Sustainable Strategies for Crystalline Solar Cell Recycling: A Review on Recycling Techniques, Companies, and Environmental Impact Analysis

Abstract

:1. Introduction

- A thorough investigation of environment-friendly recycling procedures that focuses on chemical processes of high-purity silicon for recycling to increase its sustainability.

- Discussion of new opportunities and problems to assess the advantages of the current PV recycling system and pinpoint the obstacles of recycling companies.

- Identify recycling companies across the world that are approaching and developing new technologies for reducing the current environmental issues.

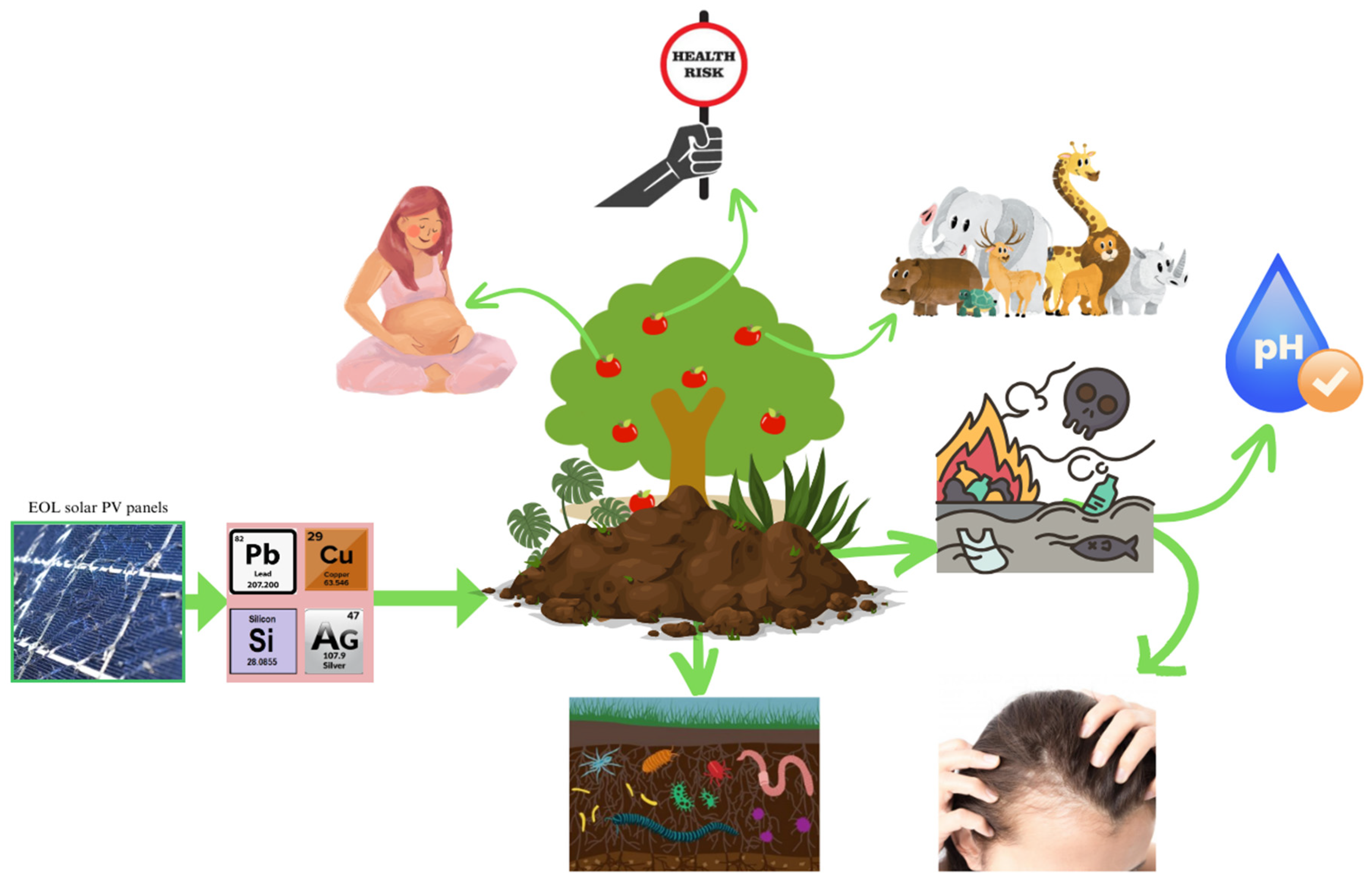

- Impact of Pb, Cu, Ag, and Si after disposing of the cell from the PV module in the environment.

