Abstract

The crucial shift towards sustainable and circular practices is evident in the dynamic and environmentally focused landscape of the fast fashion industry. This study explores how internet of things (IOT) and big-data-driven supply chain (BDSC) technologies mitigate the environmental footprint of fast fashion manufacturing. A survey was conducted on individuals (n = 342) employed in the fast fashion manufacturing sector in Guangzhou, China. Deriving from the resource-based view (RBV) theory, IOT shows a significantly positive influence on firm performance through the mediation of green supply chain management (GSCM) and circular economy (CE) practices. Moreover, moderation of BDSC further strengthens the influence of IOT, GSCM and CE practices. Our empirical analysis investigates the synergistic impact of IOT and BDSC technologies to enhance the overall performance of CE supply chains. The research provides novel insights to improve the environmental sustainability of fast fashion sector.

1. Introduction

Adopting sustainable and circular practices has become indispensable in the fast-paced and environmentally impactful landscape of the fast fashion industry. This study delves into the transformative potential of IOT technology, coupled with BDSC practices, in mitigating the environmental footprint of fast fashion manufacturing. Our empirical investigation is conducted on fast fashion manufacturers in Guangzhou, China, a region grappling with its substantial contribution to the escalating environmental crisis. Recent research by the Intergovernmental Panel on Climate Change (IPCC) indicates that even a mere 1.5 °C rise in global temperatures could lead to catastrophic consequences, heightened natural disasters and irreversible harm to ecosystems [1]. The fashion industry exacerbates this problem through substantial GHG emissions and textile waste [2]. The fashion industry contributed around 2.1 billion metric tons of greenhouse gas emissions in 2018, which accounted for approximately 4% of the total global emissions [3]. If existing production rates persist, projections indicate that fashion-related GHG emissions could potentially rise by 2.7 billion metric tons by 2030. Such a trajectory would exceed the IPCC’s 1.5 °C limit, further accelerating the alarming trend in global average temperatures.

China, being the world’s largest emitter of greenhouse gases, especially carbon dioxide, holds a pivotal role in this narrative [4]. The rapid industrialization and urbanization processes driving China’s economic ascent contribute significantly to its carbon footprint [5]. The production value of apparel in China surged from 2015 to 2019, exceeding 23.54 billion [6]. Within this context, the fast fashion industry stands out as a major contributor to China’s greenhouse gas emissions, representing approximately 8% of the nation’s total [7]. Guangzhou, the epicenter of China’s textile and garment industry, magnifies this impact, hosting over 44,000 clothing manufacturers and representing 31.6 percent of global trade, serving as the world’s largest clothing production base [8,9].

China has adopted a comprehensive set of strategies to facilitate its transition to a circular economy, equivalent to the ambitions of the European Green Deal [10]. These strategies encompass various facets such as industrial symbiosis through eco-industrial parks [11], significant investments in research and development [12], financial incentives like green bonds and subsidies, public awareness campaigns and international collaborations [13]. Through initiatives like the Belt and Road Initiative and partnerships with international organizations, China is integrating circular economy principles into global development agendas [14]. The strategic alignment of these measures underscores China’s commitment to fostering sustainable development and resource efficiency. Despite China’s CE strategies toward sustainable development in various industries, the fast fashion manufacturing sector lags in embracing sustainable practices [2,15]. Nevertheless, China has implemented various policies to encourage the adoption of circular economy principles, green supply chain practices, reduce environmental impact and promote sustainability within the fast fashion industry [16,17], including the Circular Economy Promotion Law, Extended Producer Responsibility, Green Development Guidelines and the Action Plan for Carbon Neutrality by 2030, indicating a commitment to improving the sector’s environmental performance. Given these challenges, there is a need for transformative solutions, and our research positions IOT [18,19] and BDSC practices as potential game-changers [20] by integrating the GSCM and CE practices.

Subsequently, we introduce a novel framework grounded in RBV theory [21,22], which offers fresh insights into sustainable firm performance within the fast fashion industry. By leveraging RBV’s emphasis on internal resources and capabilities, our framework explores the impacts of IOT adoption, BDSC, GSCM practices and CE practices. Hence, the following research questions need to be addressed:

- How does the IOT adoption influence firm performance through the mediating effects of GSCM practices and CE practices?

- How does the moderation of BDSC further strengthen the influence of IOT, GSCM practices and CE practices on firm performance within CE supply chain?

Addressing the answers to these research questions, the IOT has the potential to significantly enhance firm performance by integrating GSCM and CE practices. IOT enables real-time monitoring and data collection, which are crucial for optimizing supply chain operations and minimizing environmental impacts [23]. For instance, IOT devices can track energy consumption, emissions and waste production throughout the supply chain, allowing firms to identify inefficiencies and areas for improvement [18]. By providing detailed insights into resource usage and process flows, IOT helps firms implement GSCM practices more effectively, such as sustainable procurement, eco-friendly manufacturing processes and efficient reverse logistics [24]. Moreover, IOT supports the principles of the CE by facilitating the creation of closed-loop systems wherein products and materials are reused, remanufactured and recycled [25]. This is achieved through enhanced tracking and traceability of materials, enabling better management of product life cycles and end-of-life processes [19]. The integration of IOT with CE practices helps firms reduce waste, lower resource consumption and improve overall environmental performance [25]. The ability to continuously monitor and adjust operations based on real-time data ensures that firms can maintain high standards of sustainability and resource efficiency, aligning with China’s strategic goals of promoting circular economy principles [12]. In the sustainability context, other technologies like RFID and blockchain have been discussed but often lack the comprehensive, real-time data integration capabilities that IOT provides [26,27,28]. However, IOT fills this gap by enabling a more interconnected and responsive supply chain network.

BDSC practices can further strengthen the impact of IOT, GSCM and CE practices on sustainable firm performance by leveraging large volumes of data to drive decision-making and optimization. BDSC involves the collection, analysis, and utilization of vast amounts of data generated by IOT devices and other sources within the supply chain [29], can uncover patterns, predict future trends and make informed decisions that enhance sustainability [30]. The combination of IOT and BDSC enables firms to optimize their supply chains more comprehensively [24]. For example, predictive analytics can forecast demand and supply fluctuations, helping firms to adjust their production and inventory levels to minimize waste and reduce excess inventory [31]. Additionally, BDSC can identify opportunities for further integrating GSCM and CE practices, such as pinpointing where material reuse or recycling can be most effectively implemented [31], leading to a more resilient and adaptive supply chain capable of maintaining sustainability goals even under changing conditions [32]. While other technologies like advanced analytics and AI have been applied in various sectors for sustainability purposes, they often fall short in addressing the dynamic and real-time needs of supply chains as comprehensively as BDSC [28,33]. However, IOT and BDSC together fill this gap by providing a holistic, data-driven approach to sustainability. Despite the potential of IOT and BDSC, there is a gap in the literature regarding their combined application in the fast fashion industry, particularly in the context of China’s extensive industrial and environmental landscape. While IOT and BDSC have been studied individually in various sectors, their synergistic effects on GSCM and CE practices within the fast fashion industry remain underexplored. Our study aims to fill this gap by demonstrating how these technologies can be harnessed together to achieve significant improvements in sustainable firm performance, providing a model that other industries can adapt and implement.

Overall, IOT adoption’s ability to positively influence GSCM practices and CE practices emerges as a beacon of hope [34], and the optimization prowess of BDSC practices introduces a layer of efficiency, synergizing with sustainable practices to drive overall firm performance for CE supply chains [31,35]. Our study stands apart due to its focus on the synergistic impact of IOT adoption and BDSC practices. In a pioneering approach, we unveil how these two transformative forces synergize to amplify the positive outcomes of sustainable and circular practices within the fast fashion manufacturing context. The unique contribution lies in the recognition that real-time monitoring, enabled by IOT [19] and combined with the optimization prowess of BDSC practices, can significantly enhance the overall performance of CE supply chains [31,36]. As the fashion industry grapples with the pressing need for eco-friendly solutions, our research provides a nuanced comprehension of the interplay among technology, sustainability and business outcomes, paving the way for strategic interventions to address environmental crises in the fast fashion sector.

