Abstract

When exposed to sun radiation and heat, asphalt binders age, resulting in reduced flexibility, cracking, and pavement failure. Given the increasing demands of traffic, environmental concerns, and resource scarcity, highway agencies and researchers are actively seeking solutions that meet performance requirements and demonstrate awareness of using non-renewable resources. Epoxy asphalt (EA) promotes sustainability concepts due to its production at significantly lower mixing and compaction temperatures, enhanced durability, improved serviceability, reduced maintenance needs, and successful recycling and reuse in hot asphalt mixtures. Crumb rubber, a widely recognized recycled waste tire material, is considered a viable option for promoting sustainability and enhancing asphalt binder properties. This study aims to enhance the durability and long-term performance of asphalt binders by utilizing sustainable materials. Six types of asphalt binders were employed: PG 67-22 base asphalt binder; styrene–butadiene–styrene (SBS)-modified PG 76-22 and PG 88-22H (3.5% and 7.0% dosage rates, respectively); a hybrid PG 76-22CS-modified asphalt binder prepared with SBS and crumb rubber modifiers; and 25EAB and 50EAB epoxy-modified asphalt binders prepared at 25 and 50% dosage rates, respectively. Results indicate that the sustainable asphalt binders PG 76-22CS, 25EAB, and 50EAB demonstrated comparable or superior performance compared to SBS-modified asphalt binders, as measured by rutting and fatigue factors. Additionally, epoxy asphalt binders had better anti-aging and cracking resistance, as shown by the outcomes of Fourier-transform infrared spectroscopy and linear amplitude sweep tests, respectively. This study contributes valuable insights into the potential of sustainable materials to enhance the overall performance and resilience of asphalt binders.

1. Introduction

The production of asphalt binders releases a significant amount of greenhouse gases (GHGs), contributing to environmental pollution and global warming. In 2019, the United States produced approximately 422 million tons of asphalt mixture, resulting in 21.7 million tons of GHG emissions, constituting 0.3% of the country’s total GHG inventory [1,2]. This prompted the Federal Highway Administration (FHWA) to set four key methods to quantify sustainability in pavement engineering: performance assessment, life cycle cost analysis (LCCA), life cycle assessment (LCA), and rating systems [3,4,5]. Furthermore, concerns about asphalt durability and long-term performance have grown among state Departments of Transportation (DOTs) and transportation agencies due to increasing environmental challenges and traffic demands. Exposure to sunlight and heat causes aging in asphalt binder, leading to a loss of flexibility and eventual pavement structure cracking and failure [6,7].

The asphalt binder undergoes expansion and contraction due to daily and seasonal temperature fluctuations, resulting in the formation of thermal cracks. For instance, low temperatures associated with the winter season make asphalt binders stiff and brittle, leading to cracking and reduced flexibility [8]. Furthermore, water freeze–thaw cycles exert expansion and contraction forces within the asphalt pavement, leading to thermal cracking. This increases the risk of pavement distress, such as raveling and potholes, reducing the pavement’s durability and lifespan [9]. Conversely, high temperatures associated with the summer season soften the asphalt binder and negatively affect its resistance to permanent deformation (i.e., rutting). Additionally, the presence of oxygen and ultraviolet light further accelerates asphalt binder aging, leading to premature cracks and failure. Water can also accelerate the loss of soluble substances from the asphalt binder, increasing the rate of aging and crack formation [10,11]. Addressing asphalt binder aging is essential for pavement sustainability and long-term performance, requiring thorough evaluation during pavement design and construction. To mitigate the effects of aging, various types of additives and rejuvenators can be used in pavement construction. These additives decrease the effect of aging on asphalt binders and improve the long-term performance of pavements [12,13]. This aligns with FHWA guidelines to promote sustainability by producing long-lasting pavements with reduced maintenance requirements.

Styrene–butadiene–styrene (SBS), one of the most highly utilized polymers in flexible pavements, is a type of polymer that is added to asphalt binders to improve its rheological properties, durability, and overall performance [14]. It improves the asphalt binder’s flexibility, resistance to cracking, and aging resistance [14,15]. Moreover, SBS-modified asphalt binder has increased elasticity at high temperatures, enhanced flexibility at low temperatures, and decreased temperature susceptibility [16]. Furthermore, higher amounts of SBS (>6% by weight of asphalt binder) can be incorporated into a base asphalt binder to further improve its performance [16,17,18]. Also, crumb rubber modifier (CRM), a recycled material derived from waste tires, serves as an effective modifier in enhancing the flexibility and crack resistance of asphalt binders [19,20] in addition to improving anti-aging properties and long-term performance [21,22]. For instance, the asphalt binder modified with CRM exhibits increased stiffness and elasticity at a high temperature, improved fatigue life, and decreased stiffness at a low temperature [23,24,25]. When CRM is combined with SBS, the resulting modified asphalt binder exhibits superior resistance to low-temperature cracking, improved durability, and enhanced resistance to rutting [26,27]. Epoxy-modified asphalt binder (EAB) consists of a two-phase chemical reaction between a thermosetting resin (commonly referred to as Part A) and a base asphalt binder and curing agent (commonly referred to as Part B) [28,29,30]. The blending of Parts A and B forms a thermosetting EAB that will not melt after being fully cured because of its irreversible chemical reaction nature [31,32]. Many studies showed that EAB was successfully incorporated into pavement construction and has numerous benefits, such as improved stiffness, elasticity, thermal stability, adhesion, and anti-aging properties [33,34].

Studies show that modified asphalt binder (e.g., containing SBS or CRM) has less aging susceptibility and superior durability compared to unmodified asphalt binders. However, these additives tend to degrade because of the continuous oxidation reaction (i.e., aging), which significantly affects long-term performance and results in increased brittleness and cracking [35]. For example, researchers found that the SBS polymer degradation caused by oxidative aging negatively changes the asphalt binder’s chemical structure and rheological properties [36,37]. Moreover, the effect of aging on EAB rheological and chemical properties has not been thoroughly addressed in the literature. Therefore, it is of great importance to better understand the aging mechanism and its effect on different types of asphalt binders.

Some studies have suggested that using the standard laboratory pressure aging vessel (PAV) (i.e., 20 h at 2.1 MPa and 100 °C) to simulate aging in the field may not be accurate [38,39]. Therefore, some researchers have reported that using 2PAVs may be more adequate for simulating the aging process in the field [40,41]. This paper presents the results of rheological and chemical tests of unmodified and modified asphalt binders containing high polymers, crumb rubber, and EAB to improve their long-term performance and durability.