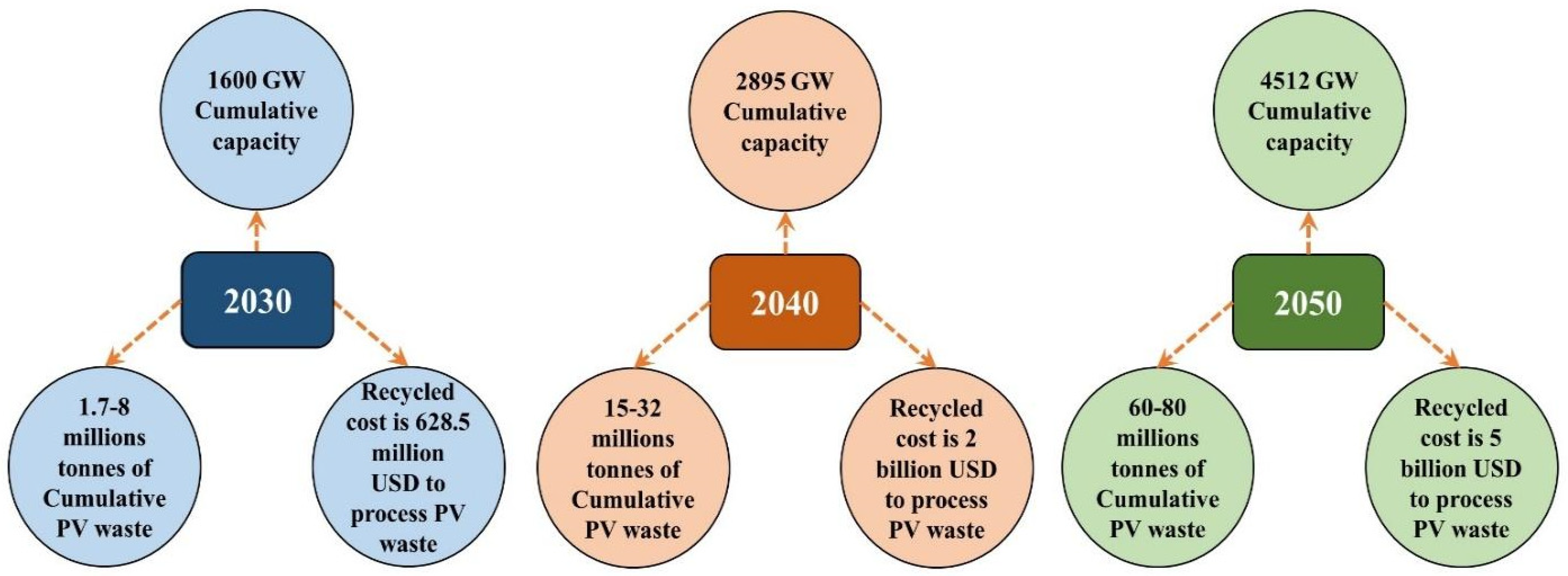

2. Global PV Capacity and Estimated Projection of PV Waste

2.1. Global Projection of Cumulative Capacity, Cumulative PV Waste, and Recycling Cost

2.2. Market Share of PV Panel Module Type

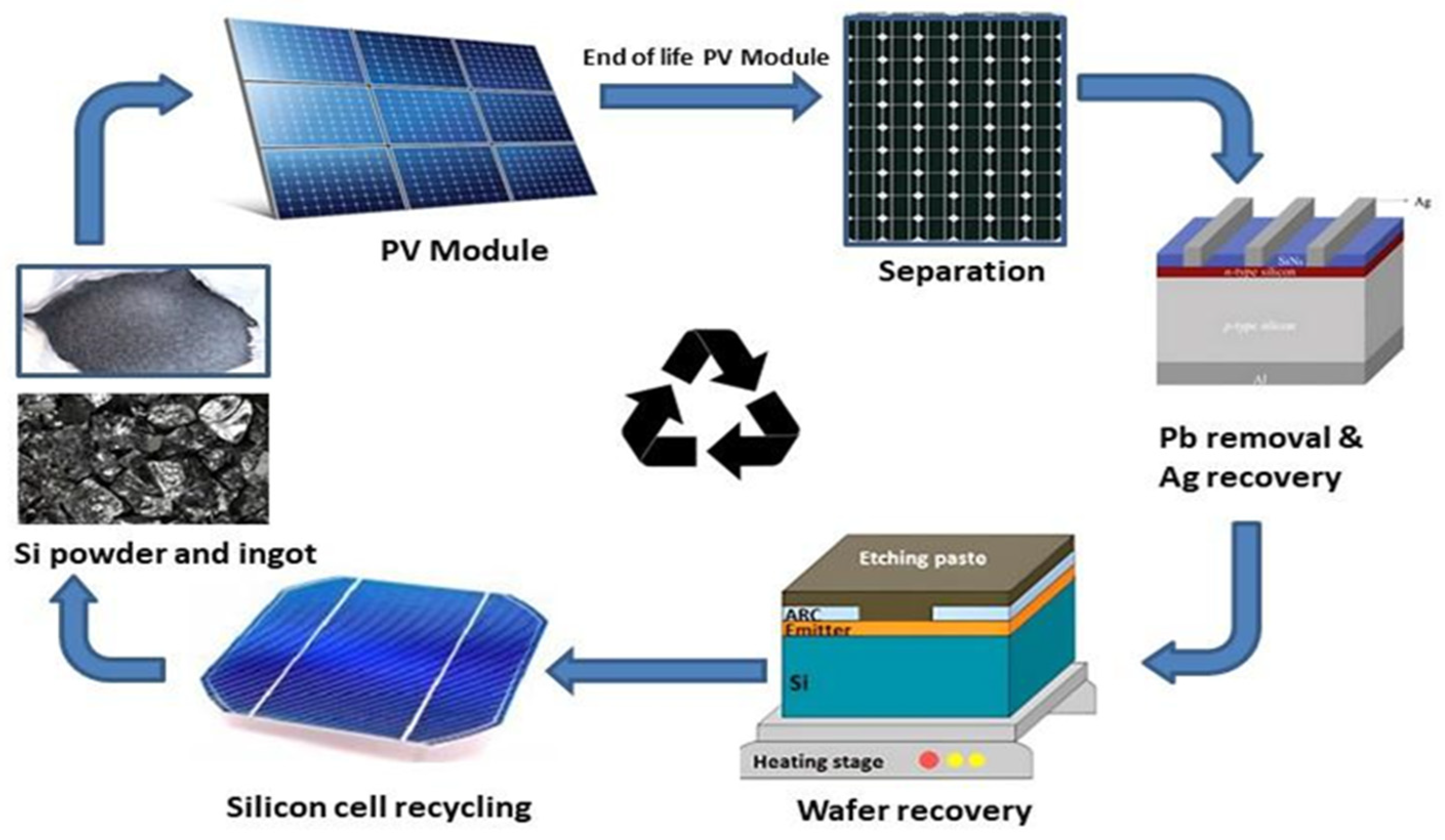

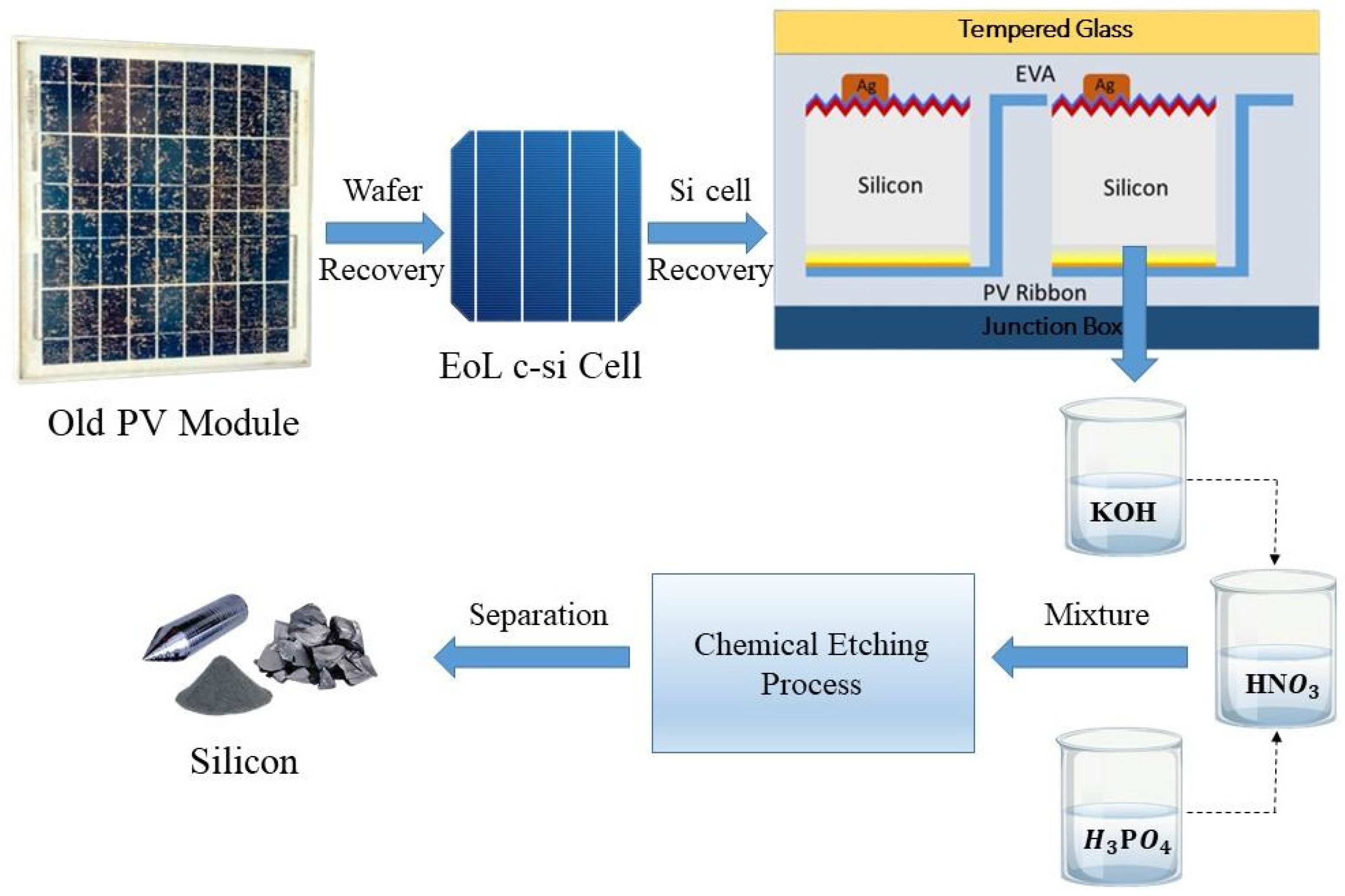

2.3. Technologies for Recycling Crystalline Silicon Cells

2.4. An Overview of the c-Si PV Panel EoL Recycling Process

- Glass, encapsulation layers, semiconductor components, and other materials make up PV cells.

- Thermal methods are used to break down the covering layers and remove the PV cells.

- The glass, EVA sheet, ribbon, and back sheet from the module are removed after the metal frame. Lead, silver, silicon, and other module components are recovered from the semiconductor by further recycling processes using etching techniques.

3. Recent Studies and Research on Crystalline Silicon Cell Recycling

3.1. Comparison of Chemical Treatment

3.2. An Overview of Recycling Companies

3.3. Technical Comparison and Economic Potential of Recyclable Materials

3.4. Concerns of Recycling Companies

3.5. Comparative Analysis of Recycling Companies

3.6. Impact of Improper Disposal of Si Solar Cells

3.7. Severe Problems of Improper Disposal

3.8. Minor Problems of Improper Disposal

4. Discussion and Recommendation

4.1. Barriers to Recycling PV Waste

4.2. Incentives for Waste Disposal

4.3. Approaches of Different Countries in PV Recycling

- (i)

- Australia: The Australian government has made it a priority to ensure that systems for dealing with complaints about solar PV waste are in place. Modern systems that decrease the environmental impact of solar PV technology throughout their lives will be the consequence of the Australian Ministry’s decision [90].

- (ii)

- USA: Since the state of California DTSC has raised its recycling capacity and renewed its facilities for the disposal of PV waste management, the responsibility for solar waste recycling has also been taken by them when the capacity of European facilities is reduced. First Solar manufacturing company, which is a USA-based firm, has factories in different regions such as the USA, Germany, and Malaysia that use recycling technologies.

- (iii)

- Japan: solar panel producers collaborate with local companies on recycling technology research connected to recycling technology in Europe, while the Japanese Environment Ministry oversees the recycling of waste from solar panels.

- (iv)

