Abstract

In the paper, the role of ergonomics in promoting social sustainability within the workplace has been investigated and supported by evidence from the literature. Empirical research was conducted among 147 assembly line workers to gain insights into work-related discomfort and fatigue. This study used an ergonomic risk assessment (ERA) method to evaluate the ergonomic quality of workstations and correlated these findings with employees’ subjective experiences. The results showed a relationship between objective ergonomic assessments and subjective perceptions of work itself and company organizational factors, which were orally stated to the assessors, emphasizing the critical role of ergonomics in advancing social sustainability goals. The proposed DMAIC model was implemented to integrate ergonomic innovations into business processes to achieve social sustainability goals. Further research is needed to operationalize ergonomics in sustainability efforts.

1. Introduction

Companies are increasingly pointing to additional objectives for their business, i.e., not just profit orientation but also a range of benefits for their employees, such as social sustainability. Many researchers look for correlations in these issues to describe both sides of the equation, where one side is the benefit to the employer and the other is the value received by the employee. Ergonomics, the science of adapting the work environment to the worker, can play a significant role in this, along with the ergonomic axiom that the best adaptation is when the human–technical object system is provided with the optimum level of efficiency over a long period, ensuring the worker’s ability to do the job and finding satisfaction with it [1]. When considering aggregates that can simultaneously improve work efficiency and workload, the concept of social sustainability becomes intertwined with other aspects of sustainability and business objectives. Tietz, Abdelgawad, and Pasquini [2] delve into social innovation and investigate the intersection of commercial success and social progress. Missimer and Mesquita [3] propose a research agenda for systemic change toward social sustainability in business. Palakshappa, Dodds, and Grant [4] explore the ethical paradoxes within women-focused sustainable organizations, exploring the tensions between business strategies and personal values. Carmer [5] provides insights into corporate strategy that balance profitability with environmental responsibility. Finally, Harsanto and colleagues [6] systematically review innovation in social enterprises, highlighting sustainable impacts on society and the environment. Thus, many authors advance the understanding of how businesses can integrate social sustainability into their core operations, providing valuable models and strategies for future research and practice. This article aims to investigate how sustainability in the area of employee social responsibility, as declared and researched by best practice in a manufacturing company, is perceived by manufacturing employees and independent observers. Thus, the research problem is to determine the extent to which the practice of sustainable employee development is perceived as socially sustainable.

2. Social Sustainability and Ergonomic Sustainability within Companies

Social sustainability within a production company refers to considering and implementing social aspects, such as equity, health, and empowerment, alongside economic and environmental factors. It involves ensuring the well-being and safety of employees, promoting gender balance, and addressing social issues throughout the production planning and product development processes. However, the literature shows that social sustainability has received less attention than economic and environmental aspects [7]. Companies face barriers in implementing social sustainability, but some solutions have been identified, including strengthening communication transparency, promoting awareness, and using technology to document and promote social sustainability. Protecting worker well-being is crucial for social sustainability, and methods such as IoT systems and questionnaires can be used to assess various factors related to worker well-being [8]. Implementing corporate social responsibility programs can also contribute to social sustainability and help companies achieve sustainability and legitimacy within their communities [9].

The search for appropriate workloads and balanced working conditions has been the focus of work organization researchers for some time, particularly those associated with ergonomics. The combinations of research in this area are varied in terms of the titles of the abstracts and the direction of the study of relationships. Many authors present frameworks for evaluating employee well-being and performance within the context of social sustainability, incorporating factors such as autonomous motivation, job engagement, job satisfaction, perceived organizational support, leadership styles (green transformational and transactional), attitudes toward the environment, and environmental commitment [10]. Gajsek, along with her respected colleagues [11], promotes the adoption of ergonomic methods (OWAS and REBA) to enhance social sustainability and advocates for linking assessment results with improvement proposals and indicators to measure social sustainability outcomes. Many authors point to a rather obvious correlation, namely that sustainable, ergonomic programs contribute to corporate social responsibility [12]. In practical terms, however, such a formulation is only declarative because while it is even pointed out that it is necessary to juxtapose the workload needs of an employee by specific activities with the productivity of these activities and the technologies linking them, the authors do not focus on the possible operationalization of these factors. For many studies that declaratively indicate a relationship between ergonomics, ergonomic design of working conditions, and sustainability, only the easily measurable factors relating to ergonomic working conditions are investigated. In contrast, sustainability factors are considered to belong, also, with indicators developed for measuring sustainability and ergonomics, such as the Sustainable Work Index (SWI) [13]; the sustainable factor is only marketing in nature because it identifies the following factors known from an ergonomics point of view: Human Work Factor, Workstation Design Factor, Organizational Environment Factor, and Environmental Conditions Factor [13]. In the Table 1, social sustainability factors were discussed and their respective links in relation to ergonomic considerations.

