Deep Low-Carbon Economic Optimization Using CCUS and Two-Stage P2G with Multiple Hydrogen Utilizations for an Integrated Energy System with a High Penetration Level of Renewables

Abstract

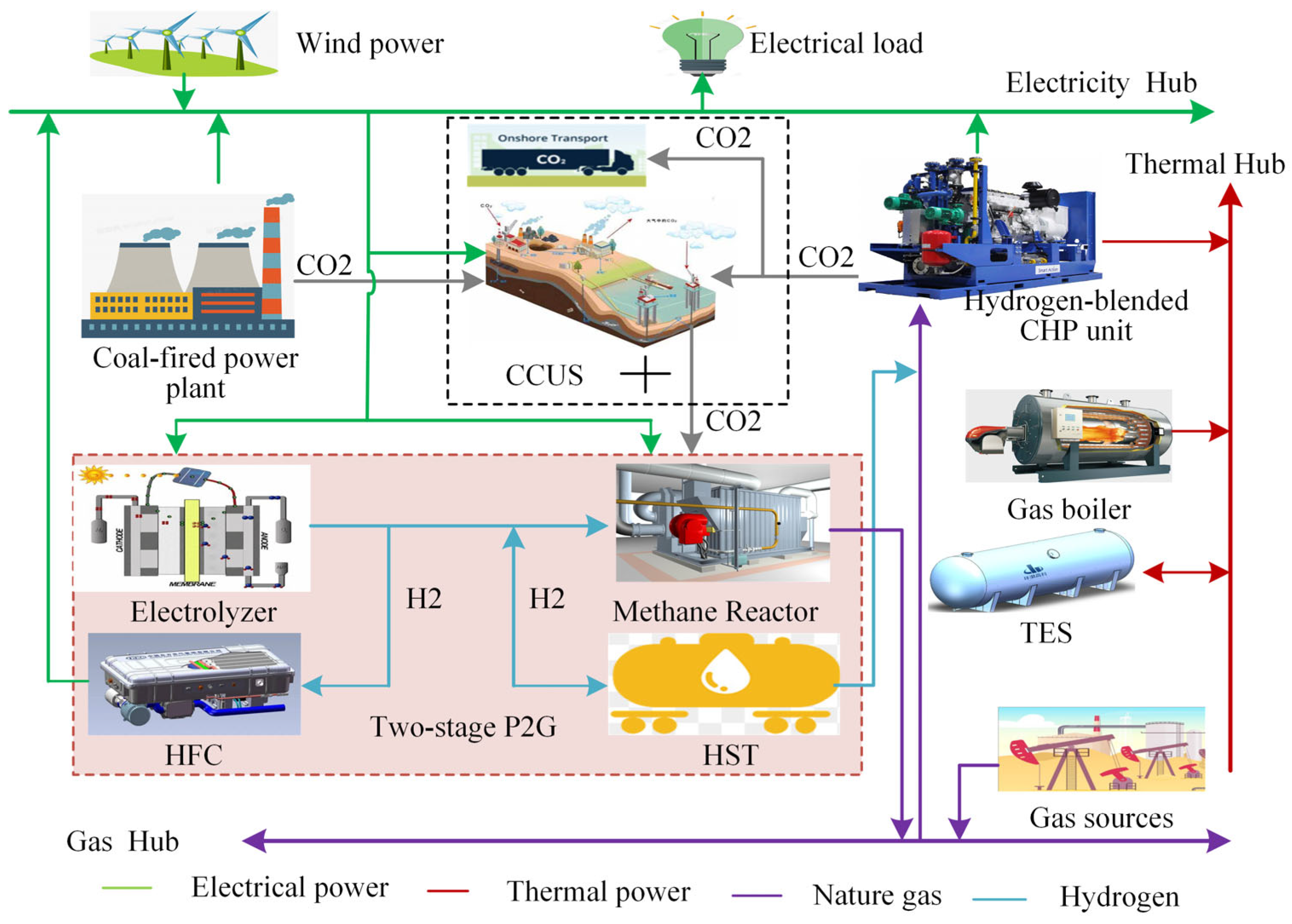

:1. Introduction

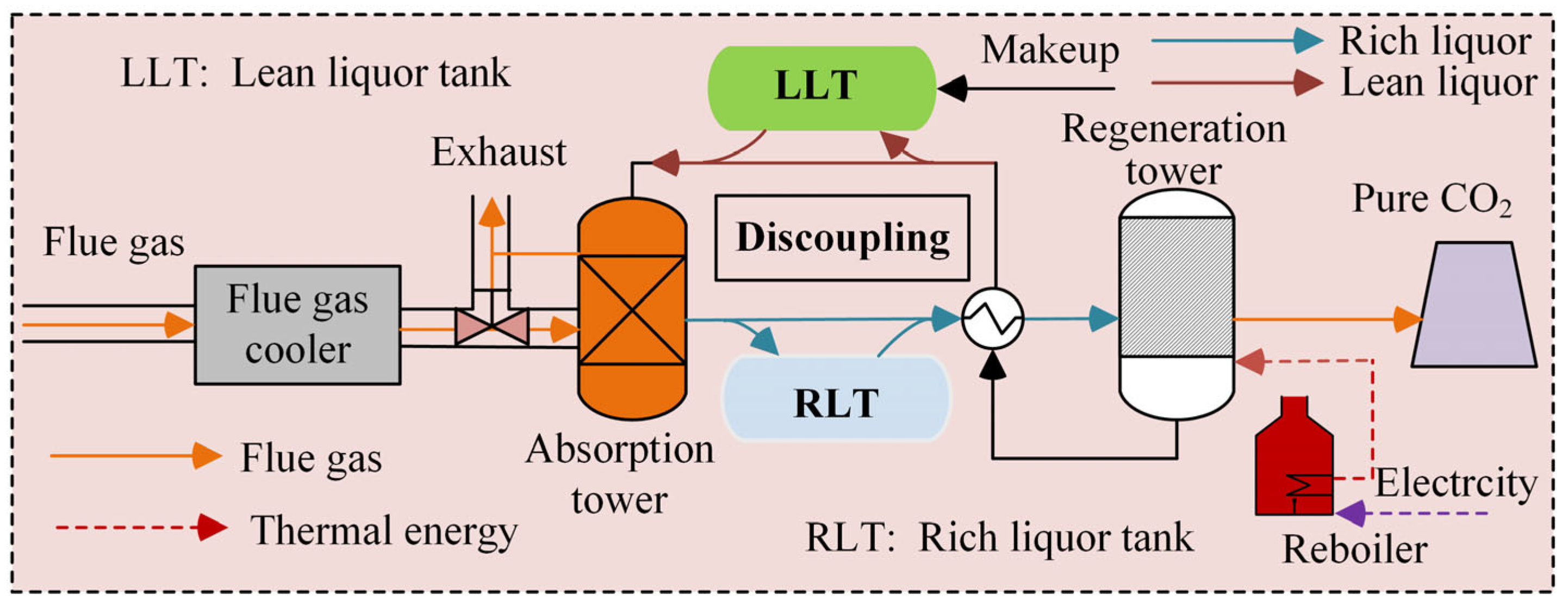

2. Analysis and Modeling of CCUS

2.1. The Model of Integrated Flexible CCS

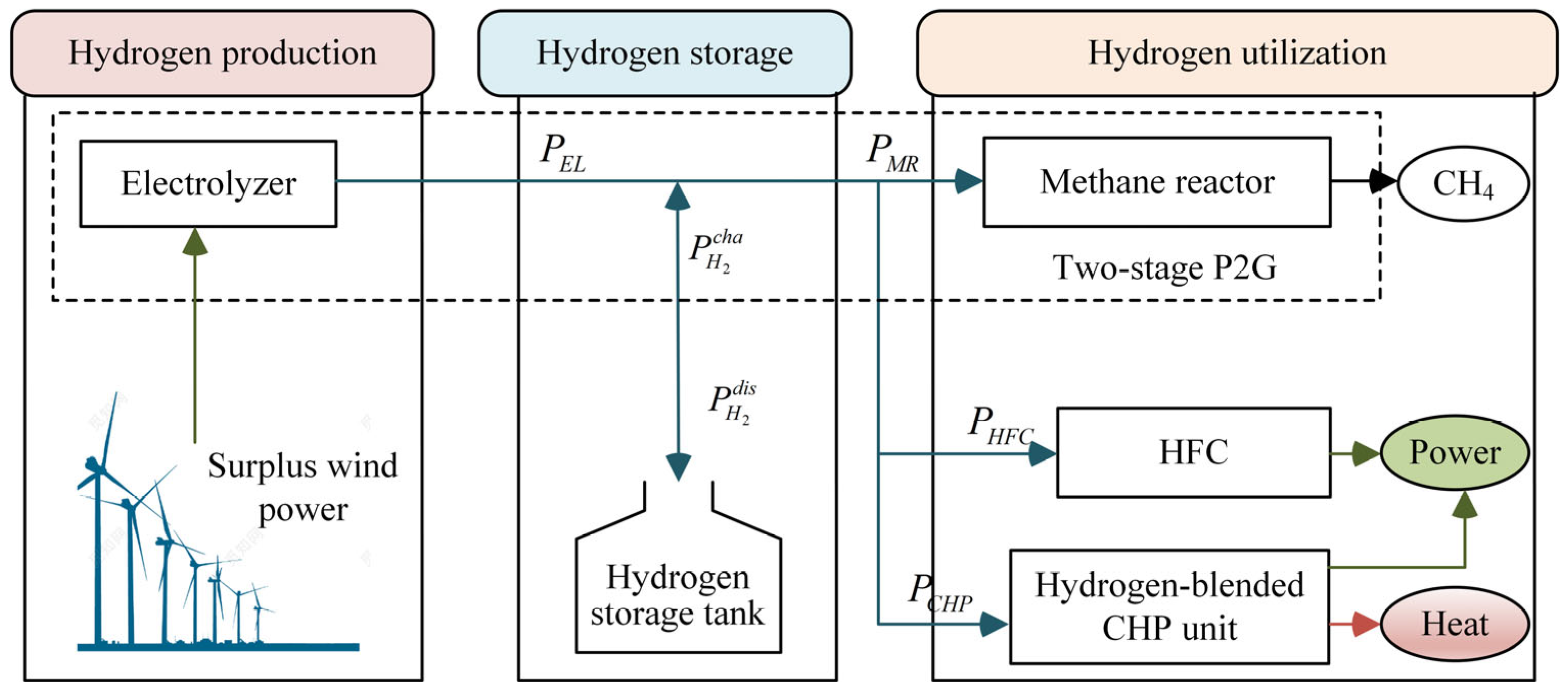

2.2. The Model of Two-Stage P2G with Hydrogen Multiple Utilization

3. Deep Low-Carbon Economic Optimization

3.1. Stepwise Carbon Trading Model

3.2. Integrated Demand Response Model

3.3. Objective Function

3.4. Constraints

3.4.1. Energy Balance Constraints

3.4.2. Device Operation Constraints

3.4.3. Purchase Constraints of Natural Gas

3.5. Solution

4. Case Study

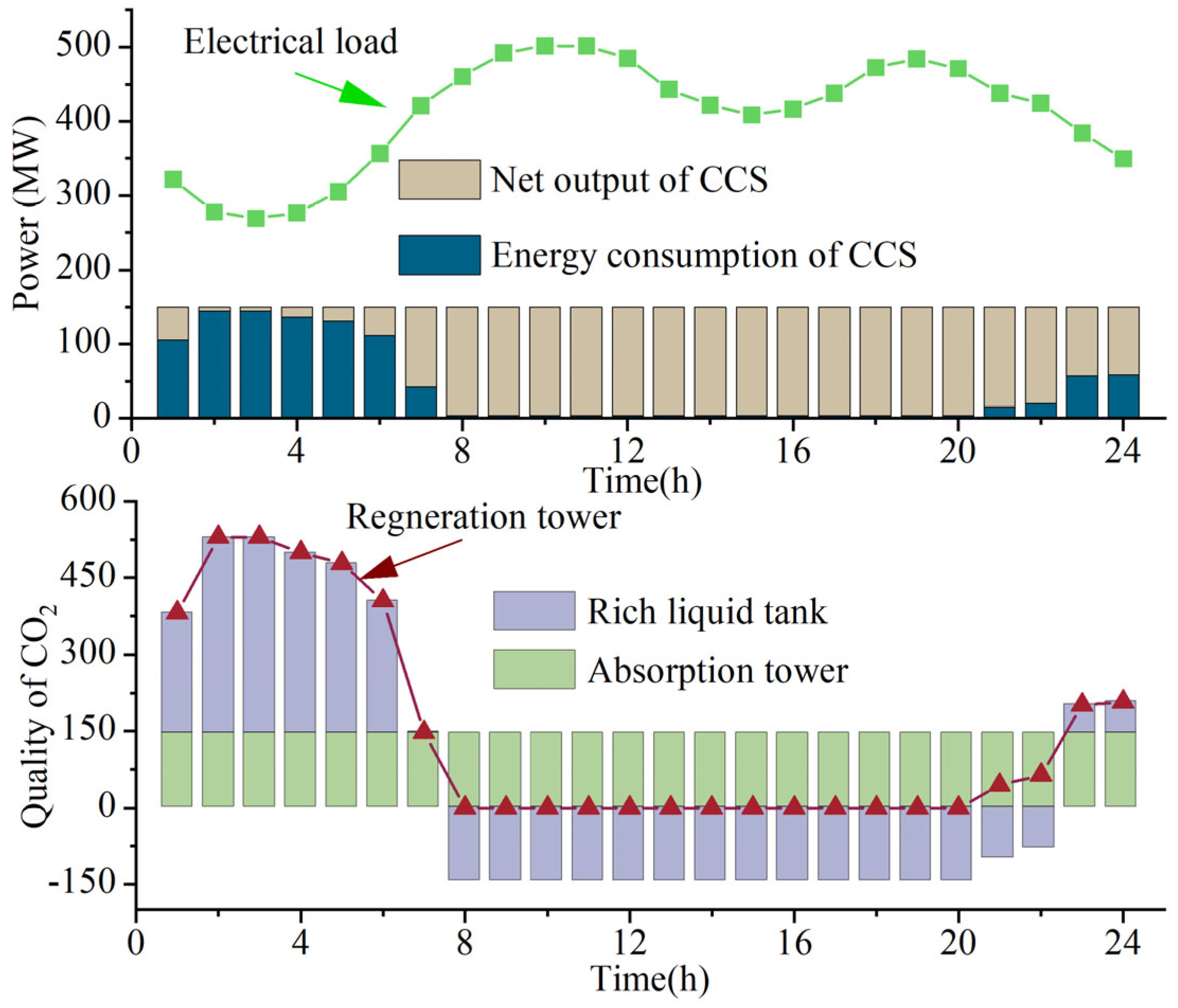