- China: The Chinese government aggressively encourages the recycling and remanufacturing of solar panel components through several laws and programs. For instance, the Ministry of Industry and Information Technology (MIIT) is elevating standards and promoting the creation of new technologies to control the anticipated rise in solar panel waste. Likewise, several provinces have established demonstration lines and pilot programs for recycling technologies, including Jiangxi, Hebei, Henan, Jiangsu, and Ningxia (PV Tech) (GovCN) (Yicai Global) (PV magazine International). Dedicated recycling firms in China include China National Building Material Group Corporation (CNBM), Jiangxi LDK Solar Hi-Tech, GCL-Poly Energy Holdings Limited, and Ningbo Solar Electric Power Co., Ltd.

- (v)

- India: waste management regulations for solar PV waste recycling are still under consideration by the Indian authority.

5. Conclusions

- ▪

- Advancements in recovery efficiency, process streamlining, and identification of key components are critical for bridging the financial gap in recycling technology.

- ▪

- Implementing circular economy concepts and modifying legislative and regulatory frameworks are essential for sustainable photovoltaic (PV) waste management.

- ▪

- Collaboration among researchers, stakeholders, governments, and industry players is crucial to promote innovation, provide regulatory support, and establish responsible disposal structures for waste modules.

- ▪

- The present state of PV recycling, including opportunities, challenges, and prospects, is examined. Without appropriate disposal, the future production of PV waste could reach 78 million tons by 2050, necessitating large-scale recycling initiatives.

- ▪

- Companies worldwide are developing technologies and processes to maximize PV waste recycling. Commendable programs focus on advanced recycling systems to recover and reuse valuable materials.

- ▪

- The high cost of recycling remains a significant barrier to the widespread adoption of PV recycling systems, limiting scalability and practicality despite the environmental need.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jung, B.; Park, J.; Seo, D.; Park, N. Sustainable System for Raw-Metal Recovery from Crystalline Silicon Solar Panels: From Noble-Metal Extraction to Lead Removal. ACS Sustain. Chem. Eng. 2016, 4, 4079–4083. [Google Scholar] [CrossRef]

- Huang, W.-H.; Shin, W.J.; Wang, L.; Sun, W.-C.; Tao, M. Strategy and technology to recycle wafer-silicon solar modules. Sol. Energy 2017, 144, 22–31. [Google Scholar] [CrossRef]

- Kang, S.; Yoo, S.; Lee, J.; Boo, B.; Ryu, H. Experimental investigations for recycling of silicon and glass from waste photovoltaic modules. Renew. Energy 2012, 47, 152–159. [Google Scholar] [CrossRef]

- Park, J.; Kim, W.; Cho, N.; Lee, H.; Park, N. An Eco-friendly method for reclaimed silicon wafer from photovoltaic module: From separation to cell fabrication. Green Chem. 2015, 18, 1706–1714. [Google Scholar] [CrossRef]

