Mapping the Sustainability of Waste-to-Energy Processes for Food Loss and Waste in Mexico—Part 1: Energy Feasibility Study

Abstract

:1. Introduction

2. Methodology

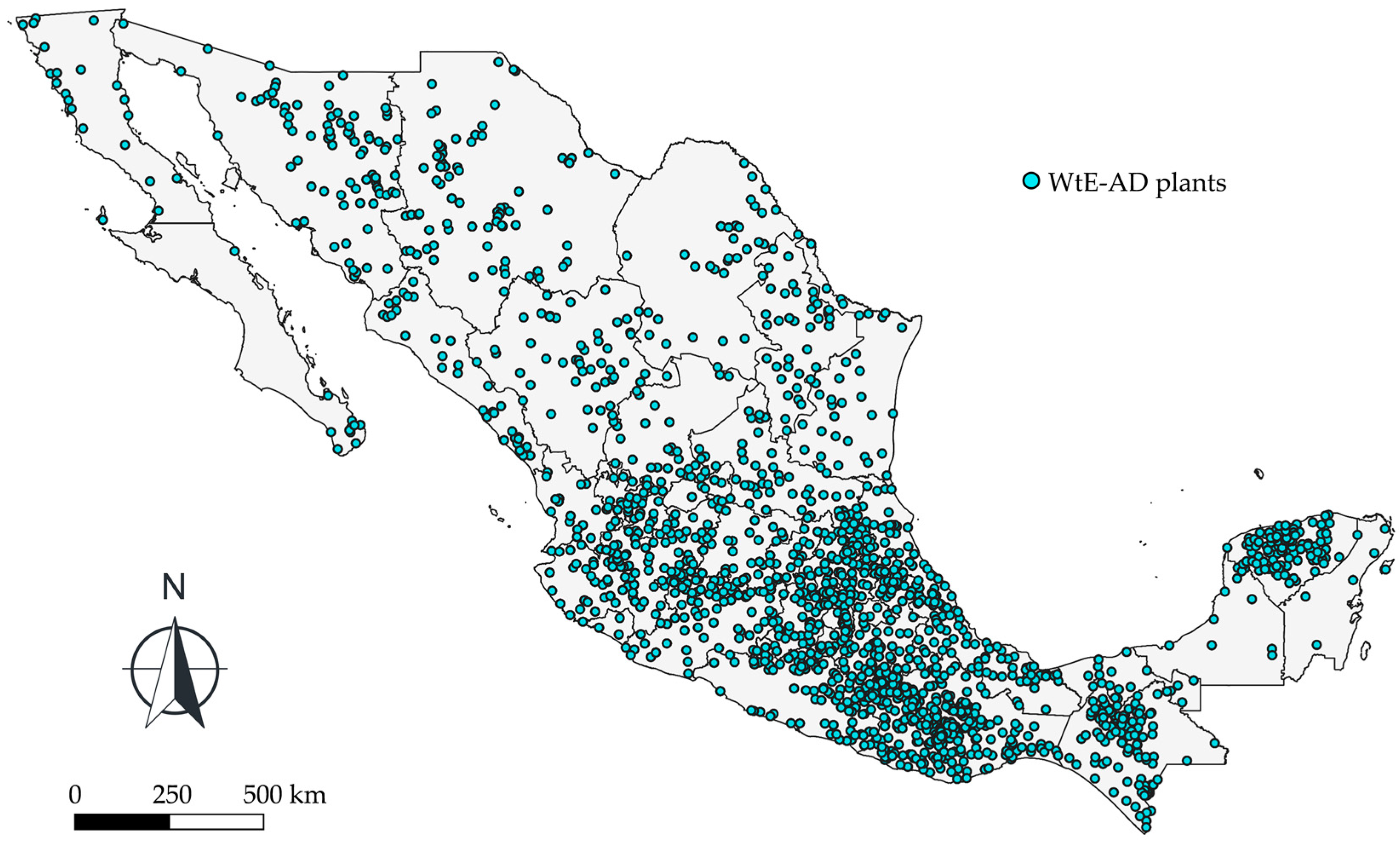

2.1. Geographic Localization of WtE-AD Plants and FLW Generation

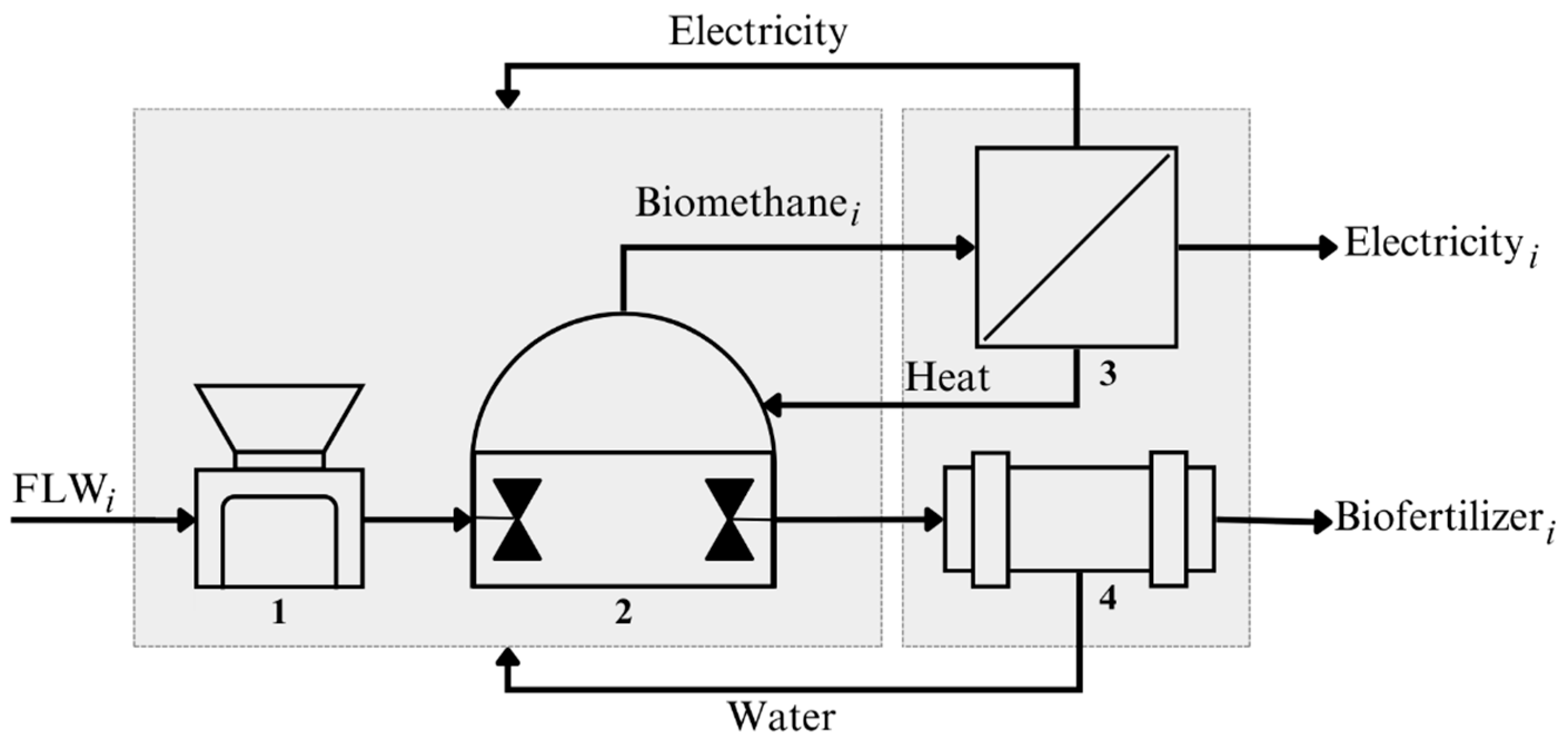

2.2. Energy Consumption Model for WtE-AD Plants

2.3. Methane Production and Energetic Feasibility Analysis

2.4. Sensitivity Analysis

3. Results and Discussion

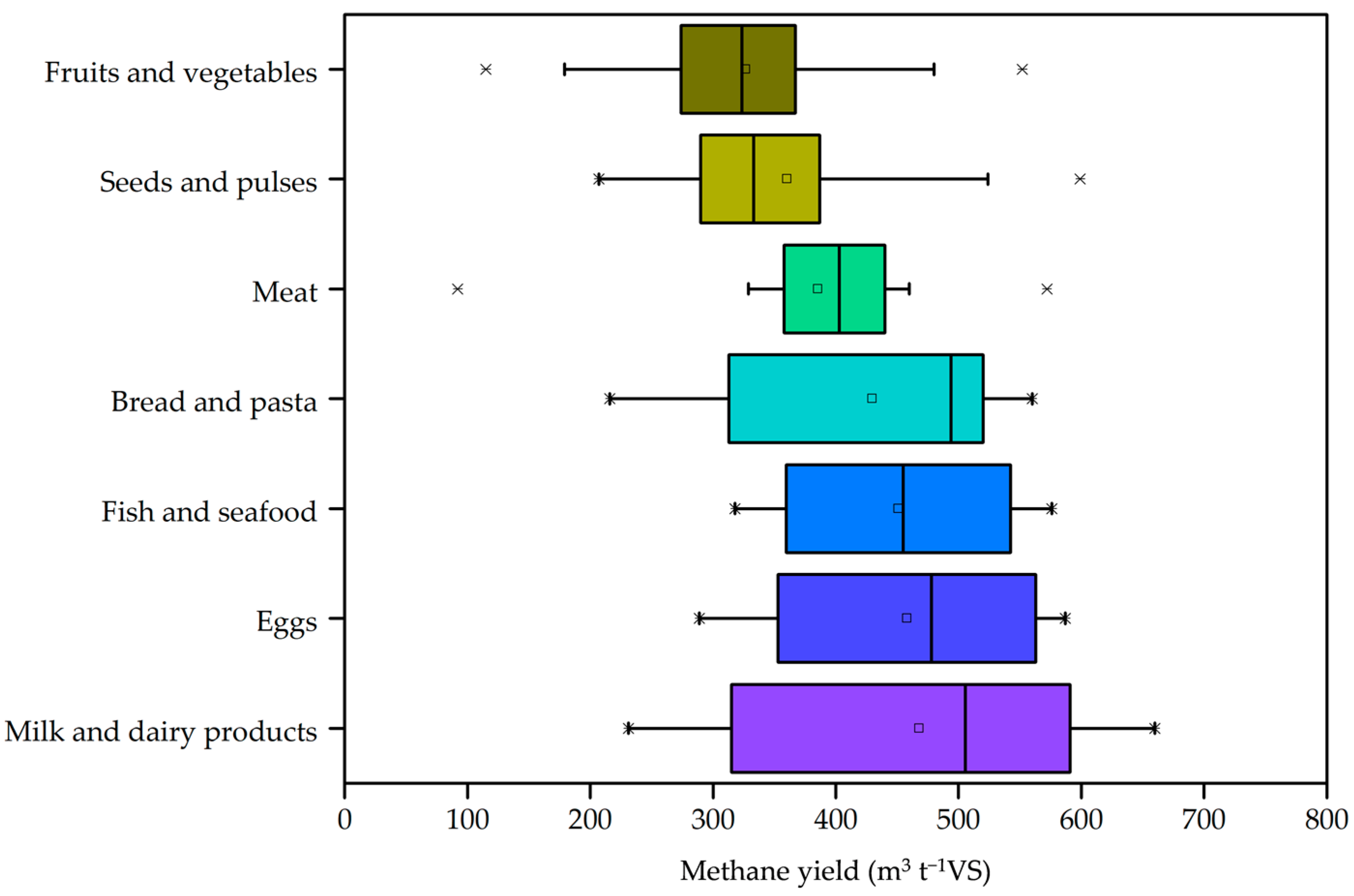

3.1. Statistical Analysis of Methane Yield of Food Categories

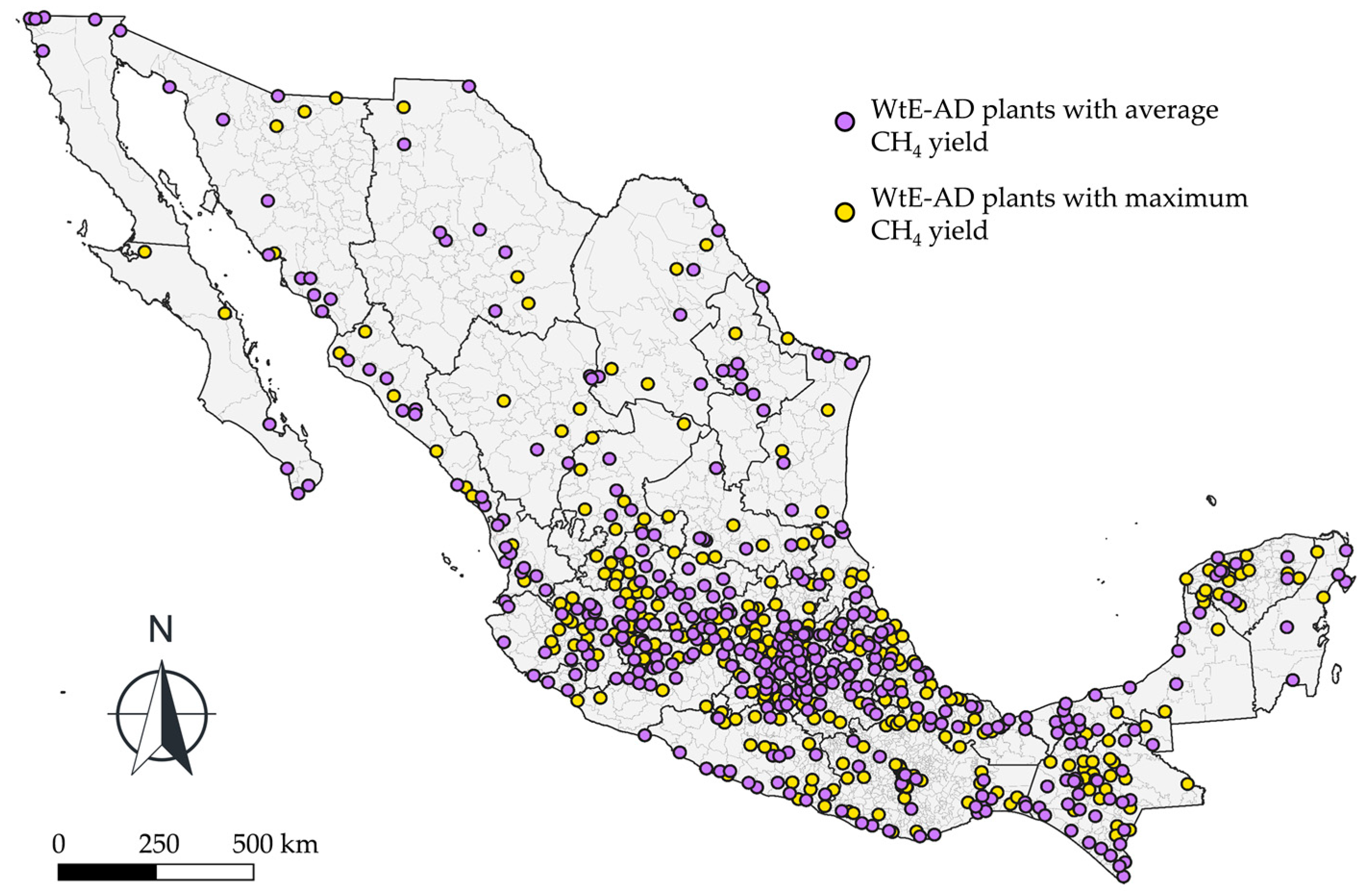

3.2. Anaerobic Digestion Waste-to-Energy Process Simulation and Sensitivity Analysis for Energetic Improvement

- Prioritize the location of WtE-AD plants in proximity to sites with high FLW generation. The geographic distribution of FLW should guide the siting of new plants to minimize transportation distances and associated energy costs.