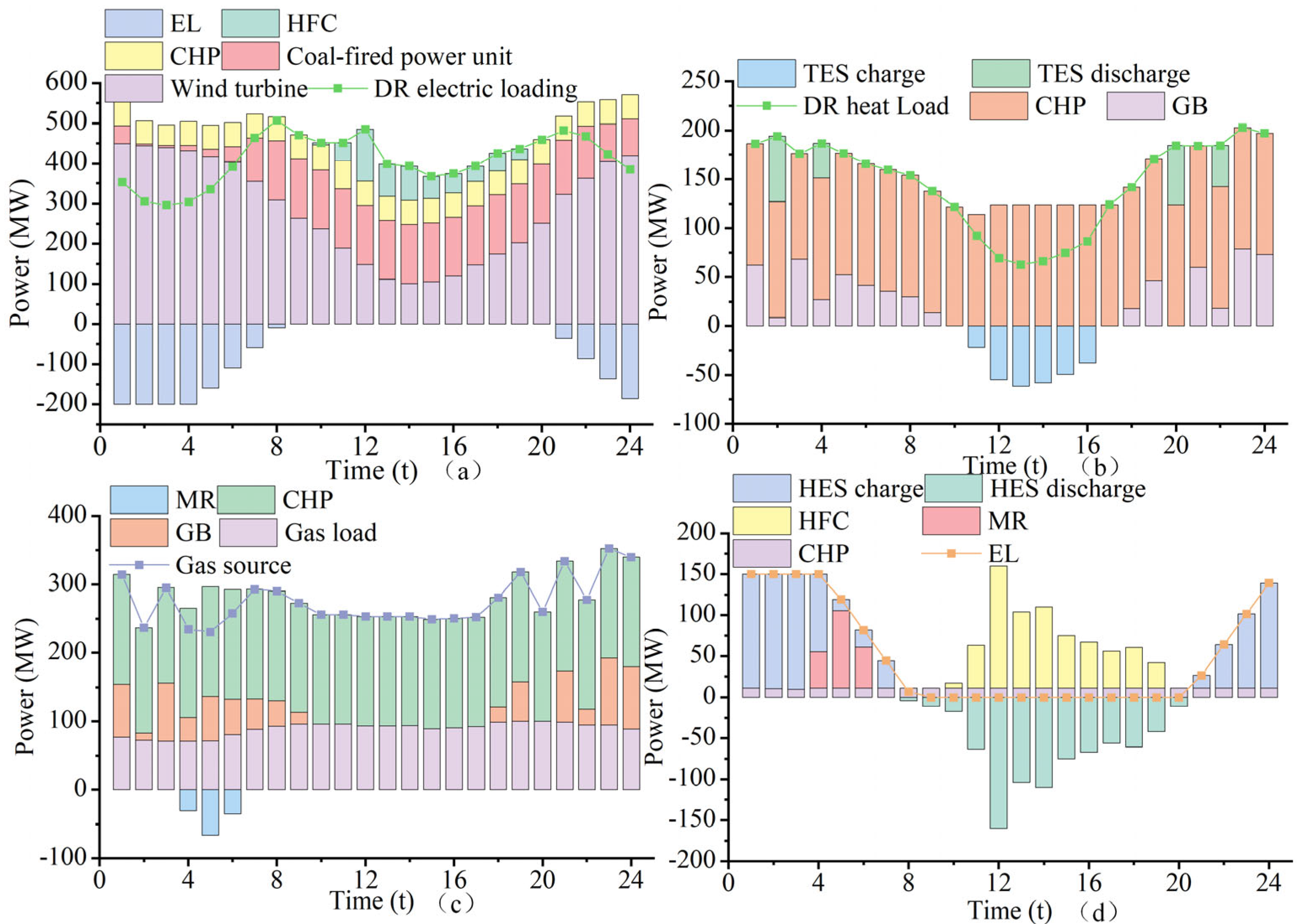

4.1. Optimization Results

4.2. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| P2G | Power to gas |

| CCS | Carbon capture storage |

| CCUS | Carbon capture, utilization and storage |

| IES | Integrated energy system |

| CHP | Combined heat and power |

| EL | Electrolyzer |

| MR | Methane reaction |

| HFC | Hydrogen fuel cell |

| GB | Gas boiler |

| TES | Thermal energy storage |

| HST | Hydrogen storage tank |

| WP | Wind energy |

| NG | Natural gas |

| Symbol | |

| P | Electrical power |

| H | Heating power |

| Energy consumption of carbon dioxide | |

| Split ratio of flue gas | |

| E | Mass of carbon dioxide |

| Efficiency | |

| V | Capacity of liquid tank |

| Hydrogen blending ratio of fuel gas | |

| LHV | Low heating value |

