Experimental Study on the Physical and Mechanical Properties of Modified Clay Using Xanthan Gum and Guar Gum Composite Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

2.1.1. Clay

2.1.2. Biopolymer

2.2. Specimen Preparation and Test Program

3. Results and Discussion

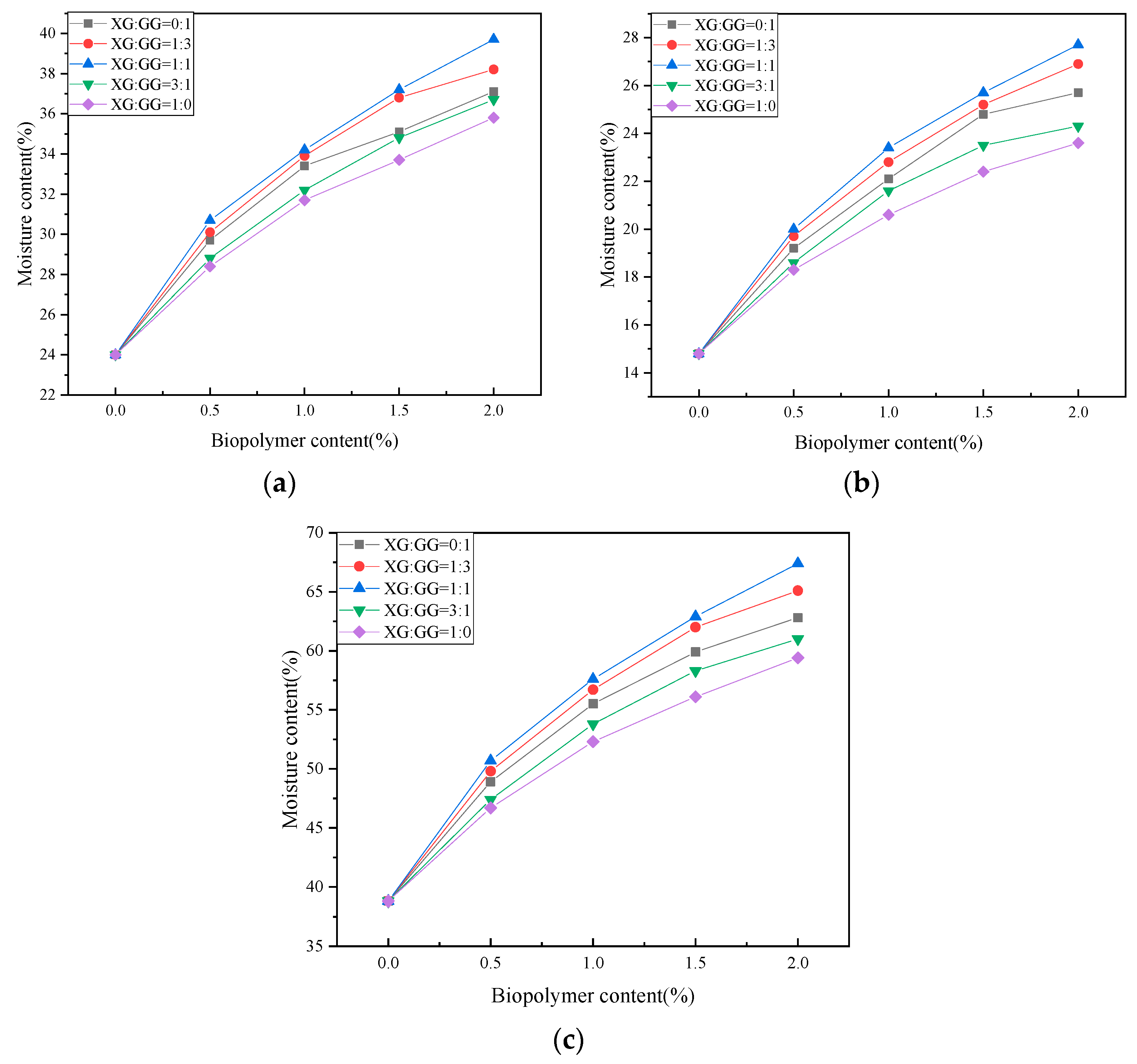

3.1. Atterberg Limits of Biopolymer-Treated Clays

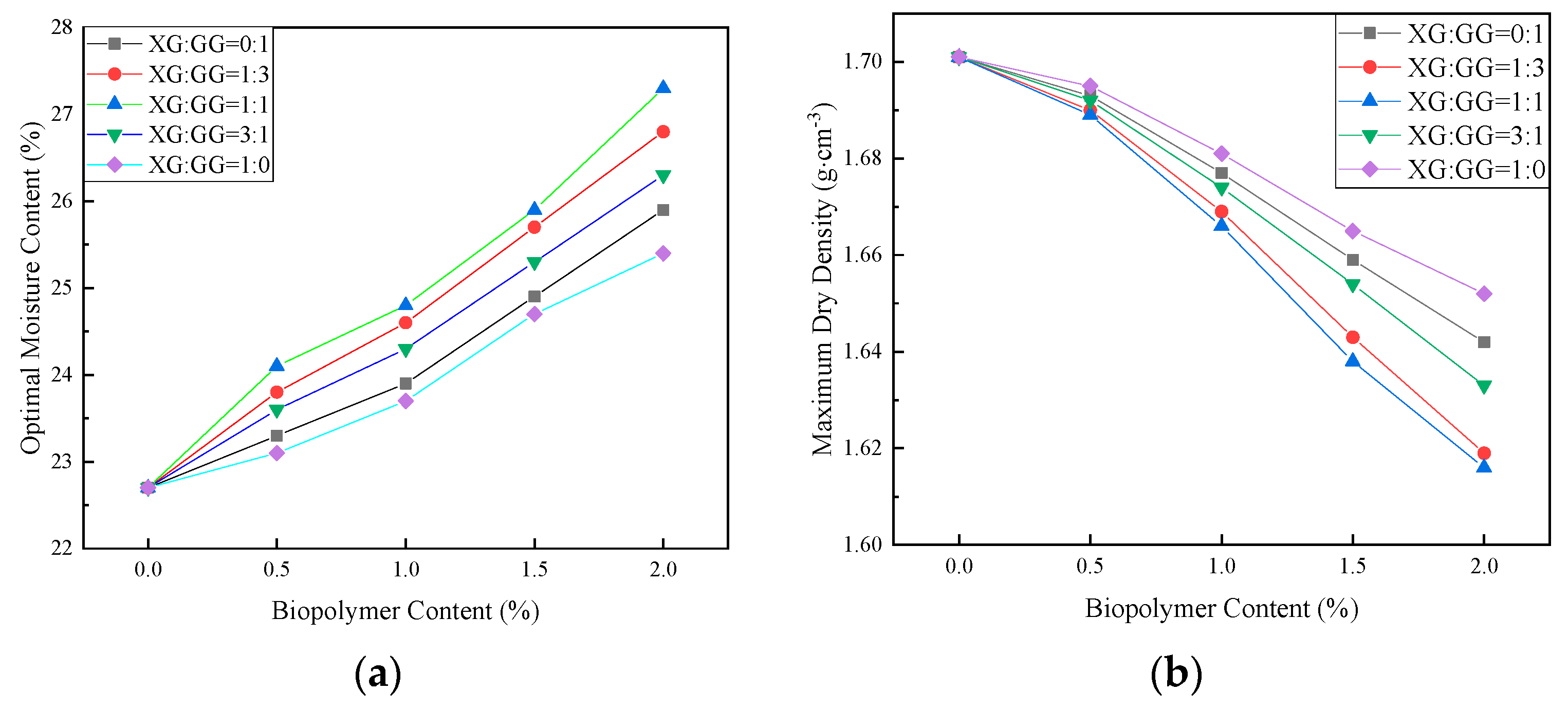

3.2. Compaction Properties of Clay Treated with Biopolymer Compounding

3.3. Shear Strength Characteristics of Biopolymer Compound-Treated Clay

3.3.1. Stress–Strain Characteristics of Clay Treated with Xanthan Gum and Guar Gum Compounding

