Hazard Identification and Risk Assessment for Sustainable Shipyard Floating Dock Operations: An Integrated Spherical Fuzzy Analytical Hierarchy Process and Fuzzy CoCoSo Approach

Abstract

:1. Introduction

- Hazard identification: recognize all potential hazards and situations that may cause any harm or loss.

- Identify people at risk and how they may be harmed: determine who may be affected and how they may be harmed by each hazard.

- Document findings and implement control measures: incorporate the results of the risk assessment into training and practice.

- Continuously observe the risk assessment and update it as necessary: review the implemented measures and revise them if the process unfolds differently than planned.

2. Literature Review

2.1. Fuzzy MCDM in the Context of Risk Assessment

2.2. Fuzzy MCDM in the Context of Risk Assessment for Shipyard Floating Dock Operations

3. Materials and Methods

3.1. Definition of Criteria

- Consequence (C): the severity of the consequences for an employee in the event of threats or hazards is the primary factor in determining the likelihood of a potential accident.

- Frequency (F): this factor describes the rate at which hazardous events occur.

- Probability (P): this factor refers to the probability of a dangerous event occurring.

- Number of people at risk (NP): the number of people at risk indicates the density of employees in the work area.

3.2. The Proposed Emergency Occupational Hazard Risk Assessment (EOHRA) Model

3.3. Spherical Fuzzy Analytic Hierarchy Process (SF-AHP)

- Stage 1. Creating a hierarchical structure.A linguistic comparative decision matrix is built for fuzzy analysis, with the criteria (i, j = 1, 2, …, n), hazards (h = 1, 2, …, m), experts (k = 1, 2, … p), and pairwise comparison matrices (s = 1, 2, … o).

- Stage 2. Pairwise comparison matrices of the criteria are created using spherical fuzzy expressions and linguistic terms (Table 3) [34].Equations (3) and (4) are used to calculate the score indices for each criterion:for AMI, VHI, HI, SMI, and EI;for SLI, LI, VLI, and ALI.

- Stage 3. Checking the consistency of all pairwise comparison matrices.The consistency calculation is performed using a 10% Consistency Ratio (CR) threshold as follows:The Consistency Index (CI) is calculated according to Equation (6):where λmax is the max eigenvalue of the matrix and n represents the number of criteria [35].

- Stage 4. Obtaining fuzzy criterion weights.The relative weight of each criterion is calculated using Equations (7) and (8).

- Stage 5. Computing the overall weights using hierarchical layer sorting.The final order is determined by adding up the spherical weights at each hierarchical level. Equation (9) is used to smooth out the criterion weights.The criterion weights are normalized and then used in the spherical fuzzy product (Equations (10) and (11)).

3.4. Fuzzy Combined Compromise Solution (F-CoCoSo)

- Step 1. Achieving a fuzzy decision matrix ()Creating a decision matrix based on expert opinions is the initial step in MCDM. This set of default criteria is , and for is the criterion weight. represents the assessment of m selections using a matrix formed based on the linguistic terms related to the n criteria selected by experts [37].

- Step 2. Transforming the linguistic variables into fuzzy numbersThe decision matrix in Step 1 is transformed into fuzzy numbers using the linguistic variables (Table 4), and a decision matrix is obtained based on Equation (13) where i denotes an alternative, and j denotes a criterion).

- Step 3. Creating an integrated decision matrixAn integrated decision matrix is created by using Spherical Weighted Arithmetic Mean (SWAM) and Spherical Weighted Geometric Mean (SWGM) operators, considering the weights assigned to each criterion and the opinions of dm experts according to Equations (7) and (8).

- Step 4. Achieving a normalized fuzzy decision matrix ()The decision matrix is normalized based on the benefit and harm criteria (Equations (14) and (15)).

- Step 5. The power weight of comparability () and the sum of weighted comparability () sequences for each alternative are calculated as follows [38]:

- Step 6. Calculating evaluation scores for three different strategiesThe comparative scores of WSM and WPM are calculated using Equations (18) and (19). Equation (20) is used to balance WSM and WPM [39].The value λ in Equation (18) is accepted as λ = 0.5.

- Step 7. Obtaining evaluation scores

- Step 8. Computing crisp scoresThe final scores are determined using Equation (24). These determined scores represent the sum of the arithmetic mean and the geometric mean of the three calculated strategies. Therefore, the alternative is the one with the highest score [39].

