Self-Leveling Mortars Produced with Different Types of Cement: Physical–Mechanical Properties and Carbon Emissions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Self-Leveling Mortars (SLMs) Batching Study

2.2.2. Mortars Production

2.3. CO2 Emissions

- = Total emissions of cement (kgCO2/kg);

- = Clinker production emissions (kgCO2/kg);

- = Clinker percentage of cement used.

- = Emission from electric energy used in the process (kWh/kg);

- = Electric energy emission factor (kgCO2/kg).

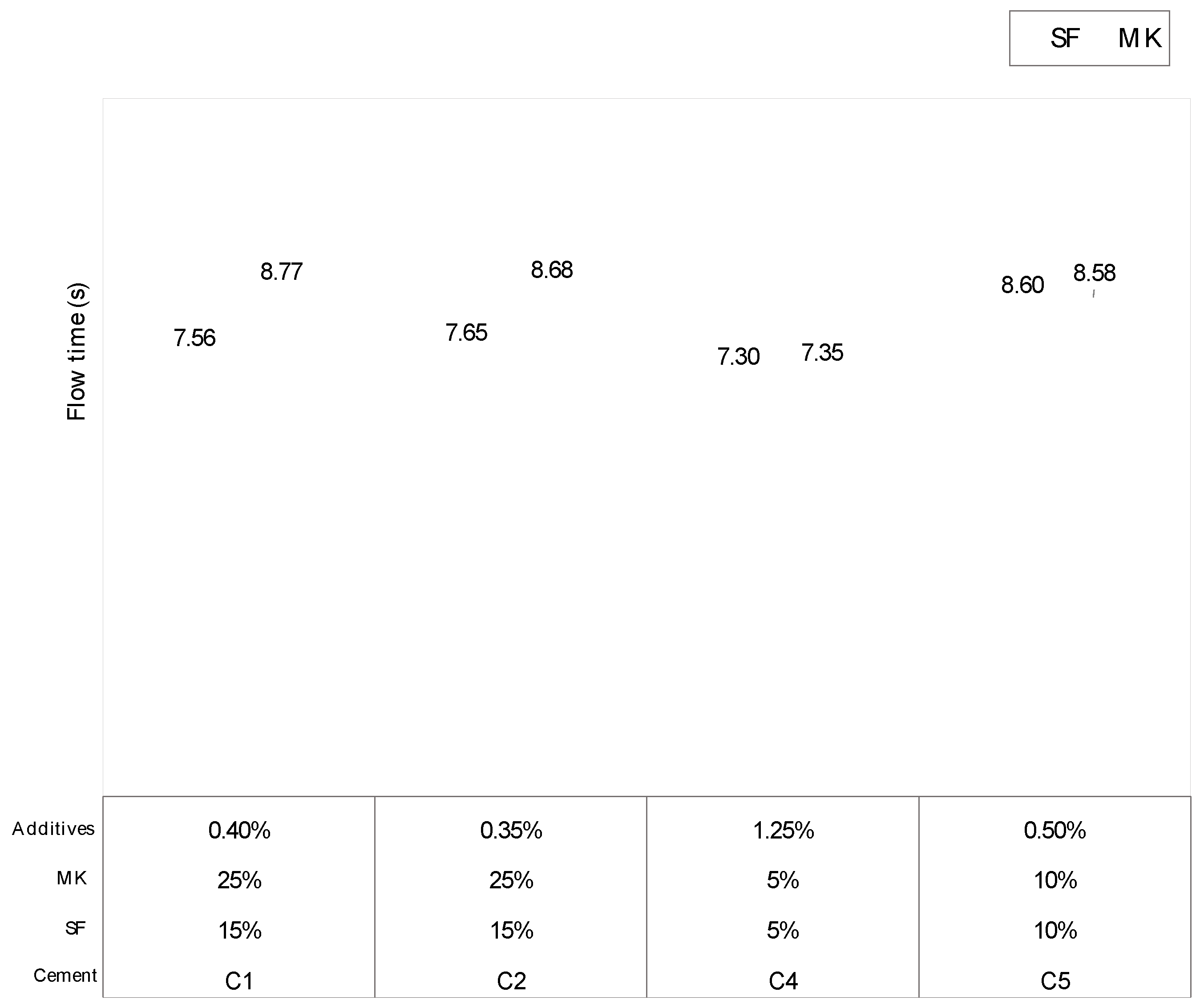

| Mixtures | EFNARC Parameters (2002) | Martins’ Parameters (2009) | ||

|---|---|---|---|---|

| Average Spreading: 240 to 260 mm | Flow Time: 7 to 11 s | Edges | Segregation | |

| C1.SF15 | 257 | 7.56 | U | SS |

| C2.SF15 | 252 | 7.65 | U | SS |

| C4.SF05 | 259 | 7.30 | U | SS |

| C5.SF10 | 248 | 8.60 | U | SS |

| C1.MK25 | 242 | 8.77 | U | SS |

| C2.MK25 | 244 | 8.68 | U | SS |

| C4.MK05 | 259 | 7.35 | U | SS |

| C5.MK10 | 248 | 8.58 | U | SS |

- CI = Carbon Index, at kg·m−3·MPa−1;

- CCO2 = CO2 emissions associated with materials production that make up the SLM (cradle-to-gate scope). fck = compressive strength at 28 days.

