Short Jute Fiber Reinforced Cement Mortar for Out-of-Plane Strengthening of Masonry Prisms

Abstract

:1. Introduction

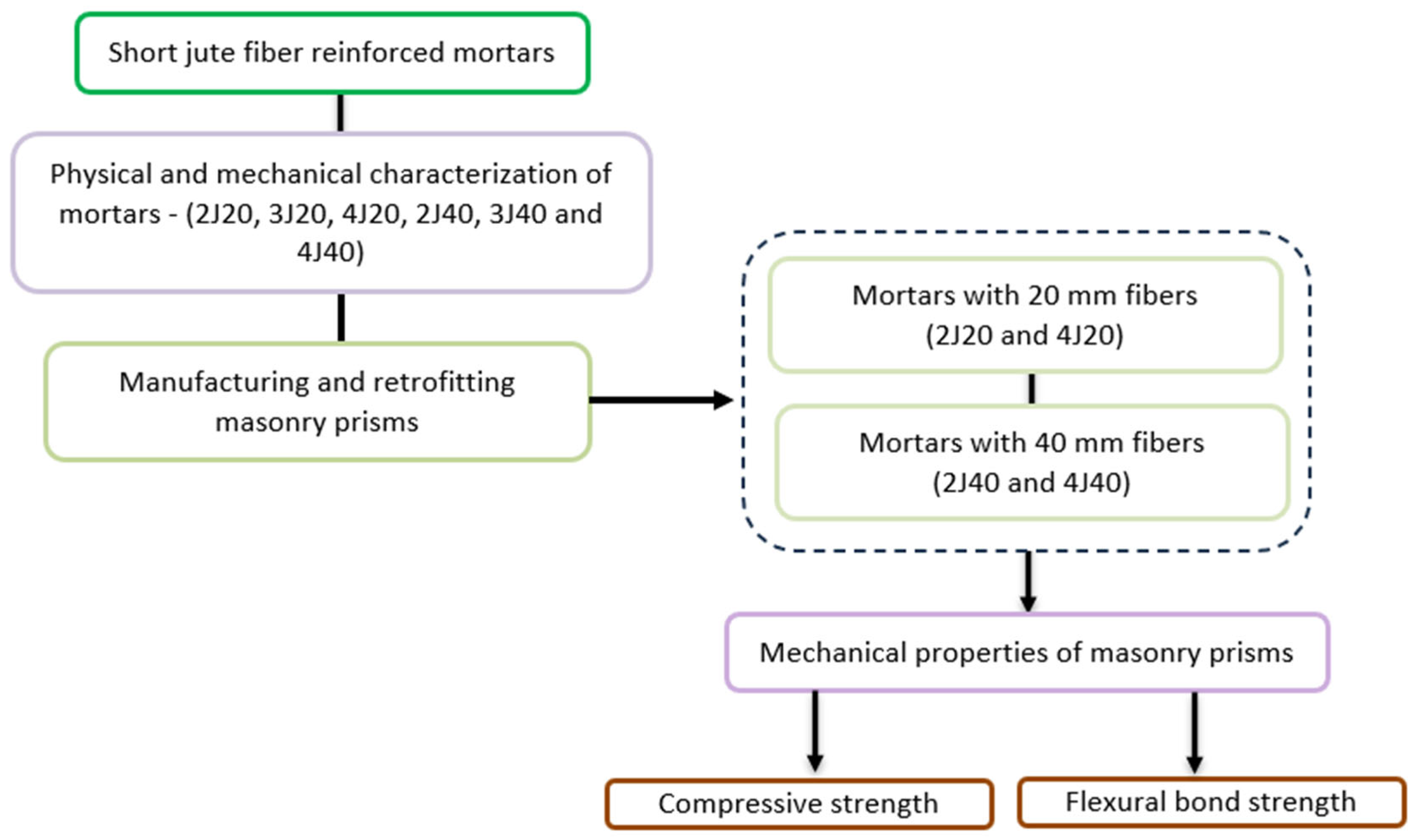

2. Materials and Methods

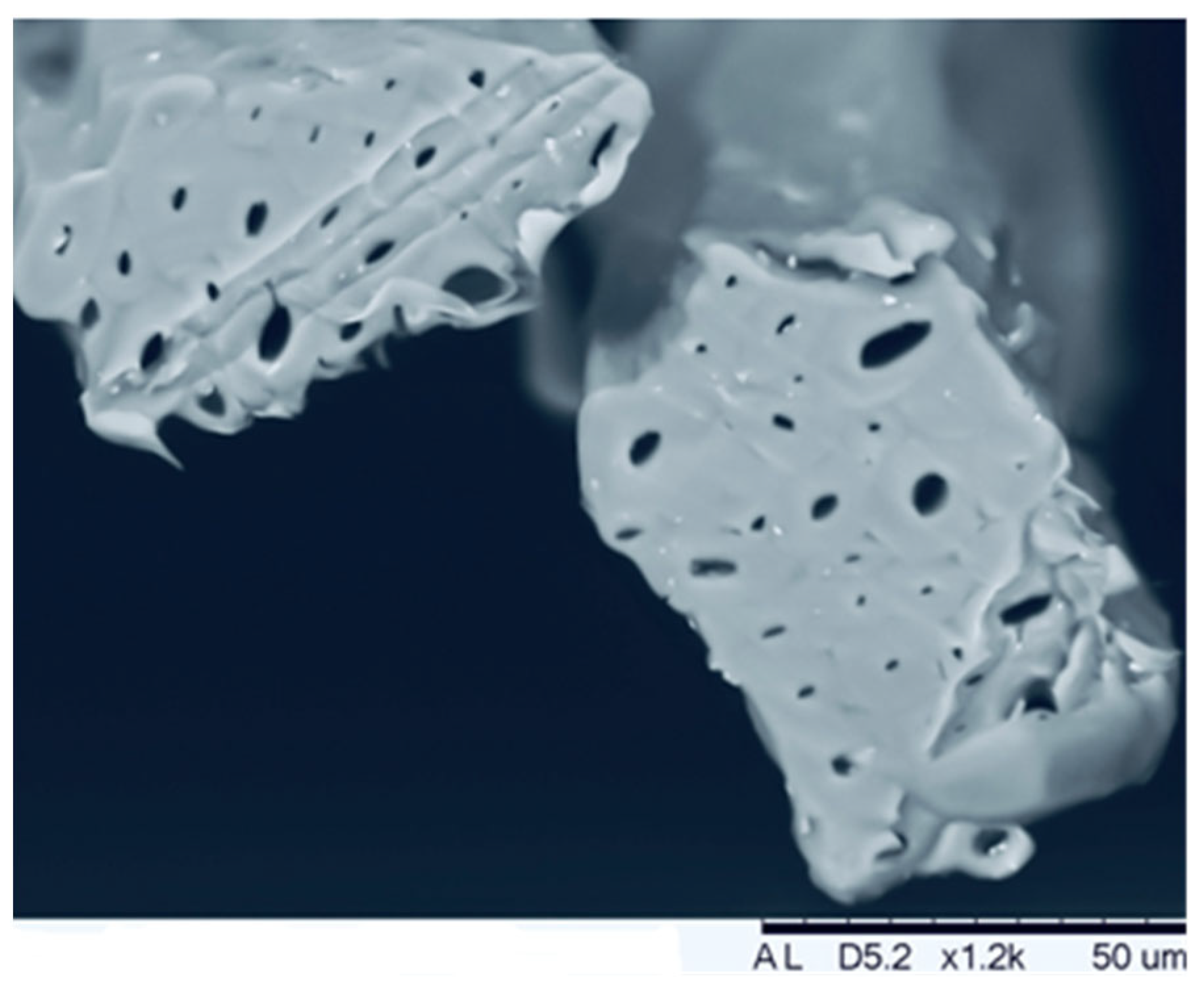

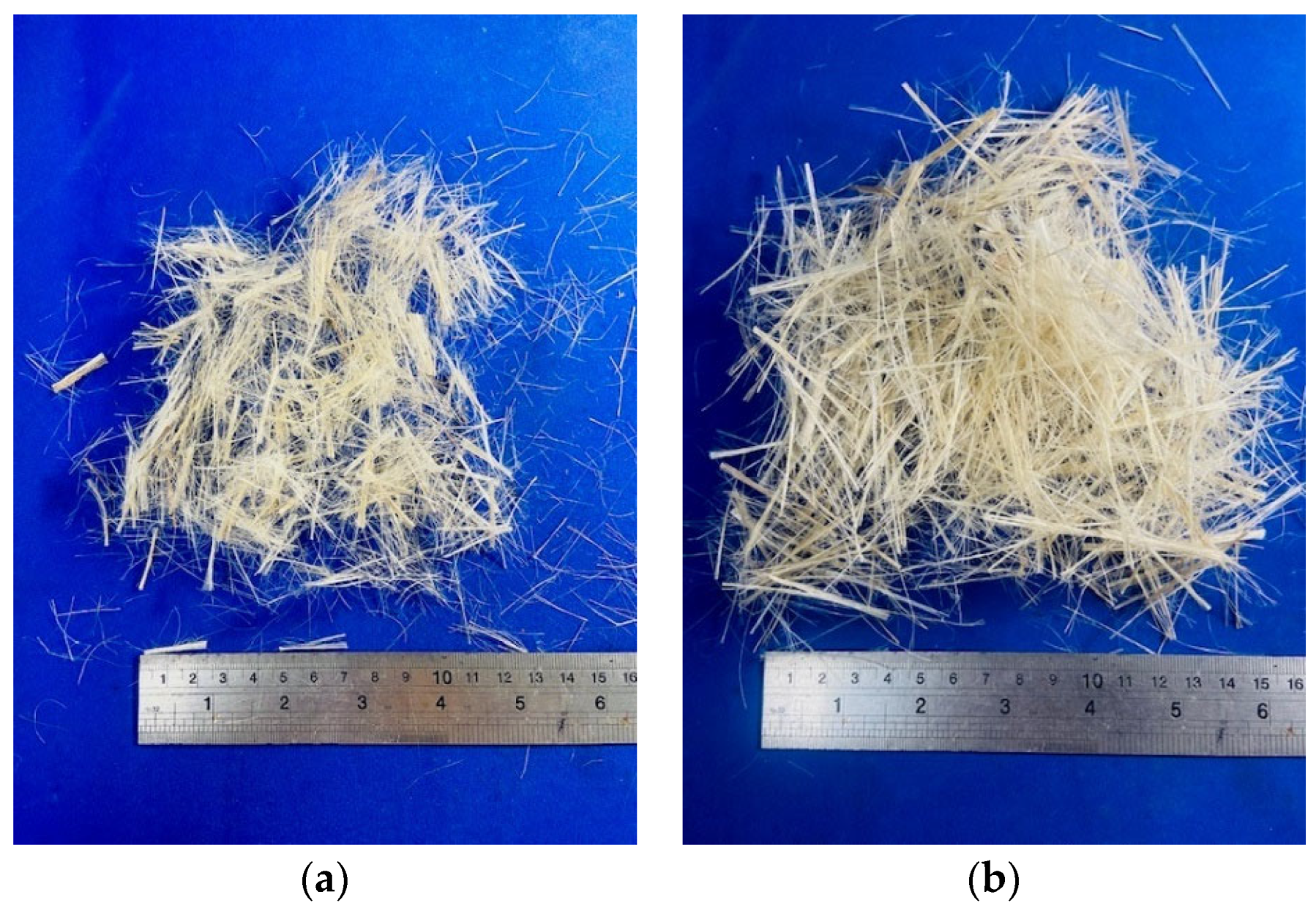

2.1. Jute Fibers

2.2. Short Jute-Fiber-Reinforced Mortars (SJFRM)

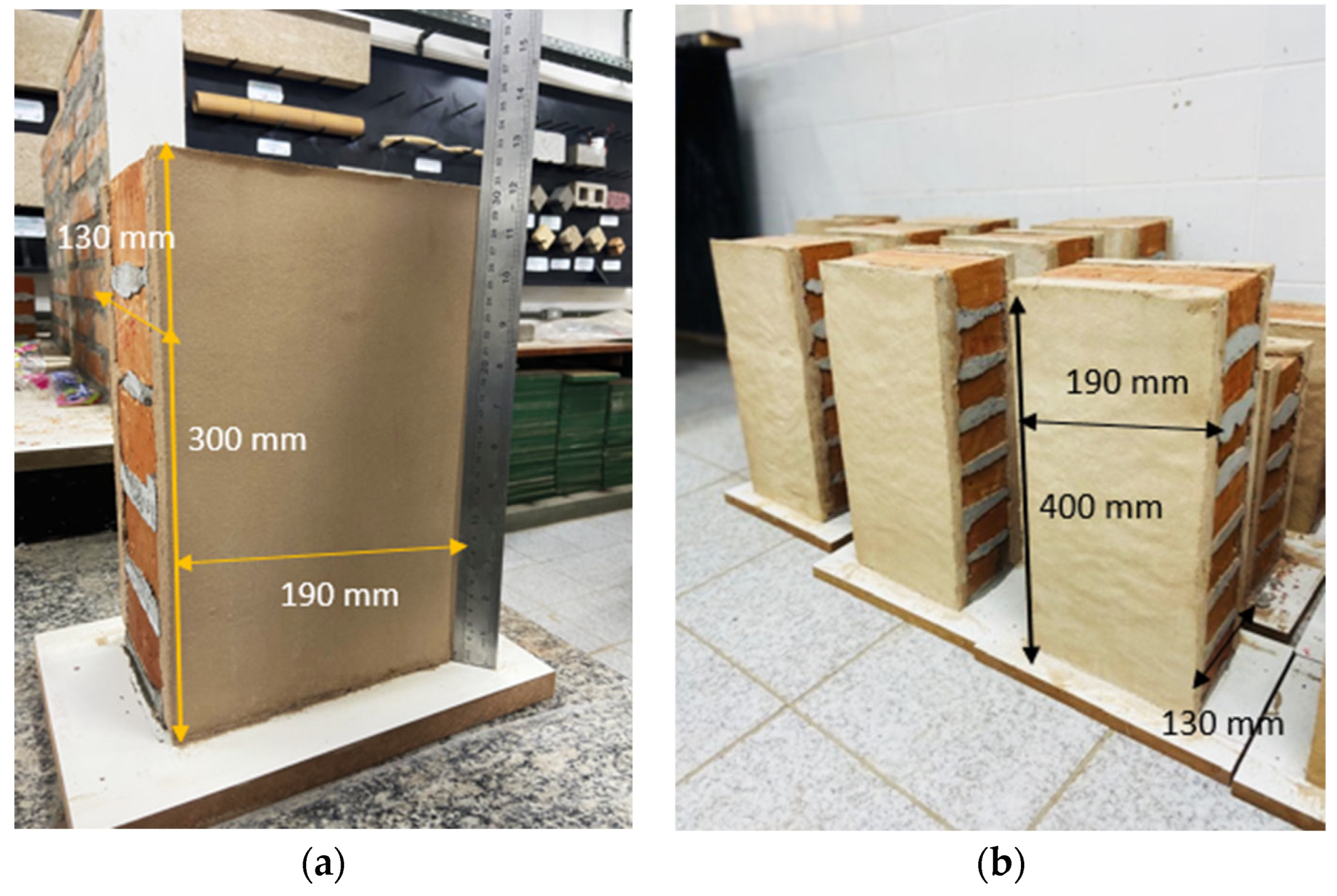

2.3. Retrofitting of Walls

3. Results

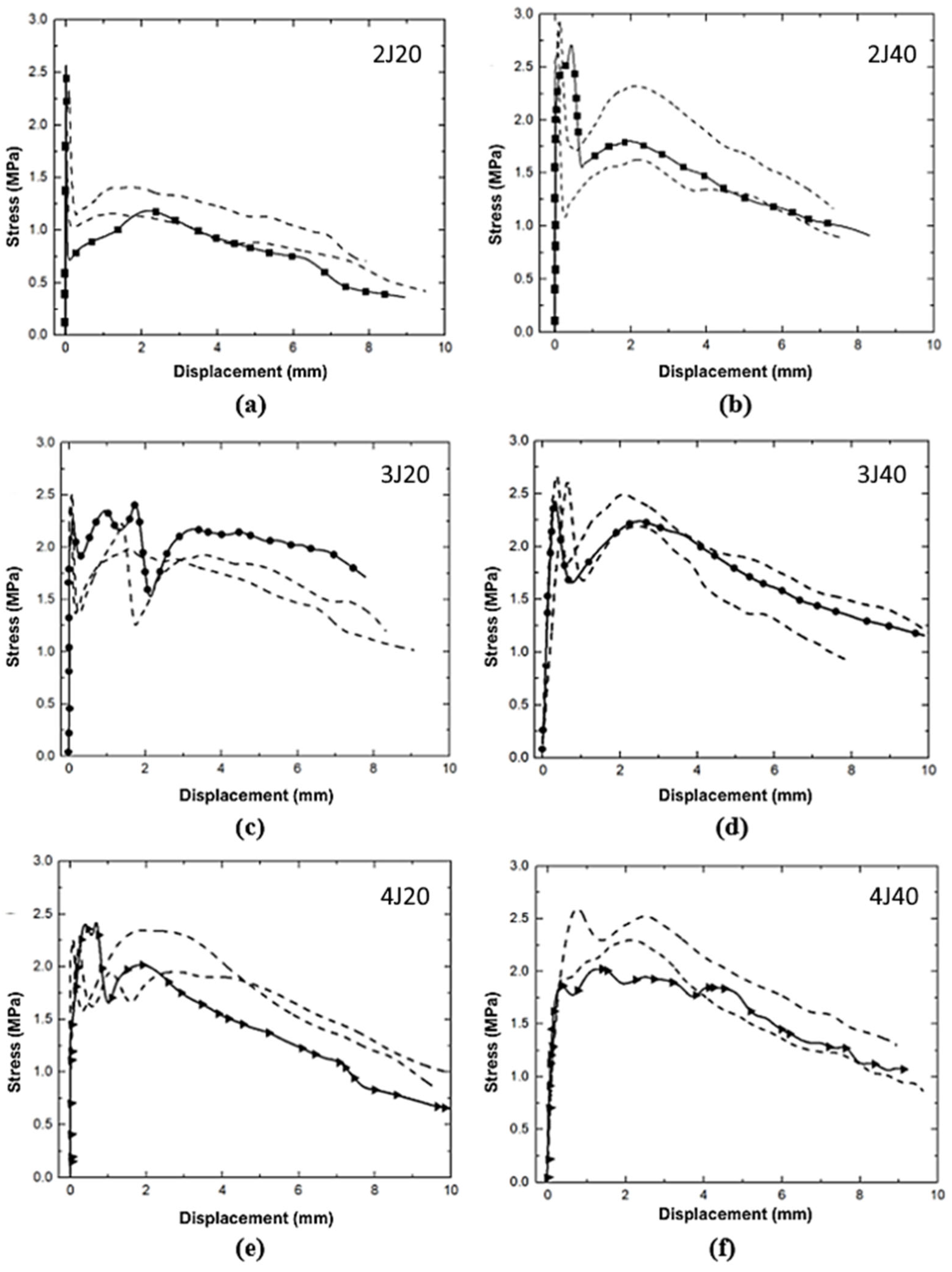

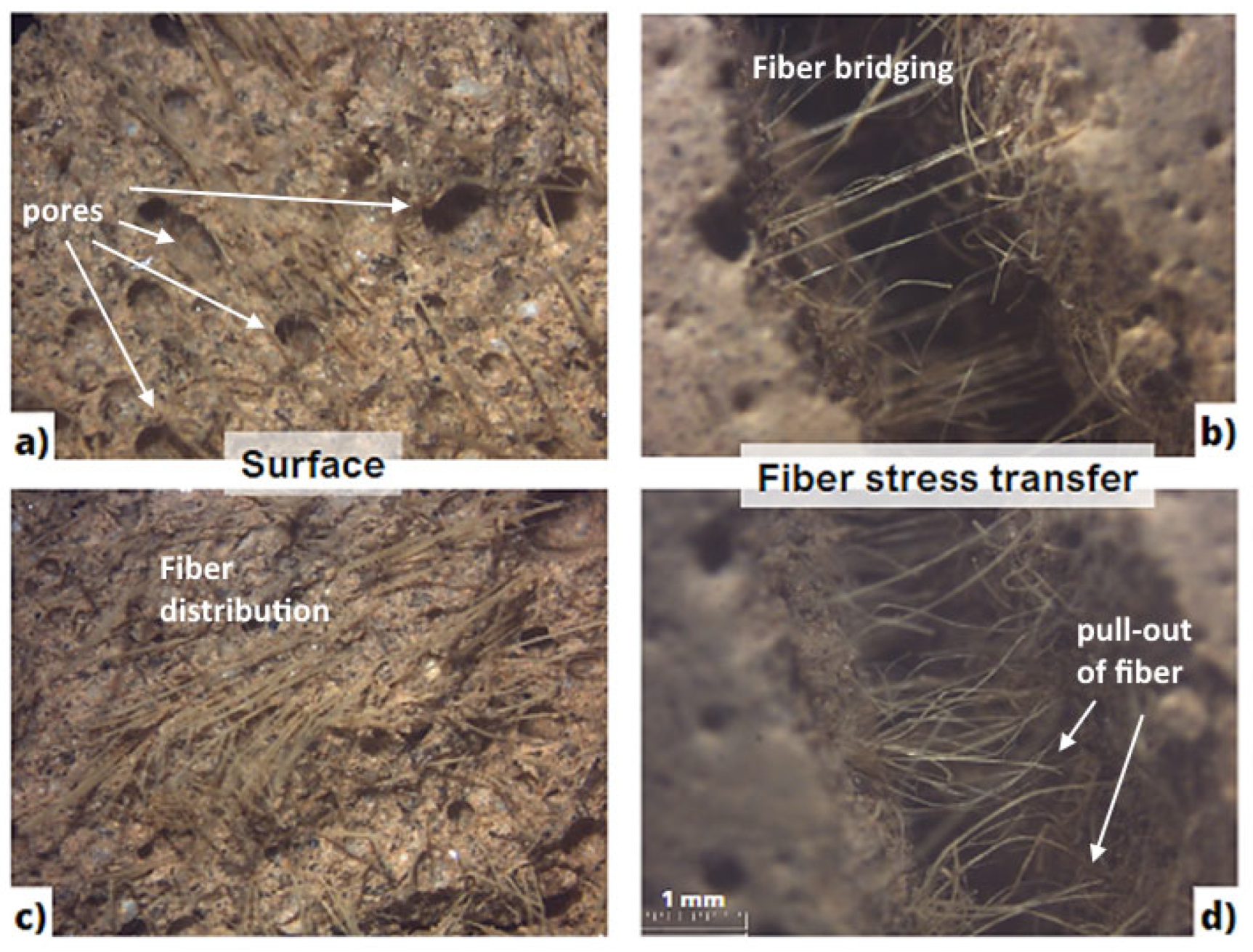

3.1. SJFRM Assessement

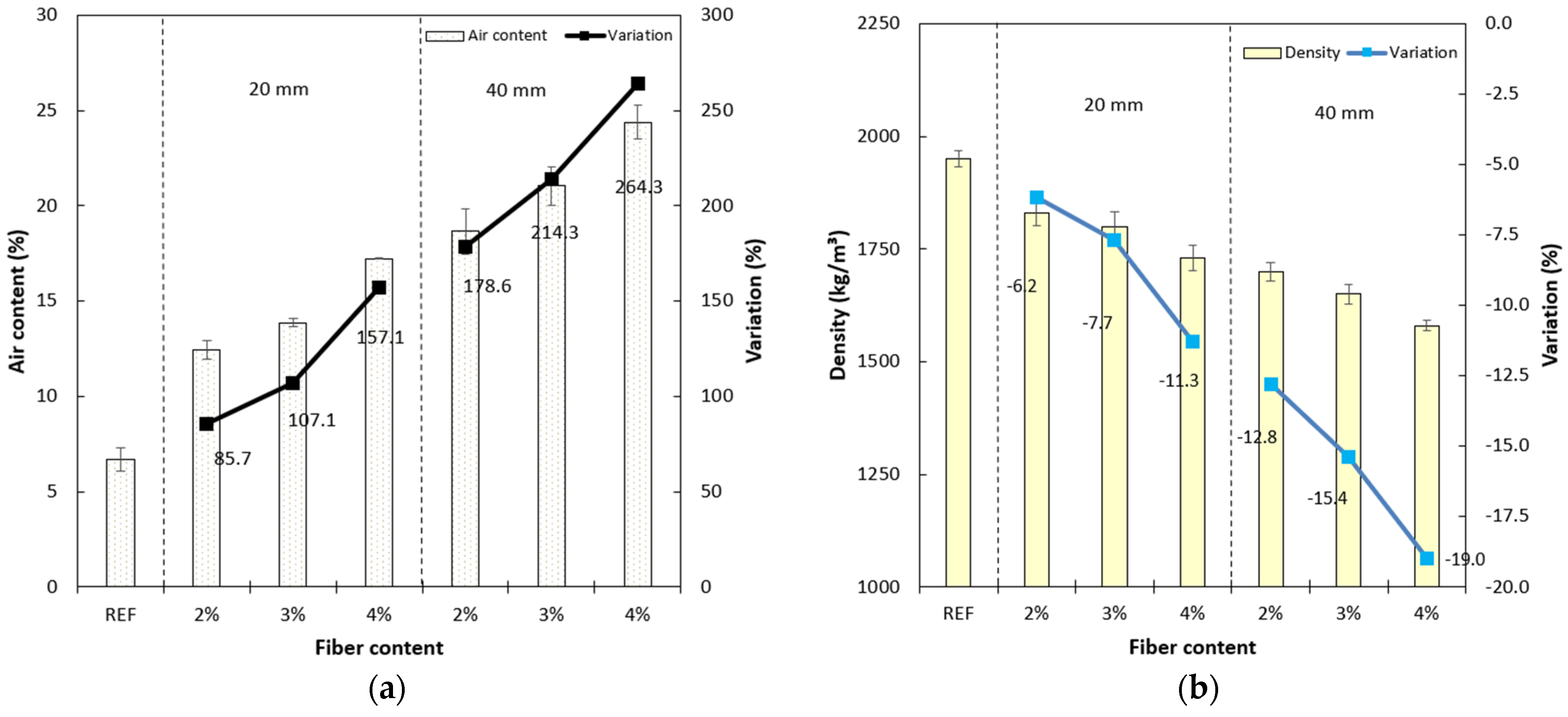

3.1.1. Properties in the Fresh State

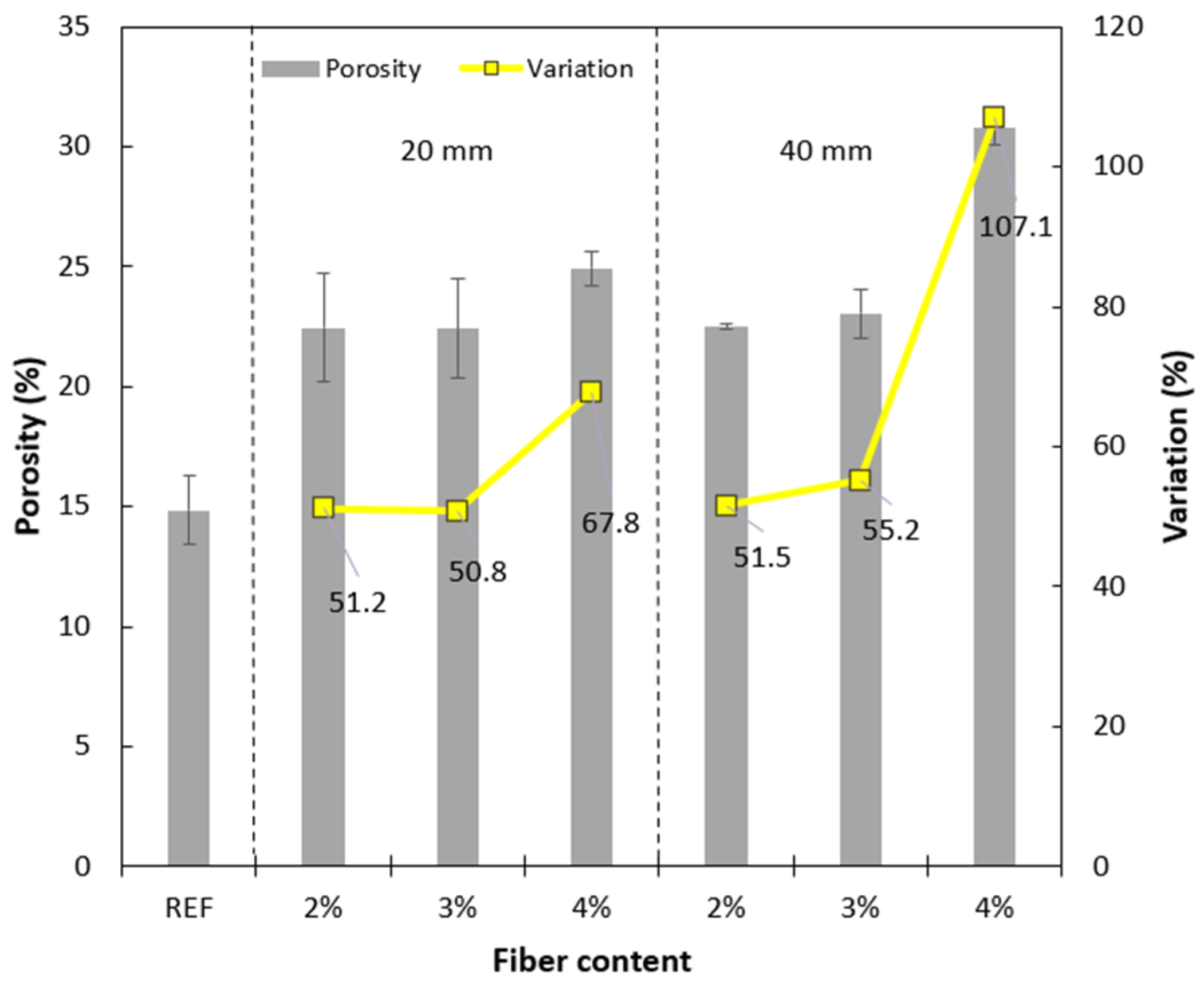

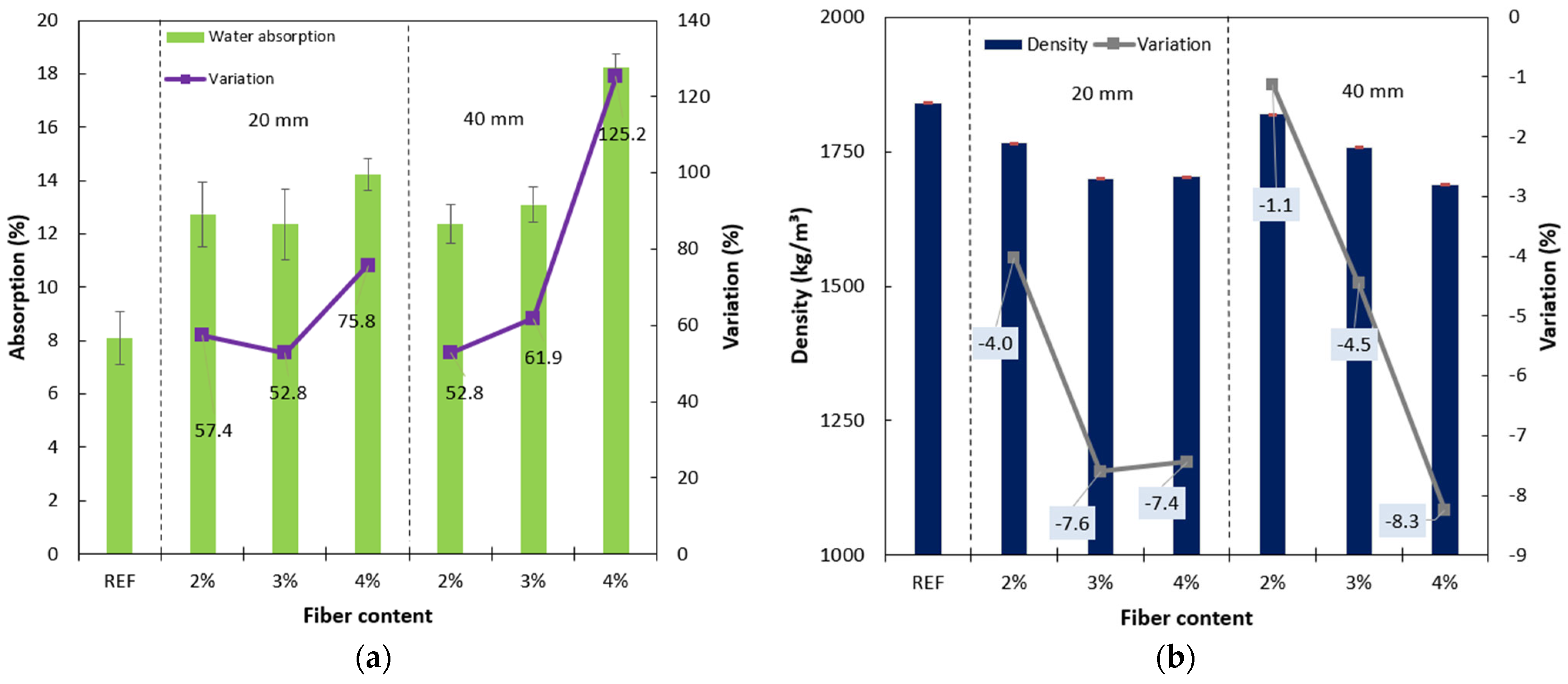

3.1.2. Physical Properties

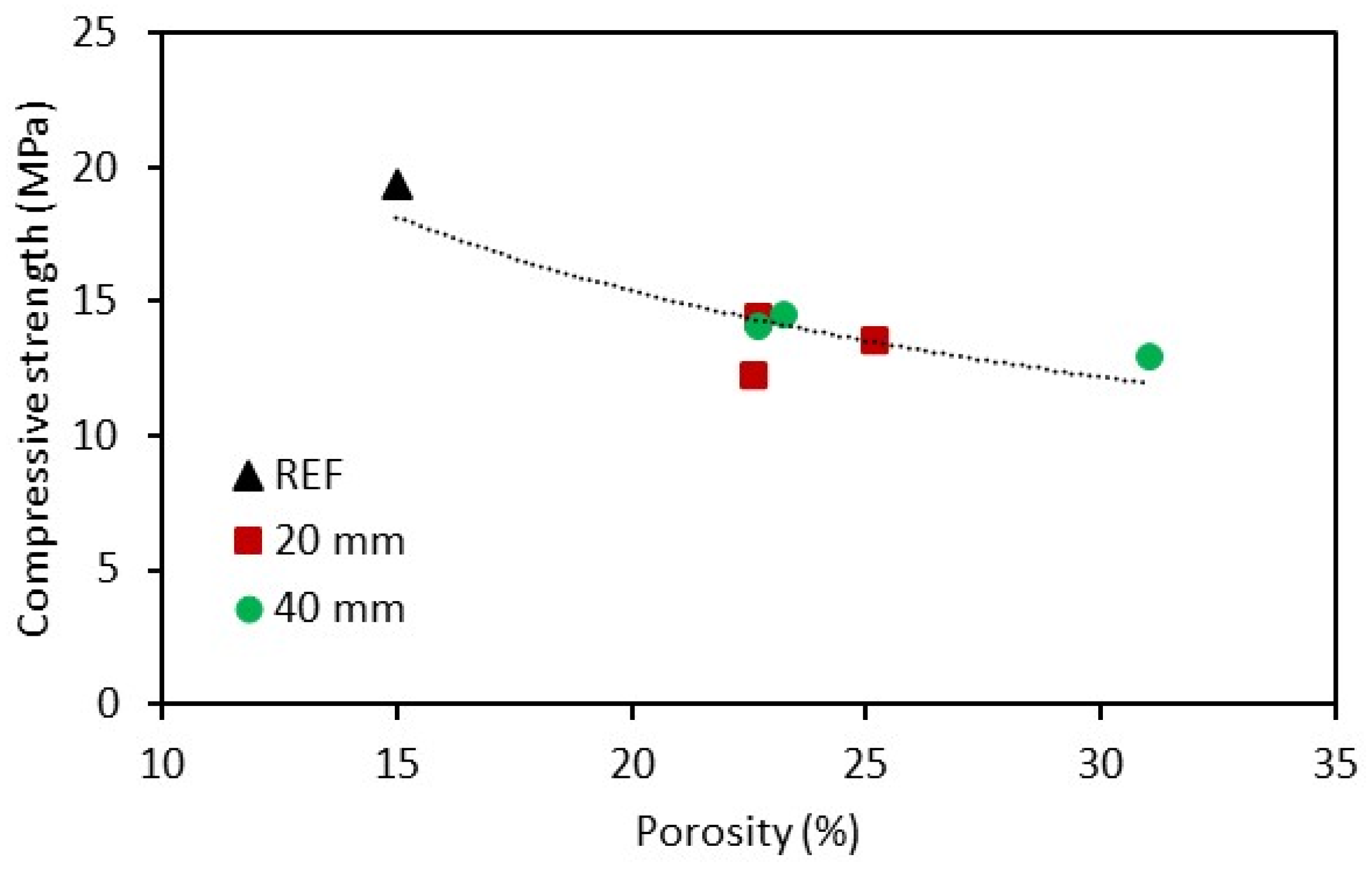

3.1.3. Mechanical Properties

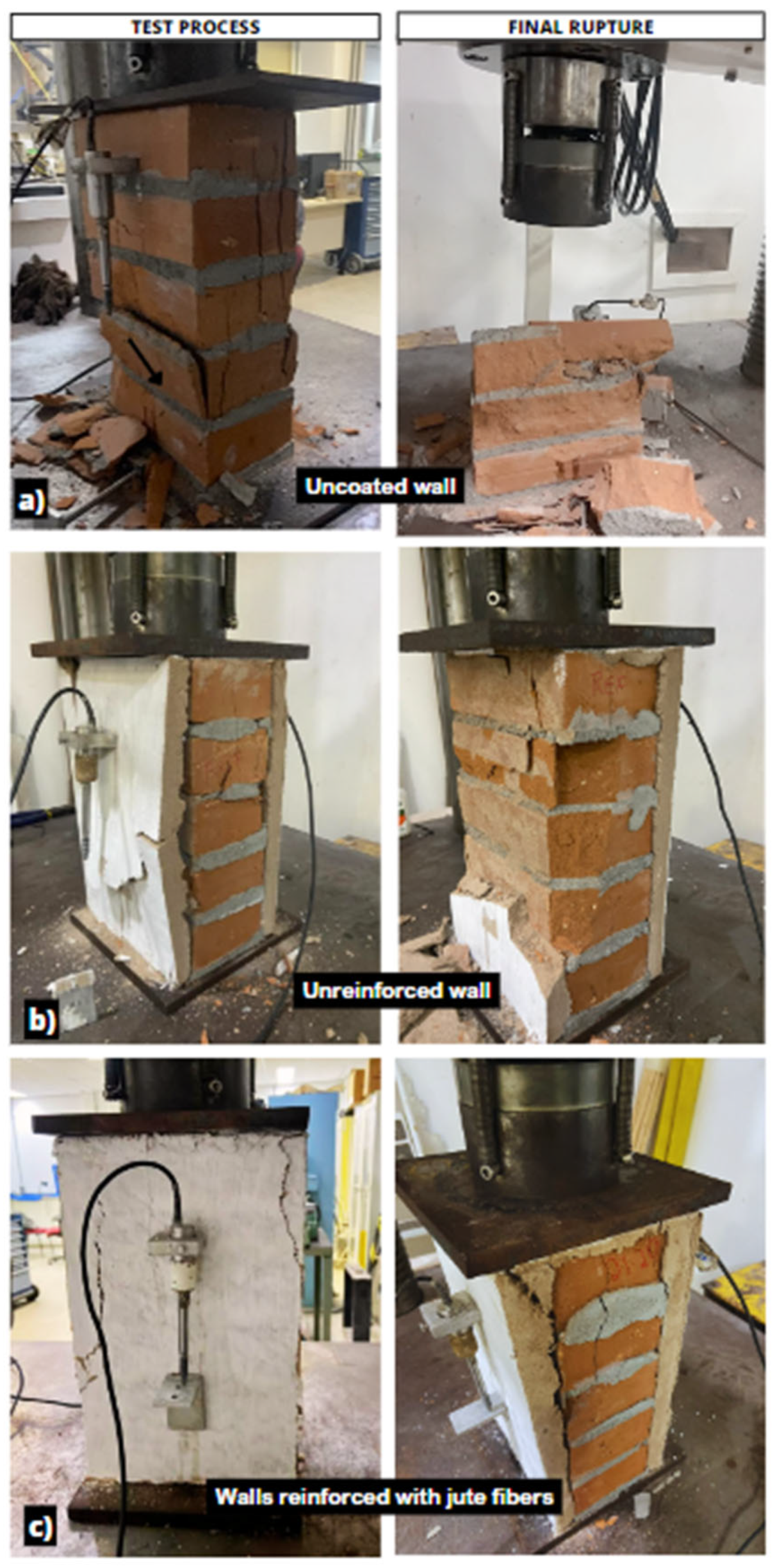

3.2. Retrofitting of Ceramic Brick Prisms

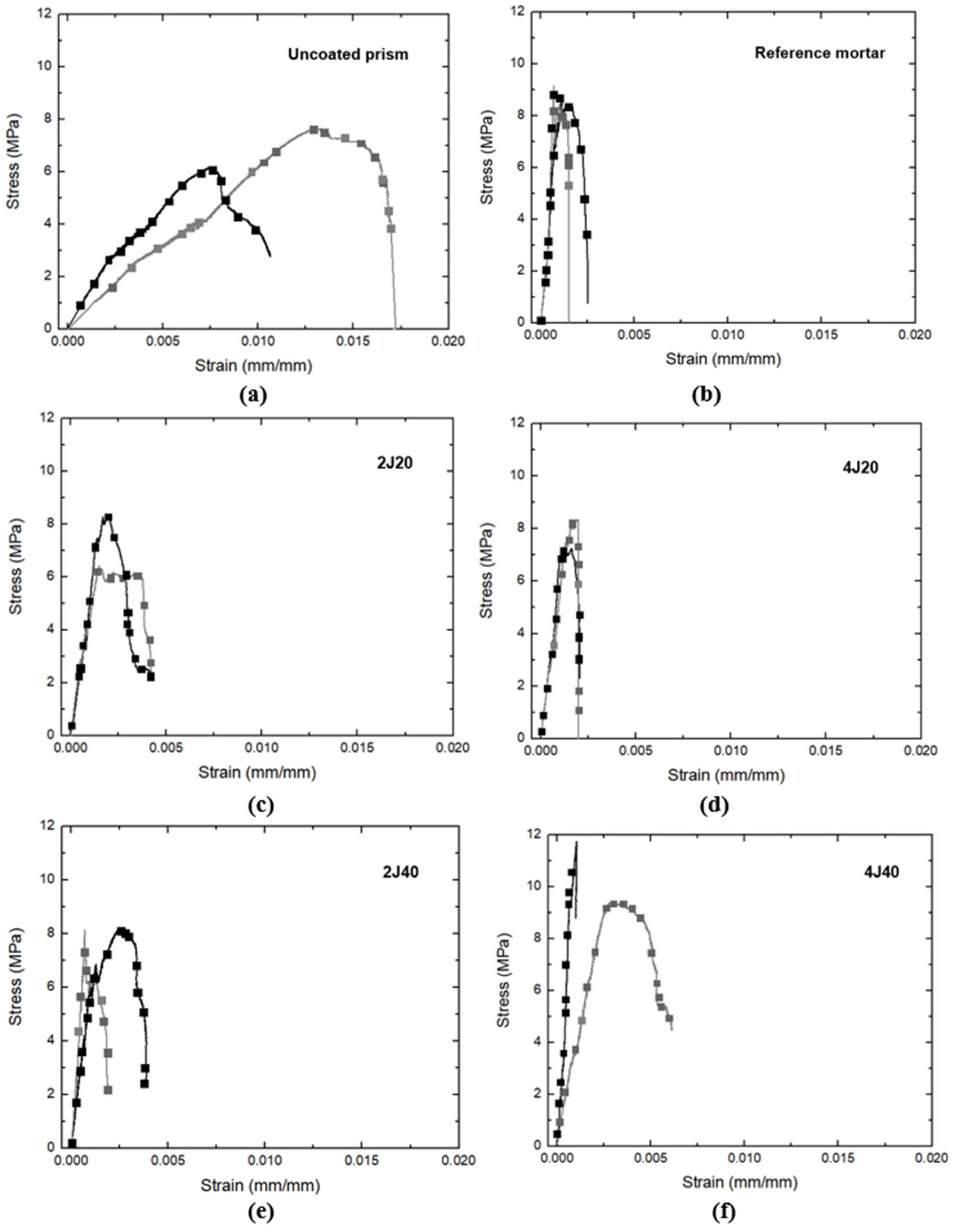

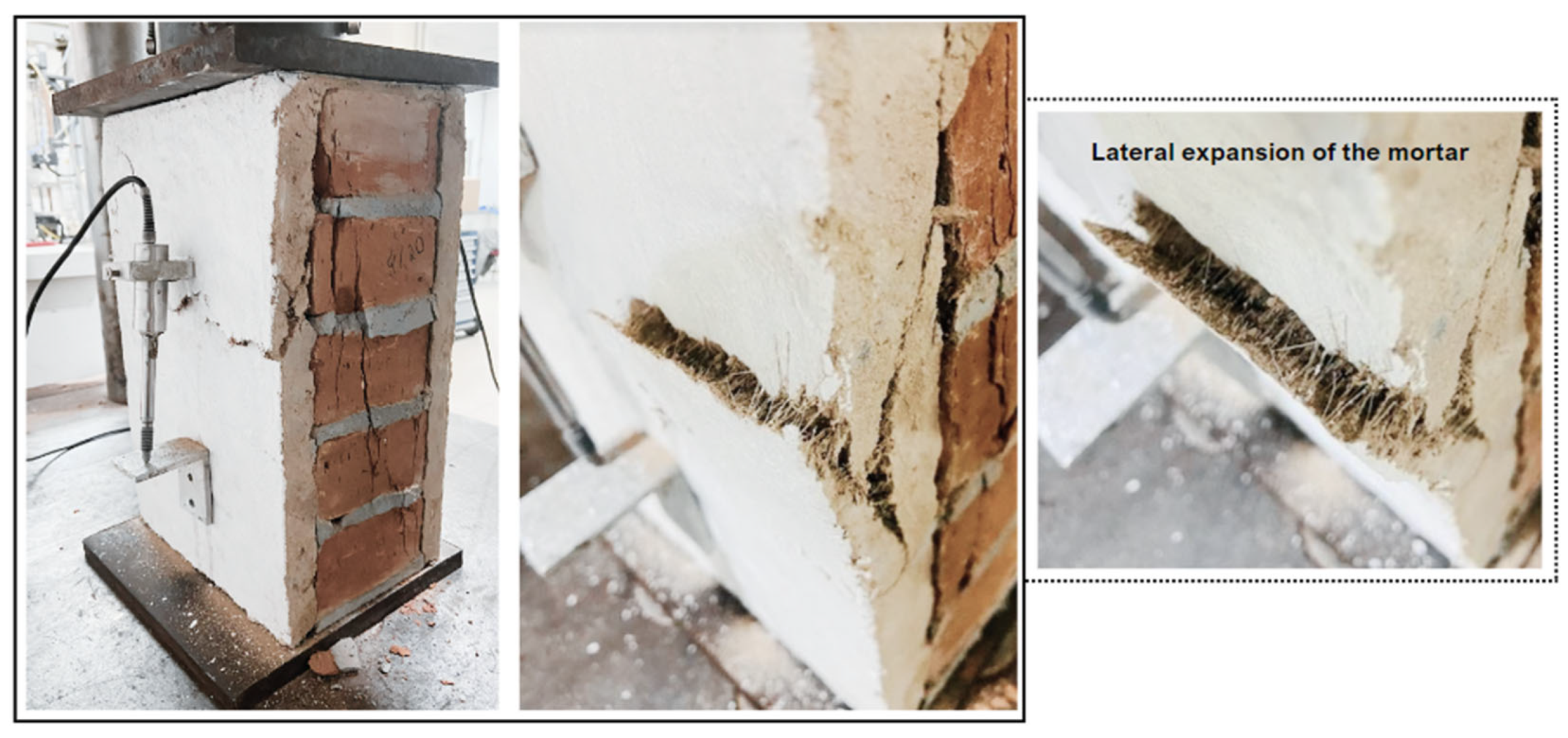

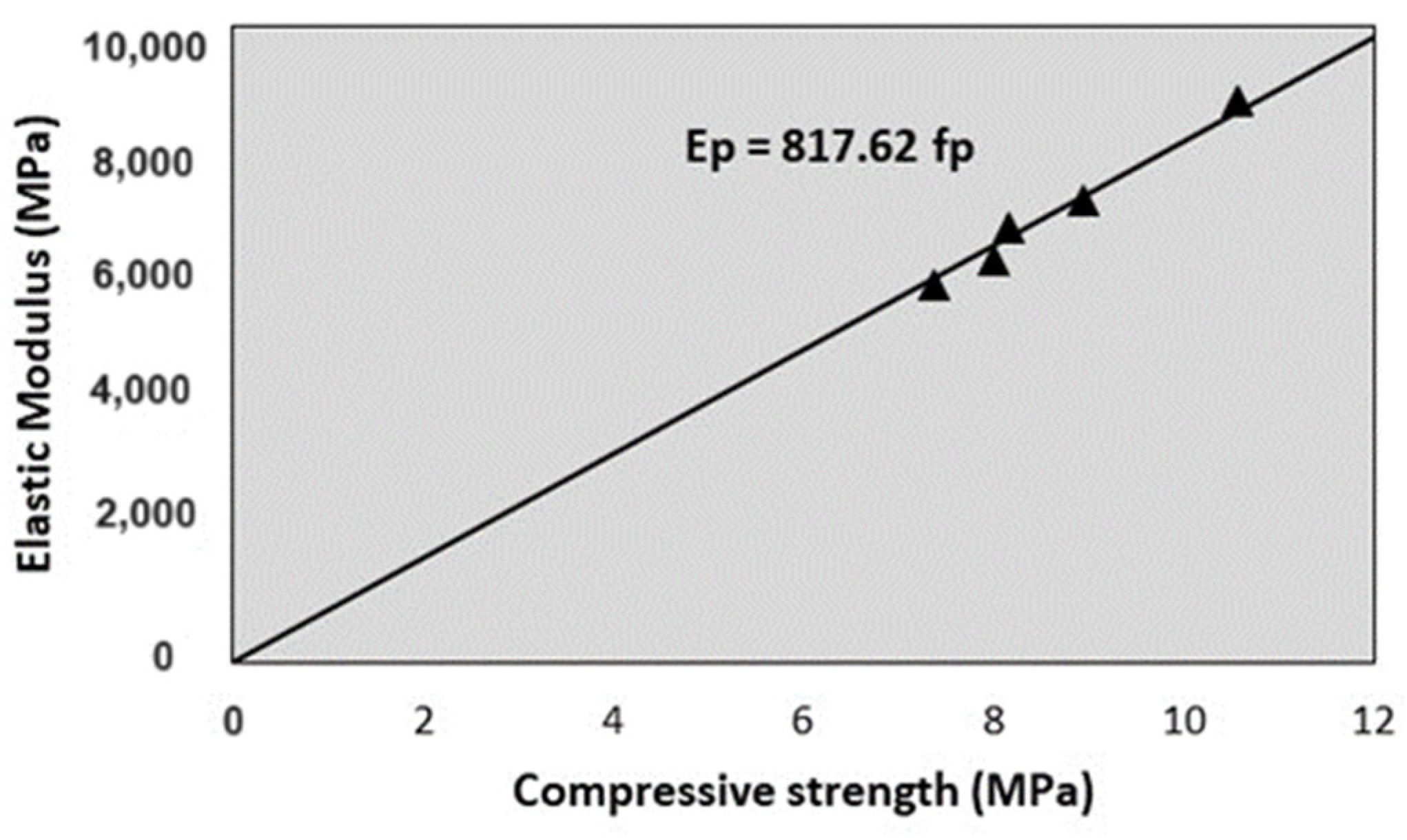

3.2.1. Compressive Behavior

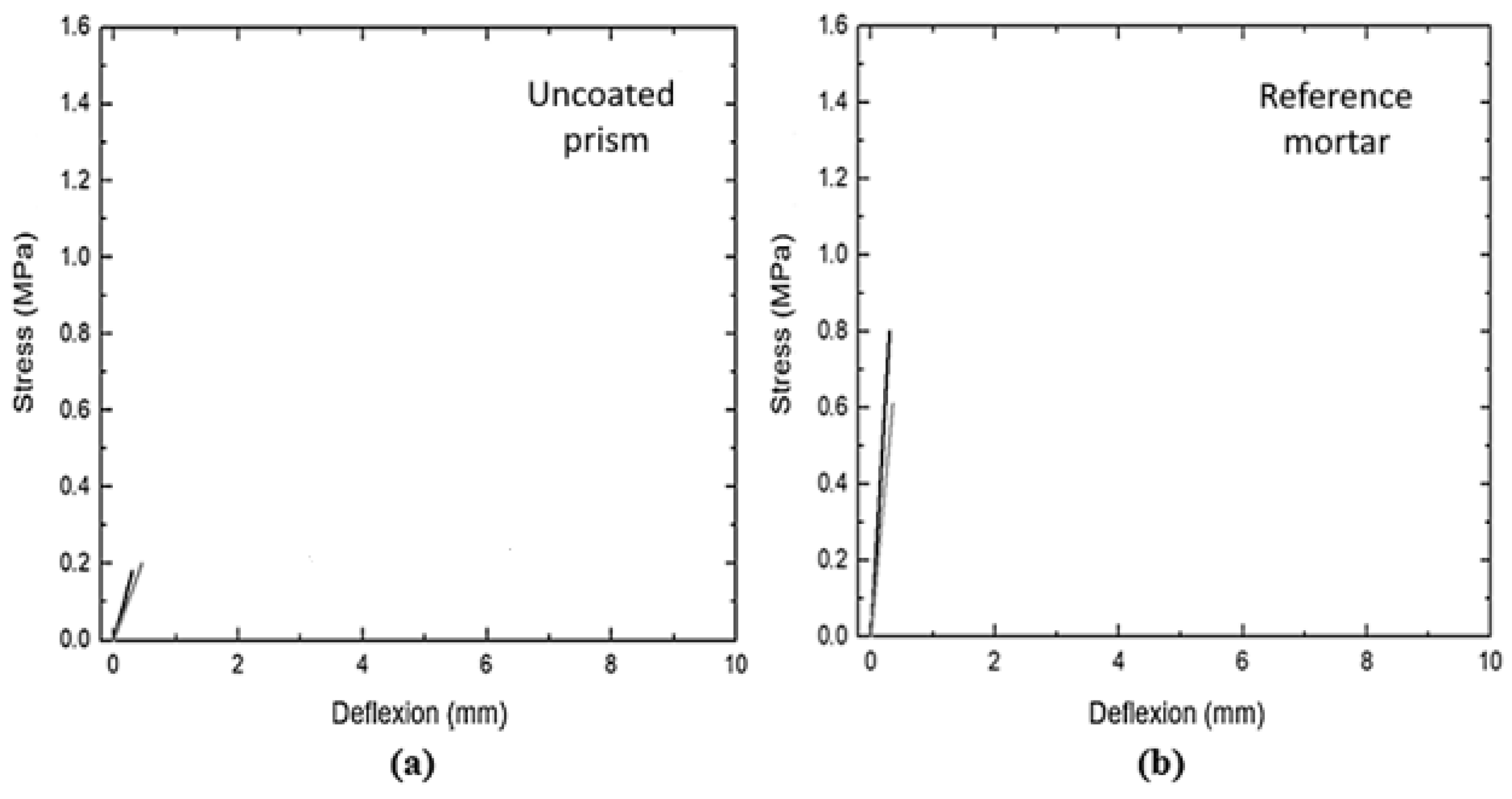

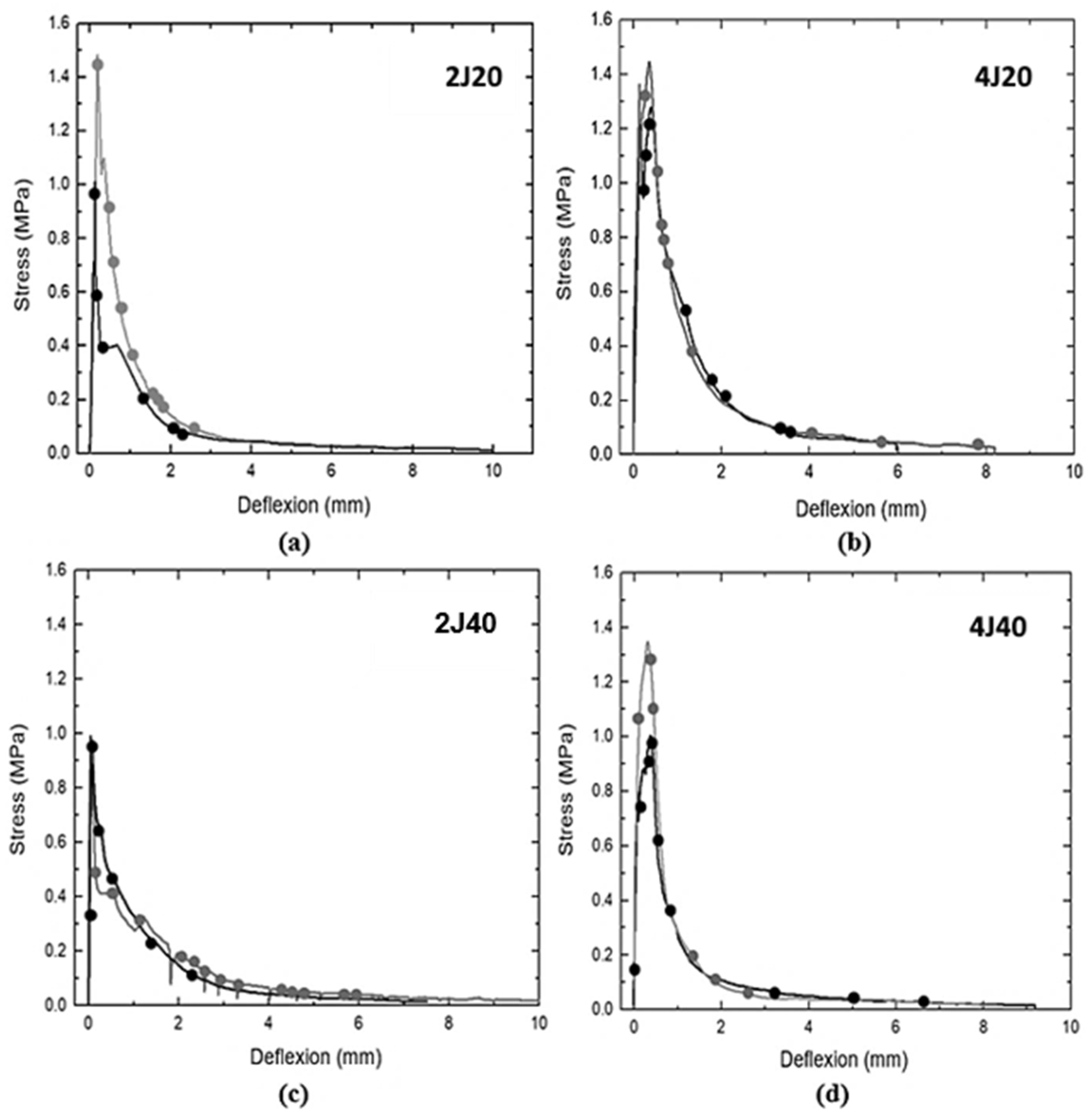

