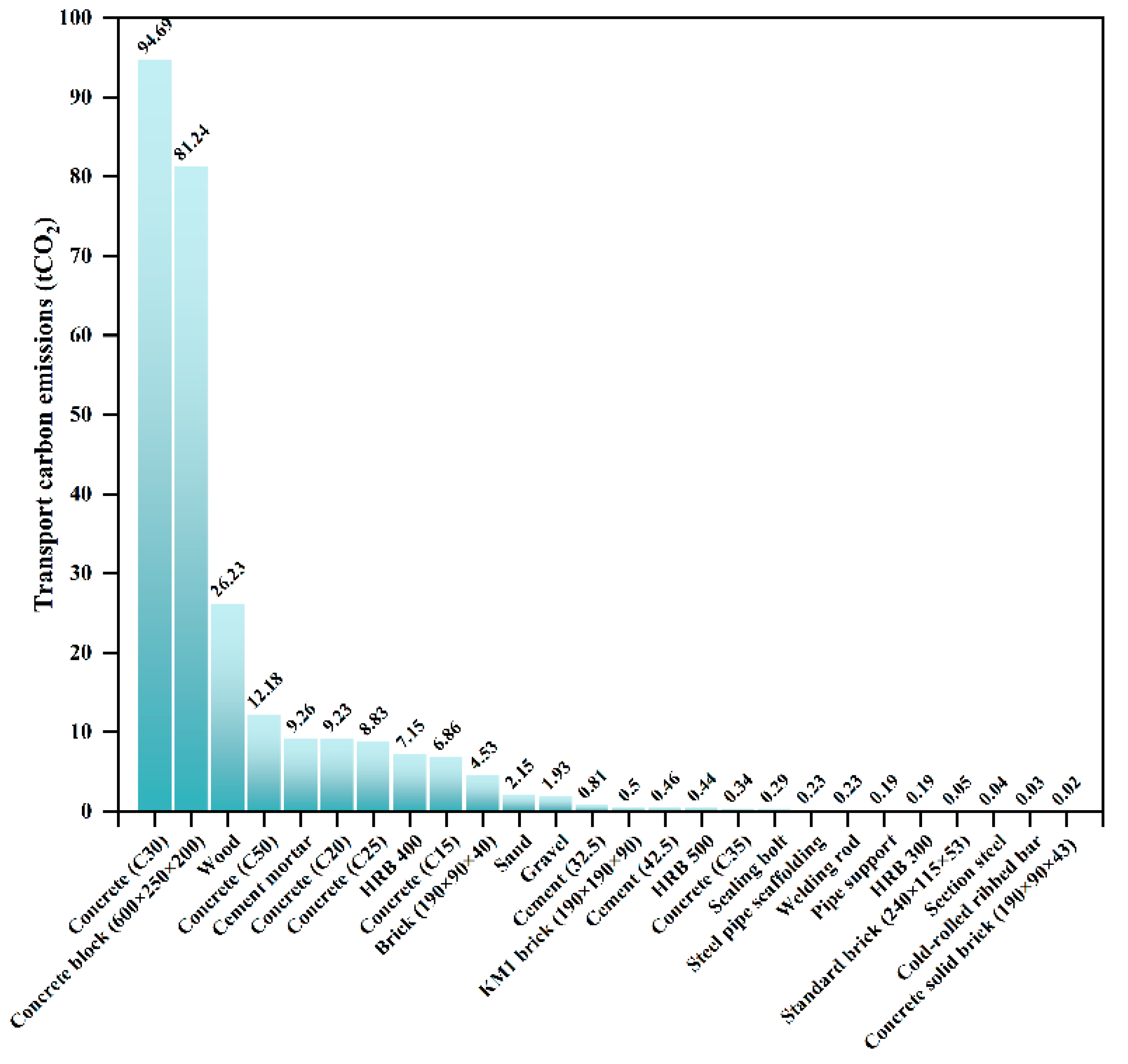

3.1.2. Transport

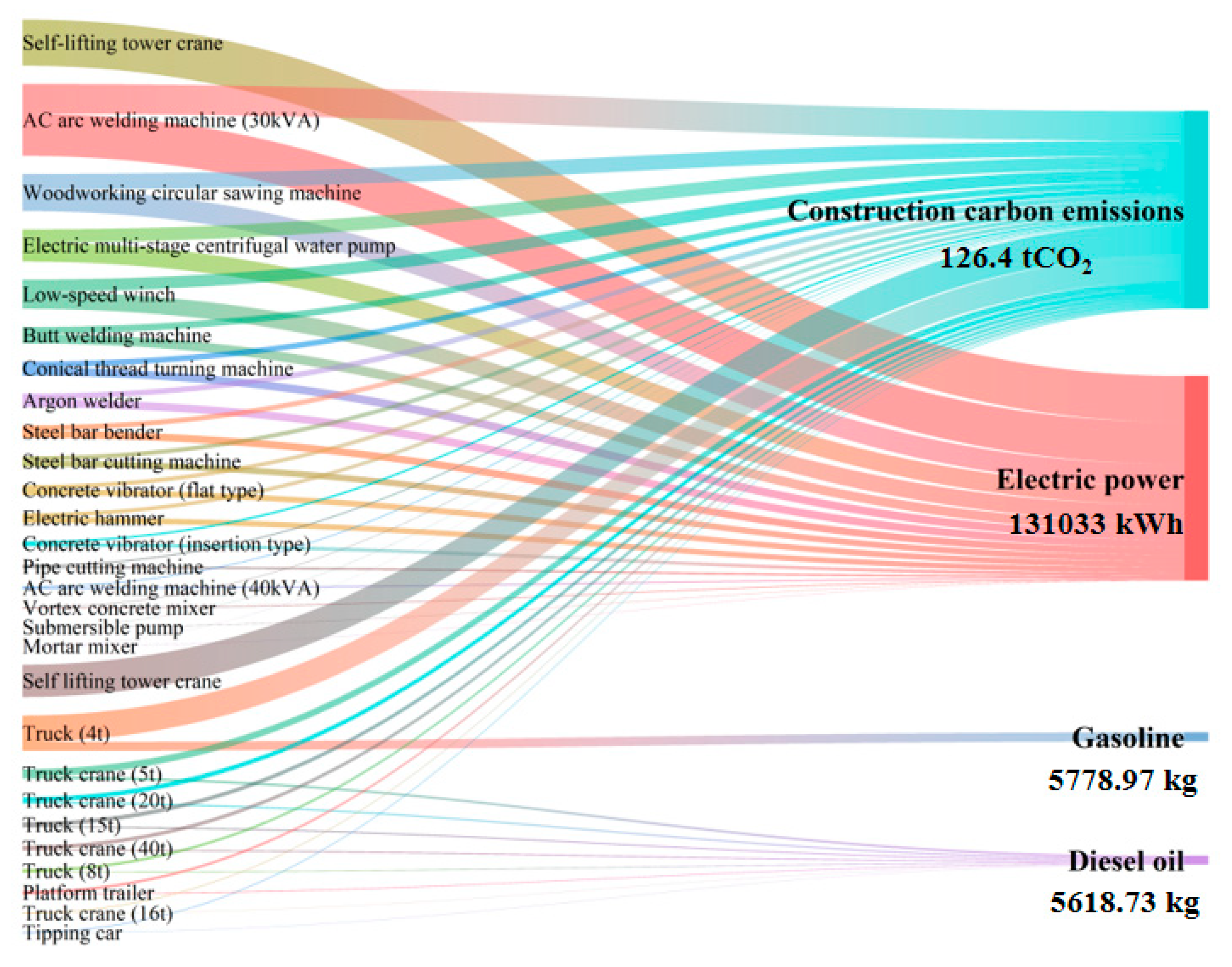

3.1.3. Construction

3.2. Operational Carbon Emissions

3.3. Demolition Carbon Emissions

3.4. Life Cycle Carbon Emissions

3.5. Comparison of Stock Cases

4. Discussion

4.1. Comparison of Inpatient Building and Stock Cases

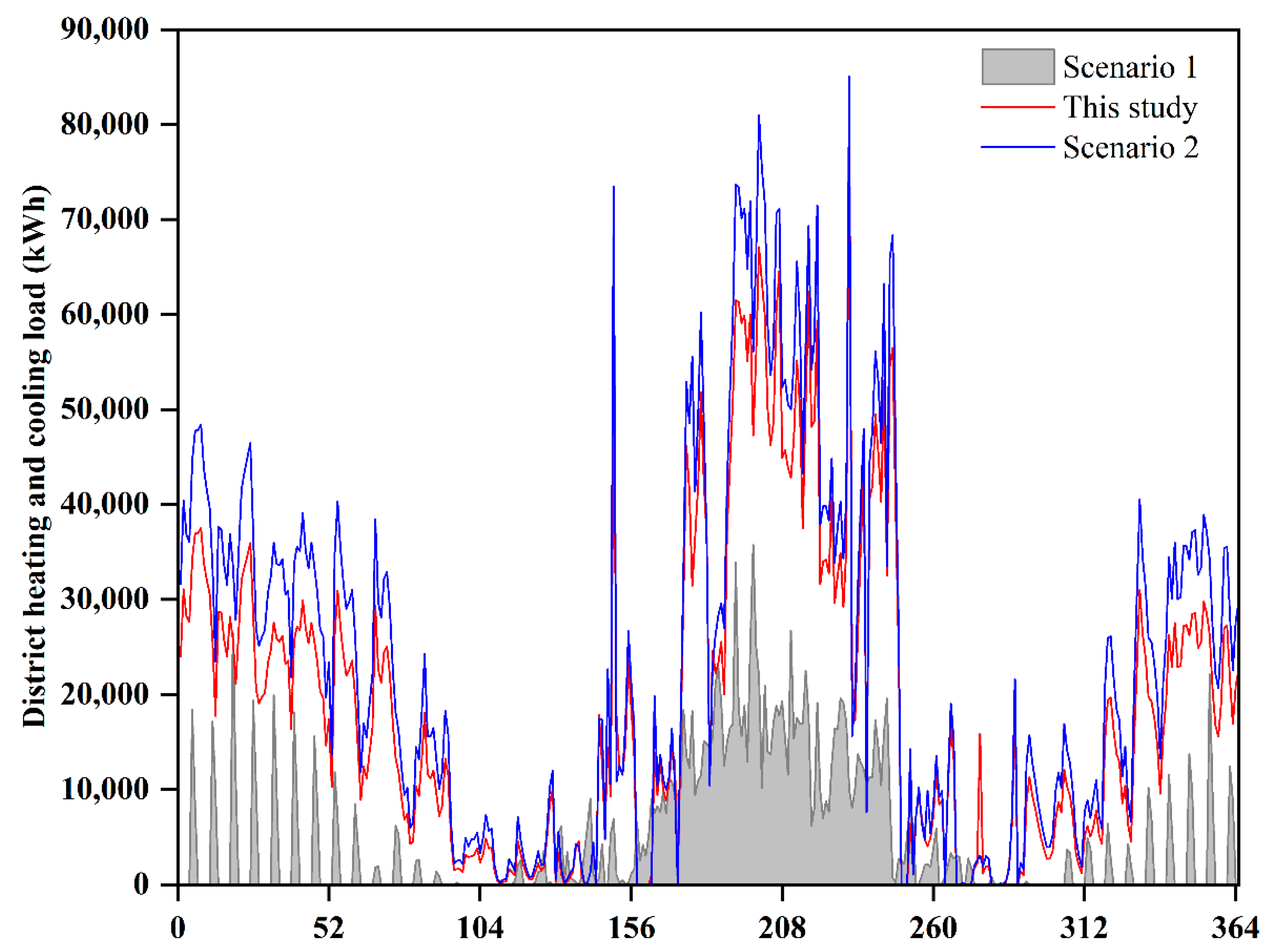

4.2. Impact of Operating Modes on Carbon Emissions

4.3. Limitation

5. Conclusions

- The carbon intensity of the inpatient building was 10,459.94 kgCO2/m2, of which 94.68% was operational carbon emissions, 4.54% was embodied carbon emissions, and only 0.38% was demolition carbon emissions. HVAC, equipment, and lighting were the largest contributors to carbon emissions, accounting for 52.57%, 27.85%, and 10.11%, respectively. HRB400 steel and C30 concrete were the two building materials with the largest carbon emissions.

- By comparing the life cycle carbon emissions of office buildings, schools, emporiums, factories, and hospitals, the most significant differences were found in the operational stage. Regarding operational carbon intensity, hospitals were second only to emporiums, with 1.71 and 1.41 times the carbon intensity of schools and office buildings, respectively. The inpatient building was 3 and 1.7 times that of the medical complex and the outpatient building, respectively, and although all three were part of the hospital, the different operating modes resulted in significant differences in carbon emissions.

