Optimization Strategies for the Envelope of Student Dormitories in Hot Summer and Cold Winter Regions: Multi-Criteria Assessment Method

Abstract

:1. Introduction

2. Materials and Methods

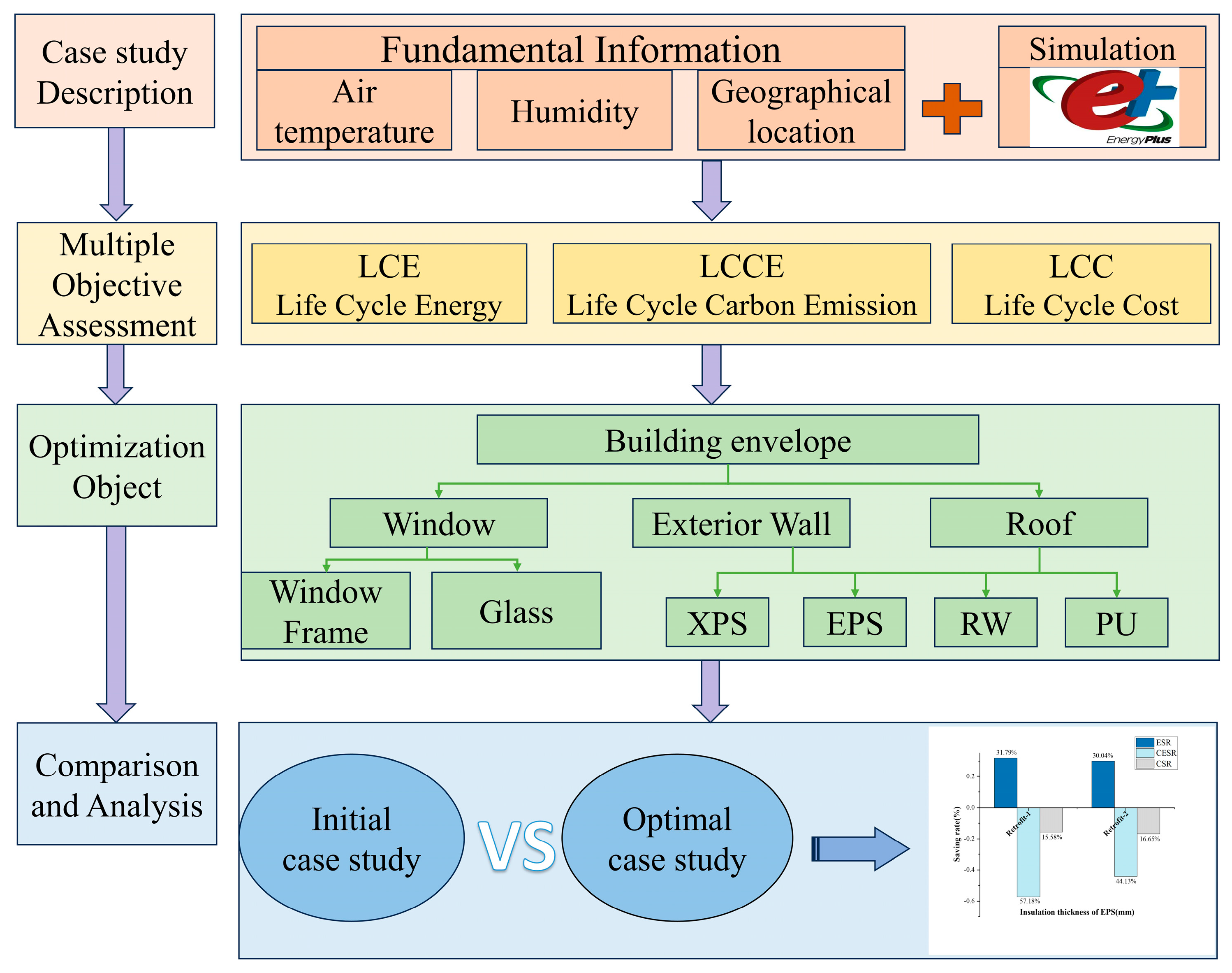

2.1. Research Flowchart

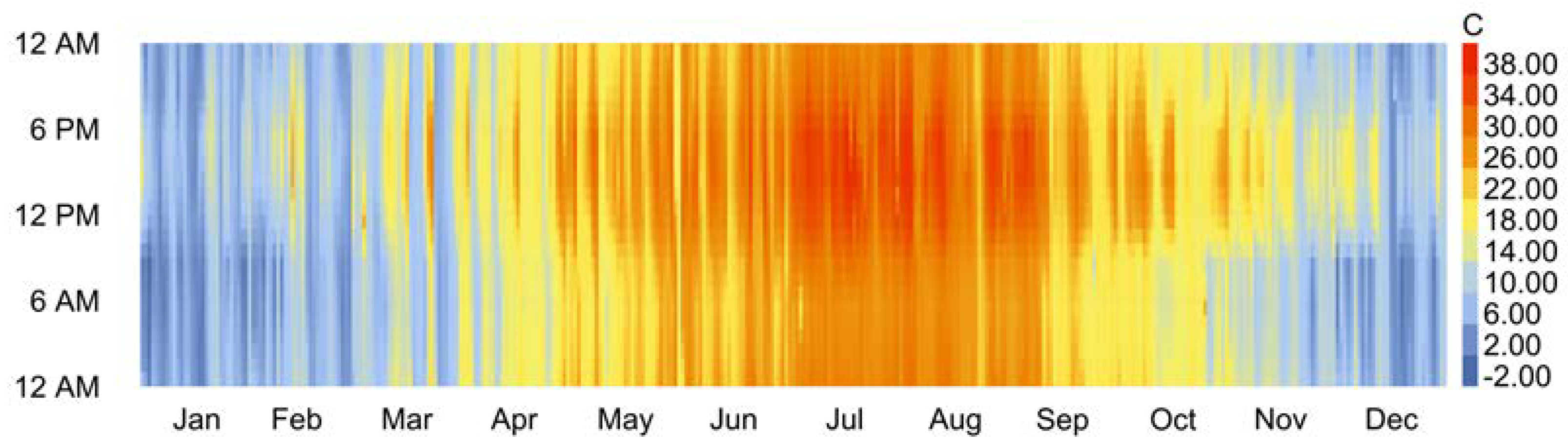

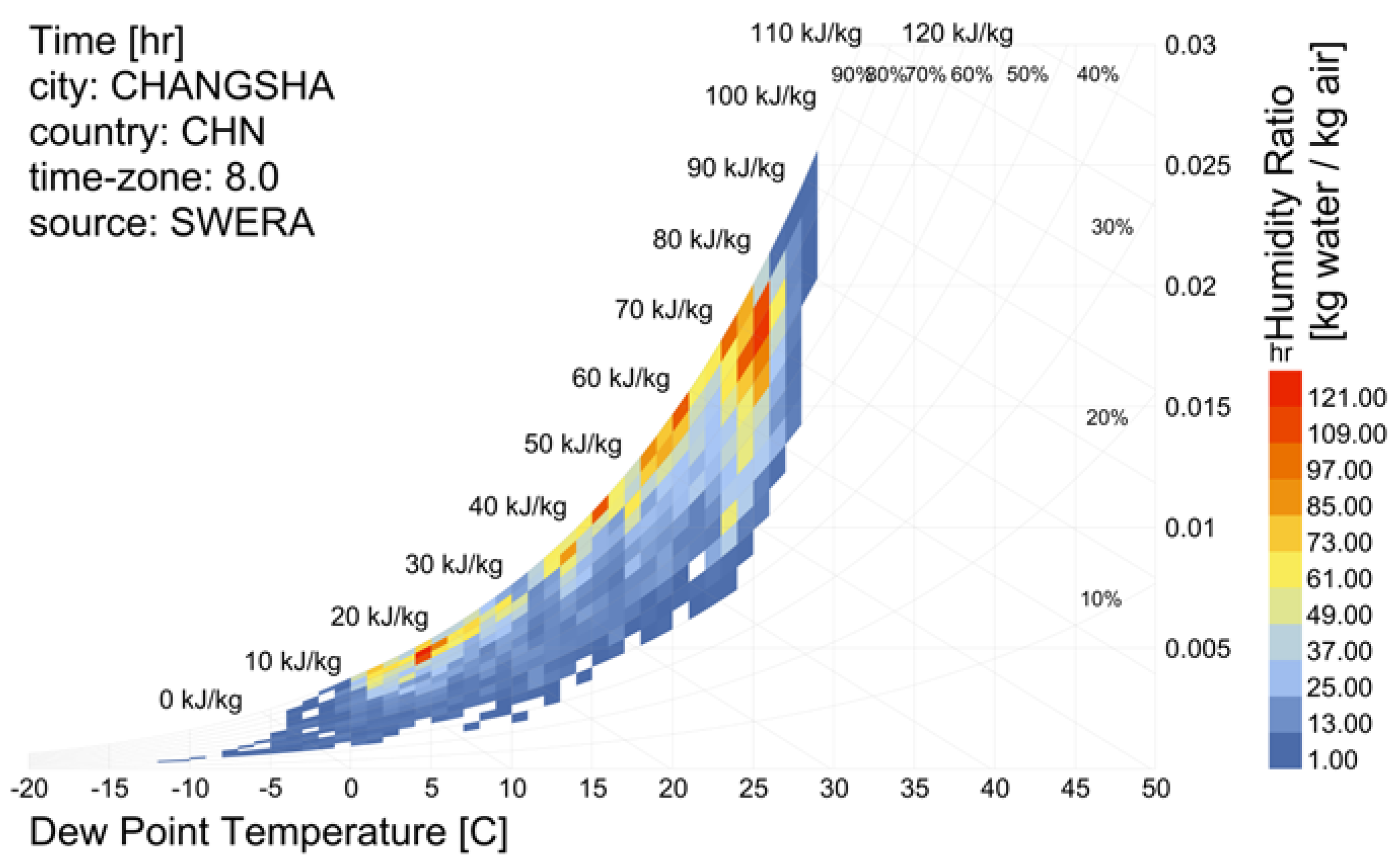

2.2. Case Study