3.2.2. Flexural Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vicente, R.; Lagomarsino, S.; Ferreira, T.M.; Cattari, S.; Mendes da Silva, J.A.R. Cultural Heritage Monuments and Historical Buildings: Conservation Works and Structural Retrofitting. In Strengthening and Retrofitting of Existing Structures; 2018; pp. 25–57. Available online: https://link.springer.com/chapter/10.1007/978-981-10-5858-5_2 (accessed on 8 February 2024).

- Soleymani, A.; Jahangir, H.; Nehdi, M.L. Damage Detection and Monitoring in Heritage Masonry Structures: Systematic Review. Constr. Build. Mater. 2023, 397, 132402. [Google Scholar] [CrossRef]

- Torres, B.; Ivorra, S.; Javier Baeza, F.; Estevan, L.; Varona, B. Textile reinforced mortars (TRM) for repairing and retrofitting masonry walls subjected to in-plane cyclic loads. An experimental approach. Eng. Struct. 2020, 231, 111742. [Google Scholar] [CrossRef]

- Capozucca, R.; Magagnini, E. Brickwork Wall Models Strengthened with Diagonal and Horizontal GFRP Strips. Compos. Struct. 2021, 271, 114062. [Google Scholar] [CrossRef]

- Deboucha, W.; Alachek, I.; Plassiard, J.P.; Plé, O. New Composite Material for Masonry Repair: Mortar Formulations and Experimental Studies. Materials 2021, 14, 912. [Google Scholar] [CrossRef]