In our paper, we structure the content as follows: first, we present the theoretical foundation, development of hypotheses and framework introduction. Then, we outline our survey-based methodology, including construct operationalization, the sampling strategy for data collection from Guangzhou’s fast fashion manufacturers and data collection methods. We provide a comprehensive account of strategies addressing potential biases. In the Section 5, we utilize SEM to explain how we handle common method bias, address endogeneity testing and present the measurement model, concluding with the results of hypotheses testing. Following the analysis, we observe the results, emphasizing theoretical, practical and policy implications. In conclusion, we summarize key findings and propose further research avenues.

2. Theoretical Background

2.1. Internet of Things

RBV posits that firms can achieve competitive advantage by acquiring and deploying unique, valuable resources [22]. In the context of IOT, RBV provides a lens to comprehend how firms can leverage interconnected devices and sensors to create unique and valuable capabilities [37]. The IOT’s ability to facilitate real-time monitoring and data-driven decision-making significantly enhances production processes [19]. Through interconnected sensors and devices, manufacturers gain unprecedented visibility into the entire production lifecycle, enabling precise tracking of resources, materials, and finished goods [23]. The seamless connectivity afforded by IoT fosters improved communication and coordination across the production line, resulting in a more agile and responsive manufacturing ecosystem [38].

2.2. Big-Data-Driven Supply Chain

RBV suggests that firms can gain competitive advantage by leveraging data as a strategic resource [21]. BDSC management involves collecting, analyzing and utilizing large volumes of data to enhance decision-making and operational efficiency [36]. From an RBV perspective, firms can develop capabilities in data analytics, predictive modeling and real-time visibility to optimize supply chain processes and improve performance [31], aligning with RBV’s focus on leveraging internal resources for competitive advantage. RBV emphasizes the importance of leveraging internal resources and capabilities to achieve superior firm performance [39]. Scholars argue that the incorporation of big data technologies into SC practices offers unprecedented opportunities for real-time monitoring, optimization and decision-making [40]. By harnessing vast amounts of data generated throughout the supply chain, companies can gain insights into resource utilization, production processes and consumer behavior [36]. Big data facilitates the identification of inefficiencies, reduction of waste and minimization of environmental impact [31]. Moreover, it enables predictive modeling and demand forecasting, allowing for strategic planning and inventory management [39]. Studies highlight the potential of BDSC practices to align with CE principles, highlighting the significance of utilizing data-driven approaches to achieve sustainable objectives [41,42].

2.3. Green Supply Chain Management Practices

RBV underscores the importance of building internal capabilities related to environmental sustainability [22]. GSCM practices, including eco-design, green procurement and reverse logistics, enable firms to reduce environmental impact, comply with regulations and meet evolving consumer preferences for sustainability [43]. By effectively managing their green supply chains, firms differentiate themselves from competitors, enhance brand reputation and achieve better performance, reflecting RBV’s emphasis on developing valuable internal resources [44]. Through the implementation of green initiatives such as recycling, reverse logistics and sustainable sourcing, GSCM contributes to minimizing environmental impact while aligning with regulatory requirements and consumer preferences for ethical production [35]. The literature suggests that GSCM not only serves as a mechanism for environmental conservation but also offers strategic advantages by enhancing brand reputation, operational efficiency and resilience in the face of evolving sustainability expectations and regulations in the fast fashion industry [43].

2.4. Circular Economy Practices

RBV emphasizes the creation of value and sustainable competitive advantage through the development of internal capabilities [22]. CE practices, such as product remanufacturing, recycling and resource recovery, align with RBV principles by enabling firms to minimize resource consumption, reduce waste and capitalize on secondary materials [45]. By integrating CE practices into their operations, firms can drive cost savings, foster innovation and enhance resilience, thus reinforcing the RBV logic of leveraging internal resources for competitive advantage. CE entails reimagining traditional linear supply chains by promoting practices such as recycling, refurbishing and remanufacturing [46]. The adoption of circular principles practices aligns with the ethos of resource efficiency, closing material loops and fostering a cradle-to-cradle approach [47]. CE is depicted as a strategic response to the ecological consequences of fast fashion, emphasizing the need for a regenerative system that goes beyond mere sustainability [45].

2.5. Firm Performance for CE Supply Chain

RBV emphasizes the critical role of internal resources and capabilities in driving superior firm performance [21]. Within CE supply chains, firms can enhance performance by effectively managing resources related to sustainability, innovation and operational efficiency [48]. The implementation of CE practices contributes to operational efficiency, innovation and the creation of value for stakeholders [49]. Firms embracing CE principles are better positioned to meet evolving consumer expectations for sustainable and ethical production, thereby fostering brand loyalty and market competitiveness [48]. The literature underscores the strategic advantage of integrating CE into supply chain management, as it aligns with contemporary corporate responsibility initiatives and addresses environmental challenges [46].

2.6. Framework

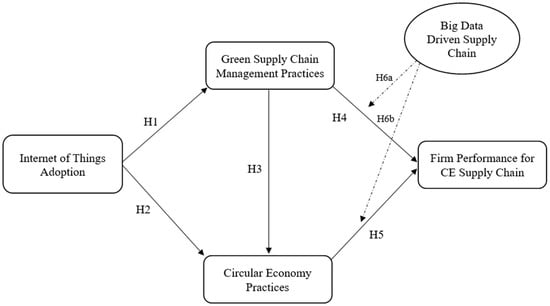

Our model, as illustrated in Figure 1, is based on the RBV theories. It proposes that IOT is associated with CE and GSCM practices. Additionally, both CE and GSCM practices contribute to firm performance, with BDSC serving in the role of moderating variable. Furthermore, the control variables are designation, firm age, number of employees and firm size. Similarly, the prior study has found that it significantly effects firm performance [50].

Figure 1.

Theoretical model.

3. Hypotheses Development

3.1. Internet of Things and GSCM Practices

The multifaceted components of IOT, including sensor devices, connectivity and data analytics, present unprecedented opportunities to elevate environmental sustainability within the intricate operations of supply chains in the fast fashion landscape [51]. The literature underscores that IOT functions as a facilitator of real-time monitoring, providing a platform for heightened visibility and traceability of products and materials across the entire supply chain network [23,52]. The seamless integration of IOT into the supply chain ecosystem is widely acknowledged as a pivotal catalyst for fostering circular economy principles [25]. As industries increasingly recognize the need for environmental stewardship, the role of IOT emerges as a linchpin in reshaping supply chain practices and steering them towards a more sustainable and circular future within the fast fashion manufacturer sector [25].

H1.

IOT exhibits a significant and positive relation with the GSCM practices.

3.2. Internet of Things and CE Practices

The transformative prowess of IOT, acting as a disruptive force capable of recalibrating traditional linear business models into circular paradigms [25]. At its core, IOT leverages interconnected sensors and robust data analytics capabilities, facilitating an unprecedented level of visibility and traceability across the entirety of the fast fashion supply chain [51]. By enabling real-time monitoring and analysis, IOT empowers businesses to seamlessly integrate practices such as product recycling, remanufacturing and end-of-life management [53]. This research endeavors to empirically explore these interconnected dynamics, considering contextual nuances and potential barriers to adoption, with the ultimate goal of providing actionable insights for industry stakeholders [54]. Through this exploration, the study seeks to contribute to the ongoing discourse on sustainability, offering practical guidance for fostering a more sustainable future [51].

H2.

IOT exhibits a significant and positive relation with the circular economy practices.

3.3. GSCM Practices and CE Practices

GSCM entails multifaceted strategies encompassing sustainable sourcing, the implementation of eco-friendly production processes, and the facilitation of efficient waste management [55]. These strategic pillars intricately align with the fundamental tenets of CE, aiming to curtail waste generation, advocate for recycling initiatives and prolong the life cycle of products [43]. Scholarly discourse suggests that the assimilation of GSCM practices transcends mere operational enhancements; it significantly contributes to the establishment of a closed-loop system [56], emblematic of CE frameworks [45]. By prioritizing sustainable sourcing and production [34], GSCM acts as a cornerstone for circular practices, mitigating the environmental footprint associated with raw material extraction while concurrently mitigating the depletion of crucial resources [57]. Thus, we hypothesize the following:

H3.