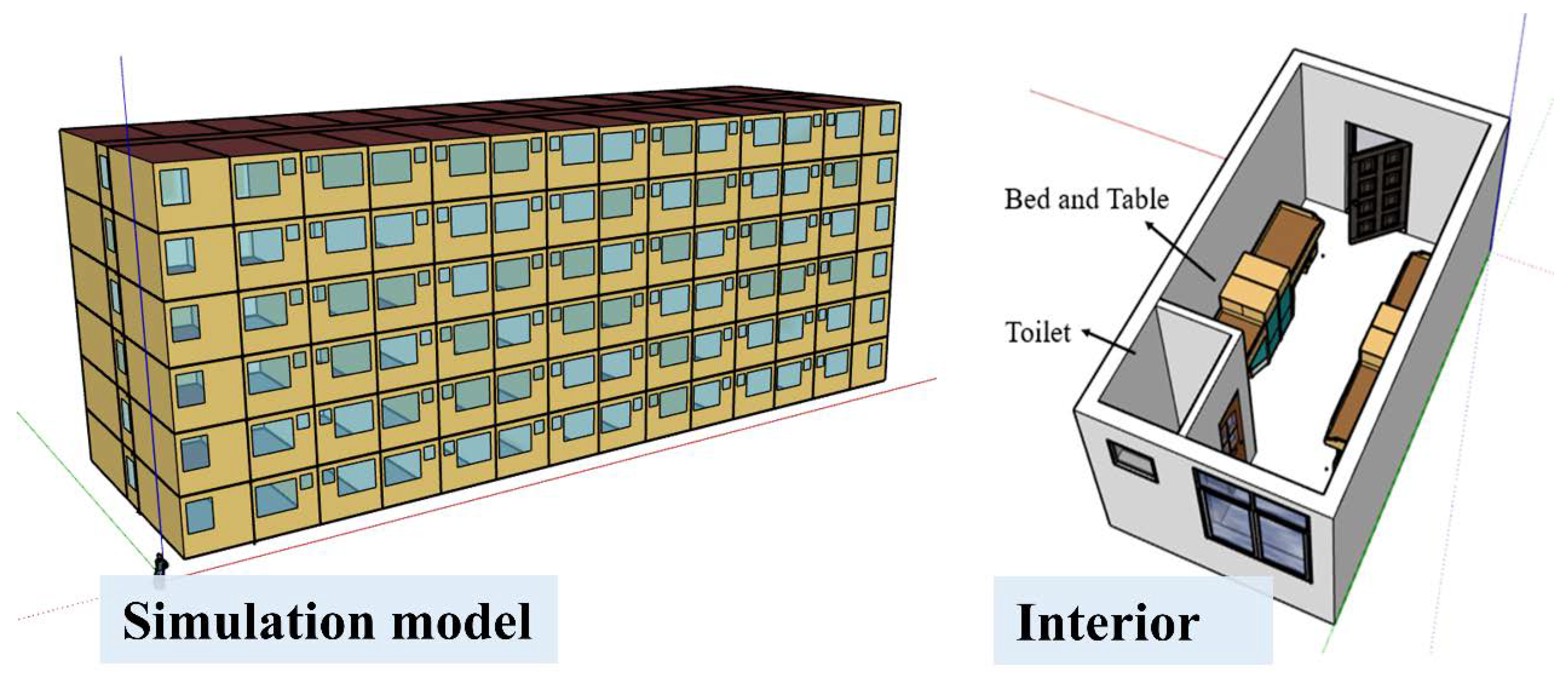

2.2.1. Building Overview

2.2.2. Simulation

2.3. Multi-Goal Optimization Model

2.3.1. Life Cycle Energy Assessment

2.3.2. Life Cycle Carbon Emission Assessment

2.3.3. Life Cycle Cost Assessment

2.3.4. Optimal Multi-Objectives

2.4. Detailed Calculation of Optimizing the Envelope

2.4.1. Exterior Window

2.4.2. Selection of Insulation Materials

