Abstract

The use of filter cake and vinasse in agriculture began in the 1970s and intensified in the 1990s. Currently, the Ukraine war and the high value of fertilizers have created opportunities for fertilization programs in agricultural systems with sustainable goals. This review presents updated data (1988–2024) and a discussion on the potential agricultural use of filter cake and vinasse and indicates the current progress of research on this subject in addition to future prospects. Filter cake stands out due to the formulation of organomineral fertilizers with direct application of composted or fresh forms, favoring the agronomic efficiency of phosphorus. The use of vinasse in fertigation is feasible and replaces potassium mineral fertilizers and other nutrients following an organic matrix. Future perspectives point to the agricultural use of filter cake and vinasse on a sustainable basis from different approaches. The aim is to potentiate their benefits in the soil-plant-atmosphere system. It is noteworthy that filter cake or vinasse, when combined with growth-promoting bacteria in irrigated crops, can nullify the negative effects of climate change due to increased productivity and, at the same time, meet the United Nations Sustainable Development Goals by 2030. This contributes to facing global challenges related to food security by recycling nutrients for agriculture and generating clean bioenergy from sugarcane biomass.

1. Introduction

Sugarcane cultivation (Saccharum officinarum L.) is one of the most important agricultural commodities globally, especially in tropical and subtropical regions, ranking as the second largest globally traded agricultural product. In 2021, global production reached the mark of 1.8 billion tons, with the main producers being Brazil (553 million tonnes), India (315 million tonnes), China (97 million tonnes), Thailand (73 million tonnes), and Pakistan (5 million tonnes) [1].

It is a lignocellulosic crop. The juice extracted from its stalks constitutes 86% of the raw material for sugar production and is also used in ethanol production [1,2]. The bagasse, the residual biomass of sugarcane, is used as a source of bioenergy, generating steam when burned in boilers, which is converted into electricity and heat, offering a sustainable alternative to fossil fuels. This process not only helps to reduce greenhouse gas emissions but also improves the energy efficiency of sugarcane mills, making production more sustainable and economical [3].

The sugarcane agroindustry generates several byproducts, such as filter cake and vinasse, which are organic waste with potential use in agriculture, offering multiple environmental and economic benefits [4]. These residues are reintegrated into the production system, reinforcing the circular economy in the sugarcane industry [5].

The use of organic waste in agriculture is a sustainable practice that increases crop productivity [6]. For example, vinasse, rich in potassium and organic matter, is often used as a liquid fertilizer, improving soil structure and water retention [7,8]. Filter cake, rich in phosphorus and organic matter, is applied as a soil conditioner, helping to reduce dependence on mineral fertilizers and promoting microbial activity and overall soil quality, thus supporting sustainable agricultural practices [4,8,9,10,11].

Agricultural production requires the intensive use of mineral fertilizers [11]. However, the excessive use of these fertilizers can result in serious environmental problems, such as nitrate pollution in water bodies, increased emissions of nitrogenous gases, and cadmium accumulation in soils due to prolonged application of phosphate fertilizers [12,13,14,15]. Recent studies have highlighted the recycling of organic waste from sugar and alcohol agro-industries as a response to rising fertilizer costs [16,17], energy crises [18,19], and the need for sustainable production systems [20,21,22]. However, the application of these residues must be carefully managed to avoid negative environmental impacts, such as soil and water contamination from excessive nutrients. Continuous research into sustainable management techniques is essential to maximize benefits and reduce risks associated with the use of organic waste.

Lastly, the instability of fertilizer prices in the global market, exacerbated by geopolitical conflicts such as the war in Ukraine, underscores the importance of seeking local and sustainable alternatives [23,24]. Diversifying nutrient sources through the use of organic waste not only strengthens the resilience of agricultural supply chains but also contributes to food security and environmental sustainability [25].

This review is timely due to the growing demand for sustainable agricultural practices and the potential for these by-products to contribute to reducing dependence on mineral fertilizers, as well as filling gaps in the literature with technological updates on the potential agricultural use of these sugar mill and distillery wastes, such as filter cake and vinasse, for purposes such as fertigation, organic-mineral fertilizer formulation, and soil conditioners. Additionally, the article highlights the sustainable use of these residues and indicates current research progress on the topic, as well as future perspectives. The development of this article was based on a comprehensive review of global literature from 1988 to 2024. This search was conducted using the terms “filter cake”, “vinasse”, and “sugarcane” on the Google Scholar, Springer Link, and Elsevier databases, chosen for their research viability and easy access, aiming to efficiently gather the necessary information. A selection of articles was made, considering the relevance of the results to the purpose of this review. Initially, an overview of the residues and by-products generated in sugar and ethanol production plants is provided. Then, the composition of filter cake is explored, with emphasis on the results of its application in soil, its influence on crop production and quality, and other agricultural uses of this residue. Similarly, the characteristics of vinasse were discussed, including its usage alternatives in both natural and concentrated forms, and its effects on soil quality. The potential environmental impacts associated with the agricultural application of these residues without proper treatment were also addressed, and sustainable usage practices were presented. Finally, this review encompasses technological advancements on the two by-products, gathered in a single publication, thus facilitating the consultation of this information by farmers seeking sustainable alternatives to the use of mineral fertilizers. Additionally, it presents future perspectives to enhance efficiency and expand potential applications based on sustainability.

