Reviewing the Roles of AI-Integrated Technologies in Sustainable Supply Chain Management: Research Propositions and a Framework for Future Directions

Abstract

:1. Introduction

2. Theoretical Background

2.1. Supply Chains and Supply Chain Management (SCM)

2.2. Supply Chain Operation Reference (SCOR)

2.3. Sustainable Supply Chain Management (SSCM)

3. Methodology

3.1. Inclusion and Exclusion Criteria

3.2. Data Sampling Process

3.3. Bibliometric Study

3.4. Text Analysis Using Topic Modeling

4. Results and Analysis

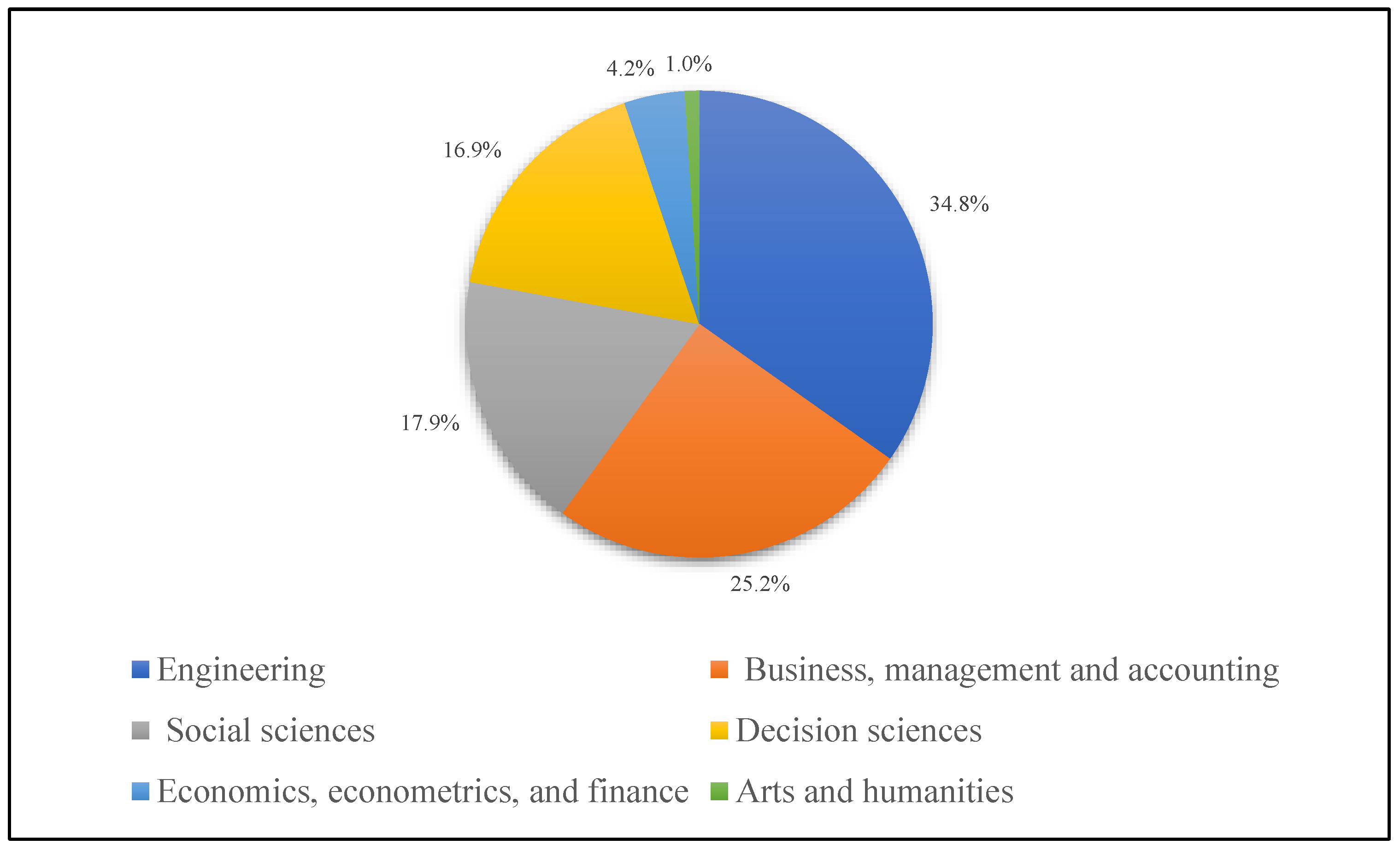

4.1. Bibliometric Analysis

4.1.1. Trend of Published Articles

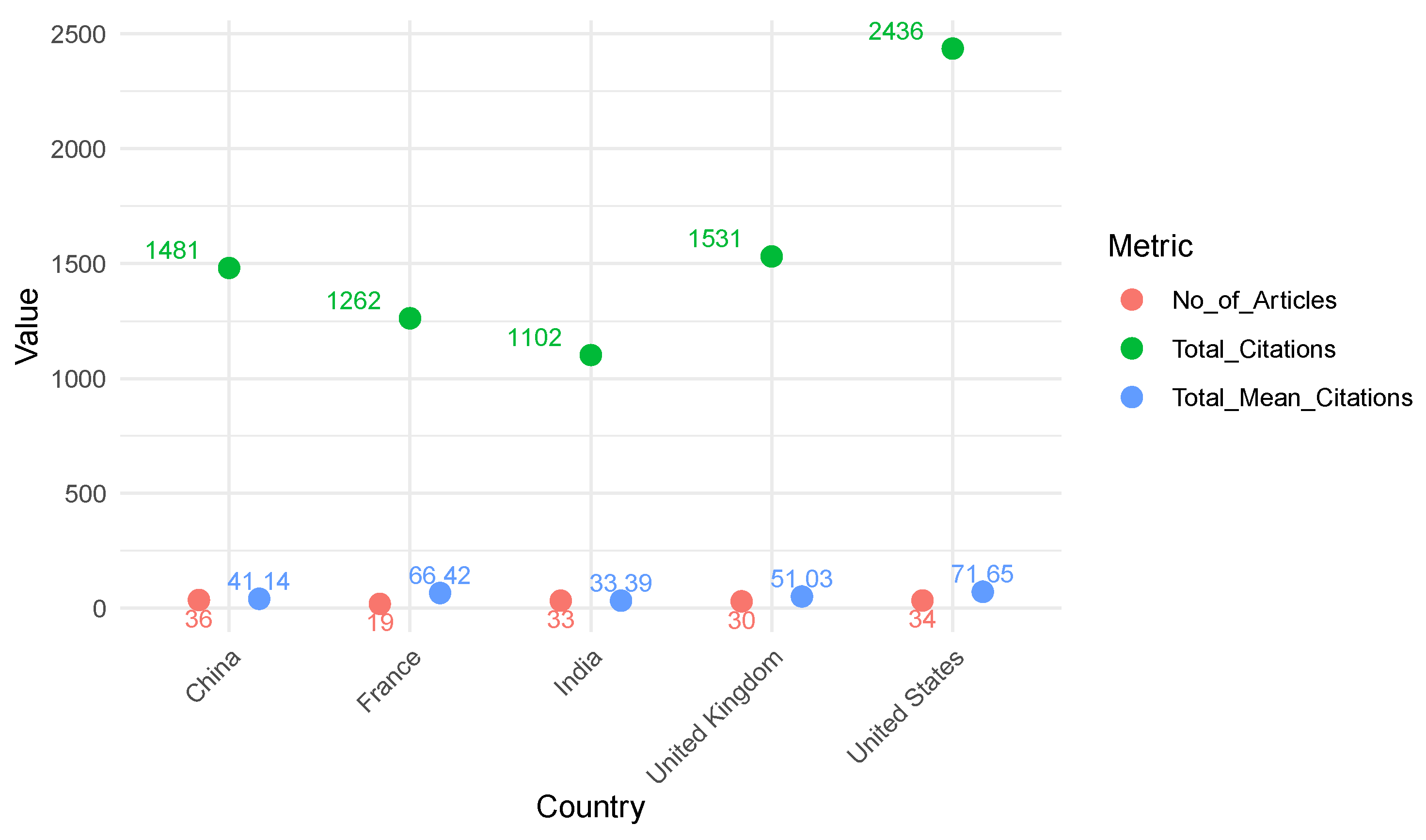

4.1.2. Country with Citation Statistics

4.1.3. Journal Statistics

4.1.4. Keyword Statistics

4.2. Text Analysis Using LDA Modeling

4.3. Propositions of Emerging Topics of AI in SSCM

4.3.1. Supplier Selection in SSCM

4.3.2. Optimizing Global SSCM through AI-Integrated Big Data

4.3.3. Food Sustainable Supply Chain Optimization

4.3.4. Smart Manufacturing in Supply Chains

4.3.5. Renewable Energy in Supply Chains

4.3.6. Transportation Optimization and Environmental Management in Supply Chains

4.3.7. Decision Support in Supply Chains

4.3.8. Sustainable Logistics Management and System Integration

4.3.9. Data-Driven Risk Management in Disruptions

4.3.10. Environmental Management in Construction Supply Chains

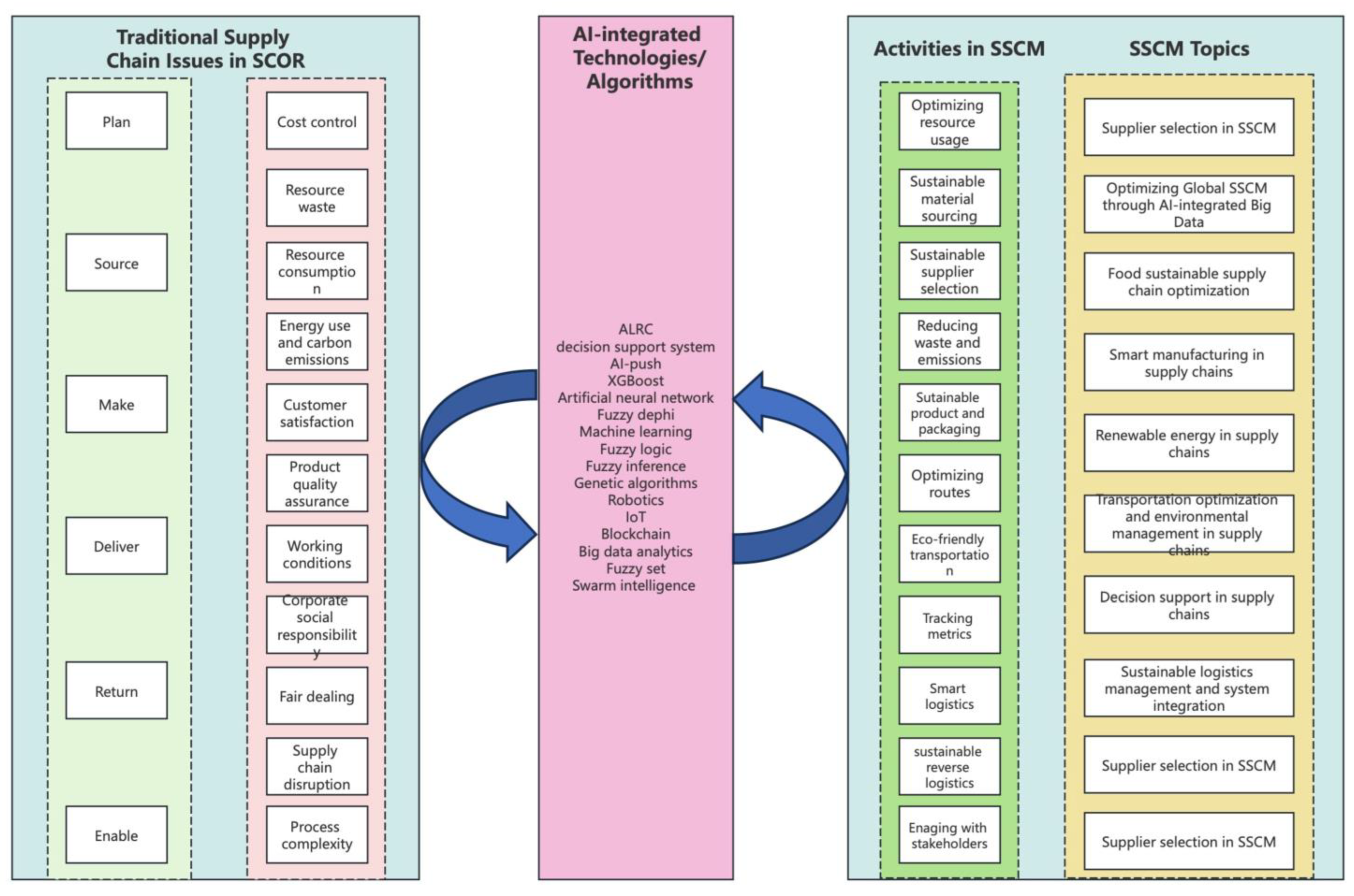

4.4. AI-Integrated Technologies with Sustainable Issues

5. Discussion and Proposed Research Framework

6. Conclusions and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gurtu, A.; Searcy, C.; Jaber, M.Y. Emissions from International Transport in Global Supply Chains. Manag. Res. Rev. 2017, 40, 53–74. [Google Scholar] [CrossRef]