| Carbon trading base price | |

| Growth rate of the carbon trading price | |

| Compensation factor | |

| F | Cost |

| Carbon content per unit calorific value of natural gas | |

| Thermoelectric conversion coefficient | |

| Carbon dioxide gas density | |

| v | Flow rate |

| Unit cost of storing carbon dioxide | |

| Superscript | |

| net | Net power |

| cha | Charging |

| dis | Discharging |

| mix | Mixed flue gas |

| Subscript | |

| t | Time |

| CP | Coal-fired power plant |

| lean | Lean liquor |

| rich | Rich liquor |

| L | Load |

| tran | Transferred |

| DR | Demand response |

| coal | Coal-fired unit |

| G | Power grid |

| cur | Curtailment |

References

- Wei, P.Y.; Bamisile, O.; Adun, H.; Cai, D.S.; Obiora, S.; Li, J.; Huang, Q. Bibliographical progress in hybrid renewable energy systems’ integration, modelling, optimization, and artificial intelligence applications: A critical review and future research perspective. Energy Sources Part A-Recovery Util. Environ. Eff. 2023, 45, 2058–2088. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Z. Construction and Application of Regional Carbon Performance Evaluation Index System: The Case of Chinese Provinces. Sustainability 2024, 16, 4460. [Google Scholar] [CrossRef]

- Zhang, C.; Su, B.; Zhou, K.; Yang, S. Decomposition analysis of China’s CO2 emissions (2000–2016) and scenario analysis of its carbon intensity targets in 2020 and 2030. Sci. Total Environ. 2019, 668, 432–442. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Li, S.; Liu, H.; Zhang, H.; Baeyens, J. Recent Research in Solar-Driven Hydrogen Production. Sustainability 2024, 16, 2883. [Google Scholar] [CrossRef]

- Holechek, J.L.; Geli, H.M.E.; Sawalhah, M.N.; Valdez, R. A Global Assessment: Can Renewable Energy Replace Fossil Fuels by 2050? Sustainability 2022, 14, 4792. [Google Scholar] [CrossRef]

- Wu, M.; Yan, R.; Zhang, J.; Fan, J.; Wang, J.; Bai, Z.; He, Y.; Cao, G.; Hu, K. An enhanced stochastic optimization for more flexibility on integrated energy system with flexible loads and a high penetration level of renewables. Renew. Energy 2024, 227, 120502. [Google Scholar] [CrossRef]

- Yan, R.; Wang, J.; Huo, S.; Qin, Y.; Zhang, J.; Tang, S.; Wang, Y.; Liu, Y.; Zhou, L. Flexibility improvement and stochastic multi-scenario hybrid optimization for an integrated energy system with high-proportion renewable energy. Energy 2023, 263, 125779. [Google Scholar] [CrossRef]