2. Background

2.1. Waste and Byproducts Generated in Sugar Production Plants and from Ethanol

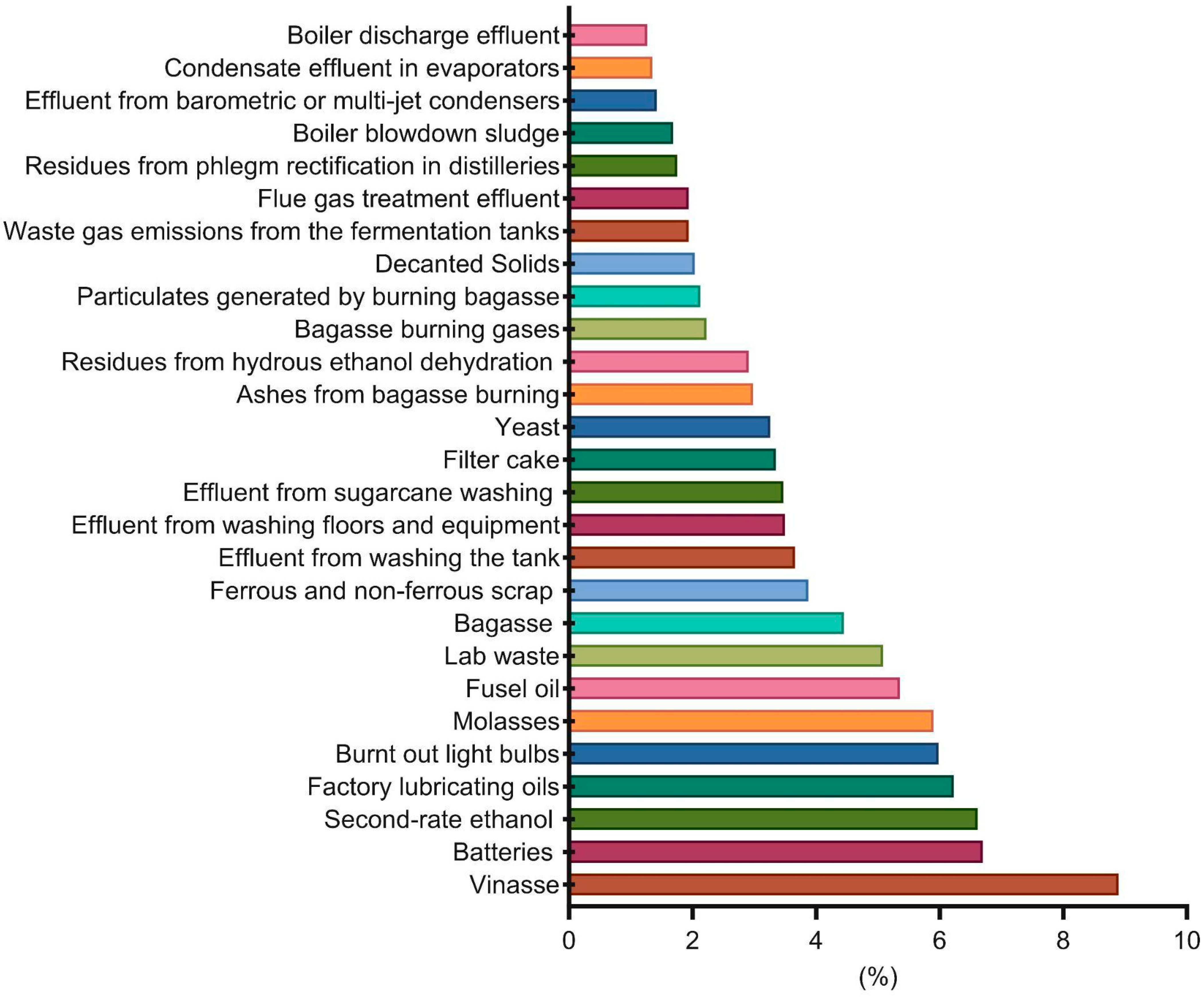

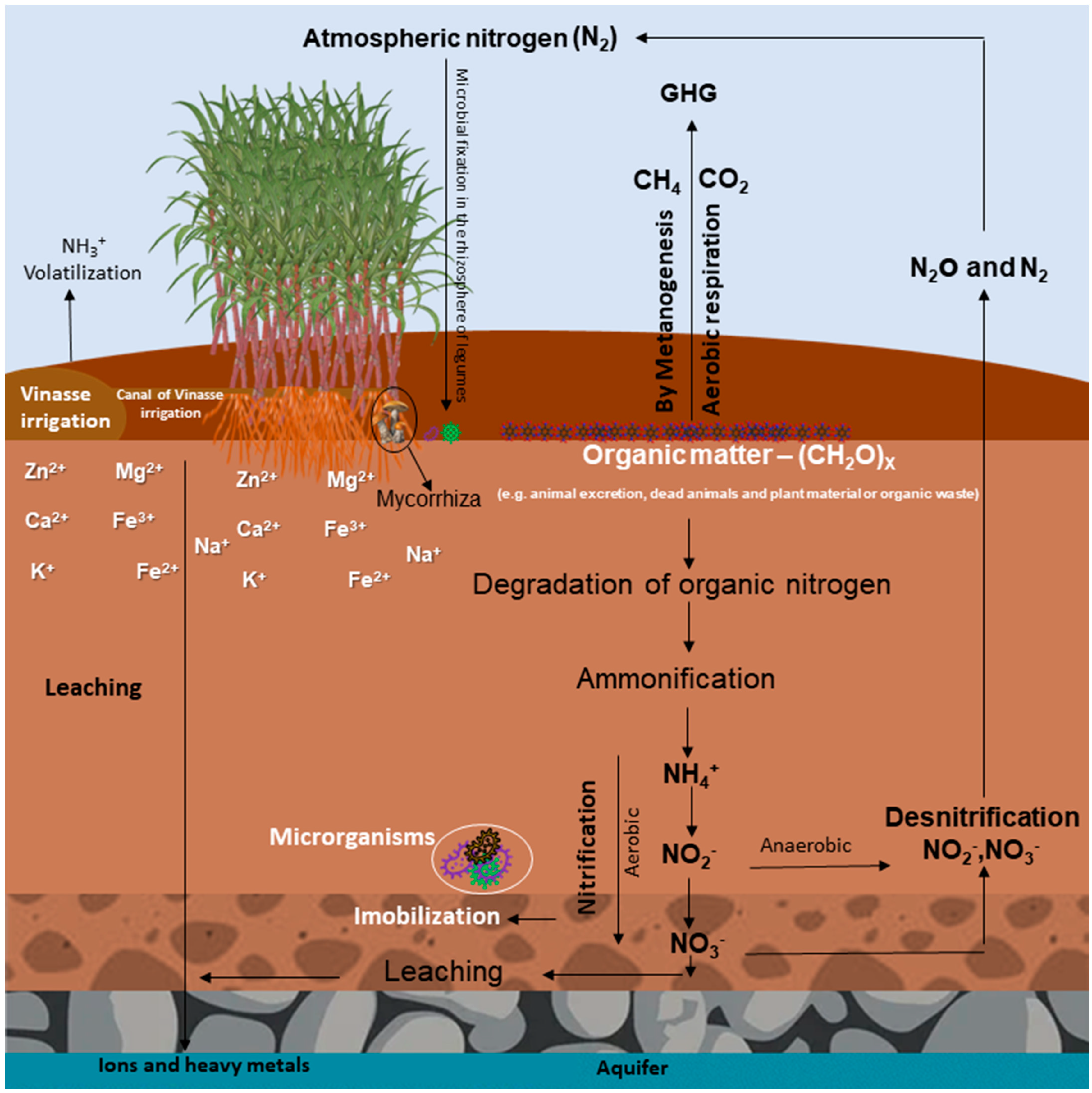

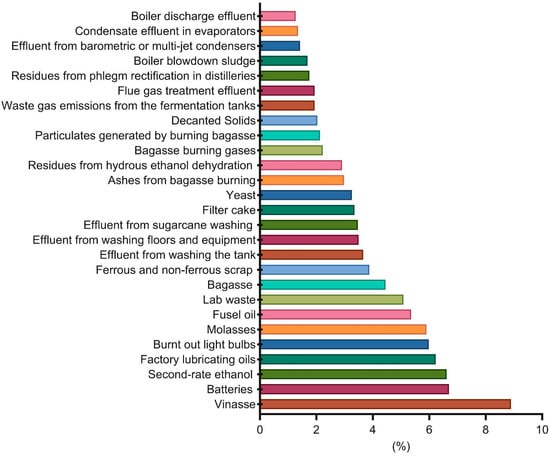

The manufacture of bioethanol and/or sugar generates twenty-seven types of solid, semi-solid, and liquid waste, each possessing distinct characteristics depending on the specific product generated [26,27,28] (Figure 1). The authors show that 67% of waste and byproducts have the potential to affect water resources, 23% soils, and 10% the atmosphere. The risk and environmental impacts associated with these wastes and byproducts depend on their concentrations and the capacity of natural systems to tolerate such levels [29].

Figure 1.

Sum of the percentage of the relative weight of environmental impact on soil, water, and atmosphere across the 27 waste and by-products. Adapted from Rebelato et al. [28].

2.2. Filter Cake

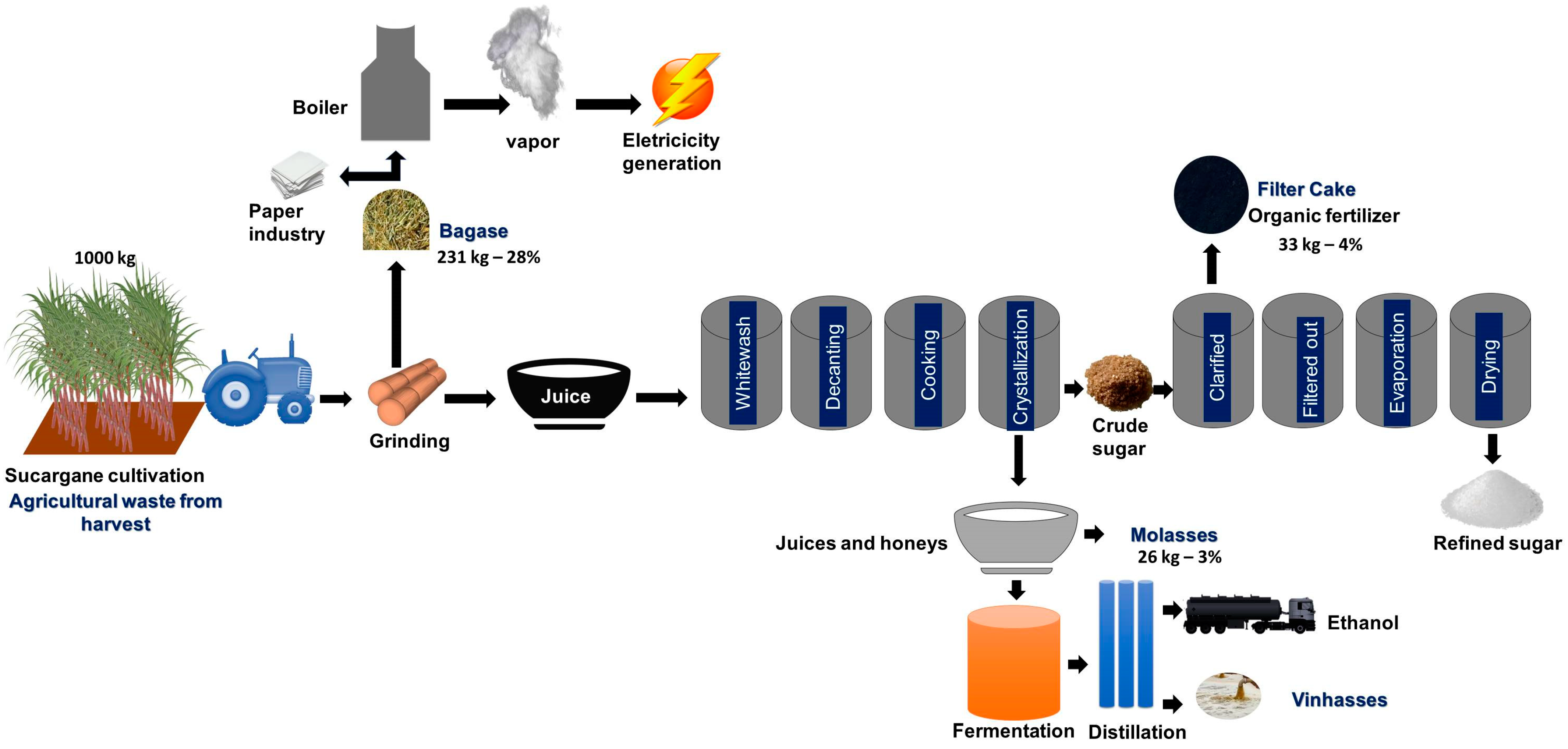

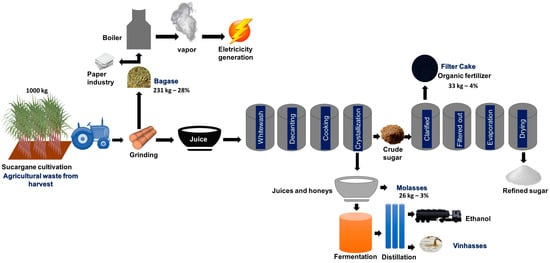

In sugar production, there are three main by-products called bagasse, molasse, and filter cake (Figure 2). Filter cake, also known as pressing mud, is a byproduct of the process of clarification and filtration of sugarcane juice after passing through a rotary filter [30]. It is composed of a mixture of ground sediment and crushed sludge, forming an organic compound with a large volume rich in organic matter, containing macronutrients in its composition [30,31].

Figure 2.

Sugar production process and waste (adapted from Montiel-Rosales et al. [31] and Pajampa et al. [20]).

The conversion of 1000 kg of fresh cane into sugar results in about 33 kg of filter cake, which contains approximately 65–75% of moisture when taken fresh from the factory, 231 kg of bagasse (28%), and 26 kg of molasse (3%), [20,32,33,34]. This by-product is widely used in agriculture in South Africa, South and Central America, and Asia [31,32,33,35,36,37], primarily for fertilizing sugarcane fields [38,39,40,41].

Therefore, it is necessary to know the composition of this material. It contains, on average, 14 g kg−1 of N, 11.7 g kg−1 of P, 2.2 g kg−1 of K, 27.4 g kg−1 of Ca, 10.8 g kg−1 of Mg, and 2.4 g kg−1 of S [42], in addition to significant amounts of Fe, Mn, Zn, and Cu [43]. This compound can be used as a partial replacement for inorganic fertilizer in many crops [44,45,46]. Its release occurs gradually through mineralization [5,36,47].

Filter cake increases the organic matter content, which can help reduce acidity in tropical soils [39,44]. Gonzalez et al. [42], in their chemical analysis of this residue, found a pH(CaCl2) of 8.2 and a total organic matter content of 29.6%. Additionally, filter cake decreases soil density and increases porosity, improving aeration and water retention capacity [48,49]. Along with these benefits, there are also gains in environmental and agricultural aspects [40,50].

2.3. Results of the Application of Filter Cake to the Soil and in the Production and Quality of Crops

The use of filter cake has shown satisfactory results regarding productivity and quality of crops such as sugarcane, sugar sorghum, wheat, soybean, corn, and lettuce [51,52,53,54,55,56,57]. In corn and soybean crops, the supply of filter cake increases productivity and favors the control of nematodes [55]. A study comparing the use of fresh and composted filter cake (10 t ha−1) in combination with plant growth-promoting bacteria in mango trees (Mangifera indica L.) found similar results as for filter cake use in soil quality and mango production [58].

Filter cake and vinasse can be recycled in a way beneficial to the soil [36] and can be applied throughout an area during pre-planting, in furrows, or between planting lines. The use of 20 t ha−1 of filter cake can provide 100% of N, 50% of P, 15% of K, 100% of Ca, and 5% of Mg to sugarcane [59].

A study evaluated the residual effects of the application of micronutrients (Zn, Cu, Mn, Fe, B, and Mo) with or without filter cake (30 t ha−1) in planting furrows in a sugarcane crop. The micronutrients and filter cake applied to the planting furrow provided micronutrients to sugarcane ratoons and increased the productivity of stalks and sugars [41].

Some studies on sugarcane have highlighted the effects of applying filter cake as a source of P because it favors the physiological and nutritional aspects of the crop [31,60,61].

Filter cake, combined with phosphate mineral fertilizers, can alter the bioavailability of P from the soil to sugarcane plants due to the competitive effect on soil P adsorption sites. Thus, Soares et al. [60], while assessing changes in soil organic and inorganic P fractions induced by phosphatic fertilizers in the presence and absence of filter cake, observed that this material, serving as a nutrient and organic matter source, plays a crucial role in maintaining more P available for plant uptake, especially when associated with the triple superphosphate fertilizer compared to Araxá natural phosphate and Bayóvar® reactive phosphate.

Arruda et al. [62] studied the effects of the combination of filter cake and phosphate fertilizers with different solubilities on sugarcane growth and phosphate nutrition. The results showed that the application of filter cake without the addition of P was effective in increasing the growth and absorption of P by plants, especially when applied directly to the soil, compared to application in furrows. Filter cake also modified the structure of the fungal and bacterial communities in the soil. The combination of filter cake with natural phosphate was more effective, resulting in greater growth and use of P by plants. It can thus be an alternative to replacing triple superphosphate.

An important contribution of filter cake is the stimulation of soil microbiological activity due to the addition of new microorganisms [63]. Caione et al. [61] studied different sources of P and filter cake, with or without enrichment by biofertilizers and liquid peat. The researchers found that filter cake enhances the effects of phosphate fertilization on sugarcane, leading to an increase in microbial population, P levels in the soil, and P absorption, regardless of the phosphorus source used. However, the addition of biofertilizer and liquid peat did not amplify this effect. Prior studies have also documented positive impacts on soil microbial activity, resulting in increased P accumulation in plants through the application of phosphates in conjunction with filter cake [64,65].

Vasconcelos et al. [52] evaluated the effects of different mineral fertilizers with and without filter cake. The results were important in showing an increase in the quality of production. The highest dose of P2O5 (360 kg ha−1) combined with 7.5 Mg ha−1 of filter cake provided the highest concentration and accumulation of P in leaves. Regarding the production of stalks, 123 Mg ha−1 was the optimal dose, and for sugar, the optimal dose was 197 kg t−1.

2.4. Other Applications of Filter Cake in Agriculture

Filter cake can serve as a composting material when combined with external materials like castor bean cakes, poultry litter, cattle manure, and other residues, either with or without additives such as gypsum and rock phosphates. This practice promotes nutrient cycling [66].

Another application of filter cake is in the production of organomineral fertilizers that can be used in the biofertilizer industry [67]. It has a potential use in the manufacture of organomineral fertilizers due to its high availability, low cost, and physical-chemical uniformity [68]. It is considered a reference for new sources of organic matter due to its chemical, physical, and microbiological characteristics, which are desirable for the production of fertilizers. Even the use of organomineral fertilizers formulated with filter cake, compared to mineral fertilizer, promotes the development of crops such as soybeans [67].