- Encourage the development of larger WtE-AD plants with higher TCs, as these plants demonstrate better resilience to increased transportation distances and variability in methane yields. Provide subsidies, grants, or favorable policies to promote the scaling up of plant capacities.

- Invest in infrastructure that supports efficient transportation logistics, such as improved road networks and centralized collection points, to reduce travel times and energy consumption in the transportation of FLW.

- Implement regulatory frameworks and incentives that promote the efficient operation of WtE-AD plants, including requirements for energy-efficient technologies and processes that optimize methane yield and reduce energy consumption.

- Develop regional strategies for waste management that consider the specific FLW generation profiles, transportation logistics, and methane yield potentials of different areas. This ensures a balanced and efficient network of WtE-AD plants across the country.

- Support research and development initiatives focused on enhancing methane yields from various FLW categories through pre-treatment technologies or co-digestion strategies.

3.3. Prospects and Limitations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms | |

| AD | Anaerobic digestion |

| CHP | Heat and power cogeneration system |

| FDS | Final disposal site |

| FLW | Food loss and waste |

| FSC | Food supply chain |

| GHG | Greenhouse gas |

| GIS | Geographic information system |

| LHV | Low heating value |

| TC | Treatment capacity |

| VS | Volatile solids |

| WtE-AD | Waste-to-energy anaerobic digestion |

| Equation variables and parameters | |

| Cpmix | Specific heat capacity |

| Ei | Energy expense of unit operation “i” |

| Ein,i | Total energy expense in plant “i” |

| Eout,i | Energy production of WtE-AD plant “i” |

| Equotient,i | Energy quotient of plant “i” |

| Etransport,i | Transportation energy needed in plant “i” |

| fi | Fraction of food category “j” present in plant “i” |

| Mi | Food loss and waste mass flow to plant “i” |

| T0 | Initial temperature |

| Tout | Ambient temperature |

| Tr | Operating temperature |

| Vdiesel,i | Diesel consumption for plant “i” |

| YCH4i,j | Methane yield of food category “j” |

References

- Economía, S. De Data México—Industria Alimentaria. Available online: https://www.economia.gob.mx/datamexico/es/profile/industry/branches-grouped-by-the-principle-of-confidentiality-212C?redirect=true (accessed on 17 June 2024).