4. Results

4.1. Application of the Framework

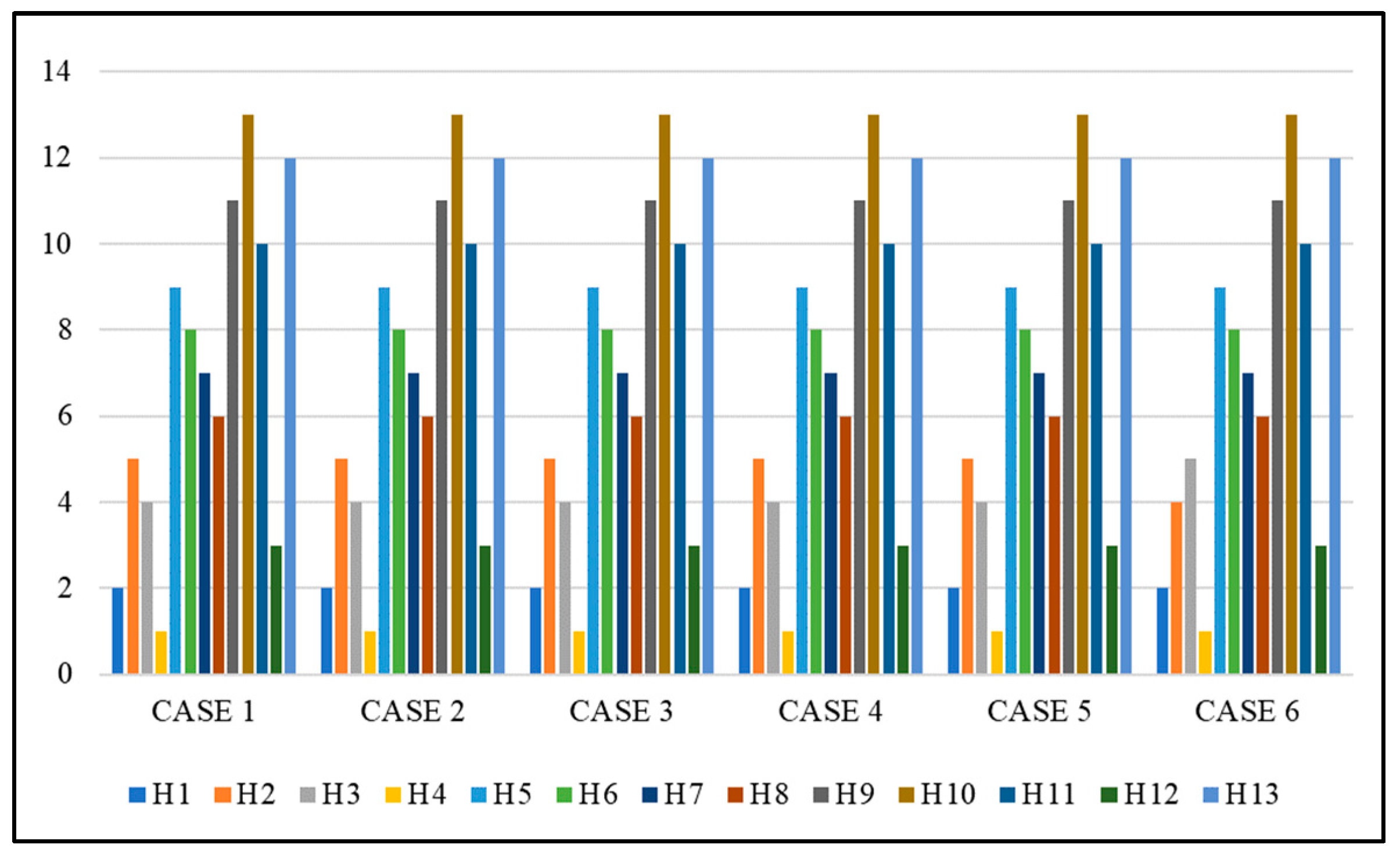

4.2. Sensibility Analysis

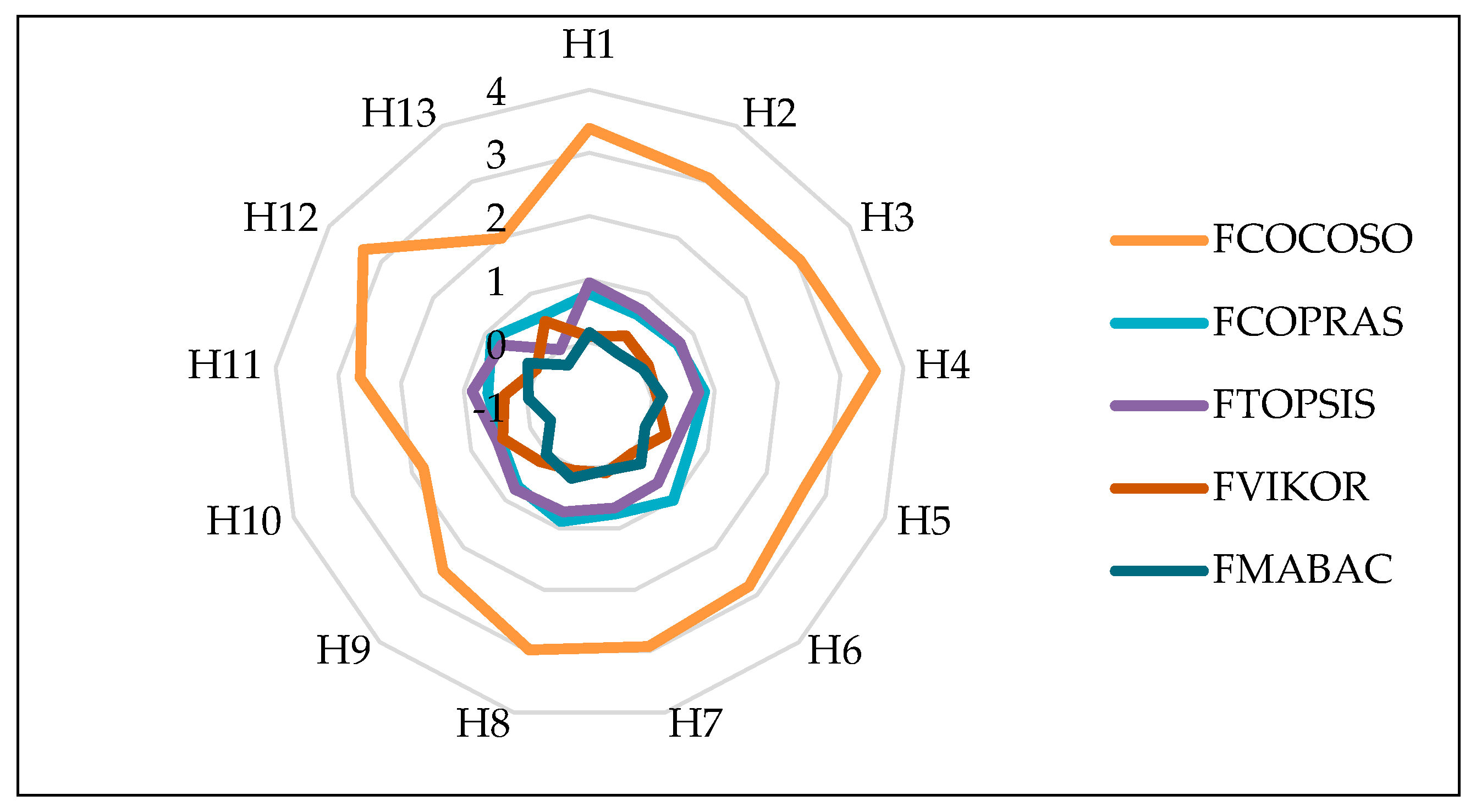

4.3. Comparison with Existing Methods

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gul, M. A review of occupational health and safety risk assessment approaches based on multi-criteria decision-making methods and their fuzzy versions. Hum. Ecol. Risk Assess. 2018, 24, 1723–1760. [Google Scholar] [CrossRef]

- Basuki, M.; Manfaat, D.; Nugroho, S.; Dinariyana, A.A.B. Probabilistic risk assessment of the shipyard industry using the bayesian method. Int. J. Technol. 2014, 5, 88–97. [Google Scholar] [CrossRef]

- Zanko, M.; Dawson, P. Occupational Health and Safety Management in Organizations: A Review. Int. J. Manag. Rev. 2012, 14, 328–344. [Google Scholar] [CrossRef]

