Smart Manufacturing and Enterprise Breakthrough Innovation: Co-Existence Test of “U-Shaped” and Inverted “U-Shaped” Relationships in Chinese Listed Companies

Abstract

:1. Introduction

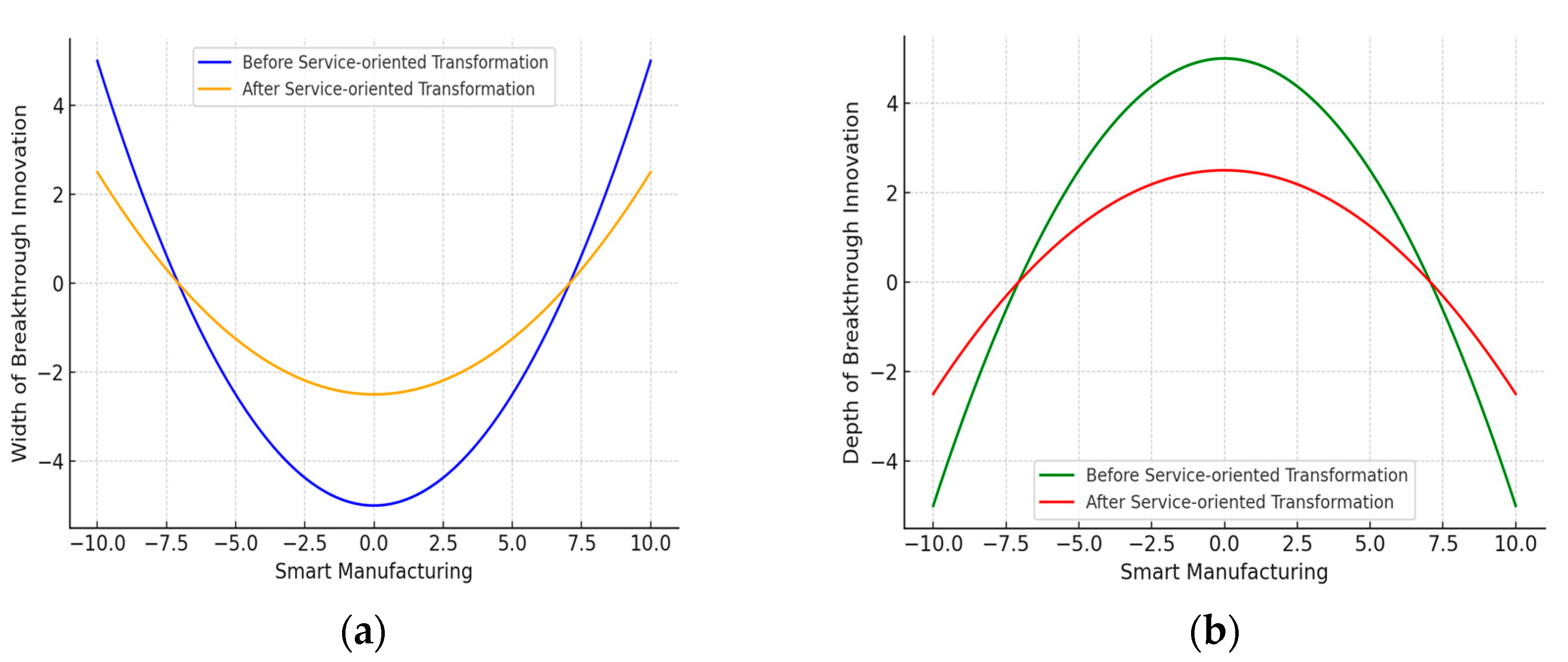

- RQ1. What differential impacts does smart manufacturing have on the width and depth of enterprise breakthrough innovation?

- RQ2. How does the service-oriented transformation of enterprises affect the relationship between smart manufacturing and both the width and depth of enterprise breakthrough innovation?