- Babaeidarabad, S.; Arboleda, D.; Loreto, G.; Nanni, A. Shear Strengthening of Un-Reinforced Concrete Masonry Walls with Fabric-Reinforced-Cementitious-Matrix. Constr. Build. Mater. 2014, 65, 243–253. [Google Scholar] [CrossRef]

- Garcia-Ramonda, L.; Pelá, L.; Roca, P.; Camata, G. In-Plane Shear Behaviour by Diagonal Compression Testing of Brick Masonry Walls Strengthened with Basalt and Steel Textile Reinforced Mortars. Constr. Build. Mater. 2020, 240, 117905. [Google Scholar] [CrossRef]

- Yavartanoo, F.; Kang, T.H.K. Retrofitting of Unreinforced Masonry Structures and Considerations for Heritage-Sensitive Constructions. J. Build. Eng. 2022, 49, 103993. [Google Scholar] [CrossRef]

- Sevil, T.; Baran, M.; Bilir, T.; Canbay, E. Use of Steel Fiber Reinforced Mortar for Seismic Strengthening. Constr. Build. Mater. 2011, 25, 892–899. [Google Scholar] [CrossRef]

- Kazem Sharbatdar, M.; Tajari, A. Experimental In-Plane Seismic Strengthening of Masonry Infilled Reinforced Concrete Frames by Engineered Cementitious Composites (ECC). Constr. Build. Mater. 2021, 293, 123529. [Google Scholar] [CrossRef]