2. Objective and Scope

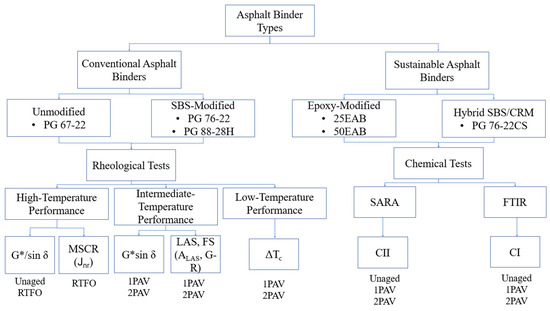

The objective of this study was to compare the rheological and chemical properties of various asphalt binder types at multiple aging levels. The study considered various asphalt binder types, including PG 67-22 base asphalt binder; styrene–butadiene–styrene (SBS)-modified PG 76-22 and PG 88-22H (3.5% and 7.0% dosage rates, respectively); a hybrid PG 76-22CS-modified asphalt binder prepared with SBS and crumb rubber modifier; and 25EAB and 50EAB epoxy-modified asphalt binders prepared at 25 and 50% dosage rates, respectively. The Superpave performance grading (PG) test was conducted for all modified asphalt binders. The high-temperature performance of asphalt binders was determined according to the rutting factor (G*/sinδ) and multiple stress creep recovery (MSCR) test parameters. The intermediate temperature performance of the asphalt binders was determined according to the fatigue factor (G*xsinδ), Glover-Rowe (G-R) parameter from the frequency sweep (FS) test, and ALAS parameter from the linear amplitude sweep test. The low-temperature performance was determined using the ΔTc parameter obtained from the bending beam rheometer (BBR) test. The chemical properties of asphalt binders were characterized using the colloidal instability index (CII) and carbonyl index (CI) parameters obtained from SARA fractionation and Fourier-transform infrared spectroscopy (FTIR) tests, respectively. It is noted that 2PAV aging level was conducted for all applicable tests as it simulates long-term aging in the field more accurately than conventional 1PAV [40,41]. Triplicate samples were used for each test, except for the MSCR and BBR, where two specimens were used. Figure 1 outlines the research methodology adopted in the study.

Figure 1.

Research methodology.

3. Experimental Design

3.1. Materials

The asphalt binder types used in this study were PG 67-22 base asphalt binder; styrene–butadiene–styrene (SBS)-modified PG 76-22 and PG 88-22H (3.5% and 7.0% dosage rates, respectively); a hybrid PG 76-22CS-modified asphalt binder prepared with SBS and crumb rubber modifier (~6.5% 30-mesh CRM and ~1.5% SBS); and 25EAB and 50EAB epoxy-modified asphalt binders prepared at 25 and 50% dosage rates, respectively.

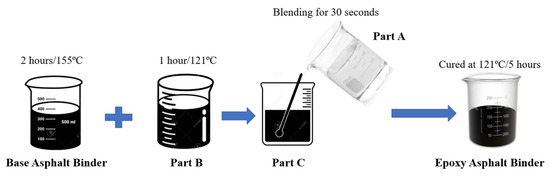

The EAB consists of three parts: Part A (epoxy resin), Part B (an asphalt binder modified with a curing agent), and a base asphalt binder (i.e., PG 67-22), which is used to dilute Parts A and B blend. According to the manufacturer’s recommendation, Parts A and B are to be blended at a certain fixed stoichiometric weight ratio (Part A = 20%, Part B = 80%). The PG 67-22 base asphalt binder and Part B were first heated to 121 °C and 155 °C, respectively, and then blended for two minutes to produce Part C. Then, Part C and Part A were placed in the oven at 121 °C for 20 min and further blended for 30 s to form EAB; see Figure 2. For illustration, 100 g of 50EAB contains 10.0 g (Part A: 100 × 20% × 50%) of epoxy resin and 90.0 g (Part B:100-10.0) of curing agent and base asphalt binder blend, the latter of which can be pre-blended for convenience. It should be noted that both 25EAB and 50EAB were cured at 121 °C for 5 h, and they have thermoplastic behavior because of the low resin content (approximately 5.0% and 10.0%, respectively). However, as the EAB approaches 100EAB (undiluted), the EAB converts to a thermoset material that does not melt under heat after being fully cured.

Figure 2.

Epoxy asphalt binder (EAB) production process.

Table 1 provides an overview of the basic properties of the asphalt binders evaluated. EAB production occurs at significantly lower temperatures than other asphalt binders. Additionally, the asphalt binder PG 76-22CS was the only one to incorporate recycled crumb rubber particles. Therefore, these three asphalt binders were classified as sustainable materials and were compared to unmodified and SBS-modified asphalt binders.

Table 1.

Asphalt binder basic properties.

3.2. Rheological and Chemical Tests

3.2.1. Performance Grading (PG) Test

The Superpave performance grading was performed on all asphalt binders using the dynamic shear rheometer (DSR) to evaluate their high-, intermediate-, and low-temperature gradings following AASHTO test method M320, “Standard Specification for Performance-Graded Asphalt Binder” [42]. The rotational viscosity (RV) was conducted at 135 °C according to AASHTO T316, “Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer” [43]. The short- and long-term aging were simulated following the standard aging procedures for the rolling thin-film oven (RTFO) test according to AASHTO T240 [44] and pressurized aging vessel (PAV) according to AASHTO R28 [45]. Moreover, the critical temperature difference (ΔTc) parameter was determined from the Superpave performance grading using the bending beam rheometer (BBR) test [46] according to Equation (1). Higher ΔTc (i.e., relatively lower negative) is desired, as it shows higher relaxation ability and better cracking resistance.

ΔTc = Ts − Tm

- Ts = critical temperature at which the flexural stiffness (S) of the beam equals 300 MPa,

- Tm = critical temperature at which the slope (m) of stiffness versus time on the log scale equals 0.300.

Note that both critical temperatures were evaluated at a creep loading time of 60 s.

The MSCR test was performed to evaluate the high-temperature rutting resistance of the asphalt binders. As the rutting performance is of concern in the short term, the RTFO-aged asphalt binder was utilized. This test was conducted at a high PG temperature using DSR in accordance with AASHTO T350 [47]. The parallel plate geometry with a 25 mm diameter and a 1 mm gap was used, and the test was conducted at 67 °C. The test initiates with 20 cycles, each involving 1 s creep loading with low shear stress of 0.1 kPa and 9 s zero stress recovery, followed immediately by the same 10 creep-recovery cycles but with an increased creep load of 3.2 kPa. A number of parameters can be determined from the MSCR test, including percentage recovery and non-recoverable creep compliance (Jnr) for each of the two stress levels of 0.1 kPa and 3.2 kPa. It has been found that Jnr evaluated at the higher stress level, denoted as Jnr3.2, is adequately correlated with the rutting performance of asphalt mixtures in the laboratory as well as in the field. In this study, Jnr3.2 and recovery% at 3.2 kPa stress level will be employed as the parameter to evaluate the effect of different modified asphalt binders on rutting performance.

3.2.2. Frequency Sweep (FS) Test

The frequency sweep test was performed to characterize the viscoelastic properties of asphalt binders at multiple temperatures and frequencies according to ASTM D7175 [48]. The parallel plate geometry with an 8 mm diameter and a 2 mm gap was used. The test temperatures were 15 °C, 30 °C, and 45 °C. For each temperature, the test was conducted at various frequencies ranging from 0.1 to 100 rad/s. The strain level was controlled at 1% to ensure the asphalt binder was in the linear viscoelastic region, and the data were used to construct the master curve for dynamic shear modulus and phase angle. Isotherms of dynamic modulus were shifted with respect to the selected reference temperature. The Christensen–Anderson model was used to fit a function on the isotherms (Equations (2)–(4)) [49].

- = dynamic shear modulus (Pa),

- = glass modulus (Pa),

- = cross-over angular frequency (rad/s),

- = reduced angular frequency (rad/s),

- R = rheological index (rpm−1),

- = measured angular frequency (rad/s),

- = shift factor,

- = reference temperature (°C), and

- and = regression coefficients for the shift factor function.

