Assessment and Driving Factors of Embodied Carbon Emissions in the Construction Sector: Evidence from 2005 to 2021 in Northeast China

Abstract

:1. Introduction

1.1. Approaches and Models for Assessing Carbon Emissions

1.2. Logarithmic Mean Divisia Index (LMDI)

1.3. Global Initiatives and Strategies for Carbon Emission Mitigation

2. Methodology

2.1. Embodied Carbon Assessment

2.2. Decomposition Model

2.3. Data Collection

3. Results and Discussion

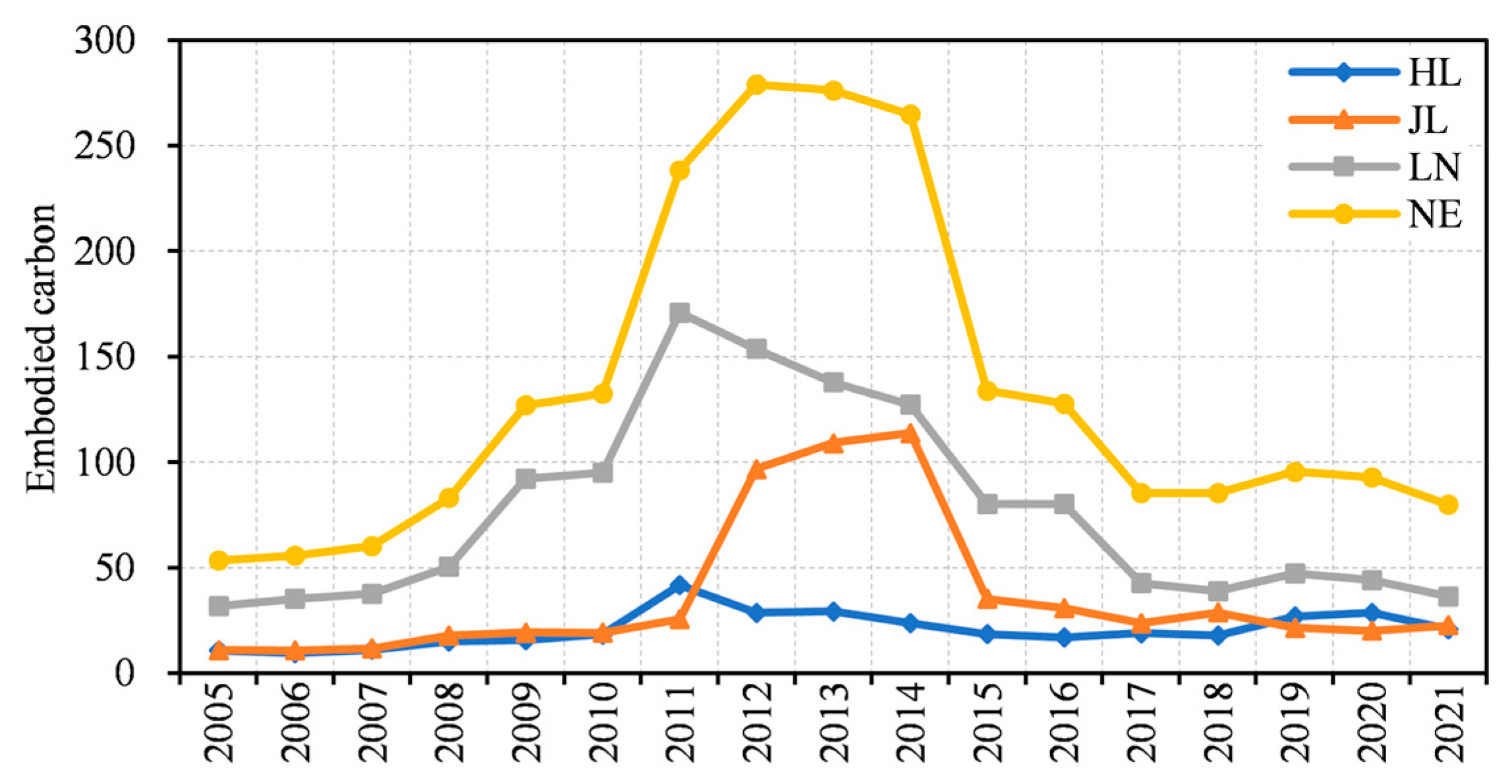

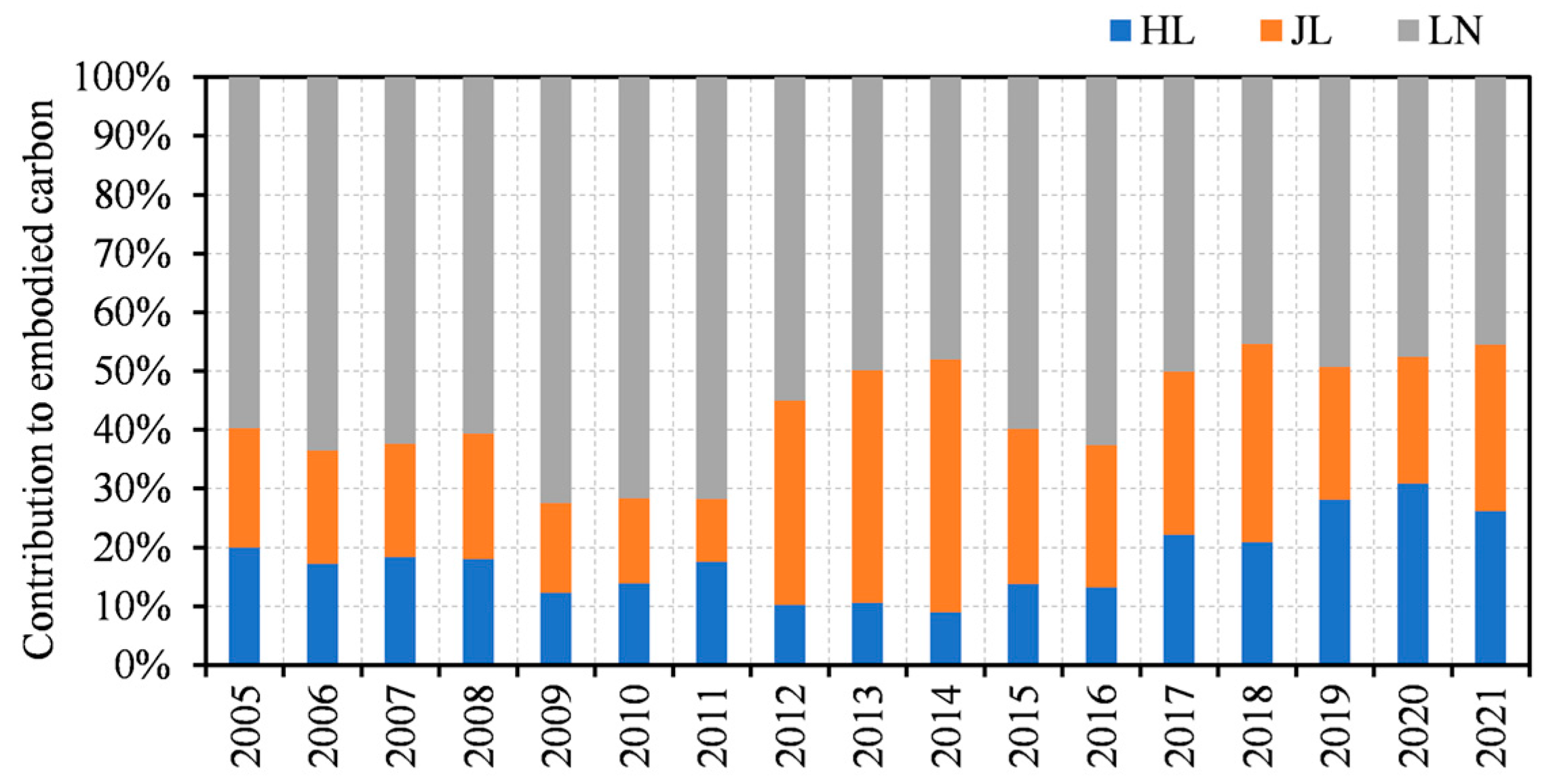

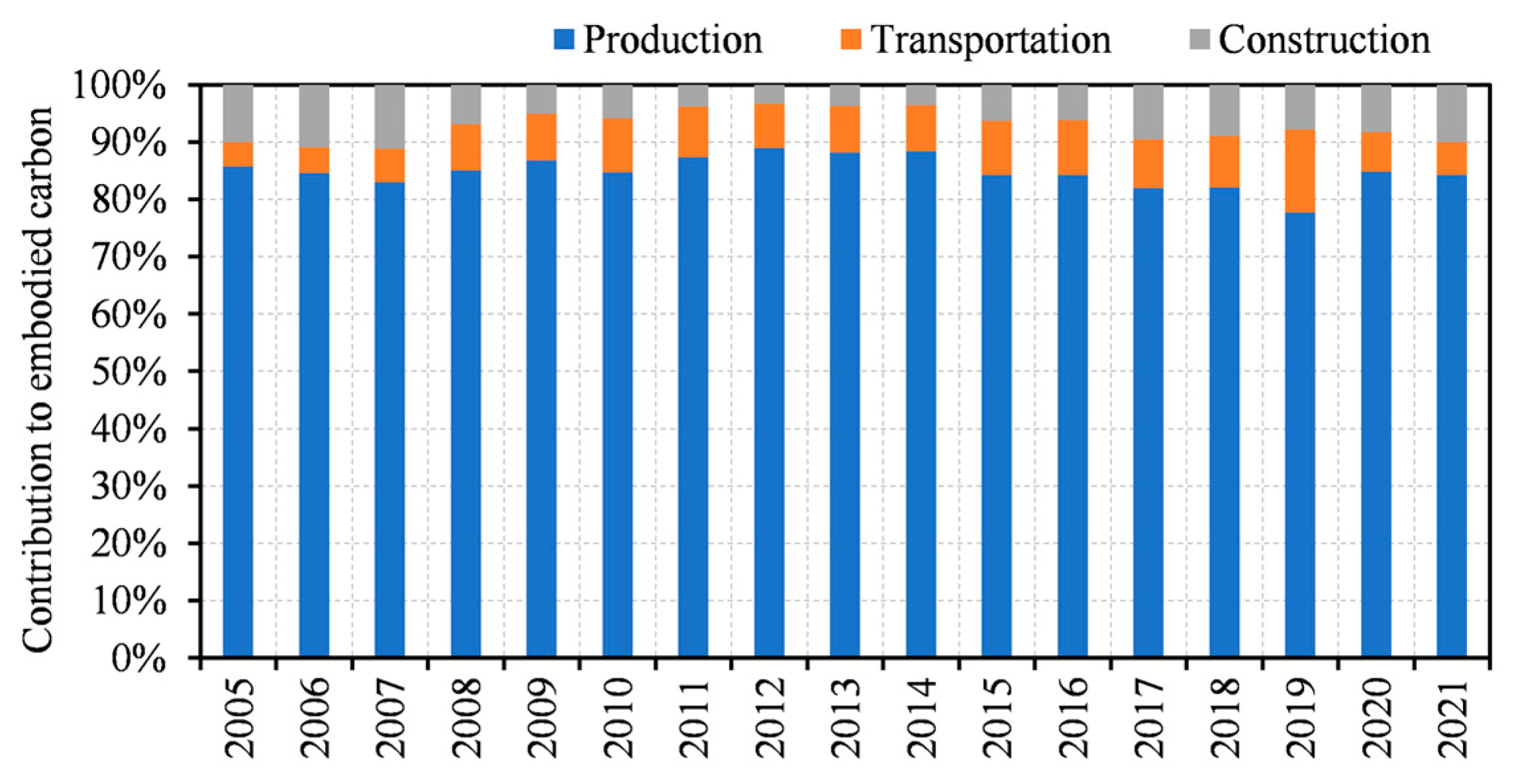