Thus, biofertilizers are sustainable alternatives for farmers, making it possible to reduce or replace soluble mineral fertilizers and contributing to the increase in sustainable crop productivity. Silva et al. [69] found that pelleted biofertilizers, formulated with sewage sludge and filter cake as organic matter sources, can replace mineral fertilizers and enhance soybean growth.

The search for alternative substrates in the production of seedlings of different species (vegetables, forestry, ornamental, medicinal, etc.) is important because it reduces costs and results in high-quality seedlings, especially in organic production systems.

A study compared different substrates, aiming to evaluate the quality of lettuce seedlings. The results showed that filter cake biofertilizer and plant growth-promoting bacteria had a similar effect as commercial substrate and animal manure on lettuce seedling development [57]. Santos et al. [70] evaluated different doses of filter cake vermicompost and compared it to a commercial substrate for the production of cabbage seedlings (Brassica oleracea). The authors observed that the use of the substrate only with vermicompost provided the best plant growth, showing the viability of using alternative substrates compared to the commercial substrate.

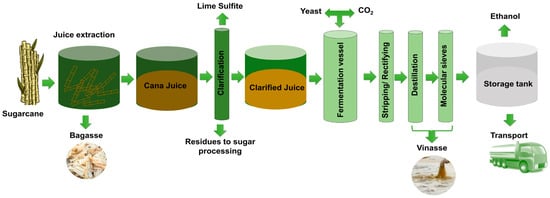

3. Vinasse

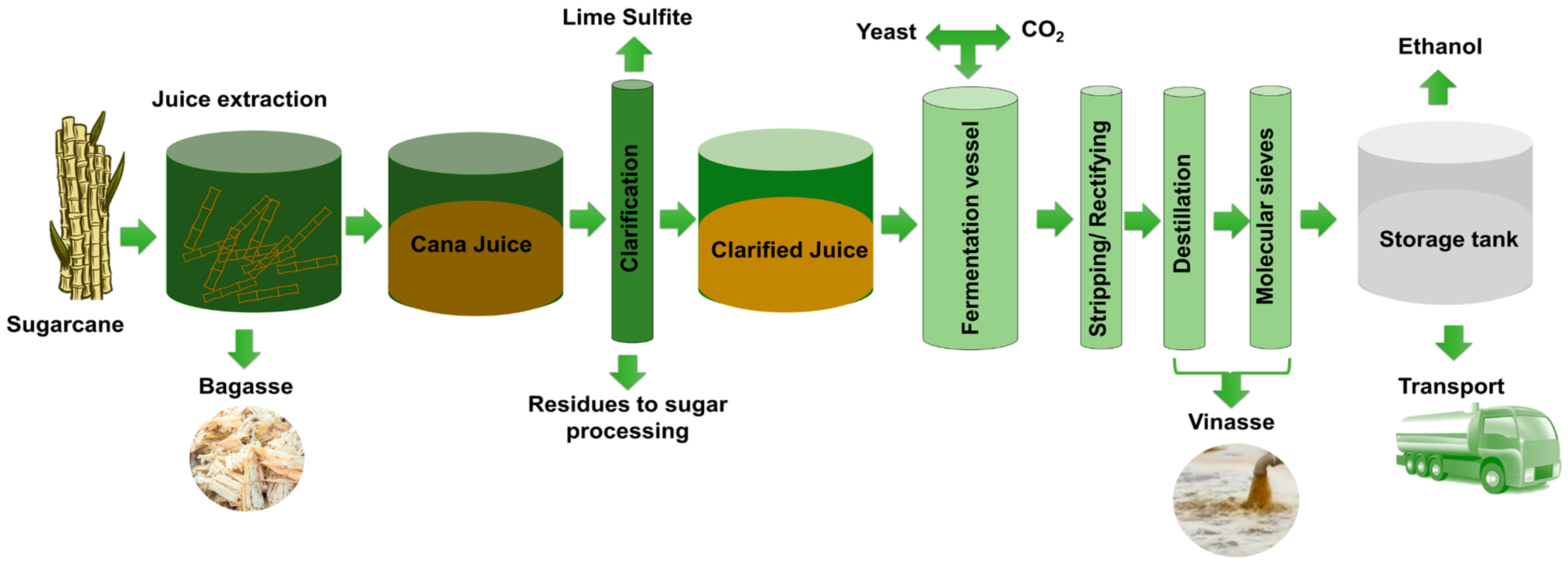

The production of alcohol from sugarcane generates large amounts of agro-industrial waste. The main one is vinasse (Figure 3). Vinasse, a liquid fraction, is produced from the operations of sugarcane grinding and ethanolic distillation at a temperature of 65–107 °C and a pH of 3–5 [71,72,73,74]. It is an effluent rich in sulfur, with a dark brown color resulting from the presence of melanoidins, and odoriferous. It has a high content of organic matter and residual contents of sugars, ethanol, and volatile compounds of high molecular weight [32,74,75,76]. Vinasse may also contain phytotoxic, antibacterial, and recalcitrant compounds, such as phenols, polyphenols, and heavy metals [72,76,77].

Figure 3.

Process of producing vinasse from sugarcane (adapted from Rodrigues et al. [75]).

During ethanol production, the fermented juice is distilled to extract ethanol as the final product, while vinasse is separated as a byproduct at high temperatures (between 90 and 100 °C) [78,79]. The ratio is approximately 12 L of vinasse for every liter of ethanol produced, which can vary depending on factors such as the use of recirculation processes in the distillery, sugar content in molasses, quality of the fermented must, and operating conditions in the distillation columns [32]. In Brazil, this annual production results in about 30 million cubic meters of ethanol and approximately 360 billion liters of vinasse [80,81].

The composition of vinasse varies according to the technique used in the processing of sugarcane and local particularities. However, in general, this effluent is basically composed of water (93%) and organic and mineral solids (7%), of which 75% are organic and biodegradable compounds and the remaining 25% are minerals [82]. Vinasse carries a significant organic load, often measured as chemical oxygen demand (COD), and exhibits high biodegradability (>96.5%) under both aerobic and anaerobic conditions [83,84].

Vinasse contains in its composition N (up to 4.2 g L−1), K (up to 17.5 g L−1), P (up to 3.0 g L−1), and sulfate due to the addition of sulfuric acid in the fermentation container [29,80,81,85]. Prado et al. [36] provided detailed information on the determination of vinasse composition (Table 1) and drew attention to the high concentration of K, which can be a source of this nutrient for crops [86].

Vinasse is poured into settling tanks before being driven through canals or pipes or transported by tanker trucks to cultivation areas. It can be applied directly to the soil or spread with sprayers and sprinklers [87]. Currently, vinasse is increasingly applied in strips near sugarcane lines as a fluid fertilizer. Environmentally, there are also benefits to applying localized vinasse, as this method allows for the application of reduced volumes of vinasse per area, thereby lowering the risk of flooding and methane emissions [66].

The costs associated with the transportation of vinasse from processing industries to fertigated areas may make this technique economically unfeasible. Fuess et al. [88] reported that it is not feasible to transport vinasse over long distances. Its use is recommended only in areas close to the processing of sugarcane.

Table 1.

Chemical requirements for oxygen (CRO), biological requirements for oxygen (BRO), electrical conductivity (EC), total dissolved solids (TDS), pH values, sodium, and macronutrient concentrations of vinasse according to reports of various authors.

Table 1.

Chemical requirements for oxygen (CRO), biological requirements for oxygen (BRO), electrical conductivity (EC), total dissolved solids (TDS), pH values, sodium, and macronutrient concentrations of vinasse according to reports of various authors.

| Determinations | Prado et al. [36] | Brito et al. [89] | Barros et al. [90] | Silva et al. [91] | Parsaee et al. [92] | Average |

|---|---|---|---|---|---|---|

| CRO (mg L−1) | 21.450 | 26.771 | 48.860 | - | 32.360 | |

| BRO (mg L−1) | 10.000 | 5.000 | 21.275 | - | 12.092 | |

| EC (dS m−1) | 14.12 | 11.5 | 9.65 | 3.6 | 9.72 | |

| TDS (mg L−1) | 7.940 | 11.352 | 19.000 | - | 12.764 | |

| pH | 4.5 | 4.4 | 4.6 | 5.7 | 4.8 | |

| N (mg L−1) | 410 | - | - | 560 | 485 | |

| P (mg L−1) | 160 | - | 175 | 190 | 175 | |

| K (mg L−1) | 3.100 | 1.123 | 1.392 | 960 | 1.644 | |

| Na (mg L−1) | 350 | 113 | 110 | - | 191 | |

| Ca (mg L−1) | 640 | 352 | 728 | 280 | 500 | |

| Mg (mg L−1) | 340 | 16 | 29 | 130 | 129 | |

| SO42− (mg L−1) | 0.014–6.4 |

-: Not determined.

The application of vinasse in agriculture must adhere to appropriate guidelines, which vary according to soil characteristics. These guidelines are regulated by environmental agencies such as the Environmental Company of the State of São Paulo (CETESB) [93]. Considering the chemical and physical properties of the soil in each region, as well as factors like the history of residue application, the intensity of cultivation, and the proximity to water sources, it is mandatory to follow specific recommendations. These measures are essential to prevent excessive use and the subsequent leaching of minerals like nitrate and potassium, which can lead to groundwater contamination [36]. Research on vinasse application methods in agricultural soils is necessary. As reported by Carpanez et al. [29], improved control over vinasse application is crucial to avoid soil salinization, groundwater contamination, and anion leaching. Environmental contamination from excessive vinasse is particularly critical in sandy soils, which facilitate leaching, and in relatively shallow soils that are prone to erosion. This is important because excessive vinasse can delay the maturation process of plants and reduce their sucrose content. It can also cause black spots during sugar recovery in the industry, thus degrading its quality.

Vinasse must be reincorporated into the soil under conditions that allow it to improve properties or increase productivity with environmental responsibility supported by the principles of circular economy. However, the qualities that render vinasse a valuable resource for meeting plant requirements are also what contribute to its status as an effluent with a high pollutant load. It possesses a substantial organic load, fostering the proliferation of microorganisms that consume dissolved oxygen in water, thereby reducing the availability of potable water and lowering pH levels (see Table 1). When applied to a lake, vinasse, compared to wastewater, would have a higher biochemical oxygen demand (BOD), but if applied to the soil, it would have very high degradability, posing no pollution risk to the soil at safe doses regulated by environmental agencies [82].

In Brazil, for environmentally responsible management, the Environmental Company of the State of São Paulo (CETESB) establishes criteria and procedures for storage, transport, and application to the soil [80]. For soil application, the K content must be taken into account and cannot be higher than 5% of the cation exchange capacity of the soil.