GSCM practices have a significant relationship to CE practices.

3.4. GSCM and Firm Performance for CE Supply Chain

As companies adopt GSCM principles, they gain the ability to optimize resource efficiency, mitigate environmental impact and bolster operational resilience [57]. This symbiotic relationship manifests as a positive feedback loop where environmental responsibility becomes a catalyst for improved business performance [46]. Moreover, the responsible approach of manufacturers, characterized by GSCM practices, not only contributes to environmental sustainability but also translates into tangible business benefits [34]. The enhancement of business performance is driven by a combination of factors such as cost savings through resource optimization, enhanced brand reputation due to eco-friendly practices and improved operational efficiency [35]. The literature highlights how companies embracing a responsible approach, particularly within the context of CE supply chains, gain a competitive edge [35]. By aligning sustainability initiatives with business objectives, manufacturers not only meet ethical and environmental standards but also experience a positive impact on financial and operational metrics, reinforcing the business case for responsible and eco-friendly practices in the manufacturing landscape [57]. Subsequently, we hypothesize the following:

H4.

GSCM practices have a substantial impact on firm performance.

3.5. CE Practices and Firm Performance for CE Supply Chain

CE empowers companies to optimize resource utilization, curtail environmental impact and fortify operational resilience [42]. This influence manifests in heightened operational efficiency, cost reductions derived from optimized resource usage, an enhanced brand reputation attributed to environmentally conscious practices and increased innovation catalyzed by an ingrained circular mindset [47]. Moreover, the responsible adoption of CE practices and principles by manufacturers leads to a substantial increase in business performance. Companies committed to circular practices exhibit greater operational efficiency, translating into cost savings and improved financial outcomes [48]. Thus, the responsible approach of manufacturers towards CE practices becomes a driving force behind the substantial increase in business performance, creating a win-win scenario for both environmental sustainability and financial success [58].

H5.

CE practices have a substantial impact on firm performance for CE supply chain.

3.6. Big-Data-Driven Supply Chains, GSCM Practices and Firm Performance

The effective integration of BD into SC operations represents a pivotal enhancement for the impact of GSCM practices on firm performance [59]. BD analytics, distinguished by its sophisticated processing and analysis capabilities, plays a transformative function in SC dynamics [60]. Through real-time insights into environmental performance metrics, BD facilitates optimized resource utilization, waste reduction and heightened operational resilience [61]. Furthermore, the integration of BDSC not only refines the relationship between GSCM and firm performance but also strengthens the responsible practices of the firm [36]. This holistic integration underscores the importance of responsible approaches in fostering sustainability and operational success [36]. A responsible brand, shaped by BD-driven environmental practices, leads to a win-win scenario [31]. This scenario is characterized by a harmonious balance between environmental sustainability and financial success, contributing substantively to the overall business performance of firms within CE supply chains [41]. In essence, the responsible brand becomes a cornerstone for achieving both ethical and financial objectives, embodying a commitment to sustainable practices and contributing to the prolonged success of the business [42].

H6a.

The strength of BDSCs moderates the effect of GSCM practices on firm performance.

3.7. Big-Data-Driven Supply Chains, CE Practices and Firm Performance

BDSC facilitates a nuanced understanding of product life cycles, optimal resource utilization and targeted waste reduction strategies [62]. This dynamic synergy between CE principles and BDSC not only enhances operational performance but also translates into substantial cost savings and heightened environmental sustainability [39]. The real-time insights provided by BDSC enable manufacturers to make data-driven decisions, thereby fostering a responsive and agile supply chain that aligns with the tenets of circularity [60]. Moreover, the integration of responsible brand practices into this symbiotic relationship creates a win-win scenario for both environmental sustainability and financial success [20]. By emphasizing responsible brand initiatives within the framework of CE and BDSC, manufacturers can strengthen their commitment to sustainable practices [31]. This commitment not only resonates with eco-conscious end users but also contributes to long-term business success [36]. Responsible branding, aligned with the fundamental concepts of CE and supported by BDSC [63], can lead to a favorable feedback cycle, wherein the environmentally sustainable image of the brand enhances financial performance and overall business success [61].

H6b.

The strength of BDSCs moderates the effect of CE practices on firm performance.

4. Research Methodology

4.1. Context Section

Our research focuses on fast fashion manufacturers situated in Guangzhou, China, a region where the fast fashion manufacturing industry significantly contributes to the escalating environmental challenges. The authors of [64] describe Guangzhou as the center of China’s textile and garment industry, boasting a complete industrial chain for clothing production. Guangzhou is recognized as the world’s largest clothing production base, accounting for about one-third of the global clothing trade, with over 44,000 clothing manufacturers and the textile sector representing 31.6 percent of global trade [8,9]. Despite China’s strides toward sustainable development in various industries, the fast fashion manufacturing sector lags in embracing sustainable practices [2,15]. This creates a pressing need for transformative solutions; our research positions IOT [18] and big-data-driven supply chain practices as potential game-changers [20].

4.2. Operationalization of Constructs

The items used to measure constructs have been sourced from standardized scales and validated instruments in the literature. The items for the IOT construct were adapted from [24]. The scale for GSCM practices, comprising five items, was adopted from [65] and CE practices’ construct, consisting of seven items, was adapted from [66,67]. The scale for firm performance, comprising 14 items, was adopted from [67] and [68]. Lastly, the four items measuring big-data-driven supply chains were adopted from [31].

4.3. Sampling Strategy and Data Collection

The investigation of research hypotheses relies on cross-sectional data obtained through a survey. The measurement of agreement with various statements employs a standard five-point response scale where one signifies strong disagreement and five signifies strong agreement. The questionnaire design involves two distinct parts. The initial section comprises demographic questions, including experience, designation, highest degree, age of the firm, no. of employees and annual turnover. The next section of the survey includes items to evaluate the hypothetical constructs.

We utilized the inverse-square root method in WarpPLS (version 7.0) software to compute the statistical power and determine the minimum sample requirements. A simple random sampling technique was implemented in this research. Data were collected from fast fashion manufacturer in Guangzhou from August 2023 to November 2023 through online questionnaire distribution and personal visits. In our data collection process, each respondent was presented with a detailed consent form prior to participation. This form outlined the study’s objectives, procedures and the rights of the participants. It assured respondents that their participation was voluntary and that they could withdraw at any time without any consequences. Additionally, the form emphasized the confidentiality of the data collected, stating that responses would be anonymized and used solely for academic research purposes, thereby addressing all privacy concerns. To further ensure comprehensive data, 450 questionnaires were issued to acquire a more representative sample from the population and 342 questionnaires were received back (response rate = 76.22%). Thirty-one (31) questionnaires were not considered due to incomplete data. Finally, 311 questionnaires were determined to be valid. All participants had been involved in IOT-related initiatives for a minimum of three years. We conducted data collection across a spectrum of industries, encompassing enterprises of different sizes, ranging from small- to medium- to large-scale businesses. This comprehensive sampling approach ensures a representative and diverse dataset, allowing for a nuanced analysis of the research variables. The capacity of Chinese firms is often measured by the number of employees and turnover (revenue). Here is a breakdown of each category: small, medium, and large firms [69]. A small firm has less than 50 employees and has a turnover of less than 5 million RMB (around $725,000 USD). A medium firm contains between 50 to 250 employees and has a turnover between 5 million and 50 million RMB (around $725,000 to $7.25 million USD). A large firm contains more than 250 employees and has a turnover of more than 50 million RMB (over $7.25 million USD). Table 1 exhibits the demographic characteristics of the participants. We acquired the maximum count of responses from managers, comprising approximately 42.12 percent, and from large firms, 78.77 percent, from firms more than 20 years old, 41.74 percent, with more than 250 employees, 78.77 percent of the total.

Table 1.

Demographic profile.

5. Data Analysis and Results

5.1. Common Method Bias and Descriptive Analysis

Harman’s single-factor analysis was used to examine the common method bias (CMB). This analysis directed that a single factor solution explained 37.913% of the total variance, which is significantly less than 50% threshold value. The outcomes of this research indicate that CMB does not pose a significant issue.