Table 1.

Ergonomic context in social sustainability.

Collectively, these studies illustrate the critical contributions of ergonomics to fostering sustainable practices in various industrial and organizational contexts, highlighting its potential to enhance the quality of life, drive innovation, and influence strategic decision-making towards sustainable growth. However, it must be said that besides the juxtaposition of ergonomics with its sustainability categories, there is no model for effectively integrating ergonomic innovations into business processes. In this article, the authors attempt to develop such a model synthetically based on case studies and interviews conducted in companies using management by ergonomics.

3. Material and Method

This research was conducted on a group of assembly line workers in a manufacturing company. This study covered 147 employees. The workstations were subjected to observation, an activity chronometer was carried out for the observed activities, and then they were valued using the ERA method (ergonomic risk assessment) [38]. As this paper aims to compare the ergonomic quality of work with the feelings and opinions of employees as a possible path to social sustainability, employees were interviewed face-to-face, and a questionnaire was carried out about their work-related discomforts and annoyances. The questions posed to the workers came from a fatigue analysis method called the ‘Japanese sheet’, which was supplemented with questions on feelings related to WRMSDs symptoms [39,40]. Workers were asked about the following: (1) general level of fatigue after a work shift, (2) confusion in the head after work, (3) eye fatigue after work, (4) whole body heaviness after work, (5) heaviness of the legs after work, and (6) nervousness level after a typical day of work. Particularly troublesome aspects of work were also asked about without providing a list to choose from. Workers often indicated problems with the work atmosphere and the pay system. They also responded to whether they saw opportunities to improve working conditions and what they thought should be done in this regard. The results were then processed and analyzed. The ERA method is based on the standard EN 1005–4:2005 Safety of machinery—Human physical performance—Part 4 [41]. The technique allows for a point assessment of the position of the torso, head/neck, left shoulder, right shoulder, left elbow, right elbow, left wrist, and right wrist. In these categories, it is also possible to consider the force necessary to perform the movement, the repeatability of activities, and the static load of muscles. The assessment of individual body segments is supplemented by considering the occurrence of vibrations in the work process, the load resulting from contact with hard and sharp edges (e.g., machines), and the load resulting from the impact phenomenon. The total number of points obtained in individual assessment categories allows us to determine the risk associated with performing work at the following levels: negligible, small, medium, large, and very large. Further workplace analysis and implementation of corrective actions are necessary in the case of medium, high, and very high risk. Features of the research subjects are presented in Table 2.

Table 2.

Features of the research subjects.

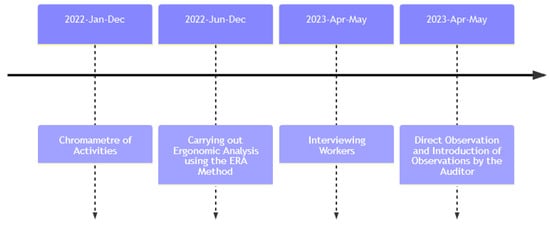

Due to the spread of research over time (time-consuming analysis) Figure 1 shows the steps in the test procedure with the timing of each research activity.

Figure 1.

The research process.