2. Theoretical Analysis and Research Hypotheses

2.1. Theoretical Analysis

2.2. Research Hypothesis

2.2.1. Smart Manufacturing and Enterprise Breakthrough Innovation

2.2.2. The Moderating Effect of Service-Oriented Transformation

3. Research Methodology

3.1. Data Sources

3.2. Measures

3.2.1. Dependent Variable: Breakthrough Innovation

3.2.2. Independent Variable: Smart Manufacturing

3.2.3. Moderator Variable: Service-Oriented Transformation

3.2.4. Control Variables

3.3. Empirical Model

4. Results

4.1. Benchmark Regression

4.2. Robustness Test

4.2.1. Re-Measuring Key Variables

4.2.2. Lagging Smart Manufacturing

4.2.3. Endogeneity Problem Handling

4.3. Heterogeneity Analysis

4.3.1. High-Tech Enterprises vs. Non-High-Tech Enterprises

4.3.2. Larger Market Size vs. Smaller Market Size

5. Discussion and Conclusions

5.1. Discussion

5.2. Conclusions

5.3. Management Implications

5.4. Limitations and Future Research

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luisa, T.T.; Indiraa, E.S.; Bernardo, G.O. On developing a green and intelligent manufacturing system. Expert Syst. Appl. 2024, 243, 122876. [Google Scholar]

- Purusottama, A.; Simatupang, T.M.; Sunitiyoso, Y. The spectrum of blockchain adoption for developing business model innovation. Bus. Process. Manag. J. 2022, 28, 834–855. [Google Scholar] [CrossRef]

- Wang, Z.X.; Shou, M.H.; Wang, S.; Dai, R.N.; Wang, K.Q. An Empirical Study on the Key Factors of Intelligent Upgrade of Small and Medium-sized Enterprises in China. Sustainability 2019, 11, 619. [Google Scholar] [CrossRef]

- Li, M.F.; Liu, Y.J. The influence of digital innovation ecosystem of high-end equipment manufacturing on the intelligent maturity of enterprise—An empirical study on the configuration of the “three-layer core-periphery” structure. Bus. Process. Manag. J. 2023, 30, 199–221. [Google Scholar] [CrossRef]

- Sun, L.P.; Saat, N.A.M. How Does Intelligent Manufacturing Affect the ESG Performance of Manufacturing Firms? Evidence from China. Sustainability 2023, 15, 4. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Bai, Y.L.; Zhang, L.X. Sustainable Development of the Rural Labor Market in China from the Perspective of Occupation Structure Transformation. Sustainability 2024, 16, 2938. [Google Scholar] [CrossRef]

- Huang, G.C.; Ma, L.L.; Xietian, Z.G. Servitization of manufacturing and China’s power status upgrading of global value network. Struct. Change Econ. Dyn. 2024, 68, 313–328. [Google Scholar] [CrossRef]

- Kohtamäki, M. Sustainable servitization in product manufacturing companies: The relationship between firm’s sustainability emphasis and profitability and the moderating role of servitization. Technovation 2024, 129, 102907. [Google Scholar] [CrossRef]

- Abudureheman, M.; Jiang, Q.Z.; Gong, J.; Yiming, A. Estimating and Decomposing the TFP Growth of Service-Oriented Manufacturing in China: A Translogarithmic Stochastic Frontier Approach. Sustainability 2023, 15, 6027. [Google Scholar] [CrossRef]

- Wang, Y.; Han, P. Digital Transformation, Service-Oriented Manufacturing, and Total Factor Productivity: Evidence from A-Share Listed Companies in China. Sustainability 2023, 15, 9974. [Google Scholar] [CrossRef]

- Momeni, B.; Rapaccini, M.; Martinsuo, M. Manufacturers managing complexity during the digital servitization journey. J. Manuf. Technol. Manag. 2024, 35, 51–72. [Google Scholar] [CrossRef]

- Liu, J.; Chang, H.H.; Lin, Y.; Yang, B.H. Influence of artificial intelligence on technological innovation: Evidence from the panel data of China’s manufacturing sectors. Technol. Forecast. Soc. Change 2020, 158, 120–142. [Google Scholar] [CrossRef]