- Islam, I.; Jadin, M.S.; Al Mansur, A.; Kamari, N.A.M.; Jamal, T.; Lipu, M.S.H.; Azlan, M.N.M.; Sarker, M.R.; Shihavuddin, A.S.M. Techno-Economic and Carbon Emission Assessment of a Large-Scale Floating Solar PV System for Sustainable Energy Generation in Support of Malaysia’s Renewable Energy Roadmap. Energies 2023, 16, 4034. [Google Scholar] [CrossRef]

- Ghosh, M.K.; Al Mansur, A.; Rifat, A.I.; Mollik, A.A.; Ghosh, A.K.; Soheb, M.; Islam, I.; Haq, M.A.U. The Prospect of Waste Management System for Solar Power Plants in Bangladesh: A Case Study. In Proceedings of the 2023 5th International Conference on Sustainable Technologies for Industry 5.0 (STI), Dhaka, Bangladesh, 9–10 December 2023; IEEE: Piscataway, NJ, USA; pp. 1–5. [Google Scholar]

- Wang, T.-Y.; Hsiao, J.-C.; Du, C.-H. Recycling of materials from silicon base solar cell module. In Proceedings of the 2012 IEEE 38th Photovoltaic Specialists Conference (PVSC), Austin, TX, USA, 3–8 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 2355–2358. [Google Scholar]

- Huang, W.-H.; Tao, M. A simple green process to recycle Si from crystalline-Si solar cells. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialists Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–4. [Google Scholar]

- Chen, W.-S.; Chen, Y.-J.; Lee, C.-H.; Cheng, Y.-J.; Chen, Y.-A.; Liu, F.-W.; Wang, Y.-C.; Chueh, Y.-L. Recovery of Valuable Materials from the Waste Crystalline-Silicon Photovoltaic Cell and Ribbon. Processes 2021, 9, 712. [Google Scholar] [CrossRef]

- Wang, J.-P.; Lee, D.-H.; Go, M.-S.; So, E.-K. A Study on the Wet Process Conditions That Affect the Selective Recovery of Si from Photovoltaic Cells by Using the Cavitation Effect. Metals 2022, 12, 222. [Google Scholar] [CrossRef]

- Punathil, L.; Mohanasundaram, K.; Tamilselavan, K.S.; Sathyamurthy, R.; Chamkha, A.J. Recovery of Pure Silicon and Other Materials from Disposed Solar Cells. Int. J. Photoenergy 2021, 2021, 5530213. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Wang, T.-Y.; Lan, C.-W.; Tai, C.Y. Recovery of silicon powder from kerf loss slurry by centrifugation. Powder Technol. 2010, 200, 216–223. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Tai, C.Y. Recovery of silicon powder from kerfs loss slurry using phase-transfer separation method. Sep. Purif. Technol. 2010, 74, 170–177. [Google Scholar] [CrossRef]

- Latunussa, C.E.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. Cells 2016, 156, 101–111. [Google Scholar] [CrossRef]

- Wang, X.; Tian, X.; Chen, X.; Ren, L.; Geng, C. A review of end-of-life crystalline silicon solar photovoltaic panel recycling technology. Sol. Energy Mater. Sol. Cells 2022, 248, 111976. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Ostrowski, P. Chemical treatment of crystalline silicon solar cells as a method of recovering pure silicon from photovoltaic modules. Renew. Energy 2010, 35, 1751–1759. [Google Scholar] [CrossRef]

- Yoon, D.-S.; Ahn, Y.-S.; Kang, G.-H.; Chang, H.S.; Lee, J.-S. Silicon Recovery from Solar Module Waste by a Physical Method. J. Korean Sol. Energy Soc. 2022, 42, 1–11. [Google Scholar] [CrossRef]

- Tao, M.; Fthenakis, V.; Ebin, B.; Steenari, B.; Butler, E.; Sinha, P.; Corkish, R.; Wambach, K.; Simon, E.S. Major challenges and opportunities in silicon solar module recycling. Prog. Photovolt. Res. Appl. 2020, 28, 1077–1088. [Google Scholar] [CrossRef]

- Thomassen, G.; Dewulf, J.; Van Passel, S. Prospective material and substance flow analysis of the end-of-life phase of crystalline silicon-based PV modules. Resour. Conserv. Recycl. 2021, 176, 105917. [Google Scholar] [CrossRef]

- Yousef, S.; Tatariants, M.; Denafas, J.; Makarevicius, V.; Lukošiūtė, S.-I.; Kruopienė, J. Sustainable industrial technology for recovery of Al nanocrystals, Si micro-particles and Ag from solar cell wafer production waste. Sol. Energy Mater. Sol. Cells 2018, 191, 493–501. [Google Scholar] [CrossRef]

- Deng, R.; Zhuo, Y.; Shen, Y. Recent progress in silicon photovoltaic module recycling processes. Resour. Conserv. Recycl. 2022, 187, 106612. [Google Scholar] [CrossRef]

- Li, J.; Yan, S.; Li, Y.; Wang, Z.; Tan, Y.; Li, J.; Xia, M.; Li, P. Recycling Si in waste crystalline silicon photovoltaic panels after mechanical crushing by electrostatic separation. J. Clean. Prod. 2023, 415, 137908. [Google Scholar] [CrossRef]

- Divya, A.; Adish, T.; Kaustubh, P.; Zade, P. Review on recycling of solar modules/panels. Sol. Energy Mater. Sol. Cells 2023, 253, 112151. [Google Scholar] [CrossRef]

- Artaş, S.B.; Kocaman, E.; Bilgiç, H.H.; Tutumlu, H.; Yağlı, H.; Yumrutaş, R. Why PV panels must be recycled at the end of their economic life span? A case study on recycling together with the global situation. Process. Saf. Environ. Prot. 2023, 174, 63–78. [Google Scholar] [CrossRef]

- Heath, G.A.; Silverman, T.J.; Kempe, M.; Deceglie, M.; Ravikumar, D.; Remo, T.; Cui, H.; Sinha, P.; Libby, C.; Shaw, S.; et al. Research and development priorities for silicon photovoltaic module recycling to support a circular economy. Nat. Energy 2020, 5, 502–510. [Google Scholar] [CrossRef]

- Tao, M. Technologies to Improve the Profitability of Silicon PV Module Recycling. In Proceedings of the 2021 28th International Workshop on Active-Matrix Flatpanel Displays and Devices (AM-FPD), Kyoto, Japan, 29 June–2 July 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 55–58. [Google Scholar]

- Santos, J.; Alonso-García, M. Projection of the photovoltaic waste in Spain until 2050. J. Clean. Prod. 2018, 196, 1613–1628. [Google Scholar] [CrossRef]