The methods chosen, combining both an objective, ergonomic risk approach in the form of the ERA method and subjective methods and a personal interview, were intended to extend this study beyond purely ergonomic factors to the combined organizational and mm-related aspects of quality of work, which are directly part of social responsibility. The use of the ERA method is due to its more screening nature, where all aspects of functional mobility can be assessed, while at the same time, the assessment can be related to the total load on the whole body, like QEC or REBA [42]. Individual response dimensions relating to body parts typically affected in assembly work, such as the back, neck, shoulders, elbows, and wrists, make it possible to relate this to how workers feel and to organizational aspects directly in the workplace. The ERA method also combines the assessment or resultant strain on individual body parts with the repetition of tasks per unit of time (a reference period of 3 min is assumed). Employees’ responses regarding areas for change were directly translated into aspects of social and corporate social responsibility. This approach is also justified by the fact that employees are not encouraged to invent needs in individual CSR categories but to point out aspects from an ergonomic perspective that can later be directly translated into social sustainability factors. In this way, a system is implemented in which social sustainability is driven by ergonomics.

4. Results

Table 3 shows descriptive statistics for surveys and compared data for the investigated workstations.

Table 3.

Descriptive statistics of the carried-out surveys and compared data.

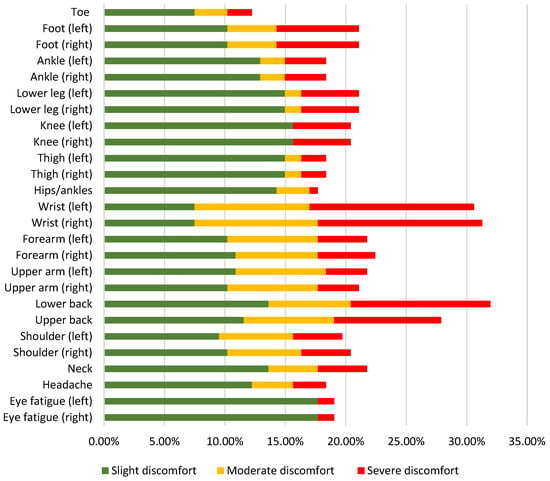

Figure 2 is a quantitative summary of the levels of discomfort felt in the areas of the individual body parts that employees value, divided into three levels: near discomfort, medium discomfort, and severe discomfort. To balance the evaluation of discomfort in particular body parts, the participants were asked how they felt under a typical working shift. In the chart presented, men and women were not separated.

Figure 2.

Levels of discomfort perceived for different parts of the body.

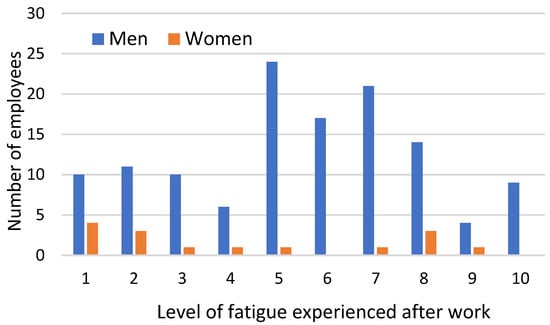

In contrast, in the next question, a question was asked about the level of fatigue after a typical working day; men and women are presented separately in the graph. Due to the smaller number of women working on the two surveyed assembly lines, the comparison of values can only be illustrative (Figure 3).

Figure 3.

Number of responses for the scale of perceived fatigue after work experienced by men and women, respectively.

All data related to the study area were compiled and subjected to statistical analysis. Given the qualitative nature of the collected data, including fatigue levels and employee ratings, an analysis was conducted using Spearman’s rank correlation coefficient (Spearman’s rho) to examine the relationships between these variables and other data valuing workplaces and employees. The results of this analysis are presented in the Table 4.

Table 4.

Summary of correlations between study variables.

Apart from the correlation with height, no statistical difference was found between men and women; therefore, this variable was not indicated in the results presented in Table 3. The results of the correlations are discussed in the next section of this article, without a detailed analysis of known relationships between similar measures, such as leg heaviness and general fatigue.