- Cheng, S.; Yin, S.; Jing, L. Comparative Experimental Analysis on the In-Plane Shear Performance of Brick Masonry Walls Strengthened with Different Fiber Reinforced Materials. Constr. Build. Mater. 2020, 259, 120387. [Google Scholar] [CrossRef]

- de Carvalho Bello, C.B.; Boem, I.; Cecchi, A.; Gattesco, N.; Oliveira, D.V. Experimental Tests for the Characterization of Sisal Fiber Reinforced Cementitious Matrix for Strengthening Masonry Structures. Constr. Build. Mater. 2019, 219, 44–55. [Google Scholar] [CrossRef]

- Cevallos, O.A.; Olivito, R.S.; Codispoti, R.; Ombres, L. Flax and Polyparaphenylene Benzobisoxazole Cementitious Composites for the Strengthening of Masonry Elements Subjected to Eccentric Loading. Compos. B Eng. 2015, 71, 82–95. [Google Scholar] [CrossRef]

- Madhavi, K.; Vinay, G.N.; Renuka Devi, M.V.; Basutkar, S.M. Shear Behavior of Brick Masonry Strengthened with Jute Fiber Reinforced Composite. Mater. Today Proc. 2019, 46, 4746–4751. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Durante, M.; Zinno, A.; Balsamo, A.; Prota, A. Structural Behaviour of Masonry Panels Strengthened with an Innovative Hemp Fibre Composite Grid. Constr. Build. Mater. 2015, 100, 111–121. [Google Scholar] [CrossRef]