The Glover-Rowe (G-R) parameter was calculated according to Equation (5) at 15 °C and a frequency of 0.005 rad/s. This parameter measures the stiffness and elastic properties of long-term aged asphalt binders. A lower value is desired as it indicates better resistance to cracking (more ductile and less brittle). The initiation of cracking is expected to occur as the G-R value approaches 180 kPa, and substantial cracking is expected to occur as the G-R value reaches 480 kPa [38,50,51].

3.2.3. Linear Amplitude Sweep (LAS) Test

The LAS test was performed according to AASHTO TP101 to evaluate the fatigue characteristics of the asphalt binders [52]. This test has been reported to show a better prediction of fatigue cracking susceptibility compared to the traditional fatigue parameter (G*sinδ) [53]. The test was conducted at 18 °C using parallel plate geometry with an 8 mm diameter and a 2 mm gap. A frequency sweep test was first performed, followed by an amplitude sweep step. The frequency sweep ranged from 0.1 to 100 rad/s at 0.1% strain amplitude, and the amplitude sweep was performed at a fixed frequency of 10 Hz by applying a torsional strain, which linearly increased from 0.1% to 30%. The LAS test result was analyzed based on viscoelastic continuum damage (VECD) theory to obtain a damage characteristic relationship. The fatigue parameter ALAS was calculated according to Equation (6). Higher ALAS values are desired as they represent higher crack resistance [49].

where

- = reference modulus (Pa),

- = regression coefficients,

- = linear viscoelastic modulus (Pa),

- = loading frequency (10 Hz),

- = 1 + (1 − )

- S = internal state variable for damage intensity,

- = S-value at failure,

- = reduced angular frequency (rad/s),

- = loading condition (temperature and frequency) factor,

- = reduced time of damage development, and

- = damage evolution rate.

3.2.4. SARA Fractionation Test

The SARA fractionation analysis was employed to determine the chemical composition of asphalt binders by breaking it down into four broad components: saturates, aromatics, resins, and asphaltenes. Asphaltenes constitute the portion of an asphalt binder that is insoluble in pentane or heptane, whereas maltenes are the soluble portion that can be further separated chromatographically into saturates, aromatics, and resins. Separation of the asphaltene component from the maltenes is conducted following ASTM D3279 standards [54]. Subsequently, the maltenes are fractionated using an Iatroscan TH-10 Hydrocarbon Analyzer to isolate saturates, aromatics, and resins. Saturates are eluted using n-pentane, while a 90/10 toluene/chloroform mixture is utilized for the elution of the aromatics. Resins remain uneluted at their origin. Asphaltenes are composed of complex polar molecules that tend to form molecular clusters, which increases the viscosity of asphalt binders [55]. Oxidative aging can also result in increased polarity through ketone formation. This polarity increase prompts the aromatic fraction to decrease, resulting in the agglomeration of the asphaltene fraction, which in turn is primarily responsible for the rise in asphalt viscosity with aging [55].

The colloidal instability index (CII) is calculated as the ratio of the combined saturates and asphaltene contents to that of the resins and aromatic contents (Equation (8)). It is noted that the SARA components are measured as percent by weight of asphalt binder. A low CII suggests a well-dispersed (homogeneous) system, while a high CII indicates a more gel-like (heterogeneous) system. Thus, asphalt binders with low CII values are desired as they demonstrate greater resistance to cracking.

3.2.5. Fourier-Transform Infrared Spectroscopy (FTIR)

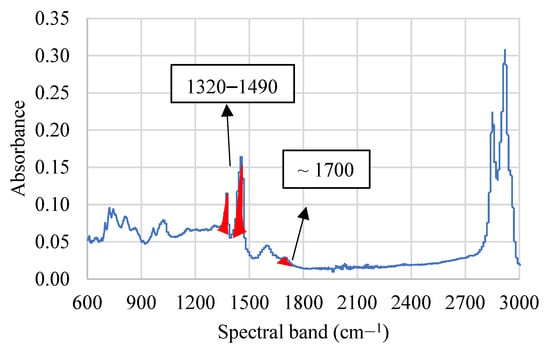

The FTIR test was conducted according to ASTM E1252 [56] to evaluate the aging level of asphalt binders by tracking oxygen-containing molecules. The level of aging can be quantified based on the identification of oxygen-containing molecules within the structure of asphalt binder [49]. The oxygen-containing group, carbonyl (C=O, a carbon atom double-bonded to an oxygen atom), can be traced at the wavenumber of 1700 cm−1. The carbonyl index (CI) was defined as a ratio of the bands’ area around 1700 cm−1 over total areas of spectra between 1320 and 1490 cm−1, as expressed in Equation (9). Lower CI values are desired because they indicate a minimal aging effect on the asphalt binder and better cracking resistance. Figure 3 shows an example of FTIR spectra and CI calculation methodology. The FTIR spectra for the asphalt binders were obtained using a Bruker Alpha FTIR spectrometer (Alpha), which uses a diamond single reflection attenuated total reflectance (ATR). An OPUS 7.2 data collection program was used for data analysis. The following settings were used for data collection: 16 scans per sample, spectral resolution 4 cm−1, and wave number range 4000–500 cm−1.

Figure 3.

FTIR spectrum for PG 76-22 asphalt binder at 1PAV.

4. Laboratory Test Results and Discussion

This section presents the analysis and discussion of the testing results. Statistical analyses of variance (ANOVA) using Fisher’s least significant difference at a 95% confidence level were performed on laboratory test data using the Statistical Package for Social Sciences (SPSS version 23) software. The means of each test result were further ranked through a multiple comparison procedure with letters A, B, C, and so forth. Letter A denotes the best performance, followed by other letters ranked in order. A double-letter designation (i.e., A/B) indicates that the difference in the means between groups is insignificant.

4.1. Performance Grading (PG) Results

Table 2 presents the performance grading test results for all asphalt binders evaluated. The rotational viscosity (RV) results show that all asphalt binders meet the requirements and have viscosities less than or equal to 3.0 Pa.s, except for the PG 88-28H asphalt binder. It is important to note that the PG 88-28H asphalt binder has a high SBS content and requires a higher mixing temperature (170 °C). The RV results indicate that the asphalt binders have adequate workability in the field. The performance grading (PG) was conducted according to AAHSTO M 320, “Standard Specification for Performance-Graded Asphalt Binder” [42], and the results show that all asphalt binders meet the requirements. It is noted that the addition of EA improved the high-temperature PG of the PG 67-22 base asphalt binder to PG 70-22 without adverse effects on the low PG grading.

Table 2.

Asphalt binder performance grading results.