5.2. Endogeneity Test

We employed the WarpPLS software to examine and analyze model endogeneity arising from predictor variables, with IOT exerting an indirect influence on firm performance for CE supply chain, a dependent variable. To address potential endogeneity, we introduced an instrumental variable (IC). This instrumental variable was created using a technique that shares a single stochastic variation. The results indicate that the p-value lacks statistical significance at the 5 percent confidence level. Consequently, we infer that endogeneity does not pose any issues in our framework.

5.3. Measurement Model

To evaluate the reliability of the constructs, we operated Cronbach’s alpha and composite reliability (CR). Primarily, items exhibiting factor loadings below 0.600 were excluded from the entire sample. Table 2 displays the findings for the items’ validity, factor loadings and reliability. Cronbach’s Alpha and CR values surpassed the permissible value of 0.700 for all items. AVE values exceeded 0.500, which accordingly demonstrates convergent validity. Cross-loading factors were assessed to evaluate discriminant validity.

Table 2.

Item loadings, reliability and validity.

Additionally, each indicator’s multicollinearity was evaluated using variance inflation factor values below five. Finally, Table 3 displays the cross-factor loadings for each item.

Table 3.

Discriminant validity—cross-loadings.

We additionally assessed discriminant validity, and the outcomes are outlined in Table 4. The table illustrates that the correlation between latent constructs was consistently smaller than the square root of the average variance extracted (AVE) for each individual construct, affirming the presence of discriminant validity in our model. Our comprehensive testing leads us to the further conclusion that the data exhibit construct validity.

Table 4.

Discriminant validity and correlation between constructs.

We examined the model fit indices, as presented in Table 5, which include average R-squared (ARS), average adjusted R-squared (AARS), average path coefficient (APC), average full collinearity VIF (AFVIF), average block VIF (AVIF) and goodness of fit (GoF). As demonstrated in Table 4, the values of ARS, AARS and APC are statistically significant at the 1% confidence level. AFVIF and AVIF fall within acceptable limits, and the GoF indicates a large value, suggesting the robustness of our model.

Table 5.

Model fit indices.

Lastly, we performed a thorough analysis of the data to scrutinize potential issues associated with causality. We computed the subsequent quality indices: R-squared contribution ratio, Sympson’s paradox ratio, non-linear bivariate causality direction ratio (NLBCDR) and statistical suppression ratio. As evidenced by the findings presented in Table 6, all test results fell within acceptable limits.

Table 6.

Quality indices.

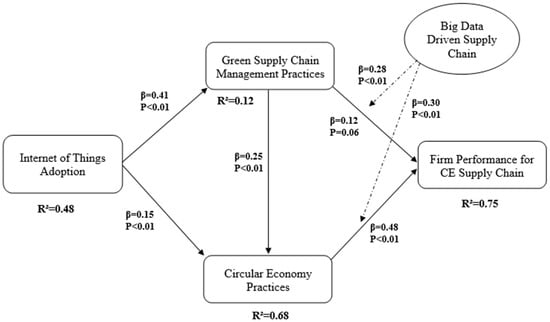

5.4. Structural Model

The subsequent step in this analysis was to evaluate the relationship of hypothesis. Table 7 displays the findings of this test. The findings demonstrated that H1: IoT → GSCM (β = 0.414, t = 7.285, p = 0.000); H2: IoT → CE (β = 0.0154, t = 2.879, p = 0.004); H3: GSCM → CE (β = 0.245, t = 3.294, p = 0.001); H4: GSCM → FP (β = 0.123, t = 1.814, p = 0.067); H5: CE → FP (β = 0.497, t = 5.977, p = 0.000); H6a: GSCM*BDSC → FP (β = 0.279, t = 4.178, p = 0.000); H6b: CE*BDSC → FP (β = 0.301, t = 4.210, p = 0.000). In this way the hypotheses H1, H2, H3, H5, H6a and H6b were positive and significant and, therefore, these are acceptable, while the hypothesis H4 is rejected. The final econometric model is shown in Figure 2.

Table 7.

Results of hypotheses testing (direct relationship).

Figure 2.

Final econometric model.

5.5. Mediation Analysis

As the final step in the analysis, we assessed the mediated relationship as presented in Table 8. The results demonstrated that H7a: IoT → GSCM → FP (β = 0.162., t = 2.978, p = 0.004); H7b: IoT → CE → FP (β = 0.302., t = 4.230, p = 0.000); H7c: IoT → GSCM → CE → FP (β = 0.501, t = 6.132, p = 0.000); H7d: IoT → GSCM*BDSC → FP (β = 0.402., t = 10.554, p = 0.000); H7e: IoT → CE*BDSC → FP (β = 0.680., t = 18.810, p = 0.000); H7f: IoT → GSCM → CE*BDSC → FP (β = 0.337, t = 8.220, p = 0.000). In this way all hypotheses are accepted.

Table 8.

Specific indirect effect (mediation test).

6. Discussion

Research suggests that IOT holds immense potential for revolutionizing green supply chain practices in the fast fashion industry, paving the pathway toward a sustainable future [51]. By embedding smart sensors and devices across all phases of the value chain, from raw material sourcing to post-consumer use, real-time data can be collected on resource consumption, energy usage and emissions [23,52]. This granular transparency empowers informed decision-making, enabling optimization of processes to minimize environmental impact [25]. By harnessing the power of IOT, fast fashion brands can shift toward a more circular economy, decoupling growth from environmental degradation and achieving true sustainability [25].

The IOT has revolutionized the fast fashion industry, offering groundbreaking opportunities to enhance circular practices and promote sustainability; our finding are supported by previous literature [25]. Real-time monitoring and traceability capabilities enabled by IOT technology have fundamentally changed the transparency and accountability of the supply chain [51]. This granular visibility empowers proactive interventions to optimize resource allocation and minimize waste streams [53]. Leveraging IOT’s advanced analytics, manufacturers can gain a deeper understanding of product life cycles, from patterns of use and consumer preferences to degradation and wear patterns [54]. This data-driven approach allows for more efficient recycling and remanufacturing processes, extending the lifecycle of product and decreasing the need for virgin materials [51]. By optimizing product disposal management, IOT enables the circular reuse and recycling of textile waste, further minimizing environmental impact [25].

This study highlights the positive impact of GSCM practices on CE practices in fast fashion. Our findings are encouraged by prior research; practices like sustainable sourcing and energy-efficient production lay the groundwork for addressing environmental issues [55]. Embracing CE principles enables manufacturers to optimize material use, implement closed-loop systems and minimize resource waste, significantly reducing the carbon emissions associated with fast fashion [45]. Incorporating these principles into the supply chain enables manufacturers to address environmental crises linked to the industry’s resource-intensive and linear production model [49].

Our findings reveal that GSCM practices have not had a significant impact on fast fashion manufacturers’ firm performance within a CE supply chain. This finding contradicts with some prior research [35], but aligns with other studies [70]. The unexpected negative impact of GSCM practices on firm performance raises intriguing points for discussion. Firstly, in the fast fashion sector, the emphasis on rapid production cycles and frequent changes in design trends may lead to challenges in aligning GSCM practices with the demands of a circular model [56]. The need for quick turnaround times and the constant pressure to introduce new collections might hinder the full integration of sustainable practices, impacting overall operational efficiency [71]. Secondly, the negative relationship could stem from the complexities of implementing green initiatives within a supply chain that inherently thrives on mass production [71]. The transition to sustainable sourcing, eco-friendly materials and responsible manufacturing processes may involve substantial upfront costs and operational disruptions. Fast fashion manufacturers might face difficulties in balancing the immediate financial impact of these changes with the long-term benefits [72].

The significant connection between embracing CE principles and firm performance is crucial for fast fashion manufacturers addressing the environment, as supported by previous literature [46]. Strategies such as efficient recycling, waste reduction and sustainable practices establish a resilient business model [35]. Fast fashion manufacturers adopting CE principles position themselves as environmentally responsible entities capable of navigating challenges, ensuring sustained firm performance in an industry prone to scrutiny [73]. This positive association with environmental responsibility results in heightened brand loyalty [74]; consumers prefer companies committed to addressing environmental crises through CE practices [73].