5. Discussion

Interestingly, the relatively objective ERA method’s category did not align with the employees’ responses regarding fatigue assessment, including eye fatigue, nervousness, and the heaviness of legs perception. A very slight but statistically significant correlation was found between the automatically recognized category resulting from the employees’ responses on individual work environment factors. This recognition was made using GPT Chat 4.0. This was conducted in the way that employees’ responses were given about their feelings about work as well as suggestions for improvement. The responses were categorized into five groups, with Group One indicating no comments and Group Five indicating significant comments on the work environment. Interestingly, the correlation between the twelfth category and the first category occurring in a slight coincidence was not reflected by its own in the overall fatigue rating expressed with a value from one to ten. This may indicate the different factors considered in the ergonomic risk assessments by the ERA method and the physical fatigue workers feel after work. It does, however, allow the very methodological conclusion that employees’ qualitative evaluations, expressed in loose terms—with their own words—can be used to assess work and be used with AI elaboration. On the other hand, it points to the need for research into the relationship between the economic burden measured by ergonomic risk methods and the subjective feelings of employees. It is assumed that, according to the principle of triangulation, employee evaluations complement and coincide with ergonomic risk—such provisions are found, for example, in ISO 16710-2 [43].

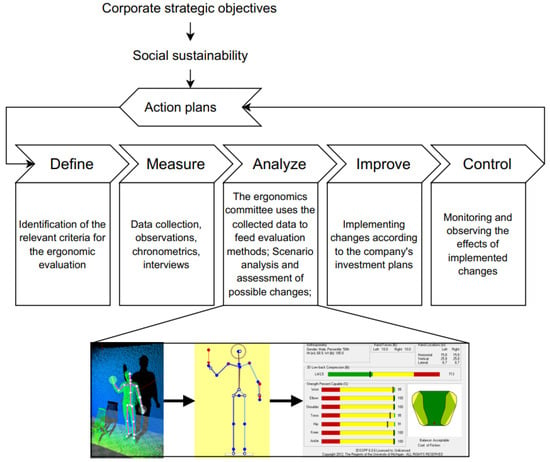

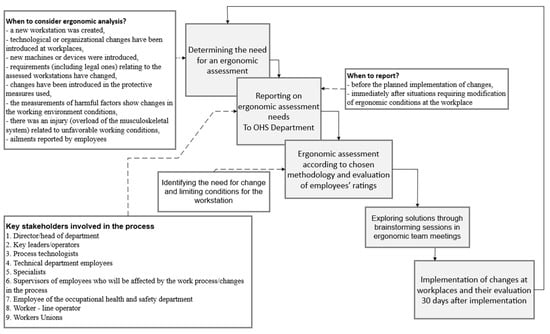

Based on the case study presented, the ergonomic improvement of work quality can consider the objectives of social sustainability in the DMAIC formula, widely used by today’s increasingly agile industry [44], as shown in Figure 4. From an ergonomic point of view, the criteria analyzed can be objective values such as workload, energy expenditure, and measured values of biomechanical loads, which can be reacted to ergonomic risks. At the same time, however, the ergonomic criteria can be supplemented by the workers’ subjective feelings regarding health, well-being, or job satisfaction. It is also possible to include qualitative and quantitative work results in the ergonomic criteria, i.e., the number of defects and losses of a qualitative and quantitative nature. These criteria are subject to measurement and supported by ergonomic analyses. Therefore, the “Analyse” phase allows the proposed changes to be evaluated before implementation. This is a precious feature of the autonomous approach in the DMAIC sense because, as shown, for example, in Figure 4, different types of simulations can be performed. In addition, the simultaneous implementation of ergonomic measures, together with the implementation of other changes, allows for greater acceptance from workers. In this respect, the use of the experience of the operators is essential, as they should be involved in the decision-making process according to the principle of the Hawthorne effect. It should, therefore, be noted that ergonomic interventions, together with an appropriate system for their implementation, provide an opportunity for a multidimensional improvement of the employee’s working environment and impact on social sustainability.

Figure 4.

A process for the ergonomic improvement of the quality of work, taking into account the objectives of social sustainability, using the DMAIC formula.