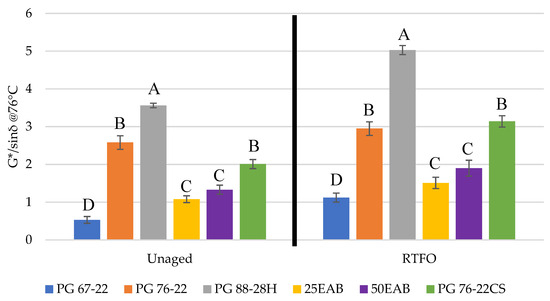

Figure 4 shows the rutting factor (G*/sinδ) results for unaged and RTFO-aged asphalt binders. The coefficient of variation (CV) for rutting factor results varied between 2% and 6%, with an average of 4%. A temperature of 76 °C was chosen because of the commonality of asphalt binder selected for the determination of the rutting factor. For the unaged and RTFO-aged asphalt binders, PG 67-22 showed the least G*/sinδ value, indicating the lowest resistance to rutting. Consequently, the addition of EA improved the rutting resistance by increasing the G*/sinδ value, highlighting the excellent stiffness of EA at high temperatures. Moreover, PG 76-22 and PG 76-22CS asphalt binders demonstrated comparable rutting factor values, suggesting that the partial replacement of SBS with crumb rubber did not negatively impact high-temperature performance. Therefore, sustainable EABs (i.e., 25EAB and 50EAB) showed better rutting resistance compared to PG 67-22 asphalt binder. Furthermore, sustainable PG 76-22CS asphalt binder showed comparable rutting resistance as compared to PG 76-22 asphalt binder (i.e., conventional SBS-modified). PG 88-28H exhibited the best rutting resistance at both aging conditions, potentially attributed to the excellent continuous cross-linking network of SBS polymers in the asphalt binder [57].

Figure 4.

Rutting factor results for unaged and RTFO-aged asphalt binders.

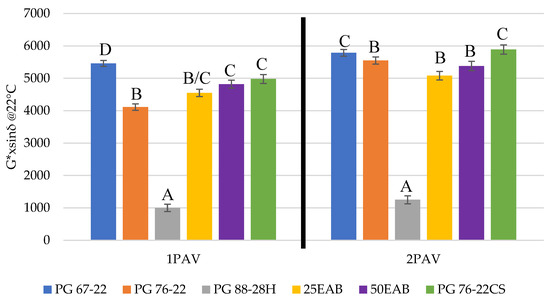

Figure 5 shows the fatigue factor (G*sinδ) results for the 1PAV and 2PAV aging levels of the asphalt binders evaluated. The coefficient of variation (CV) for fatigue factor results varied between 3% and 11%, with an average of 6%. A temperature of 26.5 °C is recommended by Section 1002 of the 2016 Louisiana Standard Specifications for Roads and Bridges for evaluating PG 67-22 and PG 76-22 [58]. However, this study incorporated multiple asphalt binder types and selected a temperature of 22 °C to highlight the impact of modifiers on cracking resistance under more stringent conditions. Lower G*xsinδ is desired as it suggests less stiffness at low temperatures and therefore better fatigue cracking resistance. At both aging levels (i.e., 1PAV and 2PAV), PG 67-22 demonstrated the least resistance to fatigue cracking. EABs (i.e., 25EAB and 50EAB) yielded significantly less stiffness as compared to PG 67-22 at both aging levels indicating improved cracking resistance. Interestingly, both EABs displayed a higher G*xsinδ than PG 76-22 at 1PAV but a lower G*xsinδ at 2PAV, suggesting less fatigue cracking at extended aging and therefore better durability. PG 76-22CS had better or similar performance as compared to PG 67-22 but worse performance than other asphalt binders. In short, the sustainable asphalt binders (i.e., 25EAB, 50EAB, and PG 76-22CS) had better or comparable fatigue cracking resistance as compared to the conventional asphalt binders (i.e., PG 67-22 and PG 76-22). PG 88-28H demonstrated the best performance for both aging conditions. This may be attributed to the abundance of polystyrene and polybutadiene, which provide strength and elasticity, respectively [57,59].

Figure 5.

Fatigue factor for 1PAV and 2PAV aging levels.

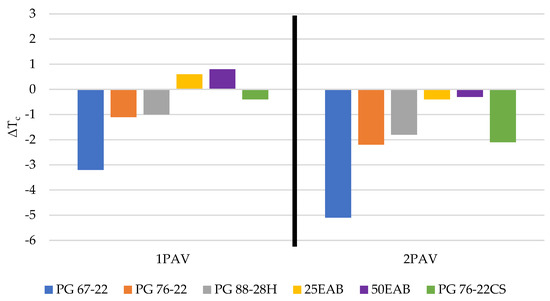

Figure 6 shows the ΔTc results for the 1PAV and 2PAV aging levels of the asphalt binders evaluated. A positive ΔTc indicates S-controlled (i.e., stiffness) asphalt binder, whereas a negative ΔTc indicates M-controlled (i.e., m-value) asphalt binder. Higher ΔTc (i.e., relatively lower negative) is desired, as it shows higher relaxation ability and better cracking resistance. According to the FHWA, researchers have established a warning limit and a failure threshold for ΔTc at −2.5 °C and −5.0 °C, respectively [60]. PG 67-22 had the lowest (i.e., relatively higher negative) ΔTc value at both PAV aging levels. This observation is attributed to the absence of modifiers in PG 67-22 asphalt binder, which adversely affected its relaxation ability. At the 1PAV aging level, the addition of EA changed the failure mode of PG 67-22 from M-controlled (i.e., lack of relaxation) to S-controlled indicating better relaxation ability and cracking resistance. The aforementioned observation suggests the excellent relaxation ability of EA, indicating better cracking resistance at low temperatures. PG 76-22 and PG 88-28H exhibited comparable results at both aging levels, whereas the PG 76-22CS sustainable asphalt binder exhibited higher and comparable ΔTc as compared to PG 76-22 at 1PAV and 2PAV, respectively, indicating good relaxation properties from crumb rubber particles. At the 2PAV aging level, all asphalt binders exhibited an M-controlled response, with PG 67-22 showing the lowest (i.e., relatively higher negative) ΔTc (susceptible to low-temperature cracking). However, the epoxy asphalt binders (EABs) exhibited the highest (i.e., relatively lower negative) ΔTc, indicating a good low-temperature cracking resistance of EA even at an extended aging level (i.e., 2PAV). It is noted that, with the exception of PG 67-22, all asphalt binders exhibited high ΔTc (i.e., relatively lower negative) at both aging levels suggesting acceptable low-temperature performance and cracking resistance.

Figure 6.

ΔTc results for 1PAV and 2PAV aging levels.

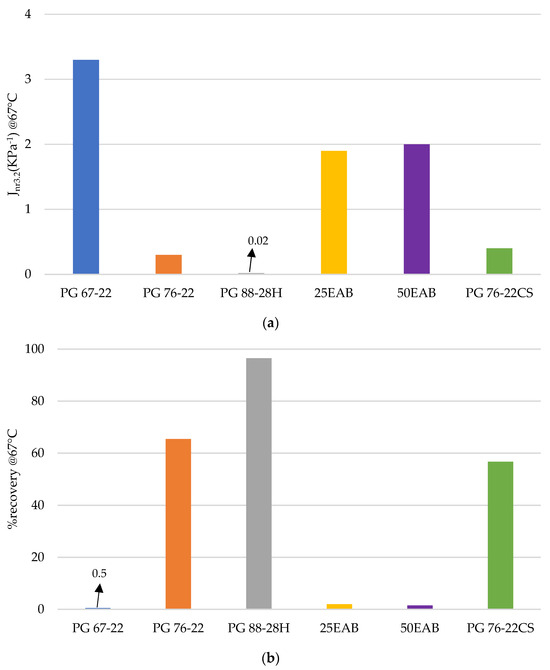

4.2. Multiple Stress Creep Recovery (MSCR) Test Results

Figure 7 shows the MSCR results for the asphalt binders evaluated, represented in Jnr and %recovery parameters. Two replicates were tested for 0.1 kPa and 3.2 kPa stress levels at 67 °C based on Section 1002 of the 2016 Louisiana Standard Specifications for Roads and Bridges [58]. A lower Jnr and higher %recovery are desired as they indicate a higher rutting resistance as well as better recovery under repeated shear loads. PG 67-22 exhibited the least resistance to rutting, whereas PG 88-28H had the highest. This can be explained by the absence of polymer modifiers in PG 67-22 and the high content of SBS in PG 88-28H. Similar to rutting factor results, the sustainable EABs (i.e., 25EAB and 50EAB) improved the rutting resistance by decreasing Jnr value and increasing %recovery, which shows the excellent stiffness of EA at high temperatures. Furthermore, the PG 76-22CS-sustainable asphalt binder showed comparable Jnr and %recovery values as the PG 76-22 conventional asphalt binder. It is noted that the RTFO aging level may not be sufficient to capture the rutting resistance and elastic response of EABs, as it may still be in the curing process.