- Wang, W.G.; Gao, G.D.; Agarwal, R. Friend or Foe? Teaming Between Artificial Intelligence and Workers with Variation in Experience. Manage. Sci. 2023, 10, 1–23. [Google Scholar] [CrossRef]

- Mitchell, R. Suspicion, inclusive leadership and team innovation: A motivated information processing approach. J. Bus. Res. 2024, 172, 114399. [Google Scholar] [CrossRef]

- Sharma, A. Supply base concentration and firm innovation performance: A contingency study of supply base breadth, depth, dispersion, and collaboration. J. Bus. Res. 2024, 174, 114450. [Google Scholar] [CrossRef]

- Liu, H.D.; Zhao, H.F. Upgrading models, evolutionary mechanisms and vertical cases of service-oriented manufacturing in SVC leading enterprises: Product-development and service-innovation for industry 4.0. Hum. Soc. Sci. Commun. 2022, 9, 387. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, W.F.; Guan, T. Evolutionary game study on multi-agent collaboration of digital transformation in service-oriented manufacturing value chain. Electron. Commer. Res. 2022, 23, 2217–2238. [Google Scholar] [CrossRef]

- Tang, G.H.; Mai, H.X. How Does Manufacturing Intelligentization Influence Innovation in China from a Nonlinear Perspective and Economic Servitization Background? Sustainability 2022, 14, 14032. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and Smart Manufacturing: An Integrated Approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Sajadieh, S.M.M.; Son, Y.H.; Noh, S.D.A. Conceptual Definition and Future Directions of Urban Smart Factory for Sustainable Manufacturing. Sustainability 2022, 14, 1221. [Google Scholar] [CrossRef]

- Zhou, J.; Guo, A.F.; Chen, Y.T.; Chen, J. Original Innovation through Inter-Organizational Collaboration: Empirical Evidence from University-Focused Alliance Portfolio in China. Sustainability 2022, 14, 6162. [Google Scholar] [CrossRef]

- Klaic, M.; Fong, J.; Crocher, V.; Davies, K. Application of the extended technology acceptance model to explore clinician likelihood to use robotics in rehabilitation. Disabil. Rehabil. Assist. Technol. 2024, 19, 52–59. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.K.; Qian, C.; Chen, J.L. How does intelligent manufacturing reconcile the conflict between process standards and technological innovation? J. Eng. Technol. Manage. 2022, 65, 101698. [Google Scholar] [CrossRef]

- Takahashi, C.K. Investigating the diffusion of innovation: A comprehensive study of successive diffusion processes through analysis of search trends, patent records, and academic publications. Technol. Forecast. Soc. Change 2024, 198, 122991. [Google Scholar] [CrossRef]

- D’Souza, G.C.; Pinto, C.N.; Exten, C. Understanding factors associated with COVID-19 vaccination among healthcare workers using the diffusion of innovations theory. Am. J. Infect. Control. 2024, 52, 509–516. [Google Scholar] [CrossRef] [PubMed]

- Fabra, I.T.; Ghobadian, A.; Troise, C. Antecedents of successful diffusion of breakthrough innovations past the formative phase: Perceptions of innovation-engaged practitioners. Technovation 2023, 127, 102851. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Hughes, L.; Ismagilova, E. Artificial Intelligence (AI): Multidisciplinary perspectives on emerging challenges, opportunities, and agenda for research, practice and policy. Int. J. Inf. Manage. 2021, 57, 101994. [Google Scholar] [CrossRef]

- Wang, Q.L.; Jiang, Q.Q.; Yu, H.X. Analysis of the Influence of Entrepreneurial Apprehension and Entrepreneurial Strategic Sustainability Orientation on Breakthrough Innovation. Sustainability 2023, 15, 7320. [Google Scholar] [CrossRef]

- Byun, S.K.; Oh, J.M.; Xia, H. Incremental vs. Breakthrough Innovation: The Role of Technology Spillovers. Manage. Sci. 2021, 67, 1779–1802. [Google Scholar] [CrossRef]