2.4.3. Determination of Insulation Material Thickness

3. Results and Discussion

3.1. Establishment of a Single Parameter Retrofit Construction Plan

3.1.1. Exterior Wall

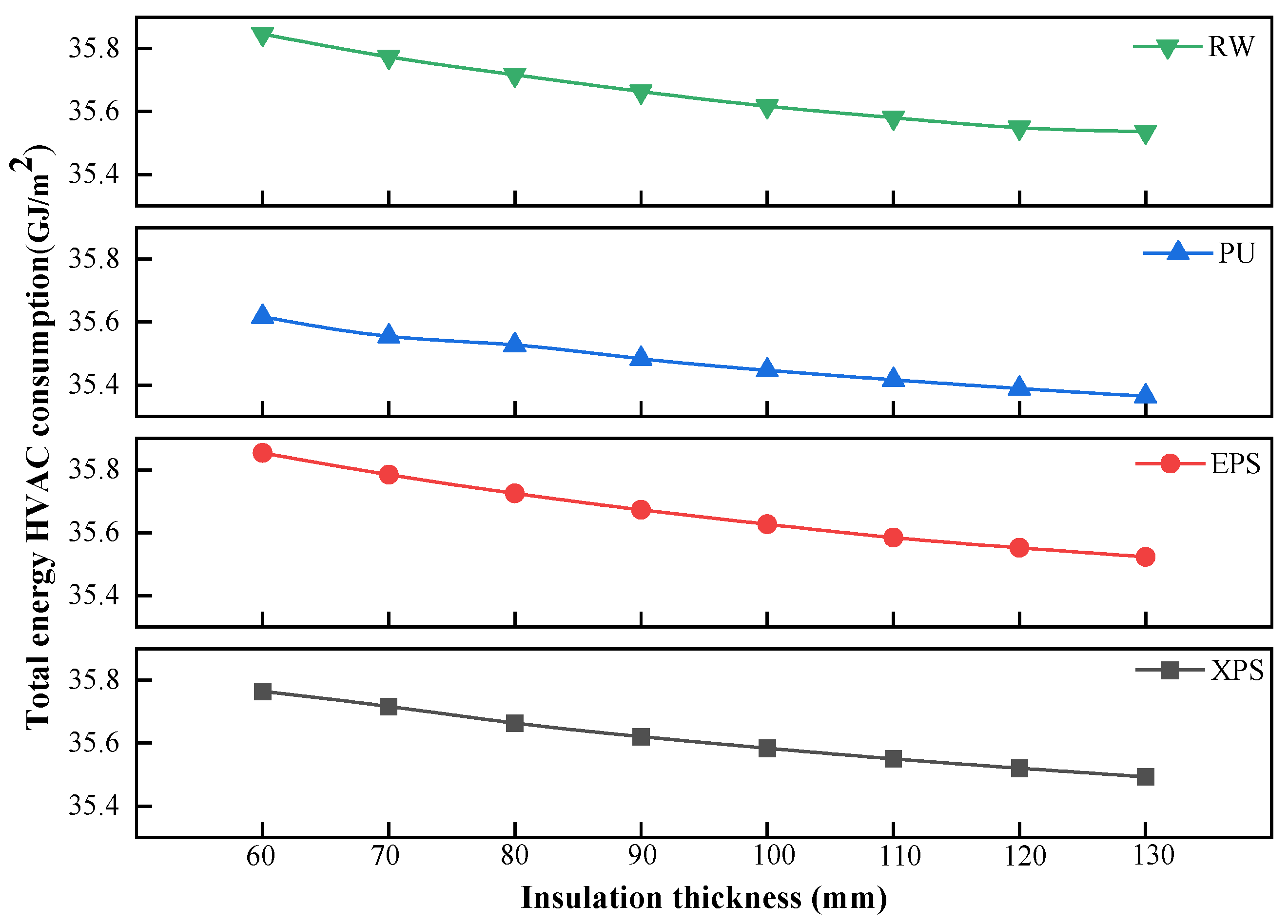

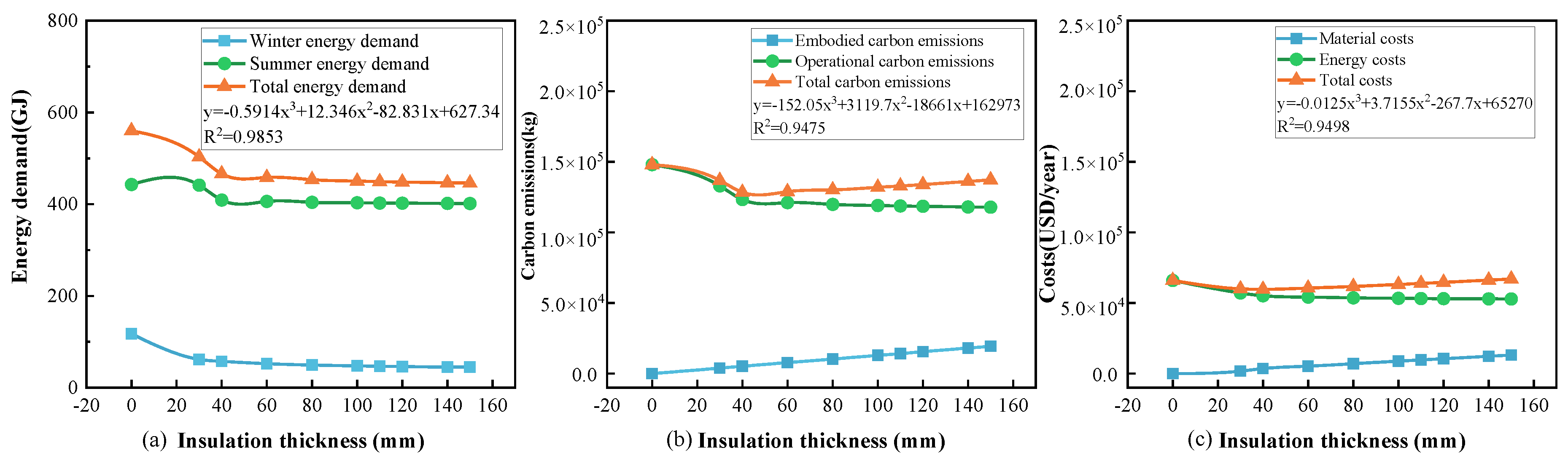

- (1)

- Multi-objective optimization analysis

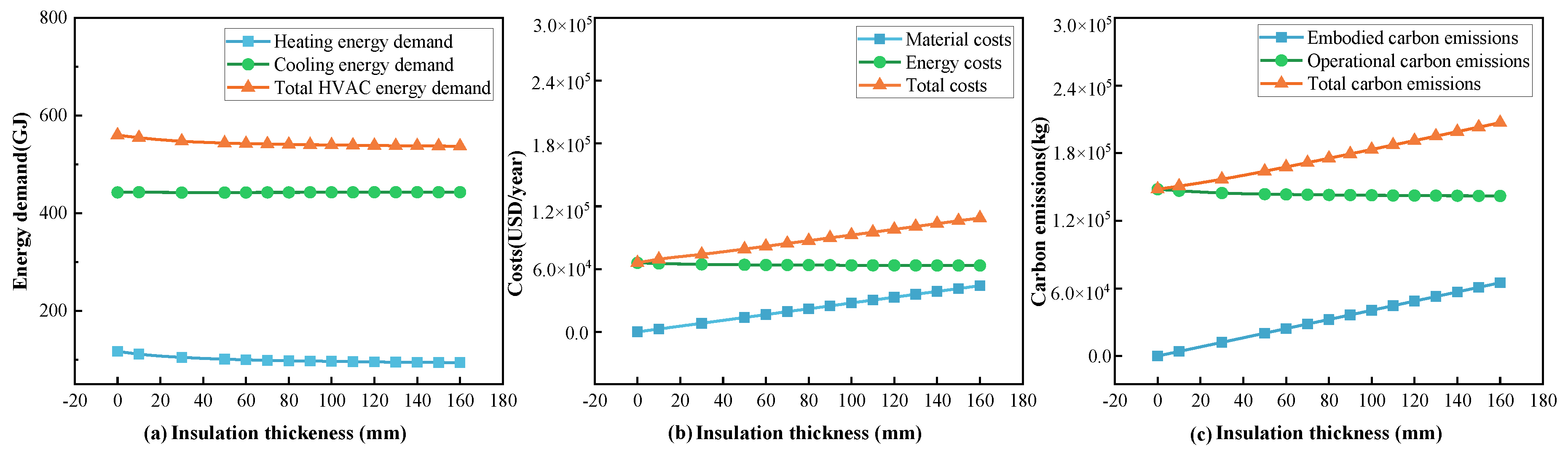

- (2)