- Commission for Environmental Cooperation. Characterization and Management of Food Loss and Waste in North America; CEC: Montreal, QC, Canada, 2017; ISBN 978-2-89700-230-5. [Google Scholar]

- López-Sánchez, A.; Luque-Badillo, A.C.; Orozco-Nunnelly, D.; Alencastro-Larios, N.S.; Ruiz-Gómez, J.A.; García-Cayuela, T.; Gradilla-Hernández, M.S. Food Loss in the Agricultural Sector of a Developing Country: Transitioning to a More Sustainable Approach. The Case of Jalisco, Mexico. Environ. Chall. 2021, 5, 100327. [Google Scholar] [CrossRef]

- Kim, M.H.; Song, H.B.; Song, Y.; Jeong, I.T.; Kim, J.W. Evaluation of Food Waste Disposal Options in Terms of Global Warming and Energy Recovery: Korea. Int. J. Energy Environ. Eng. 2013, 4, 1. [Google Scholar] [CrossRef]

- Kim, M.H.; Kim, J.W. Comparison through a LCA Evaluation Analysis of Food Waste Disposal Options from the Perspective of Global Warming and Resource Recovery. Sci. Total Environ. 2010, 408, 3998–4006. [Google Scholar] [CrossRef]

- Moult, J.A.; Allan, S.R.; Hewitt, C.N.; Berners-Lee, M. Greenhouse Gas Emissions of Food Waste Disposal Options for UK Retailers. Food Policy 2018, 77, 50–58. [Google Scholar] [CrossRef]

- Levis, J.W.; Barlaz, M.A. What Is the Most Environmentally Beneficial Way to Treat Commercial Food Waste? Environ. Sci. Technol. 2011, 45, 7438–7444. [Google Scholar] [CrossRef] [PubMed]

- Tsydenova, N.; Morillas, A.V.; Hernández, Á.M.; Soria, D.R.; Wilches, C.; Pehlken, A. Feasibility and Barriers for Anaerobic Digestion in Mexico City. Sustainability 2019, 11, 4114. [Google Scholar] [CrossRef]

- Albalate-Ramírez, A.; Rueda-Avellaneda, J.F.; López-Hernández, B.N.; Alcalá-Rodríguez, M.M.; García-Balandrán, E.E.; Evrard, D.; Rivas-García, P. Geographic Life Cycle Assessment of Food Loss and Waste Management in Mexico: The Reality of Distribution and Retail Centers. Sustain. Prod. Consum. 2024, 48, 289–300. [Google Scholar] [CrossRef]

- Secretaría de Economía. Primer Censo Nacional de Centrales de Abasto En México. 2012. Available online: http://www.protlcuem.gob.mx/work/models/Prologyca/Resource/2/1/images/DirectorioNacionaldeCentralesdeAbasto.pdf (accessed on 17 June 2024).

- CCA. Central de Abasto de La Ciudad de México (CEDA): Comprensión de La Pérdida y El Desperdicio de Alimentos En El Mercado Más Grande Del Mundo; CCA: Ciudad de México, Mexico, 2021. [Google Scholar]

- Velenturf, A.P.M.; Purnell, P. Principles for a Sustainable Circular Economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Moset, V.; Poulsen, M.; Wahid, R.; Højberg, O.; Møller, H.B. Mesophilic versus Thermophilic Anaerobic Digestion of Cattle Manure: Methane Productivity and Microbial Ecology. Microb. Biotechnol. 2015, 8, 787–800. [Google Scholar] [CrossRef]

- Montecchio, D.; Gallipoli, A.; Gianico, A.; Mininni, G.; Pagliaccia, P.; Braguglia, C.M. Biomethane Potential of Food Waste: Modeling the Effects of Mild Thermal Pretreatment and Digestion Temperature. Environ. Technol. 2017, 38, 1452–1464. [Google Scholar] [CrossRef]

- Xue, S.; Wang, Y.; Lyu, X.; Zhao, N.; Song, J.; Wang, X.; Yang, G. Interactive Effects of Carbohydrate, Lipid, Protein Composition and Carbon/Nitrogen Ratio on Biogas Production of Different Food Wastes. Bioresour. Technol. 2020, 312, 123566. [Google Scholar] [CrossRef] [PubMed]

- David, A.; Govil, T.; Tripathi, A.K.; McGeary, J.; Farrar, K.; Sani, R.K. Thermophilic Anaerobic Digestion: Enhanced and Sustainable Methane Production from Co-Digestion of Food and Lignocellulosic Wastes. Energies 2018, 11, 2058. [Google Scholar] [CrossRef]

- Capson-Tojo, G.; Rouez, M.; Crest, M.; Steyer, J.P.; Delgenès, J.P.; Escudié, R. Food Waste Valorization via Anaerobic Processes: A Review. Rev. Environ. Sci. Biotechnol. 2016, 15, 499–547. [Google Scholar] [CrossRef]