- Khan, M.; Hussain, M.; Ajmal, M.M. (Eds.) Green Supply Chain Management for Sustainable Business Practice; Advances in Logistics, Operations, and Management Science; IGI Global: Hershey, PA, USA, 2017; ISBN 978-1-5225-0635-5. [Google Scholar]

- Sanders, N.R.; Boone, T.; Ganeshan, R.; Wood, J.D. Sustainable Supply Chains in the Age of AI and Digitization: Research Challenges and Opportunities. J. Bus. Logist. 2019, 40, 229–240. [Google Scholar] [CrossRef]

- Ibrahim, M.F.; Putri, M.M.; Utama, D.M. A Literature Review on Reducing Carbon Emission from Supply Chain System: Drivers, Barriers, Performance Indicators, and Practices. IOP Conf. Ser. Mater. Sci. Eng. 2020, 722, 012034. [Google Scholar] [CrossRef]

- Abbasi, S.; Ahmadi Choukolaei, H. A Systematic Review of Green Supply Chain Network Design Literature Focusing on Carbon Policy. Decis. Anal. J. 2023, 6, 100189. [Google Scholar] [CrossRef]

- Naz, F.; Agrawal, R.; Kumar, A.; Gunasekaran, A.; Majumdar, A.; Luthra, S. Reviewing the Applications of Artificial Intelligence in Sustainable Supply Chains: Exploring Research Propositions for Future Directions. Bus. Strategy Environ. 2022, 31, 2400–2423. [Google Scholar] [CrossRef]

- Haefner, N.; Wincent, J.; Parida, V.; Gassmann, O. Artificial Intelligence and Innovation Management: A Review, Framework, and Research Agenda. Technol. Forecast. Soc. Chang. 2021, 162, 120392. [Google Scholar] [CrossRef]

- Johnson, P.C.; Laurell, C.; Ots, M.; Sandström, C. Digital Innovation and the Effects of Artificial Intelligence on Firms’ Research and Development—Automation or Augmentation, Exploration or Exploitation? Technol. Forecast. Soc. Chang. 2022, 179, 121636. [Google Scholar] [CrossRef]