The application of the DMAIC formula in the presented study covers the Define, Measure, and partial Analyze phases (with some ideas for Improve and Control parts mentioned in the discussion). This scope was intentional for the initial phase of our research due to the limited research group (147 respondents). Future research will extend into the in-depth Analyze, Improve, and Control stages, with a plan to implement and assess specific ergonomic interventions based on current findings. This progression will thoroughly evaluate the DMAIC framework’s value and effectiveness in developing sustainable management strategies within the company. The practical application of the DMAIC model to a process within a company also requires the identification of the individual stakeholders and the responsible units performing the tasks arising from the process. An essential element in this respect is also the determination of the time frame so that the implementation of the evaluation is within an acceptable time frame for the enterprise. Depending on the enterprise, the time from the activities to the completion of the implementation of the job evaluation varies from 30 to 90 days. The conclusions from the analysis of how workers feel about their work processes are incorporated into steps 1 and 2, where the need for ergonomic analysis and its documentation and justification are determined. This can be a screening procedure as part of the first step of deciding to organize workplaces, which can be conducted by stakeholders in the work improvement process. For most enterprises, the solution-finding step is also a challenge, as it requires an appropriate broad view and experience in improving workplaces. Rarely do companies choose to use more advanced design heuristics, but modeling with traditional and more modern means is a common practice in this step. Such an activity could be, for example, simulating how work is performed in a specially arranged production-like space (Figure 5).

Figure 5.

The process of the implementation of an ergonomic innovation.

As far as examples of improvements are concerned, every company in the automotive industry is constantly improving its workplaces by adjusting the heights of work areas and the places where materials are stored, but also by implementing the idea of automating certain areas, eliminating manual operations wherever possible and profitable. The use of manipulators is very often a company’s strategy. Still, it also has a downside because, in some cases, it means an increase in the duration of the activity, which is unsatisfactory both from a production point of view and a worker’s point of view. Here, of course, we can also mention the program for the re-evaluation of jobs since all the changes implemented should be monitored in terms of their maintenance but also in terms of the level of improvement in the economic quality of work in the position. It is assumed that after an implementation such as the one mentioned above, an evaluation is carried out after 30 days, and it is checked to what extent the implemented changes have contributed to improvements in the workplace. At this point, companies evaluate the implementation and visualize it by producing internal information material with a description of the before and after situation, thus promoting their social sustainability activities for employees.

6. Conclusions

This paper analyzes social and ergonomic interventions for sustainability within a manufacturing company, focusing on the ergonomic quality of employees’ work and considering the company’s broader sustainability and productivity goals. The key conclusion drawn from the literature is the importance of integrating social sustainability, which emphasizes equity, health, and empowerment of employees, with ergonomics. This integration involves the design of work environments and tasks that aim to minimize physical strain and promote the health and safety of employees, as well as using an ergonomics approach to solve problems within the company.

This research also aimed to gain an understanding of how sustainability practices, particularly those related to employee social responsibility, are perceived by manufacturing employees and independent observers. This reflects an interest in bridging the gap between theoretical social sustainability goals and their practical implementation and impact on the quality of work. This study recognizes companies’ challenges in implementing social sustainability and outlines several solutions to overcome these barriers. These solutions include improving communication and transparency, leveraging technology, and implementing corporate social responsibility programs. Observing a convergence between the employees’ statements and the ERA assessment is possible. Still, in many cases, it is felt that the employees are discouraged by the solutions implemented, even though they are considered ergonomic by the employer. Presumably, the employees do not fully understand the changes made to the workstations, or they are convinced that the changes are aimed at production goals rather than sustainability and ergonomics.

It is worth noting that implementing ergonomic interventions based on the DMAIC approach can enhance employers’ perception of social sustainability. By making data-driven ergonomic adjustments, workplaces can improve dynamics and social responsibility. However, it is essential to take a more comprehensive view of ergonomics, which includes employee perceptions and discomfort assessments. This approach recognizes that workplace ergonomics is subjective and requires a nuanced response to individual needs. However, there are significant challenges in obtaining comprehensive ergonomic evaluations, and many companies fail to collect detailed data on ergonomic impacts. This lack of thorough data collection highlights the need for more rigorous scientific analysis and widespread adoption of advanced ergonomic assessment tools to fully understand and maximize the benefits of ergonomic interventions for enhancing social sustainability. There is a need for further research to operationalize the correlation between ergonomics and social sustainability effectively. It also highlights the need to integrate ergonomic innovations into business processes and proposes developing models. Based on workers’ responses, the authors suggest more effective communication and engagement strategies to ensure that sustainability practices are well-perceived and genuinely beneficial to employees. Additionally, it calls for further research to explore the practical integration of ergonomic principles into sustainability initiatives to create work environments that are healthful, productive, and aligned with broader sustainability goals.