3. Results and Discussions

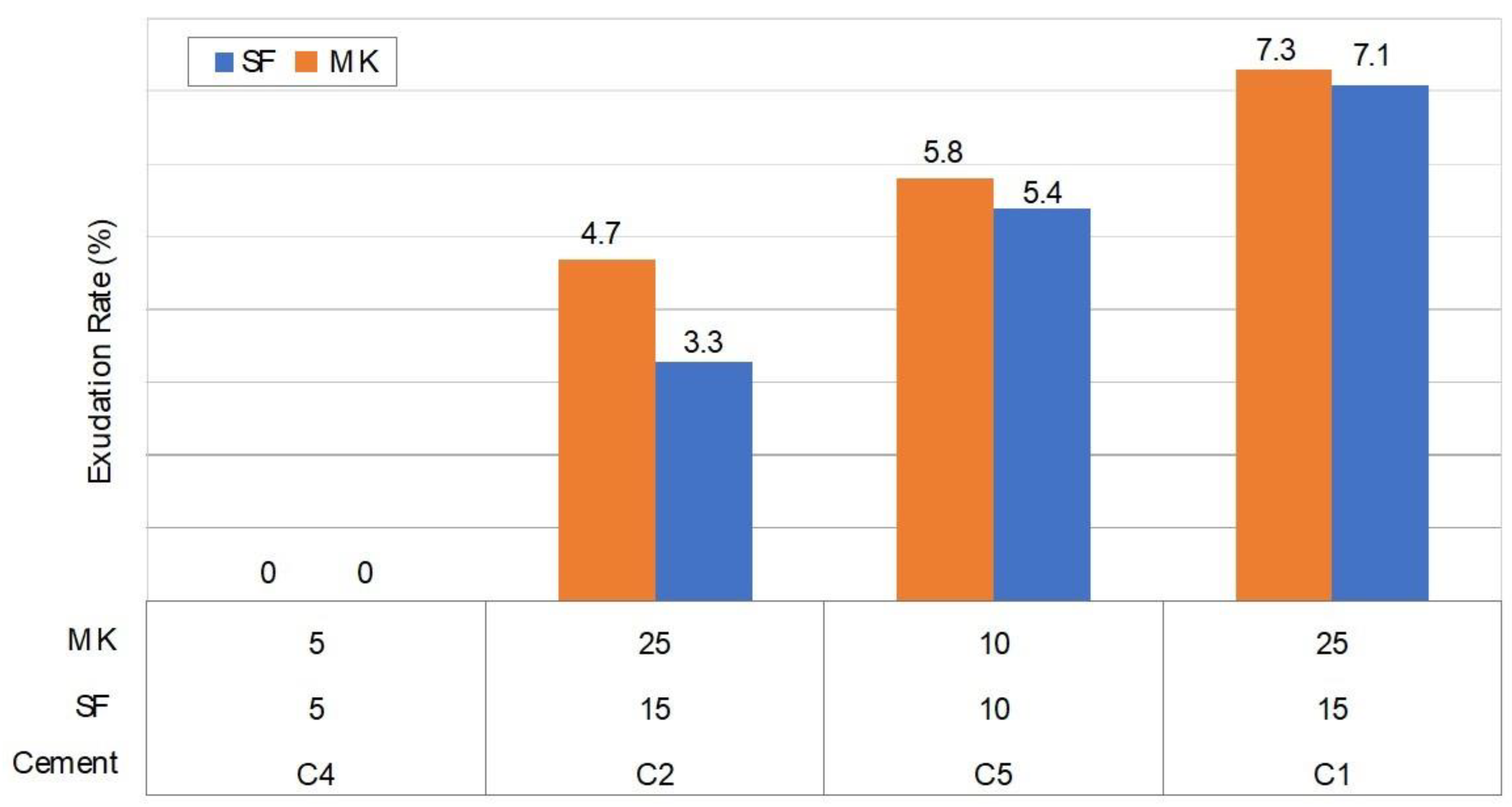

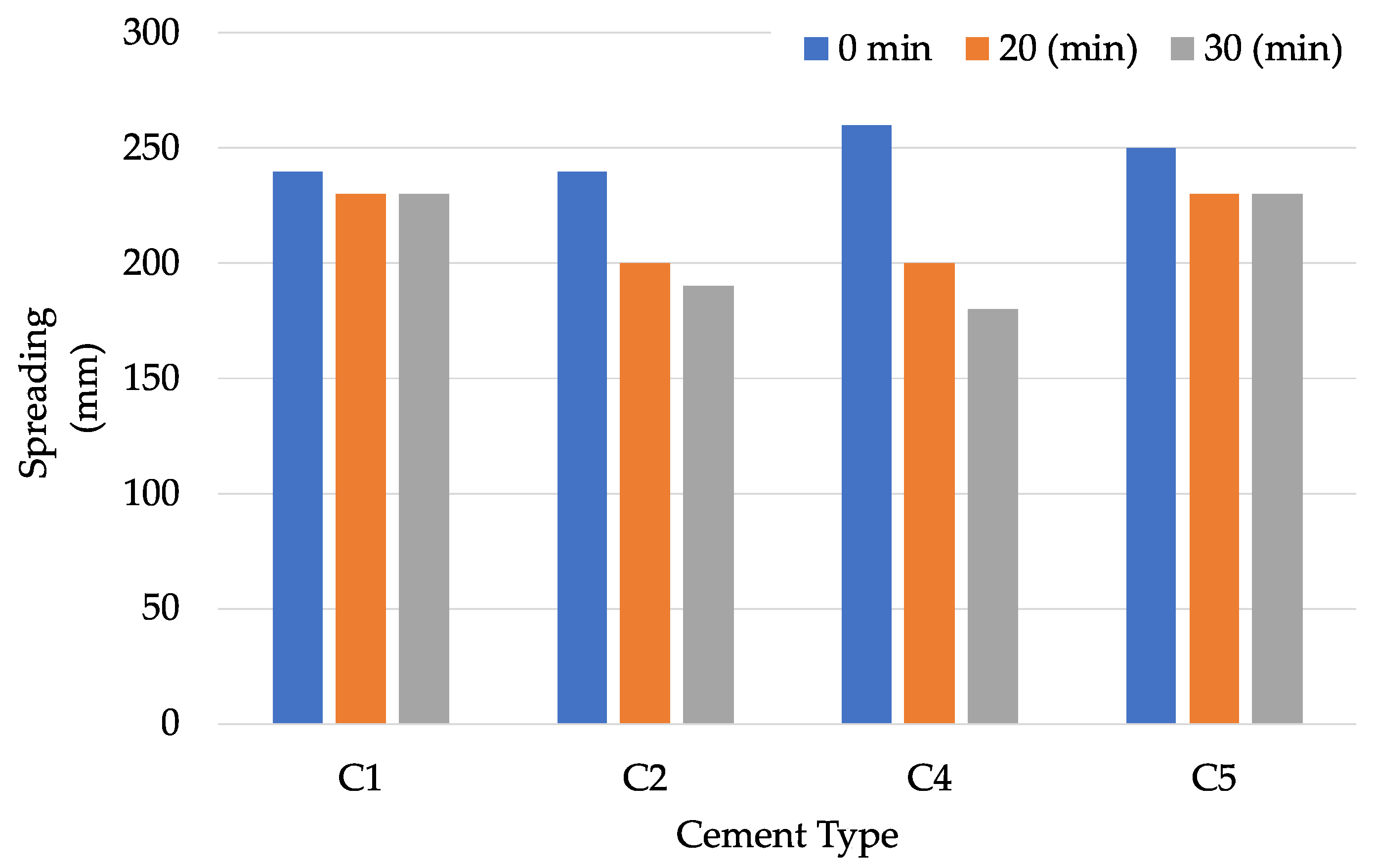

3.1. Self-Adhesion Parameters, Curing Time, Exudation Rate, and Flow Retention

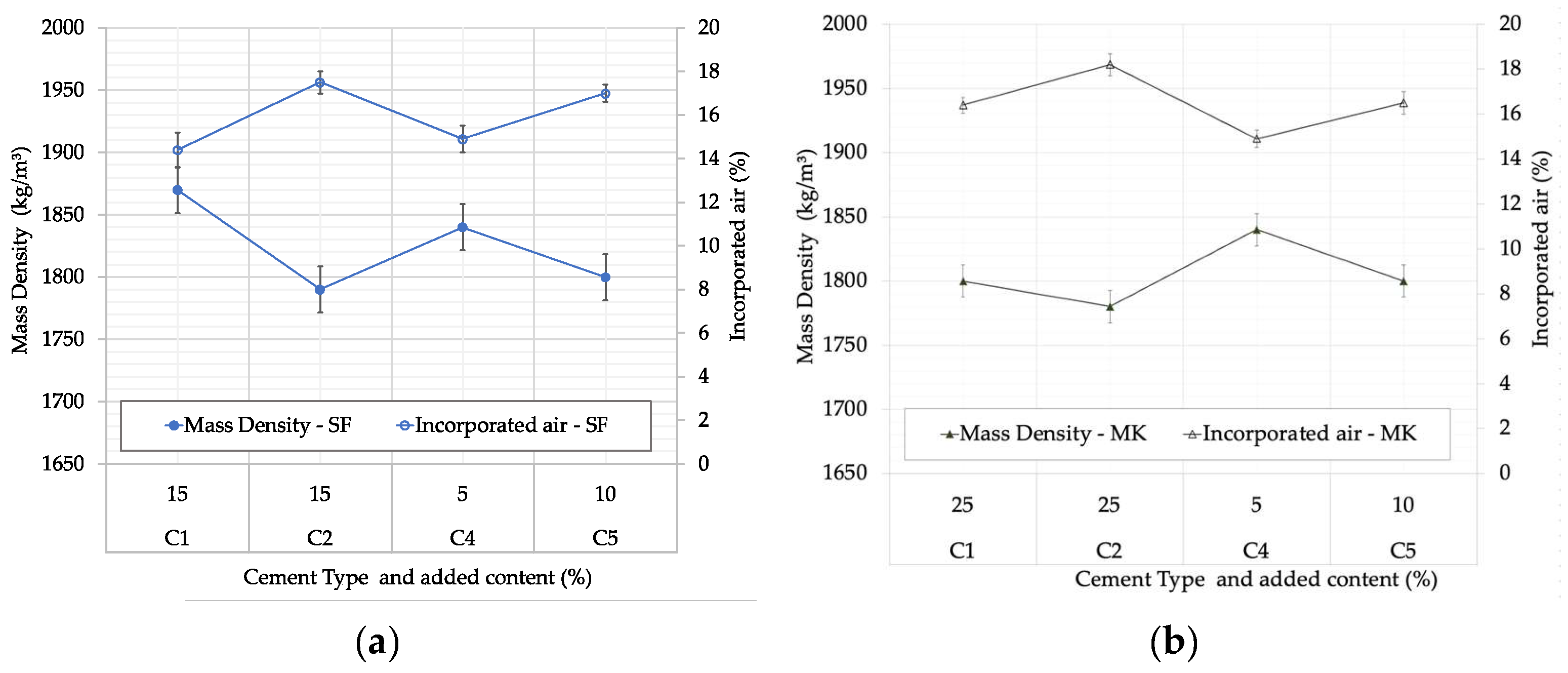

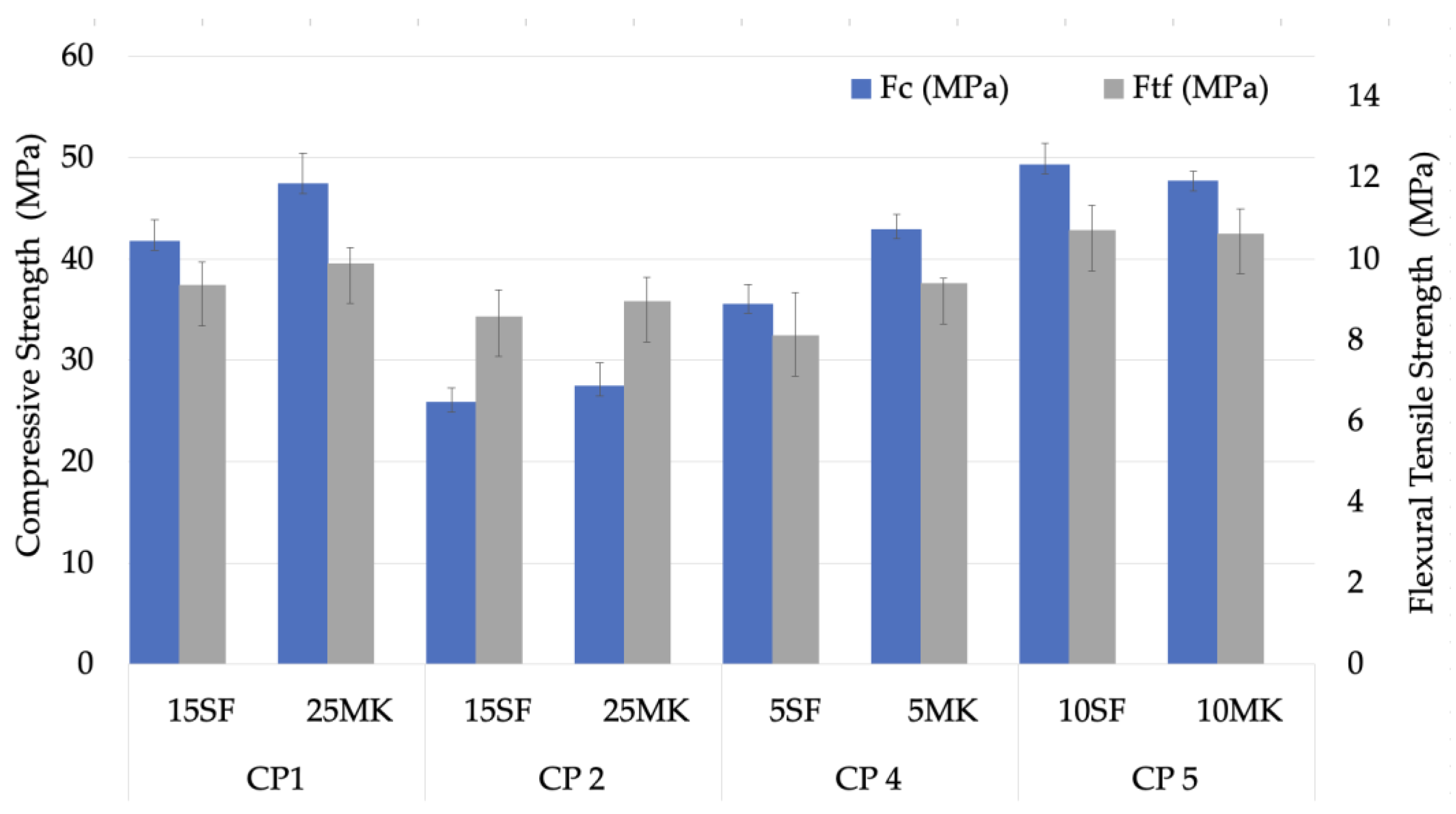

3.2. Physical–Mechanical Properties Evaluation of Mortars

3.3. Dimensional Variation Evaluation

3.4. CO2 Emissions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, W.; Fang, C.; Hu, R. Influence of Redispersible Powder on Properties of Self-Leveling Mortar of Ternary Cementitious System. Materials 2020, 13, 5703. [Google Scholar] [CrossRef]

- Carvalho, H.D.S.; Rocha, J.C.; Cheriaf, M. Influence of bottom ash and red mud additions on self-leveling underlayment properties. Cerâmica 2022, 68, 199–210. [Google Scholar] [CrossRef]

- Scolaro, T.P.; Rocha, J.C. Effect of filler nature on mechanical performance and drying shrinkage of self-leveling mortars. Rev. Ibracon Estrut. Mater. 2021, 14, 26. [Google Scholar] [CrossRef]

- Rocha, J.H.A.; de Siqueira, A.A.; de Oliveira, M.A.B.; Castro, L.D.S.; Caldas, L.R.; Monteiro, N.B.R.; Toledo Filho, R.D. Circular Bioeconomy in the Amazon Rainforest: Evaluation of Açaí Seed Ash as a Regional Solution for Partial Cement Replacement. Sustainability 2022, 14, 14436. [Google Scholar] [CrossRef]