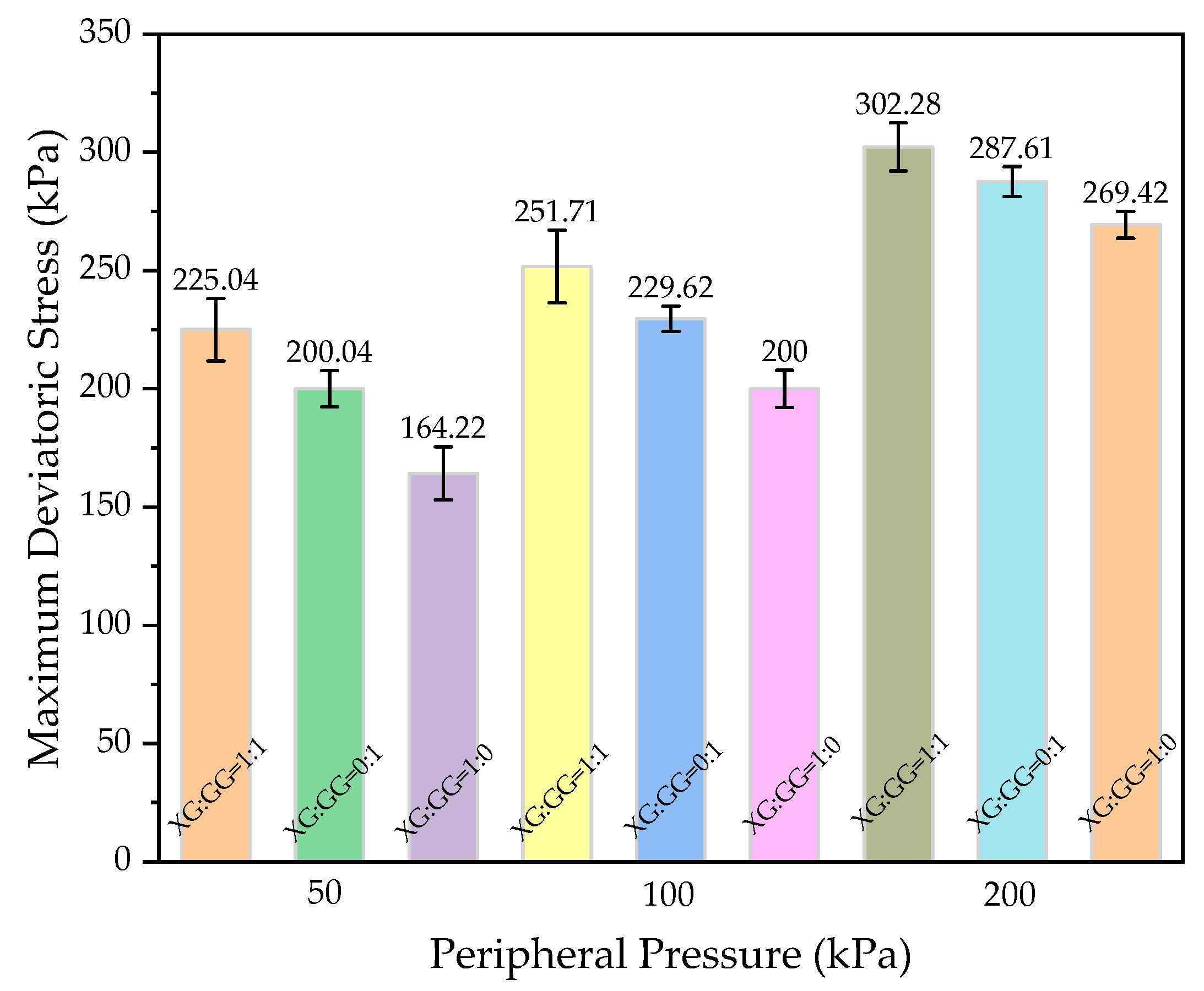

3.3.2. Shear Strength Parameters of Xanthan Gum and Guar Gum Compounding-Treated Clay

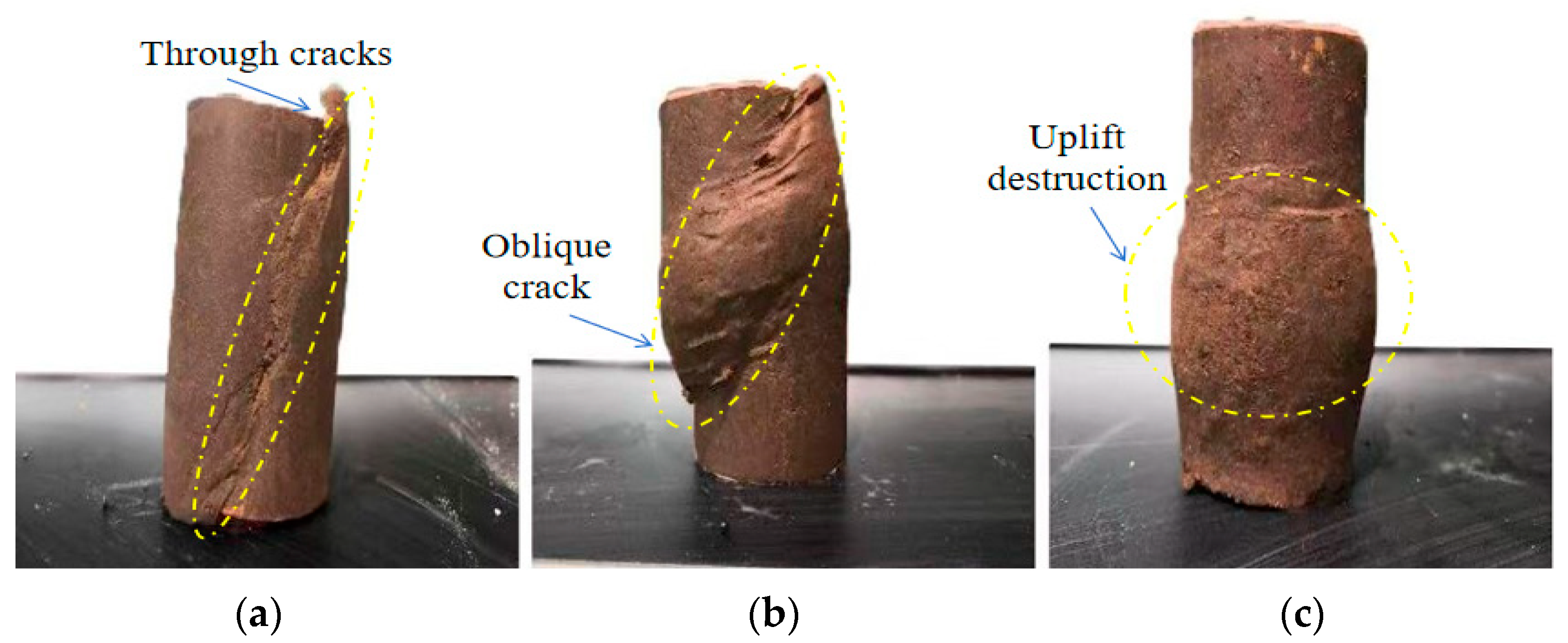

3.3.3. Triaxial Shear Failure Characteristics of Xanthan Gum- and Guar Gum-Treated Clay

4. Conclusions

- (1)

- The liquid limit, plastic limit, and plasticity index of clay increase with higher biopolymer content. For a specific biopolymer content, the liquid–plastic limit of clay initially rises and then falls as the XG and GG mixing ratio increases. The liquid–plastic limit of clay peaks at a 1:1 ratio of xanthan gum to guar gum.

- (2)

- The maximum dry density of the clay decreases and the optimum moisture content increases with the increase in biopolymer dosage. Additionally, the maximum dry density showed a trend of decreasing and then increasing with the increase in the mixing ratio, while the optimal water content showed a trend of increasing and then decreasing. Interestingly, at the mixing ratio of 1:1, although the maximum dry density is the smallest, the optimal water content is the largest.

- (3)

- The stress–strain curve of biopolymer–clay displays a strain-softening behavior. As the perimeter pressure increases, the shear strength and modulus of elasticity of the specimen also increase, resulting in a more stable biopolymer–clay specimen. Furthermore, the stress–strain relationship of biopolymer–clay shows an increase with higher biopolymer doping. When XG and GG are compounded in equal amounts, the stress–strain curves shift to the right, indicating higher plasticity. Additionally, the peak stress of the biopolymer–clay is observed to be the highest in this scenario.

- (4)

- The disordering of XG is crucial in the interaction process with guar gum. This interaction enhances the viscosity of the mixed colloid, leading to the formation of a more densely intertwined network structure with clay particles, thereby improving the engineering properties of clays.