- Johnson, P.C.; Laurell, C.; Ots, M. Digital innovation and the effects of artificial intelligence on firms’ research and development–Automation or augmentation, exploration or exploitation? Technol. Forecast. Soc. Change 2022, 179, 121636. [Google Scholar] [CrossRef]

- Lee, C.C.; Qin, S.; Li, Y.Y. Does industrial robot application promote green technology innovation in the manufacturing industry? Technol. Forecast. Soc. Change 2022, 183, 121893. [Google Scholar] [CrossRef]

- Spencer, L.; Tanner, A.; Lu, K. Using Diffusion of Innovation Theory to Address Health of the Homeless in Hawaii. Healthcare 2023, 11, 2828. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.T.; Park, Y.R.; Kwak, J. Knowledge distance and innovation performance: The moderating role of internationalization breadth and depth. Asian Bus. Manag. 2023, 22, 1131–1154. [Google Scholar] [CrossRef]

- Su, Y.; Chai, J.H.; Lu, S.C.; Lin, Z.Z. Evaluating Green Technology Innovation Capability in Intelligent Manufacturing Enterprises: A Z-number Based Model. IEEE Trans. Eng. Manage. 2024, 71, 5391–5409. [Google Scholar] [CrossRef]

- Ardolino, M.; Rapaccini, M.; Saccani, N. The role of digital technologies for the service transformation of industrial companies. Int. J. Prod. Res. 2018, 56, 2116–2132. [Google Scholar] [CrossRef]

- Kauffman, R.J.; Ma, D.; Yoo, B. Guest editorial: Market transformation to an IT-enabled services-oriented economy. Decis. Support Syst. 2015, 78, 65–66. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Literature Review of the Challenges and Opportunities of the Transition from Industry 4.0 to Society 5.0. Energies 2022, 15, 6276. [Google Scholar] [CrossRef]

- Paiola, M.; Gebauer, H. Internet of things technologies, digital servitization and business model innovation in BtoB manufacturing firms. Ind. Mark. Manage. 2020, 89, 245–264. [Google Scholar] [CrossRef]

- Tronvoll, B.; Sklyar, A.; Sörhammar, D.; Kowalkowski, C. Transformational shifts through digital servitization. Ind. Mark. Manage. 2020, 89, 293–305. [Google Scholar] [CrossRef]

- Makri, M.; Hitt, M.A.; Lane, P.J. Complementary technologies, knowledge relatedness, and invention outcomes in high technology mergers and acquisitions. Strateg. Manage. J. 2010, 31, 602–628. [Google Scholar] [CrossRef]

- Ahuja, G. Collaboration Networks, Structural Holes, and Innovation: A Longitudinal Study. Adm. Sci. Q. 2000, 45, 425–455. [Google Scholar] [CrossRef]

- Benjamin, B.; Lee, F.; Gustavo, M. Independent Boards and Innovation. J. Financ. Econ. 2017, 123, 536–557. [Google Scholar]

- Zhang, Y.; Qian, Y.; Huang, Y.; Guo, Y.; Zhang, G.Q.; Lu, J. An entropy-based indicator system for measuring the potential of patents in technological innovation: Rejecting moderation. Scientometrics 2017, 111, 1925–1946. [Google Scholar] [CrossRef]

- Fontana, R. Reassessing patent propensity: Evidence from a dataset of R&D awards, 1977-2004. Res. Policy 2013, 42, 1780–1792. [Google Scholar]

- Criscuolo, P.; Verspagen, B. Does it matter where patent citations come from? Inventor vs. examiner citations in European patents. Res. Policy 2008, 37, 1892–1908. [Google Scholar]

- Acemoglu, D.; Restrepo, P. Low-skill and high-skill automation. J. Hum. Cap. 2018, 12, 204–232. [Google Scholar] [CrossRef]