3.1. Embodied Carbon in the Construction Sector

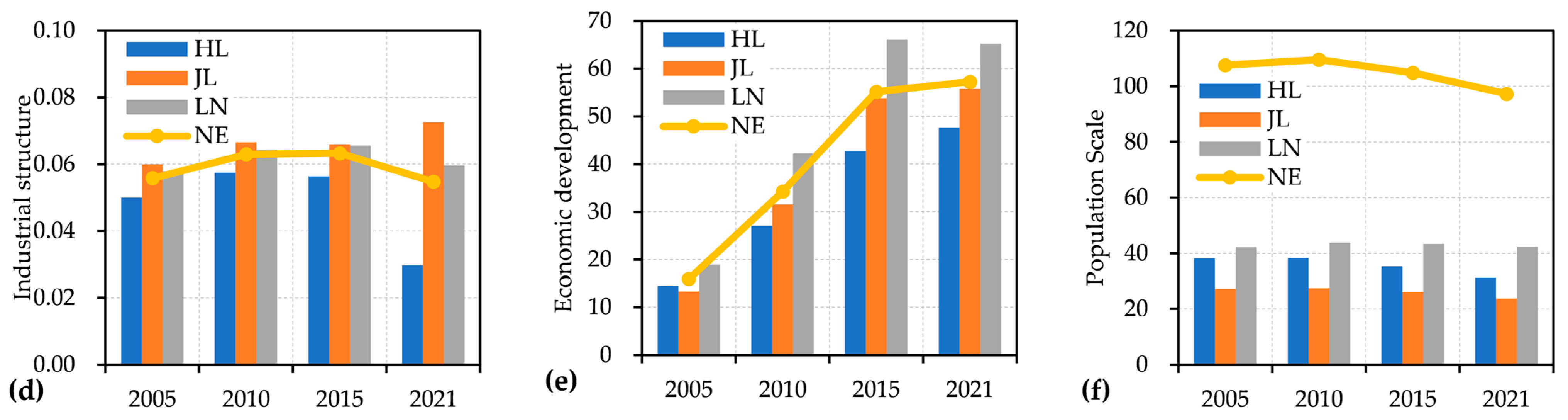

3.2. Driving Factor of Regional Construction-Embodied Carbon

3.3. Suggestions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Notations | |

| E(t) | Embodied carbon of the construction sector in Northeast China of year t |