- Multi-objective optimization outcome

3.1.2. Exterior Window

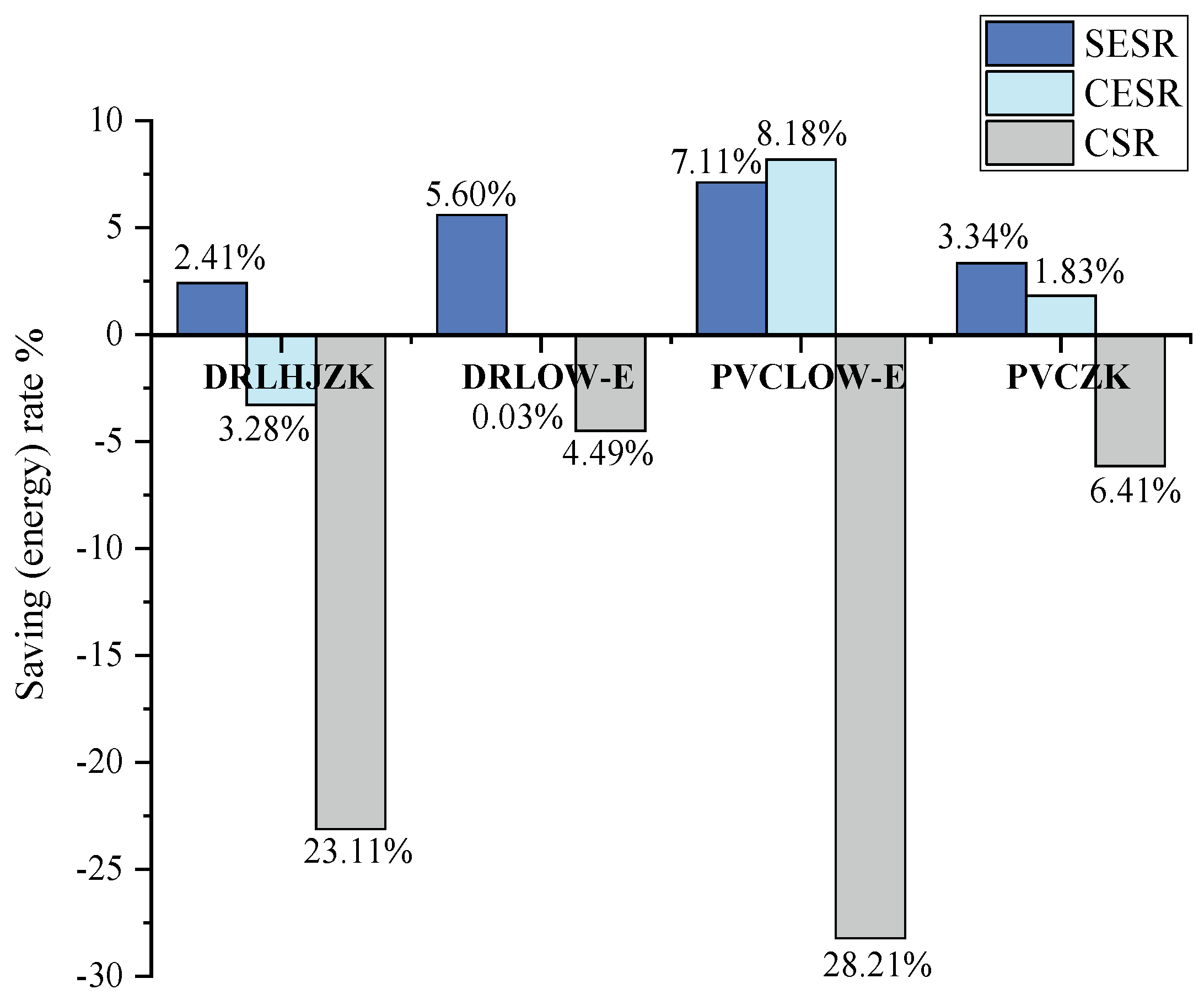

- (1)

- Multi-objective optimization analysis

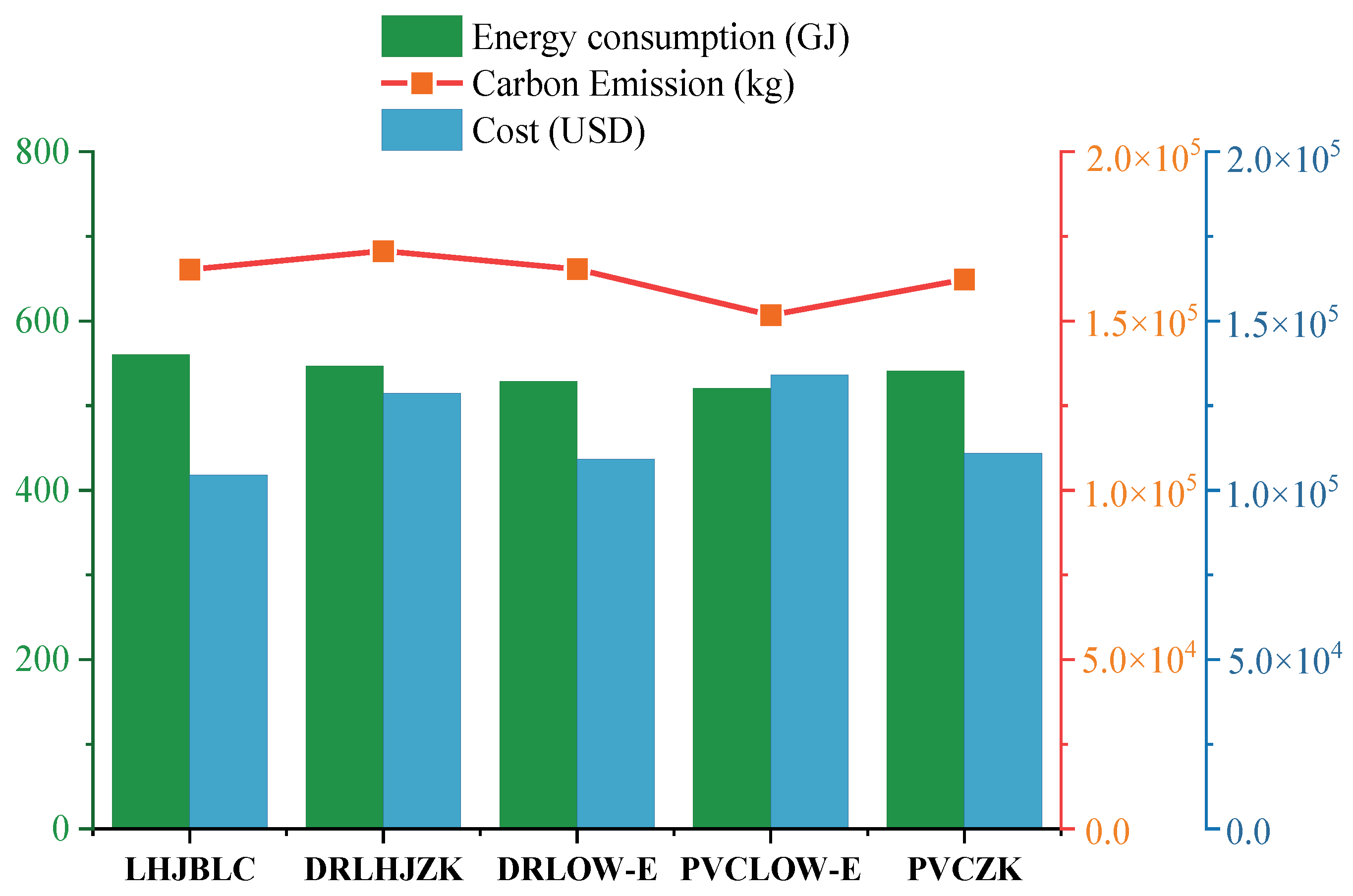

- (2)