- Kim, H.; Park, H. PV Waste Management at the Crossroads of Circular Economy and Energy Transition: The Case of South Korea. Sustainability 2018, 10, 3565. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Behnia, M. Critical assessment of renewable energy waste generation in OECD countries: Decommissioned PV panels. Resour. Conserv. Recycl. 2021, 164, 105145. [Google Scholar] [CrossRef]

- Apeh, O.O.; Meyer, E.L.; Overen, O.K. Contributions of Solar Photovoltaic Systems to Environmental and Socioeconomic Aspects of National Development—A Review. Energies 2022, 15, 5963. [Google Scholar] [CrossRef]

- Srivastava, S. An Overview on Recycling of Photovoltaic Modules at the End of Life (EoL). Int. J. Sci. Res. Eng. Manag. 2022, 6, 1–13. [Google Scholar] [CrossRef]

- Gao-shang, W. A forecast of trend of world demands of copper and aluminum in future twenty years. World Nonferrous Met. 2003, 7, 6–9. [Google Scholar]

- Louwen, A.; van Sark, W.; Schropp, R.; Faaij, A. A cost roadmap for silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 2016, 147, 295–314. [Google Scholar] [CrossRef]

- Padoan, F.C.; Altimari, P.; Pagnanelli, F. Recycling of end of life photovoltaic panels: A chemical prospective on process development. Sol. Energy 2019, 177, 746–761. [Google Scholar] [CrossRef]

- Shao, J.; Li, J.; Yao, X. Net benefits change of waste photovoltaic recycling in China: Projection of waste based on multiple factors. J. Clean. Prod. 2023, 417, 137984. [Google Scholar] [CrossRef]

- Farrell, C.; Osman, A.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.; Kumaravel, V.; Al-Muhtaseb, A.; et al. Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules. Renew. Sustain. Energy Rev. 2020, 128, 109911. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Zhang, J.; Zhang, S.; Yin, Y. Burden Surface Decision Using MODE with TOPSIS in Blast Furnace Ironmkaing. IEEE Access 2020, 8, 35712–35725. [Google Scholar] [CrossRef]

- Corrado, C.; Holt, E.; Schambach, L. Barriers to Solar Photovoltaic (PV) Adoption on a National Scale in the United States. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Philadelphia, PA, USA, 5–10 June 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1110–1117. [Google Scholar]

- Rao, R.R.; Priyadarshani, S.; Mani, M. Examining the use of End-of-Life (EoL) PV panels in housing and sustainability. Sol. Energy 2023, 257, 210–220. [Google Scholar] [CrossRef]

- Chitra; Sah, D.; Lodhi, K.; Kant, C.; Saini, P.; Kumar, S. Structural composition and thermal stability of extracted EVA from silicon solar modules waste. Sol. Energy 2020, 211, 74–81. [Google Scholar] [CrossRef]

- Al Mansur, A.; Islam, I.; Kiron, M.K.; Haq, M.A.U.; Maruf, H.; Shihavuddin, A.; Ashique, R.H.; Amin, R. Electrical experimental data collection of polycrystalline and monocrystalline photovoltaic modules in an indoor environment using artificial sun simulator. Data Brief 2022, 43, 108389. [Google Scholar] [CrossRef]

- A Solar Panel’s Life after Death: 2023 Guide of SolarPanel Recycling. Available online: https://www.maysunsolar.eu/blog/a-solar-panels-life-after-death-2023-guide-of-solarpanel-recycling (accessed on 15 June 2024).

- Corcelli, F.; Ripa, M.; Leccisi, E.; Cigolotti, V.; Fiandra, V.; Graditi, G.; Sannino, L.; Tammaro, M.; Ulgiati, S. Sustainable urban electricity supply chain—Indicators of material recovery and energy savings from crystalline silicon photovoltaic panels end-of-life. Ecol. Indic. 2018, 94, 37–51. [Google Scholar] [CrossRef]

- Lunardi, M.M.; Alvarez-Gaitan, J.P.; Bilbao, J.I.; Corkish, R. A Review of Recycling Processes for Photovoltaic Modules. In Solar Panels and Photovoltaic Materials; Intech Open: London, UK, 2018. [Google Scholar] [CrossRef]

- Maani, T.; Celik, I.; Heben, M.J.; Ellingson, R.J.; Apul, D. Environmental impacts of recycling crystalline silicon (c-SI) and cadmium telluride (CDTE) solar panels. Sci. Total. Environ. 2020, 735, 138827. [Google Scholar] [CrossRef] [PubMed]

- Riech, I.; Castro-Montalvo, C.; Wittersheim, L.; Giácoman-Vallejos, G.; González-Sánchez, A.; Gamboa-Loira, C.; Acosta, M.; Méndez-Gamboa, J. Experimental Methodology for the Separation Materials in the Recycling Process of Silicon Photovoltaic Panels. Materials 2021, 14, 581. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.; You, J.; Diao, H.; Zhao, L.; Wang, W. Back EVA recycling from c-Si photovoltaic module without damaging solar cell via laser irradiation followed by mechanical peeling. Waste Manag. 2022, 137, 312–318. [Google Scholar] [CrossRef]

- IRENA and IEA PVPS. End-of-Life Management Solar PV Panels. 2016. Available online: www.irena.org (accessed on 16 April 2024).

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strat. Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Cui, H.; Heath, G.; Remo, T.; Ravikumar, D.; Silverman, T.; Deceglie, M.; Kempe, M.; Engel-Cox, J. Technoeconomic analysis of high-value, crystalline silicon photovoltaic module recycling processes. Sol. Energy Mater. Sol. Cells 2022, 238, 111592. [Google Scholar] [CrossRef]

- Kim, J.; Rabelo, M.; Padi, S.P.; Yousuf, H.; Cho, E.-C.; Yi, J. A Review of the Degradation of Photovoltaic Modules for Life Expectancy. Energies 2021, 14, 4278. [Google Scholar] [CrossRef]

- Goe, M.; Gaustad, G. Estimating direct climate impacts of end-of-life solar photovoltaic recovery. Sol. Energy Mater. Sol. Cells 2016, 156, 27–36. [Google Scholar] [CrossRef]

- El-Fayome, E.; Abdelhamed, M.A.; El-Shazly, A.; Abouelatta, M.; Zekry, A. End of Life Management of Solar Panels. In Proceedings of the 2023 40th National Radio Science Conference (NRSC), Giza, Egypt, 30 May–1 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 286–293. [Google Scholar]

- Yu, H.F.; Hasanuzzaman, M.; Rahim, N.A.; Amin, N.; Adzman, N.N. Global Challenges and Prospects of Photovoltaic Materials Disposal and Recycling: A Comprehensive Review. Sustainability 2022, 14, 8567. [Google Scholar] [CrossRef]