- Ying, L.M.; Liu, X.J.; Li, M.H.; Sun, L.P.; Xiu, P.S. How does intelligent manufacturing affects enterprise innovation? The mediating role of organisational learning. Enterp. Inf. Syst. 2022, 16, 630–667. [Google Scholar] [CrossRef]

- Chen, S.Q.; Zhang, H. Does digital finance promote manufacturing servitization: Micro evidence from China. Int. Rev. Econ. Financ. 2021, 76, 856–869. [Google Scholar] [CrossRef]

- Pham, P.; Zhang, H.L.; Gao, W.L. Determinants and performance outcomes of artificial intelligence adoption: Evidence from US Hospitals. J. Bus. Res. 2024, 172, 114402. [Google Scholar] [CrossRef]

| Type | Variable Name | Symbol | Variable Measurement | Mean | Standard Deviation |

|---|---|---|---|---|---|

| Independent variable | Smart Manufacturing | AI | Industrial robot penetration | 6.823 | 4.035 |

| Dependent variables | Breakthrough innovation width one | innov-width1 | Enterprise t annual breakthrough innovation level based on the dispersion of patented technology | 1 | 0 |

| Breakthrough innovation width two | innov-width2 | Log (number of new patent technology categories entered by a business in five years) | 0.462 | 0.248 | |

| Breakthrough innovation width three | innov-width3 | Log (number of patent applications under the category of newly entered patent technologies in t years of enterprise) | 1.434 | 0.679 | |

| Breakthrough innovation depth one | innov-depth1 | Ln (number of citations of a patent by other later categories of patents and take logarithm +1) | 0.012 | 0.094 | |

| Breakthrough innovation depth two | innov-depth2 | Ln (number of other categories of patents cited by a patent +1) | 1.074 | 1.454 | |

| Moderator variable | Servitization transformation | Ser | Service business revenue as a percentage of total operating revenue (%) | 0.366 | 0.891 |

| Control variables | Return on total assets | ROA | Net profit/total assets | 0.03 | 0.512 |

| Asset–liability ratio | LEV | Total liabilities/total assets | 0.431 | 1.349 | |

| Capital structure | Capital | Total liabilities/total assets | 0.431 | 1.35 | |

| Cash flow level | Cash | Ratio of net cash flows from operating activities to total assets | 0.048 | 0.079 | |

| Capital intensity | Fix | Ln (ratio of total fixed assets to number of employees +1) | 1.134 | 0.03 | |

| Book-to-market ratio | BMR | Ratio of shareholders’ equity to the company’s market value | 0.334 | 0.167 | |

| Ownership concentration | Share 10 | Sum of shares held by the top 10 shareholders | 0.572 | 0.15 |

| Variables | Breakthrough Innovation | ||||

|---|---|---|---|---|---|

| Width of Breakthrough Innovation | Depth of Breakthrough Innovation | ||||

| innov-width1 | innov-width2 | innov-width3 | innov-depth1 | innov-depth2 | |

| (1) | (2) | (3) | (4) | (5) | |

| AI | −0.045 ** (−2.881) | −0.061 ** (−3.463) | −0.044 ** (−2.827) | 0.065 ** (2.579) | 0.055 * (2.047) |

| AI2 | 0.078 ** (4.957) | 0.109 ** (6.189) | 0.065 ** (4.178) | −0.100 ** (−3.980) | −0.106 ** (−3.928) |

| ROA | 0.021 ** (3.765) | 0.022 ** (3.544) | −0.000 (−0.072) | 0.032 ** (3.521) | 0.033 ** (3.418) |

| LEV | −29.000 (−0.971) | 9.473 (0.283) | 0.012 (0.000) | −2.630 (−0.055) | −22.860 (−0.444) |

| Capital | 29.095 (0.974) | −9.345 (−0.280) | 0.043 (0.001) | 2.557 (0.053) | 22.800 (0.443) |

| Cash | 0.015 ** (2.873) | 0.020 ** (3.460) | 0.011 * (2.159) | −0.019 * (−2.329) | −0.038 ** (−4.175) |