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Wachowicz, J. Comparative Analysis of Carbon, Ecological, and Water Footprints of Polypropylene-Based Composites Filled with Cotton, Jute and Kenaf Fibers. Materials 2020, 13, 3541. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Chen, K. Quantitative Assessment of Carbon Dioxide Emissions in Construction Projects: A Case Study in Shenzhen. J. Clean. Prod. 2017, 141, 394–408. [Google Scholar] [CrossRef]

- De Beus, N.; Carus, M.; Barth, M. Carbon Footprint and Sustainability of Different Natural Fibres for Biocomposites and Insulation Material. 2019. Available online: https://eiha.org/media/2019/03/19-03-13-Study-Natural-Fibre-Sustainability-Carbon-Footprint.pdf (accessed on 12 February 2024).

- Broeren, M.L.M.; Dellaert, S.N.C.; Cok, B.; Patel, M.K.; Worrell, E.; Shen, L. Life Cycle Assessment of Sisal Fibre—Exploring How Local Practices Can Influence Environmental Performance. J. Clean. Prod. 2017, 149, 818–827. [Google Scholar] [CrossRef]

- Vailati, M.; Mercuri, M.; Angiolilli, M.; Gregori, A. Natural-Fibrous Lime-Based Mortar for the Rapid Retrofitting of Heritage Masonry Buildings. Fibers 2021, 9, 68. [Google Scholar] [CrossRef]