- (5)

- The compounded XG- and GG-treated clay exhibited stronger cohesion, a smaller internal friction angle, and higher shear strength compared to the single-colloid-treated clay. Following this, the specimen with single-doped guar gum showed intermediate results, while the specimen with single-doped xanthan gum displayed the lowest cohesion, the largest internal friction angle, and the smallest shear strength. This suggests that the increase in cohesion has a greater impact on shear strength than the reduction in the internal friction angle. Therefore, compounding biopolymers is advantageous in enhancing the integrity of soil samples and improving the ability of specimens to withstand damage and deformation, ultimately contributing to the safety and stability of the project.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.-Y.; Han, R.; Yu, B.; Wei, Y.-M. Accounting process-related CO2 emissions from global cement production under Shared Socioeconomic Pathways. J. Clean. Prod. 2018, 184, 451–465. [Google Scholar] [CrossRef]

- Soldo, A.; Miletić, M.; Auad, M.L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. 2020, 10, 267. [Google Scholar] [CrossRef] [PubMed]

- Chang, I.; Im, J.; Cho, G.-C. Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2017. Earth Syst. Sci. Data 2018, 10, 2213–2239. [Google Scholar] [CrossRef]

- Umar, M.; Kassim, K.A.; Chiet, K.T.P. Biological process of soil improvement in civil engineering: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 767–774. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Ashraf, M.S.; Azahar, S.B.; Yusof, N.Z. Soil Improvement Using MICP and Biopolymers: A Review; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 012058. [Google Scholar]

- Soldo, A.; Miletić, M. Study on shear strength of xanthan gum-amended soil. Sustainability 2019, 11, 6142. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Vydehi, K.V. State-of-the-art review on efficacy of xanthan gum and guar gum inclusion on the engineering behavior of soils. Innov. Infrastruct. Solut. 2021, 6, 108. [Google Scholar] [CrossRef]

- Ayeldeen, M.K.; Negm, A.M.; El Sawwaf, M.A. Evaluating the physical characteristics of biopolymer/soil mixtures. Arab. J. Geosci. 2016, 9, 371. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Sulaiman, H.; Taha, M.R.; Abd Rahman, N.; Taib, A.M. Performance of soil stabilized with biopolymer materials–xanthan gum and guar gum. Phys. Chem. Earth Parts A/B/C 2022, 128, 103276. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Canakci, H. Direct shear tests on sand treated with xanthan gum. Proc. Inst. Civ. Eng.-Ground Improv. 2011, 164, 57–64. [Google Scholar] [CrossRef]

- Dehghan, H.; Tabarsa, A.; Latifi, N.; Bagheri, Y. Use of xanthan and guar gums in soil strengthening. Clean Technol. Environ. Policy 2019, 21, 155–165. [Google Scholar] [CrossRef]

- Bozyigit, I.; Javadi, A.; Altun, S. Strength properties of xanthan gum and guar gum treated kaolin at different water contents. J. Rock Mech. Geotech. Eng. 2021, 13, 1160–1172. [Google Scholar] [CrossRef]

- Reddy, N.; Rao, B.; Reddy, K.R. Biopolymer amendment for mitigating dispersive characteristics of red mud waste. Géotechnique Lett. 2018, 8, 201–207. [Google Scholar] [CrossRef]

- Bergmann, D.; Furth, G.; Mayer, C. Binding of bivalent cations by xanthan in aqueous solution. Int. J. Biol. Macromol. 2008, 43, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Khouryieh, H.; Herald, T.; Aramouni, F.; Alavi, S. Intrinsic viscosity and viscoelastic properties of xanthan/guar mixtures in dilute solutions: Effect of salt concentration on the polymer interactions. Food Res. Int. 2007, 40, 883–893. [Google Scholar] [CrossRef]

- Mezreli, G.; Kurt, A.; Akdeniz, E.; Ozmen, D.; Basyigit, B.; Toker, O.S. A new synergistic hydrocolloid with superior rheology: Locust bean/xanthan gum binary solution powdered by different drying methods. Food Hydrocoll. 2024, 154, 110078. [Google Scholar] [CrossRef]

- Sharma, D.; Sharma, P. Synergistic studies of Cassia tora gum with xanthan and guar gum: Carboxymethyl synthesis of cassia gum-xanthan synergistic blend and characterization. Carbohydr. Res. 2023, 523, 108723. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Test Methods. China Planning Press: Beijing, China, 2019.