The positive moderating effect of BDSC provides manufacturers with a powerful tool to enhance their GSCM initiatives. This finding is supported by previous literature [62]. By leveraging real-time data analytics, manufacturers can identify inefficiencies, reduce waste and enhance the overall efficiency of sustainable practices, as reinforced by prior investigation [31]. Data-driven strategies allow for more insightful decision-making, leading to enhanced operational efficiency and reduced costs [75]. Enhanced firm performance is not only measured financially but also in terms of ecological and social responsibility, aligning with the CE principles [63].

The advantageous moderating impact of BDSC practices offer fast fashion manufacturers a strategic edge in optimizing CE practices, as reinforced by previous research [31,35]. Through the utilization of real-time data analytics, manufacturers gain the ability to precisely execute CE principles across the supply chain [76]. The precise insights from big data contribute to reduced costs, improved operational efficiency, and enhanced sustainability metrics [41]. This integrated approach not only positively impacts financial performance but also aligns with social and environmental responsibility, reflecting a comprehensive and circular business model [60].

The positive mediation role of GSCM practices between IOT and firm performance in the circular economy (CE) supply chain is further strengthened by the moderating impact of BDSC practices [32]. Big data enables real-time monitoring of value chain, resource consumption and waste generation, providing valuable insights for proactive interventions [29]. Predictive analytics based on IOT data can forecast demand, optimize inventory management, identify potential bottlenecks, minimize waste and enhance efficiency [30]. Big data, with its advanced analytics and real-time processing capabilities, enhances the efficiency and effect of GSCM on firm performance within the CE supply chain [32]. The integration of big data analytics allows for a more comprehensive and dynamic understanding of environmental performance metrics, optimizing resource efficiency, reducing waste and enhancing operational resilience [30]. By providing real-time insights into various facets of GSCM, such as sustainable sourcing, waste reduction and closed-loop recycling, BDSC practices strengthen the mediating role of GSCM between IOT and firm performance [29].

The positive mediation role of CE practices between IOT and firm performance in the CE supply chain is further strengthened by the moderating impact of BDSC practices. Big data, as a facilitator of advanced analytics and real-time insights, contributes significantly to fortifying the mediation of CE practices between IOT implementation and firm performance in the fast fashion industry [18]. Big-data-driven supply chain practices play an essential role in enhancing the precision and responsiveness of circular initiatives such as closed-loop recycling and sustainable sourcing [63]. The seamless integration and coordination enabled by big-data-driven approaches offer a more adaptive framework, ensuring that circular practices align cohesively with the demands of the fast fashion manufacturing sector [62]. Specifically, the impact of big data lies in its ability to optimize decision-making related to resource utilization, waste reduction and overall supply chain efficiency [39]. Through this dynamic synergy with IOT, BDSC practices foster a more coherent, data-informed and sustainable implementation of circular economy principles, ultimately amplifying the substantial effect on firm performance [29]. This strategic collaboration between IOT, big data and CE practices propels the fast fashion industry toward an environmentally responsible future [32].

Conclusively, the synergistic impact of IoT and BDSC practices on firm performance within the CE supply chain is multifaceted [32]. IoT facilitates real-time data acquisition from diverse points along the supply chain, enabling enhanced visibility and traceability of resources and products [29]. This data, when analyzed through big data analytics, provides valuable insights into production processes, demand patterns and environmental impacts [30]. By leveraging IOT and big data analytics, firms can optimize resource allocation, streamline production workflows and recognize opportunities for waste minimization and recycling, thereby improving overall operational efficiency and environmental sustainability [77]. Additionally, the integration of IOT with BDSC practices enables proactive decision-making and responsive supply chain management, leading to enhanced agility and resilience in the face of dynamic market conditions and environmental challenges. Together, IOT and big-data-driven supply chain practices synergistically reinforce each other, empowering firms to achieve higher levels of firm performance while advancing sustainability objectives within the fast fashion manufacturing sector [78].

6.1. Theoretical Implications

The findings of our research carry substantial theoretical implications, particularly within the realm of fast fashion manufacturing and its progression toward a CE supply chain. The positive impact of IOT on firm performance for a CE supply chain, mediated by circular economy practices and green supply chain practices, aligns seamlessly with the foundational principles of the RBV theory. IOT, positioned as a strategic resource, amplifies interconnected devices and sensors to create unique and valuable capabilities, providing fast fashion manufacturers with a platform on which to showcase sustainable practices and mitigate environmental impact. This alignment supports the RBV theory’s core tenet of leveraging unique and valuable resources for a competitive advantage. Moreover, the positive moderating impact of BDSC practices, also grounded in the RBV theory, underscores the significance of adaptive and innovative capabilities in navigating the intersections of GSCM practices and CE practices for heightened firm performance. The role of big data as a moderator underscores its transformative influence in optimizing sustainability initiatives, contributing to the reduction of environmental crises in the fast fashion industry. These theoretical implications underscore the strategic importance of IOT and BDSC practices in advancing the objectives of circular supply chains and fostering environmental sustainability within the fast fashion manufacturing landscape.

6.2. Practical Implications

The significant findings in our research hold substantial managerial implications for fast fashion manufacturers aiming to foster a sustainable future. Firstly, managers should actively integrate CE practices into their operations. This includes adopting circular design principles, extending product lifespans, promoting reuse and recycling and fostering closed-loop material flows. IOT and BDSC technologies can be pivotal in supporting CE initiatives by running real-time insights into resource consumption, waste generation and circular material flows. Secondly, managers should leverage IOT to optimize manufacturing processes and boost supply chain efficiency. IOT-enabled sensors can monitor manufacturing activities, track material movements and identify potential bottlenecks, leading to reduced waste, improved resource allocation and enhanced operational efficiency. BDSC can further amplify these benefits by analyzing IOT data to gain deeper insights into supply chain dynamics and optimize decision-making. Thirdly, managers should embrace big data analytics to gain actionable insights and drive continuous improvement. BDSC has a capability to collect, analyze and visualize data on sustainability performance, enabling businesses to benchmark their progress, identify areas for improvement and set ambitious sustainability goals. This data-driven approach can foster a culture of continuous improvement and contribute to long-term sustainability leadership.

6.3. Policy Implication

Our findings indicate that the implementation of IOT and BDSC practices can significantly support China’s environmental policies. The integration of IOT enables real-time monitoring and efficient management of resources, aligning with the Circular Economy Promotion Law by enhancing recycling and waste reduction efforts. Big data analytics provide insights into product lifecycles, supporting the Extended Producer Responsibility by ensuring products are designed and disposed of sustainably. These technologies facilitate GSCM practices, optimizing energy use and reducing emissions, thereby adhering to the Green Development Guidelines. Furthermore, IOT and big data enhance tracking and management of carbon emissions, contributing to the Action Plan for Carbon Neutrality by 2030. Thus, the adoption of these advanced technologies not only helps firms comply with regulations but also drives innovation and sustainability in the fast fashion industry.

Based on our suggestions, policymakers should advocate for the development and implementation of supportive regulations and incentives to encourage fast fashion manufacturers to adopt these technologies. This might include providing financial incentives or tax breaks for companies investing in IOT and big data infrastructure and training programs. Additionally, policymakers should collaborate with industry associations to establish industry-wide standards for IOT and big data implementation in the context of circular practices. Furthermore, policymakers should formulate and promote policies that facilitate the integration of advanced data analytics in supply chain operations. This could comprise creating funding programs to support enterprises in adopting big-data-driven strategies, fostering cross-industry collaborations to share best practices and incentivizing the development of sustainable technologies.

7. Conclusions

In conclusion, our investigation illuminates the transformative potential of integrating IOT, BDSC, GSCM and CE practices within the fast fashion manufacturing sector in Guangzhou, China. Interestingly, our findings revealed that GSCM practices initially showed a negative effect on firm performance in the direct relationship, however, when GSCM practices were examined in the mediation analysis between IOT and firm performance, they turned out to be positive. This suggests that the incorporation of IOT technology can effectively mitigate the negative influence of conventional GSCM practices, ultimately contributing to improved firm performance in the realm of CE supply chains.