| Ej(t) | Embodied carbon of the construction sector in province j in year t |

| Emat,j(t) | Embodied carbon from the production process in province j of year t |

| Etra,j(t) | Embodied carbon from the transportation process in province j of year t |

| Econ,j(t) | Embodied carbon from the construction process in province j of year t |

| Qmat,kj(t) | Consumption of material k in province j of year t |

| Fmat,k(t) | Emission factor of material k of year t |

| γmat,k | Conversion coefficient of material k |

| Ftra,k(t) | Emission factor of transporting unit weight of material in province j |

| Qe,lj(t) | Consumption of energy l in province j of year t |

| Fe,lj(t) | Emission factor of energy l in province j of year t |

| Eij(t) | Embodied carbon from source i in province j of year t |

| Aj(t) | Building construction area in province j of year t |

| Mj(t) | Quantity of construction machinery in province j of year t |

| Vj(t) | Construction value added in province j of year t |

| Gj(t) | Regional gross domestic product in province j of year t |

| Pj(t) | Population in province j of year t |

| ESij(t) | Contribution of source i to the total embodied carbon in province j of year t |

| EIj(t) | Embodied carbon per unit construction area in province j of year t |

| CMj(t) | Ratio of building construction area to the quantity of machinery in province j of year t |

| MRj(t) | Quantity of machinery required by unit construction value added in province j of year t |

| ISj(t) | Contribution of construction value added to the total gross domestic product in province j of year t |

| EDj(t) | Gross domestic product per capita in province j of year t |

| Pj(t) | Population scale effect |

| t0 | Datum year |

| ΔE | Difference in embodied carbon within the period from year t0 to t |

| ΔEES | Difference in embodied carbon contributed by the emission source structure effect |

| ΔEEI | Difference in embodied carbon contributed by the carbon emission intensity effect |

| ΔECM | Difference in embodied carbon contributed by the construction mechanization effect |

| ΔEMR | Difference in embodied carbon contributed by the machinery requirement effect |

| ΔEIS | Difference in embodied carbon contributed by the industrial structure effect |

| ΔEED | Difference in embodied carbon contributed by the economic development effect |

| ΔEp | Difference in embodied carbon contributed by the population scale effect |

| Abbreviations | |

| LMDI | Logistic Mean Divided Index |

| GIS | Geographic information system |

| IPAT | Impact = Population × Affluence × Technology |

| STIRPAT | Stochastic impact regression based on IPAT |

| NE | Northeast China |

| HL | Heilongjiang Province |

| JL | Jilin Province |

| LN | Liaoning Province |

Appendix A

| Year | HL Province | JL Province | LN Province | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Emat,j(t) | Etra,j(t) | Econ,j(t) | Emat,j(t) | Etra,j(t) | Econ,j(t) | Emat,j(t) | Etra,j(t) | Econ,j(t) | |