- Rego, A.C.A.; Cardoso, F.A.; Pileggi, R.G. Ternary system Portland cement-calcium aluminate cement-calcium sulfate applied to self-leveling mortar: A literature review. Cerâmica 2021, 67, 65–82. [Google Scholar] [CrossRef]

- da Silva, D.B.P.; de Oliveira Cardoso Pontes, I.; Rodrigues, M.T.J.; de Lima, N.B.; Póvoas, Y.V. Pasta autonivelante de gesso para utilização como camada de contrapiso. Ambiente Construído 2021, 21, 311–329. [Google Scholar] [CrossRef]

- Anjos, M.A.S.; Araujo, T.R.; Ferreira, R.L.S.; Farias, E.C.; Martinelli, A.E. Properties of self-leveling mortars incorporating a high-volume of sugar cane bagasse ash as partial Portland cement replacement. J. Build. Eng. 2020, 32, 101694. [Google Scholar] [CrossRef]

- Nakakura, E.H.; Bucher, H.R.E. Pisos autonivelantes. Propriedades e Instalação. In Proceedings of the 2nd Brazilian Mortar Technology Symposium, Salvador, Brazil, 17–18 April 1997. [Google Scholar]

- Zhang, S.; Xu, X.; Memon, S.A.; Dong, Z.; Li, D.; Cui, H. Effect of calcium sulfate type and dosage on properties of calcium aluminate cement-based self-leveling mortar. Constr. Build. Mater. 2018, 167, 253–262. [Google Scholar] [CrossRef]

- Dong, W.Y.; Fang, C.Q.; Hu, R. Study on Properties of Binary Composite Cementitious Self-leveling Mortar. IOP Conf. Ser. Mater. Sci. Eng. 2019, 592, 012003. [Google Scholar] [CrossRef]

- Kenai, S.; Hammat, S.; Menadi, B.; Khatib, J.; Kadri, E.H. Properties of Self-Compacting Mortar Containing Slag with Different Finenesses. Civ. Eng. J. 2021, 7, 840–856. [Google Scholar] [CrossRef]

- Zhao, Z.; Xiao, J.; Duan, Z.; Hubert, J.; Grigoletto, S.; Courard, L. Performance and durability of self-compacting mortar with recycled sand from crushed brick. J. Build. Eng. 2022, 57, 104867. [Google Scholar] [CrossRef]

- Liu, B.; Meng, H.; Pan, G.; Zhou, H.; Li, D. Relationship between the fineness and specific surface area of iron tailing powder and its effect on compressive strength and drying shrinkage of cement composites. Constr. Build. Mater. 2022, 357, 129421. [Google Scholar] [CrossRef]

- Onishi, K.; Bier, T.A. Investigation into relations among technological properties, hydration kinetics and early age hydration of self-leveling underlayments. Cem. Concr. Res. 2010, 40, 1034–1040. [Google Scholar] [CrossRef]

- Ouldkhaoua, Y.; Benabed, B.; Abousnina, R.; Kadri, E.-H. Experimental study on the reuse of cathode ray tubes funnel glass as fine aggregate for developing an ecological self-compacting mortar incorporating metakaolin. J. Build. Eng. 2020, 27, 100951. [Google Scholar] [CrossRef]

- Oliveira, T.V.; Cordeiro, L.N.P.; Bessa, S.A.L. Experimental study of self-leveling mortars produced with recycled concrete aggregates. Case Stud. Constr. Mater. 2022, 17, e01294. [Google Scholar] [CrossRef]

- Pereira, V.M.; Geraldo, R.H.; Baldusco, R.; Camarini, G. Porcelain waste from electrical insulators in self-leveling mortar: Materials characterization and properties. J. Build. Eng. 2022, 61, 105297. [Google Scholar] [CrossRef]

- Possan, E. Captura de CO2 em materiais cimentícios. Concreto Construções 2019, 95, 60–66. [Google Scholar]

- Safi, B.; Saidi, M.; Daoui, A.; Bellal, A.; Mechekak, A.; Toumi, K. The use of seashells as a fine aggregate (by sand substitution) in self-compacting mortar (SCM). Constr. Build. Mater. 2015, 78, 430–438. [Google Scholar] [CrossRef]

- Barluenga, G.; Hernández-Olivares, F. Self-levelling cement mortar containing grounded slate from quarrying waste. Constr. Build. Mater. 2010, 24, 1601–1607. [Google Scholar] [CrossRef]

- Oliveira, D.R.B.; Leite, G.; Possan, E.; Marques Filho, J. Concrete powder waste as a substitution for Portland cement for environment-friendly cement production. Constr. Build. Mater. 2023, 397, 132382. [Google Scholar] [CrossRef]

- Canbaz, M.; Topçu, I.B.; Ateşin, O. Effect of admixture ratio and aggregate type on self-leveling screed properties. Constr. Build. Mater. 2016, 116, 321–325. [Google Scholar] [CrossRef]

- Mahdikhani, M.; Ramezanianpour, A.A. New methods development for evaluation rheological properties of self-consolidating mortars. Constr. Build. Mater. 2015, 75, 136–143. [Google Scholar] [CrossRef]

- NBR 12653:2015; Materiais Pozolânicos—Requisitos. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2015.

- NBR NM 248:2003; Agregados—Determinação da Composição Granulométrica. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2003.

- NBR NM 30:2001; Agregado Miúdo—Determinação da Absorção de Água. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2001.

- NBR NM 52:2009; Agregado Miúdo—Determinação da Massa Específica e Massa Específica Aparente. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2009.

- NBR NM 45:2006; Agregados: Determinação da Massa Unitária e do Volume de Vazios. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2006.