Figure 7.

Multiple stress creep recovery for 3.2 kPa stress level: (a) Jnr results and (b) %recovery results.

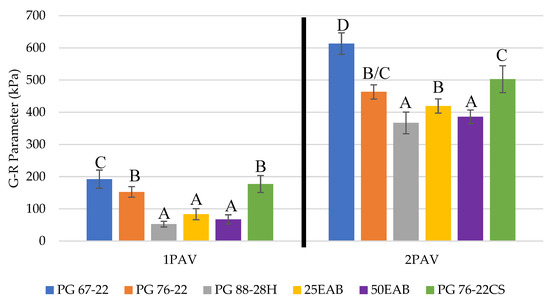

4.3. Frequency Sweep (FS) Results

Figure 8 shows the G-R parameter results for asphalt binders subjected to 1PAV and 2PAV aging levels. The coefficient of variation (CV) for G-R parameter results varied between 6% and 17%, with an average of 11%. A lower G-R value is desired as it indicates better resistance to cracking (i.e., more ductile and less brittle). Crack initiation is anticipated as the G-R value approaches 180 kPa, with substantial cracking expected as the G-R value reaches 480 kPa [38,50,51]. As can be seen in Figure 8, with the exception of PG 67-22, all asphalt binders showed G-R values lower than 180 kPa at the 1PAV aging level, indicating a minimal crack initiation. However, at the 2PAV aging level, PG 67-22 exceeded 480 kPa, indicating a high susceptibility to cracking. The PG 76-22CS-sustainable asphalt binder showed similar G-R values as PG 76-22 at both aging levels. 25EAB showed better and comparable G-R values as PG 76-22 at 1PAV and 2PAV, respectively. Notably, 50EAB had comparable results at both aging levels as the PG 88-28H superior asphalt binder. It is noted that PG 67-22 had significantly higher G-R values at both aging conditions because of the absence of a modifier. This suggests that the G-R parameter was successful in ascertaining the cracking susceptibility under long-term aging conditions between modified and unmodified asphalt binders. It is important to note that all asphalt binders exhibited higher G-R values at 2PAV compared to 1PAV, highlighting the detrimental impact of aging on long-term performance. In summary, the sustainable asphalt binders (i.e., 25EAB, 50EAB, and PG 76-22CS) demonstrated better or similar results as compared to the other conventional and superior (i.e., PG 76-22 and PG 88-28H) asphalt binders.

Figure 8.

G-R results for 1PAV and 2PAV aging levels.

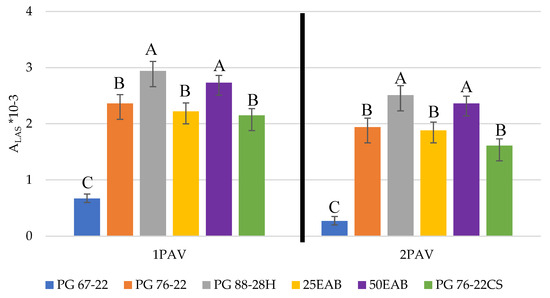

4.4. Linear Amplitude Sweep (LAS) Results

Figure 9 shows the ALAS parameter results for the 1PAV and 2PAV aging levels of the asphalt binders evaluated. The coefficient of variation (CV) for ALAS parameter results varied between 5% and 17%, with an average of 10%. Higher ALAS values are desired as they represent higher crack resistance. Three clusters of responses were observed, with PG 67-22 exhibiting the least cracking resistance, constituting the first cluster. The second cluster comprised 25EAB, PG 76-22, and PG 76-22CS, while the third cluster included 50EAB and PG 88-28H asphalt binders. It is noted that the lower dosage EAB (i.e., 25EAB) was comparable to PG 76-22 (i.e., conventional SBS-modified), whereas the higher dosage EAB (i.e., 50EAB) was comparable to PG 88-28H (i.e., high content SBS-modified). Similar to G-R results, ALAS decreased for the 2PAV condition, emphasizing the damaging effect of aging on long-term performance. Furthermore, the sustainable asphalt binders (i.e., 25EAB, 50EAB, and PG 76-22CS) displayed better or similar results as compared to the other conventional and superior (i.e., PG 76-22 and PG 88-28H) asphalt binders.

Figure 9.

ALAS results for 1PAV and 2PAV aging levels.

4.5. SARA Fractions Results

Table 3 summarizes SARA fractionation results for the unaged, 1PAV, and 2PAV aging levels of the asphalt binders considered in the study. The CII is a measure of the tendency of asphalt binder to undergo colloidal (i.e., particle) instability or separation. Colloidal instability in asphalt binders can result from the agglomeration of asphaltene and other components, especially after aging, leading to the formation of larger particles and potentially causing issues such as phase separation and thus poor asphalt binder performance [61,62,63,64].

Table 3.

SARA fractions results for unaged, 1PAV, and 2PAV aging levels.

Researchers have reported that lower CII (i.e., <0.7) is desired as it suggests that asphaltene is considered to be in a stable state (i.e., sol state), whereas higher values of CII (i.e., ≥0.9) suggest an unstable asphaltene state (i.e., gel state) [57,65]. Table 3 shows that all asphalt binders, with the exception of 50EAB, displayed CII values less than 0.7. This may suggest that the CII parameter was unable to characterize the colloidal stability of EAB. Asphaltene content increased for all asphalt binders with aging, indicating the presence of oxidation and consequently the brittleness of asphalt binders. PG 88-28H, which had the least asphaltene content, demonstrated the best performance in the preceding rheological tests, implying a positive correlation between low asphaltene content and superior performance. It is noted that asphaltene content only experienced a slight increase for both EABs, indicating the exceptional anti-aging properties of sustainable EABs as compared to other asphalt binders.