- Demirhan Arda, Y.; Soyluk, A. Investigation of Sustainable Disaster Management with Fishbone Method; Hatay Province Example. J. Archit. Sci. Appl. 2023, 8, 84–102. [Google Scholar] [CrossRef]

- Liu, R.; Liu, H.C.; Shi, H.; Gu, X. Occupational health and safety risk assessment: A systematic literature review of models, methods, and applications. Saf. Sci. 2023, 160, 106050. [Google Scholar] [CrossRef]

- Hou, L.X.; Liu, R.; Liu, H.C.; Jiang, S. Two decades on human reliability analysis: A bibliometric analysis and literature review. Ann. Nucl. Energy 2021, 151, 107969. [Google Scholar] [CrossRef]

- Papadakis, G.A.; Chalkidou, A.A. The exposure-damage approach in the quantification of occupational risk in workplaces involving dangerous substances. Saf. Sci. 2008, 46, 972–991. [Google Scholar] [CrossRef]

- Celik, E.; Gul, M. Hazard identification, risk assessment and control for dam construction safety using an integrated BWM and MARCOS approach under interval type-2 fuzzy sets environment. Autom. Constr. 2021, 127, 103699. [Google Scholar] [CrossRef]

- Saedi, A.M.; Thambirajah, J.J.; Pariatamby, A. A HIRARC model for safety and risk evaluation at a hydroelectric power generation plant. Saf. Sci. 2014, 70, 308–315. [Google Scholar] [CrossRef]

- Oliveira, M.D.; Lopes, D.F.; Bana e Costa, C.A. Improving occupational health and safety risk evaluation through decision analysis. Int. Trans. Oper. Res. 2018, 25, 375–403. [Google Scholar] [CrossRef]

- Gul, M.; Ak, M.F.; Guneri, A.F. Occupational health and safety risk assessment in hospitals: A case study using two-stage fuzzy multi-criteria approach. Hum. Ecol. Risk Assess. 2017, 23, 187–202. [Google Scholar] [CrossRef]

- Kokangül, A.; Polat, U.; Dağsuyu, C. A new approximation for risk assessment using the AHP and Fine Kinney methodologies. Saf. Sci. 2017, 91, 24–32. [Google Scholar] [CrossRef]

- Adem, A.; Çolak, A.; Dağdeviren, M. An integrated model using SWOT analysis and Hesitant fuzzy linguistic term set for evaluation occupational safety risks in life cycle of wind turbine. Saf. Sci. 2018, 106, 184–190. [Google Scholar] [CrossRef]

- Koulinas, G.K.; Marhavilas, P.K.; Demesouka, O.E.; Vavatsikos, A.P.; Koulouriotis, D.E. Risk analysis and assessment in the worksites using the fuzzy-analytical hierarchy process and a quantitative technique—A case study for the Greek construction sector. Saf. Sci. 2019, 112, 96–104. [Google Scholar] [CrossRef]

- Yilmaz, F.; Ozcan, M.S. A Risk Analysis and Ranking Application for Lifting Vehicles Used in Construction Sites with Integrated AHP and Fine-Kinney Approach. Adv. Sci. Technol. Res. J. 2019, 13, 152–161. [Google Scholar] [CrossRef]

- Mo, H. A SWOT method to evaluate safety risks in life cycle of wind turbine extended by D number theory. J. Intell. Fuzzy Syst. 2021, 40, 4439–4452. [Google Scholar] [CrossRef]

- Yucesan, M.; Kahraman, G. Risk evaluation and prevention in hydropower plant operations: A model based on Pythagorean fuzzy AHP. Energy Policy 2019, 126, 343–351. [Google Scholar] [CrossRef]

- Liu, H.C.; You, J.X.; Duan, C.Y. An integrated approach for failure mode and effect analysis under interval-valued intuitionistic fuzzy environment. Int. J. Prod. Econ. 2019, 207, 163–172. [Google Scholar] [CrossRef]

- Bakioglu, G.; Atahan, A.O. AHP integrated TOPSIS and VIKOR methods with Pythagorean fuzzy sets to prioritize risks in self-driving vehicles. Appl. Soft Comput. 2021, 99, 106948. [Google Scholar] [CrossRef]

- Akram, M.; Luqman, A.; Alcantud, J.C.R. An integrated ELECTRE-I approach for risk evaluation with hesitant Pythagorean fuzzy information. Expert Syst. Appl. 2022, 200, 116945. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Fan, S.; Han, X.; Wu, Q.; Pamucar, D. A complex spherical fuzzy CRADIS method based Fine-Kinney framework for occupational risk evaluation in natural gas pipeline construction. J. Pet. Sci. Eng. 2023, 220. [Google Scholar] [CrossRef]

- Wang, Z.C.; Ran, Y.; Chen, Y.; Yang, X.; Zhang, G. Group risk assessment in failure mode and effects analysis using a hybrid probabilistic hesitant fuzzy linguistic MCDM method. Expert Syst. Appl. 2022, 188, 11603. [Google Scholar] [CrossRef]

- Ju, Y.; Zhao, Q.; Luis, M.; Liang, Y.; Dong, J.; Dong, P.; Giannakis, M. A novel framework for FMEA using evidential BWM and SMAA-MARCOS method. Expert Syst. Appl. 2024, 243, 122796. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, D.; Goerlandt, F.; Yan, X.; Kujala, P. Use of HFACS and fault tree model for collision risk factors analysis of icebreaker assistance in ice-covered waters. Saf. Sci. 2019, 111, 128–143. [Google Scholar] [CrossRef]

- Gündoğdu, F.K.; Seyfi-Shishavan, S.A. Occupational Risk Assessment Using Spherical Fuzzy Safety and Critical Effect Analysis for Shipyards. J. Eta Marit. Sci. 2021, 9, 110–119. [Google Scholar] [CrossRef]

- Chang, C.H.; Kontovas, C.; Yu, Q.; Yang, Z. Risk assessment of the operations of maritime autonomous surface ships. Reliab. Eng. Syst. Saf. 2021, 207, 107324. [Google Scholar] [CrossRef]

- Tang, J.; Liu, X.; Wang, W. A hybrid risk prioritization method based on generalized TODIM and BWM for Fine-Kinney under interval type-2 fuzzy environment. Hum. Ecol. Risk Assess. 2021, 27, 954–979. [Google Scholar] [CrossRef]