- Yousif Alsharidah, Y.M.; Alazzawi, A. Artificial Intelligence and Digital Transformation in Supply Chain Management A Case Study in Saudi Companies. In Proceedings of the 2020 International Conference on Data Analytics for Business and Industry: Way Towards a Sustainable Economy (ICDABI), Sakheer, Bahrain, 26–27 October 2020; IEEE: Sakheer, Bahrain, 2020; pp. 1–6. [Google Scholar]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial Intelligence in Supply Chain Management: A Systematic Literature Review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Riahi, Y.; Saikouk, T.; Gunasekaran, A.; Badraoui, I. Artificial Intelligence Applications in Supply Chain: A Descriptive Bibliometric Analysis and Future Research Directions. Expert Syst. Appl. 2021, 173, 114702. [Google Scholar] [CrossRef]

- Rzepka, C.; Berger, B. User Interaction with AI-Enabled Systems: A Systematic Review of IS Research. In Proceedings of the International Conference on Information Systems, San Francisco, CA, USA, 13–16 December 2018. [Google Scholar]

- Kassa, A.; Kitaw, D.; Stache, U.; Beshah, B.; Degefu, G. Artificial Intelligence Techniques for Enhancing Supply Chain Resilience: A Systematic Literature Review, Holistic Framework, and Future Research. Comput. Ind. Eng. 2023, 186, 109714. [Google Scholar] [CrossRef]

- Perano, M.; Cammarano, A.; Varriale, V.; Del Regno, C.; Michelino, F.; Caputo, M. Embracing Supply Chain Digitalization and Unphysicalization to Enhance Supply Chain Performance: A Conceptual Framework. Int. J. Phys. Distrib. Logist. Manag. 2023, 53, 628–659. [Google Scholar] [CrossRef]

- Arunmozhi, M.; Venkatesh, V.G.; Arisian, S.; Shi, Y.; Raja Sreedharan, V. Application of Blockchain and Smart Contracts in Autonomous Vehicle Supply Chains: An Experimental Design. Transp. Res. Part E Logist. Transp. Rev. 2022, 165, 102864. [Google Scholar] [CrossRef]

- Chittipaka, V.; Kumar, S.; Sivarajah, U.; Bowden, J.L.-H.; Baral, M.M. Blockchain Technology for Supply Chains Operating in Emerging Markets: An Empirical Examination of Technology-Organization-Environment (TOE) Framework. Annu. Oper. Res. 2023, 327, 465–492. [Google Scholar] [CrossRef]

- Tsolakis, N.; Schumacher, R.; Dora, M.; Kumar, M. Artificial Intelligence and Blockchain Implementation in Supply Chains: A Pathway to Sustainability and Data Monetisation? Ann. Oper. Res. 2023, 327, 157–210. [Google Scholar] [CrossRef] [PubMed]

- Ullah, Z.; Naeem, M.; Coronato, A.; Ribino, P.; De Pietro, G. Blockchain Applications in Sustainable Smart Cities. Sustain. Cities Soc. 2023, 97, 104697. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Pratap Singh, R.; Khan, S.; Suman, R. Sustainability 4.0 and Its Applications in the Field of Manufacturing. Internet Things Cyber-Phys. Syst. 2022, 2, 82–90. [Google Scholar] [CrossRef]

- Koot, M.; Mes, M.R.K.; Iacob, M.E. A Systematic Literature Review of Supply Chain Decision Making Supported by the Internet of Things and Big Data Analytics. Comput. Ind. Eng. 2021, 154, 107076. [Google Scholar] [CrossRef]

- Matin, A.; Islam, M.R.; Wang, X.; Huo, H.; Xu, G. AIoT for Sustainable Manufacturing: Overview, Challenges, and Opportunities. Internet Things 2023, 24, 100901. [Google Scholar] [CrossRef]

- Yavari, A.; Mirza, I.B.; Bagha, H.; Korala, H.; Dia, H.; Scifleet, P.; Sargent, J.; Tjung, C.; Shafiei, M. ArtEMon: Artificial Intelligence and Internet of Things Powered Greenhouse Gas Sensing for Real-Time Emissions Monitoring. Sensors 2023, 23, 7971. [Google Scholar] [CrossRef]

- Allahham, M.; Sharabati, A.-A.A.; Hatamlah, H.; Ahmad, A.Y.B.; Sabra, S.; Daoud, M.K. Big Data Analytics and AI for Green Supply Chain Integration and Sustainability in Hospitals. WSEAS Trans. Environ. Dev. 2023, 19, 1218–1230. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Dwivedi, Y.K. Role of Institutional Pressures and Resources in the Adoption of Big Data Analytics Powered Artificial Intelligence, Sustainable Manufacturing Practices and Circular Economy Capabilities. Technol. Forecast. Soc. Chang. 2021, 163, 120420. [Google Scholar] [CrossRef]

- Behl, A.; Gaur, J.; Pereira, V.; Yadav, R.; Laker, B. Role of Big Data Analytics Capabilities to Improve Sustainable Competitive Advantage of MSME Service Firms during COVID-19—A Multi-Theoretical Approach. J. Bus. Res. 2022, 148, 378–389. [Google Scholar] [CrossRef]

- Neaga, I.; Liu, S.; Xu, L.; Chen, H.; Hao, Y. Cloud Enabled Big Data Business Platform for Logistics Services: A Research and Development Agenda. Lect. Notes Bus. Inf. Process. 2015, 216, 22–33. [Google Scholar] [CrossRef]

- Sharma, S.; Gahlawat, V.K.; Rahul, K.; Mor, R.S.; Malik, M. Sustainable Innovations in the Food Industry through Artificial Intelligence and Big Data Analytics. Logistics 2021, 5, 66. [Google Scholar] [CrossRef]

- Zamani, E.D.; Smyth, C.; Gupta, S.; Dennehy, D. Artificial Intelligence and Big Data Analytics for Supply Chain Resilience: A Systematic Literature Review. Annu. Oper. Res. 2023, 327, 605–632. [Google Scholar] [CrossRef] [PubMed]

- Zekhnini, K.; Chaouni Benabdellah, A.; Cherrafi, A. A Multi-Agent Based Big Data Analytics System for Viable Supplier Selection. J. Intell. Manuf. 2023, 1–21. [Google Scholar] [CrossRef]

- Balaman, Ş.Y.; Matopoulos, A.; Wright, D.G.; Scott, J. Integrated Optimization of Sustainable Supply Chains and Transportation Networks for Multi Technology Bio-Based Production: A Decision Support System Based on Fuzzy ε-Constraint Method. J. Clean. Prod. 2016, 172, 2594–2617. [Google Scholar] [CrossRef]

- Fikar, C. A Decision Support System to Investigate Food Losses in E-Grocery Deliveries. Comput. Ind. Eng. 2018, 117, 282–290. [Google Scholar] [CrossRef]

- Hu, G.; Bidanda, B. Modeling Sustainable Product Lifecycle Decision Support Systems. Int. J. Prod. Econ. 2009, 122, 366–375. [Google Scholar] [CrossRef]

- Pereira, A.M.; Moura, J.A.B.; Costa, E.D.B.; Vieira, T.; Landim, A.R.D.B.; Bazaki, E.; Wanick, V. Customer Models for Artificial Intelligence-Based Decision Support in Fashion Online Retail Supply Chains. Decis. Support Syst. 2022, 158, 113795. [Google Scholar] [CrossRef]

- Sahu, A.K.; Sahu, N.K.; Sahu, A.K. Knowledge Based Decision Support System for Appraisement of Sustainable Partner under Fuzzy Cum Non-Fuzzy Information. Kybernetes 2018, 47, 1090–1121. [Google Scholar] [CrossRef]