Moreover, the moderation analysis demonstrates that BDSC practices play a pivotal part in enhancing the positive relationship between GSCM practices, CE practices and firm performance. This insight provides valuable guidance for fast fashion manufacturers aiming to leverage data-driven approaches to optimize sustainability initiatives. Furthermore, the control variable firm size has a substantial impact on firm performance, highlighting the strategic advantage of larger companies in adopting IOT and BDSC practices. As a control variable, firm size becomes a key factor in enabling companies to capitalize on these technologies for enhanced overall business performance.

Our tested model, with IOT explaining 48% of the variance, GSCM practices explaining 12% and CE practices explaining 68%, offers a comprehensive understanding of the factors shaping firm performance for CE supply chains. The high explanatory power of the model, with 75% of the variance explained by firm performance, reinforces the significance of these technologies and practices in driving positive environmental and business outcomes. The most unique aspect of our study lies in its ability to shed light on how the combined forces of IOT and BDSC practices work in tandem to drive firm performance in the context of CE supply chains. IOT provides real-time monitoring with data-driven decision-making, and BDSC practices bring an additional layer of optimization, enhancing the positive impacts of green and circular practices on overall business outcomes.

Limitations and Future Lines of Research

Despite the worthwhile insights achieved from this investigation, it is essential to acknowledge some limitations. Firstly, the scope of sustainable supply chain management (SSCM) is broad and encompasses various elements beyond GSCM and CE practices, but our study focuses on these two specific aspects due to their critical relevance to the fast fashion industry in China. GSCM and CE were chosen because they are pivotal in addressing environmental challenges and promoting sustainability in this high-impact sector. However, we also acknowledge the importance of integrating other elements of SSCM, such as social and economic sustainability, to provide a comprehensive approach. This includes addressing fair labor practices, community engagement and ethical sourcing under social sustainability, as well as cost efficiency, market competitiveness and risk management under economic sustainability. These broader elements can be incorporated into future studies.

Though our study has primarily addressed the operational implementation of CE practices in the fast fashion industry through IOT and BDSC, a significant limitation is the lack of focus on how CE can be integrated into the corporate vision and policy frameworks of firms. Future research should explore this dimension, examining how businesses can make CE the centerpiece of their corporate strategies, thereby driving systemic and cultural change within organizations. Investigating the role of leadership, corporate governance and strategic management in fostering a comprehensive circular transition will provide deeper insights into achieving long-term sustainability in the fast fashion industry.

While the adoption of IOT and BDSC practices in the fast fashion industry offers substantial benefits, it is essential to acknowledge potential negative effects. These technologies may introduce issues related to data privacy and security, as the increased collection and analysis of data can lead to vulnerabilities and breaches. Furthermore, the implementation of IOT and BDSC can result in significant financial costs and require extensive changes to existing infrastructure, which may not be feasible for all firms. The rapid advancement of technology can also contribute to increased electronic waste, posing environmental and health risks. Therefore, it is imperative to integrate principles of responsible research and innovation (RRI) to mitigate these risks. RRI emphasizes the need for ethical considerations, stakeholder engagement and sustainable development throughout the innovation process. By addressing these concerns, our research not only highlights the transformative potential of IOT and BDSC but also underscores the importance of implementing these technologies responsibly to ensure long-term sustainability and ethical compliance.

Author Contributions

Conceptualization, Q.Z. and A.U.; methodology, Q.Z. and A.U.; software, A.U.; validation, Q.Z., A.U., S.A. and M.A.; formal analysis, A.U., S.A. and M.A.; investigation, A.U., S.A. and M.A.; resources, Q.Z.; data curation, A.U.; writing—original draft preparation, Q.Z. and A.U.; writing—review and editing, Q.Z., A.U., S.A. and M.A.; visualization, A.U.; supervision, Q.Z.; project administration, Q.Z.; funding acquisition, Q.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Key Project of National Social Science Foundation of China (21AGL014); Shenzhen Science and Technology Program (JCYJ20210324093208022); Shenzhen University Humanities and Social Sciences High-level Innovation Team Project for Leading Scholars (24LJXZ06).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Ethics Committee of Shenzhen University under the code 201901355.

Informed Consent Statement

Each respondent was presented with a detailed consent form prior to participation.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Masson-Delmotte Global Warming of 1.5 °C. Available online: https://api.semanticscholar.org/CorpusID:135204600 (accessed on 8 February 2021).

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Berg, A.; Granskog, A.; Lee, L.; Magnus, K. Fashion on Climate: How the Fashion Industry Can Urgently Act to Reduce Its Greenhouse Gas Emissions. Available online: www.mckinsey.com/industries/retail/our-insights/fashion-on-climate (accessed on 2 January 2022).

- Chien, F.S.; Chau, K.Y.; Sadiq, M. Impact of Climate Mitigation Technology and Natural Resource Management on Climate Change in China. Resour. Policy 2023, 81, 103367. [Google Scholar] [CrossRef]

- Yale Despite Pledges to Cut Emissions, China Goes on a Coal Spree. Available online: https://e360.yale.edu/features/despite-pledges-to-cut-emissions-china-goes-on-a-coal-spree (accessed on 24 March 2022).

- Statista China: Apparel Production Volume 2022|Statista. Available online: https://www.statista.com/statistics/1202677/china-apparel-production-volume/ (accessed on 18 December 2022).

- Filho, W.L.; Perry, P.; Heim, H.; Dinis, M.A.P.; Moda, H.; Ebhuoma, E.; Paço, A. An Overview of the Contribution of the Textiles Sector to Climate Change. Front. Environ. Sci. 2022, 10, 973102. [Google Scholar]

- Fleck, A. The World’s Biggest Exporters of Clothes|Statista. Available online: https://www.statista.com/chart/29845/worlds-biggest-exporters-of-clothes/ (accessed on 30 April 2023).

- Chu, N. The Paradoxes of Creativity in Guangzhou, China’s Wholesale Market for Fast Fashion. Cult. Theory Crit. 2018, 59, 178–192. [Google Scholar] [CrossRef]

- McDowall, W.; Geng, Y.; Huang, B.; Barteková, E.; Bleischwitz, R.; Türkeli, S.; Kemp, R.; Doménech, T. Circular Economy Policies in China and Europe. J. Ind. Ecol. 2017, 21, 651–661. [Google Scholar] [CrossRef]

- Geng, Y.; Zhang, P.; Côté, R.P.; Fujita, T. Assessment of the National Eco-Industrial Park Standard for Promoting Industrial Symbiosis in China. J. Ind. Ecol. 2009, 13, 15–26. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H. Progress Toward a Circular Economy in China. J. Ind. Ecol. 2011, 15, 435–457. [Google Scholar] [CrossRef]

- Liu, N.; Liu, C.; Xia, Y.; Ren, Y.; Liang, J. Examining the Coordination Between Green Finance and Green Economy Aiming for Sustainable Development: A Case Study of China. Sustainability 2020, 12, 3717. [Google Scholar] [CrossRef]

- Dong, L.; Yang, X.; Li, H. The Belt and Road Initiative and the 2030 Agenda for Sustainable Development: Seeking Linkages for Global Environmental Governance. Chin. J. Popul. Resour. Environ. 2018, 16, 203–210. [Google Scholar] [CrossRef]

- Esther Whieldon Lauren Costello Simone Rossi Fast on Fashion, Slow on Sustainability: Clothing Companies and the Circular Economy. Available online: https://www.spglobal.com/esg/insights/fast-on-fashion-slow-on-sustainability-clothing-companies-and-the-circular-economy (accessed on 21 December 2023).

- Koty, A.C. Sustainable Fashion in China: An Emerging Trend in the Apparel Industry. Available online: https://www.china-briefing.com/news/sustainable-fashion-in-china-an-emerging-trend-in-the-apparel-industry/ (accessed on 21 April 2022).