- Marañón, E.; Negral, L.; Suárez-Peña, B.; Fernández-Nava, Y.; Ormaechea, P.; Díaz-Caneja, P.; Castrillón, L. Evaluation of the Methane Potential and Kinetics of Supermarket Food Waste. Waste Biomass Valorization 2021, 12, 1829–1843. [Google Scholar] [CrossRef]

- de Jonge, N.; Davidsson, Å.; la Cour Jansen, J.; Nielsen, J.L. Characterisation of Microbial Communities for Improved Management of Anaerobic Digestion of Food Waste. Waste Manag. 2020, 117, 124–135. [Google Scholar] [CrossRef]

- Komemoto, K.; Lim, Y.G.; Nagao, N.; Onoue, Y.; Niwa, C.; Toda, T. Effect of Temperature on VFA’s and Biogas Production in Anaerobic Solubilization of Food Waste. Waste Manag. 2009, 29, 2950–2955. [Google Scholar] [CrossRef] [PubMed]

- Ebner, J.H.; Labatut, R.A.; Lodge, J.S.; Williamson, A.A.; Trabold, T.A. Anaerobic Co-Digestion of Commercial Food Waste and Dairy Manure: Characterizing Biochemical Parameters and Synergistic Effects. Waste Manag. 2016, 52, 286–294. [Google Scholar] [CrossRef] [PubMed]

- Carlsson, M.; Naroznova, I.; Moller, J.; Scheutz, C.; Lagerkvist, A. Importance of Food Waste Pre-Treatment Efficiency for Global Warming Potential in Life Cycle Assessment of Anaerobic Digestion Systems. Resour. Conserv. Recycl. 2015, 102, 58–66. [Google Scholar] [CrossRef]

- Batstone, D.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.M.; Siegrist, H.; Vavilin, V.A. The IWA Anaerobic Digestion Model No 1(ADM1). Water Sci. Technol. 2002, 45, 65–73. [Google Scholar] [CrossRef]

- Jin, Y.; Chen, T.; Chen, X.; Yu, Z. Life-Cycle Assessment of Energy Consumption and Environmental Impact of an Integrated Food Waste-Based Biogas Plant. Appl. Energy 2015, 151, 227–236. [Google Scholar] [CrossRef]

- Albalate-Ramírez, A.; Alcalá-Rodríguez, M.M.; Miramontes-Martínez, L.R.; Padilla-Rivera, A.; Estrada-Baltazar, A.; López-Hernández, B.N.; Rivas-García, P. Energy Production from Cattle Manure within a Life Cycle Assessment Framework: Statistical Optimization of Co-Digestion, Pretreatment, and Thermal Conditions. Sustainability 2022, 14, 16945. [Google Scholar] [CrossRef]

- Brenes-Peralta, L.; Jiménez-Morales, M.F.; Campos-Rodríguez, R.; De Menna, F.; Vittuari, M. Decision-Making Process in the Circular Economy: A Case Study on University Food Waste-to-Energy Actions in Latin America. Energies 2020, 13, 2291. [Google Scholar] [CrossRef]

- Miramontes-Martínez, L.R.; Rivas-García, P.; Briones-Cristerna, R.A.; Abel-Seabra, J.E.; Padilla-Rivera, A.; Botello-Álvarez, J.E.; Alcalá-Rodríguez, M.M.; Levasseur, A. Potential of Electricity Generation by Organic Wastes in Latin America: A Techno-Economic-Environmental Analysis. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Selvaggi, R.; Valenti, F.; Pecorino, B.; Porto, S.M.C. Assessment of Tomato Peels Suitable for Producing Biomethane within the Context of Circular Economy: A Gis-Based Model Analysis. Sustainability 2021, 13, 5559. [Google Scholar] [CrossRef]

- Quintero-Herrera, S.; Zwolinski, P.; Evrard, D.; Cano-Gómez, J.J.; Rivas-García, P. Turning Food Loss and Waste into Animal Feed: A Mexican Spatial Inventory of Potential Generation of Agro-Industrial Wastes for Livestock Feed. Sustain. Prod. Consum. 2023, 41, 36–48. [Google Scholar] [CrossRef]

- Faustine, L.; Thierry, B.; Fabrice, B.; Lynda, A. Systemic Approach of Collective Biogas Plants on a Territory Using Geographic Information Systems (GIS) to Move towards an Environmental Assessment. Network on Recycling of Agricultural Municipal and Industrial Residues in Agriculture. 2013. Available online: http://ramiran.uvlf.sk/doc13/Proceeding_2013/documents/S10.09..pdf (accessed on 17 June 2024).