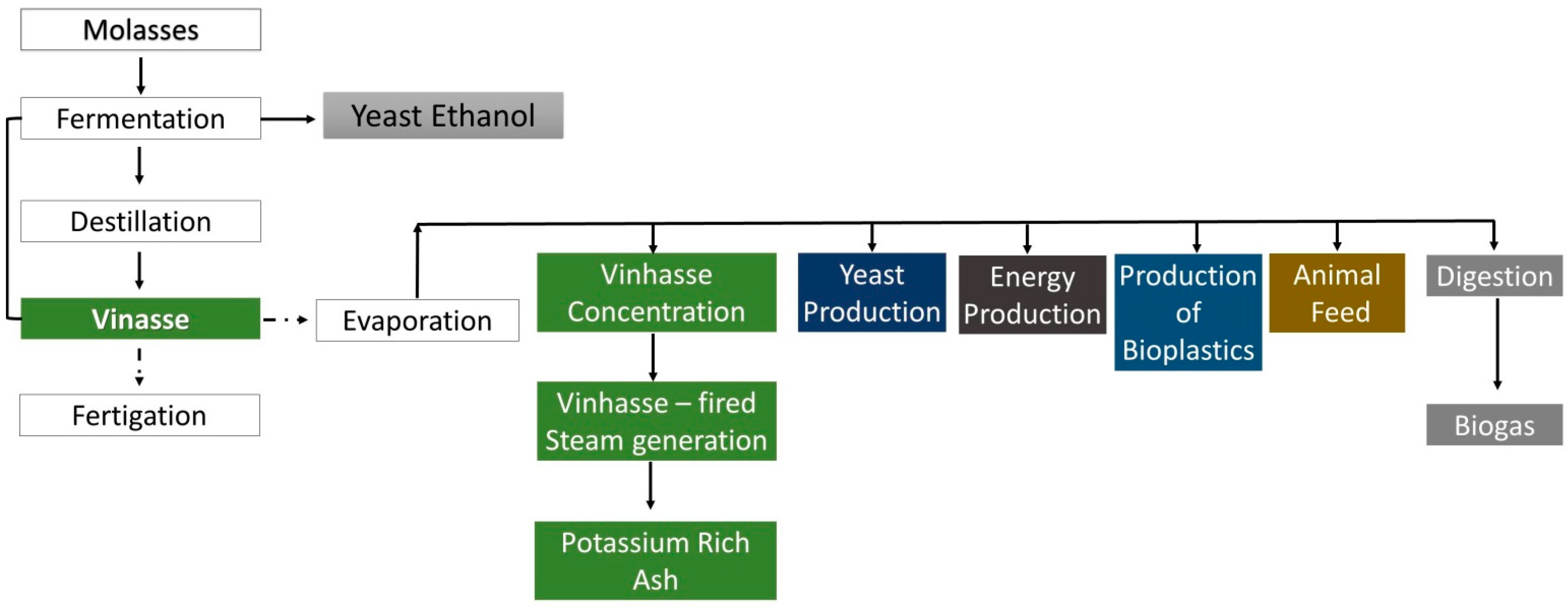

3.1. Alternatives for Use of Sugarcane Vinasse: In Natura and Concentrated

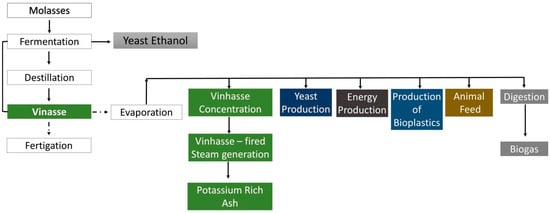

Recent studies have evaluated options to expand the treatment system and the use of sugarcane vinasse in crops [94,95,96]. Some alternatives proposed are the recycling of vinasse in fermentation, fertigation, evaporation concentration, yeast production, energy production, biotechnological applications for the production of bioplastics [55], methane-rich biogas [86,97], and raw material for the production of animal feed [98]. There are different ways of using the vinasse from sugarcane (Figure 4).

Figure 4.

Flowchart of the main alternatives for the use or disposal of vinasse from sugarcane.

Fertigation is currently the main way to reuse vinasse. It can increase crop productivity without using complex management technologies and can be done during the irrigation of sugarcane crops [99]. The use of vinasse in agriculture requires low initial investment (pipes, pumps, trucks, and settling tanks), low maintenance costs, and fast application [99,100]. It can be supplied in natura to crops [82].

The use of vinasse in fertigation is an alternative that aims for a rational use of natural resources, avoiding dumping waste into rivers [101]. It can totally or partially replace the use of mineral fertilizers, especially potassium [36]. However, there are still doubts about the environmental safety of fertigation in soils, groundwater, and the atmosphere because the excessive incorporation of vinasse into the soil modifies the soil pH and conductivity, causing environmental problems [36,102].

The continuous and unmonitored practice of fertigation with vinasse in natura can also cause nutrients to leach in the soil profile, soil salinization, water body contamination, the release of bad odors [88], and methane and nitrous oxide release by methanogenesis and incomplete denitrification, respectively [103].

Thus, the attributes that render vinasse a valuable resource for meeting plant requirements are also the same characteristics that contribute to its status as an effluent with a high pollutant load [81]. Organic compounds such as phenols, hydrocarbons, alcohols, acids, amino acids, and others are harmful substances to the environment and living organisms, potentially possessing carcinogenic, mutagenic, and teratogenic properties [104].

Garcia et al. [105] evaluated the toxic potential of vinasse on sugarcane and orange crops and observed that this byproduct could induce chromosomal aberrations in meristematic cells, particularly nuclear and anaphasic bridges, suggesting a genotoxic potential and necessitating caution in the application of these effluents to the environment.

Santana et al. [100] also pointed out that fertigation can be a palliative practice that gives the false impression of efficiently solving the problem of vinasse runoff. Prado et al. [36] pointed out that depending on the amount of vinasse applied, it may act as a pollutant or as a beneficial soil conditioner. From an economic point of view, there are problems with the high cost of large volumes of this liquid, even in sugarcane cultivation areas [87]. Vinasse in natura, because it contains 90% water [106], could help in the water supply of sugarcane. However, in the field, it may be difficult to control the amount applied, interfering with the development of sugarcane.

In this context, Fuess et al. [106] highlighted the pros and cons of fertigation using in natura sugarcane vinasse, questioning whether improvements in soil fertility compensate for environmental and bioenergy losses. The data collected between 2012 and 2016 revealed an adequate accumulation of macronutrients (K+, Ca2+, and Mg2+) and a low aluminum content (0.2–2.3%), without evidence of over fertilization or soil sodification. However, the inputs of biodegradable organic matter together with nutrients caused important environmental damage, especially uncontrolled emissions of methane (up to 732.10 kg-CO2-eq. ha−1). Energy losses in all evaluated growing areas could provide electricity to process at least 80% of the biorefinery’s daily milling capacity. However, the gains in soil fertility did not compensate for the losses in environmental quality when in natura vinasse was applied [107].

Electrodialysis (ED) is being explored as a promising technique for desalinating vinasse and recovering nutrients to produce mineral (K-struvite) and organomineral fertilizers [95]. The study assessed the use of ultrafiltered vinasse as an electrolyte solution and the development of fouling on the membrane surface during extended operation of the ED system. After 40 h of testing, the ED performance remained stable, achieving high removal (>77%) and recovery (>70%) efficiencies for potassium. The utilization of ultrafiltered vinasse did not adversely affect nutrient removal and recovery efficiencies, leading to reduced water costs, decreased chemical demand, and enhanced production of organomineral fertilizer [95].

Recently, several ethanol industrial plants began to concentrate vinasse by evaporating part of the water present in the waste. Concentrated vinasse offers the advantage of lower transportation costs. Importantly, there is no loss of solids or nutrients, and its use is similar to that of vinasse in natura [108,109]. It may even provide a higher concentration of nutrients per unit volume, as observed by Rossetto et al. [109] for N, K, and SO42−.

The N contained in the vinasse concentrate is mineralized slowly compared to that of vinasse in natura, allowing its best use by sugarcane [110]. The enrichment of concentrated vinasse with urea leads to a decrease in the volatilization of ammonia compared to the isolated supply of urea. Thus, it is essential to conduct new studies that propose alternatives to the use of vinasse other than fertigation.

An option is using sugarcane vinasse as an input for the production of organomineral fertilizers. In this case, vinasse would be reused while employing controlled practices and causing fewer environmental impacts. Negative effects associated with fertigation would thus be avoided, leading to lower transportation costs and the possibility of serving a larger planting area with the same dose of organomineral fertilizer and vinasse [29].

It should be noted that there are opportunities and environmental risks when using vinasse as a raw material for organomineral fertilizers [29]. The authors pointed out that vinasse contains most of the nutrients required by crops, with the exception of cobalt, molybdenum, and zinc, and that environmental risks can be lower compared to the use of organomineral fertilizers. The authors also concluded that the use of organomineral fertilizers expands the economic radius that limits fertigation using vinasse, that is, an area of the agricultural field to which the transport of vinasse is economically viable.

A growing number of ethanol industrial plants are now blending mineral fertilizers into concentrated vinasse to create organomineral fertilizer. The application rates vary from 7 to 30 m3 ha−1. Vinasse is poured into strips close to plant lines. Thus, in only one operation, vinasse and fertilizers are applied simultaneously, reducing logistic costs [66].

A caveat to this technology is that the application of vinasse and nitrogen fertilizer at the same time, or in a short interval, increases the emission of N2O by up to three times because of the moisture and the organic load of C present in vinasse, which stimulates the processes of nitrification and denitrification [111,112,113]. Thus, the strategy of anticipating or postponing the application of vinasse in relation to nitrogen fertilization reduces N2O emissions [114].

Another use of vinasse is its anaerobic biodigestion, which promotes nutrient mineralization and allows the production of biogas, bioenergy, and biofertilizers, with this technique having an advantage over fertigation [66,81]. This is because it reduces the polluting organic load of vinasse and increases the bioenergetic recovery potential of biogas, as well as boosting the profitability of biorefineries by generating surplus electricity through the combustion of biogas in prime movers.

Another alternative is the treatment of vinasse with the fungus Aspergillus sp. V2, a technique presented by Rulli et al. [115], who tested the phytotoxicity of the residue before and after biological treatment to assess its potential application in fertigation in two plant species commonly consumed by humans (Triticum aestivum L. and Raphanus sativus). The fungus showed high tolerance to vinasse, demonstrating excellent growth even when cultivated in undiluted residue. The biologically treated vinasse, with a cycle of spore re-inoculation, achieved a COD removal of 52%, accompanied by a pH increase from 4.4 to 6.1 by the end of the treatment. Toxicity studies showed a significant improvement in the growth parameters of plant species exposed to treated vinasse compared to those exposed to raw residue, suggesting that Aspergillus sp. V2 is effective in reclaiming this effluent, thereby enhancing its fertilizing properties.

In Indonesia, a prominent country in sugarcane production, Kusumaningtyas et al. [116] combined vinasse with other waste from the sugar industry, such as filter cake and agricultural waste, to produce a liquid organic fertilizer (LOF). This fertilizer was produced through a microbiological process to assist in the decomposition of solid organic matter and transform it into organic fertilizers useful for improving soil fertility and plant productivity. The LOFs were characterized to determine the values of organic C, the C/N ratio, and the contents of N, P, and K. The LOFs were applied to tomato plants to increase plant growth. It was concluded that the most advanced process of the valuation of vinasse is to convert it into a solid organomineral fertilizer of slow release.

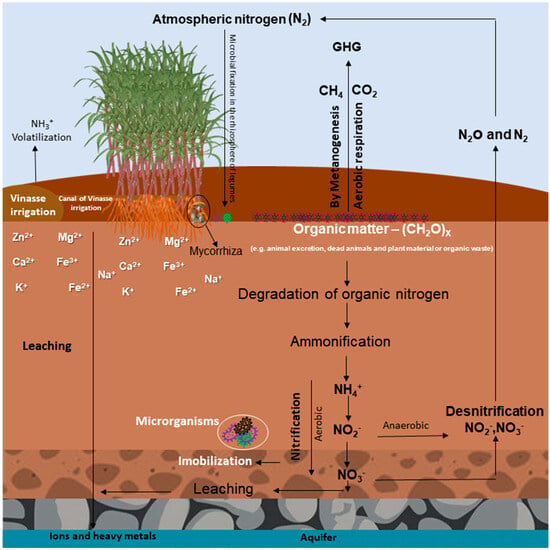

3.2. Effects of Vinasse on Soil Quality

Vinasse applied to soil promotes different modifications in soil quality. Moran-Salazar et al. [117] prepared a schematic representation of possible changes or processes that may occur in the soil with vinasse irrigation (Figure 5).

Figure 5.

Schematic representation of some processes that might be affected by the addition of vinasses to the soil (adapted from Moran-Salazar et al. [117]).

The addition of vinasse to sugarcane provided an increase in the contents of NO3− in the soil, which leached into the groundwater [118]. On the other hand, the application of biodigested vinasse is more advantageous for crop fertilization than vinasse in natura because it contains N in a chemical that is more easily absorbed by plants.

During the process of anaerobic digestion of vinasse, organic N is converted into N-ammonia, promoting this transformation in the soil. This conversion in the soil can be a source of greenhouse gas emissions (GHG) [119]. Thus, biodigested vinasse can provide more N to sugarcane crops by reducing mineral fertilizer applications and, consequently, N2O emissions [120].

Laime et al. [82] documented that the application of sugarcane vinasse to the soil yielded beneficial effects on crops and certain physicochemical characteristics. These included increased moisture retention, porosity, potassium (K+) levels, electrical conductivity (EC), and biological activity.

The use of vinasse changes the population of soil microorganisms, resulting in several changes in chemical processes, such as nitrification, denitrification, fixation of air N2, decomposition of organic matter, and increases in pH [89]. Additionally, Velásquez-Pomar et al. [121] noted a 70% increase in the length of the external mycelium of arbuscular mycorrhizal fungi, with 10% showing enhanced activity when sugarcane vinasse was applied to the soil compared to a treatment without vinasse.