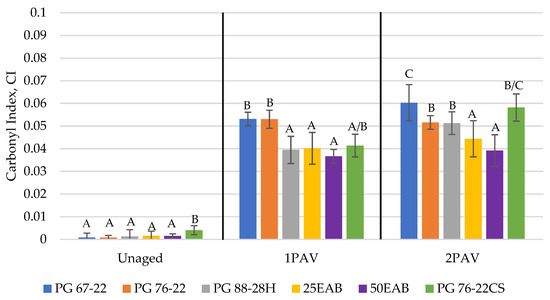

4.6. Fourier-Transform Infrared Spectroscopy (FTIR) Results

Figure 10 shows the CI parameter results for unaged, 1PAV, and 2PAV aging levels of the asphalt binders evaluated. The coefficient of variation (CV) for CI results varied between 5% and 19%, with an average of 15%. The carbonyl index serves as a quantitative measure for assessing the extent of oxidative aging in the asphalt binder. A higher carbonyl index indicates a higher degree of oxidative aging, which can adversely impact the asphalt binder’s durability and long-term performance. Therefore, a lower CI value is desired as it suggests minimal oxidative aging and thus more crack-resistant and durable asphalt binders [66,67,68]. The CI values for the unaged asphalt binders were approximately zero because of the absence of oxidative aging expected for the unaged aging asphalt binders. However, a significant increase in CI values was observed after 1PAV and 2PAV aging. This can be attributed to the development of sulfoxide and carbonyl functional groups after aging. PG 67-22 exhibited the highest CI values at 1PAV and 2PAV, indicating its lower crack resistance properties compared to the other asphalt binders. CI initially increased for PG 76-22 at 1PAV then decreased at 2PAV, possibly due to the faster decomposition of carbonyl and sulfoxide groups than their formation [69]. Remarkably, PG 76-22CS had comparable results with the superior PG 88-28H asphalt binder, and EABs demonstrated the lowest CI values at both aging levels. The superior anti-aging properties of EA are evident, as both EABs exhibited comparable CI with PG 88-28H at 1PAV and significantly lower CI values at 2PAV. This phenomenon can be explained by the difference between modifying asphalt binder with SBS and EA. The incorporation of SBS is characterized as a physical, reversible reaction, leading to the eventual degradation of the SBS network during long-term aging. In contrast, the modification of asphalt binder with EA involves a chemical reaction that is irreversible, once fully cured.

Figure 10.

FTIR results for unaged, 1PAV, and 2PAV aging levels.

5. Conclusions

This study aimed to compare the rheological and chemical properties of various asphalt binder types at multiple aging levels. Six asphalt binder types were utilized: PG 67-22 base binder; styrene–butadiene–styrene (SBS)-modified PG 76-22 and PG 88-22 (3.5% and 7.0% dosage rates, respectively); a hybrid PG 76-22CS-modified asphalt binder prepared with SBS and crumb rubber modifier (~6.5% 30-mesh CRM and ~1.5% SBS); and 25EAB and 50EAB epoxy-modified asphalt binders prepared at 25 and 50% dosage rates, respectively. A suite of rheological and chemical tests was conducted to assess the performance of asphalt binders, including Superpave performance grading (PG), frequency sweep (FS), linear amplitude sweep (LAS), SARA fractionation, and Fourier-transform infrared spectroscopy (FTIR).

The outcomes of the study lead to the following conclusions:

- PG grading showed that PG 67-22 showed the least resistance to rutting and cracking, whereas EABs and PG 88-28H exhibited mostly the best rheological performances. Only EABs had S-controlled ΔTc at 1PAV, showing the superior relaxation ability of EAB.

- MSCR results showed excellent stiffness and elastic properties of PG 88-28H, as measured by Jnr and %recovery. However, it should be noted that this test (and other conventional asphalt binder testing) may not be adequate for capturing the actual field performance of EAB.

- At the 2PAV aging level, PG 67-22 and PG 76-22CS exceeded 480 kPa, indicating a high susceptibility to cracking. PG 76-22 and 25EAB had comparable results at 2PAV, while PG 88-28H and 50EAB had comparable results at both aging conditions. Therefore, the G-R parameter was found to be successful in distinguishing between the cracking susceptibility of different asphalt binders under long-term aging conditions.

- Similar to the G-R results, the ALAS results showed that the lower dosage EAB (i.e., 25EAB) was comparable to PG 76-22 (i.e., conventional SBS-modified asphalt binder) at both aging levels, whereas the higher dosage EAB (i.e., 50EAB) was comparable to PG 88-28H (i.e., high-content SBS-modified asphalt binder) at both aging levels. Therefore, the ALAS parameter was found to be effective in characterizing the long-term cracking performance of the asphalt binders evaluated.

- The SARA fractionation results showed that asphaltene content increased for all asphalt binders with aging, indicating the presence of oxidation and consequently the embrittlement of the asphalt binders. It is noted that the sustainable asphalt binders 25EAB, 50EAB, and PG 76-22CS exhibited a low percent increase in asphaltene contents at both aging levels, which highlights the anti-aging properties of these asphalt binders.

- The CI parameter from the FTIR test was effective in ascertaining the effect of aging on the different asphalt binders. The superior anti-aging properties of EA are evident, as both EABs exhibited comparable CI as PG 88-28H at 1PAV and significantly lower CI values at 2PAV.

Rheological and chemical testing revealed that the sustainable asphalt binders 25EAB, 50EAB, and PG 76-22CS exhibit comparable or superior performance and durability compared to both unmodified and SBS-modified asphalt binders. As a result, these asphalt binders promote sustainability concepts while also meeting the required performance standards. Further analysis, including life cycle assessment (LCA) and life cycle cost analysis (LCCA), is recommended to comprehensively assess the environmental and economic benefits of these asphalt binders.

Author Contributions

The authors confirm their contribution to the paper as follows: study conception and design: A.A. and L.N.M.; data collection and analysis: A.A., M.A. and S.B.C.J.; results interpretation: A.A., L.N.M., and S.B.C.III; draft manuscript preparation: A.A., L.N.M., and S.B.C.J. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Louisiana Department of Transportation and Development (DOTD) and FHWA as part of Louisiana DOTD LTRC project 21-4B. The authors express their gratitude to the Louisiana Transportation Research Center for their support.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors acknowledge the financial support of the Louisiana DOTD. The authors would like to express their gratitude to the Louisiana Transportation Research Center for their support. John Bors, of ChemCo Systems, contributions are greatly appreciated.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shacat, J.; Willis, J.R.; Ciavola, B. GHG Emissions Inventory for Asphalt Mix Production in the United States: Current Industry Practices and Opportunities to Reduce Future Emissions; No. SIP-106; NAPA: Atlanta, GA, USA, 2022. [Google Scholar]

- Ma, F.; Dong, W.; Fu, Z.; Wang, R.; Huang, Y.; Liu, J. Life cycle assessment of greenhouse gas emissions from asphalt pavement maintenance: A case study in China. J. Clean. Prod. 2021, 288, 125595. [Google Scholar] [CrossRef]

- Ozer, H.; Al-Qadi, I.; Harvey, J. Strategies for Improving the Sustainability of Asphalt Pavements:[Techbrief]; No. FHWA-HIF-16-012; United States, Federal Highway Administration: Washington, DC, USA, 2016. [Google Scholar]

- Muench, S.T.; Van Dam, T.J. Pavement Sustainability:[Techbrief]; No. FHWA-HIF-14-012; United States, Federal Highway Administration: Washington, DC, USA, 2014. [Google Scholar]

- Movilla-Quesada, D.; Lagos-Varas, M.; Raposeiras, A.C.; Muñoz-Cáceres, O.; Andrés-Valeri, V.C.; Aguilar-Vidal, C. Analysis of greenhouse gas emissions and the environmental impact of the production of asphalt mixes modified with recycled materials. Sustainability 2021, 13, 8081. [Google Scholar] [CrossRef]