- This study discussed the differences in energy consumption and carbon emissions of the inpatient building under the following three scenarios: standard operation (Scenario 1), “normal times” operation (this study), and “emergency times” operation (Scenario 2). The energy consumption and carbon emissions in Scenario 2 were 2.08 and 2.72 times greater than those in Scenario 1, and those in this study were 1.8 and 1.74 times greater than those in Scenario 1.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alam, I.; Alam, G.; Ayub, S.; Siddiqui, A.A. Assessment of bio-medical waste management in different hospitals in Aligarh city. In Advances in Waste Management; Springer: Singapore, 2019; pp. 501–510. [Google Scholar] [CrossRef]

- Wild, M.; Ohmura, A.; Makowski, K. Impact of Global Dimming and Brightening on Global Warming. Geophys. Res. Lett. 2007, 34, 2006GL028031. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Global Status Report for Buildings and Construction: Beyond Foundations: Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar] [CrossRef]

- Balali, A.; Valipour, A. Prioritization of Passive Measures for Energy Optimization Designing of Sustainable Hospitals and Health Centres. J. Build. Eng. 2021, 35, 101992. [Google Scholar] [CrossRef]

- Rahman, N.M.A. Optimizing the Energy Saving Potential of Public Hospital through a Systematic Approach for Green Building Certification in Malaysia. J. Build. Eng. 2021, 43, 103088. [Google Scholar] [CrossRef]

- Tarkar, P. Role of Green Hospitals in Sustainable Construction: Benefits, Rating Systems and Constraints. Mater. Today 2022, 60, 247–252. [Google Scholar] [CrossRef]

- Pichler, P.-P.; Jaccard, I.S.; Weisz, U.; Weisz, H. International Comparison of Health Care Carbon Footprints. Environ. Res. Lett. 2019, 14, 064004. [Google Scholar] [CrossRef]

- Dobosi, I.S.; Tanasa, C.; Kaba, N.-E.; Retezan, A.; Mihaila, D. Building Energy Modelling for the Energy Performance Analysis of a Hospital Building in Various Locations. E3S Web Conf. 2019, 111, 06073. [Google Scholar] [CrossRef]

- Eckelman, M.J.; Sherman, J. Environmental Impacts of the U.S. Health Care System and Effects on Public Health. PLoS ONE 2016, 11, e0157014. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, B.; Eagan, P.D.; Shaner, H. Solutions to Health Care Waste: Life-Cycle Thinking and “Green” Purchasing. Environ. Health Perspect. 2001, 109, 205–207. [Google Scholar] [CrossRef]