- Roostaei, J.; Zhang, Y. Spatially Explicit Life Cycle Assessment: Opportunities and Challenges of Wastewater-Based Algal Biofuels in the United States. Algal Res. 2017, 24, 395–402. [Google Scholar] [CrossRef]

- Liu, K.F.-R.; Hung, M.-J.; Yeh, P.-C.; Kuo, J.-Y. GIS-Based Regionalization of LCA. J. Geosci. Environ. Prot. 2014, 2, 1–8. [Google Scholar] [CrossRef]

- García-Pérez, S.; Sierra-Pérez, J.; Boschmonart-Rives, J.; Lladó Morales, G.; Romero Calix, A. A Characterisation and Evaluation of Urban Areas from an Energy Efficiency Approach, Using Geographic Information Systems in Combination with Life Cycle Assessment Methodology. Int. J. Sustain. Dev. Plan. 2017, 12, 294–303. [Google Scholar] [CrossRef]

- Senán-Salinas, J.; Blanco, A.; García-Pacheco, R.; Landaburu-Aguirre, J.; García-Calvo, E. Prospective Life Cycle Assessment and Economic Analysis of Direct Recycling of End-of-Life Reverse Osmosis Membranes Based on Geographic Information Systems. J. Clean. Prod. 2021, 282, 124400. [Google Scholar] [CrossRef]

- Zea Escamilla, E.; Habert, G. Method and Application of Characterisation of Life Cycle Impact Data of Construction Materials Using Geographic Information Systems. Int. J. Life Cycle Assess. 2017, 22, 1210–1219. [Google Scholar] [CrossRef]

- Loiseau, E.; Aissani, L.; Le Féon, S.; Laurent, F.; Cerceau, J.; Sala, S.; Roux, P. Territorial Life Cycle Assessment (LCA): What Exactly Is It about? A Proposal towards Using a Common Terminology and a Research Agenda. J. Clean. Prod. 2018, 176, 474–485. [Google Scholar] [CrossRef]

- Abotalib, M.; Zhao, F.; Clarens, A. Deployment of a Geographical Information System Life Cycle Assessment Integrated Framework for Exploring the Opportunities and Challenges of Enhanced Oil Recovery Using Industrial CO2 Supply in the United States. ACS Sustain. Chem. Eng. 2016, 4, 4743–4751. [Google Scholar] [CrossRef]

- Rueda-Avellaneda, J.F.; Rivas-García, P.; Gomez-Gonzalez, R.; Benitez-Bravo, R.; Botello-Álvarez, J.E.; Tututi-Avila, S. Current and Prospective Situation of Municipal Solid Waste Final Disposal in Mexico: A Spatio-Temporal Evaluation. Renew. Sustain. Energy Transit. 2021, 1, 100007. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. Predicting the Environmental Impact of a Future Nanocellulose Production at Industrial Scale: Application of the Life Cycle Assessment Scale-up Framework. J. Clean. Prod. 2018, 174, 283–295. [Google Scholar] [CrossRef]

- Benitez-Bravo, R.; Gomez-González, R.; Rivas-García, P.; Botello-Álvarez, J.E.; Huerta-Guevara, O.F.; García-León, A.M.; Rueda-Avellaneda, J.F. Optimization of Municipal Solid Waste Collection Routes in a Latin-American Context. J. Air Waste Manag. Assoc. 2021, 71, 1415–1427. [Google Scholar] [CrossRef]

- Miramontes-Martínez, L.R.; Rivas-García, P.; Albalate-Ramírez, A.; Botello-Álvarez, J.E.; Escamilla-Alvarado, C.; Gomez-Gonzalez, R.; Alcalá-Rodríguez, M.M.; Valencia-Vázquez, R.; Santos-López, I.A. Anaerobic Co-Digestion of Fruit and Vegetable Waste: Synergy and Process Stability Analysis. J. Air Waste Manag. Assoc. 2021, 00, 1–13. [Google Scholar] [CrossRef]

- Albalate-Ramírez, A.; Alcalá-Rodríguez, M.M.; Miramontes-Martínez, L.R.; Galván-Arzola, U.; López-Hernández, B.N.; Morones-Ramírez, J.R.; Rivas-García, P. The Importance of Substrate Formulation on the Hydrolysis Process in Anaerobic Digestion: A Numerical and Experimental Study. Rev. Mex. Ing. Química 2023, 22, 1–10. [Google Scholar] [CrossRef]

- Astals, S.; Batstone, D.J.; Mata-Alvarez, J.; Jensen, P.D. Identification of Synergistic Impacts during Anaerobic Co-Digestion of Organic Wastes. Bioresour. Technol. 2014, 169, 421–427. [Google Scholar] [CrossRef] [PubMed]