- Apostolidis, P.; Liu, X.; Kasbergen, C.; Scarpas, A.T. Synthesis of asphalt binder aging and the state of the art of antiaging technologies. Transp. Res. Rec. 2017, 2633, 147–153. [Google Scholar] [CrossRef]

- Habbouche, J.; Boz, I.; Hajj, E.Y.; Morian, N.E. Influence of aging on rheology-and chemistry-based properties of high polymer-modified asphalt binders. Int. J. Pavement Eng. 2022, 23, 3285–3303. [Google Scholar] [CrossRef]

- Xu, X.; Sreeram, A.; Leng, Z.; Yu, J.; Li, R.; Peng, C. Challenges and opportunities in the high-quality rejuvenation of unmodified and SBS modified asphalt mixtures: State of the art. J. Clean. Prod. 2022, 378, 134634. [Google Scholar] [CrossRef]

- Xu, X.; Yu, J.; Xue, L.; He, B.; Du, W.; Zhang, H.; Li, Y. Effect of reactive rejuvenating system on physical properties and rheological characteristics of aged SBS modified bitumen. Constr. Build. Mater. 2018, 176, 35–42. [Google Scholar] [CrossRef]

- Yu, X.; Burnham, N.A.; Mallick, R.B.; Tao, M. A systematic AFM-based method to measure adhesion differences between micron-sized domains in asphalt binders. Fuel 2013, 113, 443–447. [Google Scholar] [CrossRef]

- Yu, J.; Dai, Z.; Shen, J.; Zhu, H.; Shi, P. Aging of asphalt binders from weathered asphalt mixtures compared with a SHRP process. Constr. Build. Mater. 2018, 160, 475–486. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, M.; Yu, J.; Han, X. Preparation and characterization of active rejuvenated SBS modified bitumen for the sustainable development of high-grade asphalt pavement. J. Clean. Prod. 2020, 273, 123012. [Google Scholar] [CrossRef]

- Lin, P.; Liu, X.; Apostolidis, P.; Erkens, S.; Ren, S.; Xu, S.; Scarpas, T.; Huang, W. On the rejuvenator dosage optimization for aged SBS modified bitumen. Constr. Build. Mater. 2021, 271, 121913. [Google Scholar] [CrossRef]

- Hao, G.; Huang, W.; Yuan, J.; Tang, N.; Xiao, F. Effect of aging on chemical and rheological properties of SBS modified asphalt with different compositions. Constr. Build. Mater. 2017, 156, 902–910. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 2023, 82, 1709–1719. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Rheological characterization of styrene-butadiene-styrene copolymer modified bitumens. Constr. Build. Mater. 1997, 11, 23–32. [Google Scholar] [CrossRef]

- Habbouche, J.; Hajj, E.Y.; Sebaaly, P.E.; Piratheepan, M. A critical review of high polymer-modified asphalt binders and mixtures. Int. J. Pavement Eng. 2020, 21, 686–702. [Google Scholar] [CrossRef]

- Lin, P.; Huang, W.; Liu, X.; Apostolids, P.; Wang, H.; Yan, C. Laboratory evaluation of the effects of long-term aging on high-content polymer-modified asphalt binder. J. Mater. Civ. Eng. 2020, 32, 04020157. [Google Scholar] [CrossRef]

- Huang, B.; Mohammad, L.N.; Graves, P.S.; Abadie, C. Louisiana experience with crumb rubber-modified hot-mix asphalt pavement. Transp. Res. Rec. 2002, 1789, 1–13. [Google Scholar] [CrossRef]

- Khasawneh, M.A.; Al-Oqaily, D.M.; Abu Alia, A.H.; Al-Omari, A.A. Evaluation of aggregate-binder bond strength using the BBS device for different road materials and conditions. Int. J. Pavement Eng. 2022, 23, 2889–2902. [Google Scholar] [CrossRef]

- Kim, H.H.; Mazumder, M.; Lee, M.S.; Lee, S.J. Evaluation of high-performance asphalt binders modified with SBS, SIS, and GTR. Adv. Civ. Eng. 2019, 1–11. [Google Scholar] [CrossRef]

- Alsheyab, M.A.; Khasawneh, M.A. Quantifying the effect of modified mixture volumetrics and compaction effort on skid resistance of asphalt pavements. Int. J. Pavement Eng. 2022, 23, 1552–1560. [Google Scholar] [CrossRef]

- Xiang, L.; Cheng, J.; Que, G. Microstructure and performance of crumb rubber modified asphalt. Constr. Build. Mater. 2009, 23, 3586–3590. [Google Scholar] [CrossRef]

- Kim, H.H.; Lee, S.J. Effect of crumb rubber on viscosity of rubberized asphalt binders containing wax additives. Constr. Build. Mater. 2015, 95, 65–73. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S. The influence of crumb rubber modifier (CRM) microstructures on the high temperature properties of CRM binders. Int. J. Pavement Eng. 2005, 6, 265–271. [Google Scholar] [CrossRef]

- Howard, I.L.; Baumgardner, G.L.; Jordan, W.S.; Hemsley, J.M.; Hopkins, C. comparing ground tire rubber, styrene-butadyene-styrene, and GTR-SBS hybrids as asphalt binder modifiers. J. Mater. Civ. Eng. 2021, 33, 04021091. [Google Scholar] [CrossRef]

- Susik, A.; Rodak, A.; Cañavate, J.; Colom, X.; Wang, S.; Formela, K. Processing, mechanical and morphological properties of GTR modified by SBS copolymers. Materials 2023, 16, 1788. [Google Scholar] [CrossRef]

- Yin, F.; Anand, A.; Moraes, R.; Tran, N.; West, R.; Gu, F. Design and Performance of Open-Graded Friction Course (OGFC) Mixtures Containing Epoxy Asphalt; NCAT Report; National Center for Asphalt Technology: Auburn, AL, USA, 2021. [Google Scholar]

- Luo, S.; Lu, Q.; Qian, Z. Performance evaluation of epoxy modified open-graded porous asphalt concrete. Constr. Build. Mater. 2015, 76, 97–102. [Google Scholar] [CrossRef]

- Xie, H.; Li, C.; Wang, Q. A critical review on performance and phase separation of thermosetting epoxy asphalt binders and bond coats. Constr. Build. Mater. 2022, 326, 126792. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, Z.; Wang, Y.; Cong, P.; Li, D.; Hui, J.; Ye, M. Phase structure characterization and compatibilization mechanism of epoxy asphalt modified by thermoplastic elastomer (SBS). Constr. Build. Mater. 2022, 320, 126262. [Google Scholar] [CrossRef]

- Cubuk, M.; Gürü, M.; Çubuk, M.K. Improvement of bitumen performance with epoxy resin. Fuel 2009, 88, 1324–1328. [Google Scholar] [CrossRef]

- Qian, Z.; Lu, Q. Design and laboratory evaluation of small particle porous epoxy asphalt surface mixture for roadway pavements. Constr. Build. Mater. 2015, 77, 110–116. [Google Scholar] [CrossRef]

- Lu, Q.; Kohler, E.R.; Harvey, J.T.; Ongel, A. Investigation of Noise and Durability Performance Trends for Asphaltic Pavement Surface Types: Three-Year Results; No. Report: UCPRC-RR-2009-01; University of California Pavement Research Center UC Davis, UC Berkeley: Davis, CA, USA, 2009. [Google Scholar]