- Wu, R. The Carbon Footprint of the Chinese Health-Care System: An Environmentally Extended Input–Output and Structural Path Analysis Study. Lancet Planet. Health 2019, 3, e413–e419. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Yvon, A.; Kalameu, O.; Asadi, S.; Choudhary, R.; Reiter, S. Impact of Climate Change on Demands for Heating and Cooling Energy in Hospitals: An in-Depth Case Study of Six Islands Located in the Indian Ocean Region. Sustain. Cities Soc. 2019, 44, 629–645. [Google Scholar] [CrossRef]

- Wise, J. COP26: Fifty Countries Commit to Climate Resilient and Low Carbon Health Systems. BMJ 2021, 375, n2734. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Zhang, Y.; Yang, Z.Y.; Yan, D.; Jiang, Y. Challenges and Opportunities for Carbon Neutrality in China’s building Sector-Modelling and Data. Build. Simul. 2022, 3, 141–155. [Google Scholar] [CrossRef]

- McAlister, S.; Morton, R.L.; Barratt, A. Incorporating Carbon into Health Care: Adding Carbon Emissions to Health Technology Assessments. Lancet Planet. Health 2022, 6, e993–e999. [Google Scholar] [CrossRef] [PubMed]

- Pichler, P.P.; Jaccard, I.S.; Weisz, U.; Weisz, H. International Comparison of Health Care Carbon Footprints. Environ. Res. Lett. 1997, 14, 064004. [Google Scholar]

- Unger, S.; Landis, A. Assessing the Environmental, Human Health, and Economic Impacts of Reprocessed Medical Devices in a Phoenix Hospital’s Supply Chain. J. Clean. Prod. 2016, 112, 1995–2003. [Google Scholar] [CrossRef]

- Yang, X.; Hu, M.; Wu, J.; Zhao, B. Building-Information-Modeling Enabled Life Cycle Assessment, a Case Study on Carbon Footprint Accounting for a Residential Building in China. J. Clean. Prod. 2018, 183, 729–743. [Google Scholar] [CrossRef]

- Fenner, A.E.; Kibert, C.J.; Li, J.; Razkenari, M.A.; Hakim, H.; Lu, X.; Kouhirostami, M.; Sam, M. Embodied, Operation, and Commuting Emissions: A Case Study Comparing the Carbon Hotspots of an Educational Building. J. Clean. Prod. 2020, 268, 122081. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Asadi, S.; Reiter, S. Estimation, Analysis and Comparison of Carbon Emissions and Construction Cost of the Two Tallest Buildings Located in United States and China. Int. J. Environ. Sci. Technol. 2022, 19, 9313–9328. [Google Scholar] [CrossRef]

- Wang, T.; Seo, S.; Liao, P.-C.; Fang, D. GHG Emission Reduction Performance of State-of-the-Art Green Buildings: Review of Two Case Studies. Renew. Sustain. Energy Rev. 2016, 56, 484–493. [Google Scholar] [CrossRef]

- Li, H.; Deng, Q.; Zhang, J.; Xia, B.; Skitmore, M. Assessing the Life Cycle CO2 Emissions of Reinforced Concrete Structures: Four Cases from China. J. Clean. Prod. 2019, 210, 1496–1506. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Life-Cycle Assessment and Control Measures for Carbon Emissions of Typical Buildings in China. Build. Environ. 2015, 86, 89–97. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, S.; Wang, K. Quantitative Study of Life Cycle Carbon Emissions from 7 Timber Buildings in China. Int. J. Life Cycle Assess. 2021, 26, 1721–1734. [Google Scholar] [CrossRef]

- Li, X.; Xie, W.; Xu, L.; Li, L.; Jim, C.Y.; Wei, T. Holistic Life-Cycle Accounting of Carbon Emissions of Prefabricated Buildings Using LCA and BIM. Energy Build. 2022, 266, 112136. [Google Scholar] [CrossRef]

- Zhou, W. Carbon Emission Estimation of Prefabricated Buildings Based on Life Cycle Assessment Model. NEPT 2021, 20, 147–152. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life Cycle Primary Energy Use and Carbon Emission of an Eight-Storey Wood-Framed Apartment Building. Energy Build. 2010, 42, 230–242. [Google Scholar] [CrossRef]

- Wu, X.; Peng, B.; Lin, B. A Dynamic Life Cycle Carbon Emission Assessment on Green and Non-Green Buildings in China. Energy Build. 2017, 149, 272–281. [Google Scholar] [CrossRef]

- Tsinghua University Building Energy Conservation Research Center. Annual Report on China Building Energy Efficiency; China Construction Industry Press: Beijing, China, 2021. (In Chinese) [Google Scholar]

- Sim, J.; Sim, J.; Park, C. The Air Emission Assessment of a South Korean Apartment Building’s Life Cycle, along with Environmental Impact. Build. Environ. 2016, 95, 104–115. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management-Life Cycle Assessment-Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Wang, Y.; Yang, X.; Hou, Q.; Tao, J.; Dong, J. Quantitative Study on the Life-Cycle Carbon Emissions of a Nearly Zero Energy Building in the Severe Cold Zones of China. Sustainability 2022, 14, 1448. [Google Scholar] [CrossRef]