- Jamalnia, A.; Gong, Y.; Govindan, K.; Bourlakis, M.; Mangla, S.K. A Decision Support System for Selection and Risk Management of Sustainability Governance Approaches in Multi-Tier Supply Chain. Int. J. Prod. Econ. 2023, 264, 108960. [Google Scholar] [CrossRef]

- Karam, A.; Reinau, K.H. A Real-Time Decision Support Approach for Managing Disruptions in Line-Haul Freight Transport Networks. IEEE Trans. Intell. Transp. Syst. 2022, 23, 24765–24777. [Google Scholar] [CrossRef]

- Vieira, A.A.C.; Figueira, J.R.; Fragoso, R. A Multi-Objective Simulation-Based Decision Support Tool for Wine Supply Chain Design and Risk Management under Sustainability Goals. Expert Syst. Appl. 2023, 232, 120757. [Google Scholar] [CrossRef]

- Brau, R.I.; Sanders, N.R.; Aloysius, J.; Williams, D. Utilizing People, Analytics, and AI for Decision Making in the Digitalized Retail Supply Chain. J. Bus. Logist. 2023, 45, e12355. [Google Scholar] [CrossRef]

- Cannas, V.G.; Ciano, M.P.; Saltalamacchia, M.; Secchi, R. Artificial Intelligence in Supply Chain and Operations Management: A Multiple Case Study Research. Int. J. Prod. Res. 2023, 62, 3333–3360. [Google Scholar] [CrossRef]

- Feizabadi, J. Machine Learning Demand Forecasting and Supply Chain Performance. Int. J. Logist. Res. Appl. 2022, 25, 119–142. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Artificial Intelligence in Operations Management and Supply Chain Management: An Exploratory Case Study. Prod. Plan. Control 2022, 33, 1573–1590. [Google Scholar] [CrossRef]

- Singh, R.K.; Modgil, S.; Shore, A. Building Artificial Intelligence Enabled Resilient Supply Chain: A Multi-Method Approach. J. Enterp. Inf. Manag. 2023, 37, 414–436. [Google Scholar] [CrossRef]

- Mastos, T.D.; Nizamis, A.; Terzi, S.; Gkortzis, D.; Papadopoulos, A.; Tsagkalidis, N.; Ioannidis, D.; Votis, K.; Tzovaras, D. Introducing an Application of an Industry 4.0 Solution for Circular Supply Chain Management. J. Clean. Prod. 2021, 300, 126886. [Google Scholar] [CrossRef]

- Sharma, R.; Shishodia, A.; Gunasekaran, A.; Min, H.; Munim, Z.H. The Role of Artificial Intelligence in Supply Chain Management: Mapping the Territory. Int. J. Prod. Res. 2022, 60, 7527–7550. [Google Scholar] [CrossRef]

- Dey, P.K.; Chowdhury, S.; Abadie, A.; Vann Yaroson, E.; Sarkar, S. Artificial Intelligence-Driven Supply Chain Resilience in Vietnamese Manufacturing Small- and Medium-Sized Enterprises. Int. J. Prod. Res. 2023, 62, 5417–5456. [Google Scholar] [CrossRef]

- Wong, L.-W.; Tan, G.W.-H.; Ooi, K.-B.; Lin, B.; Dwivedi, Y.K. Artificial Intelligence-Driven Risk Management for Enhancing Supply Chain Agility: A Deep-Learning-Based Dual-Stage PLS-SEM-ANN Analysis. Int. J. Prod. Res. 2022, 62, 5535–5555. [Google Scholar] [CrossRef]

- Lima-Junior, F.R.; Carpinetti, L.C.R. Predicting Supply Chain Performance Based on SCOR® Metrics and Multilayer Perceptron Neural Networks. Int. J. Prod. Econ. 2019, 212, 19–38. [Google Scholar] [CrossRef]

- Liu, L.; Song, W.; Liu, Y. Leveraging Digital Capabilities toward a Circular Economy: Reinforcing Sustainable Supply Chain Management with Industry 4.0 Technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Mikalef, P.; Gupta, M. Artificial Intelligence Capability: Conceptualization, Measurement Calibration, and Empirical Study on Its Impact on Organizational Creativity and Firm Performance. Inf. Manag. 2021, 58, 103434. [Google Scholar] [CrossRef]

- Schneider, J.; Abraham, R.; Meske, C.; Vom Brocke, J. Artificial Intelligence Governance for Businesses. Inf. Syst. Manag. 2022, 40, 229–249. [Google Scholar] [CrossRef]

- Lee, Y.K. Transformation of the Innovative and Sustainable Supply Chain with Upcoming Real-Time Fashion Systems. Sustainability 2021, 13, 1081. [Google Scholar] [CrossRef]

- Ebinger, F.; Omondi, B. Leveraging Digital Approaches for Transparency in Sustainable Supply Chains: A Conceptual Paper. Sustainability 2020, 12, 6129. [Google Scholar] [CrossRef]

- Labaran, M.J.; Masood, T. Industry 4.0 Driven Green Supply Chain Management in Renewable Energy Sector: A Critical Systematic Literature Review. Energies 2023, 16, 6977. [Google Scholar] [CrossRef]

- Muthuswamy, M.; Ali, A.M. Sustainable Supply Chain Management in the Age of Machine Intelligence: Addressing Challenges, Capitalizing on Opportunities, and Shaping the Future Landscape. Sustain. Mach. Intell. J. 2023, 3, 1–14. [Google Scholar] [CrossRef]

- Hangl, J.; Behrens, V.J.; Krause, S. Barriers, Drivers, and Social Considerations for AI Adoption in Supply Chain Management: A Tertiary Study. Logistics 2022, 6, 63. [Google Scholar] [CrossRef]

- Brem, A.; Giones, F.; Werle, M. The AI Digital Revolution in Innovation: A Conceptual Framework of Artificial Intelligence Technologies for the Management of Innovation. IEEE Trans. Intell. Transp. Syst. 2023, 70, 770–776. [Google Scholar] [CrossRef]

- Ojaghi, H.; Mohammadi, M.; Yazdani, H.R. A Synthesized Framework for the Formation of Startups’ Innovation Ecosystem: A Systematic Literature Review. J. Sci. Technol. Policy Manag. 2019, 10, 1063–1097. [Google Scholar] [CrossRef]

- Beamon, B.M. Supply Chain Design and Analysis: Models and Methods. Int. J. Prod. Econ. 1998, 55, 281–294. [Google Scholar] [CrossRef]

- La Londe, B.J.; Masters, J.M. Emerging Logistics Strategies: Blueprints for the Next Century. Int. J. Phys. Distrib. Logist. Manag. 1994, 24, 35–47. [Google Scholar] [CrossRef]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Larson, P.D.; Rogers, D.S. Supply Chain Management: Definition, Growth and Approaches. J. Mark. Theory Pract. 1998, 6, 1–5. [Google Scholar] [CrossRef]

- Min, S.; Zacharia, Z.G.; Smith, C.D. Defining Supply Chain Management: In the Past, Present, and Future. J. Bus. Logist. 2019, 40, 44–55. [Google Scholar] [CrossRef]

- Huan, S.H.; Sheoran, S.K.; Wang, G. A Review and Analysis of Supply Chain Operations Reference (SCOR) Model. Supply Chain Manag. Int. J. 2004, 9, 23–29. [Google Scholar] [CrossRef]

- Prakash, S.; Sandeep Gunjan, S.; Rathore, A. Supply Chain Operations Reference (SCOR) Model: An Overview and a Structured Literature Review of Its Application. In Proceedings of the International Conference on Smart Technologies for Mechanical Engineering, (STME-2013), Delhi, India, 25–26 October 2013. [Google Scholar] [CrossRef]

- Ntabe, E.N.; LeBel, L.; Munson, A.D.; Santa-Eulalia, L.A. A Systematic Literature Review of the Supply Chain Operations Reference (SCOR) Model Application with Special Attention to Environmental Issues. Int. J. Prod. Econ. 2015, 169, 310–332. [Google Scholar] [CrossRef]