- Lima, P.R.L.; Barros, J.A.O.; Roque, A.B.; Fontes, C.M.A.; Lima, J.M.F. Short Sisal Fiber Reinforced Recycled Concrete Block for One-Way Precast Concrete Slabs. Constr. Build. Mater. 2018, 187, 620–634. [Google Scholar] [CrossRef]

- Saini, K.; Matsagar, V.A.; Kodur, V.R. Recent Advances in the Use of Natural Fibers in Civil Engineering Structures. Constr. Build. Mater. 2024, 411, 134364. [Google Scholar] [CrossRef]

- Kurda, R. Effect of Silica Fume on Engineering Performance and Life Cycle Impact of Jute-Fibre-Reinforced Concrete. Sustainability 2023, 15, 8465. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Yang, W.; Wang, J.; Jin, L. Preparation and Properties of Pretreated Jute Fiber Cement-Based Composites. Ind. Crops Prod. 2024, 210, 118090. [Google Scholar] [CrossRef]

- de Klerk, M.D.; Kayondo, M.; Moelich, G.M.; de Villiers, W.I.; Combrinck, R.; Boshoff, W.P. Durability of Chemically Modified Sisal Fibre in Cement-Based Composites. Constr. Build. Mater. 2020, 241, 117835. [Google Scholar] [CrossRef]