- Braune, A.; Durán, C.R. Life Cycle Assessments—A Guide on Using the LCA; DGNB: Stuttgart, Germany, 2018. [Google Scholar]

- Cheng, B.; Li, J.; Tam, V.W.Y.; Yang, M.; Chen, D. A BIM-LCA Approach for Estimating the Greenhouse Gas Emissions of Large-Scale Public Buildings: A Case Study. Sustainability 2020, 12, 685. [Google Scholar] [CrossRef]

- GB 50849-2014; Code for Design of Infectious Diseases Hospital. China Architecture & Building Press: Beijing, China, 2014. (In Chinese)

- Buratti, C.; Moretti, E.; Belloni, E.; Cotana, F. Unsteady Simulation of Energy Performance and Thermal Comfort in Non-Residential Buildings. Build. Environ. 2013, 59, 482–491. [Google Scholar] [CrossRef]

- Zini, M.; Carcasci, C. Machine Learning-Based Monitoring Method for the Electricity Consumption of a Healthcare Facility in Italy. Energy 2023, 262, 125576. [Google Scholar] [CrossRef]

- GB 55015-2021; General Code for Energy Efficiency and Renewable Energy Application in Buildings. China Architecture & Building Press: Beijing, China, 2021. (In Chinese)

- GB 50189-2015; Design Standard for Energy Efficiency of Public Buildings. China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD). Technical Guidelines for the Construction of Negative Pressure Wards in Emergency Treatment Facilities for COVID-19 (Trial); China Architecture & Building Press: Beijing, China, 2020. (In Chinese)

- Koch, R. The 80/20 Principle: The Secret of Achieving More with Less: Updated 20th Anniversary Edition of the Productivity and Business Classic; Hachette: London, UK, 2011. [Google Scholar]

- GB 51366-2019; Standard for Building Carbon Emission Calculation. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- Peng, C. Calculation of a Building’s Life Cycle Carbon Emissions Based on Ecotect and Building Information Modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- GB/T 2589-2020; General Rules for Calculation of the Comprehensive Energy Consumption. China Architecture & Building Press: Beijing, China, 2020. (In Chinese)

- China City Greenhouse Gas Working Group, China Products Carbon Footprint Factors Database (CPCD). 2024. Available online: http://Lca.Cityghg.com (accessed on 3 March 2024).

- Guo, C.; Zhang, X.; Zhao, L.; Wu, W.; Zhou, H.; Wang, Q. Building a Life Cycle Carbon Emission Estimation Model Based on an Early Design: 68 Case Studies from China. Sustainability 2024, 16, 744. [Google Scholar] [CrossRef]

- Fenner, A.E.; Kibert, C.J.; Woo, J.; Morque, S.; Razkenari, M.; Hakim, H.; Lu, X. The Carbon Footprint of Buildings: A Review of Methodologies and Applications. Renew. Sustain. Energy Rev. 2018, 94, 1142–1152. [Google Scholar] [CrossRef]

- Rong, P.; Zhang, Y.; Qin, Y.; Liu, G.; Liu, R. Spatial Differentiation of Carbon Emissions from Residential Energy Consumption: A Case Study in Kaifeng, China. J. Environ. Manag. 2020, 271, 110895. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L. Carbon Emission Analysis of a Green Building Project in Enshi, Hubei. Constr. Wall Innov. Build. Energy 2019, 4, 34–36. (In Chinese) [Google Scholar]

- Guo, C.M.; Liu, Q.H.; Li, S.Y. Green Building Life Cycle Carbon Emission Accounting Modelling and Case Analysis Based on Green Building Evaluation System. Green Build. 2019, 11, 13–18. (In Chinese) [Google Scholar]

- Huang, Z.J.; Zhao, L.L.; Zhang, T. The Assessment Method of Life-Cycle CO2 Emission for Residential Buildings. J. Civ. Environ. Eng. 2011, 33, 103–105. (In Chinese) [Google Scholar]

- Jia, J. Research on the Carbon Emission of a Green Building in the Whole Life Cycle. Constr. Sci. Technol. 2016, 17, 78–81. (In Chinese) [Google Scholar]

- Wang, C.Y. Life Cycle Assessment of Carbon Emissions from Office Buildings in Yangtze River Delta; Southeast University: Nanjing, China, 2016. (In Chinese) [Google Scholar]

- Yin, S.C. Study of Life-Cycle Carbon Emission in Buildings; Harbin Institute of Technology: Harbin, China, 2012. (In Chinese) [Google Scholar]

- Ma, J.-J.; Du, G.; Zhang, Z.-K.; Wang, P.-X.; Xie, B.-C. Life Cycle Analysis of Energy Consumption and CO2 Emissions from a Typical Large Office Building in Tianjin, China. Build. Environ. 2017, 117, 36–48. [Google Scholar] [CrossRef]

- Wang, Y.S.; Yang, X.; Yan, H. Carbon Emission Accounting for Buildings Based on Whole Life Cycle: A Case Study of Reconstruction Project at College in Guangzhou. J. Eng. Manag. 2017, 31, 19–24. [Google Scholar]

- Peng, B. Case Study on Life Cycle Energy Consumption and CO2 Emissions of Green Buildings; Tsinghua University: Beijing, China, 2012. (In Chinese) [Google Scholar]