- Es-Satty, A.; Lemghari, R.; Okar, C. Supply Chain Digitalization Overview SCOR Model Implication. In Proceedings of the 2020 IEEE 13th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), Fez, Morocco, 2–4 December 2020; IEEE: Fez, Morocco, 2020; pp. 1–7. [Google Scholar]

- Katsaliaki, K.; Kumar, S.; Loulos, V. Supply Chain Coopetition: A Review of Structures, Mechanisms and Dynamics. Int. J. Prod. Econ. 2024, 267, 109057. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our common future—Call for action. Environ. Conserv. 1987, 14, 291–294. [Google Scholar] [CrossRef]

- Sneddon, C.; Howarth, R.B.; Norgaard, R.B. Sustainable Development in a Post-Brundtland World. Ecol. Econ. 2006, 57, 253–268. [Google Scholar] [CrossRef]

- Bossel, H. Indicators for Sustainable Development: Theory, Method, Applications; A Report to the Balaton Group; IISD: Winnipeg, MB, Canada, 1999; ISBN 978-1-895536-13-3. [Google Scholar]

- Virakul, B. Global Challenges, Sustainable Development, and Their Implications for Organizational Performance. Eur. Bus. Rev. 2015, 27, 430–446. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A Framework of Sustainable Supply Chain Management: Moving toward New Theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A Systematic Review of Sustainable Supply Chain Management in Global Supply Chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Snyder, H. Literature Review as a Research Methodology: An Overview and Guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Soni, G.; Kodali, R. A Critical Review of Empirical Research Methodology in Supply Chain Management. J. Manuf. Technol. Manag. 2012, 23, 753–779. [Google Scholar] [CrossRef]

- Busalim, A.; Fox, G.; Lynn, T. Consumer Behavior in Sustainable Fashion: A Systematic Literature Review and Future Research Agenda. Int. J. Consum. Stud. 2022, 46, 1804–1828. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef] [PubMed]

- Aliyu, M.B. Efficiency of Boolean Search Strings for Information Retrieval. Am. J. Eng. Res. 2017, 6, 216–222. [Google Scholar]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to Conduct a Bibliometric Analysis: An Overview and Guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Tarkowski, S.M. Environmental Health Research in Europe Bibliometric Analysis. Eur. J. Public Health 2007, 17, 14–18. [Google Scholar] [CrossRef] [PubMed]

- Helal, M.A.; Anderson, N.; Wei, Y.; Thompson, M. A Review of Biomass-to-Bioenergy Supply Chain Research Using Bibliometric Analysis and Visualization. Energies 2023, 16, 1187. [Google Scholar] [CrossRef]

- Raja Santhi, A.; Muthuswamy, P. Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges. Logistics 2022, 6, 81. [Google Scholar] [CrossRef]

- Rejeb, A.; Appolloni, A. The Nexus of Industry 4.0 and Circular Procurement: A Systematic Literature Review and Research Agenda. Sustainability 2022, 14, 15633. [Google Scholar] [CrossRef]

- Wu, S.R.; Shirkey, G.; Celik, I.; Shao, C.; Chen, J. A Review on the Adoption of AI, BC, and IoT in Sustainability Research. Sustainability 2022, 14, 7851. [Google Scholar] [CrossRef]

- Mageto, J. Current and Future Trends of Information Technology and Sustainability in Logistics Outsourcing. Sustainability 2022, 14, 7641. [Google Scholar] [CrossRef]

- Dhamija, P.; Bag, S. Role of Artificial Intelligence in Operations Environment: A Review and Bibliometric Analysis. TQM J. 2020, 32, 869–896. [Google Scholar] [CrossRef]

- Xing, Y.; Wu, Y.; Zhang, S.; Wang, L.; Cui, H.; Jia, B.; Wang, H. Discovering Latent Themes in Aviation Safety Reports Using Text Mining and Network Analytics. Int. J. Transp. Sci. Technol. 2024, in press. [CrossRef]

- Nikolenko, S.I.; Koltcov, S.; Koltsova, O. Topic Modelling for Qualitative Studies. J. Inf. Sci. 2017, 43, 88–102. [Google Scholar] [CrossRef]

- Jelodar, H.; Wang, Y.; Yuan, C.; Feng, X.; Jiang, X.; Li, Y.; Zhao, L. Latent Dirichlet Allocation (LDA) and Topic Modeling: Models, Applications, a Survey. Multimed. Tools Appl. 2019, 78, 15169–15211. [Google Scholar] [CrossRef]

- Blei, D.M.; Ng, A.Y.; Jordan, M.I. Latent Dirichlet Allocation. J. Mach. Learn. Res. 2003, 3, 993–1022. [Google Scholar]

- Binkley, D.; Heinz, D.; Lawrie, D.; Overfelt, J. Understanding LDA in Source Code Analysis. In Proceedings of the Proceedings of the 22nd International Conference on Program Comprehension, Hyderabad, India, 2–3 June 2014; ACM: Hyderabad, India, 2014; pp. 26–36. [Google Scholar]

- Thakuria, A.; Deka, D. A Decadal Study on Identifying Latent Topics and Research Trends in Open Access LIS Journals Using Topic Modeling Approach. Scientometrics 2024, 1–29. [Google Scholar] [CrossRef]

- Newman, D.; Asuncion, A.; Smyth, P.; Welling, M. Distributed Algorithms for Topic Models. J. Mach. Learn. Res. 2009, 10, 1801–1828. [Google Scholar]

- Airoldi, E.M.; Bischof, J.M. Improving and Evaluating Topic Models and Other Models of Text. J. Am. Stat. Assoc. 2016, 111, 1381–1403. [Google Scholar] [CrossRef]

- Arenal, A.; Armuña, C.; Feijoo, C.; Ramos, S.; Xu, Z.; Moreno, A. Innovation Ecosystems Theory Revisited: The Case of Artificial Intelligence in China. Telecommun. Policy 2020, 44, 101960. [Google Scholar] [CrossRef]

- Admin, O. US-China Competition in Artificial Intelligence: Implications on Global Governance. J. Asian Dev. Stud. 2023, 12, 481–493. [Google Scholar]

- Qu, C.; Kim, E. Dynamic Capabilities Perspective on Innovation Ecosystem of China’s Universities in the Age of Artificial Intelligence: Policy-Based Analysis. J. Infrastruct. Policy Dev. 2022, 6, 1661. [Google Scholar] [CrossRef]

- Kherwa, P.; Bansal, P. Topic Modeling: A Comprehensive Review. ICST Trans. Scalable Inf. Syst. 2018, 20, e2. [Google Scholar] [CrossRef]

- Tavana, M.; Sorooshian, S.; Mina, H. An Integrated Group Fuzzy Inference and Best–Worst Method for Supplier Selection in Intelligent Circular Supply Chains. Ann. Oper. Res. 2023, 1–42. [Google Scholar] [CrossRef]

- Neethirajan, S. Artificial Intelligence and Sensor Technologies in Dairy Livestock Export: Charting a Digital Transformation. Sensors 2023, 23, 7045. [Google Scholar] [CrossRef]

- Dadi, V.; Nikhil, S.R.; Mor, R.S.; Agarwal, T.; Arora, S. Agri-Food 4.0 and Innovations: Revamping the Supply Chain Operations. Prod. Eng. Arch. 2021, 27, 75–89. [Google Scholar] [CrossRef]

- Akbari, M.; Hopkins, J.L. Digital Technologies as Enablers of Supply Chain Sustainability in an Emerging Economy. Oper. Manag. Res. 2022, 15, 689–710. [Google Scholar] [CrossRef]