A study on different sugarcane management systems evaluated the structure and function of the microbial community and the emission of N2O [122]. The treatments studied were control with nitrogen, phosphorus, and potassium (NPK), sugarcane straw with NPK, vinasse with NP, and vinasse plus sugarcane straw with NP. The treatments with straw and vinasse residues induced changes in the microbial composition of the soil. The changes in the microbial community associated with the decomposition of different carbon compounds were more pronounced in treatments with straw addition. On the other hand, in the treatment with vinasse, the functions related to the spore-producing microorganisms were overrepresented. In addition, all residues added increased the quantity of microorganisms related to N metabolism, and the vinasse with straw had a synergistic effect on a higher emission of N2O. This is a concern because N2O has a global warming potential (GWP) 265 times greater than that of CO2 [123].

Irrigation with vinasse from sugarcane in natura in an agricultural soil tripled CO2 emissions under flood conditions (200 m3 ha−1) along with generating CH4 fluxes ranging from −42.0 to 44.3 μg m−2 h−1. The authors further reported that the annual application of 46 kg of N per hectare in the form of sugarcane vinasse resulted in N2O emissions of 0.31–0.52 kg ha−1 [124]. The emission of N2O is probably due to the addition of vinasse in natura and denitrification and nitrification routes, depending on the oxygenation conditions. In addition, an increase in soil water content makes denitrification the dominant process of emission of N2O due to the development of anaerobic sites that favor nitrogen reduction [14].

In Brazil, Pinto et al. [125] studied the effect of in natura and concentrated vinasse on the chemical and biological attributes of an Oxisol with a sandy texture and on the productivity of soybean, corn, and pasture for two years. The authors observed that vinasse increased the concentrations of C and P and decreased those of K and S. It also decreased the concentration of C in microbial biomass by 50% but increased the concentration of N in microbial biomass by 67%. Consequently, it increased the yield of soybeans, corn, and pasture.

Barbosa et al. [126] applied concentrated vinasse at doses 0, 180, and 270 kg ha−1 of K, combining doses and formulas of mineral fertilizers, and found a greater increase in productivity per area so that there was no change in the technological variables of sugarcane juice.

A study on sugarcane analyzed areas under different management systems, focusing on their effects on soil fertility and the accumulation of organic and inorganic phosphorus (P) fractions [126]. The authors observed that the moderately labile P fraction represented an average of 60% of the total soil P, mainly in soils subjected to burning before harvesting and vinasse application for three years. This fraction was less evident in treatments without burning and with burning for three years, suggesting the potential to reduce the use of mineral phosphate fertilizers over time.

In Egypt, Kheir et al. [39] studied the effects of the application of sugar beet factory lime (CMV), vinasse (V), and mixed compost (SBFL) plus vinasse on sandy soil properties and canola productivity. The authors noted that the application of CMV, followed by V and SBFL, increased the soil organic matter, N, P, and K contents and the water retention capacity, decreased soil density and hydraulic conductivity, and, consequently, increased the yield of canola seeds, oil, and protein content.

Vinasse may even contribute to decreasing the salinity of different soils by reducing the percentage of exchangeable Na. This is possibly due to the release of CO2 and organic acids during the decomposition of organic matter [127,128]. If the farmer does not use high doses of this product that exceed the contents of exchangeable K equivalent to 5% of the cation exchange capacity of the soil at pH 7.

A study on hydroponic cultivation of lettuce, watercress, and chicory using the nutrient film technique used a solution developed from vinasse with conventional salts and a conventional nutrient solution [129]. Both solutions promoted adequate nutrition for plants. The hydroponic solution proposed in the study can be applied to reuse vinasse sustainably.

Likewise, Alinejadian et al. [130] found positive effects of vinasse on the nutrient content and production of basil (Ocimum basilicum L.). In spinach and barley, Mahmoud et al. [131] studied the effects of vinasse application in the presence and absence of different doses of nitrogen, phosphate, and potassium fertilizers on the productivity and nutritional status of these plants. The authors observed that the application of vinasse plus fertilizers provided a greater dry mass than conventional fertilization. Vinasse can replace 50% of N, 40% of P, and 100% of K necessary for a good yield of spinach or barley.

Agriculture and food systems must change rapidly to achieve several United Nations Sustainable Development Goals by 2030 while respecting environmental constraints [132].

The great challenge for the high productivity of crops is to adjust food to economic security since production requires the absorption of high amounts of nutrients. It is not possible to meet this demand using only organic sources. However, it is feasible to increase efficiency using nutrients from compounds such as filter cake and vinasse for environmental sustainability.

4. Conclusions and Future Prospects

This review addresses the use of organic waste in agriculture, contributing to achieving the Sustainable Development Goals (SDGs 2 and 12) (SDG 2: End hunger, achieve food security and improved nutrition and promote sustainable agriculture and SDG 12: Ensure sustainable consumption and production patterns.) proposed in the UN’s 2030 Agenda, with several significant international policy implications. It can influence agricultural policies in various countries, contributing to reducing external dependence on mineral fertilizers, which can decrease the economic vulnerability of countries to fluctuations in the international prices of these inputs.

Both filter cake and vinasse are produced in large quantities by the sugar-alcohol agro-industries of several countries. It has potential for agricultural use. Filter cake has provided good results regarding increased crop productivity, formulation of organomineral fertilizers, direct application of composted or in natura forms, and improving the bioavailability of phosphorus due to its combination with phosphate mineral fertilizers. The utilization of vinasse in fertigation has seen an increase across various agricultural regions, substituting potassium mineral fertilizers while supplying water, organic matter, and other mineral nutrients in reduced quantities. However, the optimization of filter cake and vinasse usage should be tailored to individual agricultural systems, adhering to recommendations provided by competent agencies to mitigate environmental damage.

Furthermore, there are significant technological challenges that must be addressed for the treatment or management of both filter cake and vinasse as fertilizer alternatives. Electrodialysis and the concentration of vinasse through the evaporation of part of the water have been presented as potential treatment methods for this waste. Despite the advancements and knowledge reported for the use of filter cake and vinasse, there is no single treatment that efficiently addresses both wastes. Additionally, the technologies currently proposed for the treatment of these two wastes are not capable of processing the large volumes generated by sugar and alcohol mills. In some cases, this proves to be costly and inaccessible, making the process slow.

Future research should advance in the agricultural use of filter cake and vinasse based on sustainability and using different approaches, such as (a) detailed studies on the possible damage of these compounds in excessive doses to the soil microbiota, which may vary according to the water regime of the region; (b) expanded research on the use of these compounds to replace mineral fertilizers in an environmentally efficient way regarding emissions of greenhouse gasses; (c) the potential of biomass generated in Brazilian agribusiness as a co-substrate for the production of energy, especially electric and biomethane (biogas)—specific studies are needed on filter cake and vinasse seeking an alternative use in the production of biogas, which is a sustainable product for agribusiness in different producing regions of the world—biogas production is sustainable when using vinasse as a substrate for biomethane because it reduces greenhouse gas emissions from waste when discarded in the environment by over 90%; (d) studies to enrich filter cake and vinasse with micronutrients and silicon from the ashes of sugarcane bagasse used in burning for energy cogeneration; (e) more research on mixing filter cake and concentrated vinasse with conventional nitrogen, potassium, and sulfur fertilizers to increase nutritional efficiency; (f) using filter cake to raise the P content in sugarcane, which may induce gains in the industrial stage of broth treatment, which requires P supply to improve quality—this process could be suppressed, but research is lacking to determine the critical levels of P in the stem that produce this benefit; (g) optimized use of vinasse can suppress water deficit and favor the quality of sugarcane because it can provide water and K at the same time, which increases the efficiency of using plant water and thus can reduce phenol content, common in stressed plants, and impair the quality of the broth; and (h) in the future, agriculture will face a great challenge related to global food security and clean bioenergy, and this may be possible with a sustainable improvement of soils with filter cake or vinasse combined with growth-promoting bacteria and irrigated crops because it can nullify the negative effects of climate change and provide a positive balance due to increased productivity.

Future research should seek to solve the important challenges of the industrial and production processes of vinasse and filter cake and provide better agronomic use by exploring different opportunities. In the future, this development might ensure the safe and beneficial use of nutrient and carbon receptacles resulting from these products in sustainable agriculture.

Author Contributions

A.d.A.V.L.S. wrote the review, did the proof-reading and read the final draft. R.d.M.P., R.M.d.A.B., A.P.R.d.S., A.C.F.D., C.K. and F.d.P.B.F. wrote the review and read the final draft. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data relating to this review are available upon reasonable request from the first author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Faostat. Food and Agriculture Organization of the United Nations. 2023. Available online: http://www.fao.org/faostat/en/data/QC (accessed on 5 December 2023).

- Ungureanu, N.; Biris, V. Sustainable valorization of waste and by-products from sugarcane processing. Sustainability 2022, 14, 11089. [Google Scholar] [CrossRef]

- Awasthi, S.; Mishra, A.; Pal, D.B. Energy Production from Sugarcane Bagasse and Rice Husk. In Sustainable Clean Energy Production Using Waste Biomass; Pal, D.B., Rai, A.K., Siddiqui, S., Eds.; Clean Energy Production Technologies; Springer: Singapore, 2024. [Google Scholar] [CrossRef]

- Formann, S.; Hahn, A.; Janke, L.; Stinner, W.; Sträuber, H.; Logroño, W.; Nikolausz, M. Beyond Sugar and Ethanol Production: Value Generation Opportunities Through Sugarcane Residues. Front. Energy Res. 2020, 8, 579577. [Google Scholar] [CrossRef]

- Rossetto, R.; Dias, F.L.F.; Vitti, A.C. Nutritional problems of soils in the new sugarcane frontiers. Idea News 2008, 78, 90. [Google Scholar]

- Eden, M.; Gerke, H.H.; Houot, S. Organic waste recycling in agriculture and related effects on soil water retention and plant available water: A review. Agron. Sustain. Dev. 2017, 37, 11. [Google Scholar] [CrossRef]

- Balakrishnan, D. Exploring the potential of sugarcane vinasse for biogas and biofertilizer Production: A catalyst for advancing the bioeconomy. Sustain. Energy Technol. Assess 2024, 61, 103474. [Google Scholar] [CrossRef]

- Bridhikitti, A.; Kaewsuk, J.; Karaket, N.; Friend, R.; Sallach, B.; Chong, J.P.J.; Redeker, K.R. Balancing Agriculture and Industry through Waste Utilization for Sugarcane Sustainability. Sustainability 2023, 15, 14711. [Google Scholar] [CrossRef]

- Zheng, T.; Miltner, A.; Liang, C.; Nowak, K.M.; Kästner, M. Turnover of gram-negative bacterial biomass-derived carbon through the microbial food web of an agricultural soil. Soil Biol. Biochem. 2021, 152, 108070. [Google Scholar] [CrossRef]

- Das, B.; Pooniya, V.; Shivay, Y.S.; Zhiipao, R.R.; Biswakarma, N.; Kumar, D.; Saikia, N.; Kumar, A.; Govindasamy, P.; Barman, A.; et al. Twenty-one years’ impact of using organic amendments on the productivity of rice-wheat rotation and soil properties. Field Crops Res. 2024, 309, 109311. [Google Scholar] [CrossRef]

- Byrareddy, V.; Kouadio, L.; Mushtaq, S.; Stone, R. Sustainable production of robusta coffee under a changing climate: A 10-year monitoring of fertilizer management in coffee farms in Vietnam and Indonesia. Agronomy 2019, 9, 499. [Google Scholar] [CrossRef]

- Righi, S.; Lucialli, P.; Bruzzi, L. Health and environmental impacts of a fertilizer plant: Assessment of radioactive pollution. J. Environ. Radioact. 2005, 82, 167–182. [Google Scholar] [CrossRef]

- Zhuang, M.; Zhang, J.; Kong, Z.; Fleming, R.M.; Zhang, C.; Zhang, Z. Potential environmental benefits of substituting nitrogen and phosphorus fertilizer with usable crop straw in China during 2000–2017. J. Clean. Prod. 2020, 267, 122125. [Google Scholar] [CrossRef]

- Zhu, T.; Zhang, J.; Yang, W.; Cai, Z. Effects of organic material amendment and water content on NO, N2O, and N2 emissions in a nitrate-rich vegetable soil. Biol. Fert. Soils 2013, 49, 153–163. [Google Scholar] [CrossRef]