- Lopes, A.; Ramos, A.; Cordeiro, L.; Paes, I. Dosagem de argamassa autonivelante com resíduo do corte de mármore e granito (RCMG) para contrapiso. In Proceedings of the 3rd Symposium and Thermal Coating Solutions, Coimbra, Portugal, 11–12 October 2018. [Google Scholar]

- Tutikian, B. Método para Dosagem de Concretos Autoadensáveis. Universidade Federal do Rio Grande do Sul. Porto Alegre. 2004. Available online: http://hdl.handle.net/10183/3918 (accessed on 10 May 2024).

- C1708/C1708M:2012; Standard Test Methods for Self-Leveling Mortars Containing Hydraulic Cements. ASTM International: West Conshohocken, PA, USA, 2012.

- EFNARC. Specification and Guidelines for Self-Compacting Concrete. 2002. Available online: https://wwwp.feb.unesp.br/pbastos/c.especiais/Efnarc.pdf (accessed on 10 January 2024).

- Martins, E.J. Procedimento para Dosagem de Pastas para Argamassa Autonivelante. Dissertação (Mestrado em Engenharia Civil), Universidade Federal do Paraná, Curitiba, Brasil, 2009. Available online: https://acervodigital.ufpr.br/handle/1884/20949?show=full (accessed on 10 May 2024).

- NBR 13278:2005; Argamassa para Assentamento e Revestimento de Paredes e Tetos. Determinação da Densidade de Massa e do teor de ar Incorporado. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2005.

- NBR 15558:2005; Concreto—Determinação da Exsudação. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2008.

- NBR 13279:2005; Argamassa para assentamento e Revestimento de Paredes e Tetos—Determinação da Resistência na Tração e à Flexão. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2005.

- NBR 15261:2005; Argamassa para Assentamento e Revestimento de Paredes e Tetos-Determinação da Variação Dimensional (Retração ou Expansão Linear). Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2005.

- WBCSD; International Energy Agency. Technology Roadmap for Cement International Energy Agency. 2018. Available online: https://www.wbcsd.org/ (accessed on 10 May 2024).

- NBR 16697:2048; Cimento Portland—Requisitos. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2018.

- Tavares, S.F.; Bragança, L. Índices de CO2 para Materiais de Construção em Edificações Brasileiras. SBE16 Brazil & Portugal. Anais...Sustainable Urban Communities towards a Nearly Zero Impact Built Environment. 2016. Available online: https://sbe16.civil.uminho.pt/app/wp-content/uploads/2016/09/SBE16-Brazil-Portugal-Vol_2-Pag_927.pdf (accessed on 5 May 2024).

- NORCHEM. Silica Fume Applications in Sustainability. 2017. Available online: https://www.norchem.com/ (accessed on 10 May 2024).

- Cancio Díaz, Y.; Sánchez Berriel, S.; Heierli, U.; Favier, A.R.; Sánchez Machado, I.R.; Scrivener, K.L.; Martirena Hernández, J.F.; Habert, G. Limestone calcined clay cement as a low-carbon solution to meet expanding cement demand in emerging economies. Dev. Eng. 2017, 2, 82–91. [Google Scholar] [CrossRef]

- Ma, F.; Sha, A.; Yang, P.; Huang, Y. The Greenhouse Gas Emission from Portland Cement Concrete Pavement Construction in China. Int. J. Environ. Res. Public Health 2016, 13, 632. [Google Scholar] [CrossRef] [PubMed]

- BRASIL. Ministério da Ciência, Tecnologia, Inovações e Comunicações. Coordenação Geral do Clima. Estimativas Anuais de Emissões de Gases de Efeito Estufa no Brasil, Ministério da Ciência e Tecnologia, Inovação e Comunicação. 2022. Available online: https://repositorio.mcti.gov.br/handle/mctic/4966 (accessed on 10 May 2024).

- Zhang, C.; Wang, A.; Tang, M.; Liu, X. The filling role of pozzolanic material. Cem. Concr. Res. 1996, 26, 943–947. [Google Scholar] [CrossRef]

- Mehdipour, I.; Razzaghi, M.S.; Amini, K.; Shekarchi, M. Effect of mineral admixtures on fluidity and stability of self-consolidating mortar subjected to prolonged mixing time. Constr. Build. Mater. 2013, 40, 1029–1037. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M. Properties of self-compacting mortars with binary and ternary cementitious blends of fly ash and metakaolin. Mater. Struct. 2008, 41, 1519–1531. [Google Scholar] [CrossRef]

- Mendes, G.A.; Effting, C.; Schackow, A. Argamassa autonivelante com adição de resíduos de mármores e granitos: Propriedades físicas e mecânicas. Ambiente Construído 2020, 20, 403–418. Available online: https://www.scielo.br/j/ac/a/DdS7rbwBsGdnq3kFKBQ6FDj/ (accessed on 10 May 2024). [CrossRef]

- Hamoy, L.B. Contrapiso Autonivelante: Uma Proposta de Sistema Construtivo Racionalizado para Edificações. Dissertação (Mestrado). Universidade Federal do Pará. Belém. 2017. Available online: https://ppgau.propesp.ufpa.br/ARQUIVOS/dissertacoes/2017/Disserta%C3%A7%C3%A3o%20Luciana%20Biscaro%20Hamoy.pdf (accessed on 10 May 2024).