- Zuser, A.; Rechberger, H. Considerations of resource availability in technology development strategies: The case study of photovoltaics. Resour. Conserv. Recycl. 2011, 56, 56–65. [Google Scholar] [CrossRef]

- Abdo, D.M.; El-Shazly, A.N.; Medici, F. Recovery of Valuable Materials from End-of-Life Photovoltaic Solar Panels. Materials 2023, 16, 2840. [Google Scholar] [CrossRef] [PubMed]

- Matsenko, O.I.; Tereshchenko, V.S.; Piven, V.S.; Panchenko, A.A.; Perekhod, E.A. Socio-environmental and Economic Problems of Solar Panels Recycling. Mech. Econ. Regul. 2020, 1, 48–55. [Google Scholar] [CrossRef]

- Perez-Gallardo, J.R.; Azzaro-Pantel, C.; Astier, S. A Multi-objective framework for assessment of Recycling Strategies for Photovoltaic Modules based on Life Cycle Assessment. Waste Biomass-Valorization 2018, 9, 147–159. [Google Scholar] [CrossRef]

- Chitra, C.; Sah, D.; Saini, P.; Kumar, S. Extraction and analysis of back-sheet layer from waste silicon solar modules. Chem. Rep. 2022, 4, 256–263. [Google Scholar] [CrossRef]

- Aryan, V.; Font-Brucart, M.; Maga, D. A comparative life cycle assessment of end-of-life treatment pathways for photovoltaic backsheets. Prog. Photovolt. Res. Appl. 2018, 26, 443–459. [Google Scholar] [CrossRef]

- Boussaa, S.A.; Benkrid, A.; Boutarek, N.Z.; Ayachi, M. End of life silicon based photovoltaic panels: A review. J. Renew. Energ. 2020, 23, 201–216. [Google Scholar] [CrossRef]

- Doi, T.; Tsuda, I.; Unagida, H.; Murata, A.; Sakuta, K.; Kurokawa, K. Experimental study on PV module recycling with organic solvent method. Sol. Energy Mater. Sol. Cells 2001, 67, 397–403. [Google Scholar] [CrossRef]

- Suhani, I.; Sahab, S.; Srivastava, V.; Singh, R.P. Impact of cadmium pollution on food safety and human health. Curr. Opin. Toxicol. 2021, 27, 1–7. [Google Scholar] [CrossRef]

- Jang, J.-K.; Park, H. Workers’ Possible Exposure Hazards in Solar Energy Industries. J. Korean Sol. Energy Soc. 2013, 33, 24–33. [Google Scholar] [CrossRef]

- Wohlgemuth, J.H.; Hacke, P.; Bosco, N.; Miller, D.C.; Kempe, M.D.; Kurtz, S.R. Assessing the causes of encapsulant delamination in PV modules. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialists Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 301–304. [Google Scholar] [CrossRef]

- Kwak, J.I.; Nam, S.-H.; Kim, L.; An, Y.-J. Potential environmental risk of solar cells: Current knowledge and future challenges. J. Hazard. Mater. 2020, 392, 122297. [Google Scholar] [CrossRef] [PubMed]

- Andersen, O. Solar Cell Production. In Unintended Consequences of Renewable Energy. Green Energy and Technology; Springer: London, UK, 2013; pp. 81–89. [Google Scholar] [CrossRef]

- Santhakumari, M.; Sagar, N. A review of the environmental factors degrading the performance of silicon wafer-based photovoltaic modules: Failure detection methods and essential mitigation techniques. Renew. Sustain. Energy Rev. 2019, 110, 83–100. [Google Scholar] [CrossRef]

- International Energy Agency. Renewables 2020. 2020. Available online: https://www.iea.org/reports/renewables-2020 (accessed on 15 April 2021).

- Sonone, S.S.; Jadhav, S.; Sankhla, M.S.; Kumar, R. Water Contamination by Heavy Metals and their Toxic Effect on Aquaculture and Human Health through Food. Lett. Appl. NanoBioSci. 2021, 10, 2148–2166. [Google Scholar] [CrossRef]

- Fatima, S.; Muzammal, M.; Rehman, A.; Rustam, S.A.; Shehzadi, Z.; Mehmood, A.; Waqar, M. Water pollution of heavy metals and its effects on fishes. Int. J. Fish. Aquat. Stud. 2020, 8, 6–14. [Google Scholar]

- Martin, S.; Griswold, W. Human health effects of heavy metals. Environ. Sci. Technol. Briefs Citiz. 2009, 15, 1–6. [Google Scholar]

- Motta, C.; Cerciello, R.; De Bonis, S.; Mazzella, V.; Cirino, P.; Panzuto, R.; Ciaravolo, M.; Simoniello, P.; Toscanesi, M.; Trifuoggi, M.; et al. Potential toxicity of improperly discarded exhausted photovoltaic. Environ. Pollut. 2016, 216, 786–792. [Google Scholar] [CrossRef] [PubMed]

- Felzer, B.S.; Cronin, T.; Reilly, J.M.; Melillo, J.M.; Wang, X. Impacts of ozone on trees and crops. Extern. Geophys. Clim. Environ. 2007, 339, 784–798. [Google Scholar] [CrossRef]

- Rhind, S.M. Anthropogenic pollutants—An insidious threat to animal health and productivity? Acta Veter-Scand. 2012, 54 (Suppl. S1), S2. [Google Scholar] [CrossRef]

- Swarup, D.; Patra, R.C. Environmental pGllution and its impact on domestic animals and wildlife. Indian J. Anim. Sci. 2005, 75, 231–240. [Google Scholar]

- Ishii, T.; Masuda, A. Annual degradation rates of recent crystalline silicon photovoltaic modules. Prog. Photovolt. Res. Appl. 2017, 25, 953–967. [Google Scholar] [CrossRef]

- Kim, J.Y.; Koide, D.; Ishihama, F.; Kadoya, T.; Nishihiro, J. Current site planning of medium to large solar power systems accelerates the loss of the remaining semi-natural and agricultural habitats. Sci. Total. Environ. 2021, 779, 146475. [Google Scholar] [CrossRef] [PubMed]

- Peplow, M. Solar Panels Face Recycling Challenge. ACS Cent. Sci. 2022, 8, 299–302. [Google Scholar] [CrossRef]

- Gönen, Ç.; Kaplanoğlu, E. Environmental and economic evaluation of solar panel wastes recycling. Waste Manag. Res. 2019, 37, 412–418. [Google Scholar] [CrossRef]

- Ho, S.; Ng, S.; Munaaim, M. Disposal Method of Crystalline Silicon Photovoltaic Panels: A Case Studies in Malaysia. Asian J. Chem. 2021, 33, 1215–1221. [Google Scholar] [CrossRef]