- Ziquan, X.; Jiaqi, Y.; Naseem, M.H.; Zuquan, X. Occupational Health and Safety Risk Assessment of Cruise Ship Construction Based on Improved Intuitionistic Fuzzy TOPSIS Decision Model. Math. Probl. Eng. 2021, 2021, 5966711. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, D.; Fu, S.; Kujala, P.; Hirdaris, S. A predictive analytics method for maritime traffic flow complexity estimation in inland waterways. Reliab. Eng. Syst. Saf. 2022, 220, 108317. [Google Scholar] [CrossRef]

- Ventikos, N.P.; Sotiralis, P.; Annetis, M.; Podimatas, V.C.; Boulougouris, E.; Stefanidis, F.; Chatzinikolaou, S.; Maccari, A. The Development and Demonstration of an Enhanced Risk Model for the Evacuation Process of Large Passenger Vessels. J. Mar. Sci. Eng. 2023, 11, 84. [Google Scholar] [CrossRef]

- Kinney, G.F.; Wiruth, A.D. Calhoun: The NPS Institutional Archive DSpace Repository Practical Risk Analysis for Safety Management. Available online: https://hdl.handle.net/10945/31846 (accessed on 1 January 2024).

- Hippertt, M.P.; Junior, M.L.; Szejka, A.L.; Junior, O.C.; Loures, E.R.; Santos, E.A.P. Towards safety level definition based on the HRN approach for industrial robots in collaborative activities. Procedia Manuf. 2019, 38, 1481–1490. [Google Scholar] [CrossRef]

- Paulino, M.D.M. Avaliação de risco pelo método hazard rating number em setor de indústria produtora de biodiesel em Porto Nacional/TO. Inventionis 2019, 1, 9–18. [Google Scholar] [CrossRef]

- Kieu, P.T.; Nguyen, V.T.; Nguyen, V.T.; Ho, T.P. A spherical fuzzy analytic hierarchy process (SF-AHP) and combined compromise solution (CoCoSo) algorithm in distribution center location selection: A case study in agricultural supply chain. Axioms 2021, 10, 53. [Google Scholar] [CrossRef]

- Zolfani, S.H.; Chatterjee, P.; Yazdani, M. A Structured Framework for Sustainable Supplier Selection Using a Combined BWM-CoCoSo Model; Vilnius Gediminas Technical University: Vilnius, Lithuania, 2019. [Google Scholar] [CrossRef]

- Wen, Z.; Liao, H.; Ren, R.; Bai, C.; Zavadskas, E.K.; Antucheviciene, J.; Al-Barakati, A. Cold Chain Logistics Management of Medicine with an Integrated Multi-Criteria Decision-Making Method. Int. J. Environ. Res. Public Health 2019, 16, 4843. [Google Scholar] [CrossRef]

- Panpatil, S.S.; Prajapati, H.; Kant, R. Analysing a GSCM Enabler–Based Model for Implementation of Its Practices: A Pythagorean Fuzzy AHP and CoCoSo Approach. Process Integr. Optim. Sustain. 2023, 7, 523–543. [Google Scholar] [CrossRef]

- Demir, G.; Damjanović, M.; Matović, B.; Vujadinović, R. Toward Sustainable Urban Mobility by Using Fuzzy-FUCOM and Fuzzy-CoCoSo Methods: The Case of the SUMP Podgorica. Sustainability 2022, 14, 4972. [Google Scholar] [CrossRef]

- Ghoushchi, S.J.; Jalalat, S.M.; Bonab, S.R.; Ghiaci, A.M.; Haseli, G.; Tomaskova, H. Evaluation of Wind Turbine Failure Modes Using the Developed SWARA-CoCoSo Methods Based on the Spherical Fuzzy Environment. IEEE Access 2022, 10, 86750–86764. [Google Scholar] [CrossRef]

- Liang, W.; Zhao, G.; Wu, H.; Dai, B. Risk assessment of rockburst via an extended MABAC method under fuzzy environment. Tunn. Undergr. Space Technol. 2019, 83, 533–544. [Google Scholar] [CrossRef]

- Al Zubayer, M.A.; Ali, S.M.; Kabir, G. Analysis of supply chain risk in the ceramic industry using the TOPSIS method under a fuzzy environment. J. Model. Manag. 2019, 14, 792–815. [Google Scholar] [CrossRef]

- Rathore, R.; Thakkar, J.J.; Jha, J.K. Evaluation of risks in foodgrains supply chain using failure mode effect analysis and fuzzy VIKOR. Int. J. Qual. Reliab. Manag. 2021, 38, 551–580. [Google Scholar] [CrossRef]

- Bathrinath, S.; Kumar, P.S.; Venkadesh, S.; Suprriyan, S.S.; Koppiahraj, K.; Bhalaji, R.K.A. A fuzzy COPRAS approach for analysing the factors affecting sustainability in ship ports. Mater. Today Proc. 2021, 50, 1017–1021. [Google Scholar] [CrossRef]

- Chen, Q.Y.; Liu, H.C.; Wang, J.H.; Shi, H. New model for occupational health and safety risk assessment based on Fermatean fuzzy linguistic sets and CoCoSo approach. Appl. Soft Comput. 2022, 126, 109262. [Google Scholar] [CrossRef]

| References | Methods | Applications | Advantages |

|---|---|---|---|

| [7] | TFN, BWM, AHP | LPG storage | A new method using four variables in the probability function is presented to improve safety decision-making measures and assess risks when working with hazardous substances. |

| [8] | IT2F, BWM MARCOS | Dam construction | The value and benefit methodologies used in this study address the OSHRA issues in dam construction. |

| [9] | HIRAC model | Hydroelectric power | This approach enhances the safety protocols for occupational risks and their management. |

| [10] | IRIS, MACBETH | - | The IRIS method refines risk matrices by integrating decision analysis to address their limitations. |

| [11] | Buckley’s FAHP, FVIKOR | Hospitals | This approach identifies and prioritizes potential dangers in healthcare settings. |

| [12] | AHP, Fine–Kinney | Machine manufacturing | This approach enables a thorough risk assessment by evaluating hazard significance and identifying those requiring immediate intervention based on their categories. |

| [13] | HF, SWOT | Wind turbine | This study used a comprehensive methodology that combines qualitative analysis, expert judgment, and fuzzy logic to enhance risk assessment tools for improving OHS practices. |

| [14] | FE, AHP | Construction | This approach enables the prioritization of risks on worksites based on expert opinions and actual accident data. |

| [15] | Fine–Kinney, AHP | Construction | An approach to risk analysis is suggested, combining the constraints of the Fine–Kinney method with the AHP method. |