- Rubin, A.P. Argamassas Autonivelantes Industrializadas para Contrapiso: Análise do Desempenho Físico-Mecânico Frente às Argamassas Dosadas em obra. Dissertação (Mestrado em Engenharia). Universidade Federal do Rio Grande do Sul. Porto Alegre. 2015. Available online: https://lume.ufrgs.br/handle/10183/127871 (accessed on 10 May 2024).

- Kwan, A.K.H.; Fung, W.W.S. Roles of water film thickness and SP dosage in rheology and cohesiveness of mortar. Cem. Concr. Compos. 2012, 34, 121–130. [Google Scholar] [CrossRef]

- Adjoudj, M.; Ezziane, K.; Kadri, E.H.; Ngo, T.-T.; Kaci, A. Evaluation of rheological parameters of mortar containing various amounts of mineral addition with polycarboxylate superplasticizer. Constr. Build. Mater. 2014, 70, 549–559. [Google Scholar] [CrossRef]

- Ghoddousi, P.; Shirzadi Javid, A.A.; Sobhani, J. Effects of particle packing density on the stability and rheology of self-consolidating concrete containing mineral admixtures. Constr. Build. Mater. 2014, 53, 102–109. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; NG, P.L.; Huen, K.Y. Effects of fines content on packing density of fine aggregate in concrete. Constr. Build. Mater. 2014, 61, 270–277. [Google Scholar] [CrossRef]

- Freitas, E.R.F.; De Borja, E.V.; Dos Anjos, M.A.S.; Pereira, A.D.C.; Viana, J.S. Estudo das Adições e Aditivos Minerais nas Propriedades de Argamassas Autonivelantes. Congresso Norte Nordeste de Pesquisa e Inovação. Anais...Maceió. 2010. Available online: http://congressos.ifal.edu.br/index.php/connepi/CONNEPI2010/paper/view/1774/1030 (accessed on 10 May 2024).

- da Silva, S.H.L. Desenvolvimento de Formulações de Argamassas Autonivelantes para Pisos e Avaliação da Retração por Secagem. Dissertação (Mestrado em Engenharia). Universidade Federal do Paraná. Curitiba. 2016. Available online: https://acervodigital.ufpr.br/handle/1884/45809 (accessed on 10 May 2024).

- Yang, J.; Liu, L.; Liao, Q.; Wu, J.; Li, J.; Zhang, L. Effect of superabsorbent polymers on the drying and autogenous shrinkage properties of self-leveling mortar. Constr. Build. Mater. 2019, 201, 401–407. [Google Scholar] [CrossRef]

- Bauer, L.A.F. Materiais de Construção; LTC: Rio de Janeiro, Brazil, 2005; Volume 2. [Google Scholar]

- Possan, E.; Andrade, J.J.O.; Dal Molin, D.C.C. A conceptual framework for service life prediction of reinforced concrete structures. J. Build. Pathol. Rehabil. 2018, 3, 2. [Google Scholar] [CrossRef]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

| Samples | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | SrO | Others | Specific Mass (g/cm3) | BET Specific Area (m2/kg) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | CPI | 1.50 | 4.90 | 2.10 | 75.5 | 10.0 | 4.40 | 0.40 | 0.50 | 0.20 | 0.31 | 3.17 | 3500 |

| C2 | CPII E | 1.61 | 5.45 | 4.37 | 71.56 | 10.23 | 4.45 | 0.39 | 0.58 | 0.29 | 0.92 | 3.07 | 3000 |

| C4 | CPIV | 27.2 | 14.60 | 3.2 | 46.30 | 2.80 | 4.00 | 0.05 | 0.17 | 0.04 | 1.22 | 2.95 | 8400 |

| C5 | CPV | 1.50 | 4.24 | 4.64 | 68.79 | 10.77 | 6.95 | 0.97 | 1.34 | 0.51 | 0.23 | 3.06 | 5000 |

| SF | Silica fume | 95.75 | 1.01 | 0.06 | 0.73 | - | 1.73 | - | - | 0.73 | 0.93 | 2.26 | 22,000 |

| MK | Metakaolin | 52.54 | 34.0 | 2.10 | 0.36 | 2.42 | 0.38 | 0.41 | - | 3.38 | 10.56 | 2.56 | 19,100 |

| Silica Fume | |||||

|---|---|---|---|---|---|

| Mixtures | Cement | Sand | Water | SP | SF/MK |

| C1.SF15 | 582.50 | 1165.01 | 291.25 | 2.16 | 87.38 |

| C2.SF15 | 579.09 | 1158.18 | 289.54 | 1.97 | 86.86 |

| C4.SF05 | 589.84 | 1179.69 | 294.92 | 7.37 | 29.49 |

| C5.SF10 | 586.27 | 1172.54 | 293.13 | 2.93 | 58.63 |

| Metakaolin | |||||

| C1.MK25 | 571.91 | 1143.82 | 285.95 | 2.12 | 142.98 |

| C2.MK25 | 568.30 | 1136.61 | 284.15 | 1.93 | 142.08 |

| C4.MK05 | 590.87 | 1181.73 | 295.43 | 7.39 | 29.54 |

| C5.MK10 | 588.11 | 1176.23 | 294.06 | 2.94 | 58.81 |

| Addition | Cement Type | Exp. Adjustment | Cement | Sand | w/c | Additive (%) | Addition (%) | Edges (U/D) | Segregation (CS/SS) |