- Angulo, N.R.; Lagarda, A.M.; Urquidy, M.R.; Flores, M.T. Economías de Escala y Rendimientos Crecientes Una Aplicación En Microempresas Mexicanas. Econ. Mex. 2009, 19, 213–230. [Google Scholar]

- Le Pera, A.; Sellaro, M.; Migliori, M.; Bianco, M.; Zanardi, G. Dry Mesophilic Anaerobic Digestion of Separately Collected Organic Fraction of Municipal Solid Waste: Two-Year Experience in an Industrial-Scale Plant. Processes 2021, 9, 213. [Google Scholar] [CrossRef]

- Poliafico, M.; Murphy, J.D. Anaerobic Digestion in Ireland: Decision Support System, Department of Civil, Structural and Environmental Engineering; Cork Institute of Technology: Cork, Ireland, 2007. [Google Scholar]

- Lyng, K.-A.; Modahl, I.S.; Møller, H.; Saxegård, S. Comparison of Results from Life Cycle Assessment When Using Predicted and Real-Life Data for an Anaerobic Digestion Plant. J. Sustain. Dev. Energy Water Environ. Syst. 2021, 9, 1–14. [Google Scholar] [CrossRef]

- Li, Z.; Lu, H.; Zhang, Z.; Liu, B. Study on Scale-Up of Anaerobic Fermentation Mixing with Different Solid Content. Fermentation 2023, 9, 375. [Google Scholar] [CrossRef]

- Available online: https://www.alibaba.com/product-detail/Twin-Shaft-Shredding-Machine-Industrial-Cardboard_1600958572715.html?spm=a2700.galleryofferlist.p_offer.d_title.b2467f0cCgx3aG&s=p (accessed on 17 June 2024).

- Available online: https://www.alibaba.com/product-detail/Double-Shaft-Waste-Shredder-Blade-Shredder_1600987906528.html?spm=a2700.galleryofferlist.p_offer.d_title.b2467f0cCgx3aG&s=p (accessed on 17 June 2024).

- Available online: https://www.alibaba.com/product-detail/Metal-Shredder-Mini-Double-Shaft-Shredder_1600520129917.html?spm=a2700.galleryofferlist.p_offer.d_title.b2467f0cCgx3aG&s=p (accessed on 17 June 2024).

- Available online: https://www.alibaba.com/product-detail/8-tons-hour-industrial-twin-shaft_1600858896447.html?spm=a2700.galleryofferlist.normal_offer.d_title.b2467f0cCgx3aG (accessed on 17 June 2024).

- Available online: https://www.alibaba.com/product-detail/Industrial-vegetable-cutter-electric-vegetable-slicer_1600095330756.html?spm=a2700.galleryofferlist.normal_offer.d_title.b2467f0cCgx3aG (accessed on 17 June 2024).

- Available online: https://www.alibaba.com/product-detail/High-efficiency-metal-shredder-machine-for_1601038401804.html?spm=a2700.galleryofferlist.normal_offer.d_title.b2467f0cCgx3aG (accessed on 17 June 2024).

| Process Type | Process Efficiency |

|---|---|

| BTA © | 332 m3 t−1 VS |

| Sebac © | 220–530 m3 t−1 VS |

| Kompogas © | 390–580 m3 t−1 VS |

| Valorga © | 220–300 m3 t−1 VS |

| Waasa © | 170–320 m3 t−1 VS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albalate-Ramírez, A.; Padilla-Rivera, A.; Rueda-Avellaneda, J.F.; López-Hernández, B.N.; Cano-Gómez, J.J.; Rivas-García, P. Mapping the Sustainability of Waste-to-Energy Processes for Food Loss and Waste in Mexico—Part 1: Energy Feasibility Study. Sustainability 2024, 16, 6111. https://doi.org/10.3390/su16146111

Albalate-Ramírez A, Padilla-Rivera A, Rueda-Avellaneda JF, López-Hernández BN, Cano-Gómez JJ, Rivas-García P. Mapping the Sustainability of Waste-to-Energy Processes for Food Loss and Waste in Mexico—Part 1: Energy Feasibility Study. Sustainability. 2024; 16(14):6111. https://doi.org/10.3390/su16146111

Chicago/Turabian StyleAlbalate-Ramírez, Alonso, Alejandro Padilla-Rivera, Juan Felipe Rueda-Avellaneda, Brenda Nelly López-Hernández, José Julián Cano-Gómez, and Pasiano Rivas-García. 2024. "Mapping the Sustainability of Waste-to-Energy Processes for Food Loss and Waste in Mexico—Part 1: Energy Feasibility Study" Sustainability 16, no. 14: 6111. https://doi.org/10.3390/su16146111