| Fix | 0.133 ** (16.723) | 0.166 ** (18.672) | 0.083 ** (10.586) | −0.141 ** (−11.070) | −0.151 ** (−11.014) |

| BMR | 0.056 ** (8.492) | 0.090 ** (12.165) | 0.039 ** (5.951) | −0.009 (−0.824) | −0.027 * (−2.396) |

| Share 10 | −0.019 * (−2.359) | −0.062 ** (−7.026) | −0.016* (−2.108) | 0.165 ** (12.967) | 0.149 ** (10.867) |

| Year/Firm | Control | Control | Control | Control | Control |

| F | 68.943 | 106.867 | 30.321 | 67.336 | 57.951 |

| N | 22,096 | 22,096 | 22,096 | 22,096 | 22,096 |

| R2 | 0.031 | 0.047 | 0.014 | 0.03 | 0.026 |

| Variables | Breakthrough Innovation | ||||

|---|---|---|---|---|---|

| Width of Breakthrough Innovation | Depth of Breakthrough Innovation | ||||

| innov-width1 | innov-width2 | innov-width3 | innov-depth1 | innov-depth2 | |

| (1) | (2) | (3) | (4) | (5) | |

| AI | −0.018 ** (−1.205) | −0.061 ** (−3.468) | −0.043 ** (−2.794) | 0.065 ** (2.595) | 0.056 * (2.062) |

| AI2 | 0.007 ** (1.467) | 0.109 ** (6.190) | 0.064 ** (4.130) | −0.101 ** (−3.999) | −0.107 ** (−3.942) |

| Ser | 0.001 ** (1.247) | 0.021 ** (3.259) | 0.013* (2.220) | 0.014* (1.450) | 0.036 ** (3.551) |

| AI×Ser | −0.007 ** (−1.519) | −0.017 ** (−1.015) | −0.009 ** (−1.606) | 0.016 ** (1.690) | 0.014 ** (1.552) |

| AI2×Ser | 0.005 * (1.361) | 0.019 * (1.164) | 0.004 * (1.265) | −0.021 * (−2.910) | −0.022 * (−2.906) |

| Control variables | Yes | Yes | Yes | Yes | Yes |

| Year/Firm | Control | Control | Control | Control | Control |

| F | 7.500 | 81.141 | 23.335 | 50.762 | 44.652 |

| N | 22,096 | 22,096 | 22,096 | 22,096 | 22,096 |

| R2 | 0.005 | 0.048 | 0.014 | 0.03 | 0.027 |

| Variables | Breakthrough Innovation | ||||

|---|---|---|---|---|---|

| Width of Breakthrough Innovation | Depth of Breakthrough Innovation | ||||

| innov-width1 | innov-width2 | innov-width3 | innov-depth1 | innov-depth2 | |

| (1) | (2) | (3) | (4) | (5) | |

| AI adoption | −0.093 ** (−3.481) | −0.234 ** (−7.094) | −0.088 ** (−3.136) | 0.074 ** (3.491) | 0.040 ** (3.125) |

| AI adoption2 | 0.016 ** (3.536) | 0.033 ** (5.836) | 0.011 * (2.383) | −0.569 ** (−3.741) | −0.274 ** (−4.008) |