- Kwon, Y.-M.; Chang, I.; Lee, M.; Cho, G.-C. Geotechnical engineering behavior of biopolymer-treated soft marine soil. Geomech. Eng. 2019, 17, 453–464. [Google Scholar]

- Kim, D.; Park, K. Evaluation of the grouting in the sandy ground using bio injection material. Geomech. Eng. 2017, 12, 739–752. [Google Scholar] [CrossRef]

- Garcıa-Ochoa, F.; Santos, V.; Casas, J.; Gómez, E. Xanthan gum: Production, recovery, and properties. Biotechnol. Adv. 2000, 18, 549–579. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Jung, J.; Song, X.; Bate, B. On the soil water characteristic curves of poorly graded granular materials in aqueous polymer solutions. Acta Geotech. 2018, 13, 103–116. [Google Scholar] [CrossRef]

- Wahab, N.A.; Roshan, M.J.; Rashid, A.S.A.; Hezmi, M.A.; Jusoh, S.N.; Nik Norsyahariati, N.D.; Tamassoki, S. Strength and durability of cement-treated lateritic soil. Sustainability 2021, 13, 6430. [Google Scholar] [CrossRef]

- Eldaw, G.E. A Study of Guar Seed and Guar Gum Properties (Cyamopsis tetragonolabous); Department of Food Science and Technology, Faculty of Agriculture, University of Khartoum: Khartoum, Sudan, 1998. [Google Scholar]

- Kim, S.; Palomino, A.M. Polyacrylamide-treated kaolin: A fabric study. Appl. Clay Sci. 2009, 45, 270–279. [Google Scholar] [CrossRef]

- Singh, S.P.; Das, R. Geo-engineering properties of expansive soil treated with xanthan gum biopolymer. Geomech. Geoengin. 2020, 15, 107–122. [Google Scholar] [CrossRef]

- Casas, J.A.; Mohedano, A.F.; García-Ochoa, F. Viscosity of guar gum and xanthan/guar gum mixture solutions. J. Sci. Food Agric. 2000, 80, 1722–1727. [Google Scholar] [CrossRef]

- Nugent, R.A.; Zhang, G.; Gambrell, R.P. Effect of exopolymers on the liquid limit of clays and its engineering implications. Transp. Res. Rec. 2009, 2101, 34–43. [Google Scholar] [CrossRef]

- Khouryieh, H.; Herald, T.; Aramouni, F.; Alavi, S. Influence of mixing temperature on xanthan conformation and interaction of xanthan–guar gum in dilute aqueous solutions. Food Res. Int. 2006, 39, 964–973. [Google Scholar] [CrossRef]

- Nawab, A.; Alam, F.; Haq, M.A.; Hasnain, A. Effect of guar and xanthan gums on functional properties of mango (Mangifera indica) kernel starch. Int. J. Biol. Macromol. 2016, 93, 630–635. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Goff, H.D.; Cui, S.W. Comparison of synergistic interactions of yellow mustard gum with locust bean gum or κ-carrageenan. Food Hydrocoll. 2022, 132, 107804. [Google Scholar] [CrossRef]

- Kang, X.; Bate, B.; Chen, R.-P.; Yang, W.; Wang, F. Physicochemical and mechanical properties of polymer-amended kaolinite and fly ash–kaolinite mixtures. J. Mater. Civ. Eng. 2019, 31, 04019064. [Google Scholar] [CrossRef]

- Sun, H.; Hou, M.; Chen, C.; Ge, X. Microstructure investigation of soft clay subjected to triaxial loading. Eng. Geol. 2020, 274, 105735. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior; John Wiley & Sons: New York, NY, USA, 2005; Volume 3. [Google Scholar]

- Bagherinia, M. Mechanical, durability, and microstructure of soft clay stabilised with anionic biopolymer. Constr. Build. Mater. 2024, 417, 135343. [Google Scholar] [CrossRef]

- Gambrell, R.P.; Zhang, G.; Nugent, R.; Land, L. Physical, Chemical, and Biological Evaluation of the Application of Biodegradable Polymers to Restoring Coastal Wetlands; Louisiana Universities Marine Consortium: Chauvin, LA, USA, 2010. [Google Scholar]

- Jang, J. A review of the application of biopolymers on geotechnical engineering and the strengthening mechanisms between typical biopolymers and soils. Adv. Mater. Sci. Eng. 2020, 2020, 1465709. [Google Scholar] [CrossRef]