| [16] | D number theory, SWOT | Wind turbine | This approach provides a way to simplify information processing and offers a more intuitive and concise alternative to previous methods. |

| [17] | PF, AHP | Hydroelectric power | This study found that improving occupational safety in hydroelectric power plants led to reduced financial losses and enhanced risk management. |

| [18] | FMEA, IVIF, MABAC | Radiation therapy | A new FMEA approach is proposed, which offers a linear programming model to determine the optimal weights for risk factors. |

| [19] | PF, AHP, TOPSIS, VIKOR | Automated driving | This approach fully considers all risks associated with driverless vehicles. |

| [20] | HPF, ELECTRE-I | Health | An ELECTRE-I approach was developed for healthcare risk assessment under HPF environment. |

| [21] | Fine–Kinney Complex SF, Risk prioritization CRADIS | Pipeline construction | This study proposed an innovative risk assessment method using complex spherical fuzzy sets in the context of natural gas pipeline construction. |

| [22] | FMEA, PHF, BWM, TOPSIS | Gear grinding machine | This model combines subjective and objective risk factor weights and uses a hybrid MCDM approach to enhance risk priority ranking in FMEA. |

| [23] | FMEA, BWM, SMAA-MARCOS | Industry 4.0 | This approach reduces uncertainties in risk assessment for Industry 4.0 and smart manufacturing failure modes. |

| References | Methods | Applications | Advantages |

|---|---|---|---|

| [24] | HFACS-FTA | Maritime | This study identified and categorized collision risk factors in icebreaker-assisted navigation operations, offering insight into risk control strategies in this sector. |

| [25] | Fine–Kinney, FMEA, SF, AHP, VIKOR | Shipyard | Spherical fuzzy safety and Critical Impact Analysis was used to provide occupational risk assessment specifically for shipyards in Turkey. |

| [26] | FMEA, Bayesian | Maritime | This study provides important information about significant hazards and contributes to MASS’s overall safety assurance. |

| [27] | Fine–Kinney, IT2F, TODIM, BWM | Shipyard | Maintenance of ballast tanks is crucial when a cargo ship is loaded or in a dry dock. This approach helps prioritize risk assessment to ensure the safety and health of personnel during operations. |

| [28] | IF, TOPSIS | Maritime | This study aimed to improve the ability to assess and manage complex risks associated with cruise ship construction environments by addressing uncertainty in the decision-making process. |

| [29] | Artificial intelligence Lempel–Ziv algorithm, TOPSIS | Maritime | This study developed a method to estimate the complexity of maritime traffic on inland waterways using predictive analytics. |

| [30] | ETA, Bayesian | Maritime | This approach simplifies the analysis of various dangerous situations, ranging from shipboard emergencies to survival at sea. |

| Linguistic Variables | Spherical Fuzzy Numbers | ||

|---|---|---|---|

| Absolutely more important (AMI) | 0.9 | 0.1 | 0.1 |

| Very high important (VHI) | 0.8 | 0.2 | 0.2 |

| High important (HI) | 0.7 | 0.3 | 0.3 |

| Slightly more important (SMI) | 0.6 | 0.4 | 0.4 |

| Equally important (EI) | 0.5 | 0.5 | 0.5 |

| Slightly low important (SLI) | 0.4 | 0.6 | 0.4 |

| Low important (LI) | 0.3 | 0.7 | 0.3 |

| Very low important (VLI) | 0.2 | 0.8 | 0.2 |

| Absolutely low important (ALI) | 0.1 | 0.9 | 0.1 |

| Linguistic Scale | Triangle Fuzzy Number |

|---|---|

| Very High (VH) | (0.9, 1.0, 1.0) |

| High (H) | (0.7, 0.9, 1.0) |

| Medium High (MH) | (0.5, 0.7, 0.9) |

| Medium (M) | (0.3, 0.5, 0.7) |

| Medium Low (ML) | (0.1, 0.3, 0.5) |

| Low (L) | (0.0, 0.1, 0.3) |

| Very Low (VL) | (0.0, 0.0, 0.1) |

| Alternatives | Emergency Occupational Hazards in Shipyard Floating Dock Operations |

|---|---|

| H1 | Cranes are unable to move while entering and exiting the docking pool. |

| H2 | Failure to offer ladder and transit services for embarking and disembarking from ships during diving operations. |

| H3 | The docks and ramps to the pool areas are congested with supplies and gear. |

| H4 | When the cat bridge is accessible and the pool float is in the water, there is no suitable pathway to access the entire pool area. |

| H5 | Failure to transfer stretchers during an emergency. |

| H6 | Failure to dispatch emergency crews. |

| H7 | During shipyard maneuvers, vessels may collide with each other or with the berths in the shipyard. |

| H8 | Incapability to intervene or restricted intervention during maneuvering, functioning, and docking procedures in the event of an emergency. |

| H9 | Inability to intervene or limited intervention in the warehouses and working areas remaining at sea in cases where a ship overflows from the pier. |

| H10 | Inability to intervene or limited intervention as a result of operations that completely close the floating docks or crossings to traffic. |

| H11 | Intervention failure or delayed and limited intervention in areas such as living quarters, crane cabins, machine rooms, and poles at heights that are unreachable even with a crane. |

| H12 | Docking vessels for maintenance at shipyards with inappropriate or insufficient facilities and environments, or neglecting to address emergencies that may arise during voyages. |

| H13 | When the floating dock cover is dry (i.e., while operating on the floating dock), the control of a vessel is compromised, leading to collisions with the cover during maneuvers. Adverse weather conditions may also cause a ship to strike the cover when mooring at a pier, or damage to the cover could occur as a result of an earthquake. |

| Expert Team | Position | Years of Experience |

|---|---|---|

| Expert 1 | Project Planning Manager | 20 years |

| Expert 2 | Health and Safety Manager | 20 years |

| Expert 3 | Shipyard Berth and Dock Operation Captain | 15 years |

| Expert 4 | Leader in Operational Excellence | 10 years |

| Risk criteria | |||||||||

| Expert 1 | C | F | P | NP | Expert 3 | C | F | P | NP |

| C | EL | AMI | LI | ALI | C | EL | HI | SMI | SLI |

| F | ALI | EL | HI | SLI | F | LI | EL | VHI | LI |

| P | HI | LI | EL | SMI | P | SLI | VLI | EL | AMI |

| NP | AMI | SMI | SLI | EL | NP | SMI | HI | ALI | EL |

| Expert 2 | C | F | P | NP | Expert 4 | C | F | P | NP |

| C | EL | AMI | HI | LI | C | EL | SLI | VLI | HI |

| F | ALI | EL | AMI | HI | F | SMI | EL | SLI | VLI |

| P | LI | ALI | EL | VHI | P | VHI | SMI | EL | LI |

| NP | HI | LI | VLI | EL | NP | LI | VHI | HI | EL |

| C | F | P | NP | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | 0.500 | 0.400 | 0.400 | 0.690 | 0.362 | 0.204 | 0.398 | 0.623 | 0.199 | 0.303 | 0.716 | 0.181 |