| 2005 | 10.01 | 0.19 | 0.43 | 8.44 | 0.18 | 2.26 | 27.35 | 1.84 | 2.69 |

| 2006 | 8.86 | 0.19 | 0.49 | 8.01 | 0.16 | 2.54 | 30.09 | 2.15 | 3.02 |

| 2007 | 10.30 | 0.23 | 0.48 | 8.78 | 0.18 | 2.65 | 30.91 | 3.14 | 3.56 |

| 2008 | 13.74 | 0.66 | 0.51 | 15.31 | 0.89 | 1.57 | 41.52 | 5.12 | 3.67 |

| 2009 | 14.28 | 0.68 | 0.63 | 16.57 | 1.01 | 1.74 | 79.30 | 8.62 | 4.09 |

| 2010 | 16.53 | 0.83 | 0.96 | 16.12 | 1.00 | 2.05 | 79.46 | 10.67 | 4.79 |

| 2011 | 38.97 | 1.45 | 1.38 | 21.98 | 1.24 | 2.27 | 147.23 | 18.22 | 5.55 |

| 2012 | 26.01 | 1.04 | 1.48 | 90.63 | 3.60 | 2.55 | 131.31 | 17.04 | 5.25 |

| 2013 | 26.59 | 1.14 | 1.48 | 99.21 | 6.34 | 3.50 | 117.44 | 15.19 | 5.23 |

| 2014 | 20.89 | 1.15 | 1.58 | 103.81 | 6.57 | 3.49 | 109.11 | 13.68 | 4.42 |

| 2015 | 16.07 | 0.83 | 1.55 | 29.91 | 2.06 | 3.32 | 66.82 | 9.73 | 3.59 |

| 2016 | 14.46 | 0.82 | 1.54 | 26.08 | 1.62 | 3.21 | 67.09 | 9.77 | 3.15 |

| 2017 | 16.55 | 0.81 | 1.52 | 18.98 | 1.19 | 3.57 | 34.46 | 5.16 | 3.10 |

| 2018 | 15.36 | 0.89 | 1.48 | 23.15 | 1.56 | 4.04 | 31.44 | 5.11 | 2.18 |

| 2019 | 23.72 | 1.72 | 1.39 | 16.31 | 1.21 | 4.00 | 34.18 | 10.79 | 2.15 |

| 2020 | 25.71 | 1.59 | 1.37 | 14.76 | 1.07 | 4.19 | 38.30 | 3.74 | 2.09 |

| 2021 | 18.36 | 1.11 | 1.36 | 16.99 | 1.09 | 4.50 | 31.77 | 2.39 | 2.13 |

References

- Mallapaty, S. How China could be carbon neutral by mid-century. Nature 2020, 586, 482–483. [Google Scholar] [CrossRef] [PubMed]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- China Association of Building Energy Efficiency. 2022 Research Report on Carbon Emissions of China Urban and Rural Construction. 2023. Available online: https://www.cabee.org/upload/file/20230104/1672820934145324.pdf (accessed on 2 April 2024).

- Hashempour, N.; Taherkhani, R.; Mahdikhani, M. Energy performance optimization of existing buildings: A literature review. Sustain. Cities Soc. 2020, 72, 101967. [Google Scholar] [CrossRef]

- Rivera, M.L.; MacLean, H.L.; McCabe, B. Implications of passive energy efficiency measures on life cycle greenhouse gas emissions of high-rise residential building envelopes. Energy Build. 2021, 249, 111202. [Google Scholar] [CrossRef]

- Moran, P.; Goggins, J.; Hajdukiewicz, M. Super-insulate or use renewable technology? Life cycle cost, energy and global warming potential analysis of nearly zero energy buildings (NZEB) in a temperate oceanic climate. Energy Build. 2017, 139, 590–607. [Google Scholar] [CrossRef]

- National Bureau of Statistics. China Statistical Yearbook; China Statistics Press: Beijing, China, 2023. Available online: https://www.stats.gov.cn/sj/ndsj/2023/indexeh.htm (accessed on 2 April 2024).

- National Bureau of Statistics. China Statistical Yearbook on Construction; China Statistics Press: Beijing, China, 2022. (In Chinese)

- Swan, L.G.; Ugursal, V.I. Modeling of end-use energy consumption in the residential sector: A review of modeling techniques, Renew. Sustain. Energy Rev. 2009, 13, 1819–1835. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Scope-based carbon footprint analysis of U.S. residential and commercial buildings: An input-output hybrid life cycle assessment approach. Build. Environ. 2014, 72, 53–62. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Hybrid input-output analysis for life-cycle energy consumption and carbon emissions of China’s building sector. Build. Environ. 2016, 104, 188–197. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, D.; Hu, S.; Guo, S. Modelling of energy consumption and carbon emission from the building construction sector in China, a process-based LCA approach. Energy Policy 2019, 134, 110949. [Google Scholar] [CrossRef]

- Tan, X.; Lai, H.; Gu, B.; Zeng, Y.; Li, H. Carbon emission and abatement potential outlook in China’s building sector through 2050. Energy Policy 2018, 118, 429–439. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, J.; Zhang, X.; Wang, F. Assessment and regression of carbon emissions from the building and construction sector in China: A provincial study using machine learning. J. Clean. Prod. 2024, 450, 141903. [Google Scholar] [CrossRef]

- Geng, J.; Wang, J.; Huang, J.; Zhou, D.; Bai, J.; Wang, J.; Zhang, H.; Duan, H.; Zhang, W. Quantification of the carbon emission of urban residential buildings: The case of the Greater Bay Area cities in China. Environ. Impact Assess. Rev. 2022, 95, 106775. [Google Scholar] [CrossRef]