- Singh, A.; Vaidya, G.; Jagota, V.; Darko, D.A.; Agarwal, R.K.; Debnath, S.; Potrich, E. Recent Advancement in Postharvest Loss Mitigation and Quality Management of Fruits and Vegetables Using Machine Learning Frameworks. J. Food Qual. 2022, 2022, 6447282. [Google Scholar] [CrossRef]

- Singh, R.; Singh, R.; Gehlot, A.; Akram, S.V.; Priyadarshi, N.; Twala, B. Horticulture 4.0: Adoption of Industry 4.0 Technologies in Horticulture for Meeting Sustainable Farming. Appl. Sci. 2022, 12, 12557. [Google Scholar] [CrossRef]

- Panigrahi, R.R.; Shrivastava, A.K.; Qureshi, K.M.; Mewada, B.G.; Alghamdi, S.Y.; Almakayeel, N.; Almuflih, A.S.; Qureshi, M.R.N. AI Chatbot Adoption in SMEs for Sustainable Manufacturing Supply Chain Performance: A Mediational Research in an Emerging Country. Sustainability 2023, 15, 13743. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M. Deep Learning for Manufacturing Sustainability: Models, Applications in Industry 4.0 and Implications. Int. J. Inf. Manag. Data Insights 2022, 2, 100107. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital Twin for Sustainable Manufacturing Supply Chains: Current Trends, Future Perspectives, and an Implementation Framework. Technol. Forecast. Soc. Chang. 2022, 176, 121448. [Google Scholar] [CrossRef]

- Kombaya Touckia, J.; Hamani, N.; Kermad, L. Digital Twin Framework for Reconfigurable Manufacturing Systems (RMSs): Design and Simulation. Int. J. Adv. Manuf. Technol. 2022, 120, 5431–5450. [Google Scholar] [CrossRef] [PubMed]

- Tirkolaee, E.B.; Aydin, N.S. Integrated Design of Sustainable Supply Chain and Transportation Network Using a Fuzzy Bi-Level Decision Support System for Perishable Products. Expert Syst. Appl. 2022, 195, 116628. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Lee, H.; Aluko, O. Multi-Objective Decision Support to Enhance Environmental Sustainability in Maritime Shipping: A Review and Future Directions. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 3–18. [Google Scholar] [CrossRef]

- Bhatti, M.A.; Assemgul, B. Impact of Intelligent Inventory System on Improvement of Reverse Logistics: A Case of Saudi Manufacturing Industry. Oper. Res. Eng. Sci. Theory Appl. 2023, 6, 1–19. [Google Scholar]

- Stanisławski, R.; Szymonik, A. Impact of Selected Intelligent Systems in Logistics on the Creation of a Sustainable Market Position of Manufacturing Companies in Poland in the Context of Industry 4.0. Sustainability 2021, 13, 3996. [Google Scholar] [CrossRef]

- Moosavi, J.; Fathollahi-Fard, A.M.; Dulebenets, M.A. Supply Chain Disruption during the COVID-19 Pandemic: Recognizing Potential Disruption Management Strategies. Int. J. Disaster Risk Reduct. 2022, 75, 102983. [Google Scholar] [CrossRef] [PubMed]

- Bechtsis, D.; Tsolakis, N.; Iakovou, E.; Vlachos, D. Data-Driven Secure, Resilient and Sustainable Supply Chains: Gaps, Opportunities, and a New Generalised Data Sharing and Data Monetisation Framework. Int. J. Prod. Res. 2022, 60, 4397–4417. [Google Scholar] [CrossRef]

- Aljabhan, B. Economic Strategic Plans with Supply Chain Risk Management (SCRM) for Organizational Growth and Development. Alex. Eng. J. 2023, 79, 411–426. [Google Scholar] [CrossRef]

- Castañeda-Navarrete, J.; Hauge, J.; López-Gómez, C. COVID-19’s Impacts on Global Value Chains, as Seen in the Apparel Industry. Dev. Policy Rev. 2021, 39, 953–970. [Google Scholar] [CrossRef]

- Liu, K.-S.; Lin, M.-H. Performance Assessment on the Application of Artificial Intelligence to Sustainable Supply Chain Management in the Construction Material Industry. Sustainability 2021, 13, 12767. [Google Scholar] [CrossRef]

- Singh, A.; Dwivedi, A.; Agrawal, D.; Singh, D. Identifying Issues in Adoption of AI Practices in Construction Supply Chains: Towards Managing Sustainability. Oper. Manag. Res. 2023, 16, 1667–1683. [Google Scholar] [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Sepasgozar, S.M.E.; Kamat, V.R. Digital Twin-Enabled Prefabrication Supply Chain for Smart Construction and Carbon Emissions Evaluation in Building Projects. J. Build. Eng. 2023, 78, 107598. [Google Scholar] [CrossRef]

- Bodendorf, F.; Xie, Q.; Merkl, P.; Franke, J. A Multi-Perspective Approach to Support Collaborative Cost Management in Supplier-Buyer Dyads. Int. J. Prod. Econ. 2022, 245, 108380. [Google Scholar] [CrossRef]

- Kuźnar, M.; Lorenc, A. A Hybrid Method for Technical Condition Prediction Based on AI as an Element for Reducing Supply Chain Disruptions. Appl. Sci. 2023, 13, 12439. [Google Scholar] [CrossRef]

- Trabucco, M.; De Giovanni, P. Achieving Resilience and Business Sustainability during COVID-19: The Role of Lean Supply Chain Practices and Digitalization. Sustainability 2021, 13, 12369. [Google Scholar] [CrossRef]

- Di Vaio, A.; Palladino, R.; Pezzi, A.; Kalisz, D.E. The Role of Digital Innovation in Knowledge Management Systems: A Systematic Literature Review. J. Bus. Res. 2021, 123, 220–231. [Google Scholar] [CrossRef]

- Vernier, C.; Loeillet, D.; Thomopoulos, R.; Macombe, C. Adoption of Icts in Agri-Food Logistics: Potential and Limitations for Supply Chain Sustainability. Sustainability 2021, 13, 6702. [Google Scholar] [CrossRef]

- Tang, Y.M.; Chau, K.Y.; Lau, Y.-Y.; Zheng, Z. Data-Intensive Inventory Forecasting with Artificial Intelligence Models for Cross-Border E-Commerce Service Automation. Appl. Sci. 2023, 13, 3051. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between Industry 4.0, Sustainable Manufacturing and Circular Economy: Proposal of a Research Framework. Int. J. Organ. Anal. 2022, 30, 864–898. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the Adoption of Industry 4.0 Technologies in Improving Environmental Sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Kumar, S.; Barua, M.K. Sustainability of Operations through Disruptive Technologies in the Petroleum Supply Chain. Benchmarking 2022, 29, 1640–1676. [Google Scholar] [CrossRef]

- Roux, M.; Chowdhury, S.; Kumar Dey, P.; Vann Yaroson, E.; Pereira, V.; Abadie, A. Small and Medium-Sized Enterprises as Technology Innovation Intermediaries in Sustainable Business Ecosystem: Interplay between AI Adoption, Low Carbon Management and Resilience. Ann. Oper. Res. 2023, 1–50. [Google Scholar] [CrossRef]

- Wang, Y.; Qin, J.; Mou, S.; Huang, K.; Zhao, X. DSS Approach for Sustainable System Design of Shuttle-Based Storage and Retrieval Systems. Flex. Serv. Manuf. J. 2023, 35, 698–726. [Google Scholar] [CrossRef]

- Lechner, G.; Reimann, M. Integrated Decision-Making in Reverse Logistics: An Optimisation of Interacting Acquisition, Grading and Disposition Processes. Int. J. Prod. Res. 2020, 58, 5786–5805. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, J. Management and Information Disclosure of Electric Power Environmental and Social Governance Issues in the Age of Artificial Intelligence. Comput. Electr. Eng. 2022, 104, 108390. [Google Scholar] [CrossRef]