Author Contributions

Conceptualization, M.B.; methodology, M.B. and W.C.; validation, M.B.; formal analysis, W.C.; writing—original draft preparation, M.B. and W.C.; writing—review and editing, M.B. and W.C.; visualization, M.B. All authors have read and agreed to the published version of the manuscript.

Funding

Poznan University of Technology, Faculty of Engineering Management, project 811/SBAD/1071.

Institutional Review Board Statement

Ethical review and approval was not required for this study because the nature of the survey was related to the evaluation of the organization and not to personal characteristics, and there were no risks for the respondent in completing the questionnaire, which was communicated to the study participants. The participants did not comment on the method and tools of the survey, as they were asked to in the introduction. Given the characteristics of the research described above and the provisions of the Regulations governing the work of the Commission on Ethics of Scientific Research conducted with the participation of persons at Poznan University of Technology, this research was not subject to an opinion, also because this research began before the Commission was appointed by Rector’s Order RO/IV/15/2022.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gajšek, B.; Šinko, S.; Kramberger, T.; Butlewski, M.; Özceylan, E.; Đukić, G. Towards productive and ergonomic order picking: Multi-objective modeling approach. Appl. Sci. 2021, 11, 4179. [Google Scholar] [CrossRef]

- Tietz, M.A.; Abdelgawad, S.G.S.; Pasquini, M. Social innovation: Combining profits and progress. In Social Innovation and Sustainable Entrepreneurship; Edward Elgar Publishing: Cheltenham, UK, 2018. [Google Scholar] [CrossRef]

- Missimer, M.; Mesquita, P.L. Social Sustainability in Business Organizations: A Research Agenda. Sustainability 2022, 14, 2608. [Google Scholar] [CrossRef]

- Palakshappa, N.; Dodds, S.; Grant, S. Tension and Paradox in Women-Oriented Sustainable Hybrid Organizations: A Duality of Ethics. J. Bus. Ethic 2023, 190, 327–346. [Google Scholar] [CrossRef]

- Carmer, S.I. Corporate Environmental Strategies for Balancing Profitability with Environmental Stewardship. Ph.D. Thesis, Walden University, Minneapolis, MN, USA, 2019. [Google Scholar]

- Harsanto, B.; Mulyana, A.; Faisal, Y.A.; Shandy, V.M.; Alam, M. A Systematic Review on Sustainability-Oriented Innovation in the Social Enterprises. Sustainability 2022, 14, 14771. [Google Scholar] [CrossRef]

- Trost, M.; Claus, T.; Herrmann, F. Social Sustainability in Production Planning: A Systematic Literature Review. Sustainability 2022, 14, 8198. [Google Scholar] [CrossRef]

- Papetti, A.; Pandolfi, M.; Peruzzini, M.; Germani, M. A framework to promote social sustainability in industry 4.0. Int. J. Agil. Syst. Manag. 2020, 13, 233–257. [Google Scholar] [CrossRef]

- Rochayatun, S.; Kholifah, F. Corporate social responsibility: Grasping legitimacy, reaching sustainability. In Proceedings of the International Conference on Applied Science and Technology on Social Science, Querétaro, Mexico, 2–3 June 2021; pp. 175–183. [Google Scholar] [CrossRef]

- Prieto, L.; Amin, M.R.; Canatay, A. Examining Social Sustainability in Organizations. Sustainability 2022, 14, 12111. [Google Scholar] [CrossRef]

- Gajšek, B.; Draghici, A.; Boatca, M.E.; Gaureanu, A.; Robescu, D. Linking the Use of Ergonomics Methods to Workplace Social Sustainability: The Ovako Working Posture Assessment System and Rapid Entire Body Assessment Method. Sustainability 2022, 14, 4301. [Google Scholar] [CrossRef]

- Marková, P.; Beňo, R.; Hatiar, K. Sustainable Ergonomic Program—Basic Condition for Implementation of Corporate Social Responsibility. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2012, 20, 94–101. [Google Scholar] [CrossRef]