- Khamchiangta, D.; Yamagata, Y. Mapping urban carbon emissions in relation to local climate zones: Case of the building sector in Bangkok Metropolitan Administration, Thailand. Energy Built Environ. 2024, 5, 337–347. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, X.; Liu, K. Assessment of operational carbon emissions for residential buildings comparing different machine learning approaches: A study of 34 cities in China. Build. Environ. 2024, 250, 111176. [Google Scholar] [CrossRef]

- Luo, H.; Li, Y.; Gao, X.; Meng, X.; Yang, X.; Yan, J. Carbon emission prediction model of prefecture-level administrative region: A land-use-based case study of Xi’an city, China. Appl. Energy 2023, 348, 121488. [Google Scholar] [CrossRef]

- Wu, Y.; Shen, J.; Zhang, X.; Skitmore, M.; Lu, W. The impact of urbanization on carbon emissions in developing countries: A Chinese study based on the U-Kaya method. J. Clean. Prod. 2017, 135, 589–603. [Google Scholar] [CrossRef]

- Zou, C.; Ma, M.; Zhou, N.; Feng, W.; You, K.; Zhang, S. Toward carbon free by 2060: A decarbonization roadmap of operational residential buildings in China. Energy 2023, 277, 127689. [Google Scholar] [CrossRef]

- Zhu, C.; Chang, Y.; Li, X.; Shan, M. Factors influencing embodied carbon emissions of China’s building sector: An analysis based on extended STIRPAT modeling. Energy Build. 2022, 255, 111607. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Deng, B.; Liu, B.; Zhang, L.; Zhao, P. Emission reduction analysis of China’s building operations from provincial perspective: Factor decomposition and peak prediction. Energy Build. 2023, 296, 113366. [Google Scholar] [CrossRef]

- Ang, B.W. The LMDI approach to decomposition analysis: A practical guide. Energy Policy 2005, 33, 867–871. [Google Scholar] [CrossRef]

- Lu, Y.; Cui, P.; Li, D. Carbon emissions and policies in China’s building and construction industry: Evidence from 1994 to 2012. Build. Environ. 2016, 95, 94–103. [Google Scholar] [CrossRef]

- Chen, H.; Du, Q.; Huo, T.; Liu, P.; Cai, W.; Liu, B. Spatiotemporal patterns and driving mechanism of carbon emissions in China’s urban residential building sector. Energy 2023, 263, 126102. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, Z.; Bi, W.; Ni, P.; Lei, F.; Yao, S.; Lang, J. Prediction and scenario simulation of the carbon emissions of public buildings in the operation stage based on an energy audit in Xi’an, China. Energy Policy 2023, 173, 113396. [Google Scholar] [CrossRef]

- Du, Z.; Liu, Y.; Zhang, Z. Spatiotemporal analysis of influencing factors of carbon emission in public buildings in China. Buildings 2022, 12, 424. [Google Scholar] [CrossRef]

- Huo, T.; Ma, Y.; Cai, W.; Liu, B.; Mu, L. Will the urbanization process influence the peak of carbon emissions in the building sector? A dynamic scenario simulation. Energy Build. 2021, 232, 110590. [Google Scholar] [CrossRef]

- Kong, Y.; Zhao, T.; Yuan, R.; Chen, C. Allocation of carbon emission quotas in Chinese provinces based on equality and efficiency principles. J. Clean. Prod. 2019, 211, 222–232. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W.; Wang, H. Energy and CO2 emission performance in electricity generation: A non-radial directional distance function approach. Eur. J. Oper. Res. 2012, 221, 625–635. [Google Scholar] [CrossRef]

- Feng, C.; Chu, F.; Ding, J.; Bi, G.; Liang, L. Carbon Emissions Abatement (CEA) allocation and compensation schemes based on DEA. Omega 2015, 53, 78–89. [Google Scholar] [CrossRef]

- Xin, L.; Li, S.; Rene, E.R.; Lun, X.; Zhang, P.; Ma, W. Prediction of carbon emissions peak and carbon neutrality based on life cycle CO2 emissions in megacity building sector: Dynamic scenario simulations of Beijing. Environ. Res. 2023, 238, 117160. [Google Scholar] [CrossRef]

- Zhu, C.; Li, X.; Zhu, W.; Gong, W. Embodied carbon emissions and mitigation potential in China’s building sector: An outlook to 2060. Energy Policy 2022, 170, 113222. [Google Scholar] [CrossRef]

- Filonchyk, M.; Peterson, M.; Zhang, L.; Hurynovich, V.; He, Y. Greenhouse gases emissions and global climate change: Examining the influence of CO2, CH4, and N2O. Sci. Total Environ. 2024, 935, 173359. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Ma, X.; Cai, W.; Cai, W. Low carbon roadmap of residential building sector in China: Historical mitigation and prospective peak. Appl. Energy 2020, 273, 115247. [Google Scholar] [CrossRef]