- Pesce, M.; Tamai, I.; Guo, D.; Critto, A.; Brombal, D.; Wang, X.; Cheng, H.; Marcomini, A. Circular Economy in China: Translating Principles into Practice. Sustainability 2020, 12, 832. [Google Scholar] [CrossRef]

- Rejeb, A.; Suhaiza, Z.; Rejeb, K.; Seuring, S.; Treiblmaier, H. The Internet of Things and the Circular Economy: A Systematic Literature Review and Research Agenda. J. Clean. Prod. 2022, 350, 13143–13149. [Google Scholar] [CrossRef]

- Rejeba, A.; Simske, S.; Rejeb, K.; Treiblmaier, H.; Zailani, S. Internet of Things Research in Supply Chain Management and Logistics: A Bibliometric Analysis. Internet Things 2020, 12, 10013–10018. [Google Scholar] [CrossRef]

- Ogbuke, N.J.; Yusuf, Y.Y.; Dharma, K.; Mercangoz, B.A. Big Data Supply Chain Analytics: Ethical, Privacy and Security Challenges Posed to Business, Industries and Society. Prod. Plan. Control. 2022, 33, 123–137. [Google Scholar] [CrossRef]

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Wernerfelt, B. A Resource-Based View of the Firm. Strateg. Manag. J. 1984, 5, 171–180. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A Review of Internet of Things (IoT) Embedded Sustainable Supply Chain for Industry 4.0 Requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Pratap, S.; Jauhar, S.K.; Gunasekaran, A.; Kamble, S.S. Optimizing the IoT and Big Data Embedded Smart Supply Chains for Sustainable Performance. Comput. Ind. Eng. 2023, 2024, 10982–10988. [Google Scholar] [CrossRef]

- Voulgaridis, K.; Lagkas, T.; Angelopoulos, C.M.; Nikoletseas, S.E. IoT and Digital Circular Economy: Principles, Applications, and Challenges. Comput. Netw. 2022, 219, 109456. [Google Scholar] [CrossRef]

- Biswas, B.; Gupta, R. Analysis of Barriers to Implement Blockchain in Industry and Service Sectors. Comput. Ind. Eng. 2019, 136, 225–241. [Google Scholar] [CrossRef]

- Kshetri, N. 1 Blockchain’s Roles in Meeting Key Supply Chain Management Objectives. Int. J. Inf. Manag. 2018, 39, 80–89. [Google Scholar] [CrossRef]

- Khoo, B. RFID—From Tracking to the Internet of Things: A Review of Developments. In Proceedings of the 2010 IEEE/ACM International Conference on Green Computing and Communications GreenCom 2010 & 2010 IEEE/ACM International Conference on Cyber, Physical and Social Computing, CPSCom, Hangzhou, China, 18–20 December 2010; pp. 533–538. [Google Scholar] [CrossRef]

- Bi, Z.; Jin, Y.; Maropoulos, P.; Zhang, W.J.; Wang, L. Internet of Things (IoT) and Big Data Analytics (BDA) for Digital Manufacturing (DM). Int. J. Prod. Res. 2023, 61, 4004–4021. [Google Scholar] [CrossRef]

- Qi, Q.; Xu, Z.; Rani, P. Big Data Analytics Challenges to Implementing the Intelligent Industrial Internet of Things (IIoT) Systems in Sustainable Manufacturing Operations. Technol. Forecast. Soc. Change 2023, 190, 122401. [Google Scholar] [CrossRef]

- Del Giudice, M.; Chierici, R.; Mazzucchelli, A.; Fiano, F. Supply Chain Management in the Era of Circular Economy: The Moderating Effect of Big Data. Int. J. Logist. Manag. 2020, 32, 337–356. [Google Scholar] [CrossRef]

- Li, J.; Herdem, M.S.; Nathwani, J.; Wen, J.Z. Methods and Applications for Artificial Intelligence, Big Data, Internet of Things, and Blockchain in Smart Energy Management. Energy AI 2023, 11, 100208. [Google Scholar] [CrossRef]

- Liao, H.T.; Wang, Z. Sustainability and Artificial Intelligence: Necessary, Challenging, and Promising Intersections. In Proceedings of the 2020 Management Science Informatization and Economic Innovation Development Conference (MSIEID), Guangzhou, China, 18–20 December 2020; pp. 360–363. [Google Scholar] [CrossRef]

- Karmaker, C.L.; Al Aziz, R.; Ahmed, T.; Misbauddin, S.M.; Moktadir, M.A. Impact of Industry 4.0 Technologies on Sustainable Supply Chain Performance: The Mediating Role of Green Supply Chain Management Practices and Circular Economy. J. Clean. Prod. 2023, 419, 13824–13829. [Google Scholar] [CrossRef]

- Bag, S.; Dhamija, P.; Bryde, D.J.; Singh, R.K. Effect of Eco-Innovation on Green Supply Chain Management, Circular Economy Capability, and Performance of Small and Medium Enterprises. J. Bus. Res. 2022, 141, 60–72. [Google Scholar] [CrossRef]

- Wamba, S.F.; Dubey, R.; Gunasekaran, A.; Akter, S. The Performance Effects of Big Data Analytics and Supply Chain Ambidexterity: The Moderating Effect of Environmental Dynamism. Int. J. Prod. Econ. 2020, 222, 107498. [Google Scholar] [CrossRef]

- Rehman, S.U.; Ashfaq, K.; Bresciani, S.; Giacosa, E.; Mueller, J. Nexus among Intellectual Capital, Interorganizational Learning, Industrial Internet of Things Technology and Innovation Performance: A Resource-Based Perspective. J. Intellect. Cap. 2023, 24, 509–534. [Google Scholar] [CrossRef]

- Paiola, M.; Schiavone, F.; Grandinetti, R.; Chen, J. Digital Servitization and Sustainability through Networking: Some Evidences from IoT-Based Business Models. J. Bus. Res. 2021, 132, 507–516. [Google Scholar] [CrossRef]

- Tseng, M.L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.F.; Kuo, T.C. Circular Economy Meets Industry 4.0: Can Big Data Drive Industrial Symbiosis? Resour. Conserv. Recycl. 2018, 131, 146–147. [Google Scholar] [CrossRef]

- Meriton, R.; Bhandal, R.; Graham, G.; Brown, A. An Examination of the Generative Mechanisms of Value in Big Data-Enabled Supply Chain Management Research. Int. J. Prod. Res. 2021, 59, 7283–7310. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Dwivedi, Y.K. Role of Institutional Pressures and Resources in the Adoption of Big Data Analytics Powered Artificial Intelligence, Sustainable Manufacturing Practices and Circular Economy Capabilities. Technol. Forecast. Soc. Change 2021, 163, 120420. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Mikalef, P.; Blomsma, F.; Li, J. Towards a Business Analytics Capability for the Circular Economy. Technol. Forecast. Soc. Change 2021, 171, 120957. [Google Scholar] [CrossRef]

- Xing, Y.; Liu, Y. Integrating Product-Service Innovation into Green Supply Chain Management from a Life Cycle Perspective: A Systematic Review and Future Research Directions. Technovation 2023, 126, 102825. [Google Scholar] [CrossRef]

- Liu, S.Y.H.; Napier, E.; Runfola, A.; Cavusgil, S.T. MNE-NGO Partnerships for Sustainability and Social Responsibility in the Global Fast-Fashion Industry: A Loose-Coupling Perspective. Int. Bus. Rev. 2020, 29, 101736. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E.; Passaro, R.; Shashi. Determinants of the Transition towards Circular Economy in SMEs: A Sustainable Supply Chain Management Perspective. Int. J. Prod. Econ. 2021, 242, 108297. [Google Scholar] [CrossRef]

- Triguero, Á.; Cuerva, M.C.; Sáez-Martínez, F.J. Closing the Loop through Eco-Innovation by European Firms: Circular Economy for Sustainable Development. Bus. Strategy Environ. 2022, 31, 2337–2350. [Google Scholar] [CrossRef]