- Montoya-Reyes, M.; Gil-Samaniego-Ramos, M.; González-Angeles, A.; Mendoza-Muñoz, I.; Navarro-González, C.R. Novel Ergonomic Triad Model to Calculate a Sustainable Work Index for the Manufacturing Industry. Sustainability 2020, 12, 8316. [Google Scholar] [CrossRef]

- Sohrabi, M.S. Ergonomics Role in Sustainable Development: A Review Article for Updates the Recent Knowledge. In Congress of the International Ergonomics Association; Springer International Publishing: Cham, Switzerland, 2021; pp. 588–602. [Google Scholar] [CrossRef]

- Mokdad, M.; Mebarki, B.; Semmani, M.; Aljunaidi, S. Volunteering at the Foggara work in Touat region: A study in Social ergonomics. Soc. Occup. Ergon. 2022, 65, 102. [Google Scholar] [CrossRef]

- Chopra, S.; Clarke, R.; Crivellaro, C.; Clear, A.; Heitlinger, S.; Dilaver, O. Infrastructuring ecological sustainability through multi-scalar speculations. In Proceedings of the Participatory Design Conference 2022, Newcastle upon Tyne, UK, 19 August–1 September 2022; Volume 1, pp. 13–25. [Google Scholar]

- Dekker, S.W.; Hancock, P.A.; Wilkin, P. Ergonomics and sustainability: Towards an embrace of complexity and emergence. Ergonomics 2013, 56, 357–364. [Google Scholar] [CrossRef] [PubMed]

- Scott, P.A. The Role of Ergonomics in Securing Sustainability in Developing Countries. In Corporate Sustainability as a Challenge for Comprehensive Management; Physica-Verlag HD: Heidelberg, Germany, 2008. [Google Scholar] [CrossRef]

- Van Eerd, D.; Cole, D.C.; Steenstra, I.A. Participatory Ergonomics for Return to Work. In Handbook of Return to Work: From Research to Practice; Springer: Boston, MA, USA, 2016; pp. 289–305. [Google Scholar]

- Franus, E.A. Connective networks in ergonomics: General methodological considerations. Adv. Hum. Factors/Ergon. 1991, 16, 303. [Google Scholar]

- Thatcher, A. Green ergonomics: Definition and scope. Ergonomics 2013, 56, 389–398. [Google Scholar] [CrossRef]

- Messing, K.; Vézina, N. The “Woke” Ergonomist: How Can We, How Should We Improve Gender Equality as Well as Health? In Congress of the International Ergonomics Association; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- de Guimarães, B.M. Ergonomics and people with disabilities. Work-A J. Prev. Assess. Rehabil. 2015, 50, 529–530. [Google Scholar] [CrossRef]

- Butlewski, M. Well-Being Through Design for Dynamic Diversity: The Voice of Minorities in Design for All. In Advances in Social and Occupational Ergonomics: Proceedings of the AHFE 2019 International Conference on Social and Occupational Ergonomics, Washington DC, USA, 24–28 July 2019; Springer International Publishing: Cham, Switzerland, 2020; pp. 49–56. [Google Scholar]

- Rice, V.J.B. Evaluating and designing education: A collaborative effort between educators and ergonomists. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, San Antonio, TX, USA, 19–23 October 2009; SAGE Publications: Los Angeles, CA, USA, 2009; Volume 53, pp. 1017–1021. [Google Scholar]

- Butlewski, M.; Sławińska, M. Ergonomic method for the implementation of occupational safety systems. In Occupational Safety and Hygiene II-Selected Extended and Revised Contributions from the International Symposium Occupational Safety and Hygiene; SHO: Guimar, Portugal, 2014; pp. 621–626. [Google Scholar]

- Xie, A.; Woods-Hill, C.Z.; Berenholtz, S.M.; Milstone, A.M. Use of human factors and ergonomics to disseminate health care quality improvement programs. Qual. Manag. Healthc. 2019, 28, 117–118. [Google Scholar] [CrossRef] [PubMed]

- Wooldridge, A.R.; Grant, C.; Widdowson, A.; Rogers, C.C.; Figueroa Jacinto, R. Developing the human factors/ergonomics discipline to support diversity, equity and inclusion. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, Washington, DC, USA, 10–14 October 2022; SAGE Publications: Los Angeles, CA, USA, 2022; Volume 66, pp. 139–141. [Google Scholar]