- Wang, J.Y. BIM-Based Green Building Life Cycle Carbon Emissions Measurement and Benchmarking Research; Hunan University of Technology: Zhuzhou, China, 2019. (In Chinese) [Google Scholar]

- Zou, Y.N. Research on the Calculation of the Whole Life Cycle Carbon Emission and the Carbon Reduction Strategy of Chaoyang Wanda Plaza; Shenyang Jianzhu University: Shenyang, China, 2020. (In Chinese) [Google Scholar]

- Dong, K.H. Study on Carbon Emission Calculation from the Life-Cycle of Large-Scale Complex Building in the South; South China University of Technology: Guangzhou, China, 2018. (In Chinese) [Google Scholar]

- Liu, Y. The Carbon Emission Evaluation Model Based on Building Lifecycle; Dalian University of Technology: Dalian, China, 2015. (In Chinese) [Google Scholar]

- Lu, K.; Wang, H. Estimation of Building’s Life Cycle Carbon Emissions Based on Life Cycle Assessment and Building Information Modeling: A Case Study of a Hospital Building in China. GEP 2019, 7, 147–165. [Google Scholar] [CrossRef][Green Version]

- GB GB50736-2012; Design Code for Heating Ventilation and Air Conditioning of Civil Buildings. China Architecture & Building Press: Beijing, China, 2012. (In Chinese)

- Hu, P. A Medical Building Energy Consumption Analysis and Energy-Saving Resconstrction in Hunan Province; Hunan University: Changsha, China, 2018. (In Chinese) [Google Scholar]

- Silva, B.V.F.; Holm-Nielsen, J.B.; Sadrizadeh, S.; Teles, M.P.R.; Kiani-Moghaddam, M.; Arabkoohsar, A. Sustainable, Green, or Smart? Pathways for Energy-Efficient Healthcare Buildings. Sustain. Cities Soc. 2024, 100, 105013. [Google Scholar] [CrossRef]

| Parameters | Detailed Information |

|---|---|

| Building location | Nanjing, Jiangsu |

| Climate zone | Hot-summer, cold-winter zone |

| Construction period | Designed in 2021 and completed in 2023 |

| Area | 15,679.57 m2 |

| Height | 5 floors above ground, 1 floor below ground, total height 23.95 m |

| Structure | Frame structure |

| Form factor | 0.15 |

| Number of beds | 150 negative pressure wards with a total of 300 beds |

| Zone 1 | 3103.8 m2, including consultation room, lounge, dining room, duty room, and shower room |

| Zone 2 | 3029.2 m2, including nurses’ station, treatment room, store room, office, and healthcare corridor |

| Zone 3 | 9246.6 m2, including wards, buffer rooms, soiled storage rooms, soiled washrooms, and patient corridor |

| Parameters | Values |

|---|---|

| External walls U-value, Uwall | 0.58 W/(m2·K) |

| Roof U-value, Uroof | 0.4 W/(m2·K) |

| Window U-value, Uwindow | 2.2 W/(m2·K) |

| Solar heat gain coefficient, SHGC | SHGCeast = 0.37, SHGCwast = 0.37, SHGCsouth = 0.37, SHGCnorth = 0.37 |

| Window-to-wall ratio, WWR | WWReast = 0.24, WWRwast = 0.22, WWRsouth = 0.12, WWRnorth = 0.04 |