- Wu, M.; Fan, J.; Yan, R.; Hu, X.; Zhang, J.; He, Y.; Cao, G.; Zhao, W.; Song, D. Flexible Regulation and Synergy Analysis of Multiple Loads of Buildings in a Hybrid Renewable Integrated Energy System. Sustainability 2024, 16, 2969. [Google Scholar] [CrossRef]

- Wang, J.; Han, Z.; Guan, Z. Hybrid solar-assisted combined cooling, heating, and power systems: A review. Renew. Sustain. Energy Rev. 2020, 133, 110256. [Google Scholar] [CrossRef]

- Pal, A.; Kakran, S.; Kumar, A.; Youssef, A.B.; Singh, U.P.; Sidhu, A. Powering squarely into the future: A strategic analysis of hydrogen energy in QUAD nations. Int. J. Hydrogen Energy 2023, 49, 16–41. [Google Scholar] [CrossRef]

- Wang, H.; Hua, P.; Wu, X.; Zhang, R.; Granlund, K.; Li, J.; Zhu, Y.; Lahdelma, R.; Teppo, E.; Yu, L. Heat-power decoupling and energy saving of the CHP unit with heat pump based waste heat recovery system. Energy 2022, 250, 123846. [Google Scholar] [CrossRef]

- Pan, Z.; Guo, Q.; Sun, H. Interactions of district electricity and heating systems considering time-scale characteristics based on quasi-steady multi-energy flow. Appl. Energy 2016, 167, 230–243. [Google Scholar] [CrossRef]

- Lynch, A.; Perez, Y.; Gabriel, S.; Mathonniere, G. Nuclear fleet flexibility: Modeling and impacts on power systems with renewable energy. Appl. Energy 2022, 314, 118903. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Li, G.; Wang, J.; Zhao, D.; Chen, C. Improving operational flexibility of integrated energy system with uncertain renewable generations considering thermal inertia of buildings. Energy Convers. Manag. 2020, 207, 112526. [Google Scholar] [CrossRef]

- Chen, X.; Wang, C.; Wu, Q.; Dong, X.; Yang, M.; He, S.; Liang, J. Optimal operation of integrated energy system considering dynamic heat-gas characteristics and uncertain wind power. Energy 2020, 198, 117270. [Google Scholar] [CrossRef]

- Pan, E.; Li, H.; Wang, Z.; Peng, D.; Zhao, L.; Fan, L.; Wang, Y.; Huang, F.; Ma, Y.; Liu, L. Operation optimization of integrated energy systems based on heat storage characteristics of heating network. Energy Sci. Eng. 2021, 9, 223–238. [Google Scholar] [CrossRef]

- Deng, T.; Tian, L.; Hu, B.; Liu, X.; Liu, J.; Zhou, G.; Zhao, Y. Dynamic availability of energy storage in district heating networks for automatic generation control of a CHP plant. Appl. Therm. Eng. 2021, 183, 116198. [Google Scholar] [CrossRef]

- Wu, C.; Gu, W.; Xu, Y.; Jiang, P.; Lu, S.; Zhao, B. Bi-level optimization model for integrated energy system considering the thermal comfort of heat customers. Appl. Energy 2018, 232, 607–616. [Google Scholar] [CrossRef]

- Li, Y.; Sun, F.; Zhang, Q.; Chen, X.; Yuan, W. Numerical Simulation Study on Structure Optimization and Performance Improvement of Hot Water Storage Tank in CHP System. Energies 2020, 13, 4734. [Google Scholar] [CrossRef]

- Xue, X.; Ai, X.; Fang, J.; Yao, W.; Wen, J. Real-time schedule of integrated heat and power system: A multi-dimensional stochastic approximate dynamic programming approach. Int. J. Electr. Power Energy Syst. 2022, 134, 107427. [Google Scholar] [CrossRef]

- Yan, Z.; Quan, L.Y.U.; Yang, L.I.; Na, Z.; Haixia, W.; Hui, S.U.N. Analysis on Operation Flexibility of Combined Heat and Power Plant with Four Improved Power-Heat Decoupling Schemes. Autom. Electr. Power Syst. 2020, 44, 163–171. [Google Scholar]

- Cheng, X.; Gu, C.; An, N.; Liu, X.; Bo, L.; Zheng, H.; Cui, Y. Coordinated wind power dispatch model for an integrated heat and power system by a novel scenario-dependent algorithm. In Proceedings of the 2021 Power System and Green Energy Conference (PSGEC), Shanghai, China, 20–22 August 2021; pp. 765–774. [Google Scholar]

- Qi, Z.; Peng, S.; Wu, P.; Tseng, M.-L. Renewable Energy Distributed Energy System Optimal Configuration and Performance Analysis: Improved Zebra Optimization Algorithm. Sustainability 2024, 16, 5016. [Google Scholar] [CrossRef]