- Ramdass, K. The implementation of ergonomics as a sustainable competitive advantage in the clothing industry. In Proceedings of the PICMET’13: Technology Management in the IT-Driven Services (PICMET), Online, 28 July–1 August 2013; pp. 1669–1679. [Google Scholar]

- Suokko, T.; Reiman, A. Ergonomics is profitable–Experiences from a holistic manufacturing plant level development process. In Congress of the International Ergonomics Association; Springer International Publishing: Cham, Switzerland, 2021; pp. 89–95. [Google Scholar]

- Rathore, B.; Biswas, B.; Gupta, R.; Biswas, I. A retrospective analysis of the evolution of ergonomics for environmental sustainability (2011–2021). Ergonomics 2023, 66, 730–748. [Google Scholar] [CrossRef] [PubMed]

- Rodea, A.; Mercado, L. Ergonomics, Environment and Sustainability. In Advances in Ergonomics In Design, Usability & Special Populations: Part III; 2022; p. 388. Available online: https://www.researchgate.net/publication/360557983_Ergonomics_Environment_and_Sustainability (accessed on 17 March 2024).

- Butlewski, M.; Dahlke, G.; Drzewiecka, M.; Pacholski, L. Fatigue of miners as a critical factor in the work safety system. Procedia Manuf. 2015, 3, 4732–4739. [Google Scholar] [CrossRef]

- Restuputri, D.P.; Huda, M.C.; Mubin, A. Work safety aspects using a participatory ergonomic approach. Spektrum Ind. 2021, 19, 15–28. [Google Scholar] [CrossRef]

- Lallemand, C. Contributions of participatory ergonomics to the improvement of safety culture in an industrial context. Work 2012, 41 (Suppl. S1), 3284–3290. [Google Scholar] [CrossRef]

- Cervai, S.; Polo, F. The impact of a participatory ergonomics intervention: The value of involvement. Theor. Issues Ergon. Sci. 2018, 19, 55–73. [Google Scholar] [CrossRef]

- Straker, L. Designing work for 21st Century bodies and lifestyles. In Proceedings of the 48th Annual Human Factors and Ergonomics Society of Australia Conference 2012, HFESA 2012, Canberra, Australia, 11–14 November 2012; pp. 1–5. [Google Scholar]

- Haller. Praxiserfahrungen mit Methoden zur Arbeitsplatzbewertung. 2014. Available online: https://www.e-c-n.de/tagungsartikel/2014_Haller/index.htm (accessed on 17 March 2024).

- Cohen, A.L.; Gjessing, C.C.; Fine, L.J.; Bernard, B.P.; McGlothin, J.D. Elements of Ergonomics Programs: A Primer Based on Workplace Evaluations of Musculoskeletal Disorders; U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health: Washington, DC, USA, 1997.

- Butlewski, M. Projektowanie Ergonomiczne Wobec Dynamiki Deficytów Zasobów Ludzkich [Eng: Ergonomic Design in the Face Of dynamic Human Resource Deficits]; Wydawnictwo Politechniki Poznańskiej: Poznań, Poland, 2018. [Google Scholar]

- EN 1005-4:2005+A1:2008; Safety of Machinery. Human Physical Performance—Evaluation of Working Postures and Movements in Relation to Machinery. Available online: https://standards.globalspec.com/std/1177469/en-1005-4 (accessed on 17 March 2024).

- Rawan, M.R.M.; Daril, M.A.M.; Subari, K.; Wahab, M.I.A. A Comparative Studies of Ten Ergonomics Risk Assessment Methods. In Advanced Transdisciplinary Engineering and Technology; Springer International Publishing: Cham, Switzerland, 2022; pp. 153–169. [Google Scholar]

- ISO 16710-2; Ergonomics Methods—Part 2: A Methodology for Work Analysis to Support Design. International Organization for Standardization: Cham, Switzerland, 2014.

- Mrugalska, B.; Ahmed, J. Organizational agility in industry 4.0: A systematic literature review. Sustainability 2021, 13, 8272. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).