- Multi-objective optimization outcome

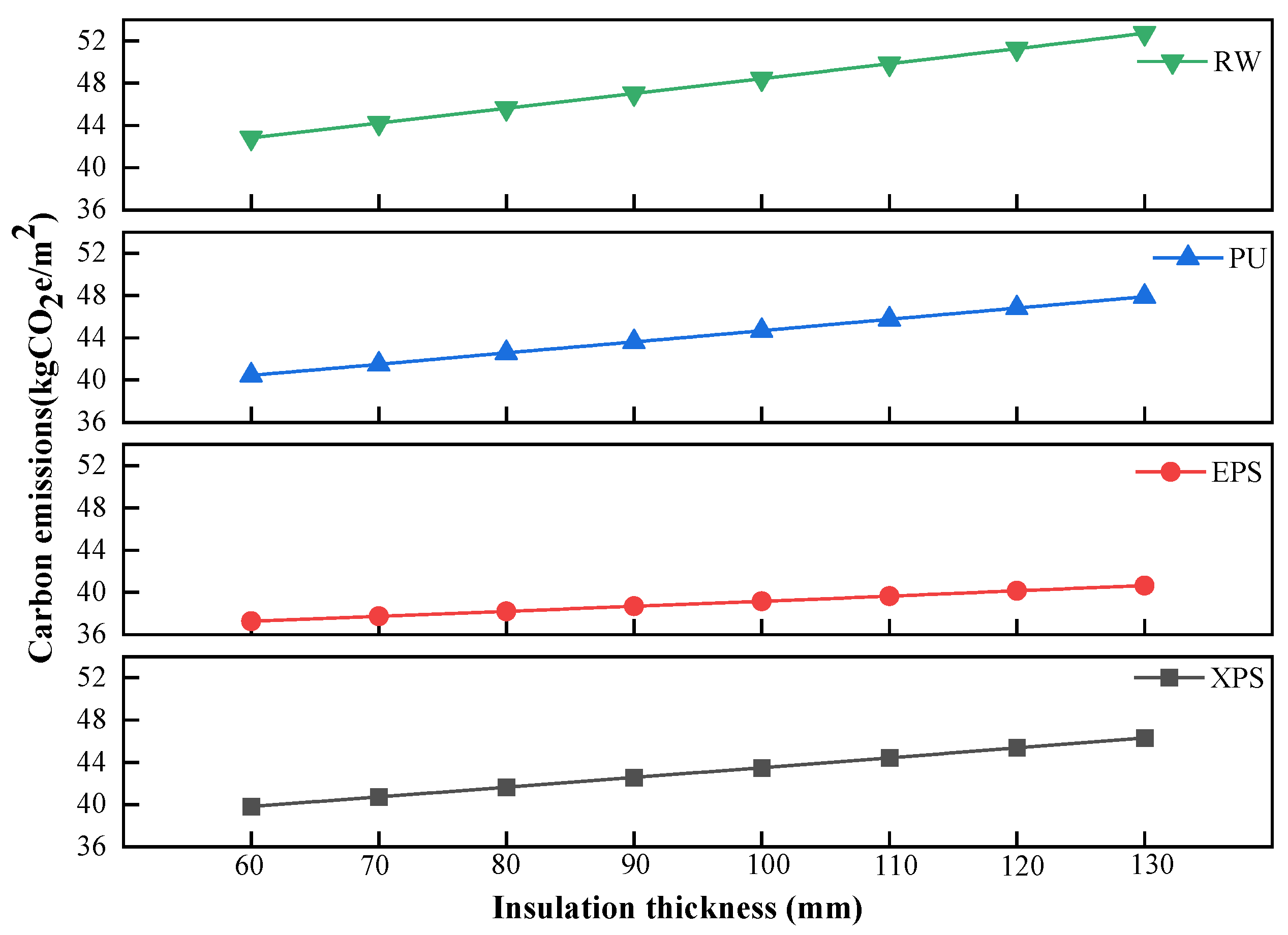

3.1.3. Exterior Roof

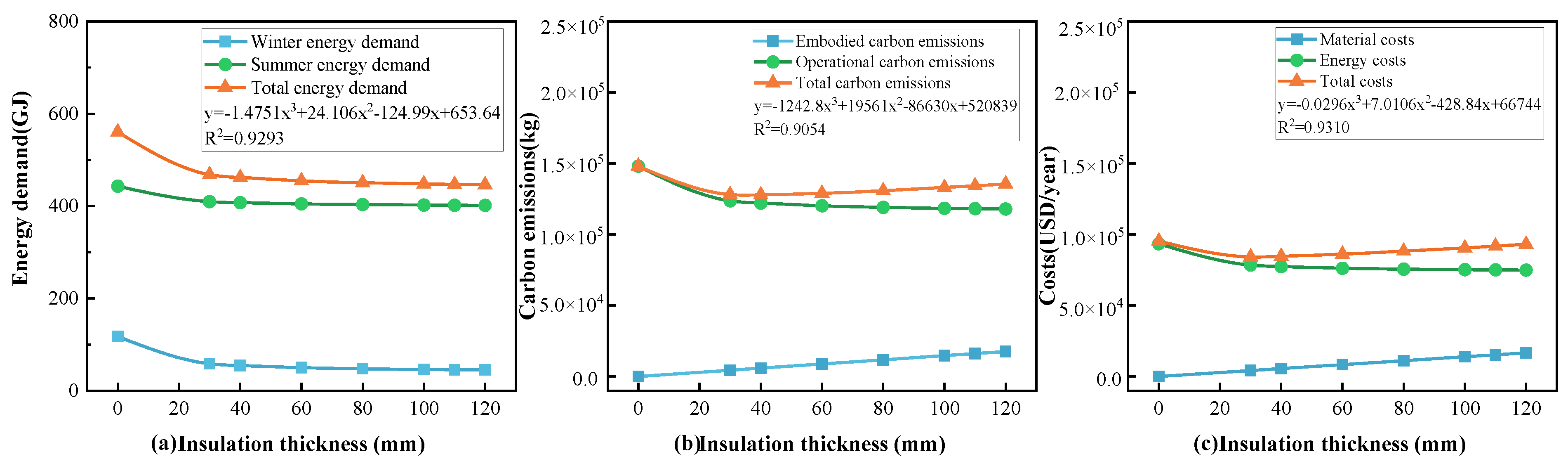

- (1)

- Multi-objective optimization analysis

- (2)

- Multi-objective optimization outcome

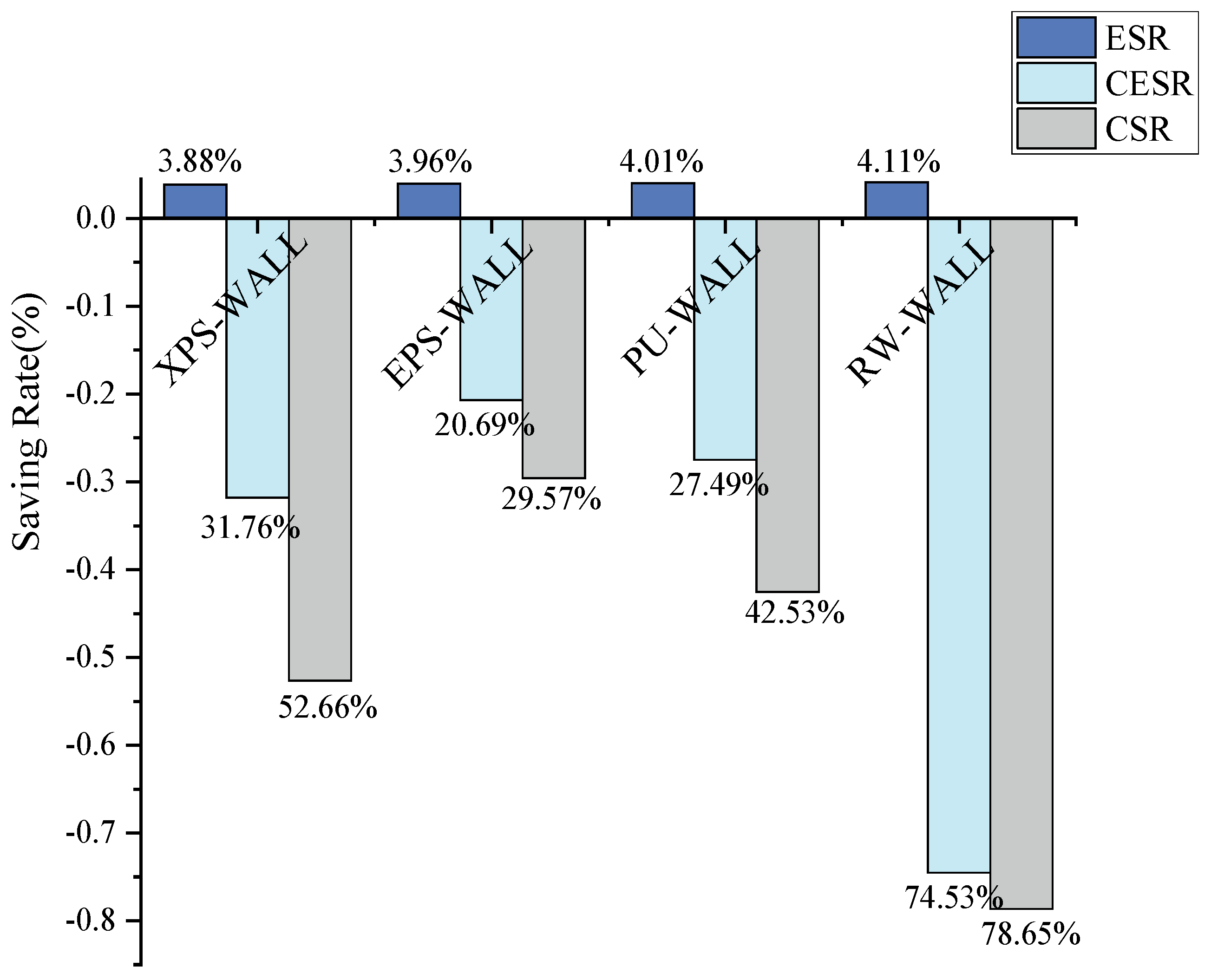

3.2. Establishment of a Combined Retrofit Construction Plan

4. Conclusions

- (1)

- Adding insulation to external walls significantly reduces heating loads and winter energy consumption. Analyzing XPS, EPS, PU, and RW insulation materials shows that RW has the highest energy-saving potential but is minimally better than the others and costs more than twice as much. Thus, EPS and PU are more advantageous for well-performing external walls.

- (2)

- For regions with hot summers and cold winters, Low-E glass with a low shading coefficient and low transmittance should be more widely used. While PVC combined with Low-E glass offers the greatest potential for energy savings and emission reductions, it comes at a higher cost. Considering that cost is often the biggest constraint in design, PVC double-glazed windows with Low-E glass are recommended.

- (3)

- Balancing energy consumption, carbon emissions, and cost, it was found that roof insulation saves energy and reduces emissions, though XPS increases costs by 5.19%. EPS and PU materials are more advantageous for poorly performing envelopes. While EPS saves 1.62% less energy than PU, its cost savings are approximately double.