- Chen, P.-H.; Chen, W.-S.; Lee, C.-H.; Wu, J.-Y. Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques. Sustainability 2024, 16, 60. [Google Scholar] [CrossRef]

- Ali, M.U.; Khan, H.F.; Masud, M.; Kallu, K.D.; Zafar, A. A machine learning framework to identify the hotspot in photovoltaic module using infrared thermography. Sol. Energy 2020, 208, 643–651. [Google Scholar] [CrossRef]

- Phinikarides, A.; Kindyni, N.; Makrides, G.; Georghiou, G.E. Review of photovoltaic degradation rate methodologies. Renew. Sustain. Energy Rev. 2014, 40, 143–152. [Google Scholar] [CrossRef]

- Rahman, T.; Al Mansur, A.; Lipu, M.S.H.; Rahman, S.; Ashique, R.H.; Houran, M.A.; Elavarasan, R.M.; Hossain, E. Investigation of Degradation of Solar Photovoltaics: A Review of Aging Factors, Impacts, and Future Directions toward Sustainable Energy Management. Energies 2023, 16, 3706. [Google Scholar] [CrossRef]

- Rajput, P.; Tiwari, G.; Sastry, O. Thermal modelling and experimental validation of hot spot in crystalline silicon photovoltaic modules for real outdoor condition. Sol. Energy 2016, 139, 569–580. [Google Scholar] [CrossRef]

- Goudelis, G.; Lazaridis, P.I.; Dhimish, M. A Review of Models for Photovoltaic Crack and Hotspot Prediction. Energies 2022, 15, 4303. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, A. Performance assessment and degradation analysis of solar photovoltaic technologies: A review. Renew. Sustain. Energy Rev. 2017, 78, 554–587. [Google Scholar] [CrossRef]

- Rathore, N.; Panwar, N.L. Strategic overview of management of future solar photovoltaic panel waste generation in the Indian context. Waste Manag. Res. 2022, 40, 504–518. [Google Scholar] [CrossRef]

- García, M.; Marroyo, L.; Lorenzo, E.; Marcos, J.; Pérez, M. Observed degradation in photovoltaic plants affected by hot-spots. Prog. Photovolt. Res. Appl. 2014, 22, 1292–1301. [Google Scholar] [CrossRef]

| Year | 2020 | 2030 | 2040 | 2050 |

|---|---|---|---|---|

| Total PV capacity (GW) | 777 | 1632 | 2895 | 4512 |

| Regular loss (Ton waste/GW) | 128.7 | 1041.67 | 5181.35 | 13,297.85 |

| Early loss (Ton waste/GW) | 1093.95 | 4901.96 | 11,053.45 | 17,287.23 |

| Refs. | Technologies | Year | Purity of Si (%) |

|---|---|---|---|

| [11] | Centrifugation separation | 2010 | 74.1% |

| [12] | Phase-transfer separation | 2010 | 71.1% |

| [13] | A heating procedure involves both acidic and alkaline treatments | 2016 | 62% |

| [14] | Chemical treatment | 2022 | 90% |

| [21] | Electrostatic separation | 2023 | 48.9% |

| Refs and Year | Chemical Process (Etching/Leaching) | Purity (%) | Remarks |

|---|---|---|---|

| [7] 2011 | HCl/H2O2/H2O (1:1:5) to remove Al; 5% HF to remove SiNx and Ag; 25% NaOH to etch silicon. | 62% | Because of the NaOH etching procedure, 38% of silicon is lost. |

| [1] 2016 | 5 M HNO3 to dissolve Ag and Cu wire: 90% H3PO4 to remove SiNx; (160 °C, 60 min) 45% KOH to remove Al (80 °C, 10 min). | 80% | Etching without hydrofluoric acid leads to partial silicon loss. |

| [16] 2010 | 30% KOH, 60 °C to remove Ag, 65% HNO3, 40% HF + 99.5% CH3COOH + Br2. Selective acidic etching, NaOH. | 74.5% | Depending on the kind of PV cells to be recycled, etching solutions must be adjusted. |

| Refs and Year | Chemical Process (Etching/Leaching) | Purity (%) | Remarks |

|---|---|---|---|

| [19] 2017 | (1) H3PO4 to remove Al along with HNO3 and HF to remove Ag, SiNx (solid to liquid ratio 0.03 g/mL). | 85% | N/A |

| [8] 2015 | (2) 48% HF + 70% HNO3 + 97% H2SO4 + 99% CH3COOH at room temperature to remove electrode, SiNx, and etch silicon. | 86% | This process is free from hydrofluoric acid and comparatively less time-consuming than treatment involving HF. |

| [17] 2022 | (3) HNO3 (30 wt%), 50 °C, 120 min, HCl (36 wt%), RT, 60 min. | 86.5% | N/A |

| [4] 2016 | (4) 60% HNO3 to remove Ag, mechanical removal of other layers, and 45% KOH to etch back silicon. | 90% | The silicon weight diminishes as a result of etching on the emitter and back surface field. |

| [2] 2017 | (5) HNO3, 10% HF, NaOH 60% HNO3, 45% KOH, 80 °C, etching paste (mostly H3PO4). | 90% | The solar-grade silicon specification aligns with the recovered silicon. |

| [2] 2017 | (6) HNO3, HF (10%), 15 min, NaOH (3%), 50 °C, 20 min. | 90% | HF usage can present dangers and corrosive properties. |

| Refs and Year | Chemical Process (Etching/Leaching) | Purity (%) | Remarks |

|---|---|---|---|

| [9] 2021 | (1) HNO3 (5 mol L−1), 80 °C, 1 h, 25 mL g−1 KOH (2 mol L−1), 80 °C, 1 h, 50 mL g−1. | 99.9% | This process does not involve HF, but it does take longer to complete compared to HF treatment. |

| [11] 2021 | (2) KOH/HNO3/H3PO4 etchant. | 99.99% | KOH is more efficient than sodium hydroxide NaOH and does not involve the use of HF. |

| [10] 2022 | (3) HNO3 (3 mol L−1), ultrasonic (150 W), ultrasonic cleaning, 60 °C, 90 min. | 98.9% | The cavitation effect of an ultrasonic cleaner improves silicon recovery and purity without the use of HF. |

| [10] 2022 | (4) HCl (3 mol L−1), ultrasonic (150 W), ultrasonic cleaner, 60 °C, 90 min. | 99.24% | The cavitation effect of an ultrasonic cleaner boosts silicon recovery and purity while avoiding the use of HF. |

| [18] 2019 | (5) 60% HNO3 to dissolve 100% Ag and break chemical bonds between spherical Al microparticles in Al paste under ultrasonic; microfiltration to extract Si; centrifugal process to separate Al; HCl to precipitate Ag. | 98% | Break the chemical connections between the spherical Al microparticles in the Al paste and dissolve 100% Ag. |