| F | 0.206 | 0.805 | 0.130 | 0.500 | 0.400 | 0.400 | 0.670 | 0.371 | 0.209 | 0.360 | 0.654 | 0.205 |

| P | 0.509 | 0.519 | 0.226 | 0.245 | 0.766 | 0.150 | 0.500 | 0.400 | 0.400 | 0.600 | 0.449 | 0.200 |

| NP | 0.580 | 0.460 | 0.214 | 0.563 | 0.467 | 0.218 | 0.274 | 0.744 | 0.156 | 0.500 | 0.400 | 0.400 |

| Spherical Fuzzy Weights | CRISP Weights | |||

| C | 0.510 | 0.504 | 0.268 | 0.258 |

| F | 0.484 | 0.529 | 0.267 | 0.243 |

| P | 0.490 | 0.517 | 0.269 | 0.246 |

| NP | 0.501 | 0.503 | 0.270 | 0.253 |

| Expert 1 | H1 | H2 | H3 | H4 | H5 | H6 | H7 | H8 | H9 | H10 | H11 | H12 | H13 |

| C | VL | L | L | VL | H | L | ML | L | ML | L | L | ML | H |

| F | ML | L | VL | L | VL | L | VL | L | ML | VL | L | L | VL |

| P | VH | VH | ML | VH | ML | L | VL | L | VH | VH | VH | VH | VL |

| NP | L | L | L | L | L | L | L | L | L | L | L | L | VH |

| Expert 2 | H1 | H2 | H3 | H4 | H5 | H6 | H7 | H8 | H9 | H10 | H11 | H12 | H13 |

| C | VH | H | H | H | H | VH | VH | VH | H | H | H | VH | VH |

| F | H | H | M | ML | VL | VL | L | VL | ML | VL | L | L | VL |

| P | L | VL | VL | L | VL | VL | L | L | VL | L | L | VL | VL |

| NP | H | H | VH | H | VH | VH | MH | H | H | VH | H | VH | H |

| Expert 3 | H1 | H2 | H3 | H4 | H5 | H6 | H7 | H8 | H9 | H10 | H11 | H12 | H13 |

| C | VL | L | L | VL | H | L | ML | L | ML | H | L | ML | VH |

| F | VL | L | VL | L | MH | ML | L | M | M | H | VH | L | VL |

| P | L | M | ML | ML | ML | L | M | VL | ML | MH | ML | VL | VL |

| NP | H | MH | MH | VH | H | MH | VH | MH | VH | H | ML | MH | VH |

| Expert 4 | H1 | H2 | H3 | H4 | H5 | H6 | H7 | H8 | H9 | H10 | H11 | H12 | H13 |

| C | M | H | MH | H | MH | VH | H | MH | M | H | MH | MH | VH |

| F | L | M | H | VL | L | L | MH | H | L | MH | H | L | MH |

| P | VL | L | MH | VL | L | L | M | VL | ML | MH | L | VL | H |

| NP | M | H | H | MH | H | VH | MH | H | M | VH | H | MH | VH |

| Alternatives | C | F | P | NP | ||||||||

| H1 | 0.745 | 0.891 | 0.982 | 0.243 | 0.541 | 0.784 | 0.489 | 0.681 | 0.787 | 0.450 | 0.700 | 0.950 |

| H2 | 0.655 | 0.855 | 1.000 | 0.243 | 0.568 | 0.811 | 0.255 | 0.426 | 0.553 | 0.400 | 0.650 | 0.900 |

| H3 | 0.527 | 0.764 | 0.945 | 0.297 | 0.541 | 0.703 | 0.340 | 0.596 | 0.809 | 0.400 | 0.600 | 0.800 |

| H4 | 0.764 | 0.909 | 1.000 | 0.486 | 0.811 | 1.000 | 0.404 | 0.638 | 0.787 | 0.400 | 0.625 | 0.850 |

| H5 | 0.018 | 0.182 | 0.436 | 0.622 | 0.865 | 1.000 | 0.383 | 0.660 | 0.872 | 0.225 | 0.425 | 0.675 |

| H6 | 0.364 | 0.509 | 0.673 | 0.486 | 0.811 | 1.000 | 0.000 | 0.894 | 1.000 | 0.200 | 0.400 | 0.625 |

| H7 | 0.436 | 0.636 | 0.873 | 0.135 | 0.432 | 0.649 | 0.383 | 0.638 | 0.809 | 0.400 | 0.700 | 0.950 |

| H8 | 0.527 | 0.745 | 0.909 | 0.243 | 0.541 | 0.757 | 0.000 | 0.915 | 1.000 | 0.350 | 0.600 | 0.850 |

| H9 | 0.327 | 0.527 | 0.764 | 0.162 | 0.514 | 0.811 | 0.255 | 0.426 | 0.574 | 0.250 | 0.475 | 0.725 |

| H10 | 0.218 | 0.382 | 0.618 | 0.135 | 0.405 | 0.622 | 0.000 | 0.213 | 0.404 | 0.175 | 0.350 | 0.575 |

| H11 | 0.509 | 0.727 | 0.909 | 0.000 | 0.297 | 0.541 | 0.213 | 0.426 | 0.596 | 0.450 | 0.725 | 1.000 |

| H12 | 0.545 | 0.745 | 0.964 | 0.432 | 0.784 | 0.973 | 0.426 | 0.553 | 0.617 | 0.450 | 0.675 | 0.900 |

| H13 | 0.000 | 0.091 | 0.291 | 0.324 | 0.595 | 0.757 | 0.574 | 0.766 | 0.851 | 0.000 | 0.150 | 0.400 |

| Alternatives | C | F | P | NP | Si | ||||||||||

| H1 | 0.380 | 0.449 | 0.263 | 0.118 | 0.286 | 0.209 | 0.245 | 0.342 | 0.127 | 0.221 | 0.362 | 0.256 | 0.964 | 1.439 | 0.855 |