- Chityala, P.K.; Khouryieh, J.; Williams, K. Effect of Xanthan-Guar Synergism on the Stability of Oil-in-water Emulsions. In Proceedings of the Abstracts of Papers of the American Chemical Society; American Chemical Society: Washington, DC, USA, 2014. [Google Scholar]

| Soil | Biopolymer | Observations | Reference |

|---|---|---|---|

| Poorly graded sand and high-plasticity silt | XG/GG | After treatment with XG and GG (2%), the permeability coefficient of sand decreased to 4% and 1%, respectively. For silt, after adding XG and GG (2%), the permeability coefficient value decreases to 10%. | [10] |

| Sand/Natural soil/Red yellow soil/Clay | XG | The compressive strength of sand/natural soil/red yellow soil/clay treated with xanthan gum (1%) and cured for 28 days is 880 kPa, 3680 kPa, 4940 kPa, and 2540 kPa, respectively. | [11] |

| Residual soil | XG/GG | Reinforcing soil at 5% XG and GG decreased the specific gravity from 2.69 to 2.19 and 2.24. | [12] |

| Sand | XG | After treating sand with xanthan gum (5%) and curing for 7 days, the internal friction angle increased by 1.9 times. | [13] |

| Sand/Clay/Silty sand | XG | After 5 days of XG treatment and curing of silicon sand/clay, the deviatoric stress increased to 1.70 MPa and 1.47 MPa, and the maximum deviatoric stress value of plain sand was extremely low. | [8] |

| Silty–clay soil | XG/GG | After treatment with XG and GG (2%), the maximum dry density of clay decreased to 17.55 kN/m3 and 17.65 kN/m3, respectively, and the optimal moisture content increased to 17.2% and 16.1%, respectively. | [14] |

| Kaolin | XG/GG | After treatment with XG and GG (2%), the liquid limit of Kaolin were increased to 74% and 83%, respectively. The UCS values of the soil samples treated with XG/GG increased, and the samples prepared at the optimal moisture content reached the maximum strength value. | [15] |

| Red mud waste | XG/GG | The turbidity value of untreated RMW ranges from 35 to 374 NTU. In contrast, the turbidity values of GG and XG corrected samples were 3 to 24 NTU and 2 to 18 NTU, respectively. | [16] |

| Liquid Limit/% | Plastic Limit/% | Plasticity Index | Specific Gravity | Optimum Moisture Content/% | Maximum Dry Density/g·cm−3 |

|---|---|---|---|---|---|

| 38.8 | 24.0 | 14.8 | 2.79 | 22.7 | 1.70 |

| Variable | Atterberg Limit Test | Compaction Test | Consolidation Undrainage Test |

|---|---|---|---|

| Biopolymer content (%) | 0; 0.5; 1.0; 1.5; 2.0 | 0; 0.5; 1.0; 1.5; 2.0 | 2 |

| XG:GG | 0:1; 1:3; 1:1; 3:1; 1:0 | 0:1; 1:3; 1:1; 3:1; 1:0 | 1:0; 1:1; 0:1 |

| XG:GG | Cohesive Force c/kPa | Internal Friction Angle φ/° |

|---|---|---|

| 1:0 | 49.3 | 15.28 |

| 0:1 | 68.8 | 13.16 |

| 1:1 | 83.7 | 12.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, J.; Ouyang, F.; Xiao, H.; Wang, L.; Tao, G. Experimental Study on the Physical and Mechanical Properties of Modified Clay Using Xanthan Gum and Guar Gum Composite Materials. Sustainability 2024, 16, 5432. https://doi.org/10.3390/su16135432

Wan J, Ouyang F, Xiao H, Wang L, Tao G. Experimental Study on the Physical and Mechanical Properties of Modified Clay Using Xanthan Gum and Guar Gum Composite Materials. Sustainability. 2024; 16(13):5432. https://doi.org/10.3390/su16135432

Chicago/Turabian StyleWan, Juan, Fan Ouyang, Henglin Xiao, Leixiang Wang, and Gaoliang Tao. 2024. "Experimental Study on the Physical and Mechanical Properties of Modified Clay Using Xanthan Gum and Guar Gum Composite Materials" Sustainability 16, no. 13: 5432. https://doi.org/10.3390/su16135432

APA StyleWan, J., Ouyang, F., Xiao, H., Wang, L., & Tao, G. (2024). Experimental Study on the Physical and Mechanical Properties of Modified Clay Using Xanthan Gum and Guar Gum Composite Materials. Sustainability, 16(13), 5432. https://doi.org/10.3390/su16135432