- Kim, M.; Kwon, S.; Ji, M.; Shin, H.; Min, B. Multi-lateral horizontal well with dual-tubing system to improve CO2 storage security and reduce CCS cost. Appl. Energy 2023, 330, 120368. [Google Scholar] [CrossRef]

- Zhu, Z.; Sheng, M.; Chen, Z. Low-carbon economic dispatching of integrated energy system considering liquid air energy storage and integrated demand response. Dianli Zidonghua Shebei/Electr. Power Autom. Equip. 2022, 42, 1–13. [Google Scholar]

- Wu, Q.; Li, C. Modeling and operation optimization of hydrogen-based integrated energy system with refined power-to-gas and carbon-capture-storage technologies under carbon trading. Energy 2023, 270, 126832. [Google Scholar] [CrossRef]

- Cui, Y.; Zeng, P.; Hui, X.; Li, H.; Zhao, J. Low-carbon Economic Dispatch Considering the Integrated Flexible Operation Mode of Carbon Capture Power Plant. Dianwang Jishu/Power Syst. Technol. 2021, 45, 1877–1885. [Google Scholar]

- Wang, Y.; Li, M.; Qi, Y. Low-carbon economic dispatching of integrated energy system with P2G considering comprehensive and flexible operation mode of carbon capture power plant. Dianli Zidonghua Shebei/Electr. Power Autom. Equip. 2023, 43, 1–8. [Google Scholar]

- Zhou, R.; Sun, H.; Tang, X.; Zhang, W.; Yu, H. Low-Carbon Economic Dispatch Based on Virtual Power Plant Made up of Carbon Capture Unit and Wind Power Under Double Carbon Constraint. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2018, 38, 1675–1683. [Google Scholar]

- Sun, H.; Sun, X.; Kou, L.; Ke, W. Low-Carbon Economic Operation Optimization of Park-Level Integrated Energy Systems with Flexible Loads and P2G under the Carbon Trading Mechanism. Sustainability 2023, 15, 15203. [Google Scholar] [CrossRef]

- Khani, H.; Farag, H.E.Z. Optimal Day-Ahead Scheduling of Power-to-Gas Energy Storage and Gas Load Management in Wholesale Electricity and Gas Markets. IEEE Trans. Sustain. Energy 2018, 9, 940–951. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H.; Zhu, Y. Optimal Operation of a Regional Integrated Energy System Considering P2G and Stepped Carbon Trading. In Proceedings of the 5th Asia Energy and Electrical Engineering Symposium, AEEES 2023, Chengdu, China, 23–26 March 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; pp. 1796–1801. [Google Scholar]

- Tao, Y.; Qiu, J.; Lai, S.; Zhao, J.; Xue, Y. Carbon-Oriented Electricity Network Planning and Transformation. Ieee Trans. Power Syst. 2021, 36, 1034–1048. [Google Scholar] [CrossRef]

- Li, X.; Li, T.; Liu, L.; Wang, Z.; Li, X.; Huang, J.; Huang, J.; Guo, P.; Xiong, W. Operation optimization for integrated energy system based on hybrid CSP-CHP considering power-to-gas technology and carbon capture system. J. Clean. Prod. 2023, 391, 136119. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, X.; Ghias, A.M.Y.M.; Chen, Z. Coordinated carbon capture systems and power-to-gas dynamic economic energy dispatch strategy for electricity-gas coupled systems considering system uncertainty: An improved soft actor-critic approach. Energy. 2023, 391, 136119. [Google Scholar] [CrossRef]

- Qiu, B.; Gao, Z.; Wang, K. IES Low-Carbon Economic Dispatch Considering Natural Gas Pressure Energy Power Generation under P2G-CCS. In Proceedings of the 2023 IEEE International Conference on Power Science and Technology, ICPST 2023, Kunming, China, 5–7 May 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; pp. 793–800. [Google Scholar]