| [21] 2020 | (6) 8 mol/L KOH at 60 °C to remove Al; 8 mol/L HNO3 at 80 °C to remove Ag and Pb. | 99% | The ultra-pure silicon powder was nano-sized to fulfill the expansion-tolerant Si criteria. Anodes used in lithium-ion batteries. |

| [20] 2018 | (7) 64% HNO3 and HCl to dissolve Ag and break chemical bond of Al layers; ultrasound yreatment 75 °C, 2 h etching of SiNx layer in an HF-based solution. | 98.3% | Electrode removal and anti-reflection coating performed at the same time |

| Module Brand | Name of Model | Module Type | Weight (Kg) | Cells/Module | Power Rating |

|---|---|---|---|---|---|

| Trina Solar | TSM-NE09RC.05 | Mono-c-Si | 21.8 | 144 | 435 W |

| TSM-DE06X.05(II) | 19.7 | 132 | 355–380 W | ||

| TSM-DE15V(II) | 26 | 252 | 470–490 W | ||

| JA Solar | JAM72D42 | Mono-c-Si | 34.6 | 144 | 630 W |

| JAM72D40 | 31.8 | 144 | 580 W | ||

| JinKo Solar | JKM635N-78HL4-BDV | Mono-c-Si | 34 | 156 | 615–635 W |

| JKM440N-54HL4 | 21 | 108 | 440 W |

| Scenario | Potential Profit |

|---|---|

| Module reuse | USD 22 |

| Component extraction | USD 18.14 |

| Material extraction | USD 10.6 |

| Country | Number | Name of Companies |

|---|---|---|

| USA | 13 | CEM, Cleanlites Recycle, Dynamic Lifecycle Innovations, Recycle PV Solar, Echo Environmental, FabTech, First Solar, Green Light Recycling, Inteco- A Metaltronics Recycler, Mitsubishi Electric, Recycler 123, Surplus Service, We Recyler Solar |

| Australia | 6 | Reclaim PV, Cyber Computer Recycling & Disposal, Elecsome, Infoactiv, Ojas Infrastructure, PV Industries |

| Germany | 5 | SolarWorld, Envaris, Reiling, Reiger and Kraft Solar, Rinovasol |

| UK | 4 | H&H Pro, ILM Highland, Recycle Solar Technologies, Solar2Recycle |

| Switzerland | 3 | Immark, KWB Planreal, SENS eRecycle |

| China | 3 | GCL-Poly Energy Holdings Limited, Jiangxi LDK Solar Hi-Tech, CNBM |

| Canada | 1 | Sunset Renewable Asset Management |

| Italy | 1 | La Mia Energia, Yousolar |

| Japan | 3 | Okaishi Construction, NPC, New Energy and Industrial Technology Development Organization |

| South Africa | 1 | Reclite |

| Singapore | 1 | EtaVolt |

| Brazil | 1 | SunR |

| Hong Kong SAR | 1 | IBA |

| Russia | 10 | AltEnergia, Astantsiya, B-Eco, Eco Energy, Energon, Energy Center, Green Energy, Moscow Solar Group, NSiA, Real Solar |

| Country | Number | Name of Companies |

|---|---|---|

| USA | 2 | CEM, Recycle PV Solar |

| Australia | 2 | Elecsome, PV Industries |

| Switzerland | 1 | KWB Planreal |

| Italy | 1 | La Mia Energia |

| Israel | 1 | Silcontel |

| Brazil | 1 | SunR |

| Russia | 1 | Green Energy |

| Country | Number | Name of Companies |

|---|---|---|

| USA | 2 | Dynamic Lifecycle Innovations, Recycle PV Solar |

| Australia | 1 | PV Industries |

| UK | 1 | Recycle Solar Technologies |

| India | 1 | Jumbo Solar |

| Italy | 1 | La Mia Energia |

| Israel | 1 | Silcontel |

| Russia | 1 | Moscow Solar Group |

| Country | Number | Name of Companies |

|---|---|---|

| USA | 1 | Dynamic Lifecycle Innovations |

| Australia | 1 | Elecsome, PV Industries |

| Italy | 1 | La Mia Energia |

| Israel | 1 | Silcontel |

| Brazil | 1 | SunR |

| Russia | 2 | Real Solar, B-Eco |

| Country | Number | Name of Companies |

|---|---|---|

| USA | 6 | Metal and Catalyst Resources, Moegen Industries, Silicon Specialist, Silrec, SRS, We Recyler Solar |

| Australia | 3 | Elecsome, PV Industries, Reclaim PV Recycling |

| Germany | 2 | SolarWorld, Aurubis, SiC Processing |

| China | 2 | Suzhou Minlai Photovoltaic New Energy, Chaoqiang Silicon Material |

| Canada | 1 | Globe Metal |

| India | 2 | Jumbo Solar, Poseidon Solar Services |

| Italy | 1 | La Mia Energia |

| Japan | 1 | Trinity |

| Israel | 1 | Silcontel |

| Brazil | 1 | SunR |

| Hong Kong SAR | 1 | IBA |

| Russia | 3 | B-Eco, Moscow Solar Group, Real Solar |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhter, M.; Al Mansur, A.; Islam, M.I.; Lipu, M.S.H.; Karim, T.F.; Abdolrasol, M.G.M.; Alghamdi, T.A.H. Sustainable Strategies for Crystalline Solar Cell Recycling: A Review on Recycling Techniques, Companies, and Environmental Impact Analysis. Sustainability 2024, 16, 5785. https://doi.org/10.3390/su16135785

Akhter M, Al Mansur A, Islam MI, Lipu MSH, Karim TF, Abdolrasol MGM, Alghamdi TAH. Sustainable Strategies for Crystalline Solar Cell Recycling: A Review on Recycling Techniques, Companies, and Environmental Impact Analysis. Sustainability. 2024; 16(13):5785. https://doi.org/10.3390/su16135785

Chicago/Turabian StyleAkhter, Mina, Ahmed Al Mansur, Md. Imamul Islam, M. S. Hossain Lipu, Tahia F. Karim, Maher G. M. Abdolrasol, and Thamer A. H. Alghamdi. 2024. "Sustainable Strategies for Crystalline Solar Cell Recycling: A Review on Recycling Techniques, Companies, and Environmental Impact Analysis" Sustainability 16, no. 13: 5785. https://doi.org/10.3390/su16135785

APA StyleAkhter, M., Al Mansur, A., Islam, M. I., Lipu, M. S. H., Karim, T. F., Abdolrasol, M. G. M., & Alghamdi, T. A. H. (2024). Sustainable Strategies for Crystalline Solar Cell Recycling: A Review on Recycling Techniques, Companies, and Environmental Impact Analysis. Sustainability, 16(13), 5785. https://doi.org/10.3390/su16135785