- (4)

- After analysis, the optimized building strategy is as follows: external walls with 164 mm EPS insulation, roof with 62 mm PU insulation, and external windows with thermal break Low-E glass. Compared to the case study building, the energy consumption is reduced by 31.79%, but carbon emissions and costs increase by 57.18% and 15.58%, respectively. It is noteworthy that this study only conducted a one-year life cycle assessment. The added insulation materials result in higher carbon emissions mainly during the material production phase, while the reduction in energy consumption and operational carbon emissions will continue throughout the building’s lifespan. Therefore, this building envelope optimization strategy can provide valuable insights for architects during the design phase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | Greek letters | ||

| CE | Carbon Emission | Roof thickness (mm) | |

| CEF | Carbon Emission Factor | Exterior wall density (kg/m3) | |

| LCA | Life Cycle Assessment | Roof mass energy (MJ/kg) | |

| LCE | Life Cycle Energy Assessment | Roof density (kg/m3) | |

| LCCE | Life Cycle Carbon Emission Assessment | Exterior wall thickness(mm) | |

| LCC | Life Cycle Cost Assessment | Exterior wall mass energy (MJ/kg) | |

| ESR | Energy Saving Rate | Carbon emission coefficient of electricity (tCO2/MWh) | |

| CESR | Carbon Emission Saving Rate | Thermal conductivity coefficient (W/(m·K)) | |

| CSR | Cost Saving Rate | Heat transfer coefficient (m2·K/W) | |

| WWR | Window-to-Wall Ratio | Correction coefficient | |

| HVAC | Heating, Ventilation and Air-Conditioning | Subscripts | |

| RMB | Ren Min Bi (Chinese Currency) | s | Summer |

| USD | United States Dollar | w | Winter |

| Symbols | ep | Lighting equipment | |

| F(x) | Objective function | m | Production stage of building material |

| E | Energy consumption (GJ) | op | The operational phase |

| C | Cost (USD) | i | The i material |

| CE | Carbon emissions (kg) | opt | Objective function value of the optimal solution |

| A | Surface area (m2) | bc | Initial function value of the building |

| PWF | Present value factor | Total energy consumption of exterior wall | |

| g | Inflation rate (%) | Total energy consumption of roof | |

| I | Loan interest rate (%) | I material of exterior wall | |

| Hourly temperature difference between indoor and outdoor (K) | K material of roof | ||

| R | Heat transfer resistance (K/W) | n | year |

| N | year |

References

- Nie, H.; Wang, L.; Tian, M. Analysis on Determinants of Carbon Emissions from Plaza Ground Paving during the Construction Stage Based on Life Cycle Assessment. Sci. Rep. 2024, 14, 136. [Google Scholar] [CrossRef]

- Tang, S.; Wu, C.; Liu, Y. Developing Global Health Education in Chinese Universities: Challenges and Opportunities. Lancet Reg. Health—West. Pac. 2023, 41, 100940. [Google Scholar] [CrossRef]

- Wang, Y. Application of Deep Learning Model in Building Energy Consumption Prediction. Comput. Intell. Neurosci. 2022, 2022, 4835259. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- NBSC (National Bureau of Statistics of China). China Statistical Yearbook-2013; China Statistics Press: Beijing, China, 2013. [Google Scholar]

- Chi, F.; Xu, Y. Building Performance Optimization for University Dormitory through Integration of Digital Gene Map into Multi-Objective Genetic Algorithm. Appl. Energy 2022, 307, 118211. [Google Scholar] [CrossRef]

- Deng, Y.; Gou, Z.; Gui, X.; Cheng, B. Energy Consumption Characteristics and Influential Use Behaviors in University Dormitory Buildings in China’s Hot Summer-Cold Winter Climate Region. J. Build. Eng. 2021, 33, 101870. [Google Scholar] [CrossRef]

- Wen, F.; Wu, N.; Gong, X. China’s Carbon Emissions Trading and Stock Returns. Energy Econ. 2020, 86, 104627. [Google Scholar] [CrossRef]

- Motuzienė, V.; Čiuprinskas, K.; Rogoža, A.; Lapinskienė, V. A Review of the Life Cycle Analysis Results for Different Energy Conversion Technologies. Energies 2022, 15, 8488. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life Cycle Assessment (LCA) and Life Cycle Energy Analysis (LCEA) of Buildings and the Building Sector: A Review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Mahlan, S.; Francis, A.; Thumuganti, V.; Thomas, A.; Sadick, A.-M.; Tokede, O. An Integrated Life Cycle Assessment and Energy Simulation Framework for Residential Building Walling Systems. Build. Environ. 2024, 257, 111542. [Google Scholar] [CrossRef]

- Feng, G.; Chi, D.; Xu, X.; Dou, B.; Sun, Y.; Fu, Y. Study on the Influence of Window-Wall Ratio on the Energy Consumption of Nearly Zero Energy Buildings. Procedia Eng. 2017, 205, 730–737. [Google Scholar] [CrossRef]

- Marino, C.; Nucara, A.; Pietrafesa, M. Does Window-to-Wall Ratio Have a Significant Effect on the Energy Consumption of Buildings? A Parametric Analysis in Italian Climate Conditions. J. Build. Eng. 2017, 13, 169–183. [Google Scholar] [CrossRef]

- Goia, F. Search for the Optimal Window-to-Wall Ratio in Office Buildings in Different European Climates and the Implications on Total Energy Saving Potential. Sol. Energy 2016, 132, 467–492. [Google Scholar] [CrossRef]

- Pandey, P.R.; Dong, B. Prediction of Window Opening Behavior and Its Impact on HVAC Energy Consumption at a Residential Dormitory Using Deep Neural Network. Energy Build. 2023, 296, 113355. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Alktranee, M.; Szabó, M.; Arıcı, M. Building Envelope-Enhanced Phase Change Material and Night Ventilation: Effect of Window Orientation and Window-to-Wall Ratio on Indoor Temperature. Renew. Energy 2023, 218, 119263. [Google Scholar] [CrossRef]

- Mangkuto, R.A.; Rohmah, M.; Asri, A.D. Design Optimisation for Window Size, Orientation, and Wall Reflectance with Regard to Various Daylight Metrics and Lighting Energy Demand: A Case Study of Buildings in the Tropics. Appl. Energy 2016, 164, 211–219. [Google Scholar] [CrossRef]

- Sadooghi, P. HVAC Electricity and Natural Gas Saving Potential of a Novel Switchable Window Compared to Conventional Glazing Systems: A Canadian House Case Study in City of Toronto. Sol. Energy 2022, 231, 129–139. [Google Scholar] [CrossRef]

- Ahmed, A.E.; Suwaed, M.S.; Shakir, A.M.; Ghareeb, A. The Impact of Window Orientation, Glazing, and Window-to-Wall Ratio on the Heating and Cooling Energy of an Office Building: The Case of Hot and Semi-Arid Climate. J. Eng. Res. 2023. [Google Scholar] [CrossRef]

- Hussien, A.; Khan, W.; Hussain, A.; Liatsis, P.; Al-Shamma’a, A.; Al-Jumeily, D. Predicting Energy Performances of Buildings’ Envelope Wall Materials via the Random Forest Algorithm. J. Build. Eng. 2023, 69, 106263. [Google Scholar] [CrossRef]

- Saboor, S.; Chelliah, A.; Gorantla, K.K.; Kim, K.-H.; Lee, S.-H.; Shon, Z.H.; Brown, R.J.C. Strategic Design of Wall Envelopes for the Enhancement of Building Thermal Performance at Reduced Air-Conditioning Costs. Environ. Res. 2021, 193, 110577. [Google Scholar] [CrossRef]

- Dombaycı, Ö.A. The Environmental Impact of Optimum Insulation Thickness for External Walls of Buildings. Build. Environ. 2007, 42, 3855–3859. [Google Scholar] [CrossRef]

- Bektas Ekici, B.; Aytac Gulten, A.; Aksoy, U.T. A Study on the Optimum Insulation Thicknesses of Various Types of External Walls with Respect to Different Materials, Fuels and Climate Zones in Turkey. Appl. Energy 2012, 92, 211–217. [Google Scholar] [CrossRef]

- Dardouri, S.; Mankai, S.; Almoneef, M.M.; Mbarek, M.; Sghaier, J. Energy Performance Based Optimization of Building Envelope Containing PCM Combined with Insulation Considering Various Configurations. Energy Rep. 2023, 10, 895–909. [Google Scholar] [CrossRef]

- Verichev, K.; Zamorano, M.; Fuentes-Sepúlveda, A.; Cárdenas, N.; Carpio, M. Adaptation and Mitigation to Climate Change of Envelope Wall Thermal Insulation of Residential Buildings in a Temperate Oceanic Climate. Energy Build. 2021, 235, 110719. [Google Scholar] [CrossRef]