- Gupta, S.; Rikhtehgar Berenji, H.; Shukla, M.; Murthy, N.N. Opportunities in Farming Research from an Operations Management Perspective. Prod. Oper. Manag. 2023, 32, 1577–1596. [Google Scholar] [CrossRef]

- Jararweh, Y.; Fatima, S.; Jarrah, M.; AlZu’bi, S. Smart and Sustainable Agriculture: Fundamentals, Enabling Technologies, and Future Directions. Comput. Electr. Eng. 2023, 110, 108799. [Google Scholar] [CrossRef]

- Kannan, D. Role of Multiple Stakeholders and the Critical Success Factor Theory for the Sustainable Supplier Selection Process. Int. J. Prod. Econ. 2018, 195, 391–418. [Google Scholar] [CrossRef]

- Guruswamy, S.; Pojić, M.; Subramanian, J.; Mastilović, J.; Sarang, S.; Subbanagounder, A.; Stojanović, G.; Jeoti, V. Toward Better Food Security Using Concepts from Industry 5.0. Sensors 2022, 22, 8377. [Google Scholar] [CrossRef]

- Khan, M.M.; Bashar, I.; Minhaj, G.M.; Wasi, A.I.; Hossain, N.U.I. Resilient and Sustainable Supplier Selection: An Integration of SCOR 4.0 and Machine Learning Approach. Sustain. Resilient Infrastruct. 2023, 8, 453–469. [Google Scholar] [CrossRef]

- Gupta, M.; Jauhar, S.K. Digital Innovation: An Essence for Industry 4.0. Thunderbird Int. Bus. Rev. 2023, 65, 279–292. [Google Scholar] [CrossRef]

- Dementiev, V.E. Technological Sovereignty and Priorities of Localization of Production. Terra Econ. 2023, 21, 6–18. [Google Scholar] [CrossRef]

- Van Meerbeek, K.; Ottoy, S.; De Meyer, A.; Van Schaeybroeck, T.; Van Orshoven, J.; Muys, B.; Hermy, M. The Bioenergy Potential of Conservation Areas and Roadsides for Biogas in an Urbanized Region. Appl. Energy 2015, 154, 742–751. [Google Scholar] [CrossRef]

- Duan, C.; Xiu, G.; Yao, F. Multi-Period E-Closed-Loop Supply Chain Network Considering Consumers’ Preference for Products and AI-Push. Sustainability 2019, 11, 4571. [Google Scholar] [CrossRef]

- Ting, S.L.; Tse, Y.K.; Ho, G.T.S.; Chung, S.H.; Pang, G. Mining Logistics Data to Assure the Quality in a Sustainable Food Supply Chain: A Case in the Red Wine Industry. Int. J. Prod. Econ. 2014, 152, 200–209. [Google Scholar] [CrossRef]

- Tatiya, A.; Zhao, D.; Syal, M.; Berghorn, G.H.; LaMore, R. Cost Prediction Model for Building Deconstruction in Urban Areas. J. Clean. Prod. 2018, 195, 1572–1580. [Google Scholar] [CrossRef]

- Kellner, F.; Lienland, B.; Utz, S. An a Posteriori Decision Support Methodology for Solving the Multi-Criteria Supplier Selection Problem. Eur. J. Oper. Res. 2019, 272, 505–522. [Google Scholar] [CrossRef]

- Orji, I.J.; Wei, S. An Innovative Integration of Fuzzy-Logic and Systems Dynamics in Sustainable Supplier Selection: A Case on Manufacturing Industry. Comput. Ind. Eng. 2015, 88, 1–12. [Google Scholar] [CrossRef]

- Wang, Z.-J.; Chen, Z.-S.; Su, Q.; Chin, K.-S.; Pedrycz, W.; Skibniewski, M.J. Enhancing the Sustainability and Robustness of Critical Material Supply in Electrical Vehicle Market: An AI-Powered Supplier Selection Approach. Ann. Oper. Res. 2023, 1–38. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Schultmann, F. Sustainable Supplier Management—A Review of Models Supporting Sustainable Supplier Selection, Monitoring and Development. Int. J. Prod. Res. 2016, 54, 1412–1442. [Google Scholar] [CrossRef]

- Bag, S.; Rahman, M.S.; Rogers, H.; Srivastava, G.; Pretorius, J.H.C. Climate Change Adaptation and Disaster Risk Reduction in the Garment Industry Supply Chain Network. Transp. Res. Part E-Logist. Transp. Rev. 2023, 171, 103031. [Google Scholar] [CrossRef]

- Agrawal, R.; Surendra Yadav, V.; Majumdar, A.; Kumar, A.; Luthra, S.; Arturo Garza-Reyes, J. Opportunities for Disruptive Digital Technologies to Ensure Circularity in Supply Chain: A Critical Review of Drivers, Barriers and Challenges. Comput. Ind. Eng. 2023, 178, 109140. [Google Scholar] [CrossRef]

- Noman, A.A.; Akter, U.H.; Pranto, T.H.; Haque, A.K.M.B. Machine Learning and Artificial Intelligence in Circular Economy: A Bibliometric Analysis and Systematic Literature Review. Ann. Emerg. Technol. Comput. 2022, 6, 13–40. [Google Scholar] [CrossRef]

- Tam, F.Y.; Lung, J.W.Y. Impact of COVID-19 and Innovative Ideas for a Sustainable Fashion Supply Chain in the Future. Foresight 2023, 25, 225–248. [Google Scholar] [CrossRef]

- Quariguasi Frota Neto, J.; Walther, G.; Bloemhof, J.; Van Nunen, J.A.E.E.; Spengler, T. From Closed-Loop to Sustainable Supply Chains: The WEEE Case. Int. J. Prod. Res. 2010, 48, 4463–4481. [Google Scholar] [CrossRef]

- Angellier-Coussy, H.; Guillard, V.; Guillaume, C.; Gontard, N. Role of Packaging in the Smorgasbord of Action for Sustainable Food Consumption. Agro Food Ind. Hi-Tech 2013, 24, 15–19. [Google Scholar]

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Journal articles and reviews. | Reports, white papers, conference articles, and chapters in books. |

| Subjects: engineering, business, management, and accounting; social sciences; decision sciences; economics, econometrics, and finance; arts and humanities; multidisciplinary. | Computer sciences; environmental science; mathematics; agricultural and biological sciences; energy; chemical engineering; physics and astronomy; biochemistry, genetics, and molecular biology; materials sciences; chemistry; psychology; earth and planetary sciences; medicine; immunology and microbiology; veterinary; pharmacology, toxicology and pharmaceutics. |

| Published from 2004 January to 2023 December. | Outside the selected time period. |

| Written in English. | Non-English papers. |

| Search Phase | Keyword and Search Strings |

|---|---|

| Step One-Keyword Search | Artificial_intelligence, sustainable supply_chain management |

| Step Two-Search String | “Artificial_intelligence” OR “blockchain” OR “machine_ learning” OR “digitalization” OR “big data analytics” OR “big data” OR “digital technologies” OR “artificial_neural_ network” OR “blockchain technology” OR “artificial_intelligence research” AND “supply_chain” |

| Journals | No. of Articles | Total Citations | h-Index |

|---|---|---|---|

| Sustainability (Switzerland) | 25 | 1022 | 185 |

| Journal of Cleaner Production | 12 | 536 | 246 |

| International Journal of Production Research | 11 | 1617 | 186 |

| Energies | 6 | 108 | 152 |

| Annals of Operations Research | 5 | 84 | 125 |

| International Journal of Production Economics | 5 | 454 | 118 |

| Technological Forecasting and Social Change | 5 | 577 | 157 |

| Topics | Keywords | FREX | Lift |

|---|---|---|---|

| 1 Supplier Selection in SSCM using decision support systems | Decision, supply_chains, supplier, support, systems, selection | continuous, continues, oscillators, agile, Denizli, focuses, triple, detection, PLS, multiproduct | ambiguity, amalgamates, robots, Asia, effectual, messaging, radical, engaged, seamless, kingdom |