| Occupancy density | 0.04 people/m2 |

| Domestic hot water | 0.21 L/(m2·day) |

| Summer setting temperature, Tsummer | 26 °C |

| Winter setting temperature, Twinter | 20 °C |

| Ventilation rate | Zone 1 = 3 ac/h, Zone 2 = 6 ac/h, Zone 3 = 12 ac/h |

| Default display lighting density | 6 W/m2 |

| Power density | 15 W/m2 |

| No. | Material Type | Unit | Amount | ||

|---|---|---|---|---|---|

| 1 | Concrete | C15 | m3 | 481.33 | 177.8 |

| 2 | C20 | m3 | 647.37 | 237.32 | |

| 3 | C25 | m3 | 619.74 | 266.18 | |

| 4 | C30 | m3 | 6642.35 | 295 | |

| 5 | C35 | m3 | 23.88 | 362.6 | |

| 6 | C50 | m3 | 854.46 | 511 | |

| 7 | Cement | 32.5 | kg | 124,597.12 | 0.621 |

| 8 | 42.5 | kg | 70,595.28 | 0.795 | |

| 9 | Cement mortar | m3 | 714.18 | 315 | |

| 10 | Steel | Section steel | kg | 5593.69 | 2.365 |

| 11 | HRB 300 | kg | 29,638.14 | 2.34 | |

| 12 | HRB 400 | kg | 1,103,654.28 | 2.34 | |

| 13 | HRB 500 | kg | 67,488.3 | 2.34 | |

| 14 | Cold-rolled ribbed bar | kg | 5243.82 | 3.368 | |

| 15 | Pipe support | kg | 28,593.13 | 2.43 | |

| 16 | Steel pipe scaffolding | kg | 35,442.28 | 2.43 | |

| 17 | Brick | Brick (190 × 90 × 40) | m3 | 51.76 | 336 |

| 18 | Standard brick (240 × 115 × 53) | One hundred | 377.17 | 49.15 | |

| 19 | KM1 brick (190 × 190 × 90) | 3934.75 | 109.17 | ||

| 20 | Concrete solid brick (190 × 90 × 43) | 149.42 | 24.71 | ||

| 21 | Concrete block (600 × 250 × 200) | m3 | 928.7 | 212 | |

| 22 | Wood | m3 | 1079.51 | 178 | |

| 23 | Others | Sand | t | 332.12 | 2.51 |

| 24 | Gravel | t | 297.75 | 2.18 | |

| 25 | Sealing bolt | kg | 6048.19 | 1.54 | |

| 26 | Welding rod | kg | 4773.85 | 3.027 | |

| No. | Machinery and Equipment | Energy Consumption per Shift | Number of Shifts | ||

|---|---|---|---|---|---|

| Gasoline (kg) | Diesel (kg) | Electricity (kWh) | |||

| 1 | Pipe cutting machine (150 mm) | / | / | 12.90 | 96.79 |

| 2 | Conical thread turning machine (45 mm) | / | / | 9.24 | 566.45 |

| 3 | Truck crane (5 t) | / | 26.43 | / | 56.10 |

| 4 | Truck crane (16 t) | / | 35.85 | / | 4.50 |

| 5 | Truck crane (20 t) | / | 38.41 | / | 28.00 |

| 6 | Truck crane (40 t) | / | 48.52 | / | 16.00 |

| 7 | Self-lifting tower crane (400 t) | / | / | 164.31 | 179.54 |

| 8 | Truck (4 t) | 25.48 | / | / | 226.80 |

| 9 | Truck (8 t) | / | 35.49 | / | 16.00 |

| 10 | Truck (15 t) | / | 56.74 | / | 15.00 |

| 11 | Platform trailer (20 t) | / | 45.39 | / | 12.00 |

| 12 | Tipping car (1 t) | / | 6.03 | / | 26.41 |

| 13 | Low-speed winch (30 kN) | / | / | 28.76 | 380.43 |

| 14 | Mortar mixer (200 L) | / | / | 8.61 | 23.41 |

| 13 | Concrete vibrator (flat type) | / | / | 6.72 | 561.01 |

| 14 | Concrete vibrator (insertion type) | / | / | 5.38 | 403.11 |

| 15 | Vortex concrete mixer (500 L) | / | / | 107.71 | 5.78 |

| 16 | Steel bar cutting machine (40 mm) | / | / | 32.10 | 123.38 |

| 17 | Steel bar bender (40 mm) | / | / | 12.80 | 365.06 |

| 18 | Woodworking circular sawing machine (500 mm) | / | / | 24.00 | 579.81 |

| 19 | Electric multistage centrifugal water pump (100 mm) | / | / | 180.40 | 66.76 |

| 20 | Submersible pump (100 mm) | / | / | 25.00 | 10.32 |

| 21 | AC arc welding machine (30 kVA) | / | / | 96.53 | 279.68 |

| 22 | AC arc welding machine (40 kVA) | / | / | 132.23 | 6.22 |

| 23 | Butt welding machine | / | / | 122.00 | 50.07 |

| 24 | Argon welder | / | / | 70.70 | 71.32 |

| 25 | Electric hammer | / | / | 4.20 | 839.68 |

| Type | CO2 Emission Factor | Data Sources |

|---|---|---|

| Gasoline | 2.93 kgCO2/kg | [42,44] |

| Diesel oil | 3.1 kgCO2/kg | |

| Natural gas | 2.16 kgCO2/m3 | |

| Tap water | 0.168 kgCO2/t | [42] |

| Electricity (Jiangsu Province) | 0.7 kgCO2/kWh | [45] |

| Material | Consumption per Unit Area |

|---|---|

| Concrete | 0.497 m3/m2 |

| Steel | 68.39 kg/m2 |

| Cement | 87.04 kg/m2 |

| Wood | 0.011 m3/m2 |

| Brick | 95.24 kg/m2 |

| Sand | 33.77 kg/m2 |

| Carbon Emission (tCO2) | Carbon Emission Intensity (kgCO2/m2) | Percentage (%) | |

|---|---|---|---|

| Embodied stage | 7446.13 | 474.91 | 4.54% |

| Production of building materials | 7050.28 | 449.66 | 4.30% |

| Transport of building materials | 269.45 | 17.19 | 0.16% |

| Construction | 126.4 | 8.06 | 0.08% |

| Operational stage | 155,925.31 | 9944.85 | 95.08% |

| Cooling | 36,745.31 | 2343.60 | 22.41% |

| Heating | 49,454.71 | 3154.20 | 30.16% |

| Lighting | 16,583.68 | 1057.70 | 10.11% |

| Equipment | 45,668.22 | 2912.70 | 27.85% |

| Domestic water | 2633.41 | 167.96 | 1.61% |

| Maintenance | 4839.98 | 308.69 | 2.95% |

| Demolition stage | 629.9 | 40.17 | 0.38% |

| Total life cycle carbon emissions | 164,001.34 | 10,459.94 | 100.00% |

| No | Location | Zone | Type | Structure | Area (m2) | Floors | Calculation Method | Sources | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 3 | ||||||||