- Nadarajan, S.; Sukumaran, S. Chemistry and toxicology behind chemical fertilizers. In Controlled Release Fertilizers for Sustainable Agriculture; Academic Press: Cambridge, MA, USA, 2021; pp. 195–229. [Google Scholar] [CrossRef]

- El-Abdeen, H.A.Z.; Heba, Y.A.M.; Wafaa, M.T.E.; Marwa, A.H.S. Studying the Efficacy of Some Organic Compounds as a Source of Potassium Fertilization and Their Effect on the Wheat-Peanut Crop System in Sandy Soil. Asian J. Soil Sci. Plant Nutr. 2024, 10, 373–388. [Google Scholar] [CrossRef]

- Gonfa, A. Effect of filter cake and bagasse ash application on selected chemical properties of acidic Nitisol. Plant Soil Sci. 2024, 15, 26. [Google Scholar] [CrossRef]

- Wongarmat, W.; Sittijunda, S.; Imai, T.; Reungsang, A. Co-digestion of filter cake, biogas effluent, and anaerobic sludge for hydrogen and methane production: Optimizing energy recovery through two-stage anaerobic digestion. Carbon Resour. Convers. 2024, 100248. [Google Scholar] [CrossRef]

- Temesgen, T.; Periyasamy, S.; Mensur, D.; Berhane, B.; Sunaina, J.M. Valorization of Wastes and By-products of Cane-Based Sugar Industry. In Value Added Products from Food Waste; Cherian, E., Gurunathan, B., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Pajampa, K.; Laloon, K.; Suksri, A.; Phadungton, S.; Ratpukdi, T.; Posom, J.; Wongwuttanasatian, T. A way towards zero-waste campaign and sustainability in sugar industries; filter cake valorisation as energy pellets. Ain Shams Eng. J. 2024, 15, 102459. [Google Scholar] [CrossRef]

- Raj, V.; Chauhan, M.S.; Pal, S.L.; Ahirwar, P.; Mishra, S.; Gujar, J.P.; Tatar, D.K. Circular Economy of Sugarcane Waste in Creation of Wealth. In From Waste to Wealth; Springer: Singapore, 2024; pp. 267–1283. [Google Scholar] [CrossRef]

- Karlen, D.L.; Veum, K.S.; Sudduth, K.A.; Obrycki, J.F.; Nunes, M.R. Soil health assessment: Past accomplishments, current activities, and future opportunities. Soil Tillage Res. 2019, 195, 104365. [Google Scholar] [CrossRef]

- Ihle, R.; Bar-Nahum, Z.; Nivievskyi, O.; Rubin, O.D. Russia’s invasion of Ukraine increased the synchronisation of global commodity prices. Aust. J. Agric. Resour. Econ. 2022, 66, 775–796. [Google Scholar] [CrossRef]

- Chepeliev, M.; Maliszewska, M.; Seara e Pereira, M.F. The war in Ukraine, food security and the role for Europe. EuroChoices 2023, 22, 4–13. [Google Scholar] [CrossRef]

- Khan, F.A.; Tomar, A.; Agarwal, Y.K.; Shukla, H.O. Agricultural Solid Waste Management: An Approach to Protect the Environment and Increase Agricultural Productivity. In Handbook of Solid Waste Management; Baskar, C., Ramakrishna, S., Baskar, S., Sharma, R., Chinnappan, A., Sehrawat, R., Eds.; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Reno, M.L.G.; Olmo, O.A.; Palacio, J.C.E.; Lora, E.E.S.; Venturini, O.J. Sugarcane biorefineries: Case studies applied to the Brazilian sugar-alcohol sector. Energy Convers. Manag. 2014, 88, 981–991. [Google Scholar] [CrossRef]

- Leite, A.F.; Janke, L.; Harms, H.; Zang, J.W.; Fonseca-Zang, W.A.; Stinner, W. Evaluation of variations in the characteristics and methane potential of the main residues of the Brazilian bioethanol industry throughout an operational station. Energy Fuels 2015, 29, 150318103543009. [Google Scholar] [CrossRef]

- Rebelato, M.G.; Madaleno, L.L.; Rodrigues, A.M. Analysis of the environmental performance of sugarcane power plants located in the Mogi Guaçu River Basin. Eng. Sanit. Ambien. 2016, 21, 579–591. [Google Scholar] [CrossRef]

- Carpanez, T.G.; Moreira, V.R.; Assisi, I.R.; Amaral, M.C.S. Sugarcane vinasse as organo-mineral fertilizers feedstock: Opportunities and environmental risks. Sci. Total Environ. 2022, 832, 154998. [Google Scholar] [CrossRef] [PubMed]

- Vasconcelos, R.L.; Cremasco, C.P.; Almeida, H.J.; Garcia, A.; Neto, A.B.; Mauad, M. Multivariate behavior of irrigated sugarcane with phosphate fertilizer and filter cake management: Nutritional state, biometry, and agroindustrial performance. J. Soil Sci. Plant Nutr. 2020, 20, 1625–1636. [Google Scholar] [CrossRef]

- Montiel-Rosales, A.; Romero, N.M.; Santamaría, L.E.G.; Herazo, L.C.S.; Santos, H.B.; Lambert, G.F. Post-industrial use of sugarcane ethanol vinasse: A systematic review. Sustainability 2022, 14, 11635. [Google Scholar] [CrossRef]

- Korndörfer, G.H.; Anderson, D.L. Use and impact of sugar-alcohol residues from vinasse and filter cake in sugarcane production in Brazil. Sugar 1997, 92, 26–35. [Google Scholar]

- Almazán, O.; Gonzalez, L.; Galvez, L. The sugar cane, its by-products and co-products. In Proceedings of the Third Annual Meeting of Agricultural Scientists, Reduit, Mauritius, 17–18 November 1998; Almazan, O., Gonzalez, l., Galvez, L., Eds.; Food and Agricultural Research Council: Reduit, Mauritius, 1998; pp. 1–13. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/20013027685 (accessed on 5 March 2023).

- Meunchang, S.; Panichsakpatana, S.; Weaver, R.W. Co-composting of filter cake and bagasse; by-products from a sugar mill. Bioresour. Technol. 2005, 96, 437–442. [Google Scholar] [CrossRef] [PubMed]

- Saleh-e-In, M.M.; Yeasmin, S.; Paul, B.K.; Ahsan, M.; Rahman, M.Z.; Roy, S.K. Chemical studies on press mud: A sugar industries waste in Bangladesh. Sugar Technol. 2012, 14, 109–118. [Google Scholar] [CrossRef]

- Prado, R.M.; Caione, G.; Campos, C.N.S. Filter cake and vinasse as fertilizers contributing to conservation agriculture. Appl. Environ. 2013, 2013, 581984. [Google Scholar] [CrossRef]

- Dotaniya, M.L.; Datta, S.C.; Biswas, D.R.; Dotaniya, C.K.; Meena, B.L.; Rajendiran, S.; Regar, K.L.; Lata, M. Use of sugarcane industrial by-products for improving sugarcane productivity and soil health. Int. J. Recycl. Org. Waste Agric. 2016, 5, 185–194. [Google Scholar] [CrossRef]

- Vitorello, V.A.; Capaldi, F.R.; Stefanuto, V.A. Recent advances in aluminum toxicity and resistance in higher plants. Braz. J. Plant Physiol. 2005, 17, 129–143. [Google Scholar] [CrossRef]

- Kheir, A.; Kamara, M. Effects of sugar beet factory lime, vinasse, and compost mixed with vinasse application on sandy soil properties and canola productivity. J. Soil Sci. Agric. Eng. 2019, 10, 69–77. [Google Scholar] [CrossRef]

- de Almeida, M.A.; Colombo, R. Production chain of first-generation sugarcane bioethanol: Characterization and value-added application of wastes. BioEnergy Res. 2023, 16, 924–939. [Google Scholar] [CrossRef]

- Crusciol, C.A.C.; McCray, J.M.; Campos, M.; Nascimento, C.A.C.; Rossato, O.B.; Adorna, J.C.; Mellis, E.V. Filter cake as a long-standing source of micronutrients for sugarcane. J. Soil Sci. Plant Nutr. 2021, 21, 813–823. [Google Scholar] [CrossRef]

- González, L.C.; Prado, R.D.M.; Hernández, A.R.; Caione, G.; Selva, E.P. Use of filter cake enriched with rock phosphate and biofertilizers in a Haplustox soil. Pesqui. Agropecu. Trop. 2014, 44, 135–141. [Google Scholar] [CrossRef]

- Cerri, C.C.; Polo, A.; Andreaux, F.; Lobo, M.C. Organic residues of the sugarcane agroindustry: Physical and chemical characteristics. Sugar Alcohol By-Prod. 1988, 6, 34–37. [Google Scholar]

- Almeida Junior, A.B.; Nascimento, C.W.A.; Sobral, M.F.; Silva, F.B.V.; Gomes, W.A. Soil fertility and uptake of nutrients by sugarcane fertilized with filter cake. Rev. Bras. Eng. Agríc. Ambient. 2011, 15, 1004–1013. [Google Scholar] [CrossRef]

- Santos, D.H.; Tiritan, C.S.; Foloni, J.S.S.; Fabris, L.B. Sugarcane yield under fertilization with filter cake enriched with soluble phosphate. Pesq. Agropec. Trop. 2011, 40, 2010. [Google Scholar] [CrossRef]

- Vazquez, G.H.; Bortolin, R.; Vanzela, L.S.; Bonini, C.S.B.; Bonini Neto, A. Use of organophosphate fertilizer and filter cake in plant-cane. Braz. J. Biosyst. Eng. 2015, 9, 53–64. [Google Scholar] [CrossRef]

- Torres, N.H.; Sartori, S.B.; Américo, J.H.P.; Ferreira, L.F.R. Sugar-alcohol industry: Management of by-products. J. Agro-Environ. Sci. 2012, 10, 225–236. Available online: http://www.unemat.br/revistas/rcaa/v10n2a2012 (accessed on 5 March 2023).

- Krishnaveni, A.; Chinnasamy, S.; Elumalai, J.; Muthaiyan, P. Sugar industry wastes as wealth of organic carbon for soil. In Environmental Factors Affecting Human Health; IntechOpen: London, UK, 2020; p. 137. [Google Scholar] [CrossRef]

- Abaza, A.; Gameh, M.A.; Attia, K.K.; Sherief, M.M. Assessment of reference and actual evapotranspiration and yield of maize under different irrigation levels with filter mud cake applications. Assiut J. Agric. Sci. 2021, 52, 70–83. [Google Scholar] [CrossRef]

- Singh, A.; Karmegam, N.; Singh, G.S.; Bhadauria, T.; Chang, S.W.; Awasthi, M.K.; Sudhakar, S.; Arunachalam, K.D.; Biruntha, M.; Ravindran, B. Earthworms and vermicompost: An eco-friendly approach for repaying nature’s debt. Environ. Geochem. Health 2020, 42, 1617–1642. [Google Scholar] [CrossRef]

- Costa, N.R.; Lima, R.A.; Silva, G.D.S.; Matoso, A.O.; Garcia, G.C.; Romeiro, E.R.; Marasca, I.; Souza, D.M.E.; Lima, C.G.R. Application of filter cake in the planting furrow on the initial development of sugarcane. Technol. Agric. Sci. 2016, 10, 1–7. Available online: https://www.researchgate.net/publication/315628626 (accessed on 8 November 2022).

- Vasconcelos, R.L.; Almeida, H.J.; Prado, R.M.; Santos, L.F.J.; Pizauro Junior, J.M. Filter cake in industrial quality and in the physiological and acid phosphatase activities in cane-plant. Ind. Crops Prod. 2017, 105, 133–141. [Google Scholar] [CrossRef]

- Gonfa, A.; Bedadi, B.; Argaw, A. Effect of bagasse ash and filter cake corrections on wheat (Triticum turgidum) production and production components in nitisol. Int. J. Recycl. Org. Waste Agric. 2018, 7, 231–240. [Google Scholar] [CrossRef]

- Silva, A.F.R.; Magalhães, N.C.; Cunha, P.V.M.; Amaral, M.C.; Koch, K. Influence of COD/SO42 ratio on vinasse treatment performance by two-stage anaerobic membrane bioreactor. J. Environ. Manag. 2020, 259, 110034. [Google Scholar] [CrossRef]

- de Oliveira, R.S.; Rios, A.D.F.; de Oliveira, M.H.R.; da Silva, R.M.; Ventura, M.V.A.; Trindade, K.L.; Francalino, P.B. Filter pie in the control of the nematode of root lesions in the soybean and corn. J. Agric. Sci. 2019, 11, 130–136. [Google Scholar] [CrossRef]

- Assis, W.O.; Faria, A.R.; Paes, R.A.; Melo, L.D.F.A.; Reis, L.S.; Medeiros, L.S.; Santos, P.S.; Assis, S.C. Development of lettuce cultivars submitted to different doses of sugarcane pie. Rev. Craibeiras Agroecol. 2019, 4, e8955. Available online: https://www.seer.ufal.br/index.php/era/article/view/8955 (accessed on 10 February 2023).