| Control variables | Yes | Yes | Yes | Yes | Yes |

| Year/Firm | Control | Control | Control | Control | Control |

| F | 6.776 | 91.543 | 12.018 | 17.472 | 28.240 |

| N | 13,698 | 13,698 | 13,698 | 13,698 | 13,698 |

| R2 | 0.005 | 0.068 | 0.009 | 0.014 | 0.022 |

| Variables | Breakthrough Innovation (After Sample Change) | ||||

|---|---|---|---|---|---|

| Width of Breakthrough Innovation | Depth of Breakthrough Innovation | ||||

| innov-width1 | innov-width2 | innov-width3 | innov-depth1 | innov-depth2 | |

| (1) | (2) | (3) | (4) | (5) | |

| AI | −0.042 ** (−2.761) | −0.059 ** (−3.327) | −0.041 ** (−2.612) | 0.063 ** (2.401) | (2.401) (2.401) |

| AI2 | 0.073 ** (4.327) | 0.106 ** (6.012) | 0.061 ** (3.827) | −0.094 ** (−3.752) | −0.103 ** (−3.721) |

| Control variables | Yes | Yes | Yes | Yes | Yes |

| Year/Firm | Control | Control | Control | Control | Control |

| F | 66.321 | 104.872 | 31.247 | 68.214 | 58.304 |

| N | 22,096 | 22,096 | 22,096 | 22,096 | 22,096 |

| R2 | 0.029 | 0.046 | 0.015 | 0.032 | 0.027 |

| Variables | Breakthrough Innovation | ||||

|---|---|---|---|---|---|

| Width of Breakthrough Innovation | Depth of Breakthrough Innovation | ||||

| innov-width1 | innov-width2 | innov-width3 | innov-depth1 | innov-depth2 | |

| (1) | (2) | (3) | (4) | (5) | |

| AI lag one year | −0.012 * (−1.849) | −0.004 * (−1.817) | −0.002 * (−1.458) | 0.028 ** (4.098) | 0.015 ** (4.113) |

| AI2 lag one year | 0.019 * (1.292) | 0.001 * (2.373) | 0.000 * (1.624) | −0.003 ** (−5.501) | −0.001 ** (−5.451) |

| Control variables | Yes | Yes | Yes | Yes | Yes |

| Year/Firm | Control | Control | Control | Control | Control |

| F | 9.459 | 96.328 | 28.338 | 63.667 | 95.585 |

| N | 22,096 | 22,096 | 22,096 | 22,096 | 22,096 |

| R2 | 0.004 | 0.043 | 0.013 | 0.029 | 0.026 |

| Variables | Instrumental Variable First-Stage Regression | Instrumental Variable Second-Stage Regression | PSM-DID | ||||

|---|---|---|---|---|---|---|---|

| Smart Manufacturing | Width of Breakthrough Innovation | Depth of Breakthrough Innovation | |||||

| AI | innov-width1 | innov-width2 | innov-width3 | innov-depth1 | innov-depth2 | ||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | |

| New generation of artificial intelligence innovation and development pilot zone policy | 0.104 ** (1.300) | - | - | - | - | - | - |

| AI | - | −0.001 ** (-1.945) | −0.067 ** (-9.808) | −0.264 ** (-11.549) | 0.348 ** (11.147) | 0.703 ** (11.986) | 0.019 ** (5.300) |

| AI2 | - | 0.115 ** (1.950) | 0.004 ** (1.066) | 0.015 ** (1.2.92) | −0.020 ** (-1.2.20) | −0.040 ** (-1.3.41) | - |

| Ser | - | 0.262 (1.897) | 0.210 (6.186) | 0.281 (7.215) | −0.213 (-6.800) | −0.258 (-6.976) | - |

| AI×Ser | - | 0.291 ** (1.884) | 0.223 ** (5.905) | 0.314 ** (6.546) | 0.237 ** (6.222) | 0.287 ** (6.354) | - |

| AI2×Ser | - | 0.331 (1.864) | 0.248 ** (5.385) | 0.359 ** (5.778) | 0.269 ** (5.573) | 0.326 ** (5.668) | - |

| Control variables | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Year/Firm | Control | Control | Control | Control | Control | Control | Control |

| Exclusivity test | - | 15.101 | 299.784 | 154.388 | 59.037 | 72.790 | - |

| Weak instrumental variable test | - | 292.013 ** | 113.791 ** | 167.170 ** | 148.873 ** | 179.854 ** | - |

| N | 22,506 | 22,506 | 22,506 | 22,506 | 22,506 | 22,506 | 19,064 |

| R2 | 0.009 | 0.007 | 0.952 | 0.758 | 0.708 | 0.514 | 0.004 |

| Variables | High-Tech Enterprises | Non-High-Tech Enterprises | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width of Breakthrough Innovation | Depth of Breakthrough Innovation | Width of Breakthrough Innovation | Depth of Breakthrough Innovation | |||||||