| H2 | 0.334 | 0.431 | 0.268 | 0.118 | 0.300 | 0.216 | 0.128 | 0.214 | 0.089 | 0.196 | 0.336 | 0.242 | 0.775 | 1.281 | 0.816 |

| H3 | 0.269 | 0.385 | 0.253 | 0.144 | 0.286 | 0.188 | 0.171 | 0.300 | 0.130 | 0.196 | 0.310 | 0.215 | 0.779 | 1.281 | 0.786 |

| H4 | 0.389 | 0.458 | 0.268 | 0.235 | 0.429 | 0.267 | 0.203 | 0.321 | 0.127 | 0.196 | 0.323 | 0.229 | 1.023 | 1.531 | 0.890 |

| H5 | 0.009 | 0.092 | 0.117 | 0.301 | 0.458 | 0.267 | 0.192 | 0.332 | 0.140 | 0.110 | 0.220 | 0.182 | 0.612 | 1.101 | 0.706 |

| H6 | 0.185 | 0.257 | 0.180 | 0.235 | 0.429 | 0.267 | 0.000 | 0.449 | 0.161 | 0.098 | 0.207 | 0.168 | 0.519 | 1.342 | 0.776 |

| H7 | 0.223 | 0.321 | 0.234 | 0.065 | 0.229 | 0.173 | 0.192 | 0.321 | 0.130 | 0.196 | 0.362 | 0.256 | 0.676 | 1.232 | 0.793 |

| H8 | 0.269 | 0.376 | 0.244 | 0.118 | 0.286 | 0.202 | 0.000 | 0.460 | 0.161 | 0.172 | 0.310 | 0.229 | 0.558 | 1.432 | 0.835 |

| H9 | 0.167 | 0.266 | 0.205 | 0.078 | 0.272 | 0.216 | 0.128 | 0.214 | 0.092 | 0.123 | 0.246 | 0.195 | 0.496 | 0.997 | 0.709 |

| H10 | 0.111 | 0.192 | 0.166 | 0.065 | 0.214 | 0.166 | 0.000 | 0.107 | 0.065 | 0.086 | 0.181 | 0.155 | 0.262 | 0.695 | 0.551 |

| H11 | 0.260 | 0.367 | 0.244 | 0.000 | 0.157 | 0.144 | 0.107 | 0.214 | 0.096 | 0.221 | 0.375 | 0.269 | 0.587 | 1.113 | 0.753 |

| H12 | 0.278 | 0.376 | 0.258 | 0.209 | 0.415 | 0.260 | 0.213 | 0.278 | 0.099 | 0.221 | 0.349 | 0.242 | 0.921 | 1.418 | 0.859 |

| H13 | 0.000 | 0.046 | 0.078 | 0.157 | 0.315 | 0.202 | 0.288 | 0.385 | 0.137 | 0.000 | 0.078 | 0.108 | 0.445 | 0.823 | 0.525 |

| Alternatives | C | F | P | NP | Pi | ||||||||||

| H1 | 0.924 | 0.943 | 0.991 | 0.686 | 0.722 | 0.889 | 0.891 | 0.824 | 0.887 | 0.807 | 0.832 | 0.975 | 3.308 | 3.321 | 3.742 |

| H2 | 0.893 | 0.924 | 1.000 | 0.686 | 0.741 | 0.903 | 0.803 | 0.651 | 0.743 | 0.782 | 0.800 | 0.950 | 3.162 | 3.116 | 3.596 |

| H3 | 0.842 | 0.873 | 0.972 | 0.723 | 0.722 | 0.843 | 0.841 | 0.771 | 0.899 | 0.782 | 0.768 | 0.896 | 3.188 | 3.134 | 3.610 |

| H4 | 0.930 | 0.953 | 1.000 | 0.825 | 0.895 | 1.000 | 0.864 | 0.798 | 0.887 | 0.782 | 0.784 | 0.923 | 3.401 | 3.430 | 3.811 |

| H5 | 0.342 | 0.424 | 0.655 | 0.881 | 0.926 | 1.000 | 0.857 | 0.811 | 0.934 | 0.669 | 0.643 | 0.825 | 2.749 | 2.803 | 3.414 |

| H6 | 0.763 | 0.712 | 0.817 | 0.825 | 0.895 | 1.000 | 0.000 | 0.945 | 1.000 | 0.649 | 0.623 | 0.794 | 2.236 | 3.174 | 3.611 |

| H7 | 0.801 | 0.796 | 0.933 | 0.586 | 0.642 | 0.811 | 0.857 | 0.798 | 0.899 | 0.782 | 0.832 | 0.975 | 3.025 | 3.068 | 3.618 |

| H8 | 0.842 | 0.862 | 0.953 | 0.686 | 0.722 | 0.874 | 0.000 | 0.956 | 1.000 | 0.754 | 0.768 | 0.923 | 2.282 | 3.309 | 3.750 |

| H9 | 0.741 | 0.724 | 0.872 | 0.615 | 0.703 | 0.903 | 0.803 | 0.651 | 0.758 | 0.689 | 0.681 | 0.854 | 2.848 | 2.758 | 3.387 |

| H10 | 0.665 | 0.616 | 0.782 | 0.586 | 0.620 | 0.794 | 0.000 | 0.459 | 0.635 | 0.626 | 0.581 | 0.762 | 1.877 | 2.276 | 2.975 |

| H11 | 0.834 | 0.852 | 0.953 | 0.000 | 0.526 | 0.742 | 0.779 | 0.651 | 0.771 | 0.807 | 0.847 | 1.000 | 2.421 | 2.876 | 3.466 |

| H12 | 0.850 | 0.862 | 0.981 | 0.799 | 0.879 | 0.987 | 0.871 | 0.742 | 0.785 | 0.807 | 0.816 | 0.950 | 3.328 | 3.300 | 3.703 |

| H13 | 0.000 | 0.299 | 0.533 | 0.740 | 0.760 | 0.874 | 0.915 | 0.874 | 0.922 | 0.000 | 0.375 | 0.638 | 1.655 | 2.308 | 2.967 |

| Alternatives | Fuzzy Fia | Crisp Fia | Fuzzy Fib | Crisp Fib | Fuzzy Fic | Crisp Fic | Final Score Fi | Final Ranking | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H1 | 0.077 | 0.087 | 0.104 | 0.089 | 5.671 | 7.492 | 5.518 | 6.227 | 1.082 | 1.617 | 0.960 | 1.220 | 3.391 | 2 |