- Martins, M.B.F.; Santos, A.H.S.; Carvalho, C.T.; Azerêdo, G.A.; Oliveira, F.L.N. Filter cake biofertilizer and plant growth-promoting bacteria in lettuce seedling production. Braz. J. Dev. 2020, 6, 67758–67768. [Google Scholar] [CrossRef]

- Ge, Y.; Abdulkreem, H.A.; Zhou, Z. Plant growth stimulating bacteria and filter mud cake improve soil quality and hose productivity (Mangifera indica). J. Soil Sci. Plant Nutr. 2022, 22, 3068–6080. [Google Scholar] [CrossRef]

- Fravet, P.R.F.; Soares, R.A.B.; Lana, R.M.Q.; Lana, A.M.Q.; Korndorfer, G.H. Efeito de doses de torta de filtro e modo de aplicação e modo de aplicação sobre a produtividade e qualidade tecnológica da soqueira de cana-de-açúcar. Sci. Agrotechnology 2010, 34, 618–624. [Google Scholar] [CrossRef]

- Soares, A.A.V.L.; Prado, R.M.; Caione, G.; Rodrigues, M.; Pavinato, P.S.; Campos, C.N.S. Phosphorus dynamics in sugarcane fertilized with filter cake and mineral phosphate sources. Front. Soil Sci. 2021, 1, 719651. [Google Scholar] [CrossRef]

- Caione, G.; Prado, R.M.; Vasconcelos, R.L.; Souza Junior, J.P.; Campos, C.N.; Silva, M.; Rosatto, L.; González, L.C. Phosphorus sources combined with doses of organic compost increased the population of soil microorganisms and P level in the soil and plant and the dry matter of sugarcane. Sugar Technol. 2021, 23, 130–138. [Google Scholar] [CrossRef]

- Arruda, B.; Rodrigues, M.; Gumiere, T.; Richardson, A.E.; Andreote, F.D.; Soltangheisi, A.; Gatiboni, L.C.; Pavinato, P.S. The impact of sugarcane filter cake on the availability of P in the rhizosphere and on the structure of the associated microbial community. Land Use Manag. 2019, 35, 334–345. [Google Scholar] [CrossRef]

- Abubakar, A.Y.; Ibrahim, M.M.; Zhang, C.; Tayyab, M.; Fallah, N.; Yang, Z.; Pang, Z.; Zhang, H. A lama filtrada melhora o crescimento da cana-de-açúcar e modifica a abundância funcional e a estrutura das populações microbianas do solo. PeerJ 2022, 10, e12753. [Google Scholar] [CrossRef]

- Gonzalez, L.C.; Prado, R.D.M.; Caione, G.; Moda, L.R.; Assisi, L.C.; Nahas, E.; Selva, E.P.; Almeida Junior, H. Effect of filter cake plus phosphate rock enriched with microorganisms on available and adsorbed P and the growth of corn in two soils. J. Fac. Agron. 2016, 33, 1–18. Available online: https://www.researchgate.net/publication/305409805 (accessed on 8 November 2022).

- Campos, C.N.S.; Prado, R.D.M.; Castellanos, G.L.; Abreu, J.M.; Moda, L.R. Phosphate sources associated with filter cake and biofertilizer on phosphorus solubilizing microorganisms and its content in the soil. Trop. Crops 2016, 37, 22–27. [Google Scholar] [CrossRef]

- Rossetto, R.; Ramos, N.P.; Pires, R.C.M.; Xavier, M.A.; Cantarella, H.; Landell, M.G.A. Sustainability in the sugarcane supply chain in Brazil. Sugar Technol. 2022, 24, 941–966. [Google Scholar] [CrossRef]

- Mota, R.P.; Camargo, R.; Lemes, E.M.; Lana, R.M.Q.; Almeida, R.F.; Moraes, E.R. Biosolid and sugarcane filter cake in the composition of organomineral fertilizer on soybean responses. Int. J. Recycl. Org. Waste Agric. 2019, 8, 131–137. [Google Scholar] [CrossRef]

- Chen, J.C.P. By-products of cane sugar processing. In Cane Sugar Handbook, 12th ed.; Chen, J.C.P., Chou, C.C., Eds.; Wiley: New York, NY, USA, 1993. [Google Scholar]

- Silva, L.G.; Camargo, R.; Lana, R.M.Q.; Delvaux, J.C.; Fagan, E.B.; Machado, V.J. Biochemical changes and development of soybean with use of pelletized organomineral fertilizer containing sewage sludge and filter cake. Acta Sci. Agron. 2020, 6, 78212–78226. [Google Scholar] [CrossRef]

- Santos, B.C.; Mendonça, A.P.L.; Carvalho, E.R.; Silva, M.V.P.; Leonardo, N.B.; Vallone, H.S. Replacement of the commercial substrate by filter cake vermicompost in the production of cabbage seedlings. Res. Technol. Innov. 2018, 2, 1–8. Available online: https://periodicos.iftm.edu.br/index.php/sepit/article/view/561 (accessed on 8 November 2022).

- Siles, J.; Garcia, A.; Martin, A.; Martin, M. Integrated ozonation and biomethanization treatments of vinasse derived from ethanol manufacturing. J. Hazard. Mater. 2011, 188, 247–253. [Google Scholar] [CrossRef] [PubMed]

- Belhadj, S.; Karouach, F.; Bari, H.E.; Joute, Y. The biogas production from mesophilic anaerobic digestion of vinasse. Appl. Biochem. Biotechnol. 2013, 172, 3862–3874. [Google Scholar] [CrossRef]

- Cardoso, E.L.B. Anaerobic Digestion of a Very High Strength and Sulfate Rich Vinasse: From Experiments to Modeling and Sustainability Assessment; Ghent University, Faculty of Bioscience Engineering: Ghent, Belgium, 2014. [Google Scholar]

- Rocha, M.H.; Neto, A.E.; Salomon, K.R.; Lora, E.E.; Venturini, O.S.; Olmo, O.S. Residues from the production of biofuels: Vinasse and glycerin. In Biofuels; Lora, E.E., Venturini, O.S., Eds.; Editora Interciência: Rio de Janeiro, Brazil, 2012; Volume 692, p. 809. [Google Scholar]

- Rodrigues, R.; Hu, B. Vinasse from sugarcane ethanol production: Better treatment or better utilization? Front. Energy Res. 2017, 5, 7. [Google Scholar] [CrossRef]

- Prasad, R.K.; Kumar, R.R.; Srivastava, S. Design of optimum response surface experiments for electro-coagulation of distillery spent wash. Water Air Soil Pollut. 2008, 191, 5–13. [Google Scholar] [CrossRef]

- Espana-Gamboa, E.; Cortes, J.M.; Perez, L.B.; Maldonado, J.D.; Zarate, G.H.; Gaviria, L.A. Vinasses: Characterization and treatments. Waste Manag. Res. 2011, 29, 1235–1250. [Google Scholar] [CrossRef] [PubMed]

- Moraes, B.S.; Zaiat, M.; Bonomi, A. Anaerobic digestion of vinasse from sugarcane ethanol production in Brazil: Challenges and perspectives. Renew. Sustain. Energy Rev. 2015, 44, 888–903. [Google Scholar] [CrossRef]

- Silva, A.F.R.; Lebron, Y.A.R.; Moreira, V.R.; Ribeiro, L.A.; Koch, K.; Amaral, M.C.S. High-retention membrane bioreactors for sugarcane vinasse treatment: Opportunities for environmental impact reduction and wastewater valorization. J. Environ. Manage. 2023, 329, 117001. [Google Scholar] [CrossRef] [PubMed]

- Mauad, F.F.; Ferreira, L.C.; Trindade, T.C.G. Renewable Energy in Brazil: Analysis of the Main Brazilian Renewable Energy Sources; University of São Paulo: São Carlos, Brazil, 2017; 349p. [Google Scholar]

- Marafon, A.C.; Salomon, K.R.; Amorim, E.L.C.; Peiter, F.S. Use of sugarcane vinasse to biogas, bioenergy, and biofertilizer production. In Sugarcane Biorefinery, Technology and Perspectives; Academic Press: Cambridge, MA, USA, 2020; pp. 179–194. [Google Scholar] [CrossRef]

- Laime, E.M.O.; Fernandes, P.D.; Oliveira, D.C.S.; Freire, E.A. Technological possibilities for the destination of vinasse: A review. J. Trop. Agric. Biol. Sci. 2011, 5, 16–29. Available online: https://www.researchgate.net/publication/284680338 (accessed on 5 March 2023).

- Mota, V.T.; Araujo, T.A.; Amaral, M.C.S. Comparison of aerobic and anaerobic biodegradation of sugarcane vinasse. Appl. Biochem. Biotechnol. 2015, 176, 1402–1412. [Google Scholar] [CrossRef]

- Silva, P.C.; Silva, M.V.; Pereira, A.D.; Costa, A.R.; Giongo, P.R.; Abreu, J.P.; Moraes, V.H. Productivity and biometric characteristics of sorghum under filter pie. Braz. J. Dev. 2020, 6, 78212–78226. [Google Scholar] [CrossRef]

- Hoarau, J.; Caro, Y.; Grondin, I.; Petit, T. Sugarcane vinasse processing: Toward a status shift from waste to valuable resource production components in nitisol. A review. J. Water Proc. Eng. 2018, 24, 11–25. [Google Scholar] [CrossRef]

- Arslanoglu, H.; Tumen, F. Potassium struvite (slow release fertilizer) and activated carbon production: Resource recovery from vinasse and grape marc organic waste using thermal processing. Process Saf. Environ. Prot. 2021, 147, 1077–1087. [Google Scholar] [CrossRef]

- Rabelo, S.C.; Costa, A.C.; Rossel, C.E.V. Industrial waste recovery. In Sugarcane: Agricultural Production, Bioenergy, and Ethanol; Santos, F., Borém, A., Caldas, C., Eds.; Elsevier: Frisco, CO, USA, 2015; pp. 365–381. [Google Scholar] [CrossRef]

- Fuess, L.T.; Garcia, M.L. Implications of stillage land disposal: A critical review on the impacts of fertigation. J. Environ. Manag. 2014, 145, 210–229. [Google Scholar] [CrossRef]

- Brito, F.L.; Rolim, M.M.; Pedrosa, E.M.R. Cations concentration in leachate from soils treated with vinasse. Eng. Agrícola 2007, 27, 773–781. [Google Scholar] [CrossRef]

- Barros, R.P.B.; Viégas, P.R.A.; Silva, T.L.; Souza, R.M.; Barbosa, L.; Viégas, R.A.; Barretto, M.C.V.; Melo, A.S. Alterações em atributos químicos de solo cultivado com cana-de-açúcar e adição de vinhaça. Pesqui. Agropecuária Trop. 2010, 40, 341–346. Available online: https://revistas.ufg.br/pat/article/view/6422 (accessed on 23 April 2023). [CrossRef]

- Silva, A.J.N.; Cabeda, M.S.V.; Carvalho, F.G.; Lima, J.F.W.F. Physical and chemical alterations of a Yellow Argisol under different use and management systems. Rev. Bras. Eng. Agrícola Ambient. 2006, 10, 76–83. [Google Scholar] [CrossRef]

- Parsaee, M.; Kiani, M.K.D.; Karimi, K. A review of biogas production from sugarcane vinasse. Biomass Bioenergy 2019, 122, 117–125. [Google Scholar] [CrossRef]

- Cetesb—Environmental Company of the State of São Paulo. Board Decision No. 045/2015/C: Technical Standard P4.231: Vinasse–Criteria and Procedures for Application in Agricultural Soil, 2015, 3 ed., Version 2, p. 15. Available online: https://cetesb.sp.gov.br/wp-content/uploads/2014/12/DD-045-2015-C.pdf (accessed on 23 April 2023).