- Lu, M.; Lai, J. Review on carbon emissions of commercial buildings. Renew. Sustain. Energy Rev. 2020, 119, 109545. [Google Scholar] [CrossRef]

- Ali, K.A.; Ahmad, M.I.; Yusup, Y. Issues, impacts, and mitigations of carbon dioxide emissions in the building sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Green Building Council Australia. A Carbon Positive Roadmap for Buildings. Available online: https://gbca-web.s3.amazonaws.com/media/documents/carbon-positive-roadmap-summary-paper-fa-web_onU8cXm.pdf (accessed on 10 June 2024).

- The UK Government. Net Zero Strategy: Build Back Greener. 2021. Available online: https://www.gov.uk/government/publications/net-zero-strategy (accessed on 10 June 2024).

- Le, A.; Rodrigo, N.; Domingo, N.; Senaratne, S. Policy Mapping for Net-Zero-Carbon Buildings: Insights from Leading Countries. Buildings 2023, 13, 2766. [Google Scholar] [CrossRef]

- Yu, M.; Wiedmann, T.; Crawford, R.; Tait, C. The carbon footprint of Australia’s construction sector. Procedia Eng. 2017, 180, 211–220. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Clarke, J.; Littlewood, J.R.; Karani, G. Developing tools to enable the UK construction industry to adopt the active building concept for net zero carbon buildings. Buildings 2023, 13, 304. [Google Scholar] [CrossRef]

- Wilkinson, S.; Ghosh, S.; Quintana Vigiola, G. Decarbonising Australian housing: Policy, problems, profiles of current stock and progress. Hous. Financ. Int. 2021, XXXVI, 40–49. [Google Scholar]

- Zhang, X.; Li, Y.; Chen, H.; Yan, X.; Liu, K. Characteristics of embodied carbon emissions for high-rise building construction: A statistical study on 403 residential buildings in China. Resour. Conser. Recycl. 2023, 198, 107200. [Google Scholar] [CrossRef]

- Filonchyk, M.; Peterson, M. Analysis of air pollution from vehicle emissions for the contiguous United States. J. Geovis. Spat. Anal. 2024, 8, 16. [Google Scholar] [CrossRef]

- Malmqvist, T.; Nehasilova, M.; Moncaster, A.; Birgisdottir, H.; Rasmussen, F.N.; Wiberg, A.H.; Potting, J. Design and construction strategies for reducing embodied impacts from buildings—Case study analysis. Energy Build. 2018, 166, 35–47. [Google Scholar] [CrossRef]

- Sun, Y.; Hao, S.; Long, X. A study on the measurement and influencing factors of carbon emissions in China’s construction sector. Build. Environ. 2023, 229, 109912. [Google Scholar] [CrossRef]

- Karimpour, M.; Belusko, M.; Xing, K.; Bruno, F. Minimising the life cycle energy of buildings: Review and analysis. Build. Environ. 2014, 73, 106–114. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, Q.; Zhang, X. Carbon emission intensity of final electricity consumption: Assessment and decomposition of regional power grids in China from 2005 to 2020. Sustainability 2023, 15, 9946. [Google Scholar] [CrossRef]

- Wu, P.; Song, Y.; Zhu, J.; Chang, R. Analyzing the influence factors of the carbon emissions from China’s building and construction industry from 2000 to 2015. J. Clean. Prod. 2019, 221, 552–566. [Google Scholar] [CrossRef]

- Huo, T.; Cong, X.; Cheng, C.; Cai, W.; Zuo, J. What is the driving mechanism for the carbon emissions in the building sector? An integrated DEMATEL-ISM model. Energy 2023, 274, 127399. [Google Scholar] [CrossRef]

- National Bureau of Statistics. China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2022. (In Chinese)

- Azizalrahman, H.; Hasyimi, V. A model for urban sector drivers of carbon emissions. Sustain. Cities Soc. 2019, 44, 46–55. [Google Scholar] [CrossRef]