- Guo, R.; Ye, H.; Zhao, Y. Low carbon dispatch of electricity-gas-thermal-storage integrated energy system based on stepped carbon trading. Energy Rep. 2022, 8, 449–455. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, J.; Wang, H.; Zhao, W.; Yang, L.; Shen, X. Optimal scheduling of integrated energy system considering carbon capture and power-to-gas. Dianli Zidonghua Shebei/Electr. Power Autom. Equip. 2023, 43, 127–134. [Google Scholar]

| Device | Parameter | Value | Device | Parameter | Value |

|---|---|---|---|---|---|

| coal-fired power plant | Upper and lower limits of coal-fired power generation output (MW) | 455/150 | Hydrogen-blended CHP unit | CHP capacity (MW) | 200 |

| Upper and lower limits of climbing power (MW) | 200/−200 | Upper and lower limits of climbing power (MW/h) | 50 | ||

| Carbon emission intensity per unit of power generation (t/(MW∙h)) | 1.02 | Comprehensive efficiency of the CHP | 0.92 | ||

| Coal cost per unit of power generation (CNY/(MW∙h)) | 420 | Upper and lower limits of heat-to-electric ratio | 0.48/2.07 | ||

| CCUS | Basic energy consumption of the CCUS (MW) | 3 | P2G | EL equipment capacity (MW) | 200 |

| Energy consumption coefficient of the CCUS operation ((MW∙h)/t) | 0.268 | Energy conversion efficiency of the EL | 0.75 | ||

| Absorption efficiency/regeneration efficiency | 0.95/0.9 | Upper and lower limits of climbing power of the EL (MW/h) | 50 | ||

| Maximum operating condition coefficient | 120% | Capacity of MR equipment (MW) | 200 | ||

| Initial liquid storage capacity of the liquid tank (m3) | 30,000 | Energy conversion efficiency of the MR | 0.7 | ||

| Maximum/minimum liquid storage capacity of the liquid tank (m3) | 60,000/3000 | Upper and lower limits of climbing power of the MR (MW/h) | 50 | ||

| GB | GB equipment capacity (MW) | 150 | HFC | Capacity of HFC equipment (MW) | 400 |

| Upper and lower limits of climbing power (MW/h) | 75/–75 | Upper and lower limits of climbing power (MW/h) | 200/–200 | ||

| Thermal efficiency of the GB | 0.8 | Electricity generation efficiency of the HFC | 0.87 | ||

| Thermal storage tank | Upper and lower limits of the heat storage capacity (MW∙h) | 270/30 | HST | Upper and lower limits of the HES capacity (MWh) | 1500/150 |

| Initial heat storage capacity (MW∙h) | 150 | Initial HES capacity (MWh) | 750 | ||

| Single maximum heat storage/release power (MW) | 75 | Single maximum hydrogen storage/release power (MW) | 500 | ||

| Heat storage/release efficiency | 0.85/0.5 | Hydrogen storage/release efficiency | 0.95/0.95 |

| Coal Purchase Cost | Gas Purchase Cost | Carbon Trading Cost | Carbon Storage Cost | Curtailment Penalty Cost | Demand Response Cost | Investment Cost of CCUS | Total Cost | Wind Power Utilization Rate/% | Net Carbon Emissions/Ton | |

|---|---|---|---|---|---|---|---|---|---|---|

| Case 1 | 1525.2 | 2786.7 | 424.5 | 0 | 1043.8 | 11.8 | 0 | 5792.1 | 69.33 | 4871.1 |

| Case 2 | 1623.9 | 2901.9 | −206.3 | 296.4 | 817.2 | 12 | 264.3 | 5709.5 | 75.99 | 2212.9 |

| Case 3 | 1759.9 | 2560.5 | −345.4 | 365.5 | 481.7 | 11.8 | 322 | 5156 | 85.85 | 1657.3 |

| Case 4 | 1512.0 | 2312.6 | −361.1 | 311.5 | 0 | 9.7 | 322 | 4166.7 | 100.00 | 1454.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Zhang, J.; Yuan, L.; Yan, R.; He, Y.; Zhao, W.; Nin, N. Deep Low-Carbon Economic Optimization Using CCUS and Two-Stage P2G with Multiple Hydrogen Utilizations for an Integrated Energy System with a High Penetration Level of Renewables. Sustainability 2024, 16, 5722. https://doi.org/10.3390/su16135722

Fan J, Zhang J, Yuan L, Yan R, He Y, Zhao W, Nin N. Deep Low-Carbon Economic Optimization Using CCUS and Two-Stage P2G with Multiple Hydrogen Utilizations for an Integrated Energy System with a High Penetration Level of Renewables. Sustainability. 2024; 16(13):5722. https://doi.org/10.3390/su16135722

Chicago/Turabian StyleFan, Junqiu, Jing Zhang, Long Yuan, Rujing Yan, Yu He, Weixing Zhao, and Nang Nin. 2024. "Deep Low-Carbon Economic Optimization Using CCUS and Two-Stage P2G with Multiple Hydrogen Utilizations for an Integrated Energy System with a High Penetration Level of Renewables" Sustainability 16, no. 13: 5722. https://doi.org/10.3390/su16135722