- Luo, Y.; Cui, D.; Cheng, N.; Zhang, S.; Su, X.; Chen, X.; Tian, Z.; Deng, J.; Fan, J. A Novel Active Building Envelope with Reversed Heat Flow Control through Coupled Solar Photovoltaic-Thermoelectric-Battery Systems. Build. Environ. 2022, 222, 109401. [Google Scholar] [CrossRef]

- Huang, X.; Li, F.; Liu, Z.; Gao, X.; Yang, X.; Yan, J. Design and Optimization of a Novel Phase Change Photovoltaic Thermal Utilization Structure for Building Envelope. Renew. Energy 2023, 218, 119269. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, J.; Cai, J.; Li, S.; He, Q. Simulation-Based Trade-off Modeling for Indoor Infection Risk of Airborne Diseases, Energy Consumption, and Thermal Comfort. J. Build. Eng. 2023, 76, 107137. [Google Scholar] [CrossRef]

- Assimakopoulos, M.-N.; De Masi, R.F.; Fotopoulou, A.; Papadaki, D.; Ruggiero, S.; Semprini, G.; Vanoli, G.P. Holistic Approach for Energy Retrofit with Volumetric Add-Ons toward nZEB Target: Case Study of a Dormitory in Athens. Energy Build. 2020, 207, 109630. [Google Scholar] [CrossRef]

- Razmi, A.; Rahbar, M.; Bemanian, M. PCA-ANN Integrated NSGA-III Framework for Dormitory Building Design Optimization: Energy Efficiency, Daylight, and Thermal Comfort. Appl. Energy 2022, 305, 117828. [Google Scholar] [CrossRef]

- Sugár, V.; Talamon, A.; Horkai, A.; Kita, M. Energy Saving Retrofit in a Heritage District: The Case of the Budapest. J. Build. Eng. 2020, 27, 100982. [Google Scholar] [CrossRef]

- Qu, K.; Chen, X.; Wang, Y.; Calautit, J.; Riffat, S.; Cui, X. Comprehensive Energy, Economic and Thermal Comfort Assessments for the Passive Energy Retrofit of Historical Buildings—A Case Study of a Late Nineteenth-Century Victorian House Renovation in the UK. Energy 2021, 220, 119646. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.; Zhang, W. Simulation-Based Approach to Optimize Passively Designed Buildings: A Case Study on a Typical Architectural Form in Hot and Humid Climates. Renew. Sustain. Energy Rev. 2018, 82, 1712–1725. [Google Scholar] [CrossRef]

- Lamberti, G.; Contrada, F.; Kindinis, A. Exploring Adaptive Strategies to Cope with Climate Change: The Case Study of Le Corbusier’s Modern Architecture Retrofitting. Energy Build. 2024, 302, 113756. [Google Scholar] [CrossRef]

- Asdrubali, F.; Grazieschi, G. Life Cycle Assessment of Energy Efficient Buildings. Energy Rep. 2020, 6, 270–285. [Google Scholar] [CrossRef]

- Zhan, J.; He, W.; Huang, J. Comfort, Carbon Emissions, and Cost of Building Envelope and Photovoltaic Arrangement Optimization through a Two-Stage Model. Appl. Energy 2024, 356, 122423. [Google Scholar] [CrossRef]

- Jami, S.; Forouzandeh, N.; Zomorodian, Z.S.; Tahsildoost, M.; Khoshbakht, M. The Effect of Occupant Behaviors on Energy Retrofit: A Case Study of Student Dormitories in Tehran. J. Clean. Prod. 2021, 278, 123556. [Google Scholar] [CrossRef]

- Moazzen, N.; Karagüler, M.E.; Ashrafian, T. Comprehensive Parameters for the Definition of Nearly Zero Energy and Cost Optimal Levels Considering the Life Cycle Energy and Thermal Comfort of School Buildings. Energy Build. 2021, 253, 111487. [Google Scholar] [CrossRef]

- Roberti, F.; Oberegger, U.F.; Lucchi, E.; Troi, A. Energy Retrofit and Conservation of a Historic Building Using Multi-Objective Optimization and an Analytic Hierarchy Process. Energy Build. 2017, 138, 1–10. [Google Scholar] [CrossRef]

- Sharif, S.A.; Hammad, A. Simulation-Based Multi-Objective Optimization of Institutional Building Renovation Considering Energy Consumption, Life-Cycle Cost and Life-Cycle Assessment. J. Build. Eng. 2019, 21, 429–445. [Google Scholar] [CrossRef]

- Su, X.; Huang, Y.; Chen, C.; Xu, Z.; Tian, S.; Peng, L. A Dynamic Life Cycle Assessment Model for Long-Term Carbon Emissions Prediction of Buildings: A Passive Building as Case Study. Sustain. Cities Soc. 2023, 96, 104636. [Google Scholar] [CrossRef]

- Ashrafian, T. Enhancing School Buildings Energy Efficiency under Climate Change: A Comprehensive Analysis of Energy, Cost, and Comfort Factors. J. Build. Eng. 2023, 80, 107969. [Google Scholar] [CrossRef]

- Kadrić, D.; Aganović, A.; Kadrić, E. Multi-Objective Optimization of Energy-Efficient Retrofitting Strategies for Single-Family Residential Homes: Minimizing Energy Consumption, CO2 Emissions and Retrofit Costs. Energy Rep. 2023, 10, 1968–1981. [Google Scholar] [CrossRef]

- Rosso, F.; Ciancio, V.; Dell’Olmo, J.; Salata, F. Multi-Objective Optimization of Building Retrofit in the Mediterranean Climate by Means of Genetic Algorithm Application. Energy Build. 2020, 216, 109945. [Google Scholar] [CrossRef]

- Wang, C.; Kilkis, S.; Tjernström, J.; Nyblom, J.; Martinac, I. Multi-Objective Optimization and Parametric Analysis of Energy System Designs for the Albano University Campus in Stockholm. Procedia Eng. 2017, 180, 621–630. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, C.; Chen, L.; Qiu, L.; Wu, W.; Wang, Q. Using BIM and LCA to Calculate the Life Cycle Carbon Emissions of Inpatient Building: A Case Study in China. Sustainability 2024, 16, 5341. [Google Scholar] [CrossRef]

- GB 50189-2015; Design Standard for Energy Efficiency of Public Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2015.

- Buratti, C.; Moretti, E.; Belloni, E.; Cotana, F. Unsteady Simulation of Energy Performance and Thermal Comfort in Non-Residential Buildings. Build. Environ. 2013, 59, 482–491. [Google Scholar] [CrossRef]

- Pan, Y. Building Energy Simulation Handbook; Chinese Architecture Publishing & Media Co., Ltd.: Beijing, China, 2013; Volume 43, p. 11. [Google Scholar]

- Xu, W. Study on the Correlation between Occupancy Characteristic and Air Conditioning Behavior during Cooling Season of College Students’ Dormitory in Chongqing. Master’s Thesis, Chongqing University, Chongqing, China, 2022. [Google Scholar]

- Feng, G.; Chen, F.; Chang, S. Multi-objective optimization of envelope structure for near zero energy building. J. Shenyang Jianzhu Univ. (Nat. Sci.) 2023, 39, 699–706. [Google Scholar] [CrossRef]

- Liu, M. Optimization Study on Energy Efficiency Technologies of High-Rise Residental in Xi’an Based on Simulation Technique. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2020. [Google Scholar]

- State Grid Zhejiang Electric Power Co., Ltd. Available online: https://www.zj.sgcc.com.cn/p1/index.html (accessed on 11 March 2024).