- Abbate, S.; Centobelli, P.; Cerchione, R. From Fast to Slow: An Exploratory Analysis of Circular Business Models in the Italian Apparel Industry. Int. J. Prod. Econ. 2023, 260, 108824. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Supply Chain Collaboration and Sustainability Performance in Circular Economy: A Systematic Literature Review. Int. J. Prod. Econ. 2022, 245, 108402. [Google Scholar] [CrossRef]

- Rodríguez-Espíndola, O.; Cuevas-Romo, A.; Chowdhury, S.; Díaz-Acevedo, N.; Albores, P.; Despoudi, S.; Malesios, C.; Dey, P. The Role of Circular Economy Principles and Sustainable-Oriented Innovation to Enhance Social, Economic and Environmental Performance: Evidence from Mexican SMEs. Int. J. Prod. Econ. 2022, 248, 108495. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Luo, Z.; Wambo, S.F.; Roubaud, D.; Foropon, C. Examining the Role of Big Data and Predictive Analytics on Collaborative Performance in Context to Sustainable Consumption and Production Behaviour. J. Clean. Prod. 2018, 196, 1508–1521. [Google Scholar] [CrossRef]

- Kachouei, M.A.; Kaushik, A.; Ali, M.A. Internet of Things-Enabled Food and Plant Sensors to Empower Sustainability. Adv. Intell. Syst. 2023, 5, 2300321. [Google Scholar] [CrossRef]

- Roy, V. Contrasting Supply Chain Traceability and Supply Chain Visibility: Are They Interchangeable? Int. J. Logist. Manag. 2021, 32, 942–972. [Google Scholar] [CrossRef]

- Meng, K.; Cao, Y.; Peng, X.; Prybutok, V.; Youcef-Toumi, K. Smart Recovery Decision-Making for End-of-Life Products in the Context of Ubiquitous Information and Computational Intelligence. J. Clean. Prod. 2020, 272, 122804. [Google Scholar] [CrossRef]

- de Oliveira, R.T.; Ghobakhloo, M.; Figueira, S. Industry 4.0 towards Social and Environmental Sustainability in Multinationals: Enabling Circular Economy, Organizational Social Practices, and Corporate Purpose. J. Clean. Prod. 2023, 430, 139712. [Google Scholar] [CrossRef]

- Mishra, J.L.; Chiwenga, K.D.; Ali, K. Collaboration as an Enabler for Circular Economy: A Case Study of a Developing Country. Manag. Decis. 2019, 59, 1784–1800. [Google Scholar] [CrossRef]

- Burke, H.; Zhang, A.; Wang, J.X. Integrating Product Design and Supply Chain Management for a Circular Economy. Prod. Plan. Control. 2023, 34, 1097–1113. [Google Scholar] [CrossRef]

- Sharma, M.; Kumar, A.; Luthra, S.; Joshi, S.; Upadhyay, A. The Impact of Environmental Dynamism on Low-Carbon Practices and Digital Supply Chain Networks to Enhance Sustainable Performance: An Empirical Analysis. Bus. Strategy Environ. 2022, 31, 1776–1788. [Google Scholar] [CrossRef]

- Borges, A.F.S.; Laurindo, F.J.B.; Spínola, M.M.; Gonçalves, R.F.; Mattos, C.A. The Strategic Use of Artificial Intelligence in the Digital Era: Systematic Literature Review and Future Research Directions. Int. J. Inf. Manag. 2021, 57, 102225. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Orji, I.J.; Gupta, H.; Kunc, M. Risks Associated with the Implementation of Big Data Analytics in Sustainable Supply Chains. Omega 2021, 105, 102502. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big Data Analytics as an Operational Excellence Approach to Enhance Sustainable Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The Impact of Big Data Analytics and Artificial Intelligence on Green Supply Chain Process Integration and Hospital Environmental Performance. Technol. Forecast. Soc. Change 2021, 165, 120557. [Google Scholar] [CrossRef]

- Gupta, S.; Chen, H.; Hazen, B.T.; Kaur, S.; Santibañez Gonzalez, E.D.R. Circular Economy and Big Data Analytics: A Stakeholder Perspective. Technol. Forecast. Soc. Change 2019, 144, 466–474. [Google Scholar] [CrossRef]

- Awan, U.; Shamim, S.; Khan, Z.; Zia, N.U.; Shariq, S.M.; Khan, M.N. Big Data Analytics Capability and Decision-Making: The Role of Data-Driven Insight on Circular Economy Performance. Technol. Forecast. Soc. Change 2021, 168, 120766. [Google Scholar] [CrossRef]

- Gao, C.; Kuah-Pearce, K.E. The Garment Industry in South China. China Perspect. 2015, 2015, 25–32. [Google Scholar] [CrossRef]

- Liu, G. Comparative Study on the Pathways of Industrial Parks towards Sustainable Development between China and Canada. Resour. Conserv. Recycl. 2018, 128, 417–425. [Google Scholar] [CrossRef]

- Zeng, H.; Chen, X.; Xiao, X.; Zhou, Z. Institutional Pressures, Sustainable Supply Chain Management, and Circular Economy Capability: Empirical Evidence from Chinese Eco-Industrial Park Firms. J. Clean. Prod. 2017, 155, 54–65. [Google Scholar] [CrossRef]

- Jain, N.K.; Panda, A.; Choudhary, P. Institutional Pressures and Circular Economy Performance: The Role of Environmental Management System and Organizational Flexibility in Oil and Gas Sector. Bus. Strategy Environ. 2020, 28, 3509–3525. [Google Scholar] [CrossRef]

- Maroufkhani, P.; Tseng, M.-L.; Iranmanesh, M.; Ismail, W.K.W.; Khalid, H. Big Data Analytics Adoption: Determinants and Performances among Small to Mediumisized Enterprises. Int. J. Inf. Manag. 2020, 54, 102–190. [Google Scholar] [CrossRef]

- National Bureau of statistics of China Statistical Communiqué of the People’s Republic of China on the 2021 National Economic and Social Development. Available online: https://www.stats.gov.cn/english/PressRelease/202202/t20220227_1827963.html (accessed on 16 December 2023).

- Khan, S.A.R.; Qianli, D. Impact of Green Supply Chain Management Practices on Firms’ Performance: An Empirical Study from the Perspective of Pakistan. Environ. Sci. Pollut. Res. 2017, 24, 16829–16844. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Agarwal, V.; Appolloni, A.; Saikouk, T.; Gnanavelbabu, A. Integrating Lean and Agile Practices for Achieving Global Sustainability Goals in Indian Manufacturing Industries. Technol. Forecast. Soc. Change 2021, 171, 120982. [Google Scholar] [CrossRef]

- Asgary, N.; Li, G. Corporate Social Responsibility: Its Economic Impact and Link to the Bullwhip Effect. J. Bus. Ethics 2016, 135, 665–681. [Google Scholar] [CrossRef]

- Nayal, K.; Kumar, S.; Raut, R.D.; Queiroz, M.M.; Priyadarshinee, P.; Narkhede, B.E. Supply Chain Firm Performance in Circular Economy and Digital Era to Achieve Sustainable Development Goals. Bus. Strategy Environ. 2022, 31, 1058–1073. [Google Scholar] [CrossRef]

- Patwa, N.; Sivarajah, U.; Seetharaman, A.; Sarkar, S.; Maiti, K.; Hingorani, K. Towards a Circular Economy: An Emerging Economies Context. J. Bus. Res. 2021, 122, 725–735. [Google Scholar] [CrossRef]

- Liu, P. Pricing Policies and Coordination of Low-Carbon Supply Chain Considering Targeted Advertisement and Carbon Emission Reduction Costs in the Big Data Environment. J. Clean. Prod. 2019, 210, 343–357. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the Future of Sustainable Supply Chain Management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Sestino, A.; Prete, M.I.; Piper, L.; Guido, G. Internet of Things and Big Data as Enablers for Business Digitalization Strategies. Technovation 2020, 98, 102173. [Google Scholar] [CrossRef]

- Côrte-Real, N.; Ruivo, P.; Oliveira, T. Leveraging Internet of Things and Big Data Analytics Initiatives in European and American Firms: Is Data Quality a Way to Extract Business Value? Inf. Manag. 2020, 57, 103141. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).