|---|---|---|---|---|---|---|---|---|---|

| SF | C1 | 1 | 1 | 2 | 0.5 | 0.40 | 5 | U | CS |

| 2 | 1 | 2 | 0.5 | 0.40 | 10 | U | CS | ||

| 3 | 1 | 2 | 0.5 | 0.40 | 15 | U | SS | ||

| C2 | 1 | 1 | 2 | 0.5 | 0.35 | 5 | D | CS | |

| 2 | 1 | 2 | 0.5 | 0.35 | 10 | U | CS | ||

| 3 | 1 | 2 | 0.5 | 0.35 | 15 | U | SS | ||

| C4 | 1 | 1 | 2 | 0.5 | 1.25 | 5 | U | SS | |

| C5 | 1 | 1 | 2 | 0.5 | 0.50 | 5 | U | CS | |

| 2 | 1 | 2 | 0.5 | 0.50 | 10 | U | SS | ||

| MK | C1 | 1 | 1 | 2 | 0.5 | 0.40 | 5 | U | CS |

| 2 | 1 | 2 | 0.5 | 0.40 | 10 | U | CS | ||

| 3 | 1 | 2 | 0.5 | 0.40 | 15 | U | CS | ||

| 4 | 1 | 2 | 0.5 | 0.40 | 20 | U | CS | ||

| 5 | 1 | 2 | 0.5 | 0.40 | 25 | U | SS | ||

| C2 | 1 | 1 | 2 | 0.5 | 0.35 | 5 | D | CS | |

| 2 | 1 | 2 | 0.5 | 0.35 | 10 | D | CS | ||

| 3 | 1 | 2 | 0.5 | 0.35 | 15 | U | CS | ||

| 4 | 1 | 2 | 0.5 | 0.35 | 20 | U | CS | ||

| 5 | 1 | 2 | 0.5 | 0.35 | 25 | U | SS | ||

| C4 | 1 | 1 | 2 | 0.5 | 1.25 | 5 | U | SS | |

| C5 | 1 | 1 | 2 | 0.5 | 0.50 | 5 | U | CS | |

| 2 | 1 | 2 | 0.5 | 0.50 | 10 | U | SS |

| Variables | Data (kgCO2/kg) | Reference | |

|---|---|---|---|

| Eclinker | 0.834 | WBCSD [38] | |

| % clinker | CP I 1 | 90–95% | NBR 16697 [39] |

| CP II 1,2 | 46–89% | ||

| CP IV 1,2 | 40–80% | ||

| CP V 1,3 | 85–95% | ||

| Esand | 0.03 | Taveres and Bragança [40] | |

| ESF | 0.014 | Norchem [41] | |

| EMK | 0.279 | Díaz et al. [42] | |

| Ead | 1.065 | Ma et al. [43] | |

| Eenergy | 0.108 kWh/kg | WBCSD [38] | |

| FEenergy | 0.08 kgCO2/kwh | MCTI [44] | |

| Mixtures | Curing Time (Min) |

|---|---|

| C1.SF15 | 15 |

| C2.SF15 | 15 |

| C4.SF05 | 10 |

| C5.SF10 | 10 |

| C1.MK25 | 20 |

| C2.MK25 | 15 |

| C4.MK05 | 15 |

| C5.MK10 | 10 |

| Mixtures | Readings (mm) | Standard Deviation | Variation Coefficient | |||

|---|---|---|---|---|---|---|

| ε0 | ε1 | ε7 | ε28 | |||

| C1.SA15 | 0.00 | −0.22 | −0.48 | −0.67 | 0.23 | 0 |

| C2.SA15 | 0.00 | 0.31 | −0.12 | −0.61 | 0.46 | 3 |

| C4.SA05 | 0.00 | −0.09 | −0.5 | −0.85 | 0.38 | 1 |

| C5.SA10 | 0.00 | −0.64 | −0.97 | −1.64 | 0.51 | 0 |

| C1.MC25 | 0.00 | −0.26 | −0.73 | −0.73 | 0.27 | 0 |

| C2.MC25 | 0.00 | −0.03 | −0.68 | −0.76 | 0.40 | 1 |

| C4.MC05 | 0.00 | −0.15 | −0.82 | −0.95 | 0.43 | 1 |

| C5.MC10 | 0.00 | −0.32 | −1.28 | −2.19 | 0.93 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, B.M.O.; Teixeira, M.d.C.; Bernardo, K.S.M.; Cordeiro, L.d.N.P.; Possan, E. Self-Leveling Mortars Produced with Different Types of Cement: Physical–Mechanical Properties and Carbon Emissions. Sustainability 2024, 16, 5898. https://doi.org/10.3390/su16145898

Alves BMO, Teixeira MdC, Bernardo KSM, Cordeiro LdNP, Possan E. Self-Leveling Mortars Produced with Different Types of Cement: Physical–Mechanical Properties and Carbon Emissions. Sustainability. 2024; 16(14):5898. https://doi.org/10.3390/su16145898

Chicago/Turabian StyleAlves, Brenda Maiara Oliveira, Misley da Cruz Teixeira, Karen Suely Martins Bernardo, Luciana de Nazaré Pinheiro Cordeiro, and Edna Possan. 2024. "Self-Leveling Mortars Produced with Different Types of Cement: Physical–Mechanical Properties and Carbon Emissions" Sustainability 16, no. 14: 5898. https://doi.org/10.3390/su16145898

APA StyleAlves, B. M. O., Teixeira, M. d. C., Bernardo, K. S. M., Cordeiro, L. d. N. P., & Possan, E. (2024). Self-Leveling Mortars Produced with Different Types of Cement: Physical–Mechanical Properties and Carbon Emissions. Sustainability, 16(14), 5898. https://doi.org/10.3390/su16145898