- Xie, F.; Wu, Y.; Zhou, X.; Zhang, S. Analysis of Standard Unit Carbon Emission and Cost Assessment of the Changing Building Envelope over Material Production Phase. Sci. Total Environ. 2024, 928, 172382. [Google Scholar] [CrossRef] [PubMed]

- GB/T 51366-2019; Building Carbon Emission Calculation Standard. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Mao, C.; Tao, X.; Yang, H.; Chen, R.; Liu, G. Real-Time Carbon Emissions Monitoring Tool for Prefabricated Construction: An IoT-Based System Framework. In Proceedings of the International Conference on Construction and Real Estate Management 2018, Charleston, SC, USA, 9–10 August 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 121–127. [Google Scholar]

- GB 50176-2016; Code for Thermal Design of Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- Su, X. Life Cycle Inventory Comparison of Different Building Insulation Materials and Uncertainty Analysis. J. Clean. Prod. 2016, 112, 275–281. [Google Scholar] [CrossRef]

- Ma, L.; Jiang, Q.; Zhao, C. Life Cycle Assessment of Typical Rock Wood Board Production in China. J. Wuhan Univ. Technol. 2013, 35, 43–47. [Google Scholar] [CrossRef]

- Huang, J. Research on Comparative of Carbon Emissions during the Life Cycle of External Wall Insulation Systems in Cold Regions. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2024. [Google Scholar]

- GB/T 51350-2019; Technical Standard for Near Zero Energy Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Zhang, L.; Liu, Z.; Hou, C.; Hou, J.; Wei, D.; Hou, Y. Optimization Analysis of Thermal Insulation Layer Attributes of Building Envelope Exterior Wall Based on DeST and Life Cycle Economic Evaluation. Case Stud. Therm. Eng. 2019, 14, 100410. [Google Scholar] [CrossRef]

- Shadram, F.; Bhattacharjee, S.; Lidelöw, S.; Mukkavaara, J.; Olofsson, T. Exploring the Trade-off in Life Cycle Energy of Building Retrofit through Optimization. Appl. Energy 2020, 269, 115083. [Google Scholar] [CrossRef]

- Fu, M. Fundamental Research on Prefabricated Residential Building Envelope Based on Thermodynamic Method. Master’s Thesis, Hunan University, Changsha, China, 2018. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Stories | 6 | / |

| Building total height | 21 | m |

| Window opening area | 583.92 | m2 |

| Gross roof area | 702.24 | m2 |

| Gross wall area | 2210.40 | m2 |

| Gross total area | 4213.44 | m2 |

| Gross area of typical floor | 702.24 | m2 |

| Floor height | 3 | m |

| Gross window-to-wall ratio | 26.42 | % |

| Envelope Structure | Thickness and Material of Each Layer (From Outside to Inside) | Thermal Conductivity K [W/(m·K)] |

|---|---|---|

| Roof | 50 mm C20 concrete + 6 mm waterproof coil + 10 mm cement mortar + 120 mm reinforced concrete roof panel + 10 mm cement mortar | 3.376 |

| Window | Aluminum alloy ordinary hollow window | 4.2 |

| Wall | 2 mm paint + 5 mm cement mortar + 200 mm concrete block | 0.965 |

| Open Date | Opening Time | |

|---|---|---|

| Spring Semester (Summer) | 1 July–15 August | 12:00 a.m.–14:00 p.m./18:30 p.m.–8:00 a.m. |

| Summer Semester (Winter) | 1 December–15 January | 12:00 a.m.–14:00 p.m./18:30 p.m.–8:00 a.m. |

| Time and Room Ratio | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Room ratio | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 50% | 20% | 20% | 20% | 50% |

| Time | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| Room ratio | 100% | 100% | 20% | 20% | 50% | 50% | 70% | 70% | 70% | 90% | 100% | 100% |

| Summer | Winter | ||||

|---|---|---|---|---|---|

| Cooling Capacity (W) | Cooling Power (W) | Cooling Energy Consumption Ratio | Heating Capacity (W) | Heating Power (W) | Heating Energy Consumption Ratio |

| 3500 | 1080 | 3.28 | 3850 | 1120 | 3.44 |

| Type | Thickness (mm) | Costs (USD/m2) | |

|---|---|---|---|

| Ordinary | Aluminium alloy plate glass window | 3 + 6A + 3 | 66.14 |

| Retrofitted | Broken heat aluminum alloy hollow glass window | 3 + 12A + 3 | 110.23 |

| Low-E insulating glass window of aluminum alloy | 5 + 12A + 3 | 80.83 | |

| PVC plastic steel Low-E hollow glass window | 5 + 12A + 3 | 124.92 | |

| PVC plastic steel hollow glass window | 3 + 12A + 3 | 80.83 |

| Structure | Type | Carbon Emission Factor (kg CO2 e/m2) |

|---|---|---|

| Window | Aluminum–wood composite window | 147 |

| Broken hot aluminum alloy window | 254 | |

| PVC plastic steel window | 121 | |

| Glass | Ordinary insulating glass | 15.6 |

| Insulating glass | 23.45 | |

| Low-E glass | 24.12 |

| Type | Thermal Conductivity ([W/(m·K)]) | Energy Consumption (MJ/kg) | Density (kg/m3) | Carbon Emission Factor (kg CO2 e/t) |

|---|---|---|---|---|

| EPS | 0.041 | 102.9 | 18~22 | 5020 |

| PU | 0.024 | 87.3 | 40 | 5220 |

| RW | 0.04 | 37.8 | 140 | 1980 |

| XPS | 0.03 | 85.4 | 30 | 6120 |

| Climatic Region | Thermal Conductivity/[W/(m·K)] | ||

|---|---|---|---|

| Exterior Wall | Roof | Exterior Window | |

| Hot summer and cold winter zone | 0.15~0.40 | 0.15~0.35 | ≤2.0 |

| Ri([(m2·K)/W]) | Re ([(m2·K)/W]) | |

|---|---|---|

| / | Summer | Winter |

| 0.11 | 0.05 | 0.04 |

| Exterior Wall | Exterior Roof | |||||

|---|---|---|---|---|---|---|

| Type | Initial Thickness (mm) | Thickness Interval (mm) | Thickness Replacement (mm) | Initial Thickness (mm) | Thickness Interval (mm) | Thickness Replacement (mm) |

| XPS | 50 | 50–160 | 20 | 80 | 80–190 | 10 |

| EPS | 60 | 60–220 | 20 | 110 | 110–260 | 10 |

| PU | 40 | 40–130 | 20 | 70 | 70–150 | 10 |

| RW | 50 | 30–200 | 20 | / | / | / |

| Type | Relation | R2 | Limit Thickness (mm) | Specification Range (mm) | Optimum Thickness (mm) |

|---|---|---|---|---|---|

| XPS | y = 0.0012x2 − 0.3117x + 557.91 | 96.79% | 130 | [40,165] | 130 |

| EPS | y = 0.0007x2 − 0.23x + 556.94 | 95.57% | 164 | [55,226] | 164 |

| PU | y = 0.002x2 − 0.4057x + 557.7 | 95.64% | 101 | [32,132] | 101 |

| RW | y = 0.0006x2 − 0.2284x + 556.8 | 95.06% | 190 | [54,220] | 190 |

| XPS (mm) | EPS (mm) | PU (mm) | ||||

|---|---|---|---|---|---|---|

| Life Cycle Energy Assessment | 177.73 | 85.60 | 116.01 | 263.99 | 199.42 | 59.91 |

| Life Cycle Carbon Emissions Assessment | 64.87 | 178.88 | 96.94 | 237.99 | 42 | 540.21 |

| Life Cycle Cost Assessment | 24 | 254 | 68.66 | 309.20 | 21.10 | 211.44 |

| Optimal thickness | 179 | 238 | 62 | |||

| Configuration of Envelope Structure | Life Cycle Energy Assessment (GJ) | Life Cycle Carbon Emissions Assessment (×103 kg CO2e) | Life Cycle Costs Assessment (×103 USD) | |

|---|---|---|---|---|

| Ordinary | / | 560.08 | 165.24 | 104.57 |

| Retrofit-1 | Wall (164 mm EPS) + window (DRLow-E) + roof (62 mm PU) | 381.99 | 259.73 | 120.86 |

| Retrofit-2 | Wall (55 mm EPS) + window (DRLow-E) + roof (62 mm PU) | 391.84 | 238.16 | 121.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, F.; Wu, Y.; Wang, X.; Zhou, X. Optimization Strategies for the Envelope of Student Dormitories in Hot Summer and Cold Winter Regions: Multi-Criteria Assessment Method. Sustainability 2024, 16, 6172. https://doi.org/10.3390/su16146172

Xie F, Wu Y, Wang X, Zhou X. Optimization Strategies for the Envelope of Student Dormitories in Hot Summer and Cold Winter Regions: Multi-Criteria Assessment Method. Sustainability. 2024; 16(14):6172. https://doi.org/10.3390/su16146172

Chicago/Turabian StyleXie, Fangyuan, Yi Wu, Xinqi Wang, and Xiling Zhou. 2024. "Optimization Strategies for the Envelope of Student Dormitories in Hot Summer and Cold Winter Regions: Multi-Criteria Assessment Method" Sustainability 16, no. 14: 6172. https://doi.org/10.3390/su16146172

APA StyleXie, F., Wu, Y., Wang, X., & Zhou, X. (2024). Optimization Strategies for the Envelope of Student Dormitories in Hot Summer and Cold Winter Regions: Multi-Criteria Assessment Method. Sustainability, 16(14), 6172. https://doi.org/10.3390/su16146172