| C1 | Guangdong | IV | Office | Reinforced concrete | 192,181 | 36 | SimaPro | SimaPro | SimaPro | [22] |

| C2 | Xiamen | IV | Office | Frame | 24,533.19 | 9 | Main materials (10 types) | DeST-c | Estimation | [48] |

| C3 | Enshi | III | Office | Frame-shear wall | 44,615.56 | 9 | Main materials (3 types) | IBE | Estimation | [49] |

| C4 | Tianjin | II | Office | Steel | 12,878.5 | 5 | Detailed list | Measurement | Estimation | [50] |

| C5 | Enshi | III | Office | Frame-shear wall | 20,036.81 | 9 | Main materials (3 types) | IBE | Estimation | [51] |

| C6 | Shenzhen | IV | Office | Frame | 25,023.9 | 5 | Detailed list | Measurement | Estimation | [21] |

| C7 | Shanghai | III | Office | Reinforced concrete | 24,261 | 7 | Main materials (11 types) | E-Quest | Estimation | [52] |

| C8 | Harbin | I | Office | Concrete | 15,514 | 28 | Main materials (14 types) | Energyplus | List | [53] |

| C9 | Xi’an | II | Office | Frame | 11,351 | 6 | Detailed list | Designbuilder | List | [54] |

| C10 | Tianjin | II | Office | Frame | 57,000 | 9 | Detailed list | Measurement | List | [55] |

| C11 | Zhejiang | III | School | Reinforced concrete | 4981 | 5 | SimaPro | SimaPro | SimaPro | [22] |

| C12 | Guangzhou | IV | School | Frame | 27,066.7 | 10 | Main materials (6 types) | Statistic | Estimation | [56] |

| C13 | Hangzhou | III | School | Frame | 20,933 | 5 | Detailed list | Statistic | Estimation | [57] |

| C14 | Changsha | III | School | Shear wall | 2347.43 | 3 | Revit | GBS | List | [58] |

| C15 | Nanjing | III | School | Concrete | 16,873 | 15 | Revit | Prediction model | Estimation | [53] |

| C16 | Chaoyang | I | Emporium | Frame | 97,000 | 5 | Detailed list | Measurement | Estimation | [59] |

| C17 | Foshan | IV | Emporium | Frame | 130,000 | 4 | Detailed list | Measurement | Estimation | [60] |

| C18 | Beijing | II | Factory | Steel | 50,461.14 | 2 | Main materials (10 types) | Statistic | Estimation | [61] |

| C19 | Guangdong | IV | Hospital | Reinforced concrete | 1601 | 7 | SimaPro | SimaPro | SimaPro | [22] |

| C20 | Chuzhou | III | Hospital | Frame | 6367 | 4 | Revit | GBS | Estimation | [62] |

| Carbon Emission Intensity (kg CO2/m2) | Embodied Stage | Operational Stage | Demolition Stage | Total |

|---|---|---|---|---|

| Office | 795.14 | 2844.19 | 30.21 | 3669.39 |

| School | 679.84 | 2345.74 | 77.56 | 3103.67 |

| Emporium | 482.20 | 4603.54 | 48.01 | 5133.75 |

| Hospital | 604.19 | 4004.20 | 229.87 | 4842.76 |

| This study | 474.91 | 9944.85 | 40.17 | 10,459.94 |

| No | Operational Scheme | Energy Consumption [kWh/(m2·Year)] | Operational Carbon Intensity (kg CO2/m2) |

|---|---|---|---|

| Scenario 1 | Zone 1 = 2 ac/h, Zone 2 = 2 ac/h, Zone 3 = 2 ac/h | 149.98 | 5725.89 |

| This study | Zone 1 = 3 ac/h, Zone 2 = 6 ac/h, Zone 3 = 12 ac/h | 270.52 | 9944.85 |

| Scenario 2 | Zone 1 = 12 ac/h, Zone 2 = 12 ac/h, Zone 3 = 12 ac/h | 312.04 | 15,587.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Guo, C.; Chen, L.; Qiu, L.; Wu, W.; Wang, Q. Using BIM and LCA to Calculate the Life Cycle Carbon Emissions of Inpatient Building: A Case Study in China. Sustainability 2024, 16, 5341. https://doi.org/10.3390/su16135341

Zhao L, Guo C, Chen L, Qiu L, Wu W, Wang Q. Using BIM and LCA to Calculate the Life Cycle Carbon Emissions of Inpatient Building: A Case Study in China. Sustainability. 2024; 16(13):5341. https://doi.org/10.3390/su16135341

Chicago/Turabian StyleZhao, Li, Cheng Guo, Leduan Chen, Liping Qiu, Weiwei Wu, and Qingqin Wang. 2024. "Using BIM and LCA to Calculate the Life Cycle Carbon Emissions of Inpatient Building: A Case Study in China" Sustainability 16, no. 13: 5341. https://doi.org/10.3390/su16135341

APA StyleZhao, L., Guo, C., Chen, L., Qiu, L., Wu, W., & Wang, Q. (2024). Using BIM and LCA to Calculate the Life Cycle Carbon Emissions of Inpatient Building: A Case Study in China. Sustainability, 16(13), 5341. https://doi.org/10.3390/su16135341