| innov-width1 | innov-width2 | innov-width3 | innov-depth1 | innov-depth2 | innov-breadth1 | innov-breadth2 | innov-breadth3 | innov-depth1 | innov-depth2 | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | |

| AI | −0.008 * (−1.537) | −0.047 * (−2.318) | −0.045 ** (−2.664) | 0.067 * (2.351) | 0.043 * (1.409) | −0.033 (−0.753) | −0.104 ** (−2.804) | −0.078 * (−2.176) | 0.070 (1.258) | 0.019 * (1.982) |

| AI2 | 0.006 * (0.135) | 0.141 ** (3.774) | 0.105 ** (2.910) | −0.098 ** (−3.431) | −0.089 ** (−2.898) | 0.006 (0.135) | 0.095 ** (4.671) | 0.065 ** (3.796) | −0.127 * (−2.257) | 0.017 (1.323) |

| Controls | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Year/Firm | Control | Control | Control | Control | Control | Control | Control | Control | Control | Control |

| N | 17,185 | 17,185 | 17,185 | 17,185 | 17,185 | 4911 | 4911 | 4911 | 4911 | 4911 |

| R2 | 0.004 | 0.050 | 0.014 | 0.033 | 0.028 | 0.015 | 0.032 | 0.011 | 0.016 | 0.011 |

| Variables | Larger Market Size | Smaller Market Size | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width of Breakthrough Innovation | Depth of Breakthrough Innovation | Width of Breakthrough Innovation | Depth of Breakthrough Innovation | |||||||

| innov-breadth1 | innov-breadth2 | innov-breadth3 | innov-depth1 | innov-depth2 | innov-breadth1 | innov-breadth2 | innov-breadth3 | innov-depth1 | innov-depth2 | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | |

| AI | −0.035 ** (−1.623) | −0.058 * (−2.244) | −0.047 * (−2.213) | 0.070 * (1.805) | 0.053 * (2.364) | −0.010 (−1.612) | −0.031 (−1.089) | −0.035 (−1.315) | −0.033 (−1.303) | 0.043 (1.292) |

| AI2 | 0.022 ** (1.013) | 0.100 ** (3.829) | 0.065 ** (3.015) | −0.091* (−2.346) | −0.069 ** (−3.052) | 0.032 (1.029) | 0.044 (1.529) | 0.060* (2.256) | 0.034 (1.339) | −0.071 * (−2.126) |

| Controls | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Year/Firm | Control | Control | Control | Control | Control | Control | Control | Control | Control | Control |

| N | 9958 | 9958 | 9958 | 9958 | 9958 | 12,138 | 12,138 | 12,138 | 12,138 | 12,138 |

| R2 | 0.009 | 0.049 | 0.022 | 0.028 | 0.016 | 0.008 | 0.007 | 0.018 | 0.017 | 0.018 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guang, H.; Liu, Y.; Feng, J.; Wang, N. Smart Manufacturing and Enterprise Breakthrough Innovation: Co-Existence Test of “U-Shaped” and Inverted “U-Shaped” Relationships in Chinese Listed Companies. Sustainability 2024, 16, 6181. https://doi.org/10.3390/su16146181

Guang H, Liu Y, Feng J, Wang N. Smart Manufacturing and Enterprise Breakthrough Innovation: Co-Existence Test of “U-Shaped” and Inverted “U-Shaped” Relationships in Chinese Listed Companies. Sustainability. 2024; 16(14):6181. https://doi.org/10.3390/su16146181

Chicago/Turabian StyleGuang, Hui, Ying Liu, Jiao Feng, and Nan Wang. 2024. "Smart Manufacturing and Enterprise Breakthrough Innovation: Co-Existence Test of “U-Shaped” and Inverted “U-Shaped” Relationships in Chinese Listed Companies" Sustainability 16, no. 14: 6181. https://doi.org/10.3390/su16146181