- Ferreira, S.R.; de Silva, F.A.; Lima, P.R.L.; Toledo Filho, R.D. Effect of Hornification on the Structure, Tensile Behavior and Fiber Matrix Bond of Sisal, Jute and Curauá Fiber Cement Based Composite Systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Silva, F.D.A.; Lima, P.R.L.; Toledo Filho, R.D. Effect of fiber treatments on the sisal fiber properties and fiber-matrix bond in cement based systems. Constr. Build. Mater. 2017, 101, 730–740. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic Fiber Reinforced Cement-Based Composites: A Review of Recent Research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Liu, J.; Lv, C. Research Progress on Durability of Cellulose Fiber-Reinforced Cement-Based Composites. Int. J. Polym. Sci. 2021, 2021, 1014531. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Andrade Silva, F.; Mobasher, B.; Müller, S.; Mechtcherine, V. Interface Characteristics of Jute Fiber Systems in a Cementitious Matrix. Cem. Concr. Res. 2019, 116, 252–265. [Google Scholar] [CrossRef]

- ABNT NBR 13276; Mortars Applied on Walls and Ceilings—Determination of the Consistence Index. ABNT: Rio de Janeiro, Brazil, 2016.

- ABNT NBR 13278; Mortars Applied on Walls and Ceilings—Determination of the Specific Gravity and the Air Entrained Content in the Fresh Stage. ABNT: Rio de Janeiro, Brazil, 2005.