- Zhang, F.; Zhang, L.; Muhammad, Y.; Cai, Z.; Guo, X.; Guo, Y.; Huang, K. Study on preparation and properties of new thermosetting epoxy asphalt. Constr. Build. Mater. 2021, 311, 125307. [Google Scholar] [CrossRef]

- Wasiuddin, N.; Hossain, R.; Arafat, S.; Noor, L. Field Implementation of Handheld FTIR Spectrometer for Polymer Content Determination and for Quality Control of RAP Mixtures; No. FHWA/LA. 17/649; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 2022. [Google Scholar]

- Zhang, D.; Zhang, H.; Shi, C. Investigation of aging performance of SBS modified asphalt with various aging methods. Constr. Build. Mater. 2017, 145, 445–451. [Google Scholar] [CrossRef]

- Anderson, R.M.; King, G.N.; Hanson, D.I.; Blankenship, P.B. Evaluation of the relationship between asphalt binder properties and non-load related cracking. Assoc. Asph. Paving Technol. 2011, 80, 615–649. [Google Scholar]

- Haghshenas, H.F.; Fini, E.; Rea, R.; Khodaii, A. Increasing the efficacy of recycling agents with simultaneous addition of zinc diethyldithiocarbamate as an antioxidant. Constr. Build. Mater. 2021, 271, 121892. [Google Scholar] [CrossRef]

- Bowers, B.F.; Huang, B.; Shu, X. Refining laboratory procedure for artificial RAP: A comparative study. Constr. Build. Mater. 2014, 52, 385–390. [Google Scholar] [CrossRef]

- Oldham, D.; Hung, A.; Parast, M.M.; Fini, E.H. Investigating bitumen rejuvenation mechanisms using a coupled rheometry-morphology characterization approach. Constr. Build. Mater. 2018, 159, 37–45. [Google Scholar] [CrossRef]

- AASHTO M320; Standard Specification for Performance-Graded Asphalt Binder. AASHTO: Washington, DC, USA, 2022.

- AASHTO T350; Standard Method of Test for Multiple Stress Creep Recovery Test of Asphalt Binder Using a Dynamic Shear Rheometer. AASHTO: Washington, DC, USA, 2022.

- AASHTO T316; Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. AASHTO: Washington, DC, USA, 2022.

- AASHTO T240; Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test). AASHTO: Washington, DC, USA, 2022.

- AASHTO R28; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). AASHTO: Washington, DC, USA, 2022.

- AASHTO T313; Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). AASHTO: Washington, DC, USA, 2022.

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM: West Conshohocken, PA, USA, 2023.

- Barghabany, P.; Zhang, J.; Mohammad, L.N.; Cooper, S.B., III; Cooper, S.B., Jr. Chemical and rheological characterization of asphalt binders: A comparison of asphalt binder aging and asphalt mixture aging. Transp. Res. Rec. 2022, 2676, 147–157. [Google Scholar] [CrossRef]

- Hajj, R.; Bhasin, A. The search for a measure of fatigue cracking in asphalt binders–a review of different approaches. Int. J. Pavement Eng. 2018, 19, 205–219. [Google Scholar] [CrossRef]

- Anderson, D.A.; Le Hir, Y.M.; Marasteanu, M.O.; Planche, J.P.; Martin, D.; Gauthier, G. Evaluation of fatigue criteria for asphalt binders. Transp. Res. Rec. 2001, 1766, 48–56. [Google Scholar] [CrossRef]

- AASHTO TP101; Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep. AASHTO: Washington, DC, USA, 2014.

- Sabouri, M.; Mirzaiyan, D.; Moniri, A. Effectiveness of Linear Amplitude Sweep (LAS) asphalt binder test in predicting asphalt mixtures fatigue performance. Constr. Build. Mater. 2018, 171, 281–290. [Google Scholar] [CrossRef]

- ASTM D3279; Standard Test Method for n-Heptane Insolubles. ASTM: West Conshohocken, PA, USA, 2019.

- Cao, W.; Barghabany, P.; Mohammad, L.; Cooper, S.B., III; Balamurugan, S. Chemical and rheological evaluation of asphalts incorporating RAP/RAS binders and warm-mix technologies in relation to crack resistance. Constr. Build. Mater. 2019, 198, 256–268. [Google Scholar] [CrossRef]

- ASTM E1252; Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis. ASTM: West Conshohocken, PA, USA, 2021.

- Wu, W.; Cavalli, M.C.; Jiang, W.; Kringos, N. Differing perspectives on the use of high-content SBS polymer-modified bitumen. Constr. Build. Mater. 2024, 411, 134433. [Google Scholar] [CrossRef]

- Louisiana Department of Transportation and Development. Louisiana Standard Specifications for Roads and Bridges, 2018th ed.; Louisiana Department of Transportation and Development: Baton Rouge, LA, USA, 2018.

- Schaur, A.; Unterberger, S.; Lackner, R. Impact of molecular structure of SBS on thermomechanical properties of polymer modified bitumen. Eur. Polym. J. 2017, 96, 256–265. [Google Scholar] [CrossRef]

- Baumgardner, G. Delta Tc Binder Specification Parameter; No. FHWA-HIF-21-042; United States, Federal Highway Administration: Washington, DC, USA, 2021. [Google Scholar]

- Salehfard, R.; Behbahani, H.; Dalmazzo, D.; Santagata, E. Effect of colloidal instability on the rheological and fatigue properties of asphalt binders. Constr. Build. Mater. 2021, 281, 122563. [Google Scholar] [CrossRef]

- Wang, J.; Wang, T.; Hou, X.; Xiao, F. Modelling of rheological and chemical properties of asphalt binder considering SARA fraction. Fuel 2019, 238, 320–330. [Google Scholar] [CrossRef]

- Li, P.; Ding, Z.; Ma, L.X.; Feng, Z.G. Analysis of viscous flow properties of asphalt in aging process. Constr. Build. Mater. 2016, 124, 631–638. [Google Scholar] [CrossRef]

- Roja, K.L.; Masad, E. Influence of chemical constituents of asphalt binders on their rheological properties. Transp. Res. Rec. 2019, 2673, 458–466. [Google Scholar] [CrossRef]

- Siddiqui, M.N.; Ali, M.F. Studies on the aging behavior of the Arabian asphalts. Fuel 1999, 78, 1005–1015. [Google Scholar] [CrossRef]

- Lopes, M.; Zhao, D.; Chailleux, E.; Kane, M.; Gabet, T.; Petiteau, C.; Soares, J. Characterisation of ageing processes on the asphalt mixture surface. Road Mater. Pavement Des. 2014, 15, 477–487. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, Z.; Zhang, X. Linking chemical to rheological properties of asphalt binder with oxidative aging effect. Road Mater. Pavement Des. 2021, 22, 2014–2028. [Google Scholar] [CrossRef]

- Nie, Y.; Gao, W.; Zhou, C.; Yu, P.; Song, X. Evaluation of ageing behaviors of asphalt binders using FTIR tests. International J. Pavement Res. Technol. 2021, 14, 615–624. [Google Scholar] [CrossRef]

- Lu, Y.; Asadi, B.; Hajj, R. Rheological, Mechanical, Microscopic, and Chemical Characterization of Asphalt Binders at Extended Aging Levels. J. Mater. Civ. Eng. 2023, 35, 04023256. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).