| 2 Optimizing Global SSCM through AI-integrated Big Data | Data, supply_chain, management, digital, artificial_intelligence, sustainability | many, moderating, conflicting, sample, dearth, exhibited, UCS, exploration, grown, listed | radically, regulation, animal, discovery, excellence, metric, required, managing, optimization, globalized |

| 3 Food Sustainable Supply Chain Optimization | Supply, sustainable, digital, chain, food, management, technologies | inventory, learn, pinning, scenario, descriptive, empower, trade, environment, entire, exhibit, makings | previously, prominent, SCM, horticulture, feasibility, integration, precision, involvement, live, hybridized |

| 4 Smart Manufacturing in Supply Chains | Supply, chain, sustainable, industry, manufacturing, artificial, intelligence, data | match, local, put, sectors, dissemination, faced, trends, footage, methodologically, analyze | readers, public, SMAC, largest, generally, manufacturer-supplier, radio, model-based, reduced, bank |

| 5 Renewable Energy in Supply Chains | Industry, supply, analysis, sustainable, energy, data, artificial_intelligence, sustainability | implementing, influences, scarce, secondly, depletion, competencies, twenty, enabled, profitable, Malaysia | pivot, post-fuel, summarized, first-stage, almost, realities, involving, shocks, indirectly |

| 6 Transportation Optimization and Environmental Management in Supply Chains | Supply, sustainability, food, chain, research, industry | inductive, intersection, phase, seaports, country, derivatives, twenty, forecasts, maximizing, merge | philosophies, powerful, scalable, medium, behaviors, endless, sensor, meta-ontology, ranking, get |

| 7 Decision Support in Supply Chains | Supply, system, sustainable, manufacturing, environmental, product | known, mapping, RR, scanners, data-intensive, Europe, trying, crippled, cost-effectiveness, beyond | problem-solving, ration, situational, effect, blending, interplay, remotely, ArcelorMittal, API, CMS |

| 8 Sustainable Logistics Management and System Integration | Smart, energy, supply, management, systems, logistics | letter, mere, pure, SDG, design-science, deployment, unnecessary, goal, programming, pre-COVID, loss | protective, redesign, six, insufficiently, fundamental, formally, Scopus, optimizing, sense, implementing |

| 9 Data-driven Risk Management in Disruptions | Supply_chain, research, review, management, industry, literature | Finland, formation, parameters, scan, edge, firm, treatment, emergence, package, bitcoin | metrics, monitor, sampling, long-lasting, hotspot, micron-controller, routing, improves, rule, cationic |

| 10 Environmental Management in Construction Supply Chains | Supply_chain, construction, risk, sustainability, management, environmental | holds, Indian, paths, sales, deep, evidence, according, deeply, massively, loss | path, portfolios, satisfaction, demand-markets, establishing, lithium-ion, algorithm, essence, real, hegemony |

| AI-Integrated Technologies | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |||

| Machine Learning | Big Data Analytics | Fuzzy | Internet of Things | Decision Support System | Robotic | XGBoost | Deep Learning | Explained AI | Digital Twin | Block Chain | |||

| SSCM- Environmental Issues | 1 | Resource waste | [19] | X | X | [102,103,124,125] | X | [103] | [126] | X | X | X | X |

| 2 | Energy use and carbon emissions | [19] | [23,127,128] | [129] | [22] | [130,131] | X | X | X | X | [120] | X | |

| SSCM- Economic issues | 3 | Cost control | X | X | X | X | [131,132] | X | X | X | [133] | X | X |

| 4 | Supply chain disruption | [121,122] | [25] | X | [123] | [36] | X | X | X | X | [109] | [114] | |

| 5 | Resource consumption | X | [27] | X | X | X | X | [126] | X | X | X | X | |

| SSCM- Social issues | 6 | Working conditions | X | [134] | X | [134] | X | X | X | X | X | X | [134] |

| 7 | Fair dealing | X | X | X | X | X | X | X | X | X | X | [135] | |

| 8 | Corporate social responsibility | X | [120] | [136] | X | X | X | X | X | X | X | X | |

| SSCM- Management issues | 9 | Product quality assurance | [104] | [48] | X | X | [110,133] | [137] | [126] | X | X | [109] | X |

| 10 | Processes complexity | X | X | X | X | X | [137] | X | [107] | X | [137] | X | |

| 11 | Customers satisfaction | [138] | [48] | X | X | X | [139] | X | X | X | X | ||

| 12 | Supplier selection | [138] | [29] | [100] | X | X | X | [126] | X | X | X | [52] | |

| 13 | Risk management | [122] | [48] | X | X | X | X | [126] | X | X | X | X | |

| 14 | SSCs’ transparency | X | [52] | X | X | X | X | X | X | X | X | [135,137] | |

| SCOR | Sustainable Activities | AI-Integrated Technologies/Algorithms |

|---|---|---|

| Plan | Developing plans that prioritize resource efficiency and minimize environmental impact [116,142,143]; | AI and Adaptive Logistic Regression Classifier (ALRC); decision support system; AI-push XGBoost; Artificial neural network. |

| Utilizing forecasting tools to optimize resource usage and reduce waste [126,144]; | ||

| Incorporating sustainability goals into the overall supply chain strategy [37,42,140,141]. | ||

| Source | Sustainable supplier selection [29,100,136,138,145,146,147,148]; | Fuzzy Delphi; Decision support systems; Machine learning; Fuzzy logic; Fuzzy inference; Genetic algorithms; Robotic. |

| Sustainable material sourcing [48,118]. | ||

| Make | Reducing waste and emissions during production [22,120,130]; | Machine learning; IoT; Blockchain. |

| Utilizing renewable energy sources in production facilities [53]. | ||

| Deliver | Optimizing routes to reduce fuel consumption and emissions; | Big data analytics; Decision support system; Blockchain. |

| Using eco-friendly transportation options like electric or hybrid vehicles [15,30,36,110,111,149]; | ||

| Implementing smart logistics solutions to enhance efficiency [15]. | ||

| Return | Establishing systems for the return, recycling, and disposal of products [142,150,151,152] | Machine learning; Big data analytics; AI-push; Blockchain; IoT; decision support system. |

| Managing end-of-life products responsibly to minimize environmental impact [132,153]. | ||

| Enable | Implementing lean principles to reduce excess inventory and waste [112,126]; | Decision support systems; Big data; Fuzzy set; IoT; Swarm intelligence algorithms. |

| Sustainable product and packaging [154]; | ||

| Working with suppliers to improve their sustainability practices [24]; | ||

| Tracking sustainability metrics such as carbon footprint, energy usage, and waste [34,148] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, C.; Kim, E. Reviewing the Roles of AI-Integrated Technologies in Sustainable Supply Chain Management: Research Propositions and a Framework for Future Directions. Sustainability 2024, 16, 6186. https://doi.org/10.3390/su16146186

Qu C, Kim E. Reviewing the Roles of AI-Integrated Technologies in Sustainable Supply Chain Management: Research Propositions and a Framework for Future Directions. Sustainability. 2024; 16(14):6186. https://doi.org/10.3390/su16146186

Chicago/Turabian StyleQu, Chen, and Eunyoung Kim. 2024. "Reviewing the Roles of AI-Integrated Technologies in Sustainable Supply Chain Management: Research Propositions and a Framework for Future Directions" Sustainability 16, no. 14: 6186. https://doi.org/10.3390/su16146186