- Lima, V.O.; Barros, V.G.; Duda, R.M.; Oliveira, R.A. Anaerobic digestion of vinasse and water treatment plant sludge increases methane production and stability of UASB reactors. J. Environ. Manag. 2022, 327, 116451. [Google Scholar] [CrossRef]

- Silva, A.F.R.; Ribeiro, L.A.; Amaral, M.C.S. Efficiency of nutrients recovery from sugarcane vinasse treatment by different electrodialysis configurations and in sequential-batch operation. Sep. Purif. Technol. 2023, 311, 123295. [Google Scholar] [CrossRef]

- Moreira, V.R.; Carpanez, T.G.; Magalhães, N.C.; Ladeira, Y.F.; Lange, L.C.; Amaral, M.C.S. Ultrafiltration as pre-treatment technology to improve vinasse biomethanation. Process Saf. Environ. Prot. 2023, 169, 718–724. [Google Scholar] [CrossRef]

- Del Nery, V.; Alves, I.; Damianovic, M.H.R.Z.; Pires, E.C. Hydraulic and organic rates applied to pilot scale UASB reactor for sugar cane vinasse degradation and biogas generation. Biomass Bioenergy 2018, 119, 411–417. [Google Scholar] [CrossRef]

- Navarro, A.R.; Sepúlveda, M.C.; Rubio, M.C. Bio-concentration of vinasse from the alcoholic fermentation of sugar cane molasses. Waste Manag. 2000, 20, 581–585. [Google Scholar] [CrossRef]

- Camargo, J.A.; Pereira, N.; Cabello, P.R.; Teran, F.J.C. Feasibility of the application of the respirometric method of Bartha for the analysis of microbial activity of soils under the application of vinasse. Environ. Eng. 2009, 12, 71–78. [Google Scholar] [CrossRef]

- Santana, V.S.; Fernandes-Machado, N.R.C. Photocatalytic degradation of the vinasse under solar radiation. Catal. Today 2008, 133, 606–610. [Google Scholar] [CrossRef]

- Giachini, C.F.; Ferraz, M.V. Benefícios da utilização de vinhaça em terras de plantio de cana-de-açúcar—Revisão de literatura. Rev. Científica Eletrônica Agron. 2009, 3, 1–15. [Google Scholar]

- Christofoletti, C.A.; Escher, J.P.; Correia, J.E.; Marinho, J.F.; Fontanetti, C.S. Sugarcane vinasse: Environmental implications of its use. Waste Manag. 2013, 33, 2752–2761. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, B.G.; Carvalho, J.L.N.; Cerri, C.E.P.; Cerri, C.C.; Feigl, B.J. Greenhouse gas emissions from sugarcane vinasse transportation by open channel: A case study in Brazil. J. Clean. Prod. 2015, 94, 102–107. [Google Scholar] [CrossRef]

- Ramos, R.L.; Moreira, V.R.; Lebron, Y.A.R.; Santos, A.V.; Santos, L.V.S.; Amaral, M.C.S. Phenolic compounds seasonal occurrence and risk assessment in surface and treated waters in Minas Gerais-Brazil. Environ. Pollut. 2021, 268, 115782. [Google Scholar] [CrossRef]

- Garcia, C.F.H.; Souza, R.B.; Souza, C.P.; Christofoletti, C.A.; Fontanetti, C.S. Toxicity of two effluents from agricultural activity: Comparing the genotoxicity of sugar cane and orange vinasse. Ecotoxicol. Environ. Saf. 2017, 142, 216–221. [Google Scholar] [CrossRef]

- Fuess, L.T.; Altoé, M.E.; Felipe, M.C.; Garcia, M.L. Pros and cons of fertirrigation with in natura sugarcane vinasse: Do improvements in soil fertility offset environmental and bioenergy losses? J. Clean. Prod. 2021, 319, 128684. [Google Scholar] [CrossRef]

- Robles-González, V.; Poggi-Varaldo, H.M.; Galíndez-Mayer, J.; Ruiz-Ordaz, N. Combined treatment of mezcal vinasses by ozonation and activated sludge. Water Environ. Res. 2018, 90, 1985–1996. [Google Scholar] [CrossRef]

- Barbosa, V.; Ramos, A.; Durigan, A.M.P.; Gloria, N.A.; Mutton, M.A. Uso de vinhaça concentrada na adubação de soqueira de cana-de-açúcar. Stab 2006, 24, 6–8. [Google Scholar]

- Rossetto, R.; Silva, A.; Vitti, A.C.; Piemonte, M.; Dias, F.L.F.; Cantarella, H. Concentrated vinasse applied in sugarcane ratoon: Yield and soil fertility. Proc. Int. Soc. Sugar Cane Technol. 2016, 29, 1095–1099. Available online: https://issct.org/wp-content/uploads/proceedings/2016/Agronomy-posters/12-RaffaellaRossetto.pdf (accessed on 23 April 2023).

- da Silva, A.M.R.; Lopes, I.G.; Braos, L.B.; Crus, M.C. P da. Nitrogen Mineralization and Sugarcane Growth in Soils Fertilized with Vinasse. Sugar Tech 2020, 22, 1076–1085. [Google Scholar] [CrossRef]

- Carmo, J.B.; Filoso, L.C.; Zotelli, E.; Sousa Neto, L.M.; Pitombo, P.J.; Duarte Neto, V.P.; Vargas, C.A.; Andrade, G.J.C.; Gava, R.; Rossetto, H.; et al. Infield greenhouse gas emissions from sugarcane soils in Brazil: Effects from synthetic and organic fertilizer application and crop trash accumulation. Glob. Chang. Biol. Bioenergy 2013, 5, 267–280. [Google Scholar] [CrossRef]

- Lawrence, K.S.; Cassman, N.A.; Cantarella, H.; Kuramae, E.E. Nitrosospira sp. nov. govern nitrous oxide emissions in a tropical soil amended with residues of bioenergy crop. Front. Microbiol. 2018, 10, 674. [Google Scholar] [CrossRef]

- Lawrence, K.S.; Dimitrov, M.R.; Soares, J.R.; Carmo, J.B.; Kuramae, E.E. Dominance of bacterial ammonium oxidizers and fungal denitrifiers in the complex nitrogen cycle pathways related to nitrous oxide emission. Glob. Chang. Biol. Bioenergy 2018, 10, 645–660. [Google Scholar] [CrossRef]

- Lourenço, K.S.; Rossetto, R.; Vitti, A.C.; Montezano, Z.F.; Soares, J.R.; Sousa, R.M.; Carmo, J.B.; Kuramae, E.E.; Cantarella, H. Strategies to mitigate the nitrous oxide emissions from nitrogen fertilizer applied with organic fertilizers in sugarcane. Sci. Total Environ. 2019, 650, 1476–1486. [Google Scholar] [CrossRef]

- Rulli, M.M.; Villegas, L.B.; Colin, V.L. Treatment of sugarcane vinasse using an autochthonous fungus from the northwest of Argentina and its potential application in fertigation practices. J. Environ. Chem. Eng. 2020, 8, 104371. [Google Scholar] [CrossRef]

- Kusumaningtyas, R.D.; Hartanto, D.; Rohman, H.A.; Mitamaytawati, Q.N.D. Valorization of sugarcane-based bioethanol industry waste (vinasse) to organic fertilizer. In Valorization of Agro-Industrial Residues; Zakaria, Z., Aguilar, C., Kusumaningtyas, R., Binod, P., Eds.; Springer: Cham, Switzerland, 2020; Volume 2, pp. 203–223. [Google Scholar] [CrossRef]

- Moran-Salazar, R.G.; Sanchez-Lizarraga, A.L.; Rodriguez-Campos, J.; Davila-Vázquez, G.; Marino-Marmolejo, E.N.; Dendooven, L.; Contretas-Ramos, S.M. Utilization of vinasses as soil amendment: Consequences and perspectives. SpringerPlus 2016, 5, 1007. [Google Scholar] [CrossRef] [PubMed]

- Moraes, B.S.; Junqueira, T.L.; Pavanello, L.G.; Cavalett, O.; Mantelatto, P.E.; Bonomi, A.; Zaiat, M. Anaerobic digestion of vinasse from sugarcane biorefineries in Brazil from energy, environmental, and economic perspectives: Profit or expense? Appl. Energy 2014, 113, 825–835. [Google Scholar] [CrossRef]

- Moraes, B.S.; Petersen, S.O.; Zaiat, M.; Sommer, S.G.; Triolo, J.M. Reduction in greenhouse gas emissions from vinasse through anaerobic digestion. Appl. Energy 2017, 189, 21–30. [Google Scholar] [CrossRef]

- Buller, L.S.; Romero, C.W.S.; Lamparelli, R.A.C.; Ferreira, S.F.; Bortoleto, A.P.; Carneiro, T.F. A spatially explicit assessment of sugarcane vinasse as a sustainable by product. Sci. Total Environ. 2021, 765, 142717. [Google Scholar] [CrossRef]

- Velásquez-Pomar, D.C.; Sanchez, P.M. Efecto de vinazas sobre hongos que forman micorriza arbuscular en un molisol del Valle del Cauca, Colombia. Rev. Fac. Nal. Agr. Medellín 2011, 64, 5755–5767. Available online: https://www.redalyc.org/articulo.179922364002 (accessed on 23 April 2023).

- Suleiman, A.K.A.; Lawrence, K.S.; Pitombo, L.M.; Mendes, L.W.M.; Roesch, L.F.W.; Pijl, A.; Carmo, J.B.; Cantarella, H.; Kuramae, E.E. Recycling organic residues in agriculture impacts soil-borne microbial community structure, function and N2O emissions. Sci. Total Environ. 2018, 631, 1089–1099. [Google Scholar] [CrossRef] [PubMed]

- Reay, D.; Sabine, C.; Smith, P. Hymus Intergovernmental Panel on Climate Change. In Fourth Assessment Report Inter-GOVERNMENTAL Panel on Climate Change; Cambridge University Press: Cambridge, UK; Geneva, Switzerland, 2007; Available online: http://www.ipcc.ch (accessed on 23 April 2023).

- Gonçalves, O.B.; Carvalho, J.L.N.; Cerri, C.E.P.; Cerri, C.C.; Feigl, B.J. Soil greenhouse gas fluxes from vinasse application in Brazilian sugarcane areas. Geoderma 2013, 200, 77–84. [Google Scholar] [CrossRef]

- Pinto, L.E.; Cordeiro, C.F.D.S.; de Araujo, A.S.; Araujo, F.F.D. Vinasse improves soil quality and increases the yields of soybean, maize, and pasture. Rev. Bras. Eng. Agríc. Ambient. 2022, 26, 335–340. [Google Scholar] [CrossRef]

- Barbosa, E.A.A.; Arruda, F.B.; Pires, R.C.M.; Silva, T.J.A.; Sakai, E. Cana-de-açúcar fertirrigada com vinhaça e adubos minerais via irrigação por gotejamento subsuperficial: Ciclo da cana-planta. Rev. Bras. Eng. Agríc. Ambient. 2012, 16, 952–958. [Google Scholar] [CrossRef]

- Oliveira, J.S.F.; Santos, O.A.Q.; Rossi, C.Q.; Diniz, Y.V.F.G.; Fagundes, H.S.; Pinto, L.A.R.; Pereira, W.; Pereira, M.G. Assessing the effects of harvesting with and without burning and vinasse application in sugarcane crops: Evaluation of soil fertility and phosphorus pools in different ethanol production systems. Agric. Ecosyst. Environ. 2021, 307, 107233. [Google Scholar] [CrossRef]

- Litardo, R.C.M.; Bendezú, S.J.G.; Zenteno, M.D.C.; Pérez-Almeida, I.B.; Parismoreno, L.L.; García, E.D.L. Effect of mineral and organic amendments on rice growth and yield in saline soils. J. Saudi Soc. Agric. Sci. 2022, 21, 29–37. [Google Scholar] [CrossRef]

- Andrade, L.C.L.; Putti, F.F.; Cremasco, C.P.; Gabriel Filho, L.R.A. New paradigm for vinasse use as fertilizer in hydroponics. Sugar Tech 2022, 24, 1260–1271. [Google Scholar] [CrossRef]