- Huang, Y.; Matsumoto, K. Drivers of the change in carbon dioxide emissions under the progress of urbanization in 30 provinces in China: A decomposition analysis. J. Clean. Prod. 2021, 322, 129000. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, H. The impact mechanism of the ETS on CO2 emissions from the service sector: Evidence from Beijing and Shanghai. Technol. Forecast. Soc. Change 2021, 173, 121114. [Google Scholar] [CrossRef]

| Source | Scale | Objective | Method | Influencing Factor |

|---|---|---|---|---|

| Zhu et al. [21] | National | Embodied carbon emissions | STIRPAT | Building construction area, completed value of building area, indirect emission intensity, carbon emissions per unit energy consumed, energy intensity, and total factor productivity |

| Li et al. [22] | Provincial | Operational carbon emissions | Generalized Divisia index method | Floor space, energy consumption, population scale, and disposable income |

| Lu et al. [24] | National | Embodied carbon emissions | LMDI | Energy consumption, construction area, building equipment, building material, and construction output value |

| Chen et al. [25] | Provincial | Operational carbon emissions | LMDI | Energy consumption, urban floor space, number of urban residents, and population |

| Zhang et al. [26] | Municipal | Operational carbon emissions | LMDI | Energy consumption, energy structure, domestic gross product, and population size |

| Wu et al. [51] | National | Embodied and operational carbon emissions | LMDI | Construction value added, energy consumption, floor area of completed buildings, floor area of in-use buildings, population, infrastructure development, and material structure |

| Huo et al. [52] | - | Operational carbon emissions | Interpretive structural model | Industrial structure, clean energy proportion, policy factor, technical improvement, energy intensity, electrification rate, carbon emission factor, economic development, user behavior, awareness, urbanization rate, ownership of energy equipment, building energy efficiency, climate, population, building floor space, energy-efficient building floor space, number of households, household size, income, building form, energy consumption, and number of employees |

| Year | ΔEES | ΔEEI | ΔEAL | ΔEME | ΔEIS | ΔEED | ΔEP | ΔE |

|---|---|---|---|---|---|---|---|---|

| 2006 | 0.0 | −5.8 | 2.9 | −4.1 | 1.4 | 7.3 | 0.4 | 2.1 |

| 2007 | 0.1 | −7.1 | 0.7 | −5.3 | 0.8 | 17.1 | 0.7 | 6.9 |

| 2008 | 0.4 | 7.3 | 11.8 | −21.1 | 0.0 | 30.4 | 0.9 | 29.6 |

| 2009 | 1.1 | 35.2 | 35.5 | −52.4 | 11.8 | 41.0 | 1.3 | 73.5 |

| 2010 | 1.2 | −0.2 | 88.3 | −87.8 | 10.9 | 64.5 | 2.1 | 79.0 |

| 2011 | 2.5 | 59.5 | 120.7 | −110.9 | 13.0 | 97.8 | 2.4 | 184.9 |

| 2012 | 4.4 | 47.7 | 161.1 | −129.0 | 13.8 | 127.4 | 0.1 | 225.5 |

| 2013 | 4.5 | 39.4 | 169.6 | −148.5 | 7.8 | 151.8 | −1.8 | 222.7 |

| 2014 | 4.3 | 6.1 | 184.5 | −159.0 | 10.1 | 168.8 | −3.5 | 211.3 |

| 2015 | 2.9 | −58.4 | 159.4 | −201.8 | 11.7 | 171.9 | −5.2 | 80.5 |

| 2016 | 2.8 | −31.7 | 152.3 | −229.1 | 31.5 | 154.8 | −6.3 | 74.4 |

| 2017 | 2.6 | −55.6 | 129.2 | −227.5 | 30.9 | 159.7 | −7.3 | 32.0 |

| 2018 | 2.6 | −41.4 | 137.2 | −217.7 | −5.2 | 164.6 | −8.3 | 31.8 |

| 2019 | 2.8 | −32.5 | 155.3 | −237.2 | 8.3 | 154.7 | −9.3 | 42.1 |

| 2020 | 2.7 | −37.7 | 154.9 | −236.4 | 8.9 | 157.6 | −10.6 | 39.4 |

| 2021 | 2.6 | −59.1 | 180.8 | −261.1 | 8.7 | 165.7 | −11.4 | 26.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Zhang, X. Assessment and Driving Factors of Embodied Carbon Emissions in the Construction Sector: Evidence from 2005 to 2021 in Northeast China. Sustainability 2024, 16, 5681. https://doi.org/10.3390/su16135681

Sun X, Zhang X. Assessment and Driving Factors of Embodied Carbon Emissions in the Construction Sector: Evidence from 2005 to 2021 in Northeast China. Sustainability. 2024; 16(13):5681. https://doi.org/10.3390/su16135681

Chicago/Turabian StyleSun, Xujie, and Xiaocun Zhang. 2024. "Assessment and Driving Factors of Embodied Carbon Emissions in the Construction Sector: Evidence from 2005 to 2021 in Northeast China" Sustainability 16, no. 13: 5681. https://doi.org/10.3390/su16135681