| H2 | 0.071 | 0.081 | 0.100 | 0.084 | 4.866 | 6.764 | 5.281 | 5.637 | 0.871 | 1.439 | 0.916 | 1.075 | 3.063 | 4 |

| H3 | 0.071 | 0.081 | 0.100 | 0.084 | 4.896 | 6.774 | 5.178 | 5.616 | 0.875 | 1.438 | 0.883 | 1.066 | 3.050 | 5 |

| H4 | 0.080 | 0.091 | 0.107 | 0.092 | 5.955 | 7.908 | 5.695 | 6.519 | 1.149 | 1.720 | 1.000 | 1.290 | 3.553 | 1 |

| H5 | 0.061 | 0.072 | 0.093 | 0.075 | 3.994 | 5.888 | 4.753 | 4.878 | 0.688 | 1.236 | 0.793 | 0.906 | 2.645 | 10 |

| H6 | 0.050 | 0.083 | 0.099 | 0.077 | 3.329 | 7.031 | 5.141 | 5.167 | 0.583 | 1.507 | 0.872 | 0.987 | 2.810 | 8 |

| H7 | 0.067 | 0.079 | 0.100 | 0.082 | 4.403 | 6.550 | 5.207 | 5.387 | 0.759 | 1.384 | 0.890 | 1.011 | 2.924 | 7 |

| H8 | 0.051 | 0.087 | 0.104 | 0.081 | 3.506 | 7.456 | 5.449 | 5.470 | 0.627 | 1.608 | 0.938 | 1.058 | 2.979 | 6 |

| H9 | 0.060 | 0.069 | 0.093 | 0.074 | 3.610 | 5.466 | 4.747 | 4.608 | 0.557 | 1.120 | 0.796 | 0.824 | 2.490 | 11 |

| H10 | 0.039 | 0.054 | 0.080 | 0.058 | 2.134 | 4.023 | 3.899 | 3.352 | 0.295 | 0.780 | 0.619 | 0.565 | 1.803 | 13 |

| H11 | 0.054 | 0.073 | 0.096 | 0.074 | 3.698 | 5.978 | 4.963 | 4.880 | 0.659 | 1.250 | 0.846 | 0.918 | 2.651 | 9 |

| H12 | 0.077 | 0.086 | 0.103 | 0.089 | 5.521 | 7.396 | 5.513 | 6.143 | 1.035 | 1.592 | 0.965 | 1.197 | 3.344 | 3 |

| H13 | 0.038 | 0.057 | 0.079 | 0.058 | 2.695 | 4.531 | 3.792 | 3.673 | 0.500 | 0.925 | 0.589 | 0.671 | 1.991 | 12 |

| Scripts | (C) | (F) | (P) | (NP) |

|---|---|---|---|---|

| Current | 0.258 | 0.243 | 0.246 | 0.253 |

| S 1 | 0.243 | 0.258 | 0.246 | 0.253 |

| S 2 | 0.246 | 0.243 | 0.258 | 0.253 |

| S 3 | 0.253 | 0.243 | 0.246 | 0.258 |

| S 4 | 0.258 | 0.246 | 0.243 | 0.253 |

| S 5 | 0.258 | 0.253 | 0.246 | 0.243 |

| S 6 | 0.258 | 0.243 | 0.253 | 0.246 |

| Rank | Alternatives | Corrective and Preventive Actions |

|---|---|---|

| 1 | H4 | The docks and ramps leading to the pool must always remain open, except in cases where closures are necessary for disaster and emergency services. |

| 2 | H1 | The operations manager evaluates the safe slope and trim for cranes to prevent movement during diving and ascending. |

| 3 | H12 | Ensuring ongoing communication, prohibiting hot work on offshore vessels, and providing emergency training for ship personnel are essential. Other actions include implementing a systematic external shipyard communication process and sharing it with relevant departments. Compiling a list of missing tools, equipment, and supplies for emergencies in outer shipyards and arranging their transfer in potential situations are needed. |

| 4 | H2 | It is ensured that there is always a barrier surrounding the pools. All scenarios are predetermined. |

| 5 | H3 | When transition ladder and crane services are unavailable, work on the ships is halted. In ship-related emergencies, a cross or side ladder is used for intervention with attention to access and opening conditions. |

| 6 | H8 | The work is stopped immediately. Evacuation takes place. Security measures are provided in the area. Necessary conditions are provided for the response teams to carry out their work. |

| 7 | H7 | Tugboats intervene when there are fires during navigation until the ship stops moving. |

| 8 | H6 | All operations are halted, and slope trim is inspected. Cranes are utilized for the rescue operations. |

| 9 | H11 | Inaccessible areas are determined for unforeseen situations and mountaineering, and rescue and first aid training is given to the teams that will intervene in these areas. Periodic examinations of these teams are carried out in more detail. |

| 10 | H5 | The marine vehicle is kept in reserve at all times. |

| 11 | H9 | The accessible ship area for the dock’s seaside cranes is marked and passages are opened to reach the remaining working areas beyond this. Stretchers and intervention equipment are then positioned in these areas. |

| 12 | H13 | Floating docks are subjected to regular technical inspections by authorized institutions. Maintenance and repairs should be performed by docking the ships in a different pool every five years. |

| 13 | H10 | The health cabinet is informed. Alternative transportation routes are determined instantly. In cases where no action can be taken, the operation is stopped. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bayhun, S.; Demirel, N.Ç. Hazard Identification and Risk Assessment for Sustainable Shipyard Floating Dock Operations: An Integrated Spherical Fuzzy Analytical Hierarchy Process and Fuzzy CoCoSo Approach. Sustainability 2024, 16, 5790. https://doi.org/10.3390/su16135790

Bayhun S, Demirel NÇ. Hazard Identification and Risk Assessment for Sustainable Shipyard Floating Dock Operations: An Integrated Spherical Fuzzy Analytical Hierarchy Process and Fuzzy CoCoSo Approach. Sustainability. 2024; 16(13):5790. https://doi.org/10.3390/su16135790

Chicago/Turabian StyleBayhun, Semra, and Nihan Çetin Demirel. 2024. "Hazard Identification and Risk Assessment for Sustainable Shipyard Floating Dock Operations: An Integrated Spherical Fuzzy Analytical Hierarchy Process and Fuzzy CoCoSo Approach" Sustainability 16, no. 13: 5790. https://doi.org/10.3390/su16135790