- ABNT NBR 9778; Hardened Mortar and Concrete—Determination of Water Absorption by Immersion—Void Index and Mass Specific. ABNT: Rio de Janeiro, Brazil, 2009.

- ABNT NBR 7170; Ceramic Solid Brick for Masonry-Specification. ABNT: Rio de Janeiro, Brazil, 1983.

- ASTM C1314-16; Standard Test Method for Compressive Strength of Masonry Prisms. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM E518/E518M-15; Standard Test Methods for Flexural Bond Strength of Masonry. ASTM International: West Conshohocken, PA, USA, 2021.

- Shi, X.; Park, P.; Rew, Y.; Huang, K.; Sim, C. Constitutive Behaviors of Steel Fiber Reinforced Concrete under Uniaxial Compression and Tension. Constr. Build. Mater. 2020, 233, 117316. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Frattolillo, A.; Valdes, M.; Mancusi, G.; Martinelli, E. Jute Fiber-Reinforced Mortars: Mechanical Response and Thermal Performance. J. Build. Eng. 2023, 66, 105888. [Google Scholar] [CrossRef]

- Song, H.; Liu, J.; He, K.; Ahmad, W. A Comprehensive Overview of Jute Fiber Reinforced Cementitious Composites. Case Stud. Constr. Mater. 2021, 15, e00724. [Google Scholar] [CrossRef]

- BS EN 998-1; Specification for Mortar for Masonry-Part 1: Rendering and Plastering Mortar. BS EN: Brussels, Belgium, 2016.

- Thamboo, J.; Bandara, J.; Perera, S.; Navaratnam, S.; Poologanathan, K.; Corradi, M. Experimental and Analytical Study of Masonry Subjected to Uniaxial Cyclic Compression. Materials 2020, 13, 4505. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.H.; Park, J.H. Investigation of Steel Fiber-Reinforced Mortar Overlay for Strengthening Masonry Walls by Prism Tests. Appl. Sci. 2020, 10, 6395. [Google Scholar] [CrossRef]

- Yu, J.H.; Park, J.H. Compressive and Diagonal Tension Strengths of Masonry Prisms Strengthened with Amorphous Steel Fiber-Reinforced Mortar Overlay. Appl. Sci. 2021, 11, 5974. [Google Scholar] [CrossRef]

- Lucchini, S.S.; Facconi, L.; Minelli, F.; Plizzari, G. Retrofitting Unreinforced Masonry by Steel Fiber Reinforced Mortar Coating: Uniaxial and Diagonal Compression Tests. Mater. Struct. 2020, 53, 144. [Google Scholar] [CrossRef]

- Fortes, E.S.; Parsekian, G.A.; Camacho, J.S.; Fonseca, F.S. Compressive Strength of Masonry Constructed with High Strength Concrete Blocks. Rev. IBRACON De Estrut. E Mater. 2017, 10, 1273–1319. [Google Scholar] [CrossRef]

- Caldeira, F.E.; Nalon, G.H.; de Oliveira, D.S.; Pedroti, L.G.; Ribeiro, J.C.L.; Ferreira, F.A.; de Carvalho, J.M.F. Influence of Joint Thickness and Strength of Mortars on the Compressive Behavior of Prisms Made of Normal and High-Strength Concrete Blocks. Constr. Build. Mater. 2020, 234, 117419. [Google Scholar] [CrossRef]

- Drougkas, A.; Roca, P.; Molins, C. Numerical Prediction of the Behavior, Strength and Elasticity of Masonry in Compression. Eng. Struct. 2015, 90, 15–28. [Google Scholar] [CrossRef]

- Padalu, P.K.V.R.; Singh, Y.; Das, S. Efficacy of Basalt Fibre Reinforced Cement Mortar Composite for Out-of-Plane Strengthening of Unreinforced Masonry. Constr. Build. Mater. 2018, 191, 1172–1190. [Google Scholar] [CrossRef]

| Cement | FA | Metakaolin | Sand | Water | SP | Fiber | VMA |

|---|---|---|---|---|---|---|---|

| 291.25 | 116.50 | 174.75 | 1165.01 | 349.50 | 5.24 | - | - |

| 288.67 | 115.46 | 173.19 | 1154.66 | 346.39 | 15.39 | 11.54 | 1.04 |

| 287.39 | 114.95 | 172.43 | 1149.56 | 344.86 | 22.99 | 17.24 | 1.04 |

| 285.20 | 114.08 | 171.12 | 1140.81 | 342.24 | 28.52 | 22.82 | 1.25 |

| Mix | Fiber Content | Fiber Length |

|---|---|---|

| REF | No fiber | No fiber |

| 2J20 | 2% | 20 mm |

| 3J20 | 3% | |

| 4J20 | 4% | |

| 2J40 | 2% | 40 mm |

| 3J40 | 3% | |

| 4J40 | 4% |

| Mix | Compressive Strentgh (MPa) | Elastic Modulus (GPa) | σf (MPa) | σu (MPa) |

|---|---|---|---|---|

| REF | 19.36 (0.23) | 20.99 (3.37) | 3.14 (0.06) | - |

| 2J20 | 14.41 (0.49) | 16.36 (2.62) | 2.46 (0.07) | 1.28 (0.17) |

| 3J20 | 12.27 (0.12) | 15.28 (5.47) | 2.45 (0.02) | 2.17 (0.50) |

| 4J20 | 13.59 (1.12) | 17.09 (4.46) | 2.37 (0.07) | 2.29 (0.26) |

| 2J40 | 14.01 (0.24) | 12.58 (0.29) | 2.97 (0.08) | 1.83 (0.46) |

| 3J40 | 14.45 (1.72) | 13.83 (2.71) | 2.64 (0.07) | 2.44 (0.03) |

| 4J40 | 12.94 (0.61) | 13.02 (2.49) | 2.34 (0.24) | 2.25 (0.24) |

| Coating Type | Sample | Compressive Strength (MPa) | Stiffness (MPa) | Mode of Failure |

|---|---|---|---|---|

| Uncoated | 1 | 6.16 | 1254.23 |  |

| 2 | 7.62 | 641. 84 | ||

| Average | 6.89 | 948.03 | ||

| SD | 1.04 | 433.03 | ||

| REF | 3 | 8.75 | 7334.78 |  |

| 4 | 9.14 | 7171.07 | ||

| Average | 8.94 | 7252.92 | ||

| SD | 0.27 | 115.76 | ||

| 2J20 | 5 | 8.32 | 5290.54 |  |

| 6 | 6.42 | 6548.89 | ||

| Average SD | 7.37 | 5919.71 | ||

| 1.35 | 889.79 | |||

| 4J20 | 7 | 7.23 | 6672.78 |  |

| 8 | 8.77 | 5960.01 | ||

| Average | 8.00 | 6316.40 | ||

| SD | 1.09 | 504.01 | ||

| 2J40 | 9 | 8.17 | 6951.50 |  |

| 10 | 8.14 | 6692.31 | ||

| Average | 8.16 | 6821.90 | ||

| SD | 0.02 | 183.27 | ||

| 4J40 | 11 | 11.73 | 9218.45 |  |

| 12 | 9.41 | 8428.60 | ||

| Average | 10.57 | 8823.52 | ||

| SD | 1.64 | 558.51 |

| Coating Type | Sample | Flexural Strength (MPa) | Ultimate Deflection (mm) | Toughness (N·mm) |

|---|---|---|---|---|

| Uncoated | 1 | 0.18 | 0.05 | 0.04 |

| 2 | 0.20 | 0.02 | 0.05 | |

| Average | 0.19 | 0.03 | 0.04 | |

| SD | 0.01 | 0.02 | 0.00 | |

| REF | 3 | 0.80 | 0.15 | 0.16 |

| 4 | 0.61 | 0.13 | 0.22 | |

| Average | 0.71 | 0.14 | 0.19 | |

| SD | 0.13 | 0.02 | 0.04 | |

| 2J20 | 5 | 1.00 | 10.00 | 0.87 |

| 6 | 1.48 | 7.92 | 1.25 | |

| Average SD | 1.24 | 8.96 | 1.06 | |

| 0.34 | 1.47 | 0.26 | ||

| 4J20 | 7 | 1.28 | 5.97 | 1.61 |

| 8 | 1.45 | 8.19 | 1.73 | |

| Average | 1.37 | 7.08 | 1.67 | |

| SD | 0.12 | 1.57 | 0.09 | |

| 2J40 | 9 | 0.98 | 9.99 | 1.03 |

| 10 | 0.01 | 7.51 | 0.07 | |

| Average | 1.01 | 8.75 | 1.07 | |

| SD | 1.38 | 1.76 | 1.16 | |

| 4J40 | 11 | 1.01 | 9.18 | 1.07 |

| 12 | 1.38 | 8.30 | 1.16 | |

| Average | 1.20 | 8.74 | 1.11 | |

| SD | 0.26 | 0.63 | 0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farias, L.d.N.; Lima, P.R.L.; Filho, R.D.T. Short Jute Fiber Reinforced Cement Mortar for Out-of-Plane Strengthening of Masonry Prisms. Sustainability 2024, 16, 5675. https://doi.org/10.3390/su16135675

Farias LdN, Lima PRL, Filho RDT. Short Jute Fiber Reinforced Cement Mortar for Out-of-Plane Strengthening of Masonry Prisms. Sustainability. 2024; 16(13):5675. https://doi.org/10.3390/su16135675

Chicago/Turabian StyleFarias, Lidianne do Nascimento, Paulo Roberto Lopes Lima, and Romildo Dias Toledo Filho. 2024. "Short Jute Fiber Reinforced Cement Mortar for Out-of-Plane Strengthening of Masonry Prisms" Sustainability 16, no. 13: 5675. https://doi.org/10.3390/su16135675

APA StyleFarias, L. d. N., Lima, P. R. L., & Filho, R. D. T. (2024). Short Jute Fiber Reinforced Cement Mortar for Out-of-Plane Strengthening of Masonry Prisms. Sustainability, 16(13), 5675. https://doi.org/10.3390/su16135675